Patents

Literature

42results about How to "Good molding consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

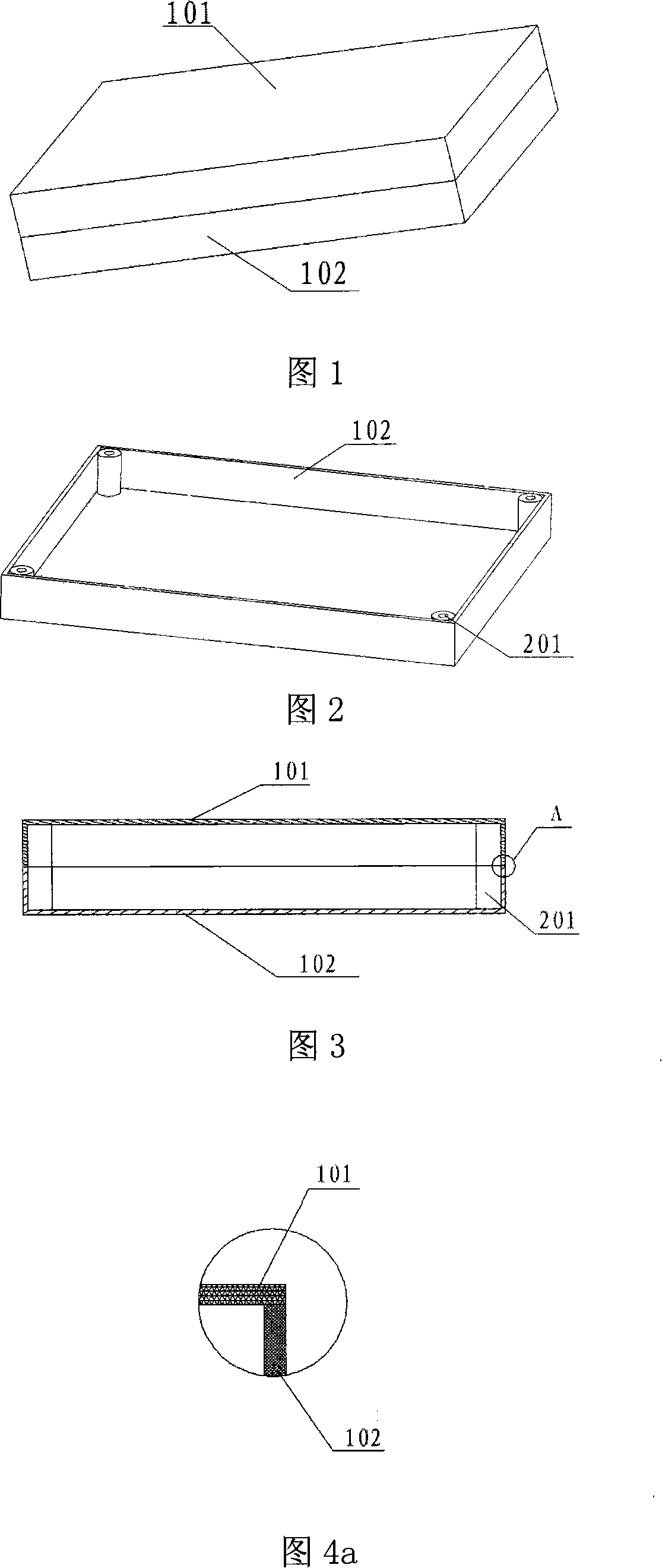

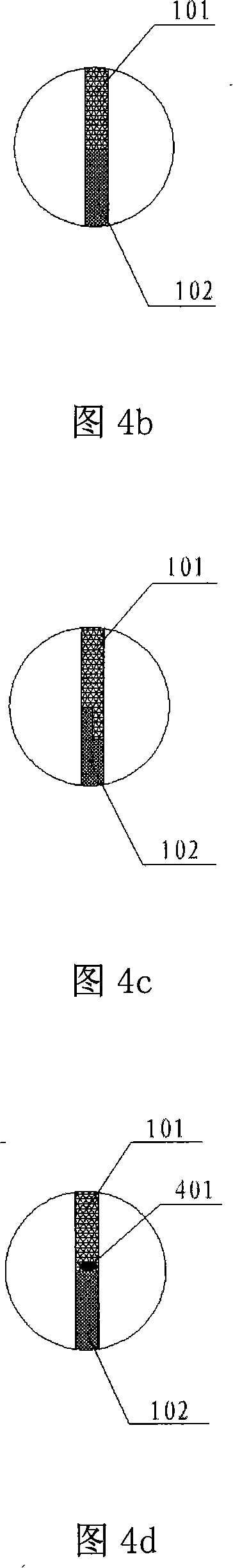

Plastic shielding shell

InactiveCN101150947AOvercoming Manufacturing ComplexityOvercome appearanceMagnetic/electric field screeningLap jointElectromagnetic shielding

The invention discloses a plastic shield casing, comprising an upper cover and a lower cover, one of which is a conductive plastic piece, the other one is a metal piece or a conductive plastic piece. By adopting the plastic shield casing, the invention has advantages of without need of machining treatment, good moulding consistency, high production efficiency and low cost, overcomes the disadvantages of production complexity of the metal shield casing and simplex appearance in the prior art, also improves the electromagnetic shielding effect of the casing. By utilizing reasonable filler with better performance, the combination form of the upper and the lower covers is more abundant, the lap joint form of the casing is simplified to avoid increase of lap joint gap depth and overlap area. The plastic shield casing can be applied to structure electromagnetic shielding of electronic products.

Owner:ZTE CORP

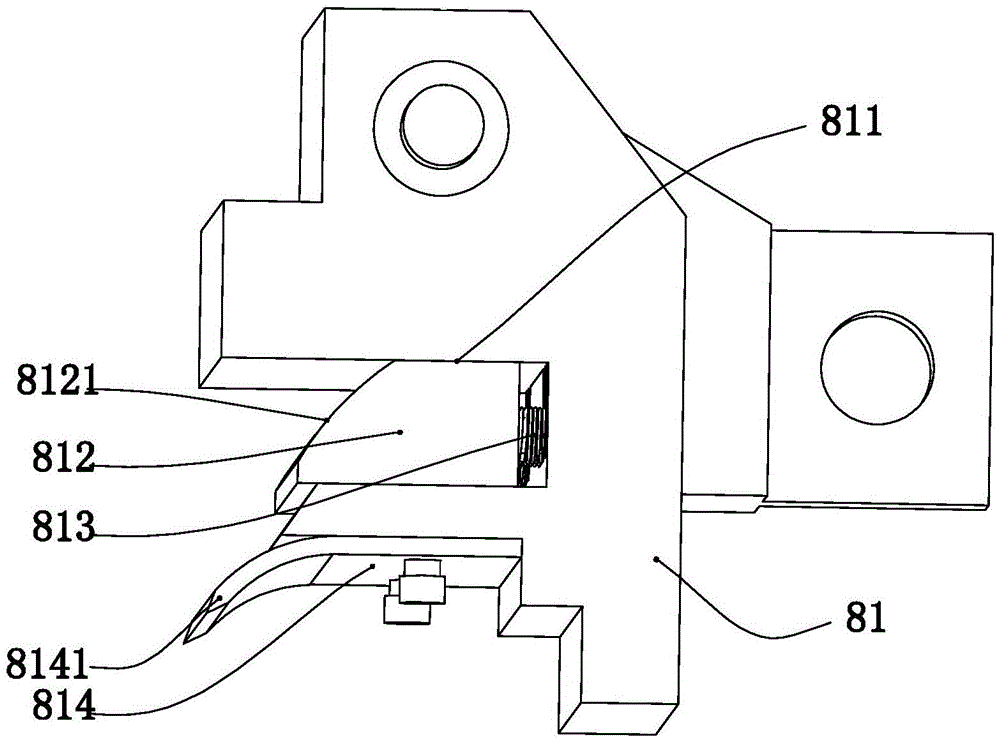

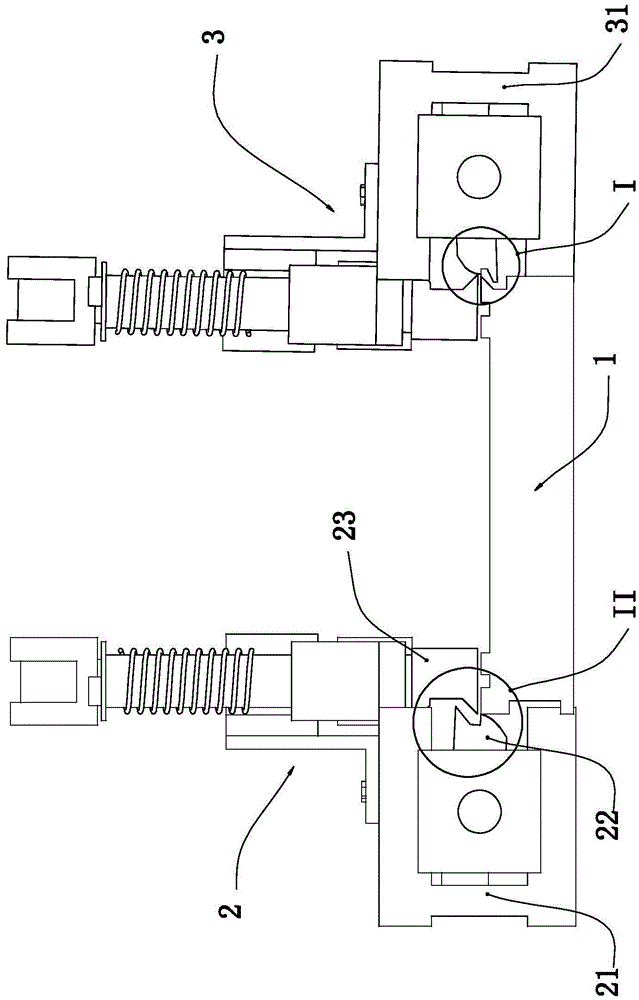

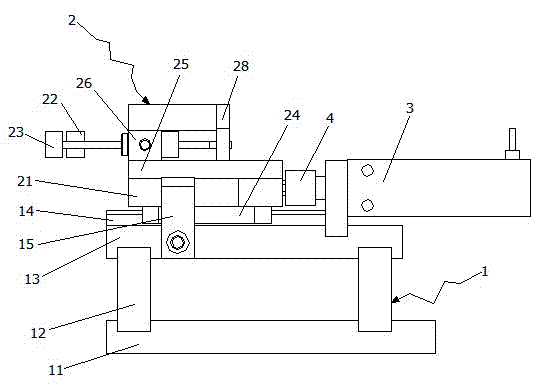

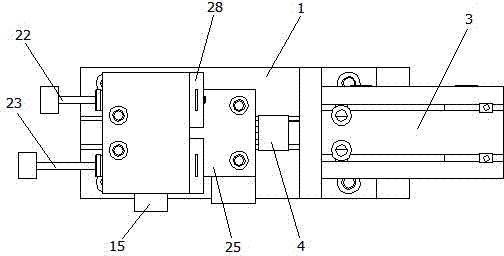

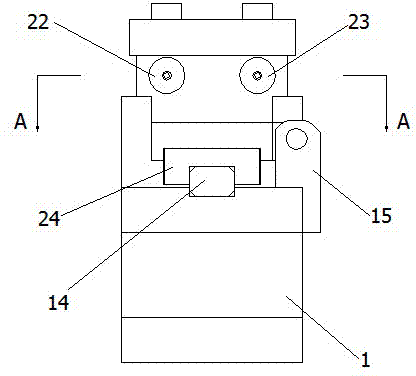

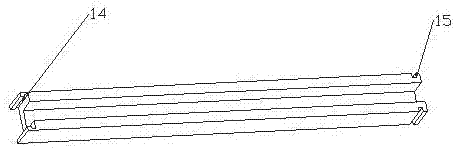

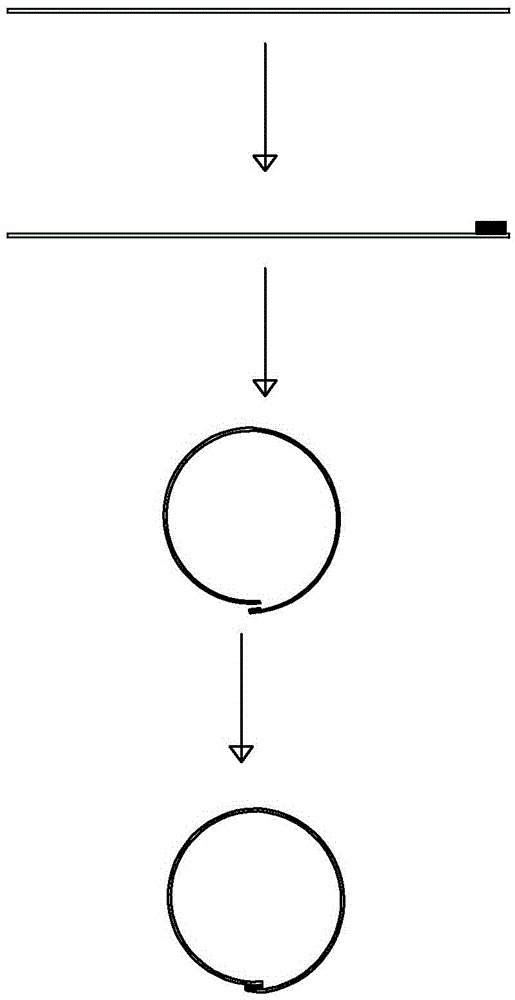

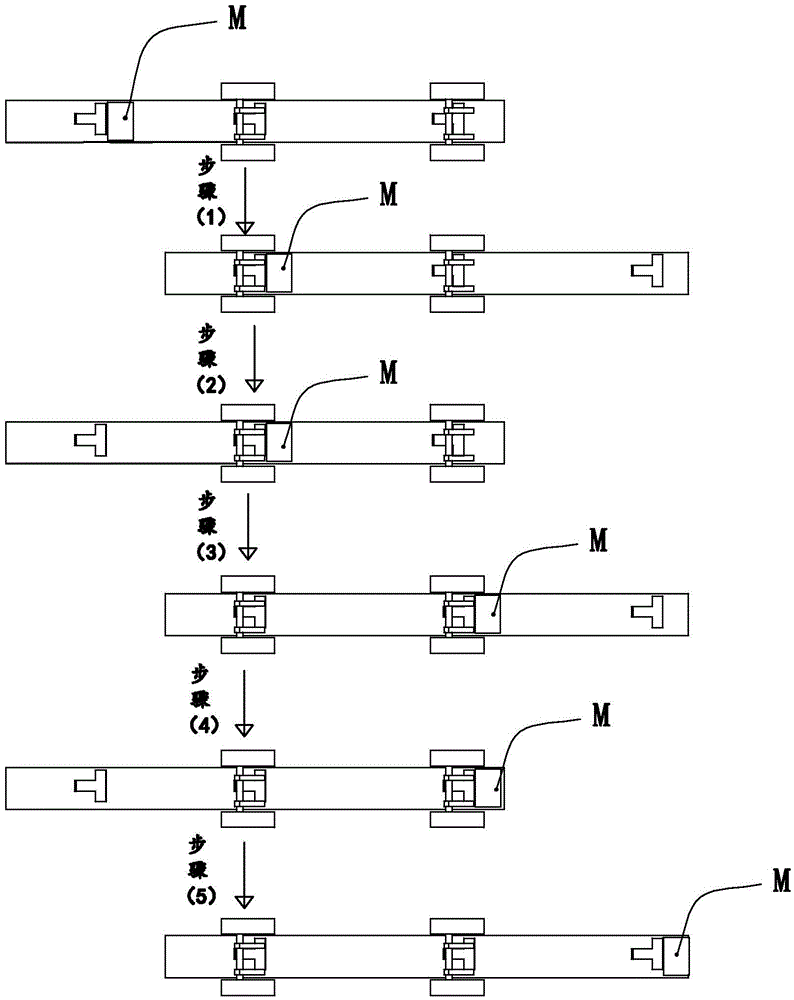

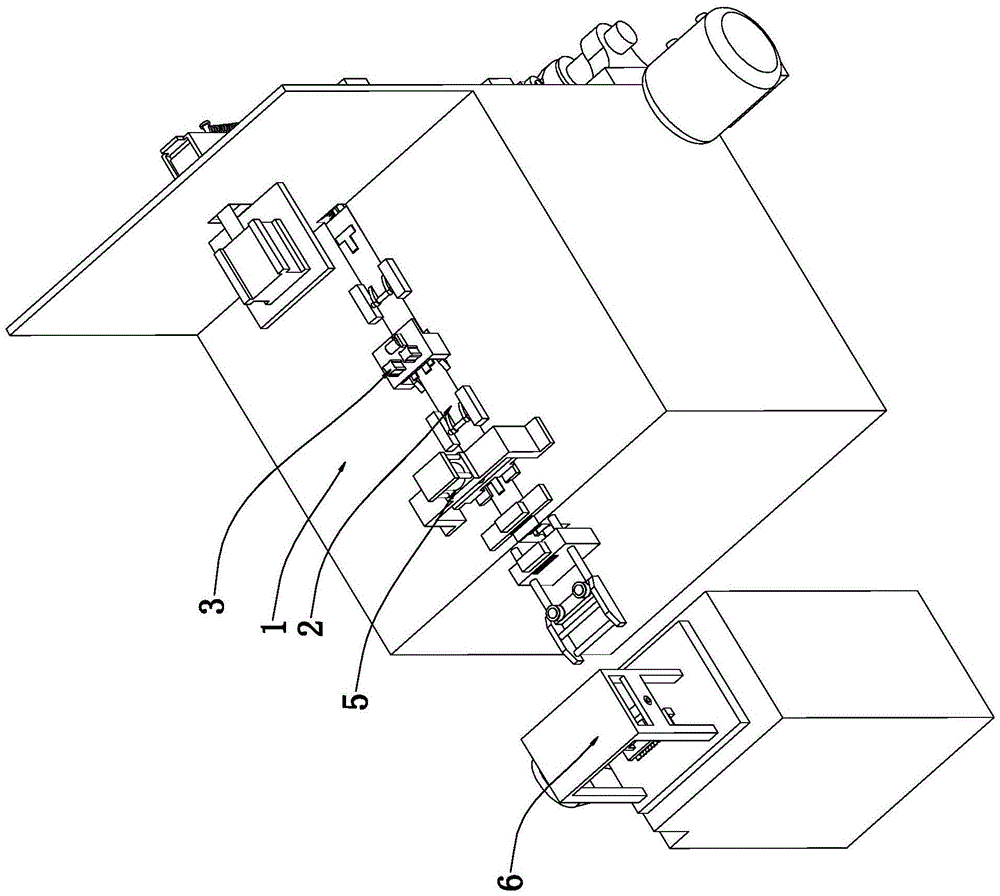

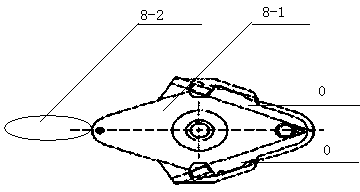

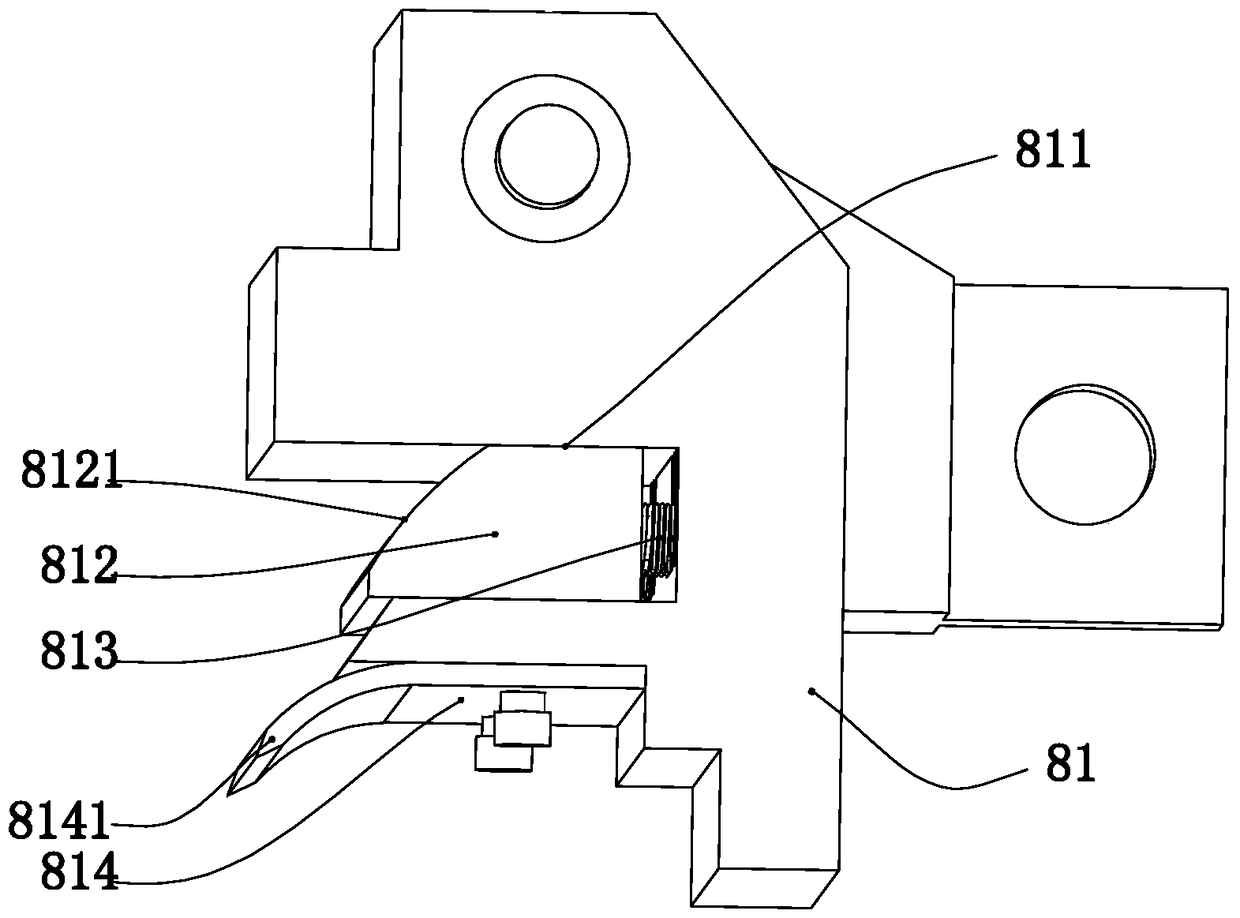

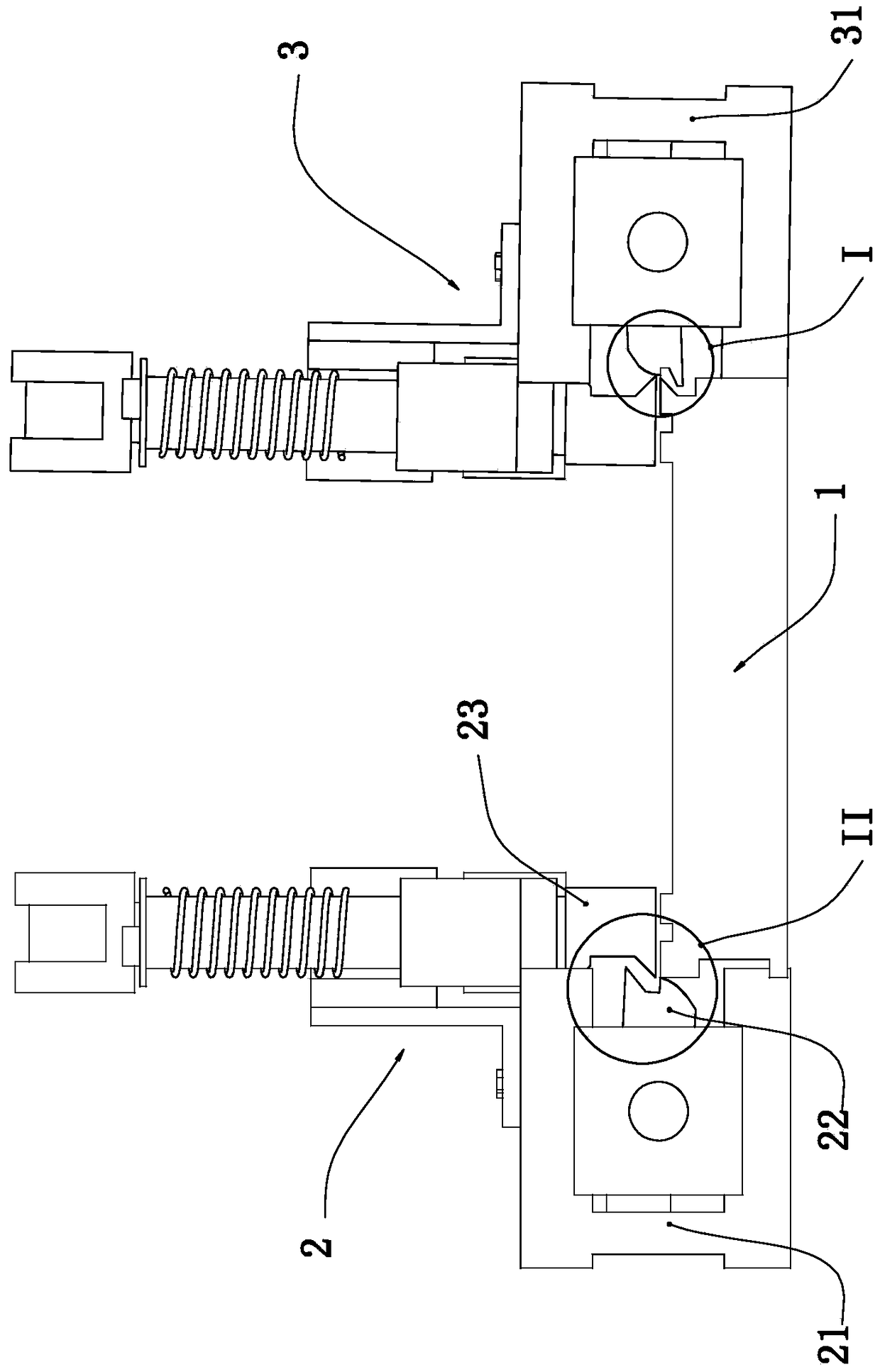

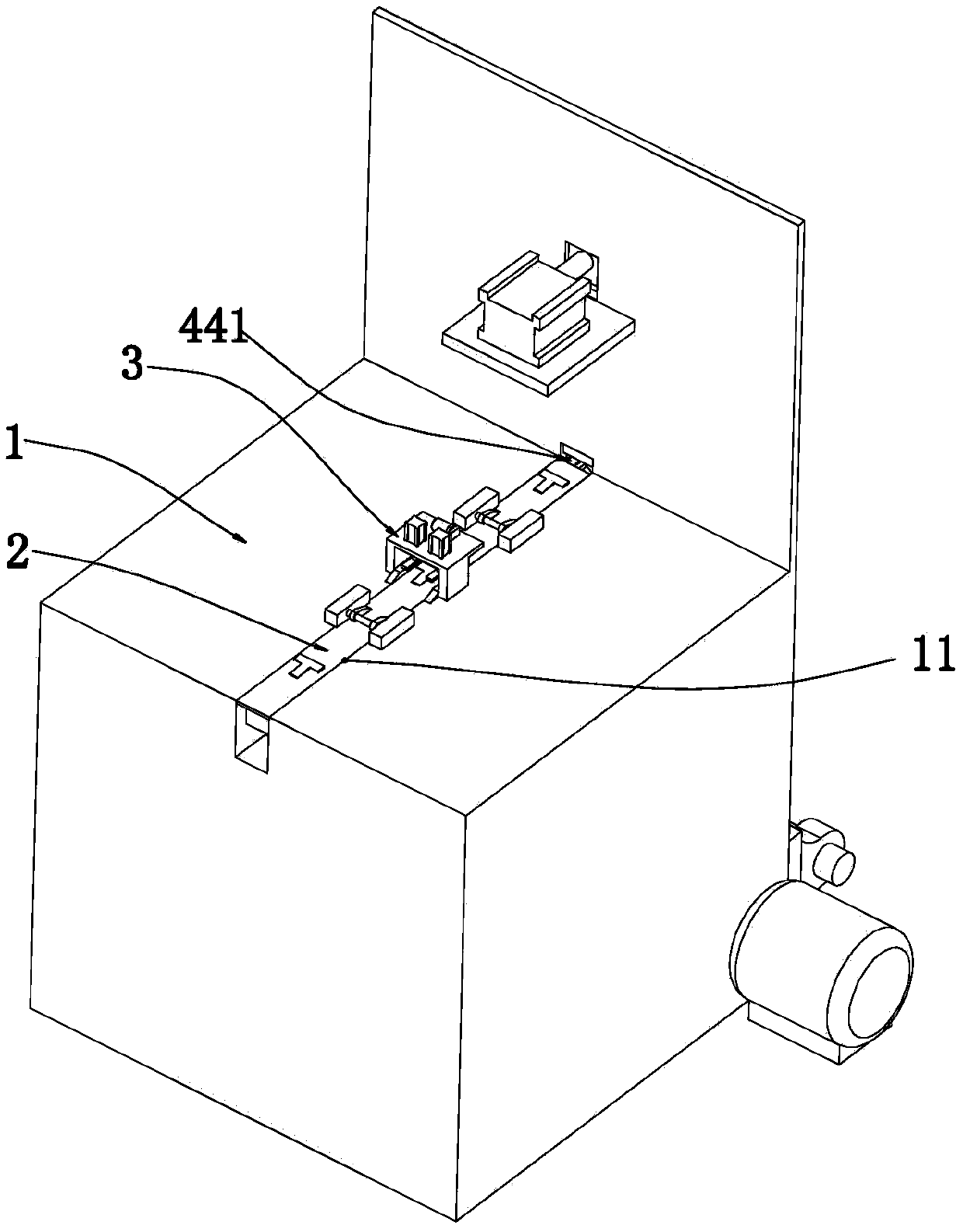

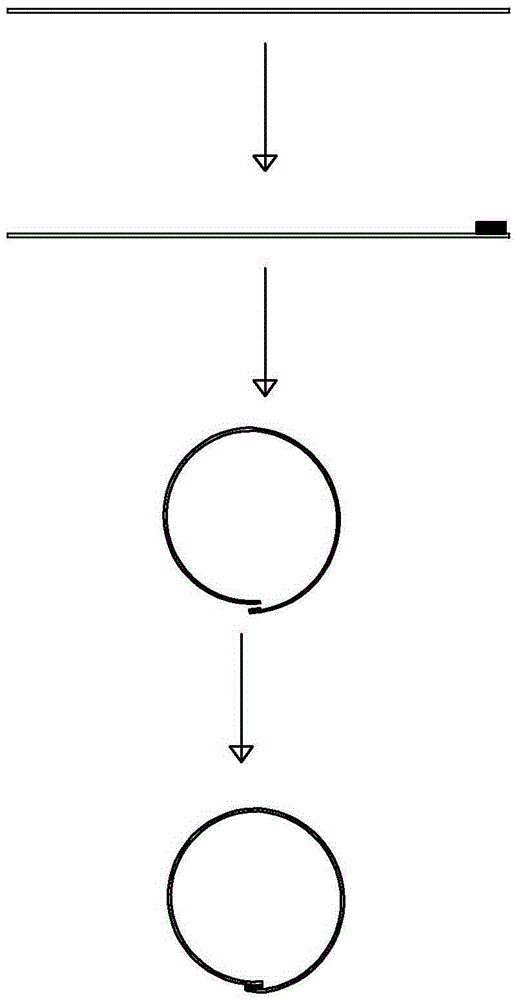

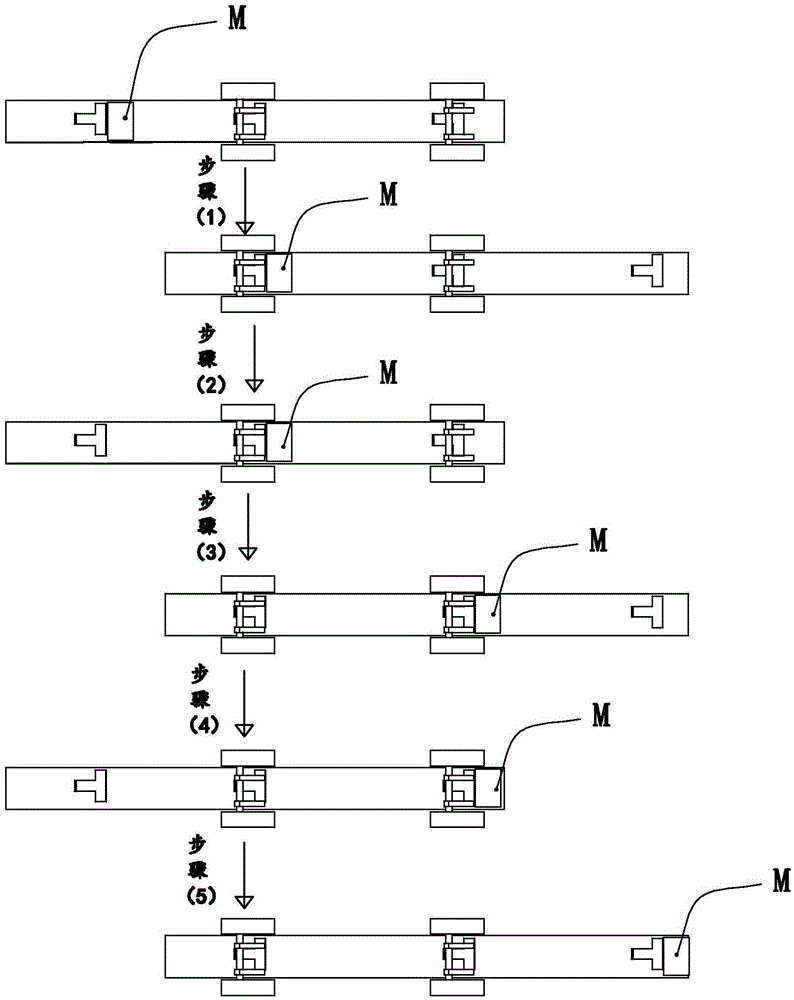

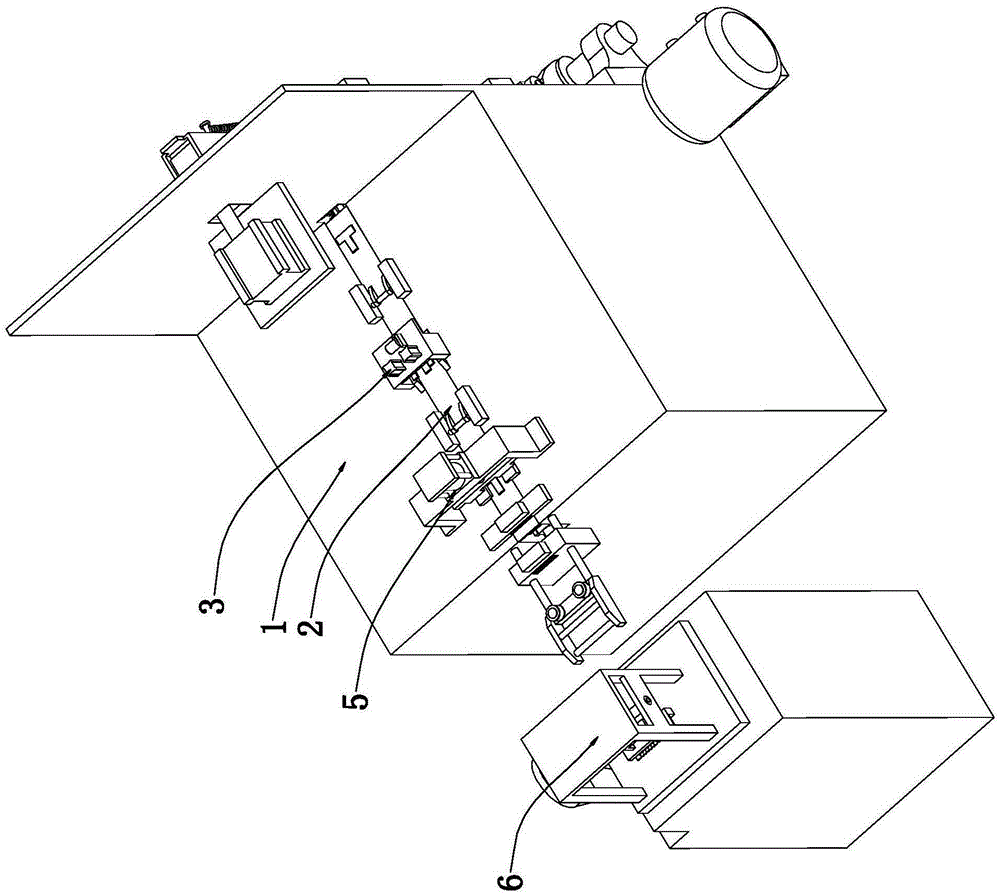

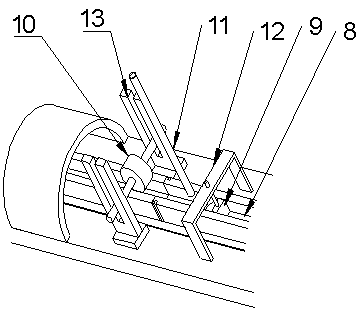

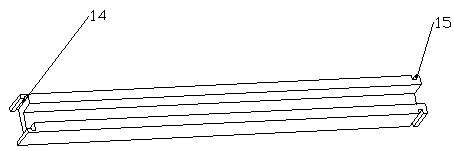

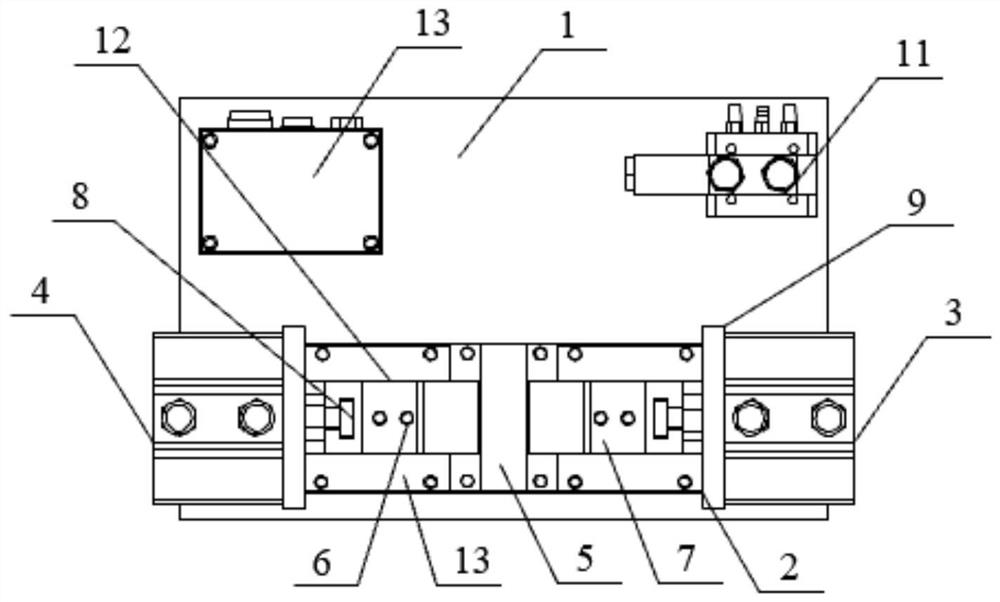

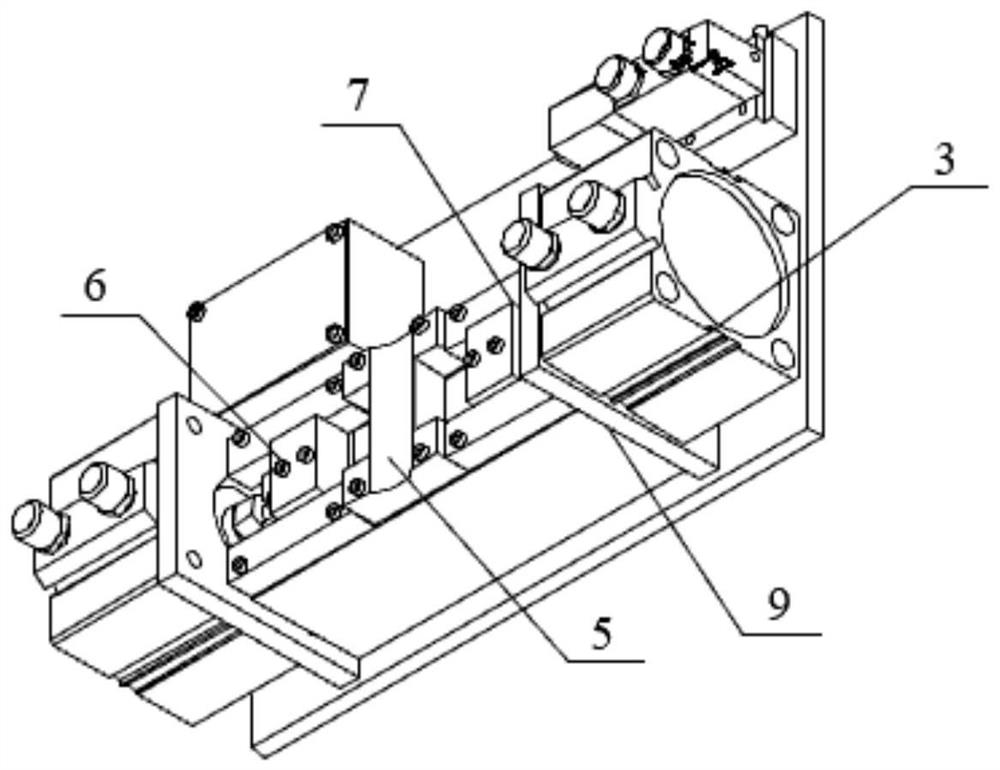

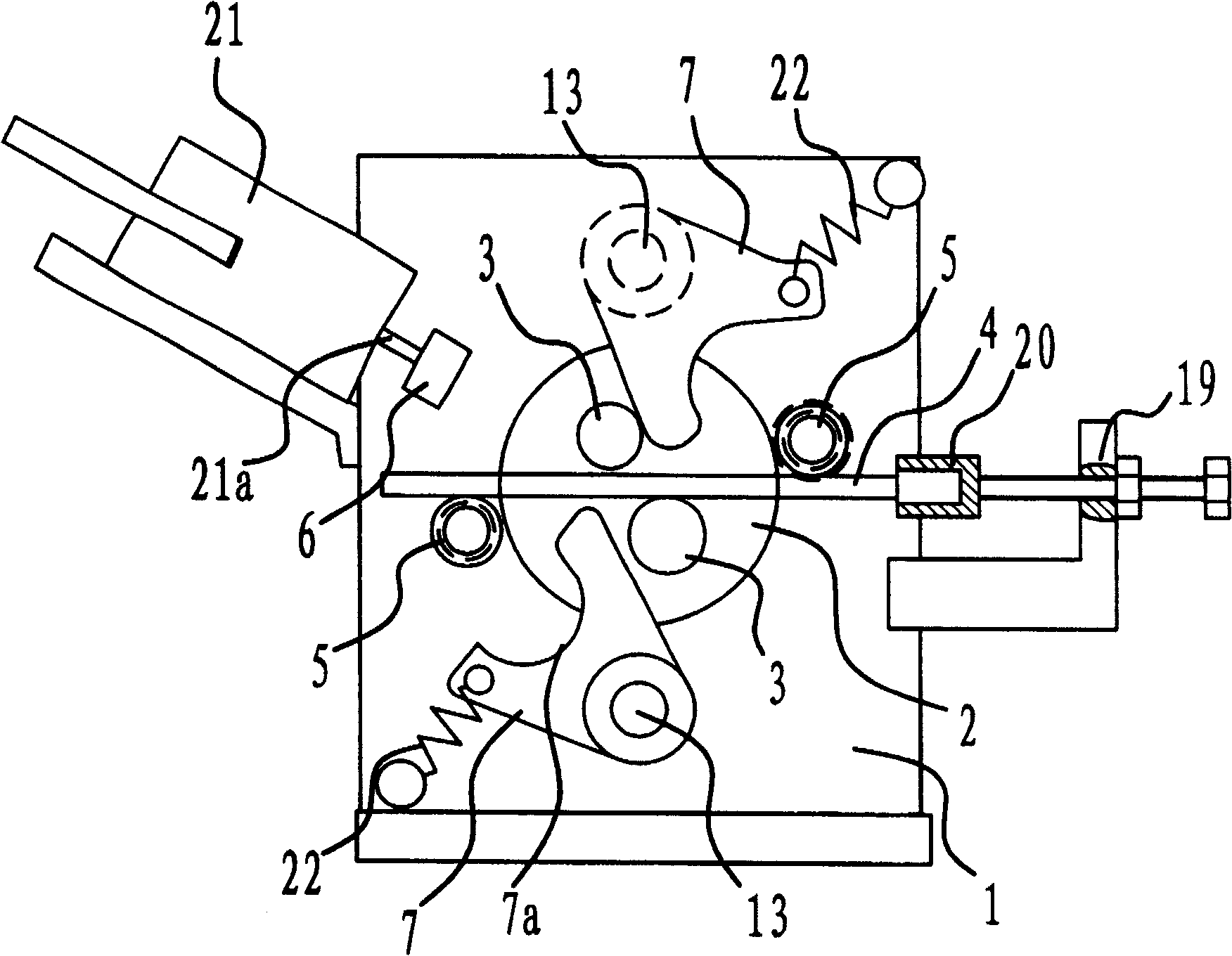

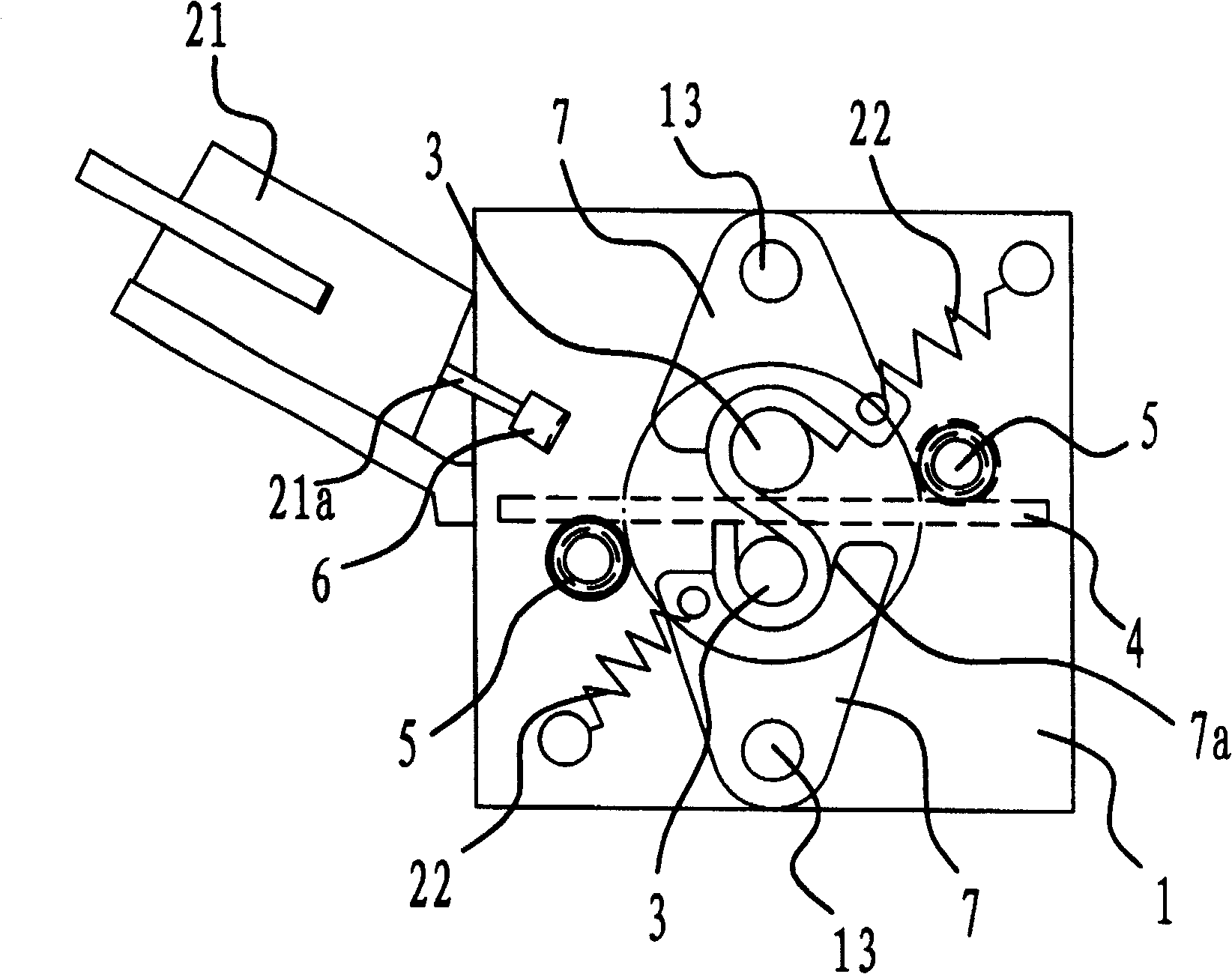

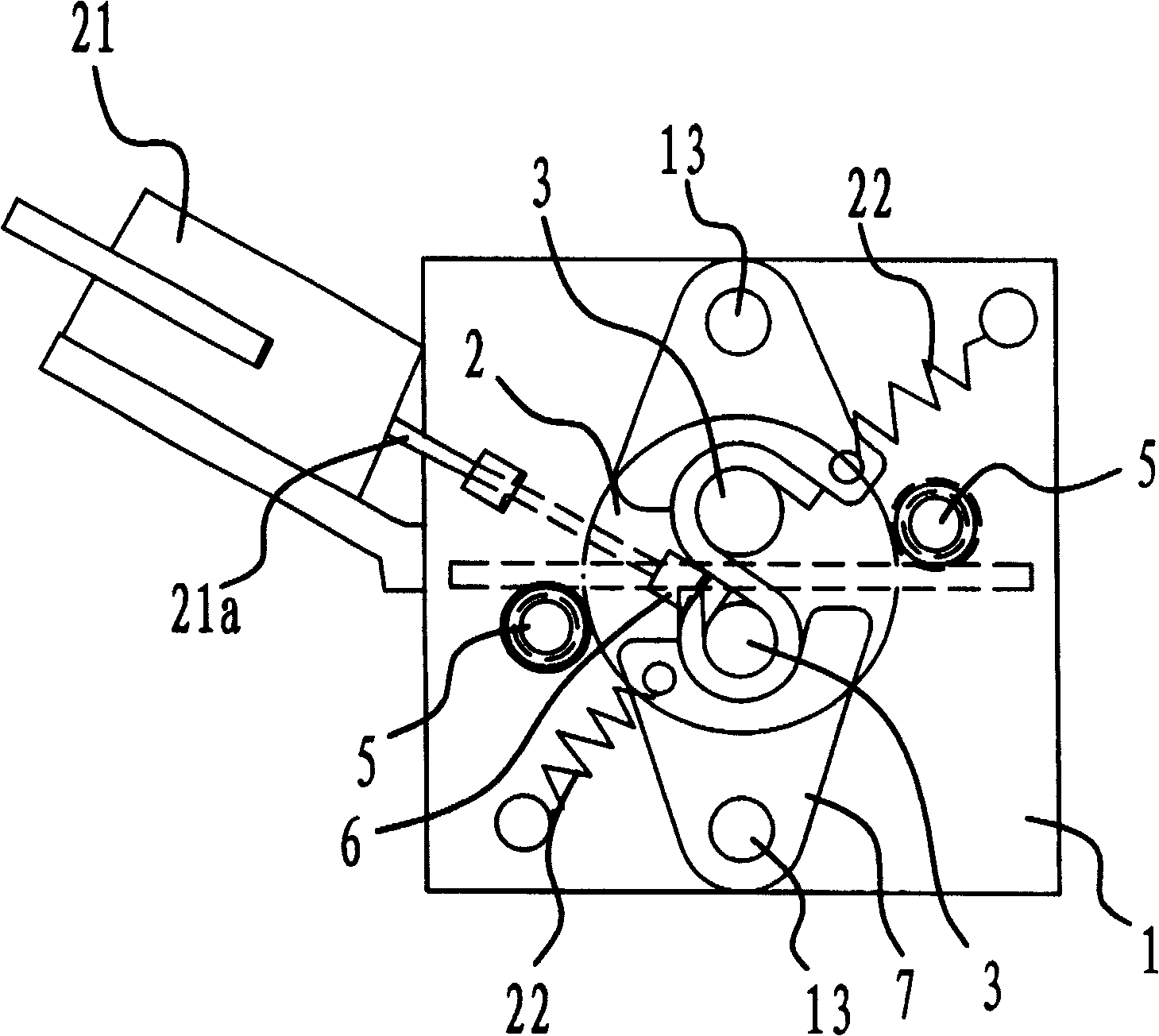

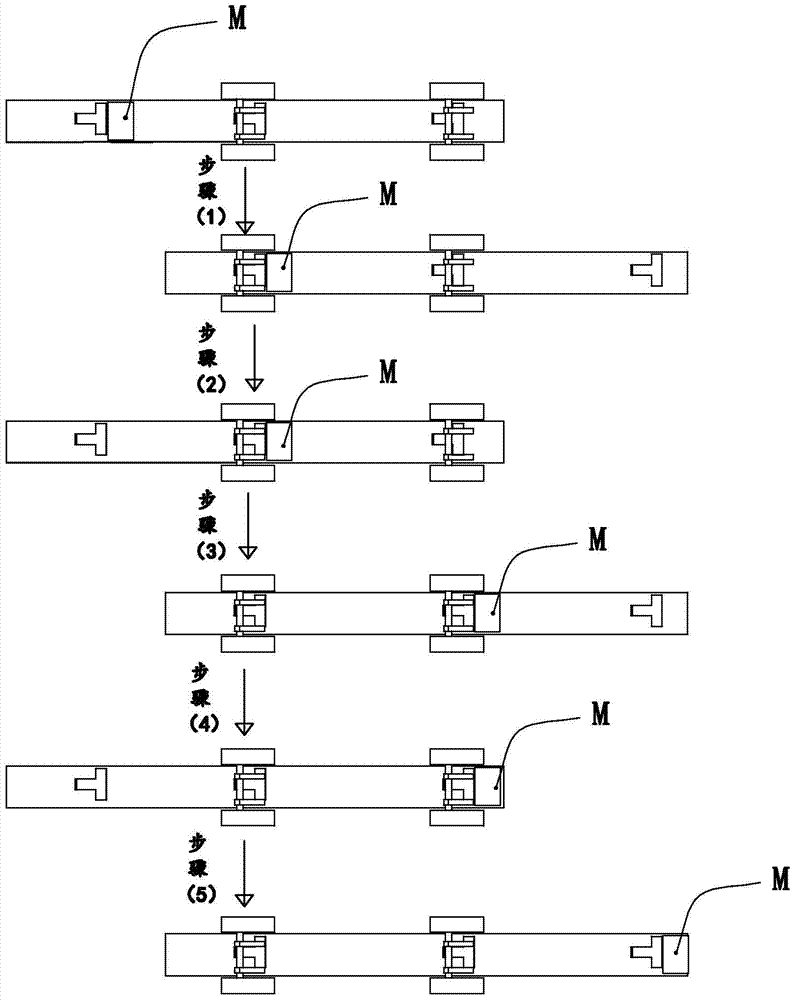

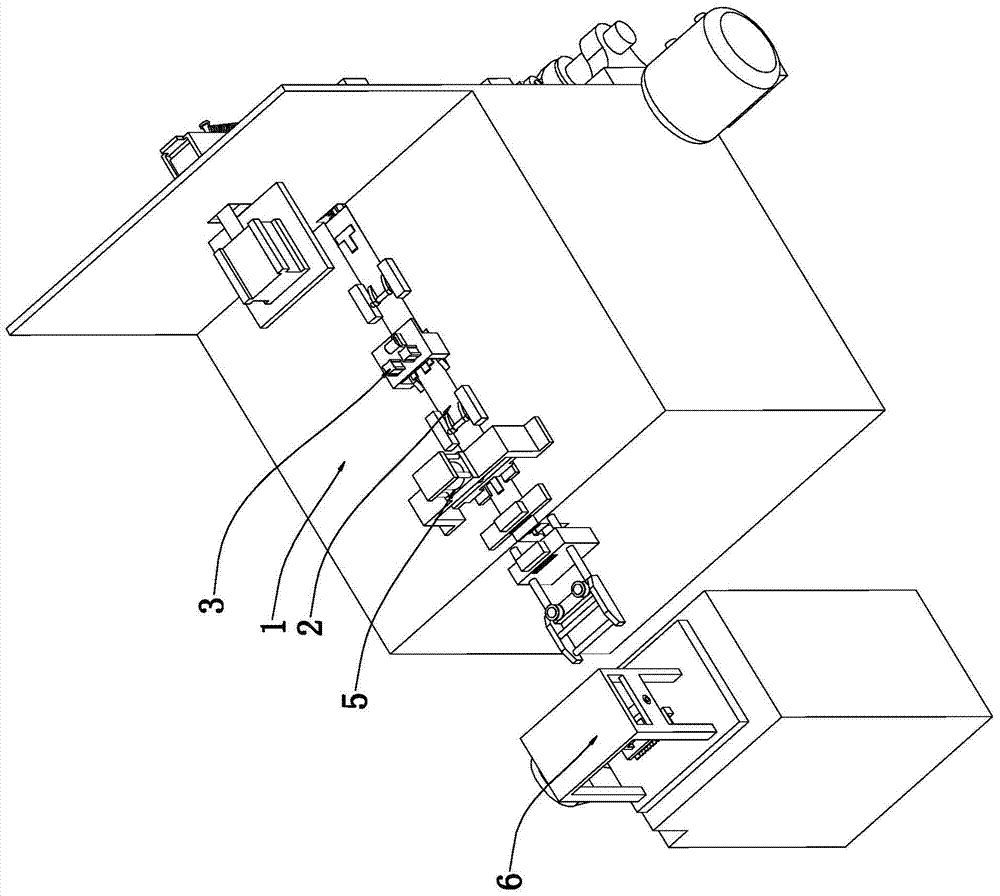

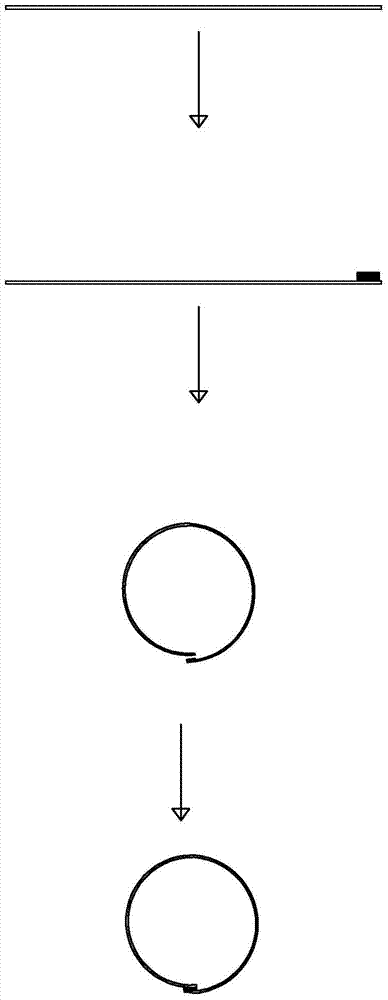

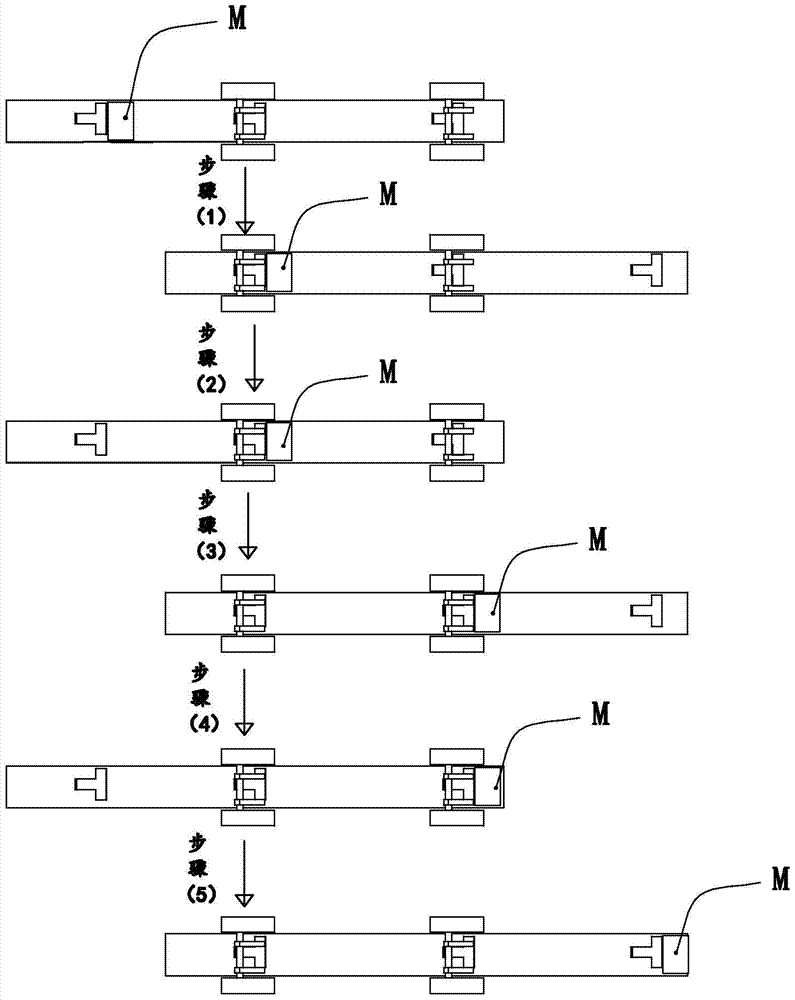

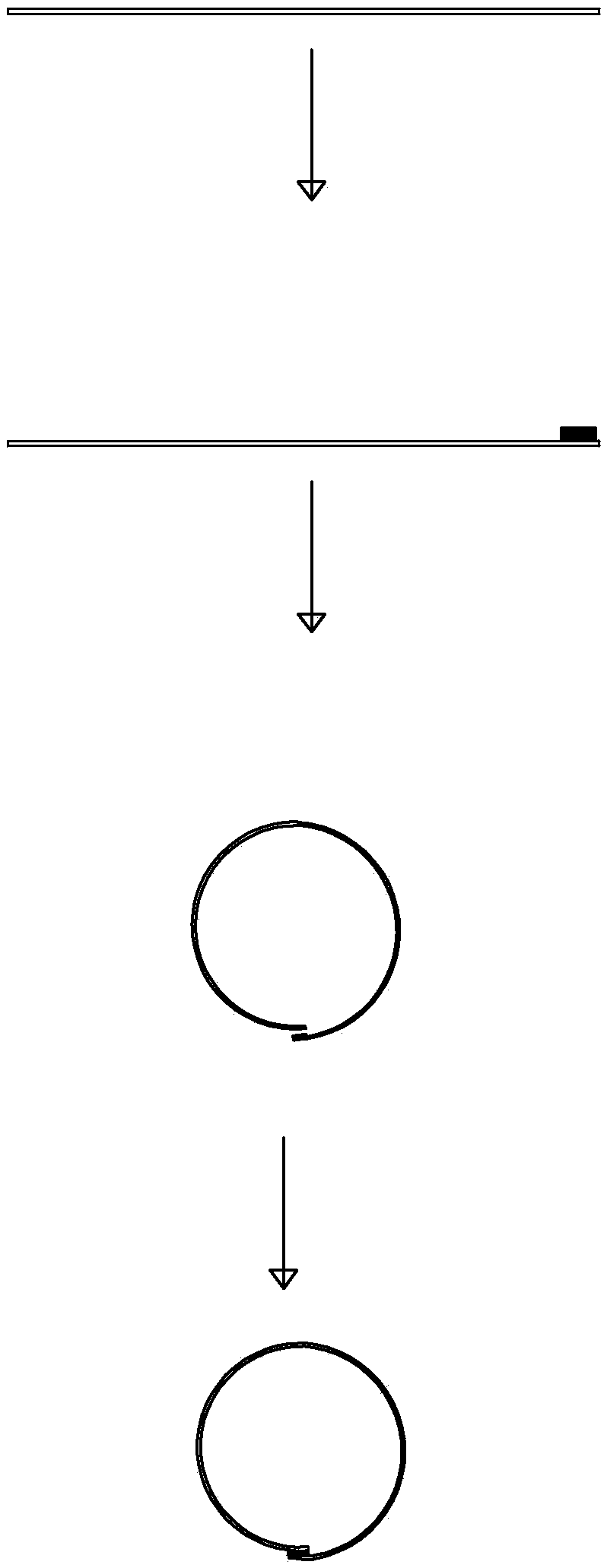

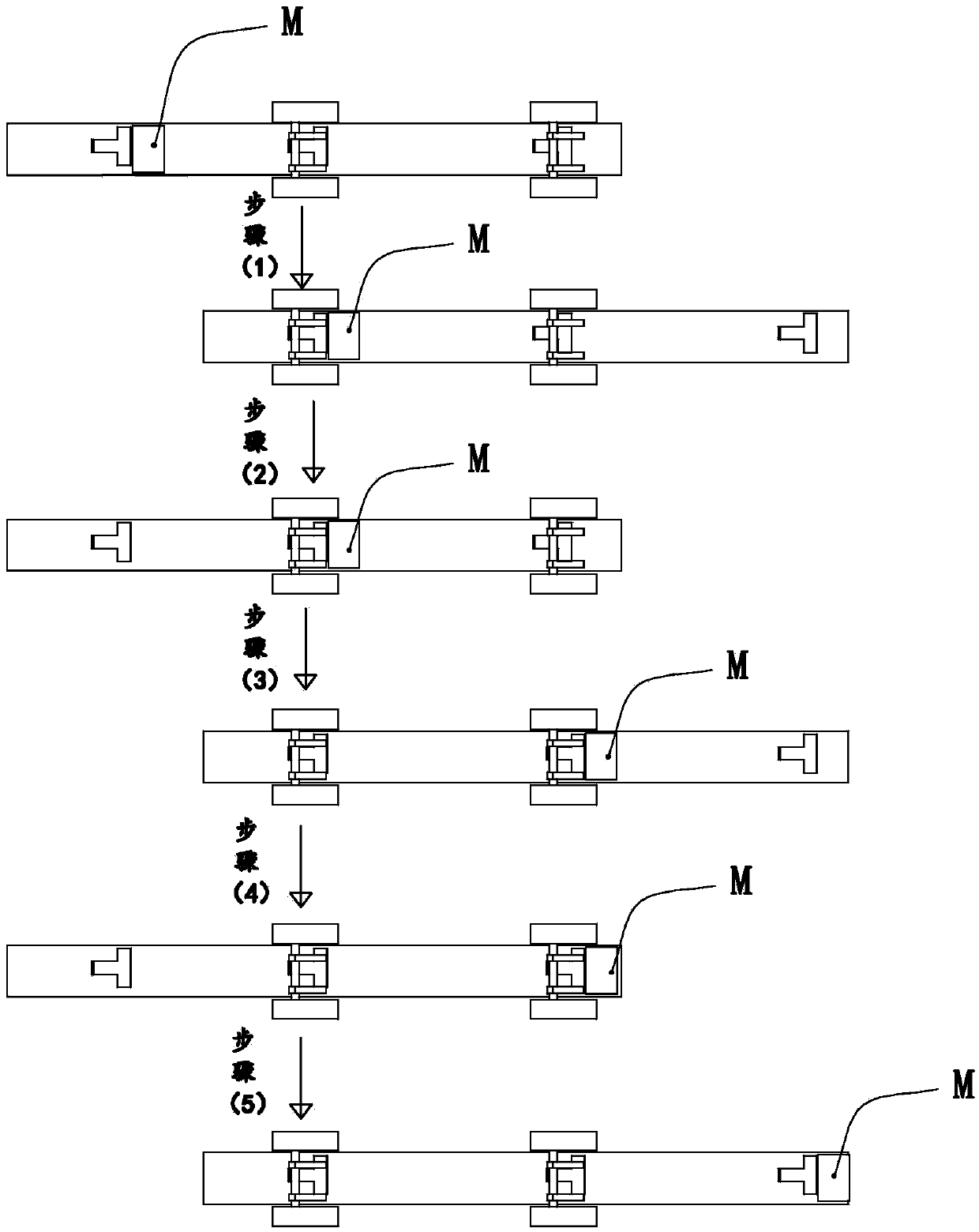

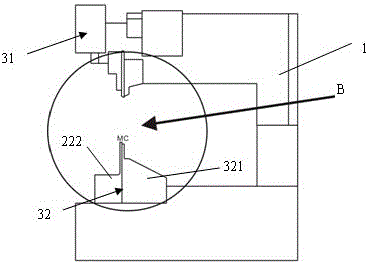

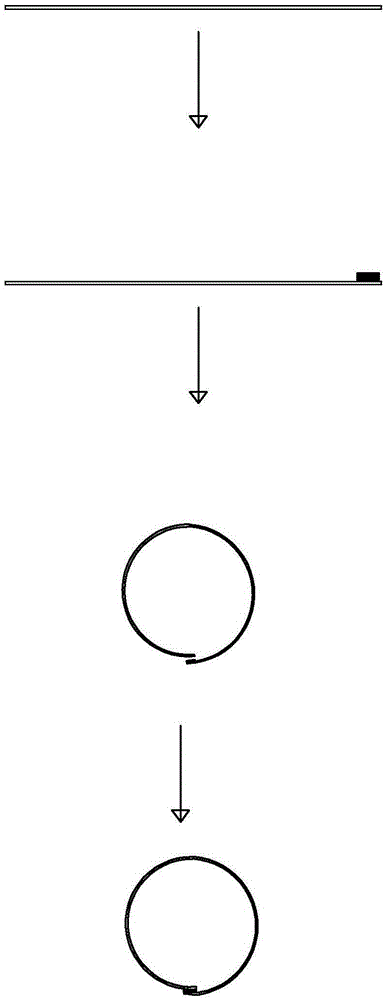

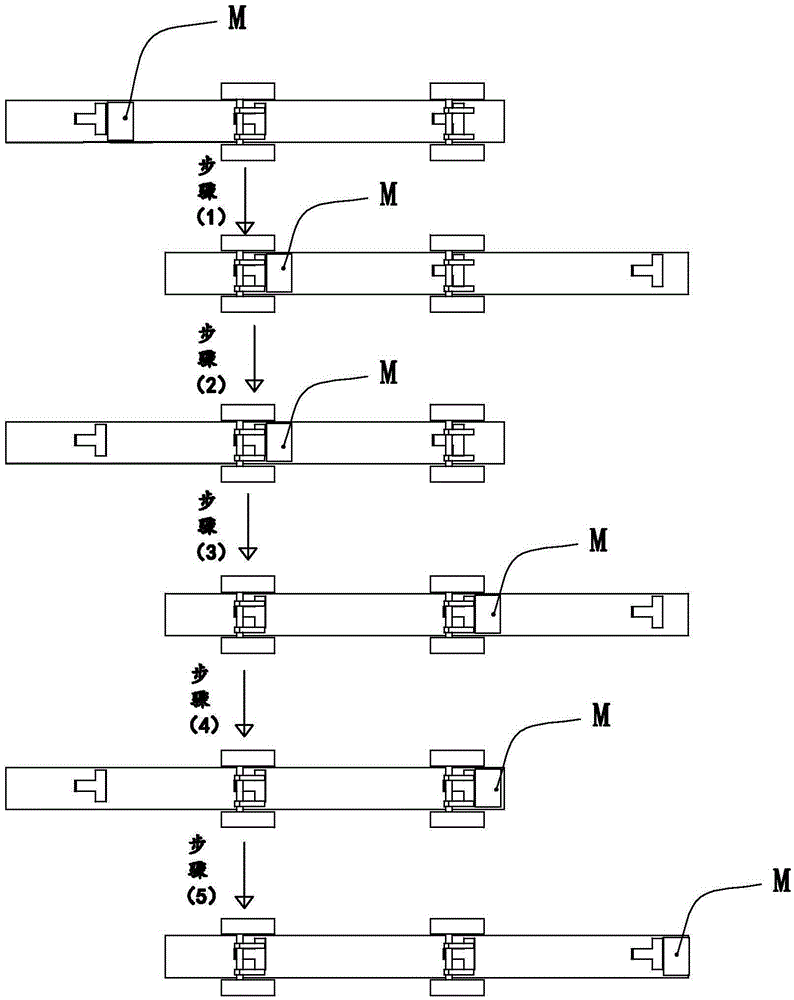

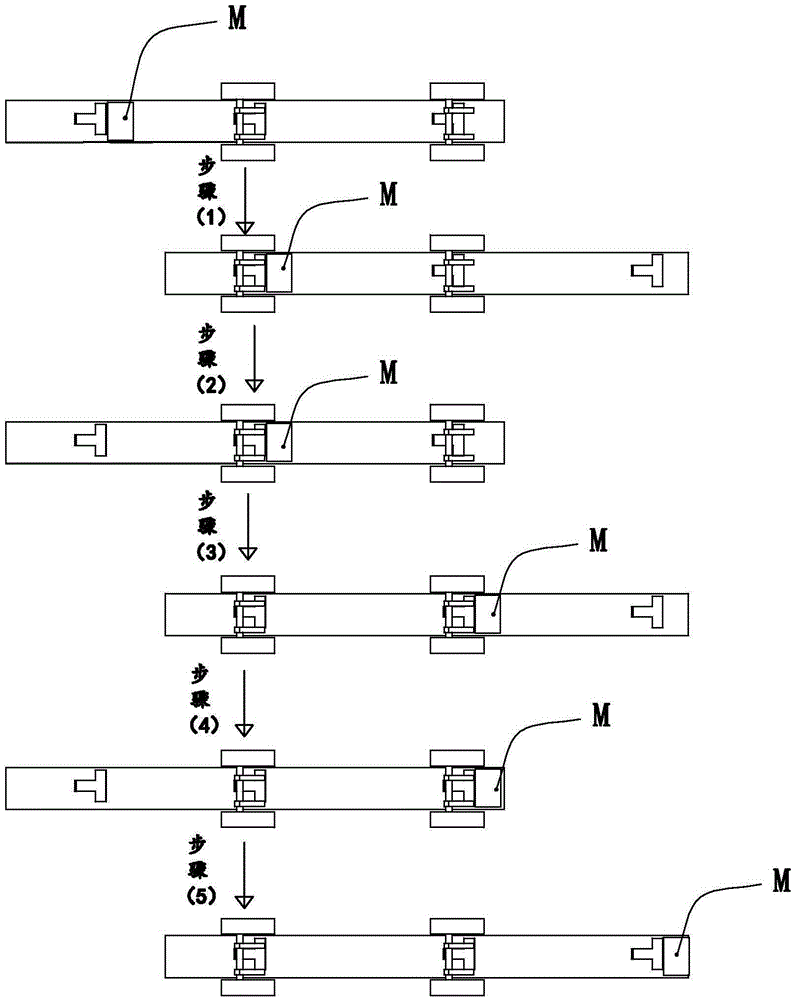

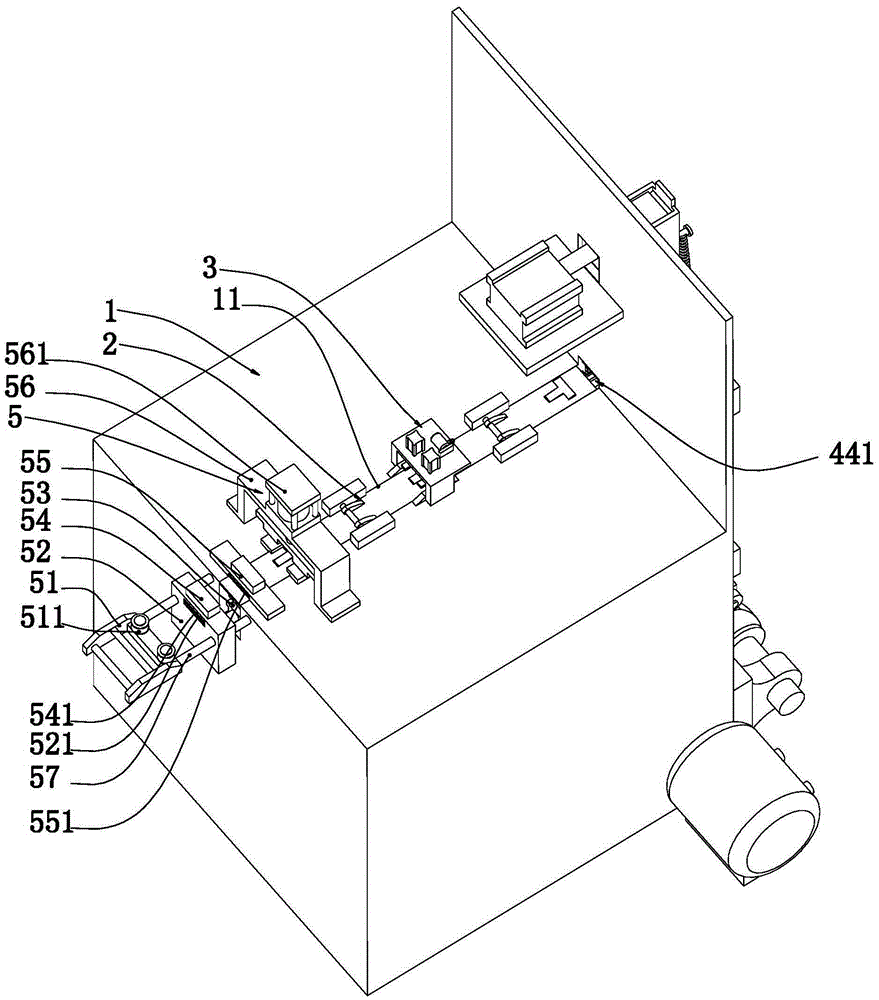

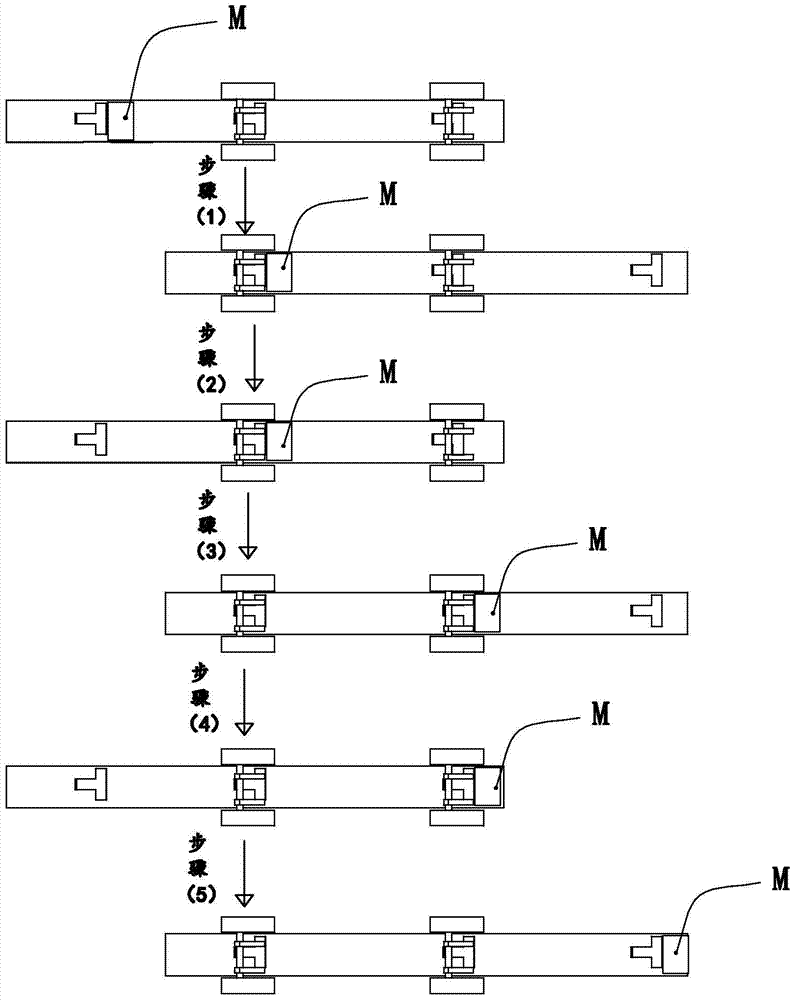

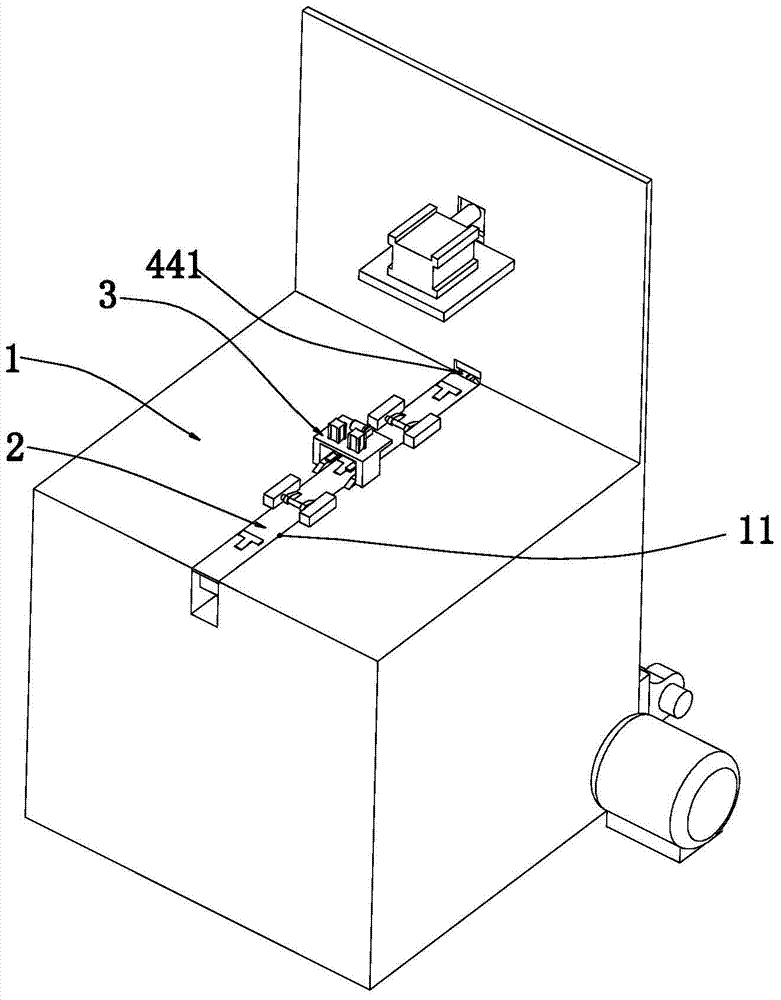

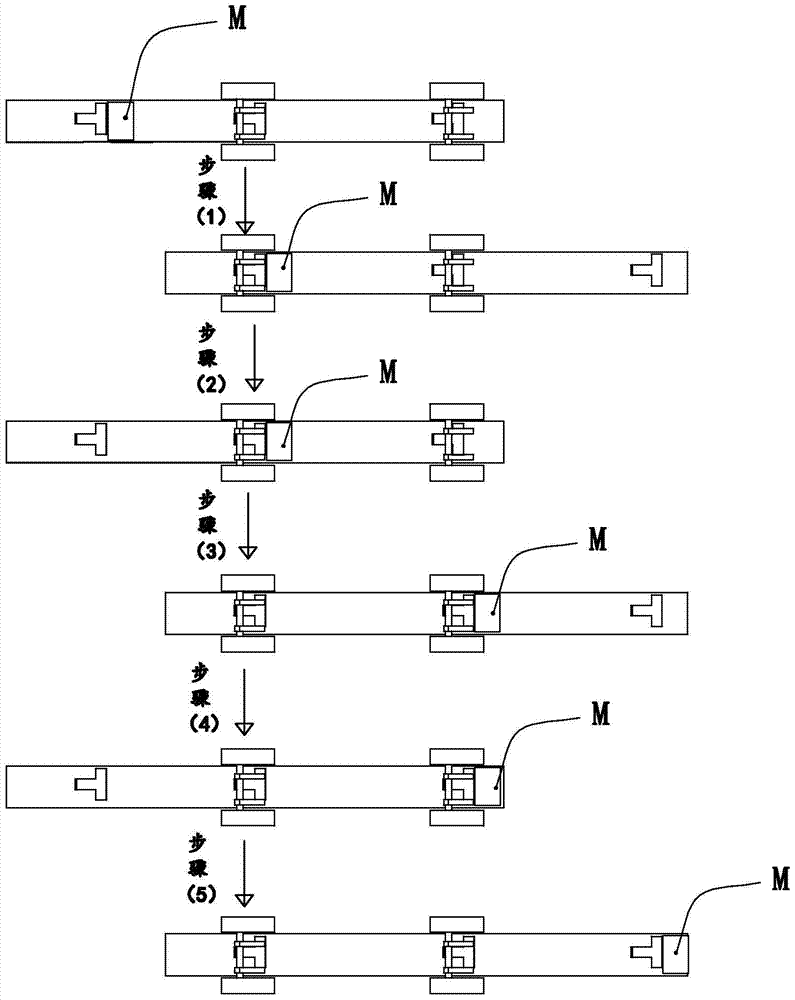

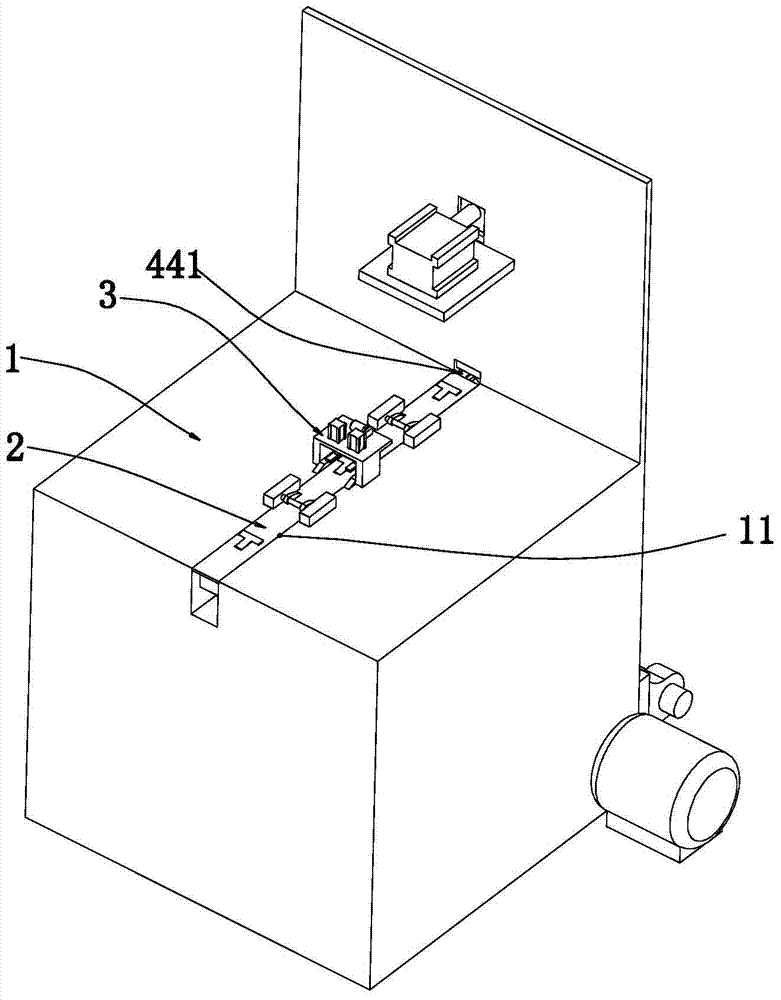

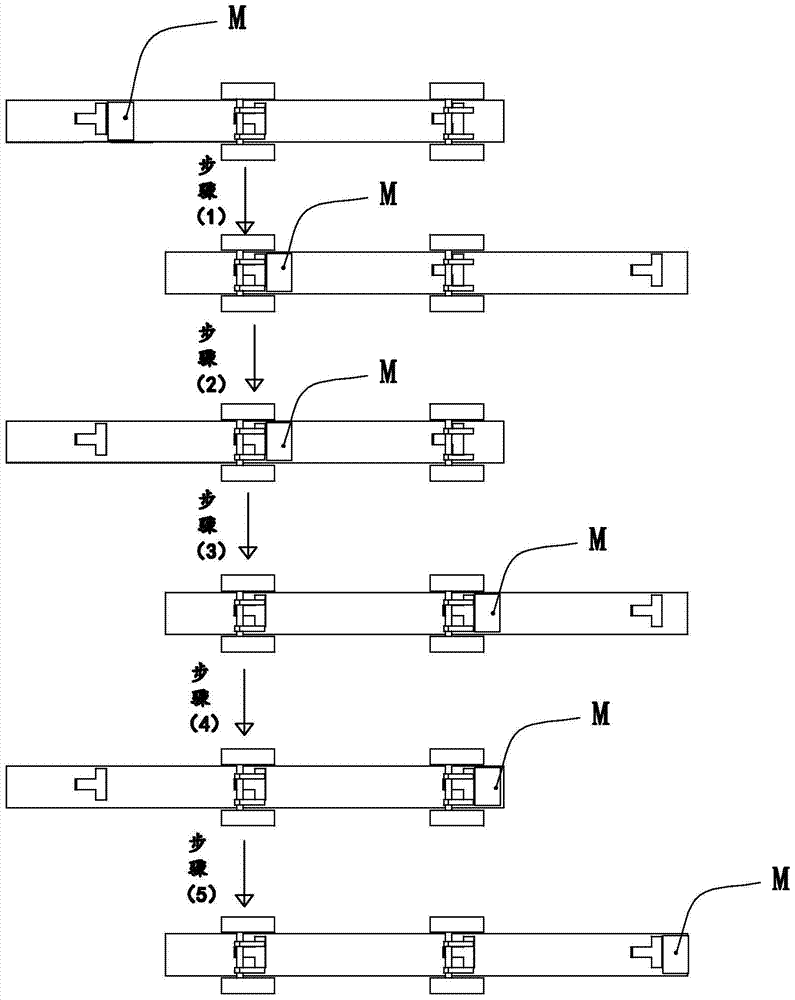

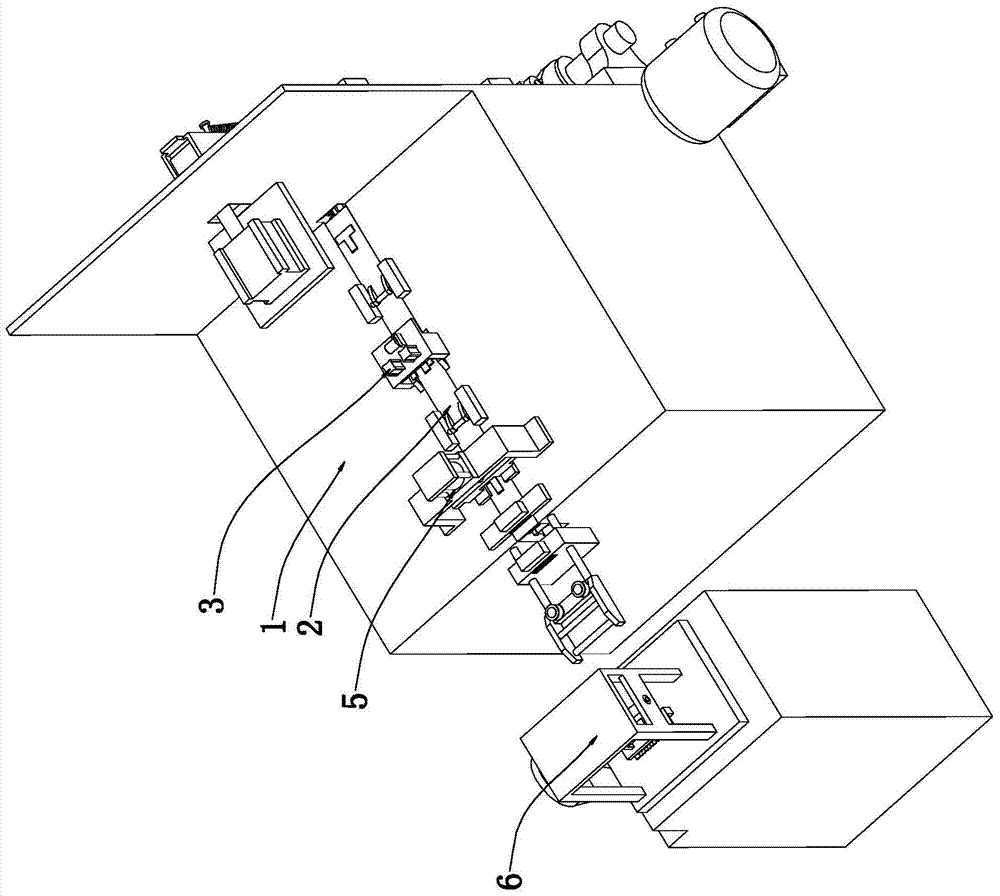

Edge folding, embracing and edge clamping device of filter center pipe forming machine

ActiveCN105598242AImprove molding processing efficiencyGood molding consistencyMetal-working feeding devicesPositioning devicesForm processingForms processing

The invention discloses an edge folding, embracing and edge clamping device of a filter center pipe forming machine. The device comprises an edge folding mechanism and an embracing-edge clamping mechanism connected to the discharge end of the edge folding mechanism, wherein the edge folding mechanism comprises a sheet transporting rail, and a left edge folding assembly and a right edge folding assembly arranged on left and right sides of the sheet transporting rail; the embracing-edge clamping mechanism comprises a support plate, an embracing mandrel, an embracing positioning pressing plate, an edge clamping top block and two embracing force application assemblies arranged on left and right sides of an embracing die, and the support plate is provided with a feed inlet. The edge folding, embracing and edge clamping device has the advantages of high forming processing efficiency and good product forming consistency.

Owner:温州市法法服饰有限公司

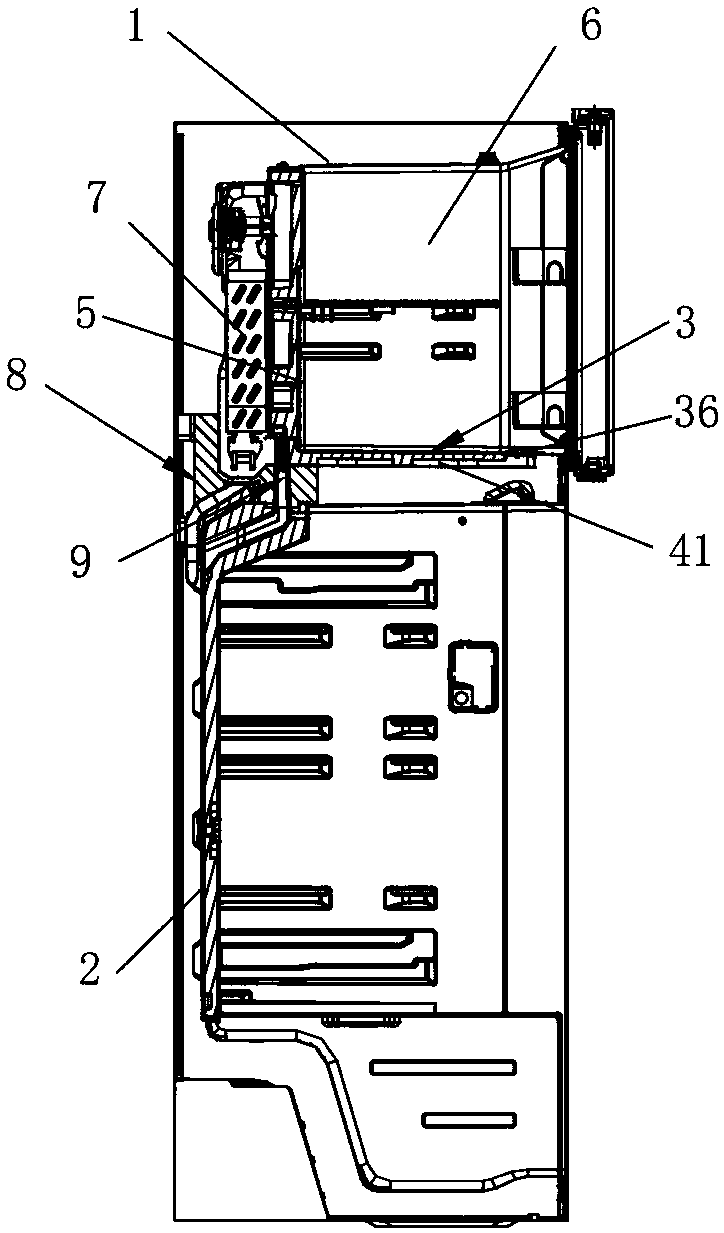

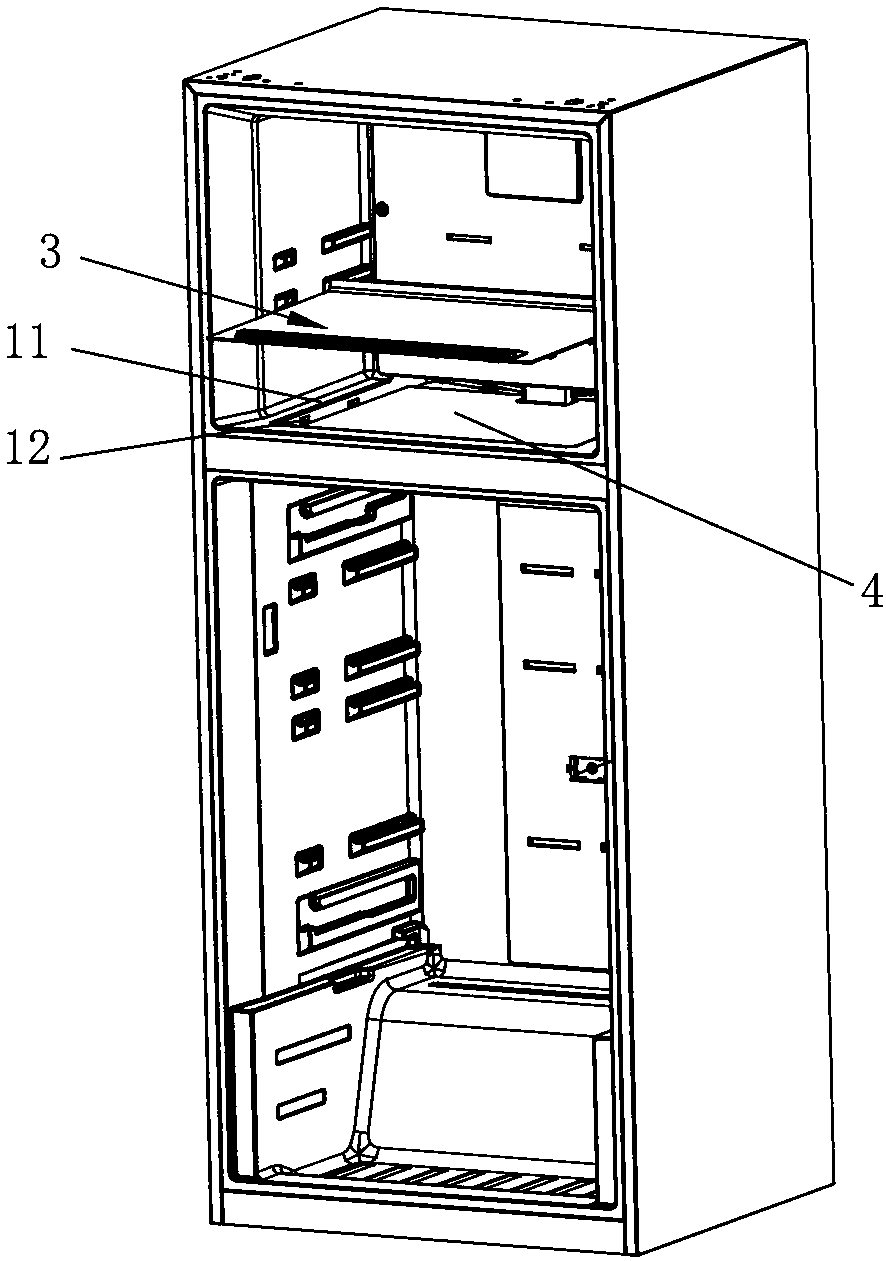

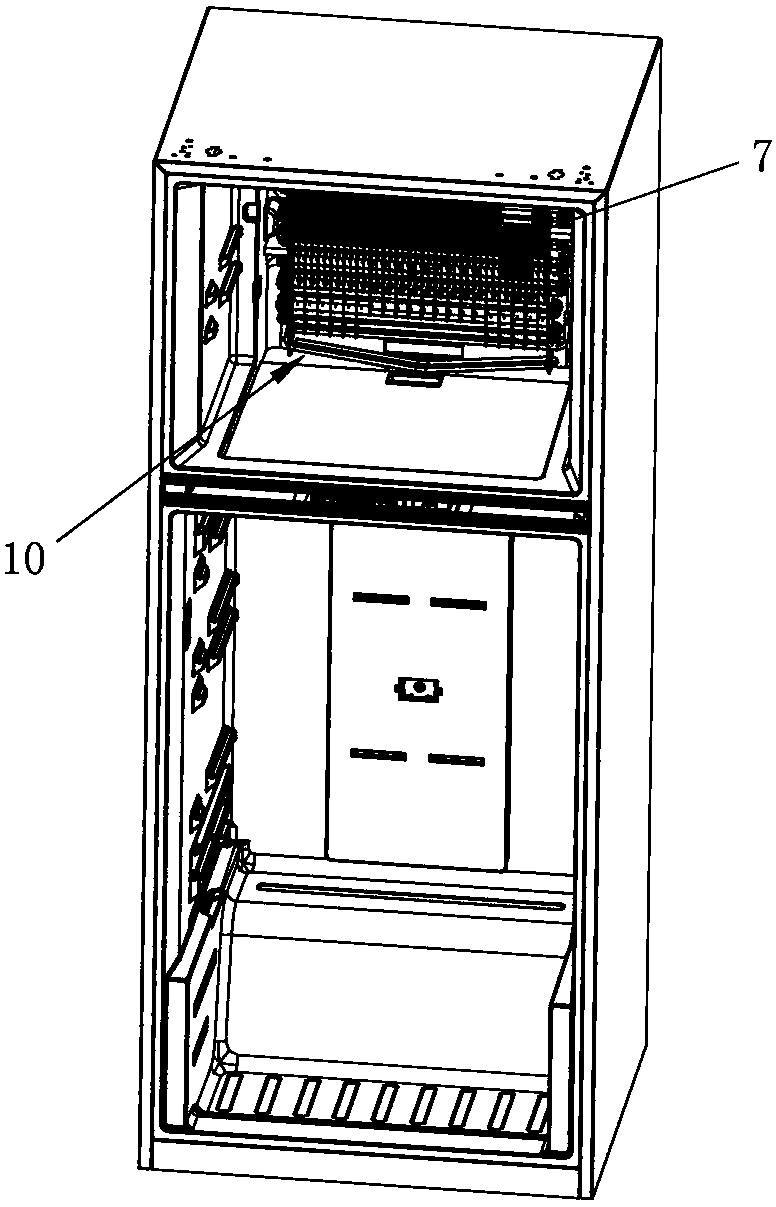

Air-cooled refrigerator

InactiveCN108253694ASimple structureGood molding consistencyLighting and heating apparatusDomestic refrigeratorsEvaporatorPre embedding

The invention relates to the technical field of refrigerators, and discloses an air-cooled refrigerator. The air-cooled refrigerator comprises a freezing box and a refrigerating box, the freezing boxis located above the refrigerating box, and a wind cavity groove communicating with the freezing box is formed in the bottom of the freezing. The freezing box includes a freezing compartment, and a front air return duct assembly is mounted, corresponding to the bottom of the freezing compartment, on the wind cavity groove; and a wind cavity is limited by the front air return duct assembly and thewind cavity groove, and the wind cavity communicates with the bottom of an evaporator located at the back of the freezing compartment. A return air inlet is formed, corresponding to the front end of the bottom of the freezing compartment, in the front air return duct assembly, so that cold air in the freezing compartment flows into the wind cavity through the return air inlet and flows back to thebottom of the evaporator. The air-cooled refrigerator can solve the existing problems that pre-embedded air ducts in the freezing box are difficult to assemble due to the large size and the strengthis prone to being poor after debinding.

Owner:GUANGZHOU MIDEA HUALING REFRIGERATOR

Automatic eyebrow pencil tip assembling and clamping mechanism

InactiveCN103862422ARealize continuous online productionSpeed blockMetal-working hand toolsEconomic benefitsMechanical engineering

The invention discloses an automatic eyebrow pencil tip assembling and clamping mechanism. The automatic eyebrow pencil tip assembling and clamping mechanism comprises an assembling rack, wherein a dual-station pencil tip push rod assembly is mounted on an upper plate face of the assembling rack in a sliding manner; the dual-station pencil tip push rod assembly comprises a push rod bottom plate, a first pencil tip push rod and a second pencil tip push rod, wherein the push rod bottom plate is in sliding fit with the upper plate face, and the first pencil tip push rod and the second pencil tip push rod are arranged on the push rod bottom plate side by side to form two work stations; a clamping work air cylinder is mounted on the upper plate face and pushes the push rod bottom plate to drive the first pencil tip push rod and the second pencil tip push rod to slide back and forth, the first pencil tip push rod touches a pencil tip entering a station where the first pencil tip push rod is located, so as to confirm the positions of the pencil tip and a pencil holder, and the second pencil tip push rod presses the confirmed pencil tip, which enters a station where the second pencil tip push rod is located, into the pencil holder, so as to realize the automated online assembly of eyebrow pencil tips. The automatic eyebrow pencil tip assembling and clamping mechanism can realize the automated online continuous assembly of the eyebrow pencil tips and has the characteristics of high speed and high efficiency, the labor cost can be reduced, the labor loss is reduced, and the economic benefit of enterprises is increased.

Owner:WENZHOU POLYTECHNIC

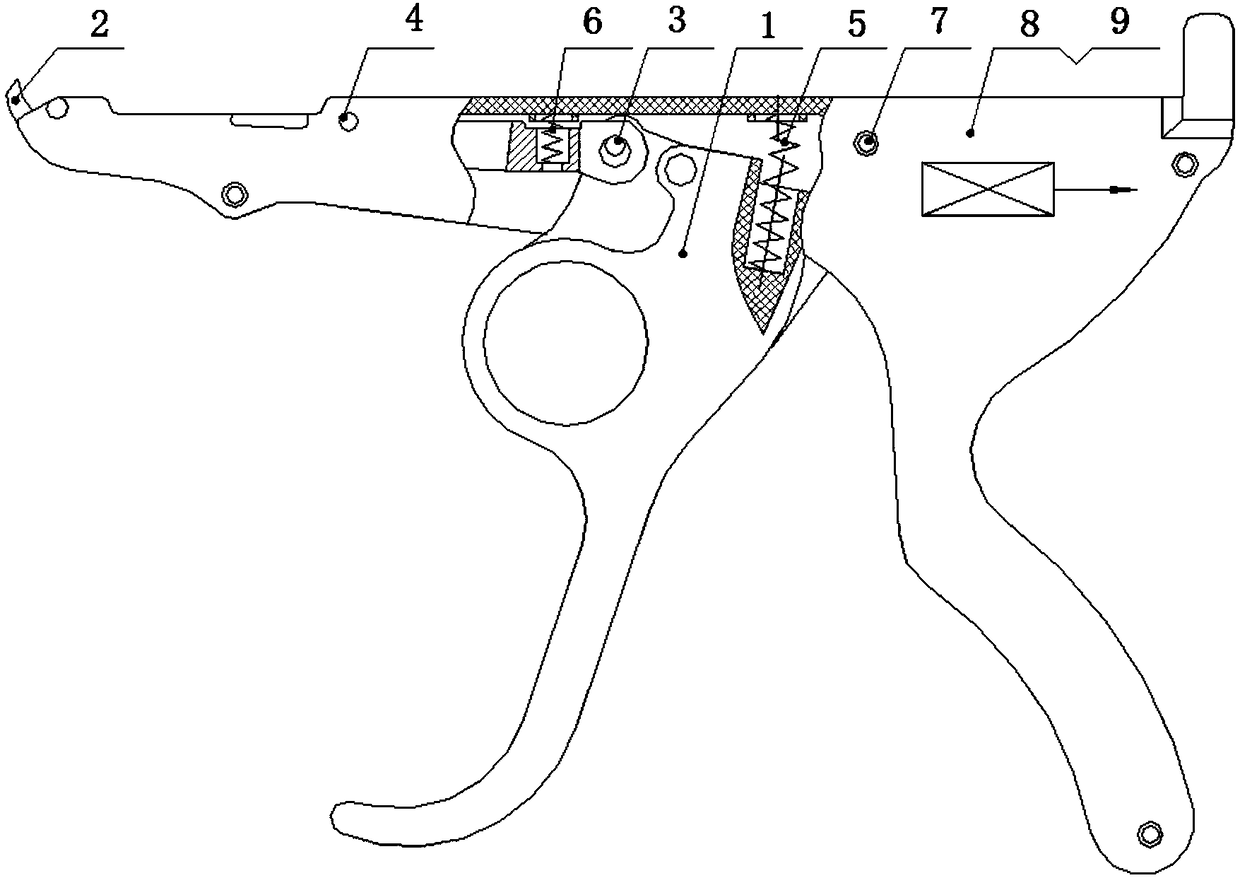

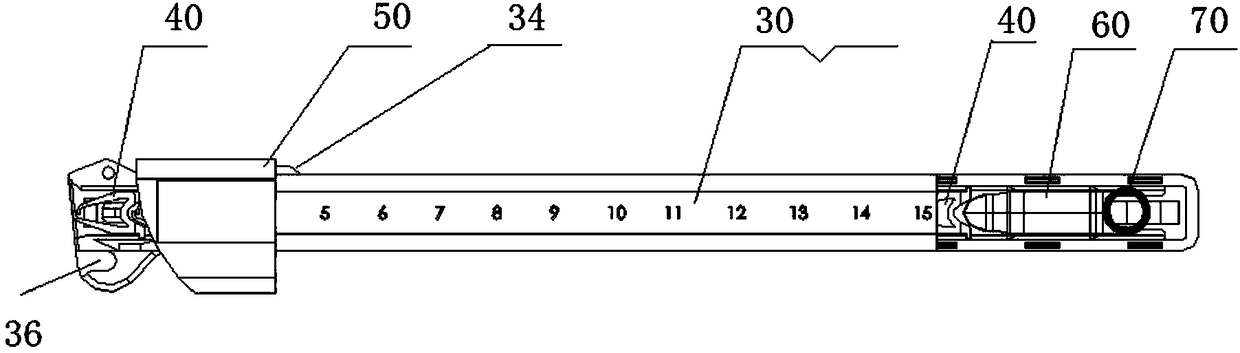

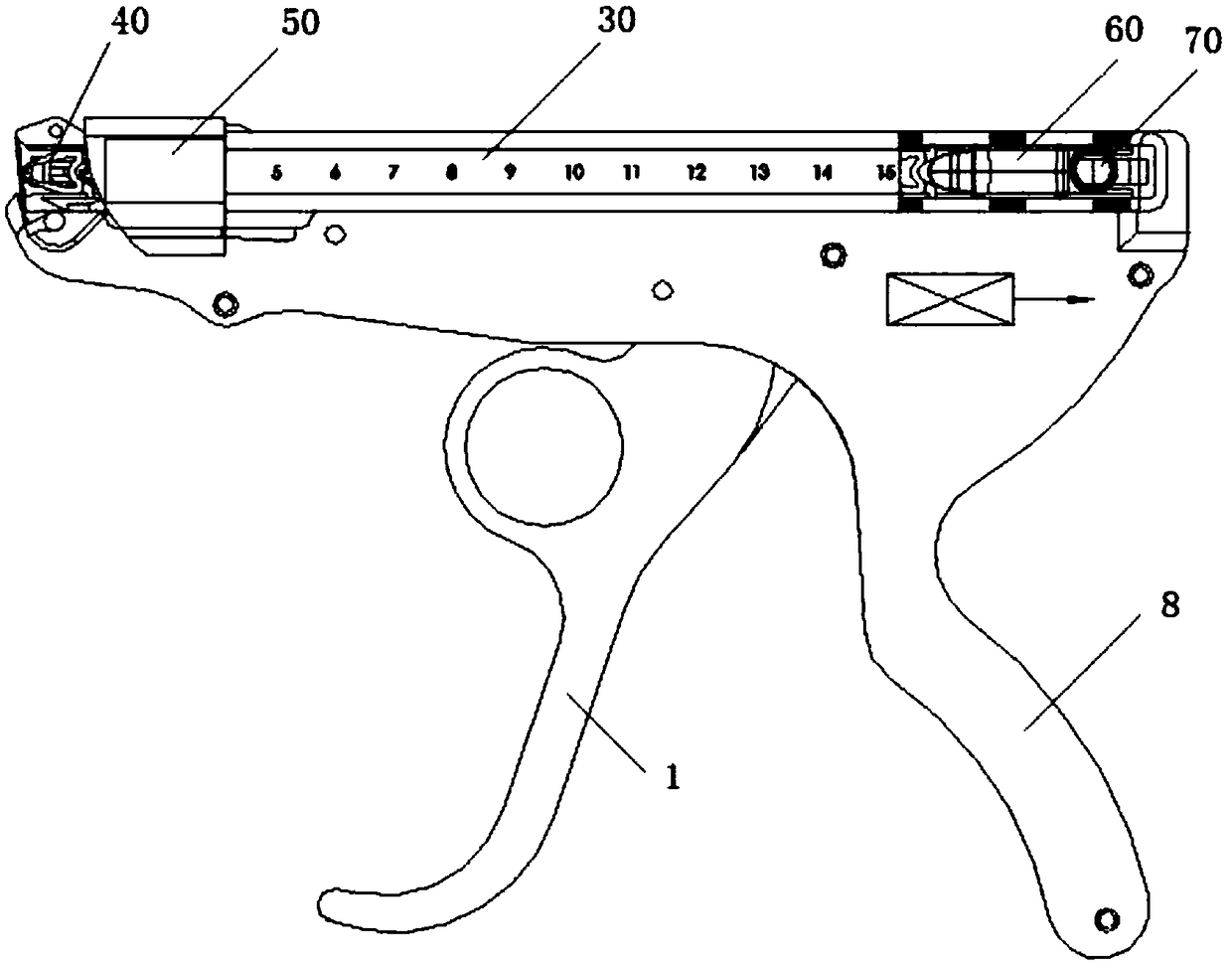

Continuous push type scalp clamping device

The invention discloses a continuous push type scalp clamping device which includes a scalp clamp and a scalp clamping box. The scalp clamp includes a percussion handle, a control lever, an elastic cylindrical pin, a positioning pin, a screw, a large spring, a small spring, a left half gun casing and a right half gun casing. The scalp clamping box includes a clip, scalp clips, a clip locking button, a conveying block and a coil spring. The scalp clamping box is mounted on the scalp clamp, the percussion handle is triggered, the head of the control lever abuts against the lower rear portion ofthe scalp clip to make the scalp clip automatically opened, the opened scalp clip is placed on the scalp, the percussion handle is loosened, and the scalp clip automatically clamps the scalp; and by continuous triggering and loosening of the percussion handle, the plurality of scalp clips can be released continuously to clamp the scalp. The device is convenient to operate and use and can automatically shortens the scalp clamping operation time and greatly improve operation efficiency; at the same time, the amount of bleeding of scalp during the scalp clamping operation can be greatly reduced,the operation time can be reduced by 2 / 3, and the amount of anesthetic used during an operation can also be reduced.

Owner:元毓医疗科技(上海)有限公司

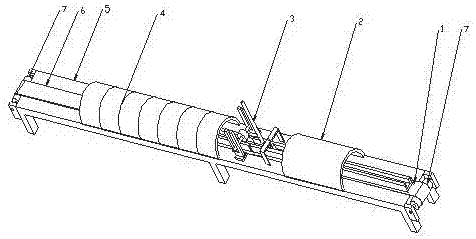

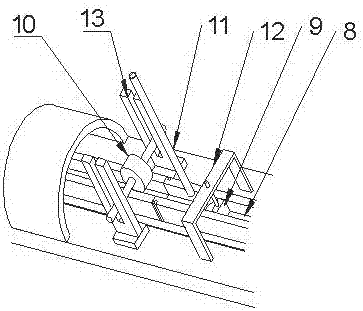

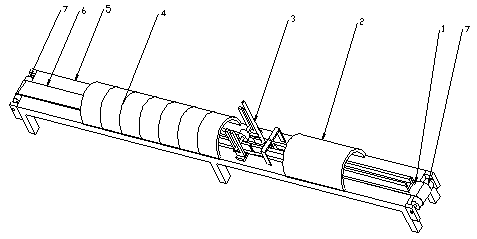

Optical glass small strip material molding device

ActiveCN107500514AReduce cutting processAvoid stickingGlass reforming apparatusInstabilityPower apparatus

The invention discloses an optical glass small strip material molding device, and belongs to the technical field of optical glass molding. The optical glass small strip material molding device solves the problems that optical glass forming devices in the prior art cannot overcome production instability and low yield rate caused by mold sticking and deformation of small strip material glass. The optical glass small strip material molding device is characterized in that the optical glass small strip material molding device comprises a transmission mechanism, a preheating part, a forming part and an annealing part, wherein the transmission mechanism comprises a frame body, a roller, a conveyer belt and a power device; the preheating part, the forming part and the annealing part are respectively located at the front end, the middle end and the terminal end of the transmission mechanism; the conveying belt is provided with a forming groove which passes through the preheating part, the forming part and the inner cavity of the annealing part, molten glass moves synchronously with the forming groove when molded in the forming part, and the upper surface can be leveled by a rolling wheel. Small strip material glass with the end surface with the side length of 5 mm or more can be drawn, the optical glass small strip material molding device has the advantages of small and uniform cold marks and high forming consistency, by use of the thin square material, the cutting process of large blocks of glass can be saved, excess glass material and loss are less, and labor cost is low.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

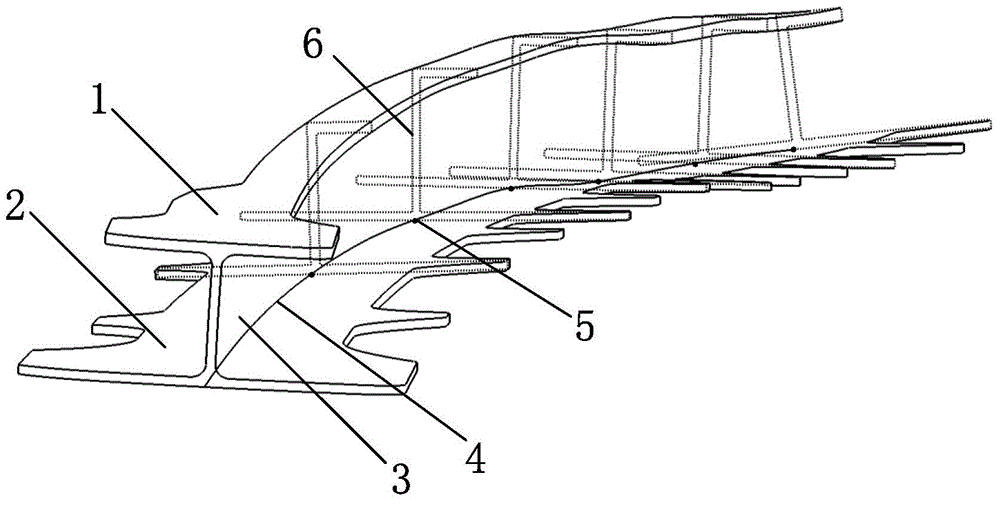

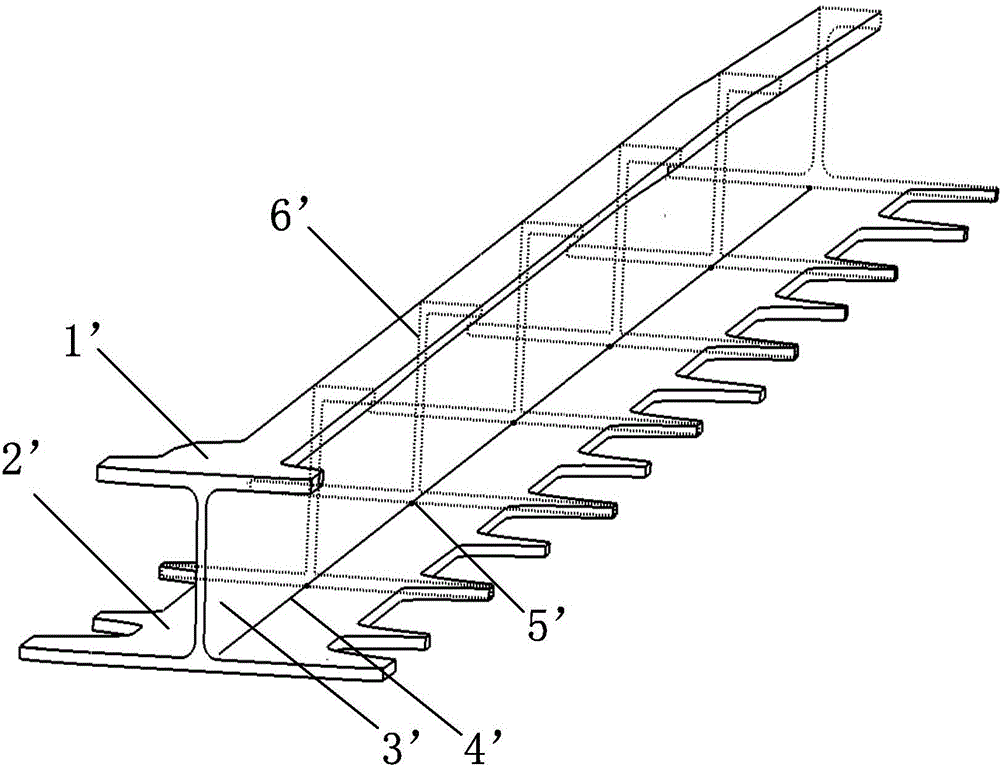

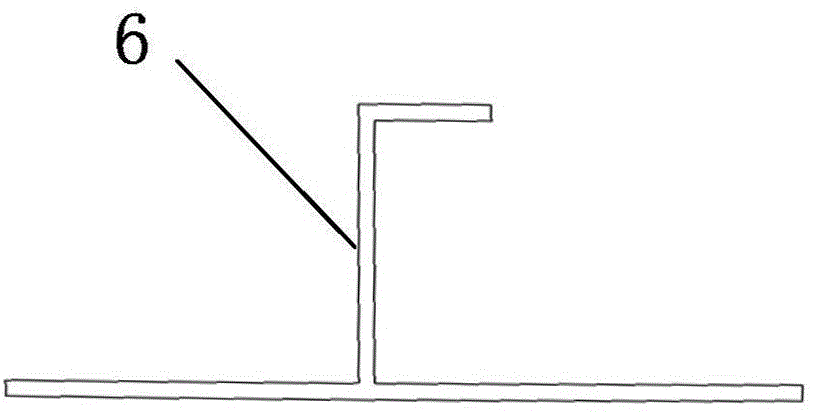

Unfolding plate blank for bent and twisted stringer

InactiveCN104890854AGood molding consistencyImprove consistencyFuselage framesVertical barMarine engineering

The invention provides an unfolding plate blank for a bent and twisted stringer. The unfolding plate blank is obtained through straightening and unfolding a design digital model of the bent and twisted stringer, and comprises an upper web plate, a lower web plate and vertical bars, wherein the vertical bars are used for connecting the upper web plate and the lower web plate; a crossing line of a vertical bar reference surface and a lower web plate reference surface is a reference line for the unfolding plate blank; the reference line is a straight line section; the length of the reference line is identical to the length of the reference line of the design digital model of the bent and twisted stringer; the normal section of the upper web plate, the lower web plate and the vertical bras in any position on the reference line is identical to the normal section of the upper web plate, the lower web plate and the vertical bars in a position, corresponding to the reference line, in the design digital model of the bent and twisted stringer; and the vertical bar reference surface of the unfolding plate blank is a plane.

Owner:XIAN AIRCRAFT BRANCH OF XIAN AIRCRAFT INT

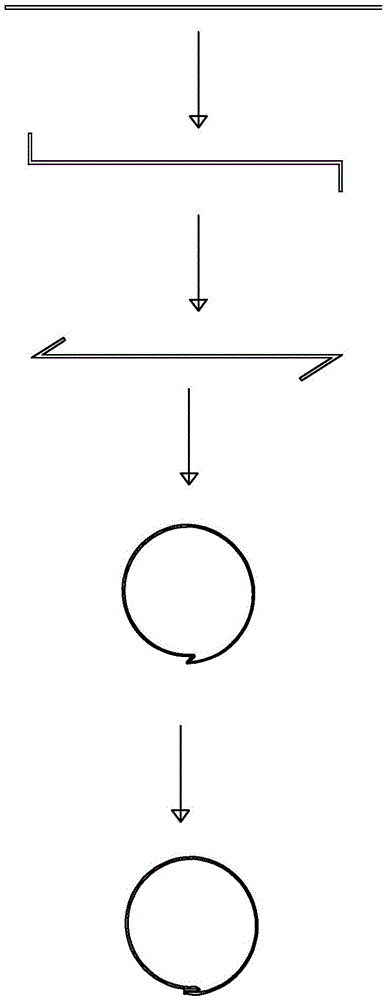

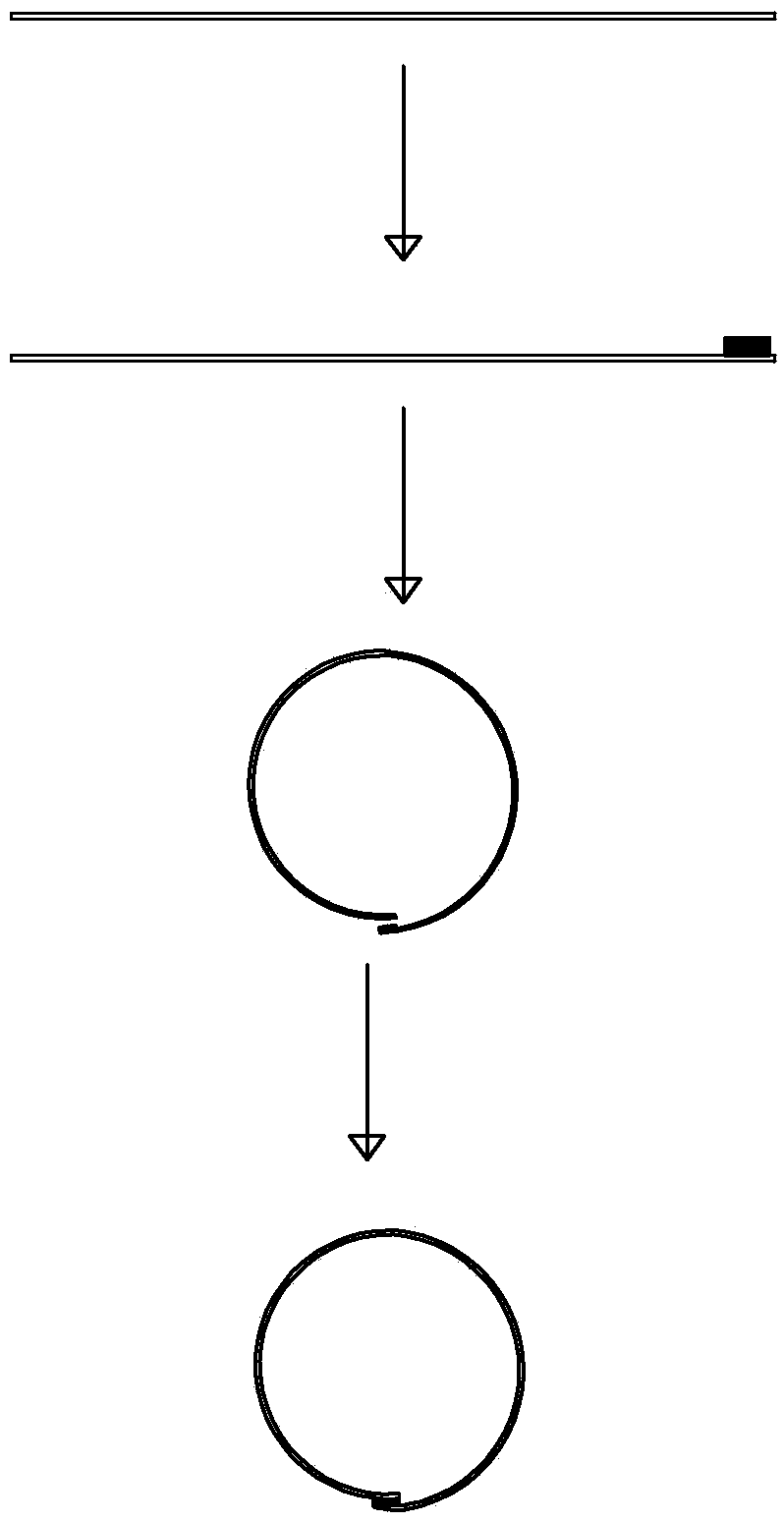

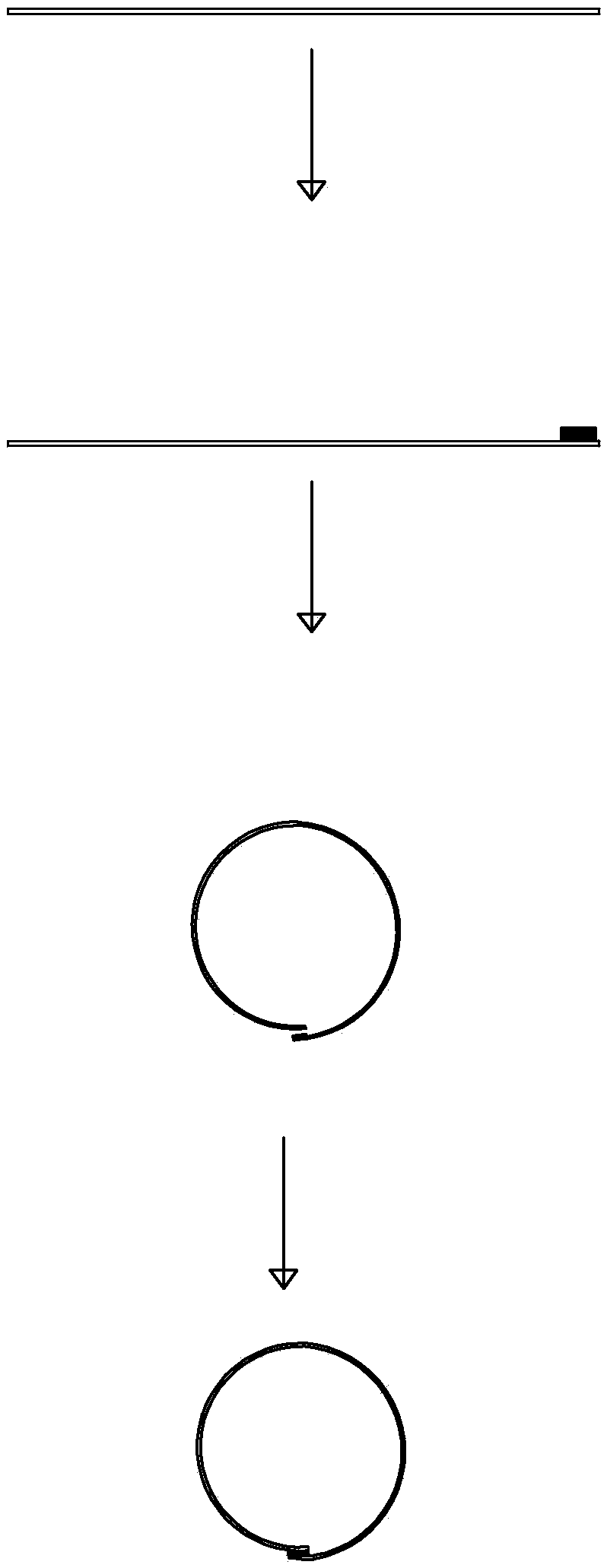

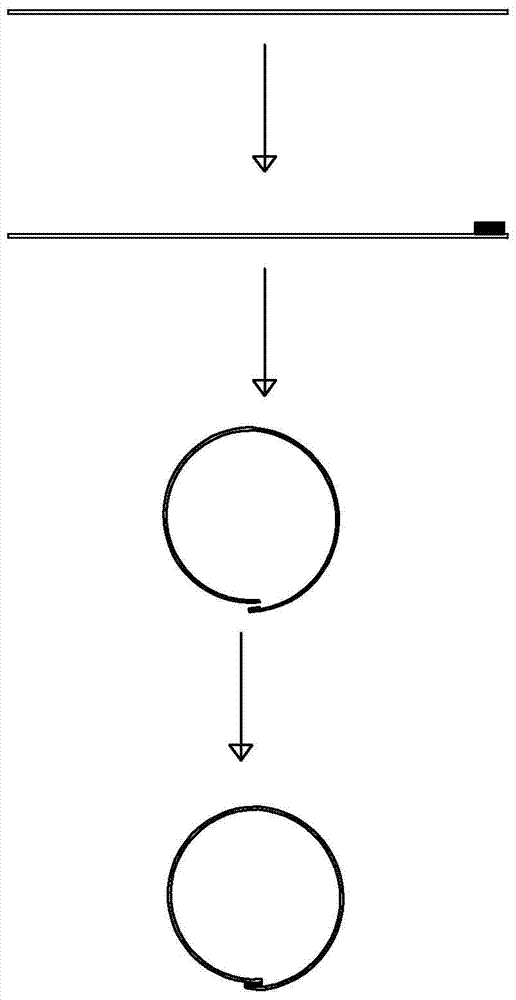

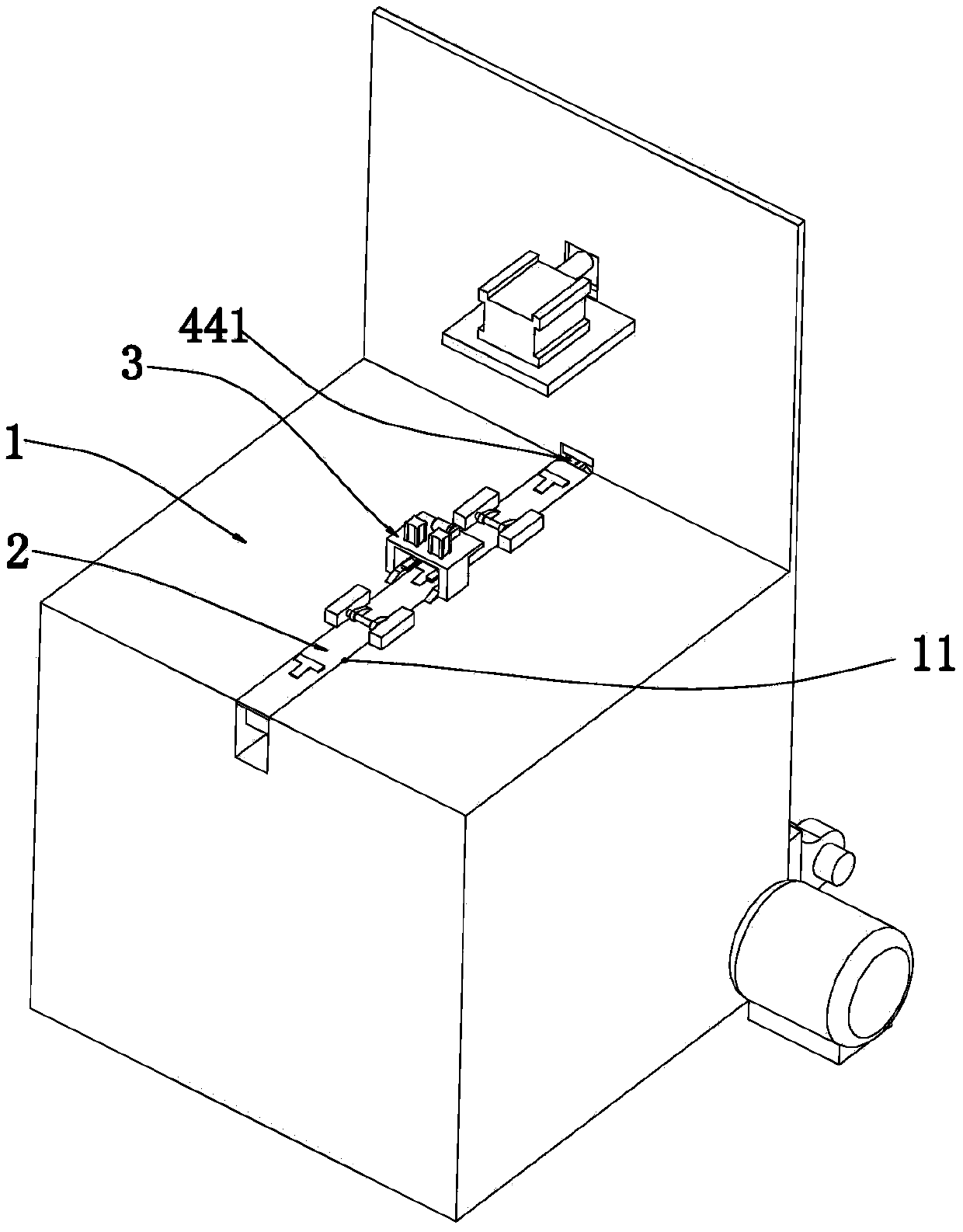

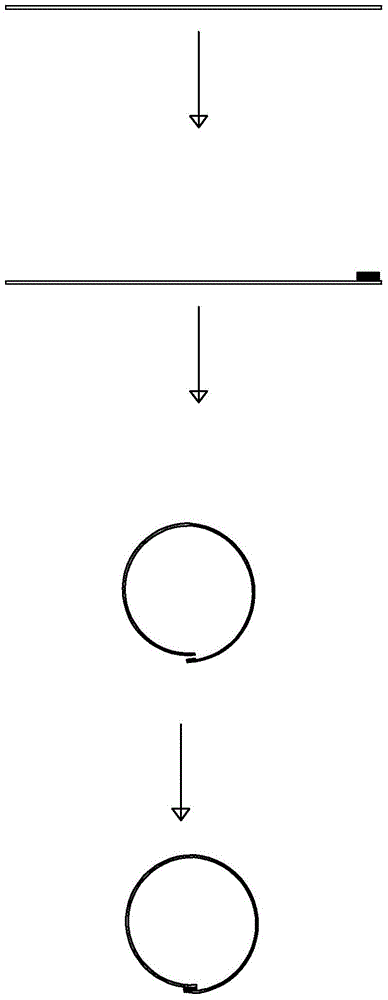

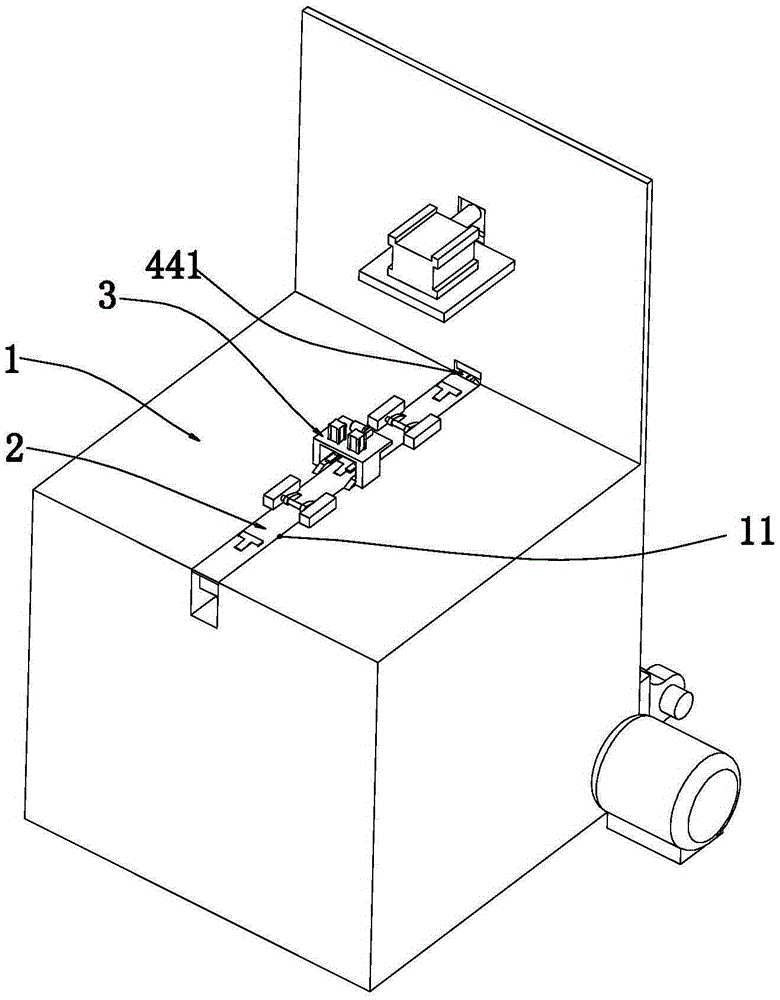

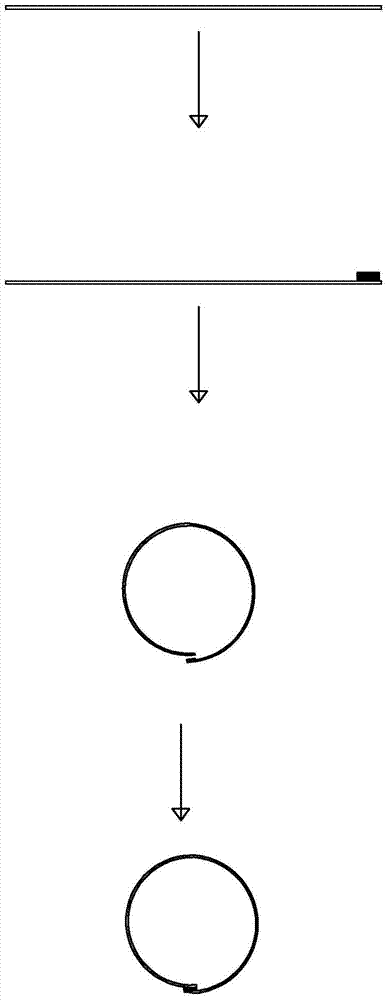

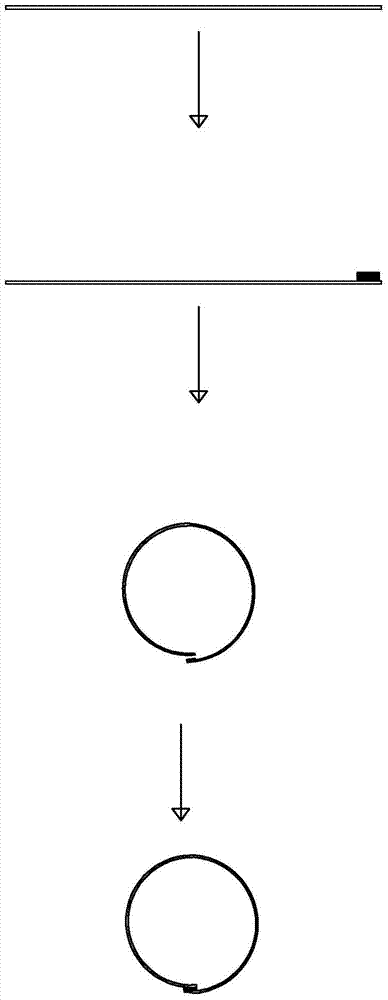

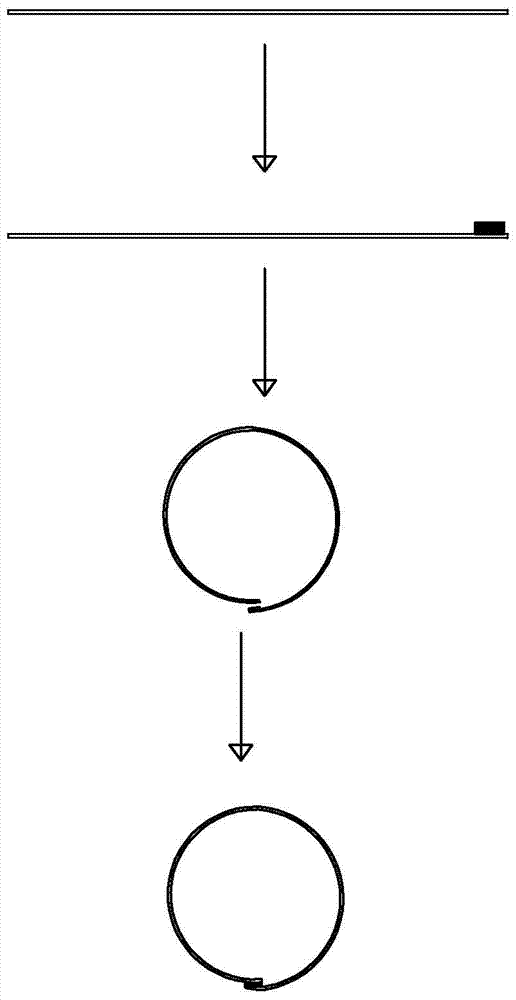

Tubular corrugated paper sleeve forming machine with tapping mechanism and material cutting mechanism

ActiveCN105479820AImprove molding processing efficiencyProduct molding consistency is goodPaper/cardboard articlesForming forceEngineering

The invention discloses a tubular corrugated paper sleeve forming machine with a tapping mechanism and a material cutting mechanism. The tubular corrugated paper sleeve forming machine comprises a machine frame, a feeding mechanism, an edge gluing mechanism and a circle forming edge baking mechanism, wherein the feeding mechanism comprises a feeding rail plate and a feeding rail plate gliding driving cylinder; the edge gluing mechanism is arranged on a gluing baseplate above the feeding rail plate; the circle forming edge baking mechanism comprises a supporting plate, a circle forming mandrel, a circle forming positioning pressing plate, an edge clamping top plate and two circle forming force application assemblies arranged on the left side and the right side of a circle forming mold, wherein a feeding hole is formed in the supporting plate and is connected to a discharging end of the feeding mechanism; a hot air cavity is formed in the edge clamping top plate; a plurality of hot air holes which communicate with the hot air cavity are formed in a top plate of the edge clamping top plate; a calorifier which is connected with a hot air cavity pipe is also arranged on the supporting plate. The tubular corrugated paper sleeve forming machine disclosed by the invention has the advantages of being reasonable in structure design, high in processing efficiency, and good in forming consistency of products.

Owner:重庆独角兽知识产权管理咨询有限公司

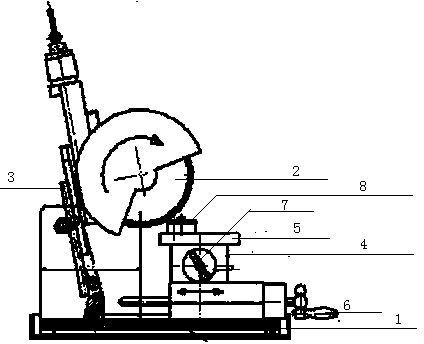

Tool sharpener

InactiveCN104070425AGuaranteed parallelismEnsure consistencyOther manufacturing equipments/toolsGrinding work supportsManufacturing technologyEngineering

The invention relates to a tool sharpener, in particular to a tool sharpener capable of machining two tools at the same time. The tool sharpener aims to solve the problem that according to an existing blade manufacturing technology, consistency and manufacturing efficiency cannot be considered at the same time. The tool sharpener comprises a base plate, a tool sharpening grinding wheel, a grinding wheel frame and a tool sharpening frame assembly. The grinding wheel frame is fixed to the base plate through a hinge. A clamping groove is formed in the grinding wheel frame. The tool sharpening grinding wheel is fixed to the grinding wheel frame along the clamping groove. The tool sharpening frame assembly comprises a supporting frame, a rotating shaft frame, a tool feeding and discharging adjusting handle and a locating adjusting handle, wherein the tool feeding and discharging adjusting handle and the locating adjusting handle are used for adjusting the position of the supporting frame. The tool sharpening frame assembly further comprises a rotating tool sharpening frame die. The rotating tool sharpening frame die comprises a rhombic clamp body. The blade manufactured through the tool sharpener is small in assembly error and good in forming consistency. Besides, two blades can be manufactured at the same time, and therefore the production efficiency is high.

Owner:范昕昀

Tubular corrugated paper sleeve forming machine provided with video monitoring camera

ActiveCN105365270AImprove efficiencyGood molding consistencyPaper/cardboard articlesMetal working apparatusRoundingAir heater

The invention discloses a tubular corrugated paper sleeve forming machine provided with a video monitoring camera. The tubular corrugated paper sleeve forming machine comprises a machine frame, a punching mechanism, a cutting mechanism, a feeding mechanism, an edge gluing mechanism, a rounding and edge drying mechanism and the video monitoring camera. The feeding mechanism comprises a feeding rail plate and a feeding rail plate sliding driving air cylinder. The edge gluing mechanism is arranged on a gluing base plate above the feeding rail plate. The rounding and edge drying mechanism comprises a support plate, a rounding core mold, a rounding positioning pressing plate, an edge clamping top plate and two rounding force applying assemblies arranged on the left side and the right side of a rounding mold. A feeding hole is formed in the support plate and connected with the discharging end of the feeding mechanism. A hot air cavity is formed in the edge clamping top plate. A plurality of hot air holes communicated with the hot air cavity are formed in a top plate body of the edge clamping top plate. The support plate is further provided with an air heater connected with a pipeline of the hot air cavity. The tubular corrugated paper sleeve forming machine has the advantages of being reasonable in structural design, high in machining efficiency, and good in product forming consistency.

Owner:泰州市茂华纸品有限公司

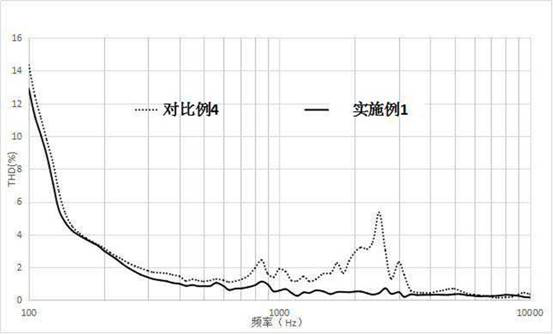

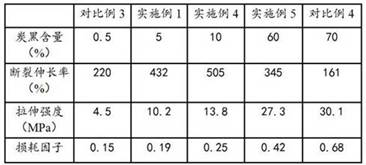

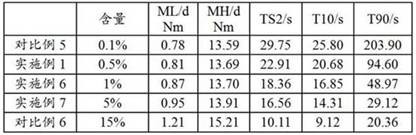

Diaphragm of sound production device and sound production device

ActiveCN111866699AThe overall performance of the diaphragm is goodImprove rigidityElectrical transducersElastomerPolysulfide rubber

The invention discloses a diaphragm of a sound production device and the sound production device. The diaphragm comprises at least one elastomer layer, and the elastomer layer is made of a rubber compound; the rubber compound is obtained by mixing raw materials containing raw rubber and a filler reinforcing agent, the raw rubber comprises polysulfide rubber, and the particle size of the filler reinforcing agent is 10 nm to 10 mum. The obtained diaphragm is good in comprehensive performance, can normally work under high and low temperature extreme conditions, can keep good rigidity, rebound resilience and damping performance, is low in distortion, and restores sound essence.

Owner:GOERTEK INC

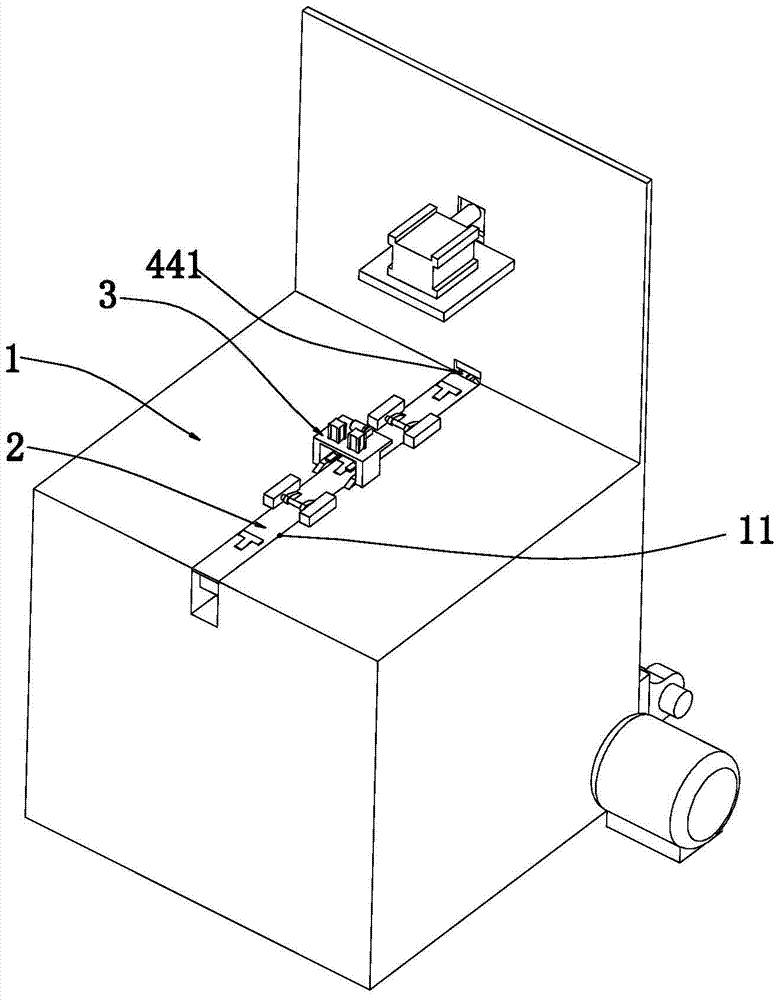

Folding, rounding and clamping devices of filter central tube forming machine

ActiveCN105598242BStable lifting drive structureRotating structure is stableMetal-working feeding devicesPositioning devicesHoopingEngineering

Owner:温州市法法服饰有限公司

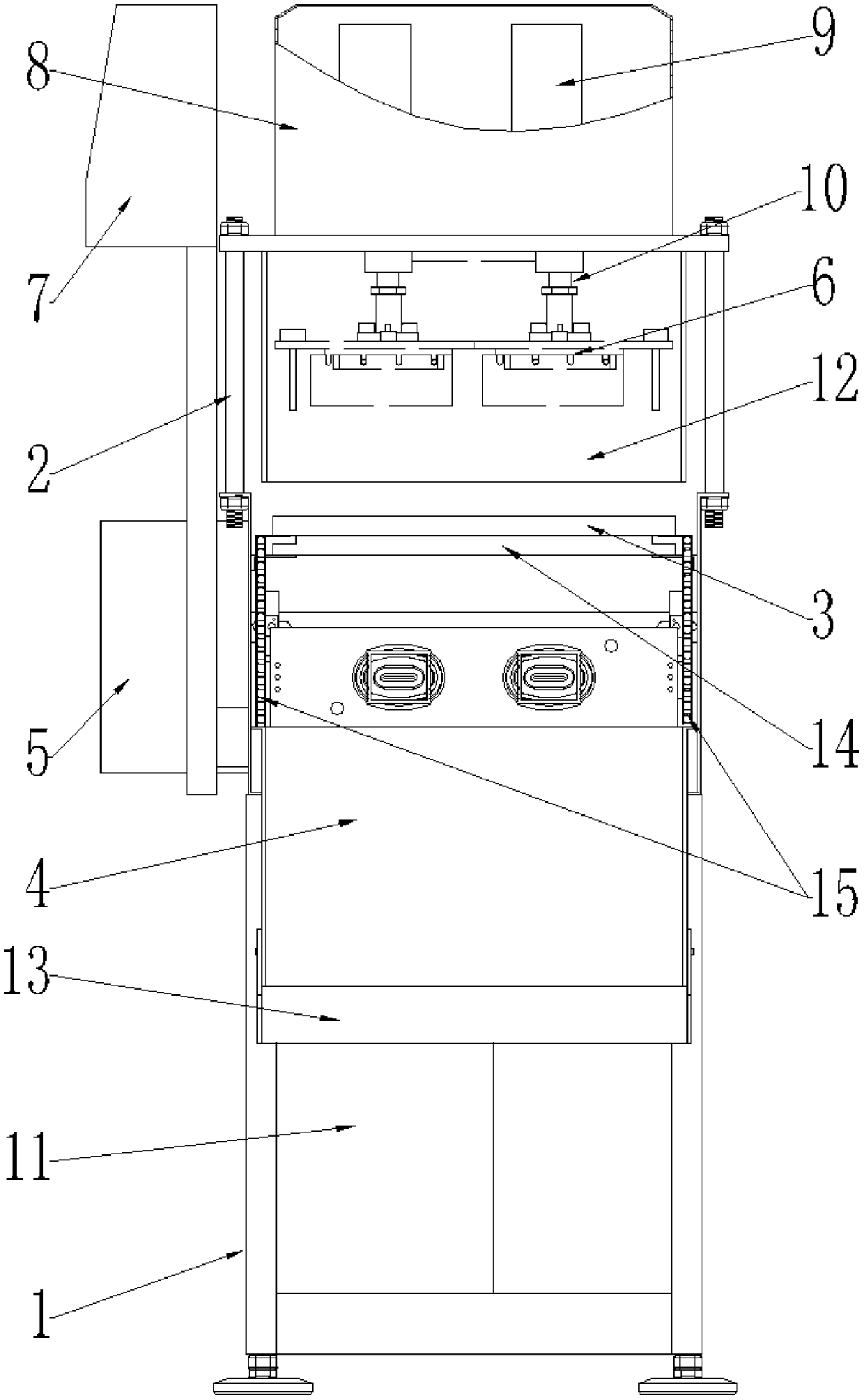

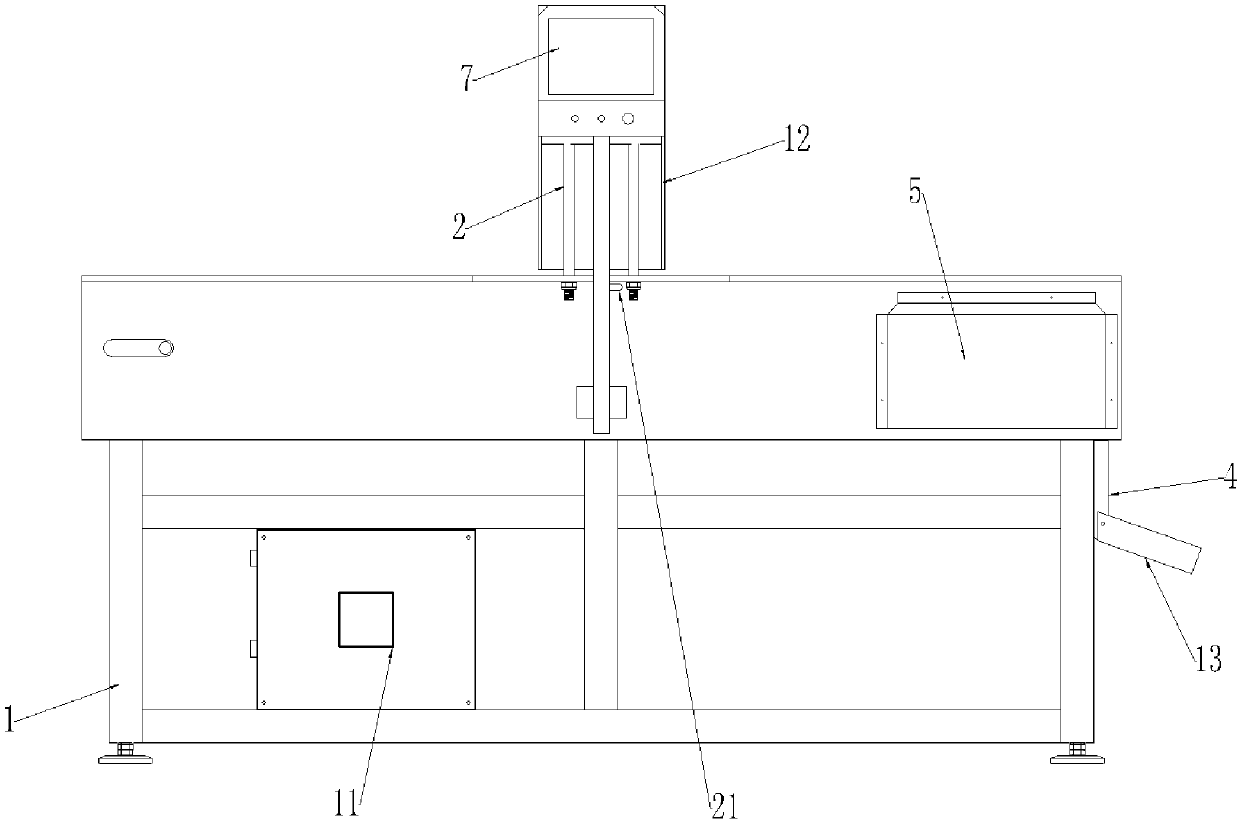

Meat automatic forming machine

PendingCN109514618AImprove cutting efficiencyGood molding consistencyCleaning using gasesMetal working apparatusChain deviceEngineering

The invention relates to a meat automatic forming machine. The meat automatic forming machine comprises a machine frame, and the machine frame is provided with a conveying chain device; the conveyingchain device comprises two conveying chains arranged on the machine frame, a plurality of mold plates are arranged between the two conveying chains, and containing grooves are formed in the mold plates; a cutter seat is fixed to the machine frame, driving rods which are close to or away from the mold plates are fixed to the cutter seat, and at least one cutter device is fixed to the ends, facing towards the mold plates, of the driving rods; each cutter device comprises a cutter frame connected with the driving rods, a forming cutter is fixed to the cutter frame, and a cutter groove matched with the forming cutter is arranged in the corresponding containing groove; and the other ends of the driving rods are connected with a lifting driving device. The meat automatic forming machine furthercomprises a supporting plate fixed to the machine frame, and the supporting plate is at least located under the forming cutters and supported to the lower sides of the mold plates which are in the conveying state; and the machine frame is provided with a position detecting switch which is used for detecting whether the mold plates are located under the forming cutters or not. Mechanical operationis achieved, the pressing cutting efficiency is high, and the forming consistency is good.

Owner:山东中创暖通科技有限公司

Sparking plug paper sleeve forming machine provided with elastic glue injection box bottom plate and video monitoring camera

ActiveCN105365268AAvoid hearing damageImprove processing efficiencyPaper/cardboard articlesVideo monitoringRounding

The invention discloses a sparking plug paper sleeve forming machine provided with an elastic glue injection box bottom plate and a video monitoring camera. The sparking plug paper sleeve forming machine comprises a machine frame, a feeding mechanism, an edge gluing mechanism, a rounding and edge drying mechanism and the video monitoring camera. The feeding mechanism comprises a feeding rail plate and a feeding rail plate sliding driving air cylinder. The edge gluing mechanism is arranged on a gluing base plate above the feeding rail plate. The rounding and edge drying mechanism comprises a support plate, a rounding core mold, a rounding positioning pressing plate, an edge clamping top plate and two rounding force applying assemblies arranged on the left side and the right side of a rounding mold. A feeding hole is formed in the support plate and connected with the discharging end of the feeding mechanism. A hot air cavity is formed in the edge clamping top plate. A plurality of hot air holes communicated with the hot air cavity are formed in a top plate body of the edge clamping top plate. The support plate is further provided with an air heater connected with a pipeline of the hot air cavity. The sparking plug paper sleeve forming machine has the advantages of being reasonable in structural design, high in machining efficiency, and good in product forming consistency.

Owner:株洲纽拜特汽车零部件有限公司

Tubular corrugated paper sleeve forming machine with elastic glue injection box bottom plate and monitoring camera

ActiveCN105398093AImprove processing efficiencyGood molding consistencyPaper/cardboard articlesRoundingSurveillance camera

The invention discloses a tubular corrugated paper sleeve forming machine with an elastic glue injection box bottom plate and a monitoring camera. The tubular corrugated paper sleeve forming machine comprises a machine frame, a hole forming mechanism, a cutting mechanism, a feed mechanism, an edge glue-coating mechanism, a rounding and edge drying mechanism and the monitoring camera. The feed mechanism comprises a feed rail plate and a feed rail plate sliding driving air cylinder. The edge glue-coating mechanism is arranged on a glue-coating base plate above the feed rail plate. The rounding and edge drying mechanism comprises a support plate, a rounding core mold, a rounding locating pressing plate, a side-clamping top plate and two rounding force application assemblies arranged on the left side and the right side of a rounding mold. The support plate is provided with a feed hole, and the feed hole is connected to the discharge end of the feed mechanism. A hot air cavity is formed in the side-clamping top plate, a plurality of hot air holes communicated with the hot air cavity are formed in a top plate body of the side-clamping top plate, and the support plate is further provided with an air heater connected to the hot air cavity through a pipeline. The tubular corrugated paper sleeve forming machine has the advantages that the structural design is reasonable, the machining efficiency is high, and the forming uniformity of products is good.

Owner:平湖市涛强机械有限公司

Optical glass strip forming device

ActiveCN107500514BReduce cutting processAvoid stickingGlass reforming apparatusOptical glassMolten glass

The invention discloses an optical glass small strip material molding device, and belongs to the technical field of optical glass molding. The optical glass small strip material molding device solves the problems that optical glass forming devices in the prior art cannot overcome production instability and low yield rate caused by mold sticking and deformation of small strip material glass. The optical glass small strip material molding device is characterized in that the optical glass small strip material molding device comprises a transmission mechanism, a preheating part, a forming part and an annealing part, wherein the transmission mechanism comprises a frame body, a roller, a conveyer belt and a power device; the preheating part, the forming part and the annealing part are respectively located at the front end, the middle end and the terminal end of the transmission mechanism; the conveying belt is provided with a forming groove which passes through the preheating part, the forming part and the inner cavity of the annealing part, molten glass moves synchronously with the forming groove when molded in the forming part, and the upper surface can be leveled by a rolling wheel. Small strip material glass with the end surface with the side length of 5 mm or more can be drawn, the optical glass small strip material molding device has the advantages of small and uniform cold marks and high forming consistency, by use of the thin square material, the cutting process of large blocks of glass can be saved, excess glass material and loss are less, and labor cost is low.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

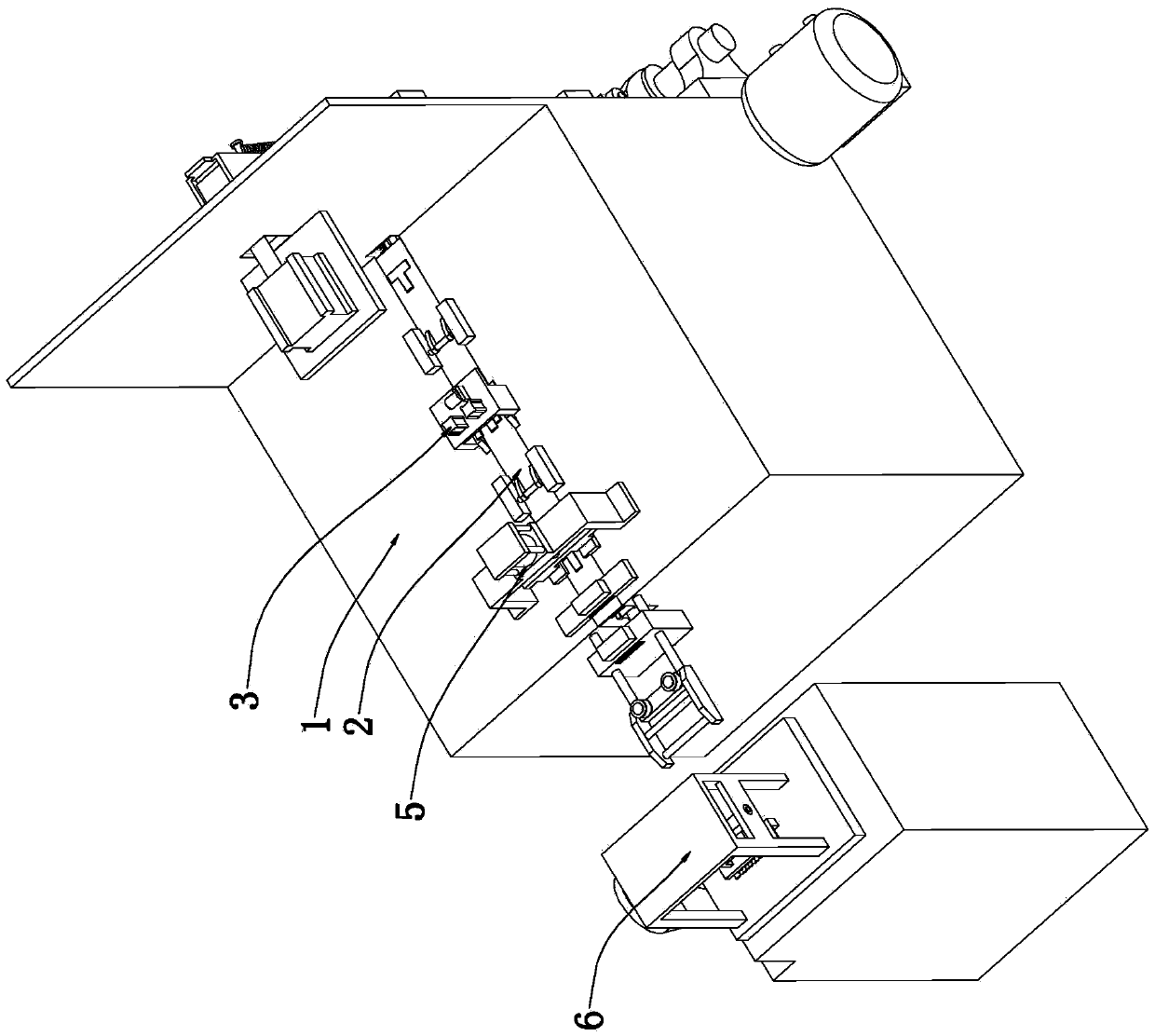

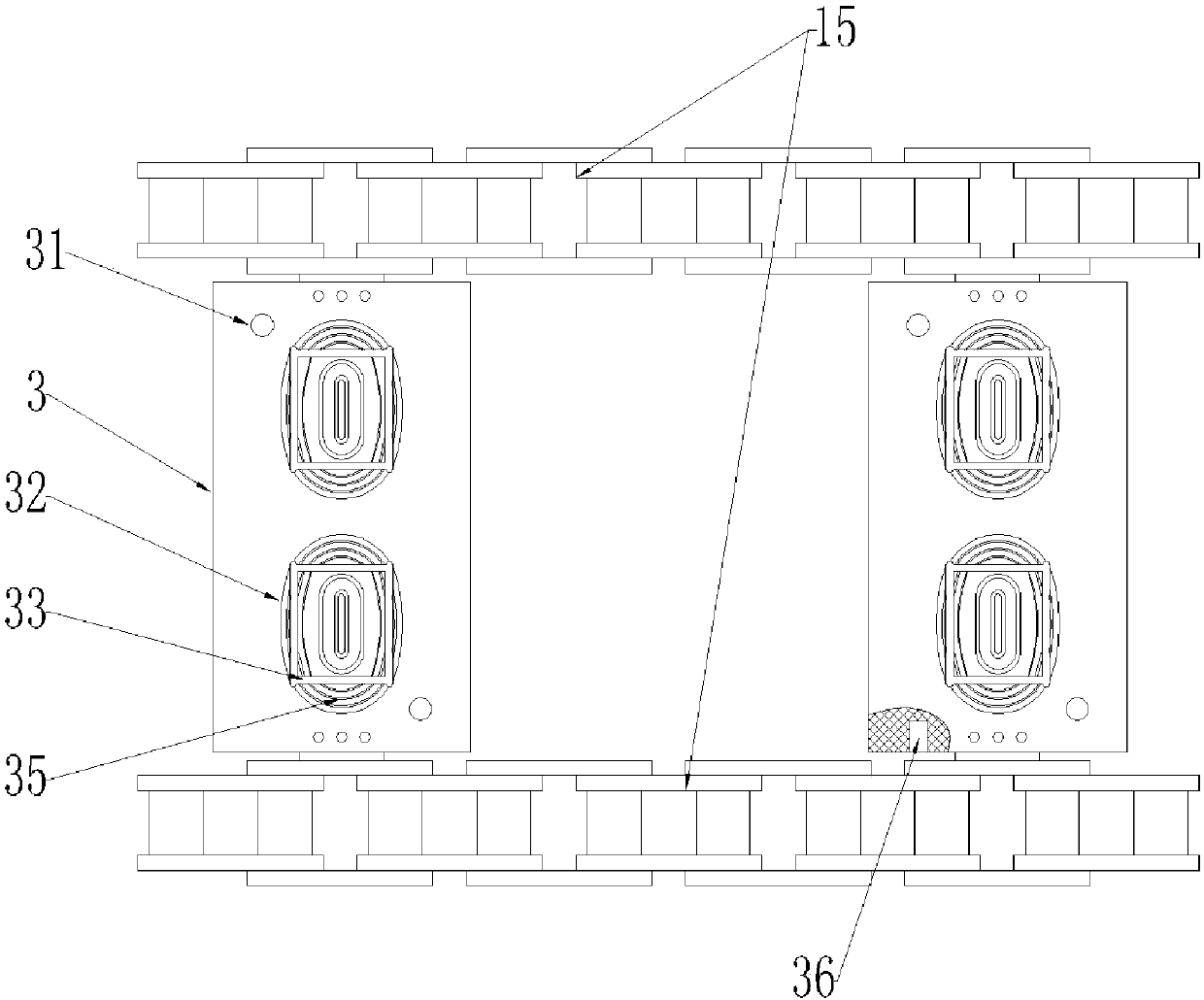

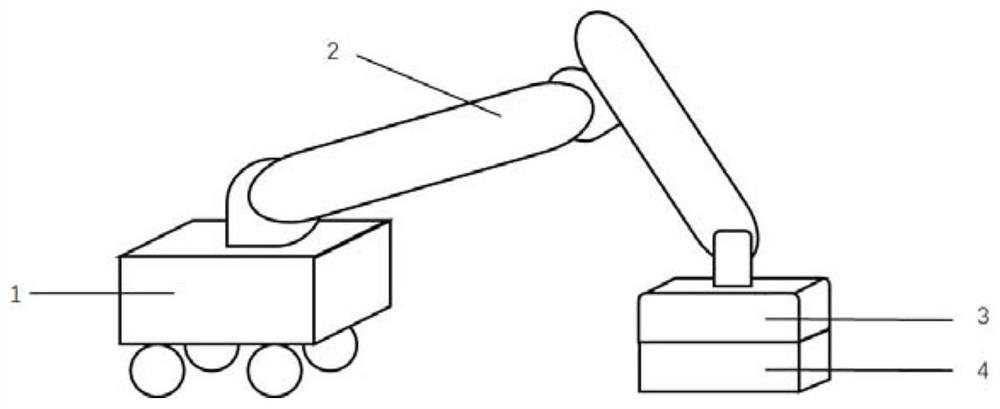

Device for carrying out molding pin arrangement on inductor

InactiveCN112958726AGood molding consistencyQuick insertInductances/transformers/magnets manufactureMolding machineStructural engineering

The invention discloses a device for carrying out molding pin arrangement on an inductor and relates to the field of inductor manufacturing. The device comprises a mounting bottom plate; a pin cutting forming mechanism is arranged on the mounting bottom plate; a first air cylinder and a second air cylinder are arranged on the two sides of the pin cutting forming mechanism; the pin cutting forming mechanism comprises a magnetic core containing area, a first forming pressing block and a second forming pressing block; the first forming pressing block and the second forming pressing block are distributed on the two sides of the magnetic core containing area; pin cutters are arranged on the sides, away from the magnetic core containing area, of the first forming pressing block and the second forming pressing block correspondingly; and the pin cutters are connected with the first air cylinder and the second air cylinder correspondingly through an air cylinder fixing plate. The method can improve the yield and reduce the production cost.

Owner:WUHAN CHENYANG ELECTRONICS TECH

Wire hook former

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

Moon-based landing platform and construction method thereof

The invention relates to a moon-based landing platform and a construction method thereof, in particular to a platform used when a spacecraft lands on the moon and a construction method of the platform, and belongs to the technical field of deep space exploration of the moon. According to the invention, the microwave sintering molding of the multi-component simulated lunar soil material with small particles, light weight and large specific surface area in the aerospace field is realized, the molding precision and density requirements of a spacecraft landing platform are met, a technical basis is provided for subsequent lunar base construction and lasting operation, and good economic benefits and social benefits are achieved.

Owner:BEIJING SATELLITE MFG FACTORY

Tubular Corrugated Sleeve Forming Machine With Video Surveillance Camera

ActiveCN105365270BSimple structureConvenient lengthPaper/cardboard articlesMetal working apparatusVideo monitoringPunching

Owner:泰州市茂华纸品有限公司

Spark plug sleeve forming machine with elastic injection box base plate and video surveillance camera

ActiveCN105365268BAvoid hearing damageImprove processing efficiencyPaper/cardboard articlesVideo monitoringSurveillance camera

The invention discloses a sparking plug paper sleeve forming machine provided with an elastic glue injection box bottom plate and a video monitoring camera. The sparking plug paper sleeve forming machine comprises a machine frame, a feeding mechanism, an edge gluing mechanism, a rounding and edge drying mechanism and the video monitoring camera. The feeding mechanism comprises a feeding rail plate and a feeding rail plate sliding driving air cylinder. The edge gluing mechanism is arranged on a gluing base plate above the feeding rail plate. The rounding and edge drying mechanism comprises a support plate, a rounding core mold, a rounding positioning pressing plate, an edge clamping top plate and two rounding force applying assemblies arranged on the left side and the right side of a rounding mold. A feeding hole is formed in the support plate and connected with the discharging end of the feeding mechanism. A hot air cavity is formed in the edge clamping top plate. A plurality of hot air holes communicated with the hot air cavity are formed in a top plate body of the edge clamping top plate. The support plate is further provided with an air heater connected with a pipeline of the hot air cavity. The sparking plug paper sleeve forming machine has the advantages of being reasonable in structural design, high in machining efficiency, and good in product forming consistency.

Owner:株洲纽拜特汽车零部件有限公司

Sparking plug paper sleeve forming machine

ActiveCN105365269AImprove processing efficiencyGood molding consistencyPaper/cardboard articlesEngineeringAir heater

The invention discloses a sparking plug paper sleeve forming machine. The sparking plug paper sleeve forming machine comprises a machine frame, a feeding mechanism, an edge gluing mechanism and a rounding and edge drying mechanism. The feeding mechanism comprises a feeding rail plate and a feeding rail plate sliding driving air cylinder. The edge gluing mechanism is arranged on a gluing base plate above the feeding rail plate. The rounding and edge drying mechanism comprises a support plate, a rounding core mold, a rounding positioning pressing plate, an edge clamping top plate and two rounding force applying assemblies arranged on the left side and the right side of a rounding mold. A feeding hole is formed in the support plate and connected with the discharging end of the feeding mechanism. A hot air cavity is formed in the edge clamping top plate. A plurality of hot air holes communicated with the hot air cavity are formed in a top plate body of the edge clamping top plate. The support plate is further provided with an air heater connected with a pipeline of the hot air cavity. The sparking plug paper sleeve forming machine has the advantages of being reasonable in structural design, high in machining efficiency, and good in product forming consistency.

Owner:孙瑜

Spark plug paper cover forming machine

ActiveCN105365269BImprove processing efficiencyGood molding consistencyPaper/cardboard articlesAir heaterSpark plug

The invention discloses a sparking plug paper sleeve forming machine. The sparking plug paper sleeve forming machine comprises a machine frame, a feeding mechanism, an edge gluing mechanism and a rounding and edge drying mechanism. The feeding mechanism comprises a feeding rail plate and a feeding rail plate sliding driving air cylinder. The edge gluing mechanism is arranged on a gluing base plate above the feeding rail plate. The rounding and edge drying mechanism comprises a support plate, a rounding core mold, a rounding positioning pressing plate, an edge clamping top plate and two rounding force applying assemblies arranged on the left side and the right side of a rounding mold. A feeding hole is formed in the support plate and connected with the discharging end of the feeding mechanism. A hot air cavity is formed in the edge clamping top plate. A plurality of hot air holes communicated with the hot air cavity are formed in a top plate body of the edge clamping top plate. The support plate is further provided with an air heater connected with a pipeline of the hot air cavity. The sparking plug paper sleeve forming machine has the advantages of being reasonable in structural design, high in machining efficiency, and good in product forming consistency.

Owner:孙瑜

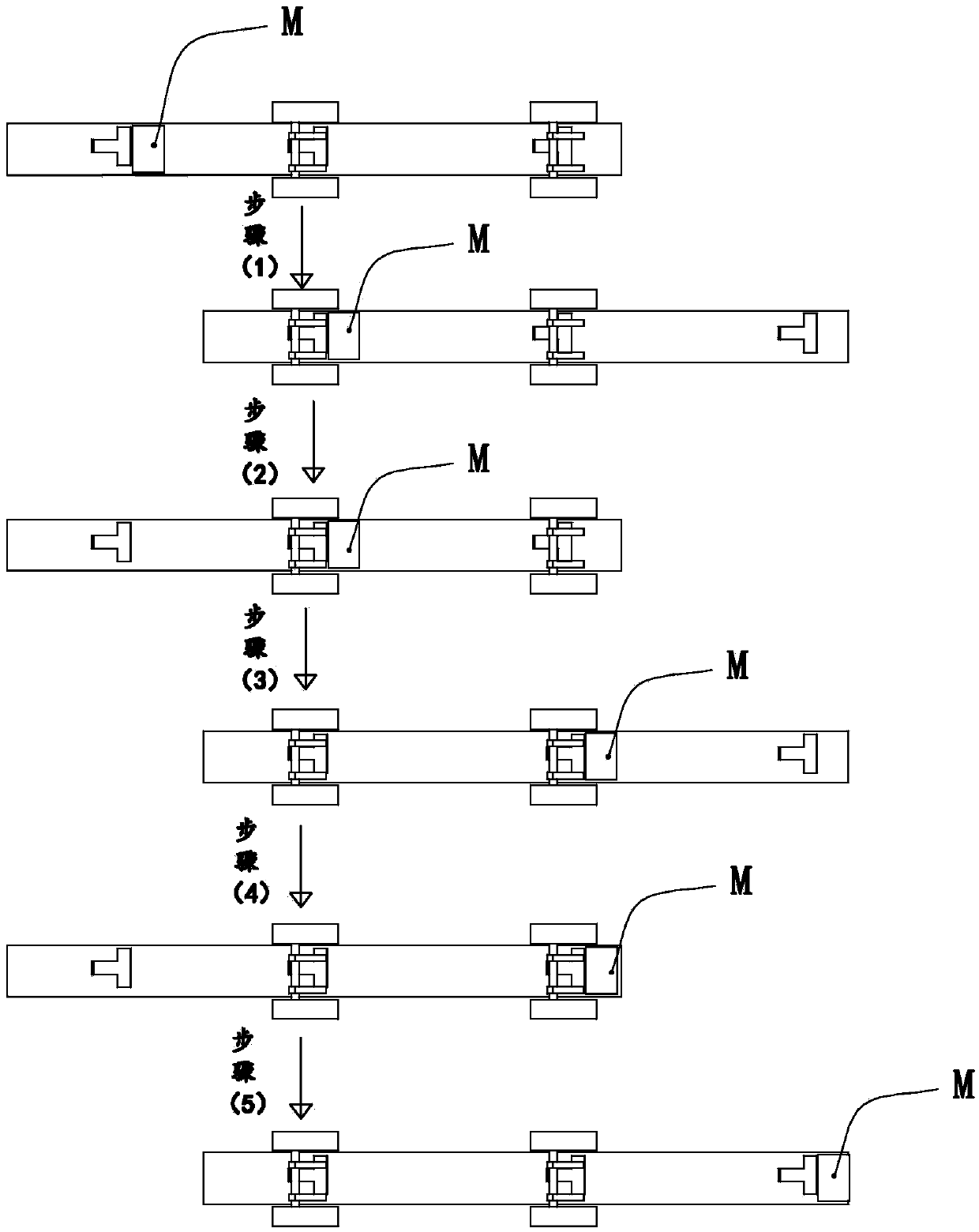

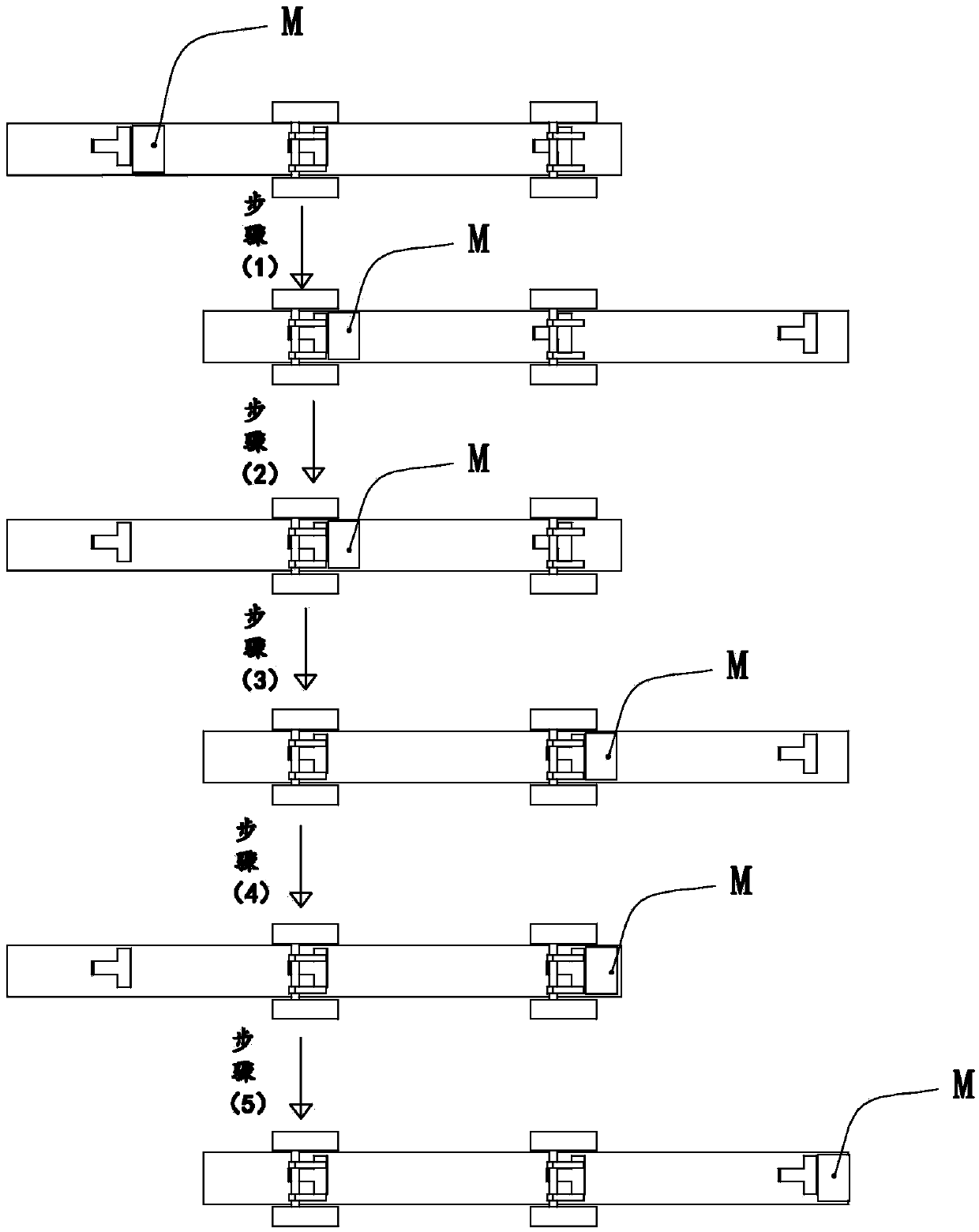

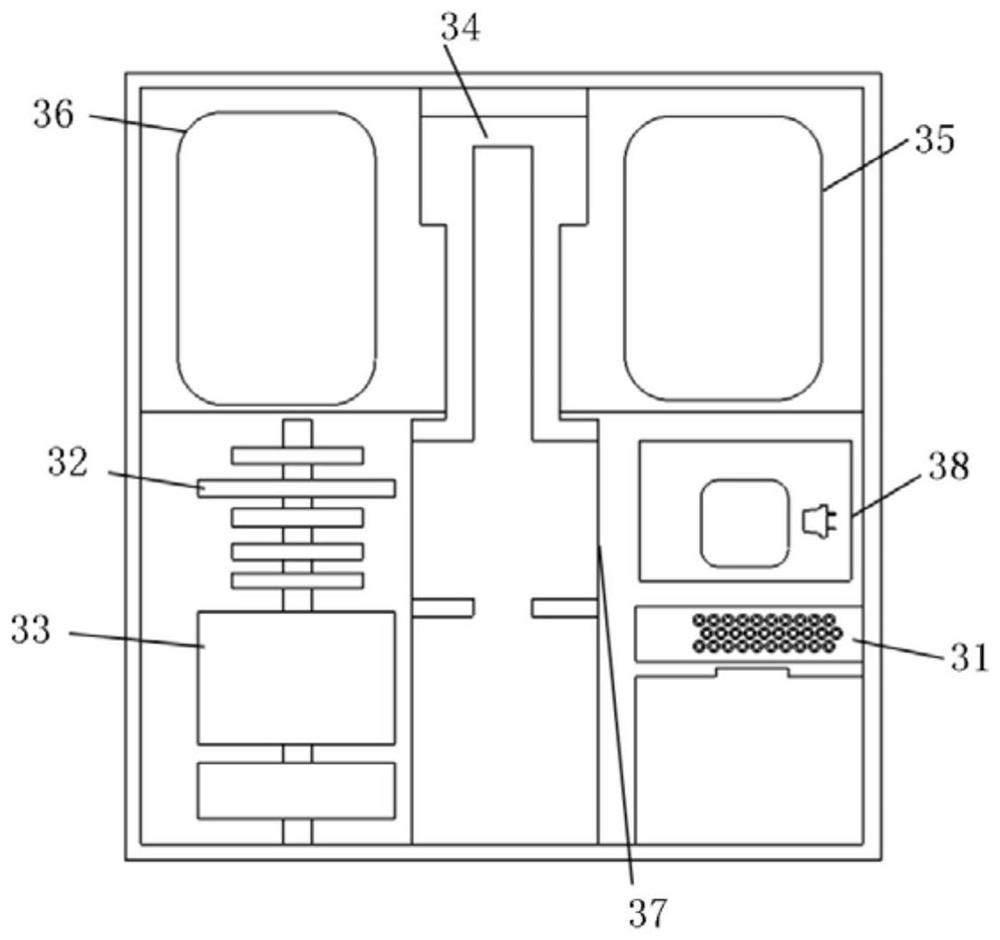

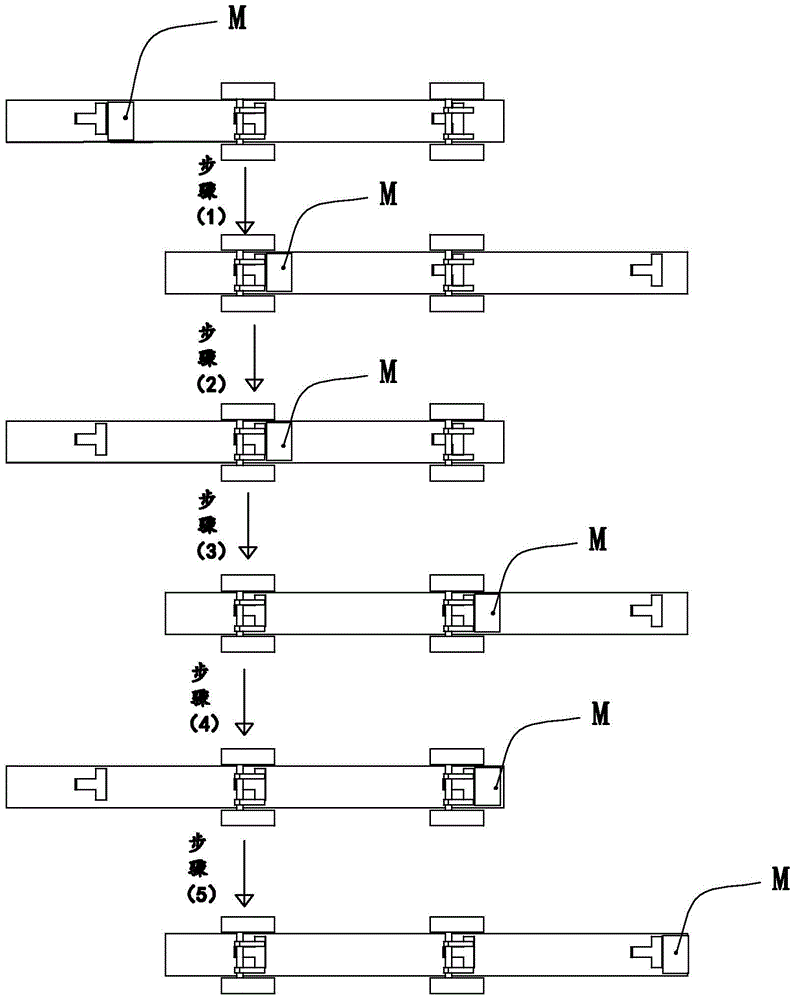

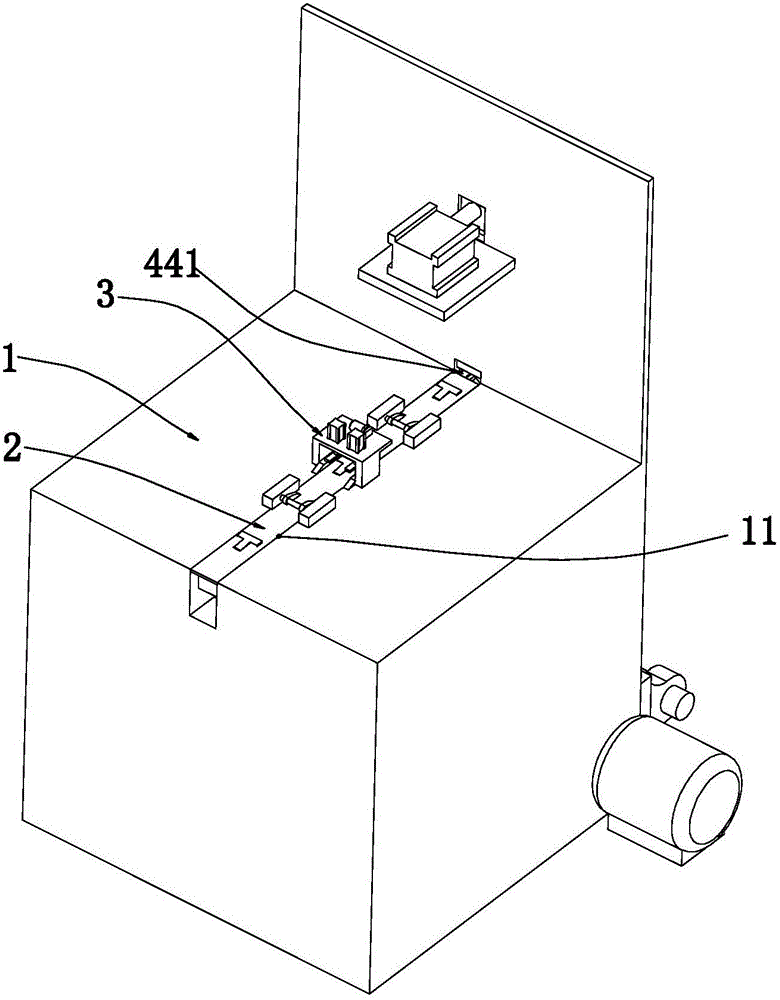

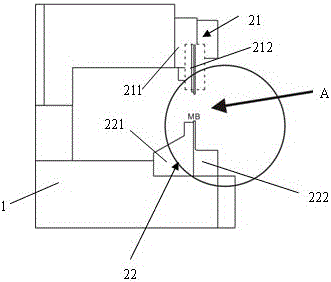

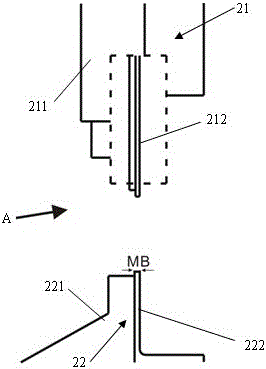

Semi-automatic molding process technology and equipment for multi-pin surface mount devices

ActiveCN103658320BHigh precisionGood molding consistencyMetal working apparatusShoulder widthMicrometer scale

The invention discloses a semi-automatic forming technology of a multi-pin surface mount device. The technology includes the steps that the shoulder width B is acquired, the thickness MB of an adjustment module, the thicknesses F of pins, the distance H between the lower surfaces of the pins and the bottom plane of a multi-pin surface mount device body, parameters D of the pins, the length C of a single-edge forming cut foot and the bending radius R are acquired; a shoulder width adjustment parameter X(E), a standing height adjustment parameter X(G) and a welding face length adjustment parameter X(C) are acquired according to the following equations: X(E)=B-MB, X(G)=D-H and X(C)=C-MC+R+F; the multi-pin surface mount device is placed on a device fixture to be located on the same plane with the face of the fixture, and the machining lateral side of the multi-pin surface mount device abuts against a forming station lower module; after X(E), X(G) and X(C) are set on a digital micrometer of a die, pin forming is carried out. Good forming uniformity, good coplanarity and high forming precision of the multi-pin surface mount device are achieved by controlling X(E), X(G) and X(C).

Owner:上海航天控制工程研究所

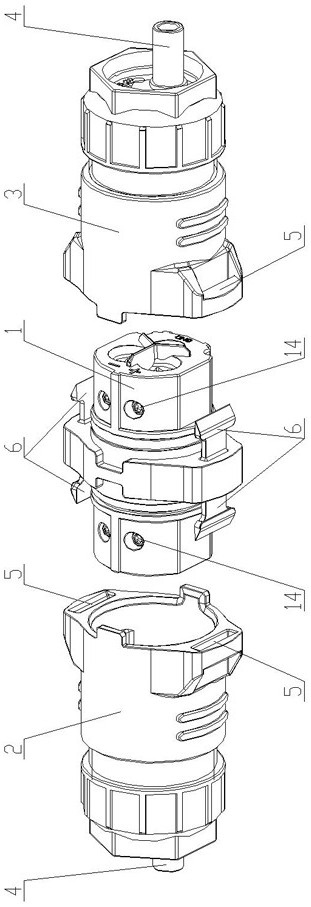

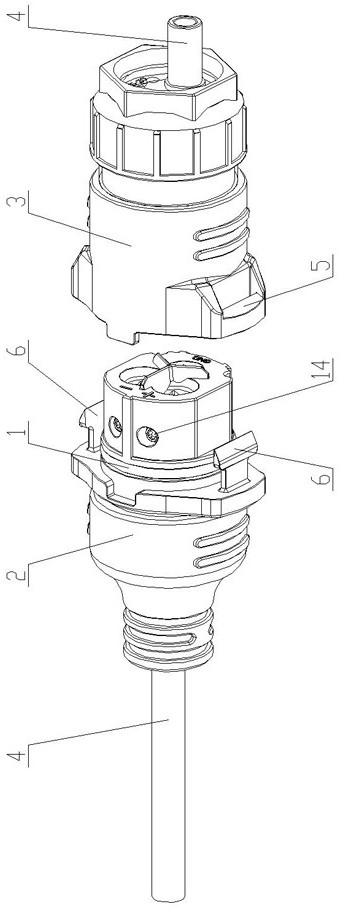

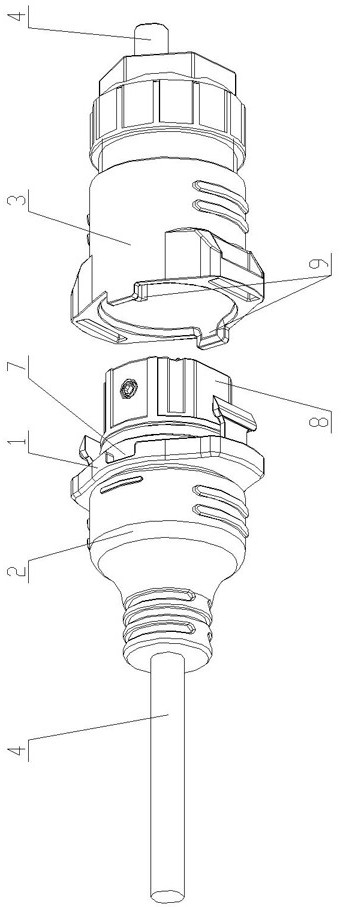

Novel power line adapter connector

PendingCN114243406AReduce the number of disassemblyReduce stepsSecuring/insulating coupling contact membersTwo-part coupling devicesStructural engineeringMechanical engineering

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Sparking plug paper sleeve forming machine with video monitoring camera

ActiveCN105291488AAvoid hearing damageImprove processing efficiencyPaper/cardboard articlesVideo monitoringEngineering

The invention discloses a sparking plug paper sleeve forming machine with a video monitoring camera. The sparking plug paper sleeve forming machine with the video monitoring camera comprises a machine frame, a feeding mechanism, an edge gluing mechanism, a rounding and side baking mechanism and the video monitoring camera. The feeding mechanism comprises a feeding rail plate and a feeding rail plate sliding driving air cylinder. The edge gluing mechanism is arranged on a gluing substrate above the feeding rail plate. The rounding and side baking mechanism comprises a support plate, a rounding core mould, a rounding positioning pressure plate, a side clamping top plate and two rounding force applying assemblies arranged on the left side and the right side of the rounding mould. A feeding hole is formed in the support plate and connected to the discharging end of the feeding mechanism. A hot wind cavity is formed inside the side clamping top plate. Multiple hot wind holes communicated with the hot wind cavity are formed in a top plate body of the side clamping top plate. The support plate is further provided with a hot-wind blower connected with a hot wind cavity pipeline. The sparking plug paper sleeve forming machine with the video monitoring camera has the advantages of being reasonable in structural design, high in machining efficiency and good in product forming consistency.

Owner:TIANJIN JINHANG COMP TECH RES INST

Sparking plug paper cover forming machine with elastic glue injection box bottom plate

ActiveCN105383096ASimple structureConvenient lengthPaper/cardboard articlesVideo monitoringSpark plug

The invention discloses a sparking plug paper cover forming machine with an elastic glue injection box bottom plate. The sparking plug paper cover forming machine comprises a rack, a cutting mechanism, a feeding mechanism, an edge gluing mechanism, a circle embracing edge drying mechanism and a video monitoring camera. The feeding mechanism comprises a feeding track plate and a feeding track plate sliding drive air cylinder. The edge gluing mechanism is arranged on a gluing base plate above the feeding track plate. The circle embracing edge drying mechanism comprises a support plate, a circle embracing core die, a circle embracing positioning pressing plate, an edge clamping top plate and two circle embracing force application assemblies, and the circle embracing force application assemblies are arranged on the left side and the right side of the circle embracing die; and the support plate is provided with a feeding hole, the feeding hole is connected to the discharging end of the feeding mechanism, a hot air cavity is formed in the edge clamping top plate, a plurality of hot air holes communicated with the hot air cavity are formed in a top plate part of the edge clamping top plate, and the support plate is further provided with a hot air blower in pipeline connection with the hot air cavity. The sparking plug paper cover forming machine has the advantages that the structural design is reasonable, the machining efficiency is high, and the product forming consistency is good.

Owner:平湖市涛强机械有限公司

Spark Plug Cover Forming Machine with Elastic Injection Box Bottom Plate

ActiveCN105383097BImprove processing efficiencyGood molding consistencyPaper/cardboard articlesElastic plasticEngineering

The invention discloses a sparking plug paper sleeve forming machine with an elastic glue injection box bottom plate. The sparking plug paper sleeve forming machine comprises a rack, a feeding mechanism, an edge gluing mechanism and a round edge drying mechanism. The feeding mechanism comprises a feeding rail plate and a feeding rail plate slip drive air cylinder. The edge gluing mechanism is arranged on a gluing base plate above the feeding rail plate. The round edge drying mechanism comprises a support plate, a round core mold, a round locating press plate, an edge clamping top plate and two round force application assemblies arranged on the left side and the right of a round die. A feeding hole is formed in the support plate and connected to the discharging end of the feeding mechanism. A hot air cavity is formed in the edge clamping top plate. A top plate body of the edge clamping top plate is provided with a plurality of hot air holes communicated with the hot air cavity. A hot air blower in pipe connection with the hot air cavity is arranged on the support plate. The sparking plug paper sleeve forming machine has the advantages of being reasonable in structural design, high in machining efficiency and good in product forming consistency.

Owner:TIANJIN JINHANG COMP TECH RES INST

Spark plug paper sleeve forming machine with video surveillance camera

ActiveCN105291488BAvoid hearing damageImprove processing efficiencyPaper/cardboard articlesVideo monitoringPosition circle

The invention discloses a spark plug paper cover molding machine with a video monitoring camera, which includes a frame, a feeding mechanism, an edge glue coating mechanism, a circle holding edge drying mechanism and a video monitoring camera; the feeding mechanism includes a feeding rail The plate and the feeding rail plate slide to drive the cylinder. The edge glue coating mechanism is arranged on the glued substrate above the feeding rail plate. The pressing plate, the clamping top plate, and the two circle-holding force assemblies arranged on the left and right sides of the circle-holding mold, the support plate is provided with a feeding hole, and the feeding hole is connected to the discharge end of the feeding mechanism. A hot air chamber is arranged inside the clamped top plate, and a plurality of hot air holes communicating with the hot air chamber are arranged on the top plate of the clamped top plate, and a hot air blower connected with the pipeline of the hot air chamber is also arranged on the support plate. The invention has the advantages of reasonable structural design, high processing efficiency and good product molding consistency.

Owner:TIANJIN JINHANG COMP TECH RES INST

Tubular Corrugated Sleeve Forming Machine with Elastic Injection Box Base

ActiveCN105459457BSimple structureConvenient lengthPaper/cardboard articlesElastic plasticEngineering

Owner:独角兽技术转移中心(重庆)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com