Patents

Literature

41 results about "Position circle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A position circle is a circle that can be measured both from a chart and from the surface of the earth for the purpose of position fixing. For the purposes of land or coastal navigation, a position circle can be generated by making a horizontal angle measurement between two landmarks using a sextant. Two overlapping position circles, or one position circle and one or more other observations can be used to give a position fix.

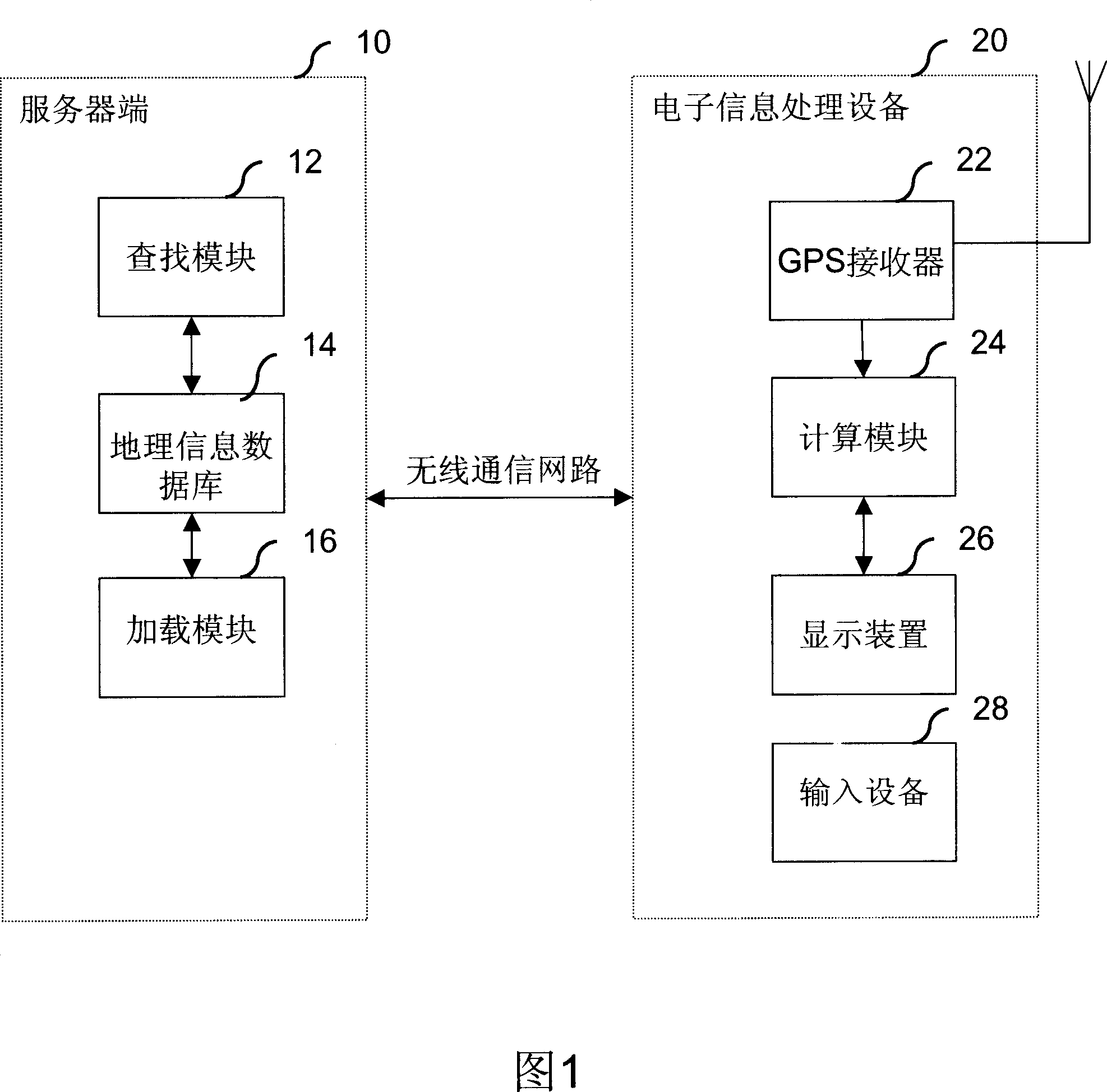

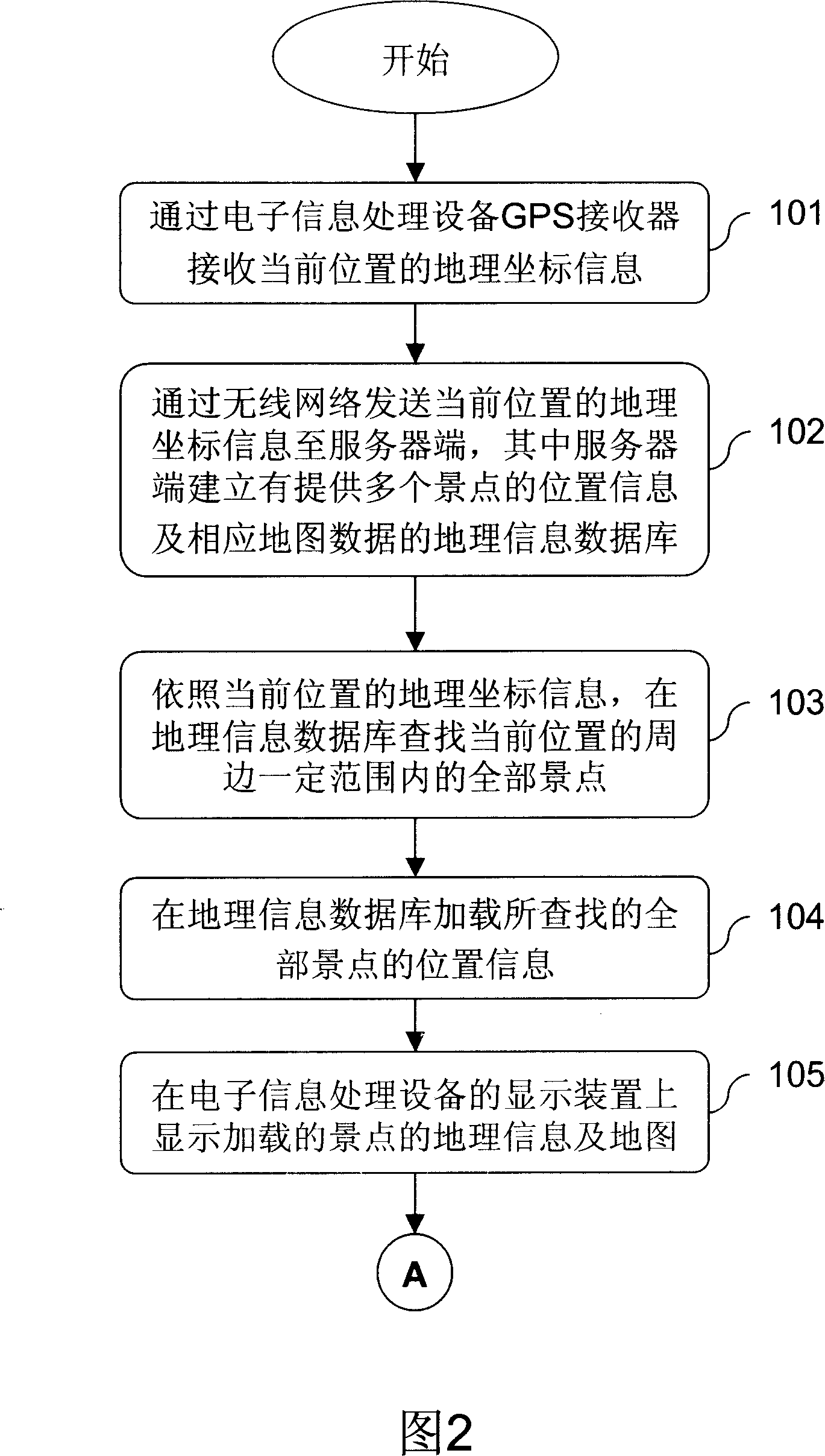

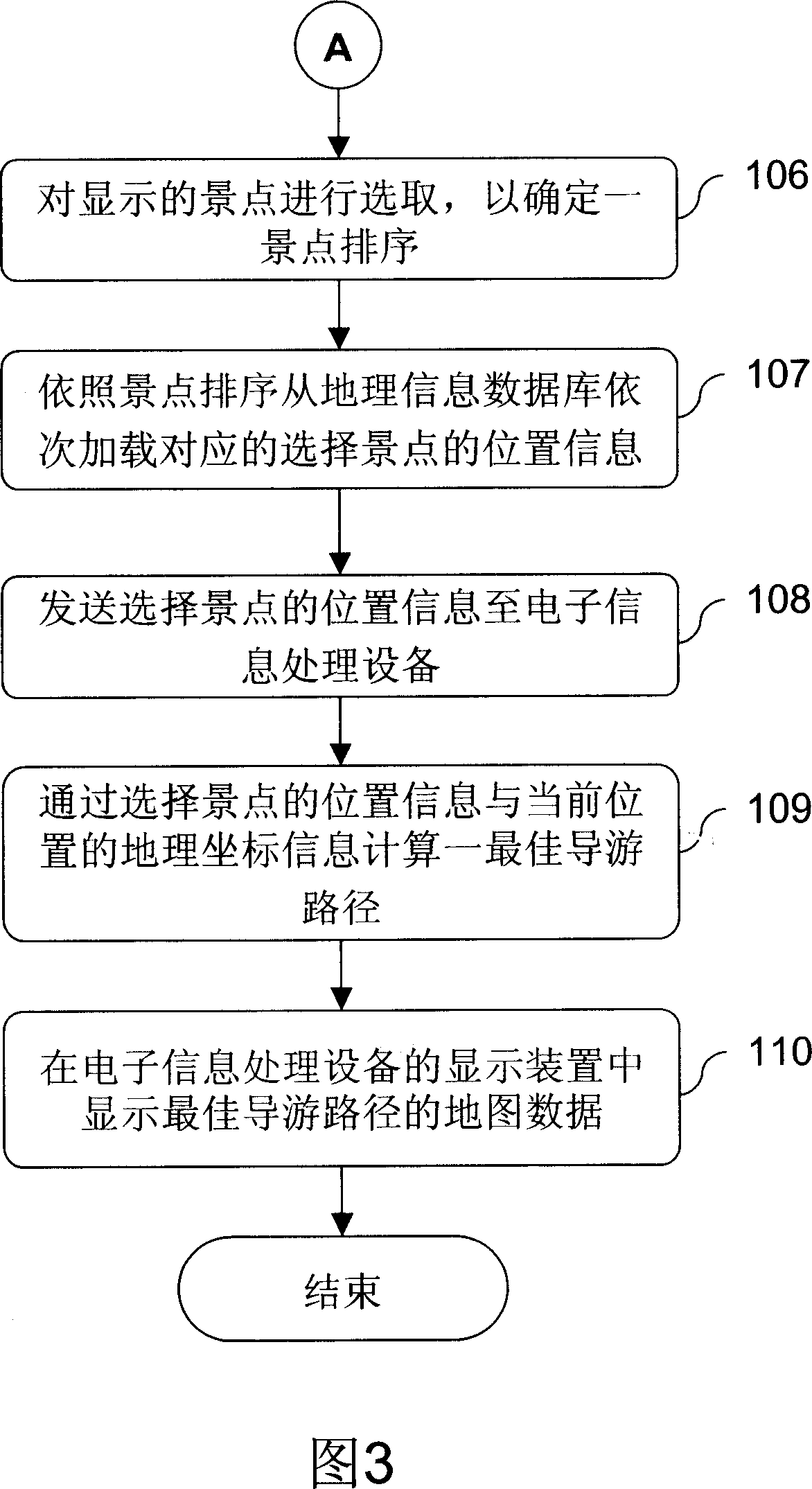

Guiding system of global positioning system and method therefor

InactiveCN101017096AConvenient Guided Tour ProgramInstruments for road network navigationBeacon systems using radio wavesPosition circleGlobal positioning system receiver

This invention relates to one global position system and method applied in one electron information process device, which comprises the following steps: sending or providing the electron information process received current position geography coordinate information to multiple scene position information and relative map data servo end; then according to current position geography coordinate information to give out current position circle certain range total scene; according to user selection and order to determine one scene order to compute the best guide route to the selected scene.

Owner:HUANDA COMPUTER (SHANGHAI) CO LTD

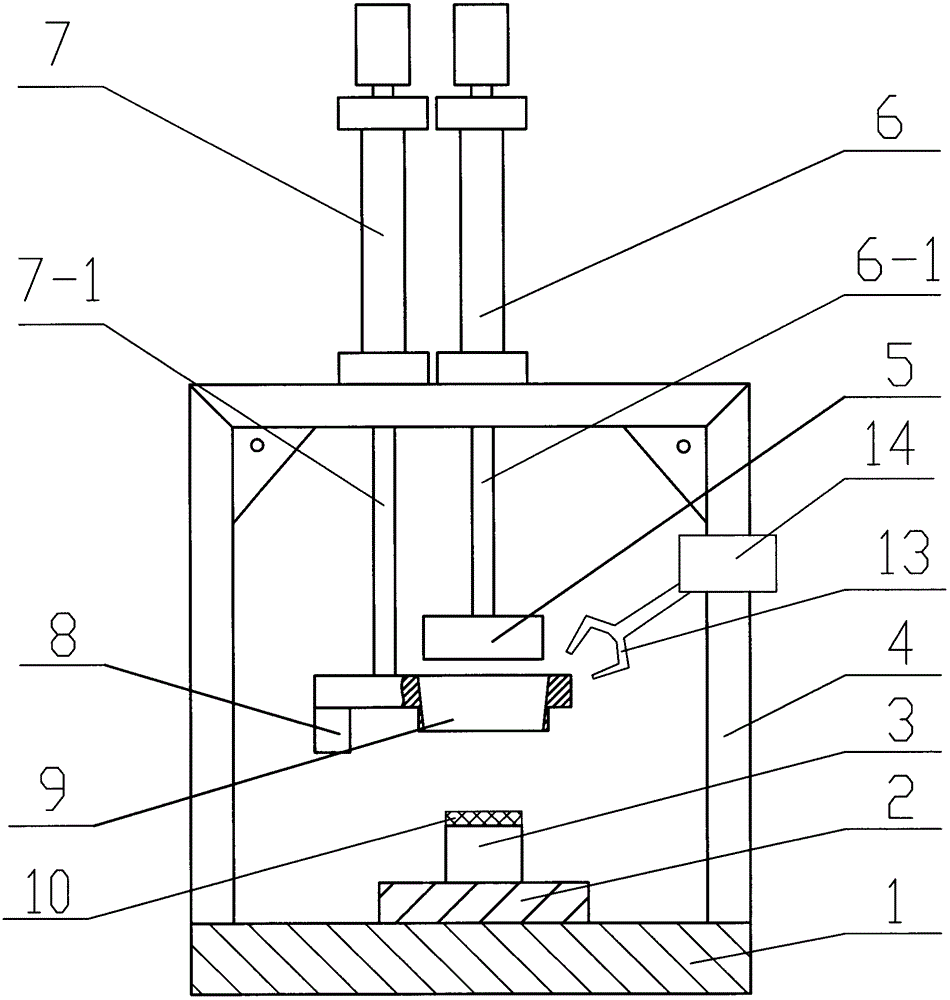

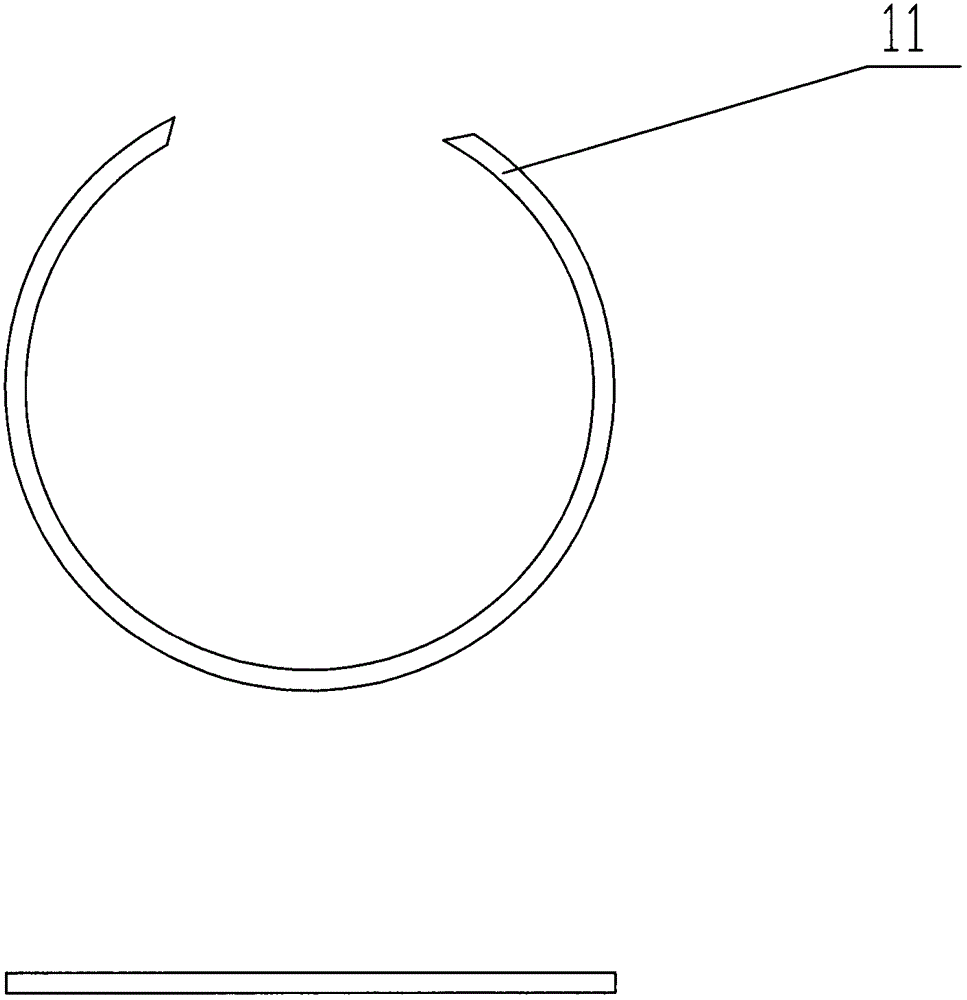

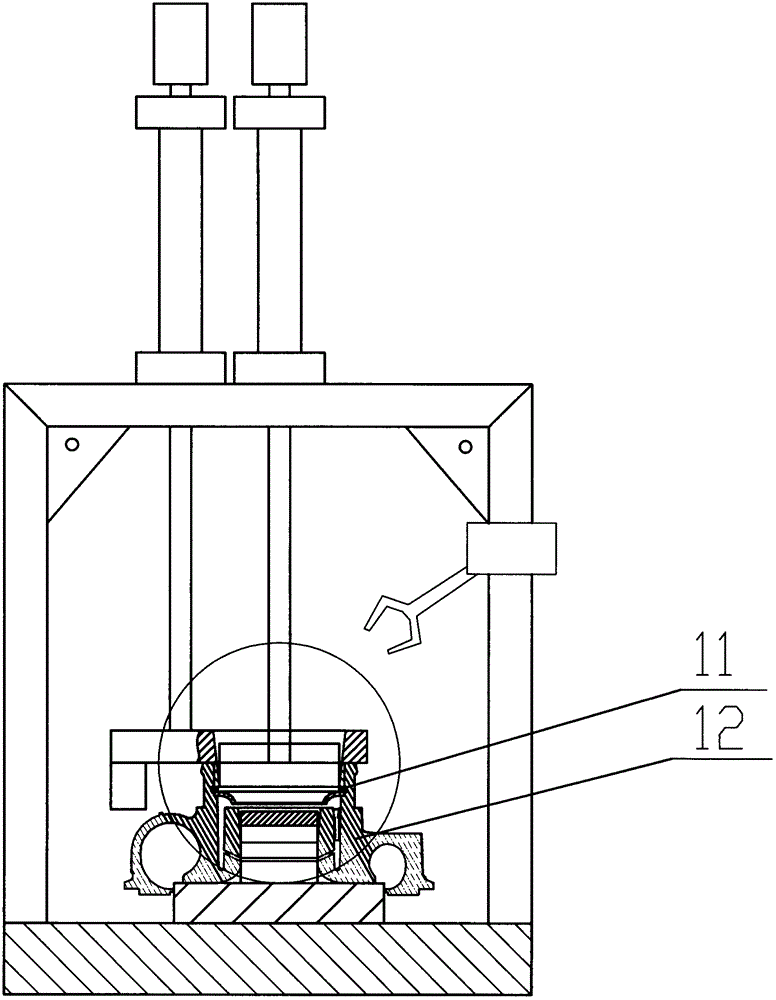

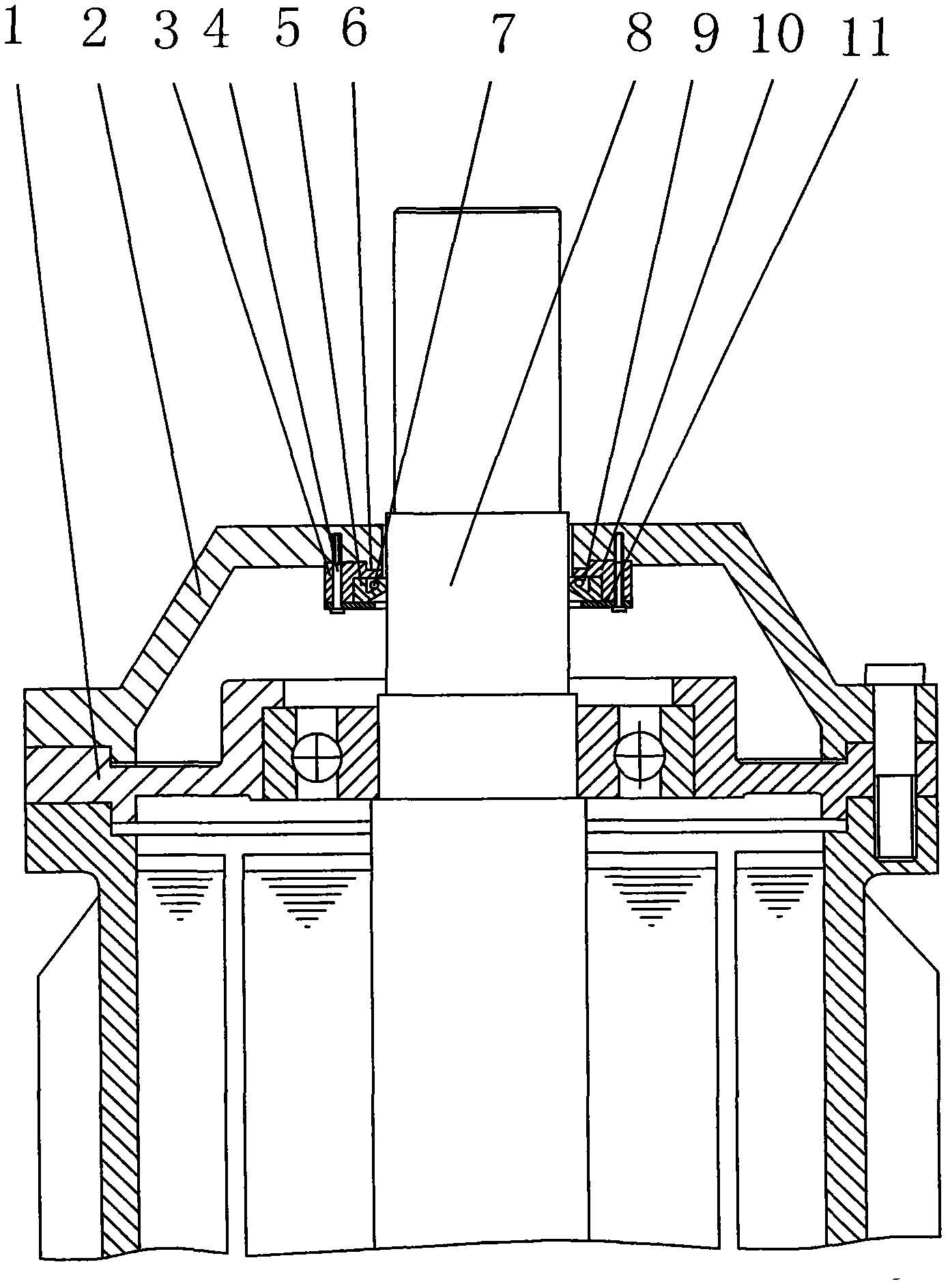

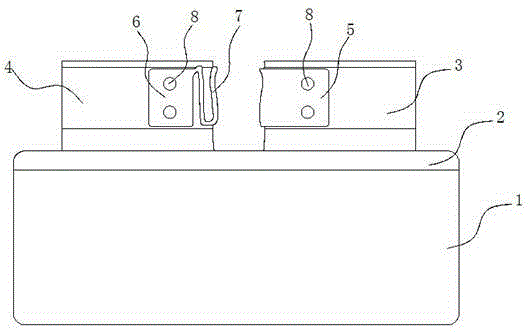

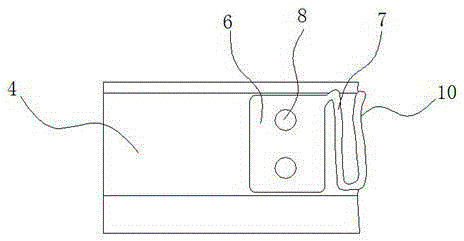

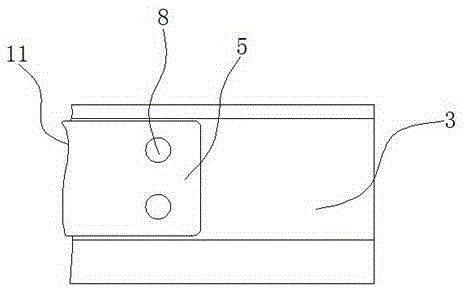

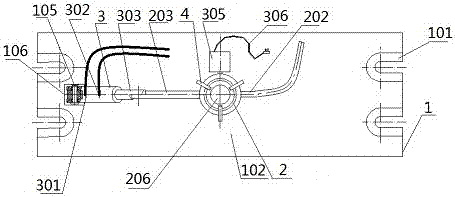

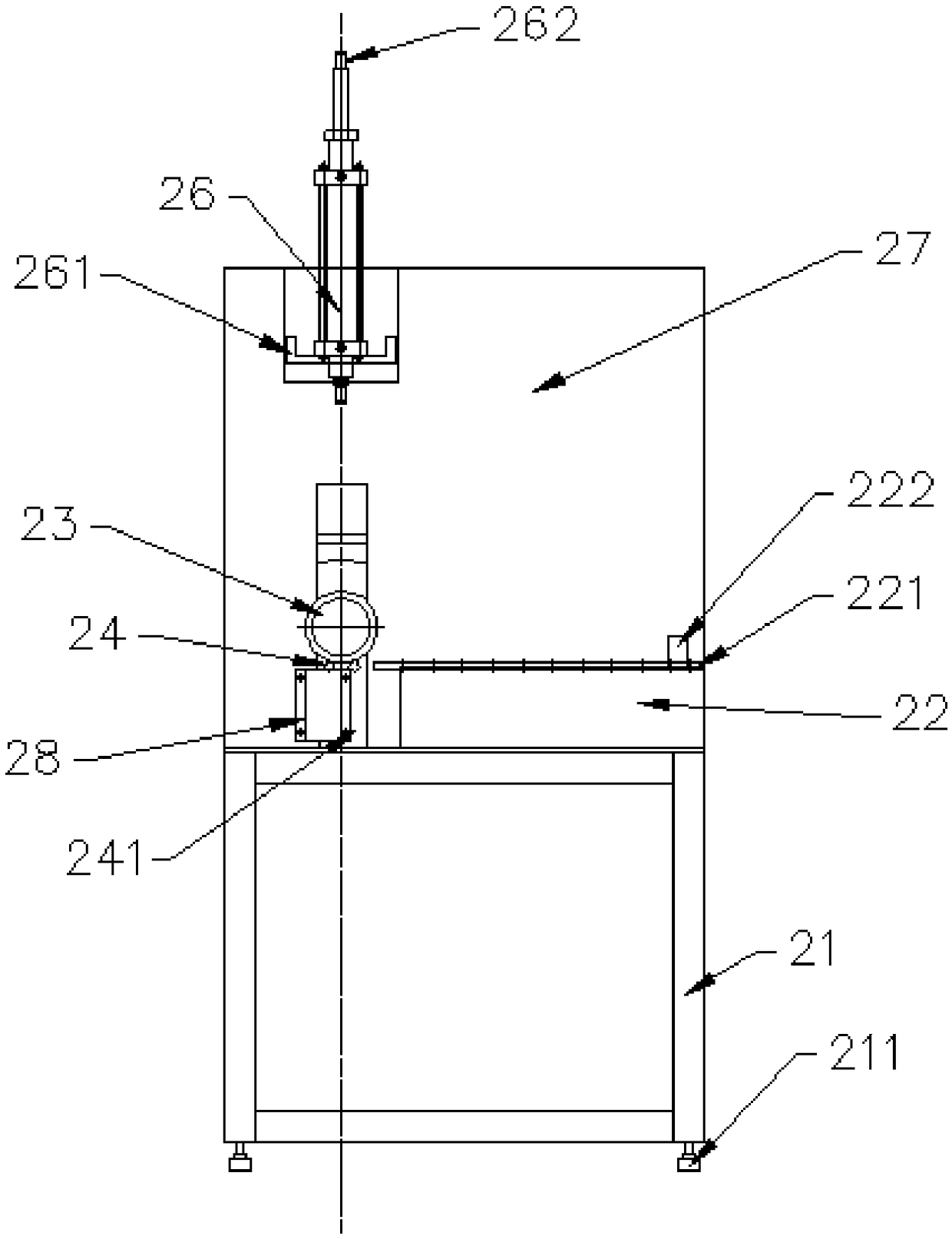

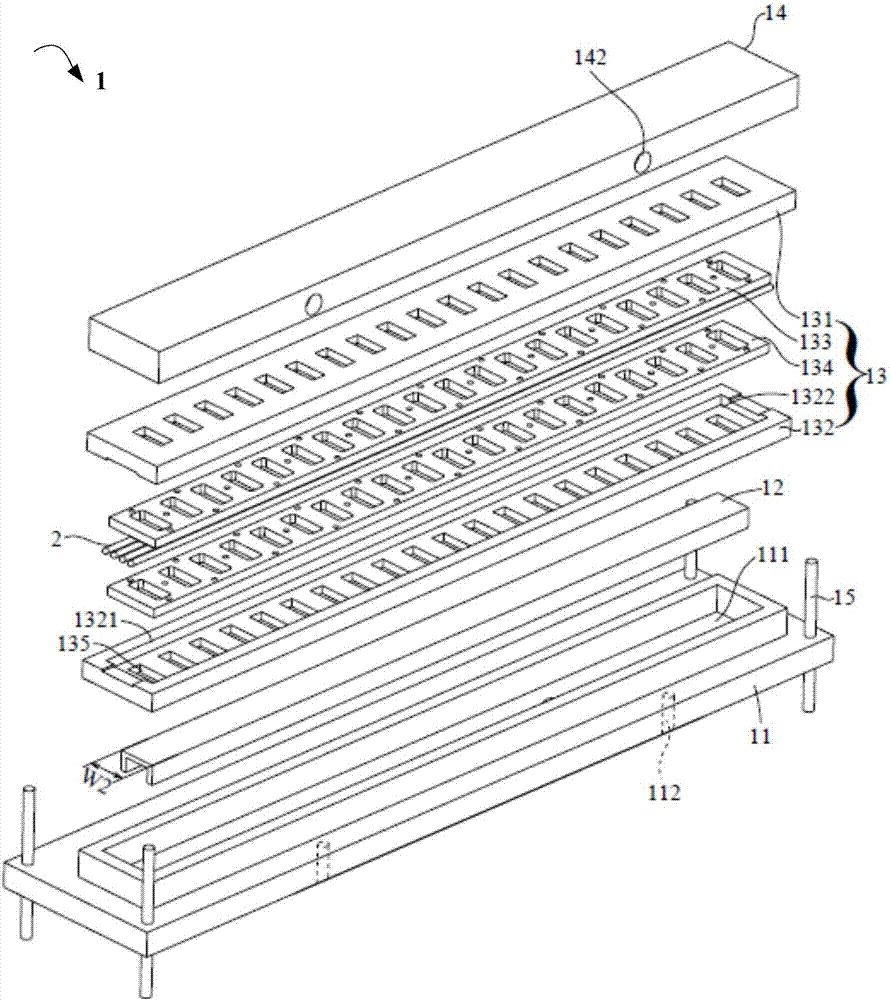

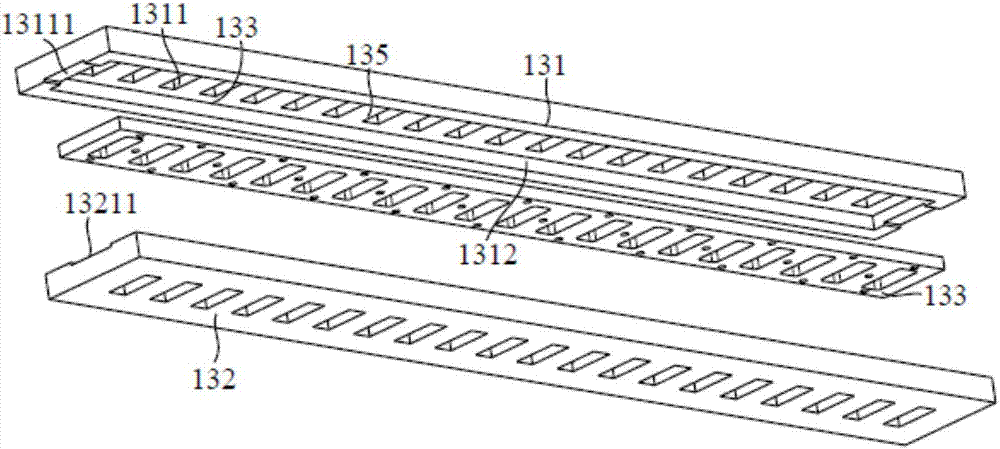

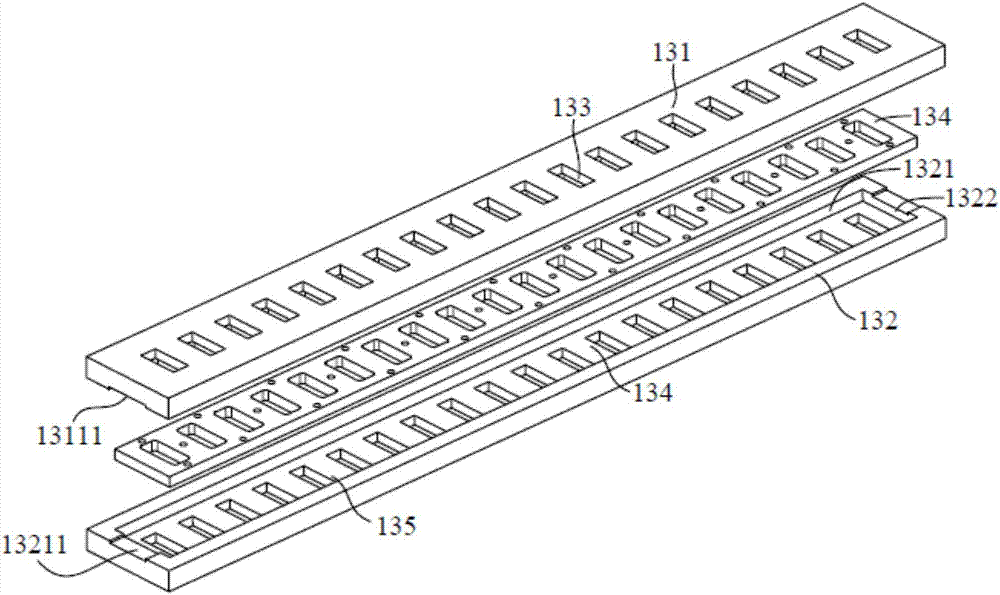

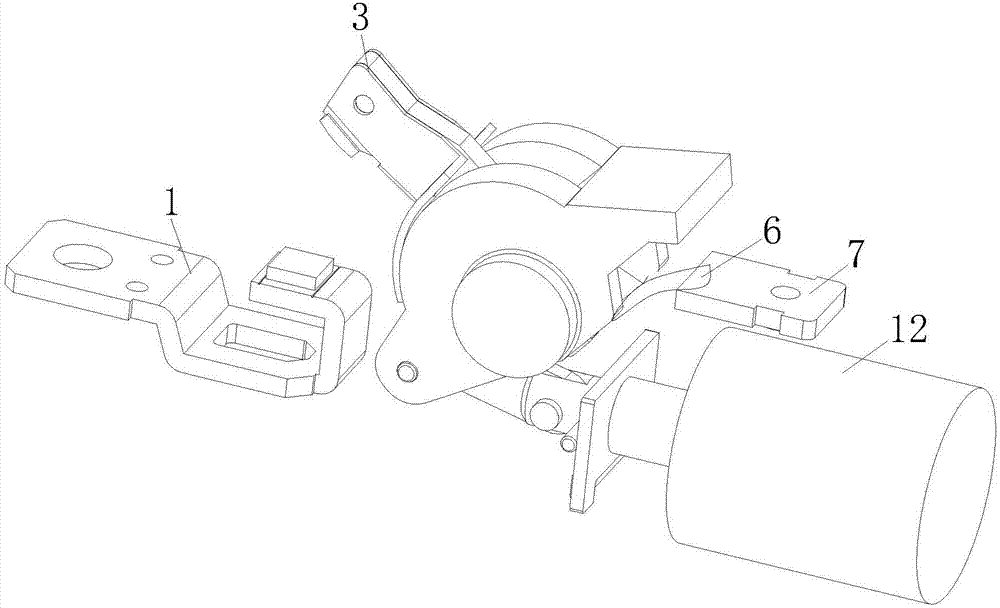

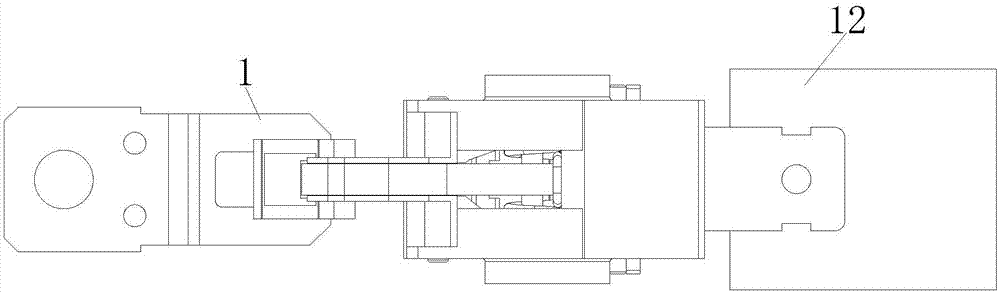

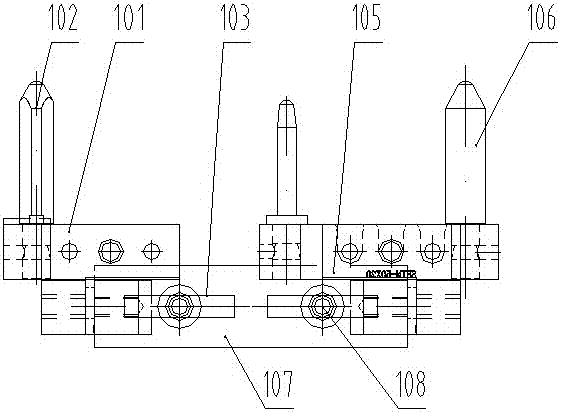

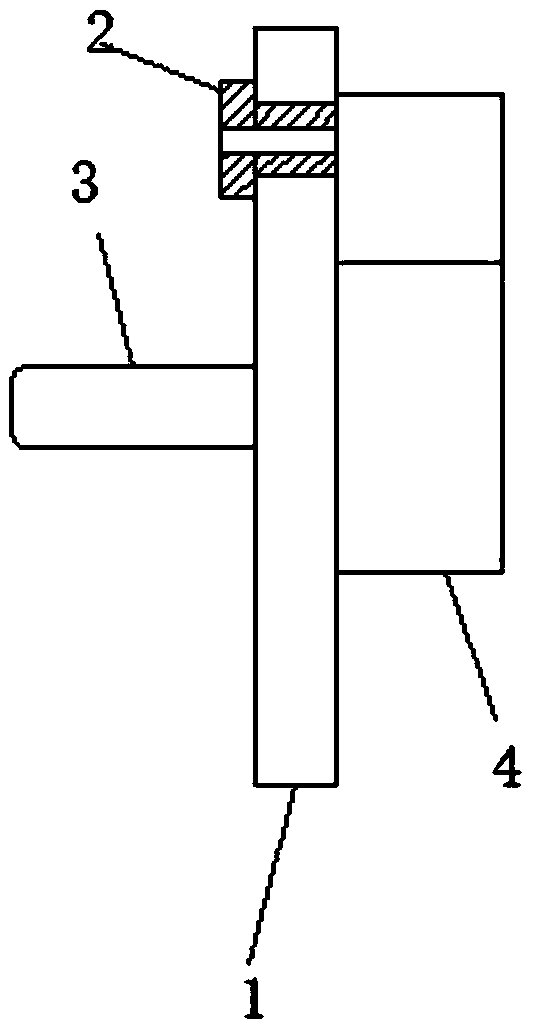

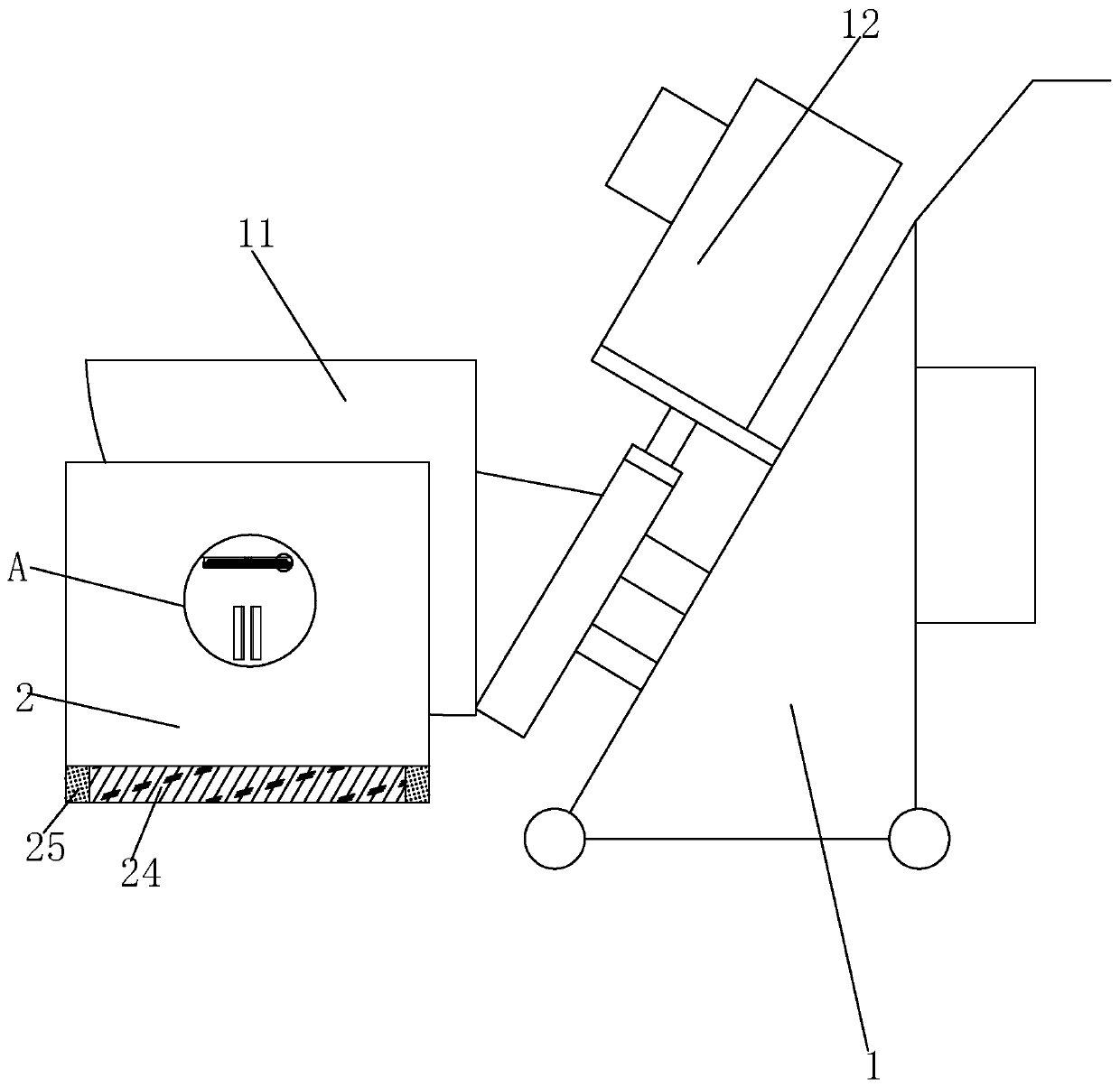

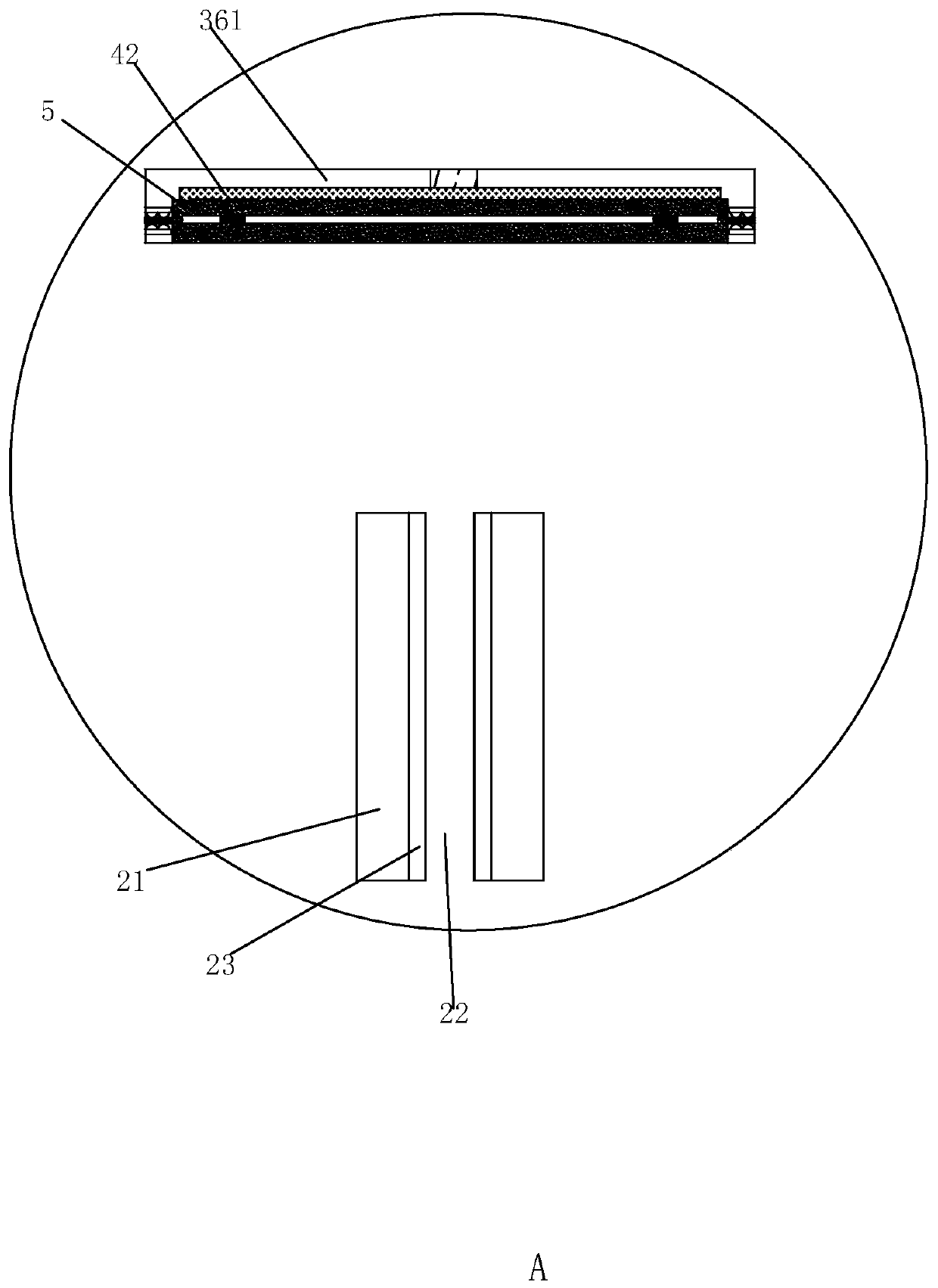

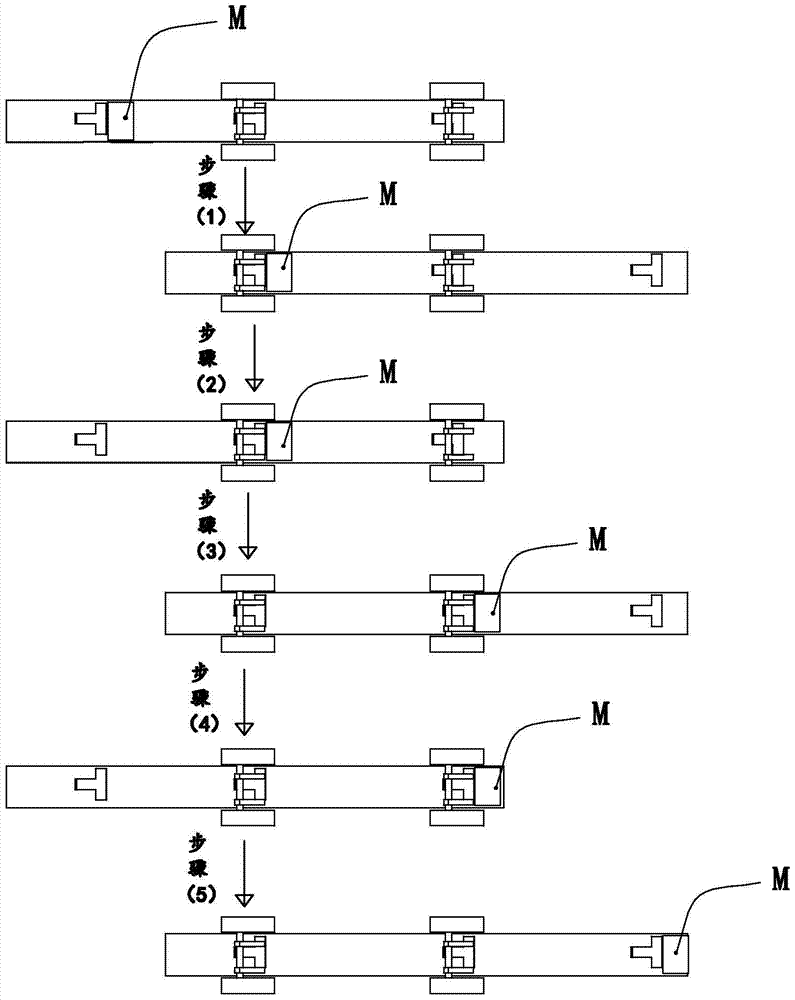

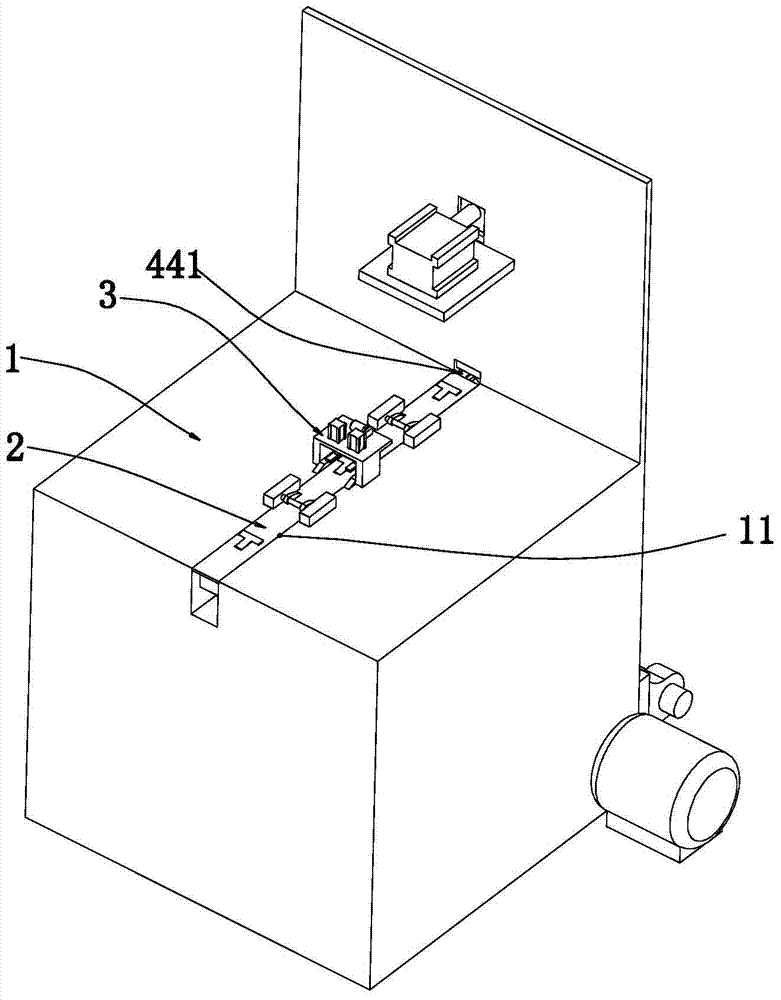

Full-automatic assembly machine for clamping spring

InactiveCN103143917AReduce generationAvoid safety hazardsMetal working apparatusPosition circleWaste product

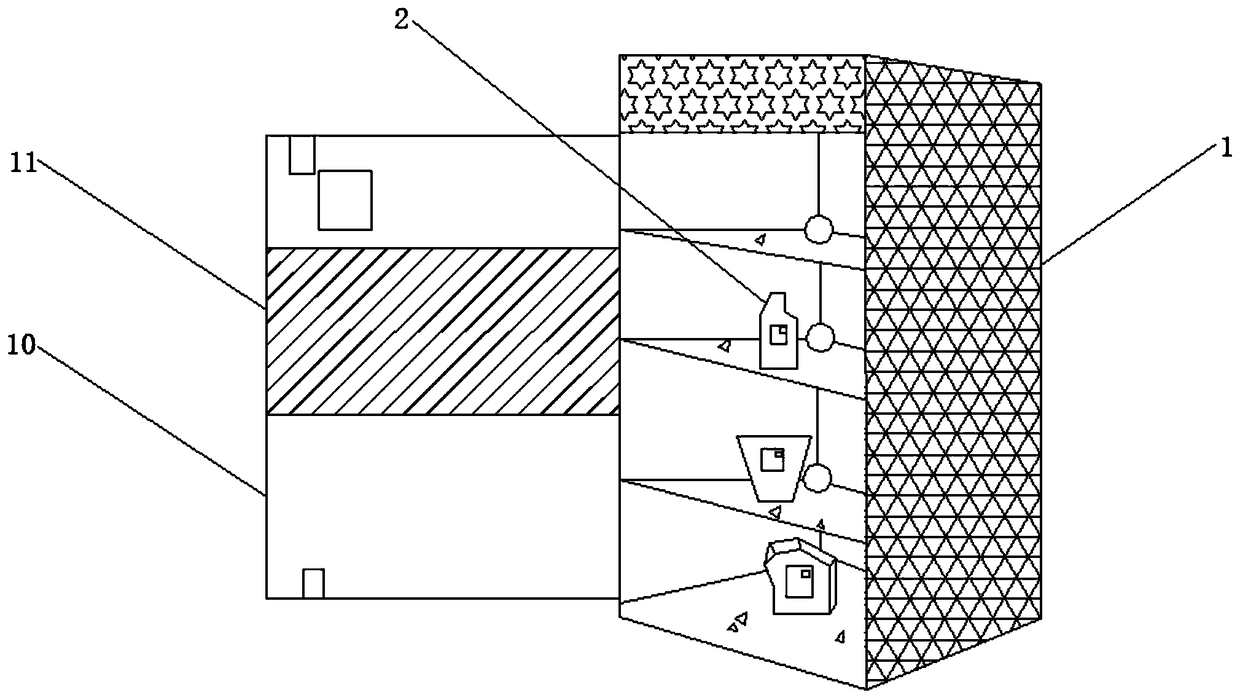

The invention relates to an assembly machine, in particular to a full-automatic assembly machine for a clamping spring and a clamping spring groove of an air inlet of a supercharger housing. The full-automatic assembly machine for the clamping spring comprises a working platform, two air cylinders, a manipulator and a bracket, wherein the air cylinders are supported above the working platform through the bracket; a piston rod of one air cylinder is arranged over against a platform surface of the working platform; the bottom of the lower end of the piston rod is fixedly connected with a pressing shaft; the bottom of the lower end of a piston rod of the other air cylinder is fixedly connected with a guide sleeve; a base is arranged on the platform surface of the working platform; a positioning circle is arranged on the base; and after a workpiece is clamped and fixed, the manipulator is used for feeding. The full-automatic assembly machine has the advantages that the assembly machine adopts pneumatic power, and adopts the manipulator for the feeding; the automation degree is high; manual operation is not required; a labor force is saved; the work efficiency is improved greatly; a finished product rate is increased greatly; waste products are reduced; and potential safety hazards of staff are avoided.

Owner:吴康伟

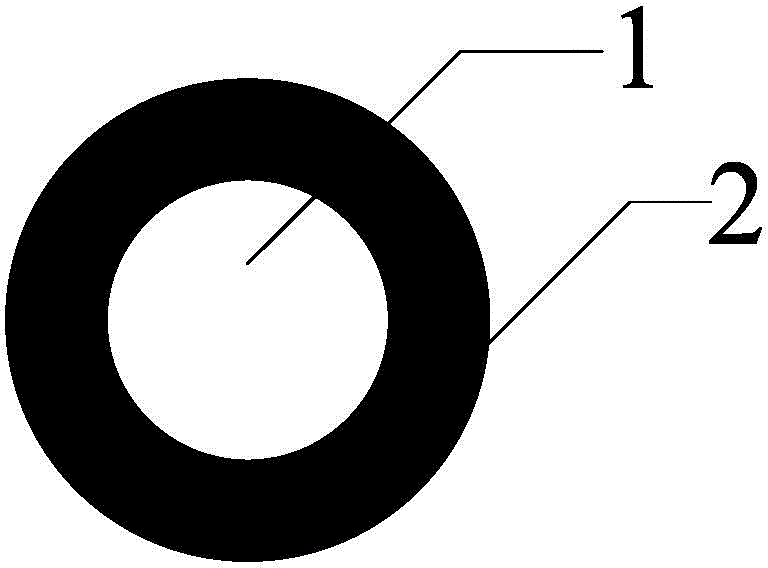

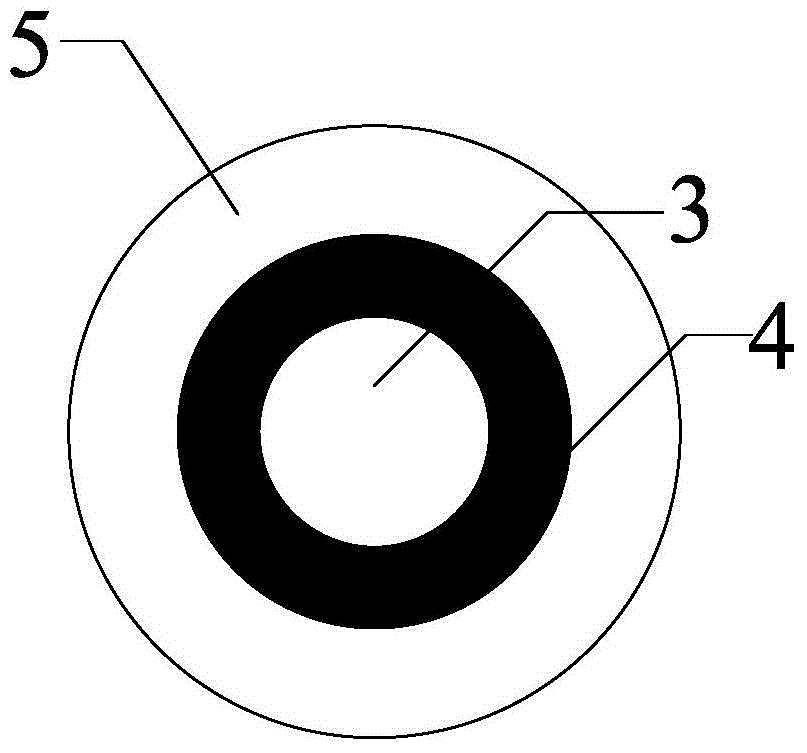

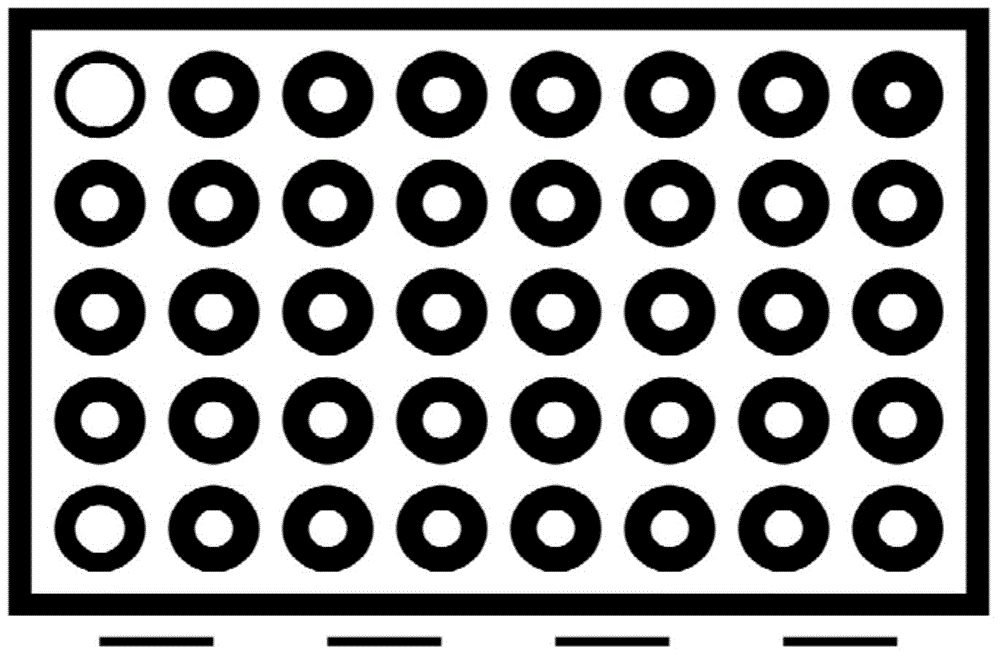

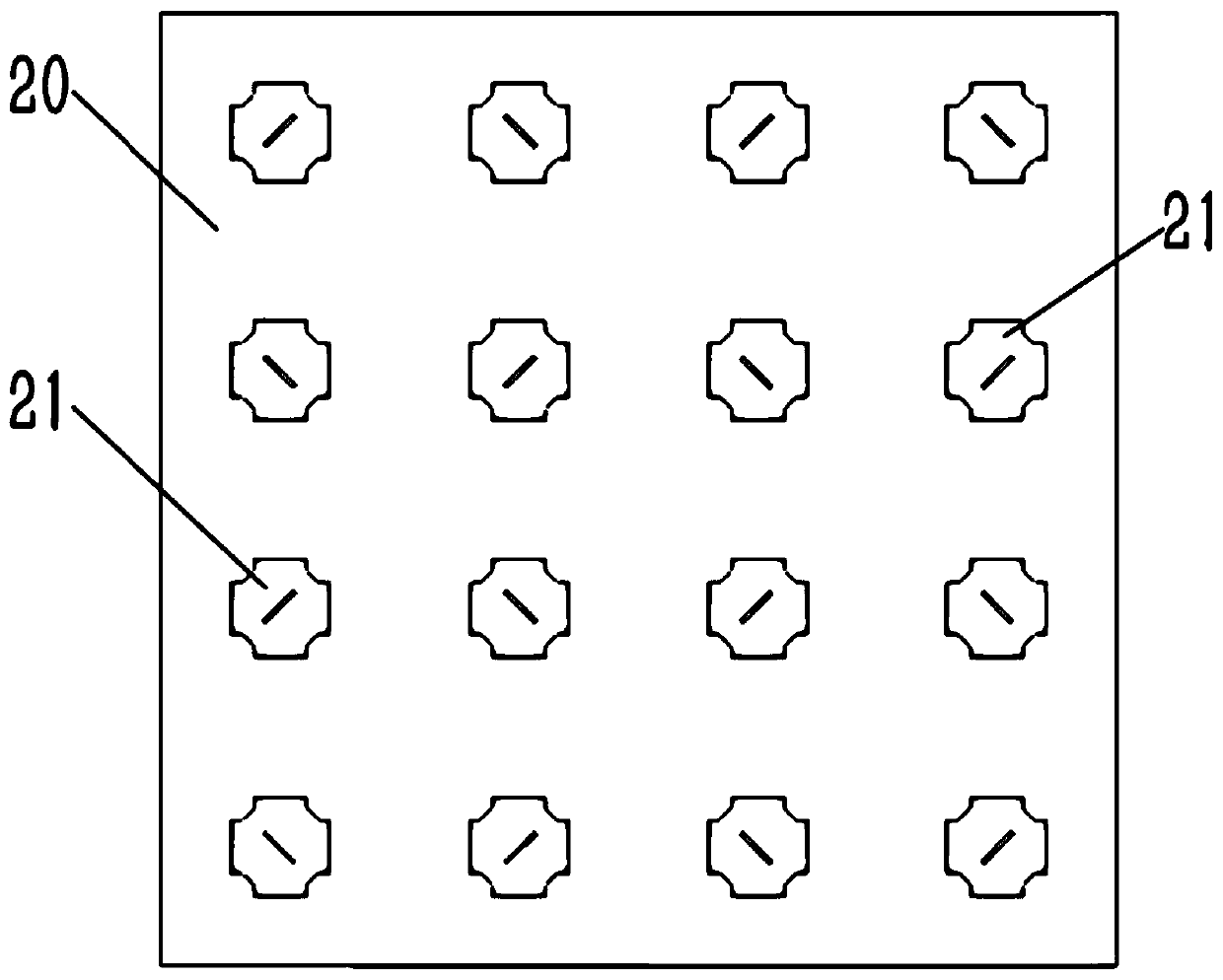

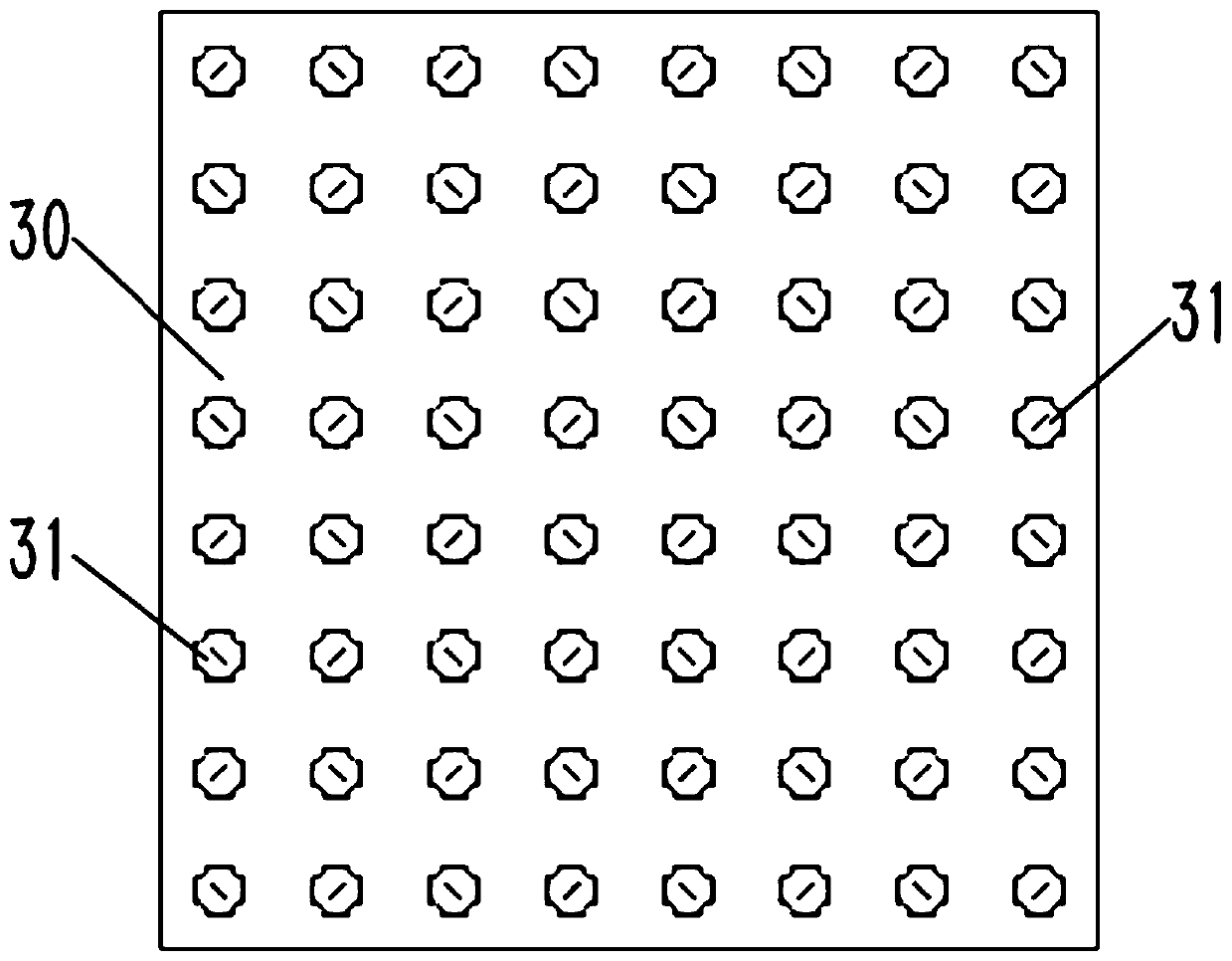

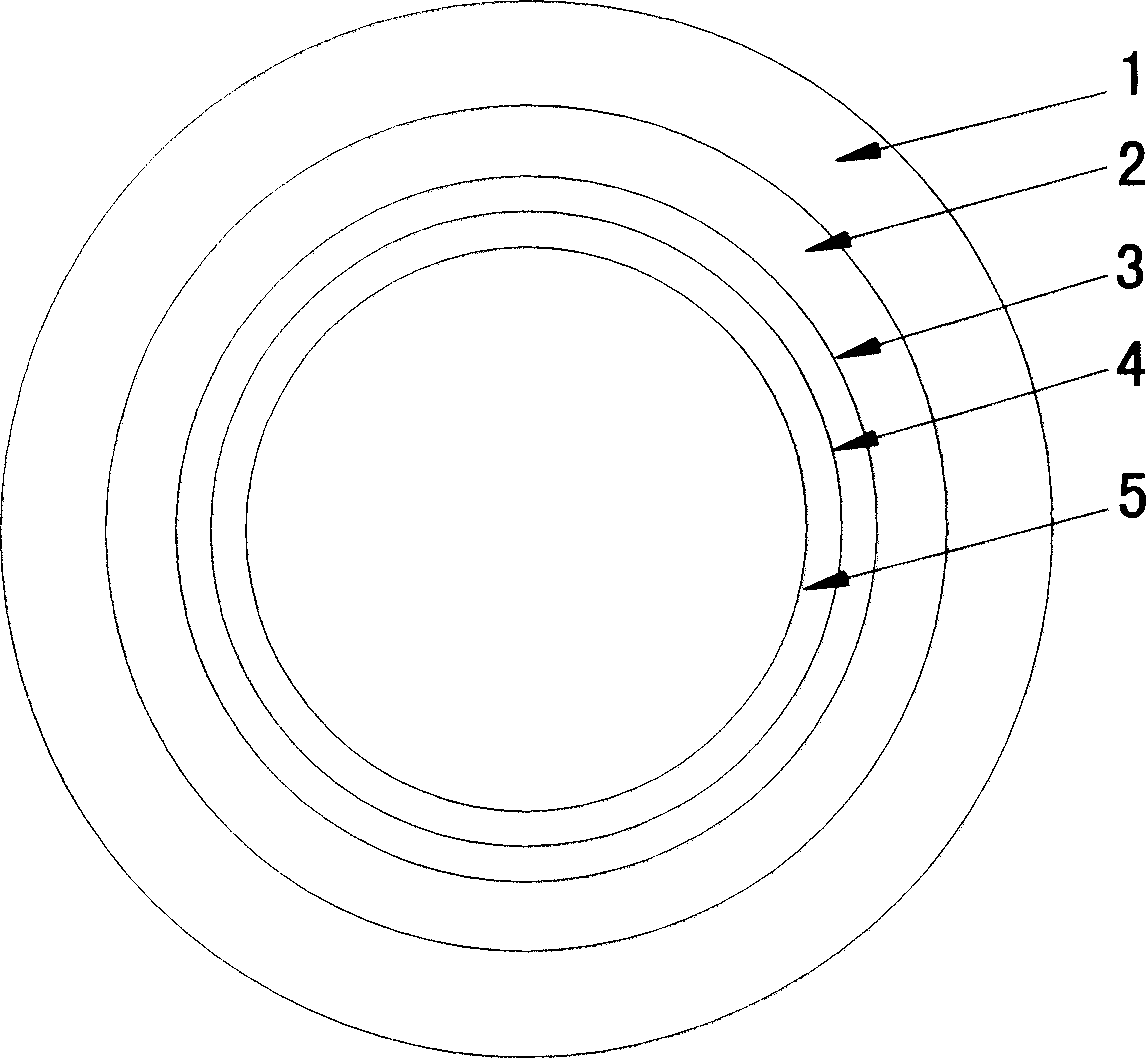

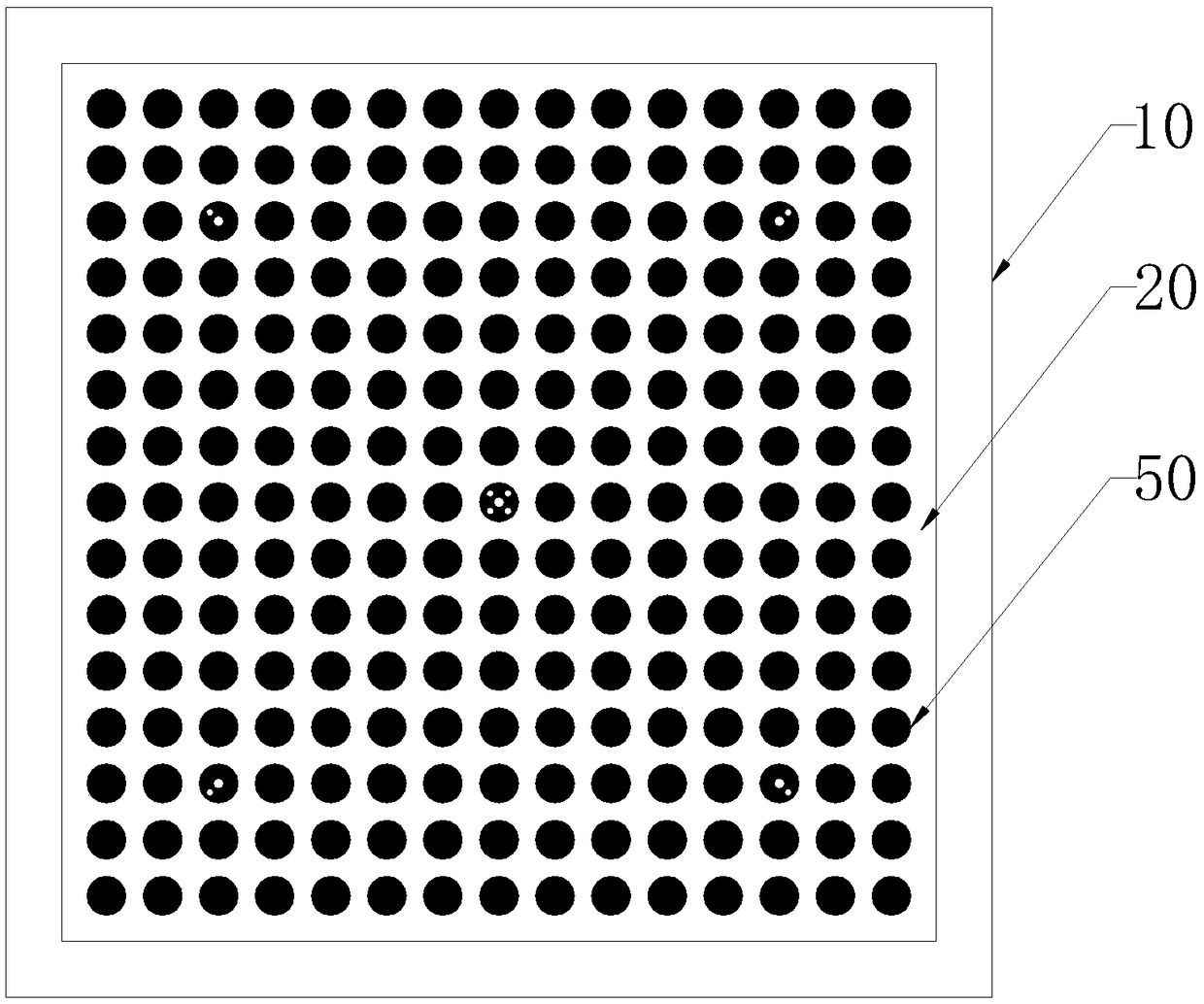

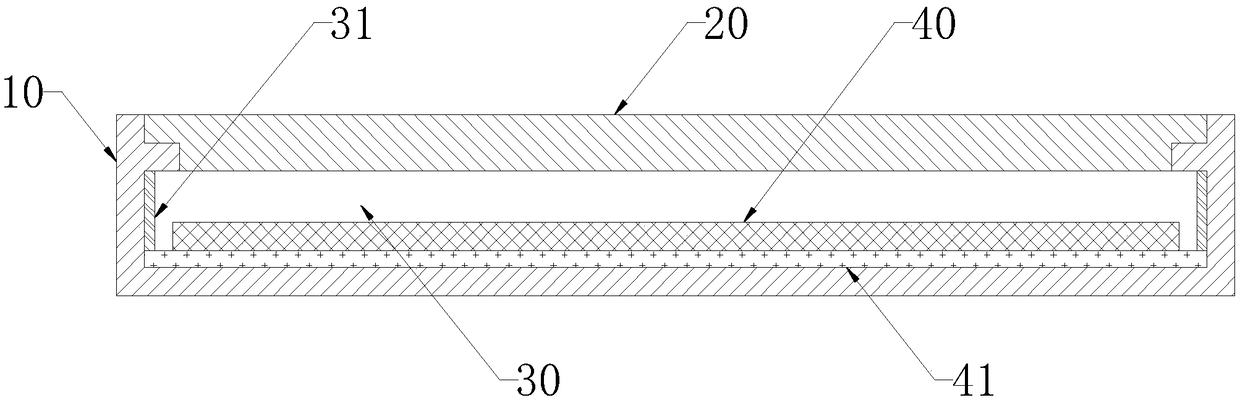

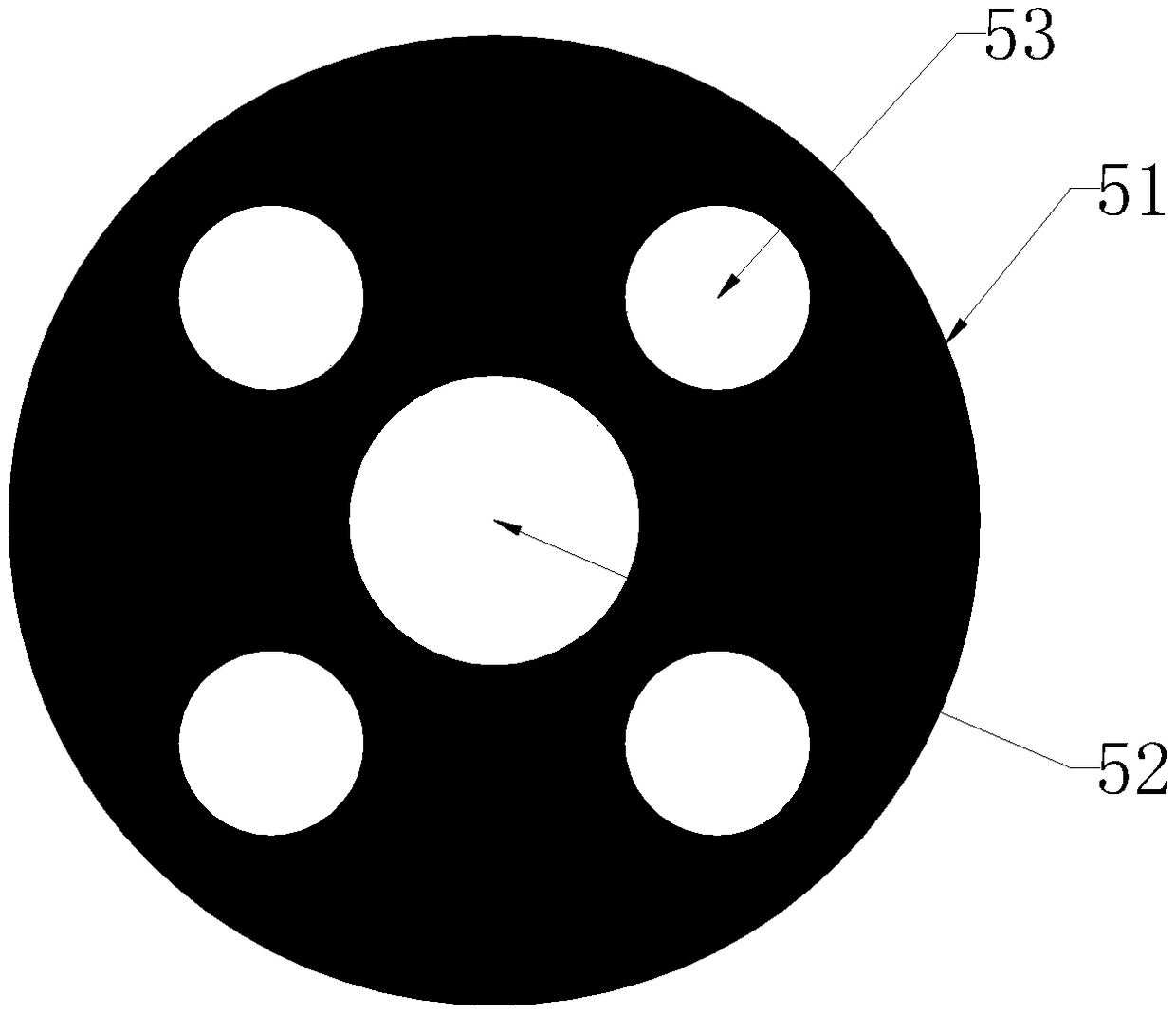

Calibration template and template detection method, device and terminal

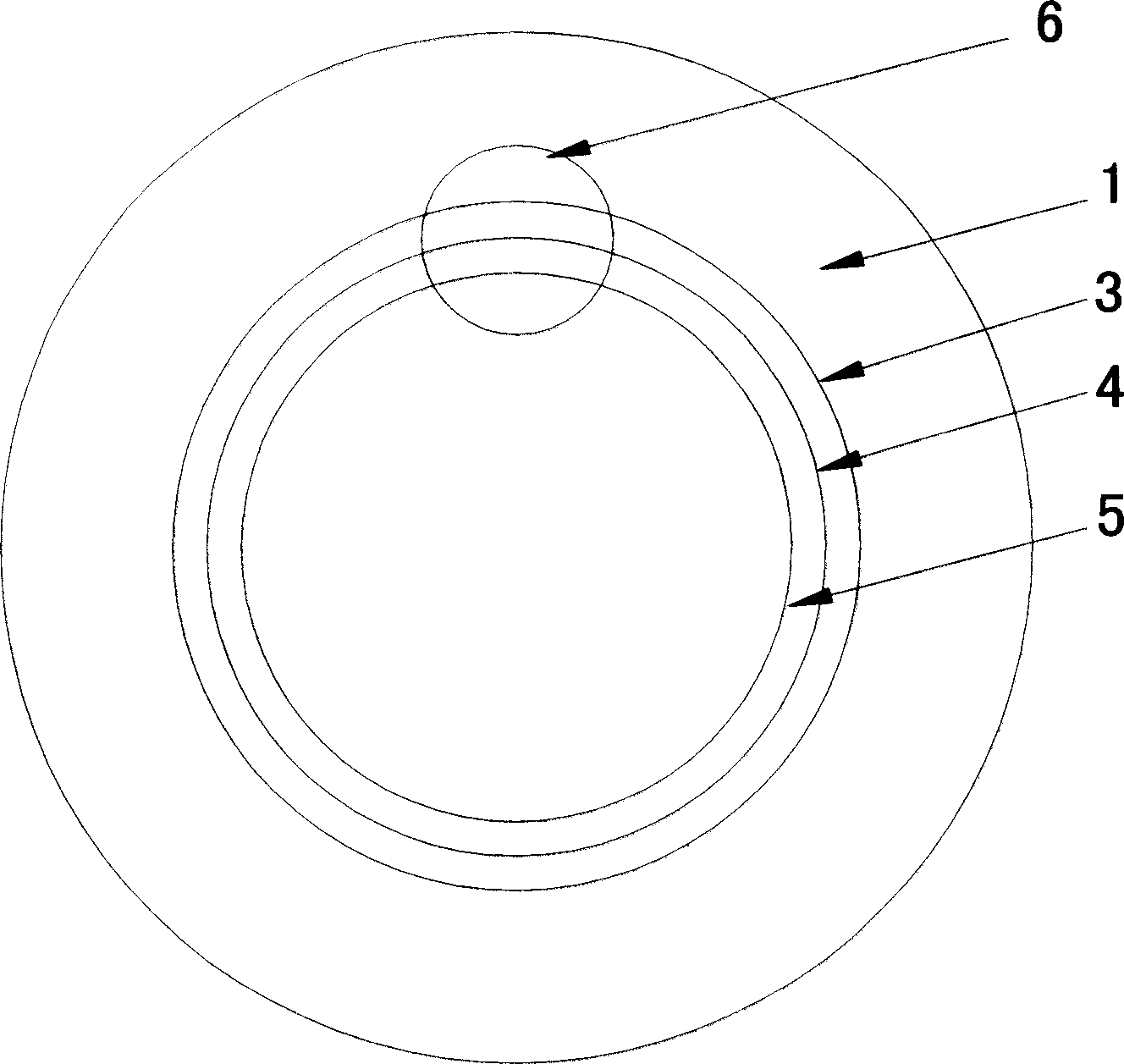

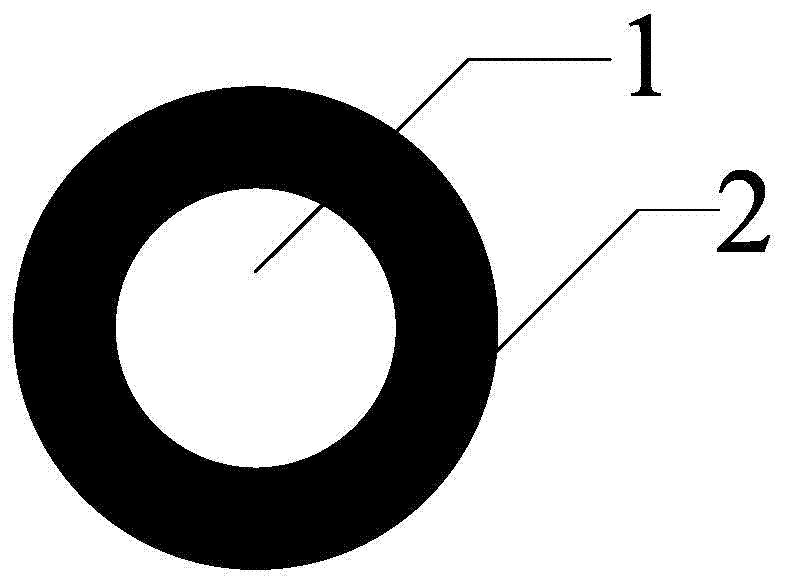

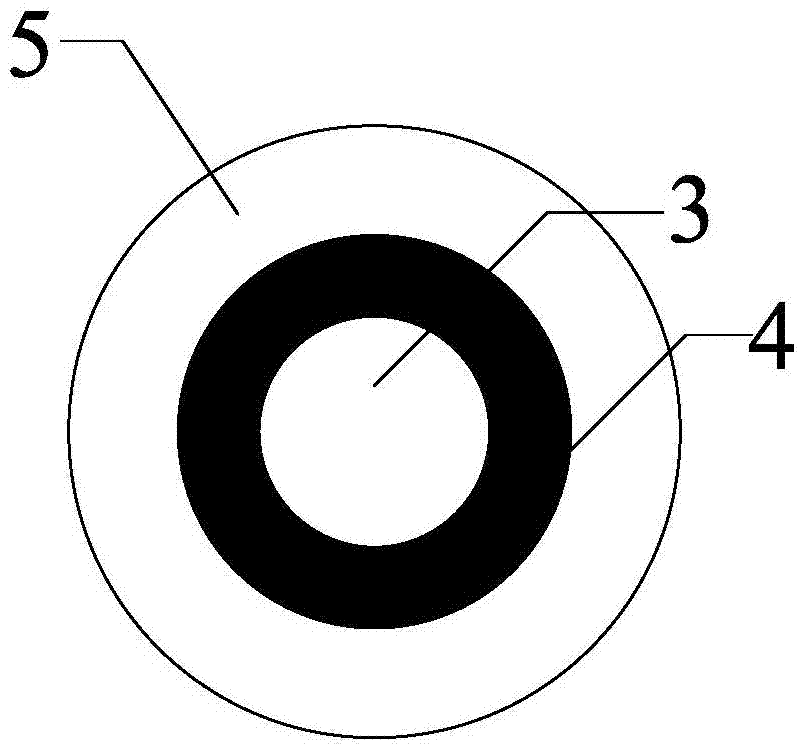

The invention discloses a calibration template and a template detection method, device and terminal. The calibration template comprises at least one calibration circle set and at least three positioning circle sets. The circle centers of the positioning circle sets are not located on the same straight line. Each calibration circle set comprises at least two calibration circles with the same circle center, a circular ring is formed by the calibration circles in each calibration circle set, and the colors of the circular rings are different from the colors of adjacent areas. Each positioning circle set comprises at least two positioning circles with the same circle centers, a circular ring is formed by the positioning circles in each positioning circle set, and the colors of the circular rings are different from the colors of adjacent areas. Each positioning circle set comprises a first characteristic ring and a second characteristic ring, wherein the radius of the first characteristic ring is not equal to that of any positioning ring in the positioning ring sets, and the radius of the second characteristic ring is not equal to that of any calibration ring in each calibration ring set. The calibration template is not prone to interference of the external environment, and the template detection accuracy is improved.

Owner:江苏亿川机电有限公司

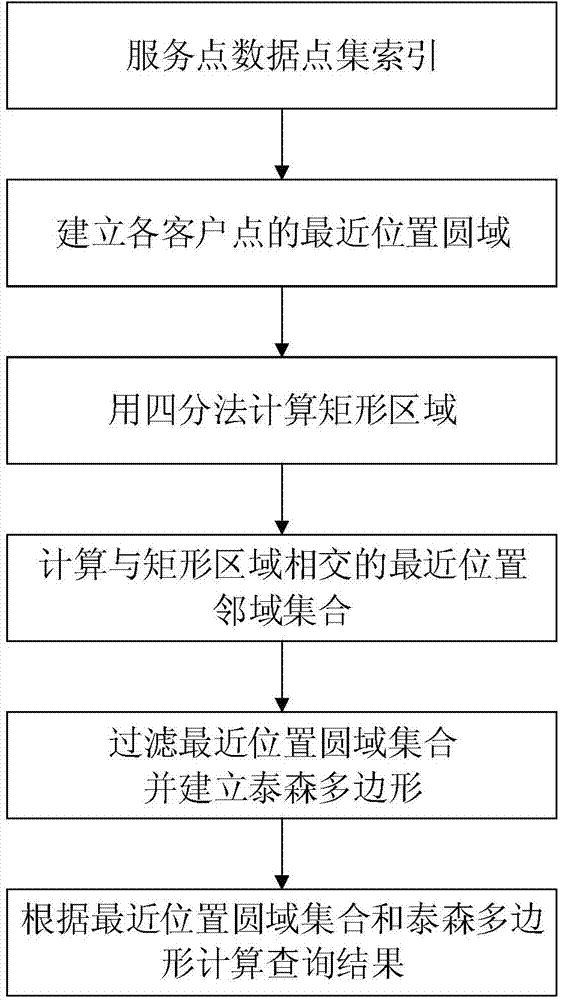

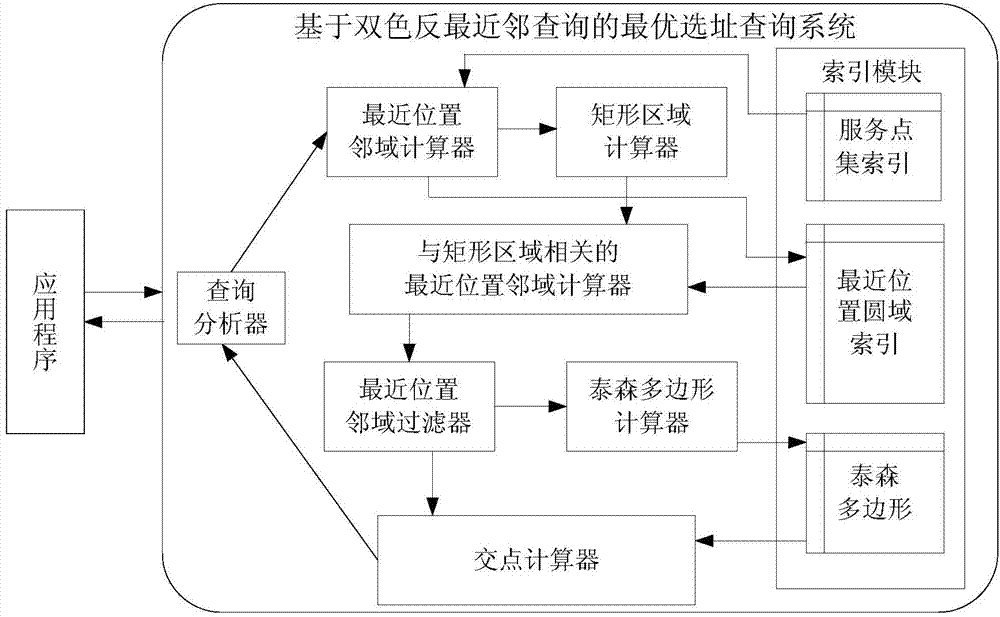

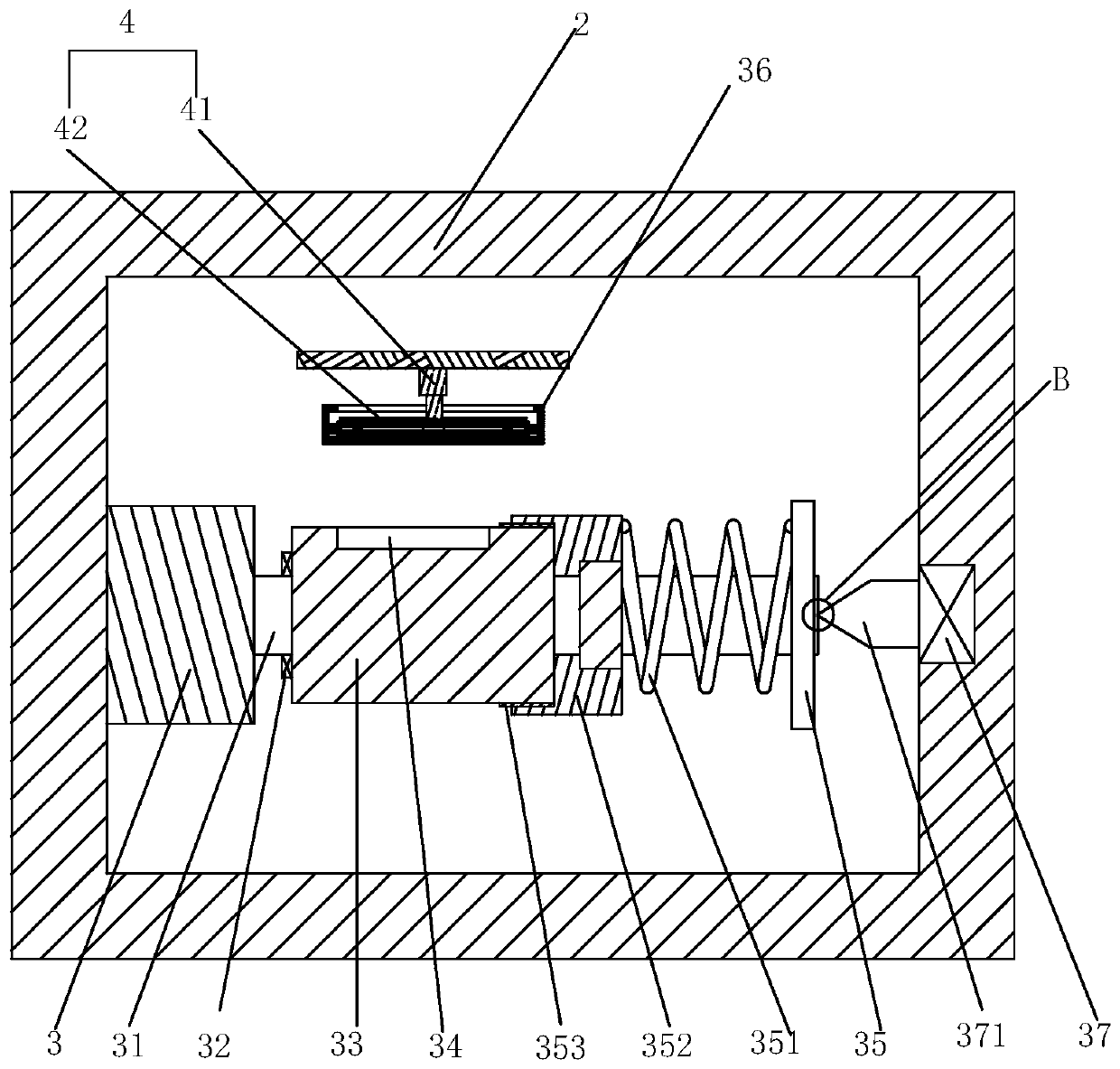

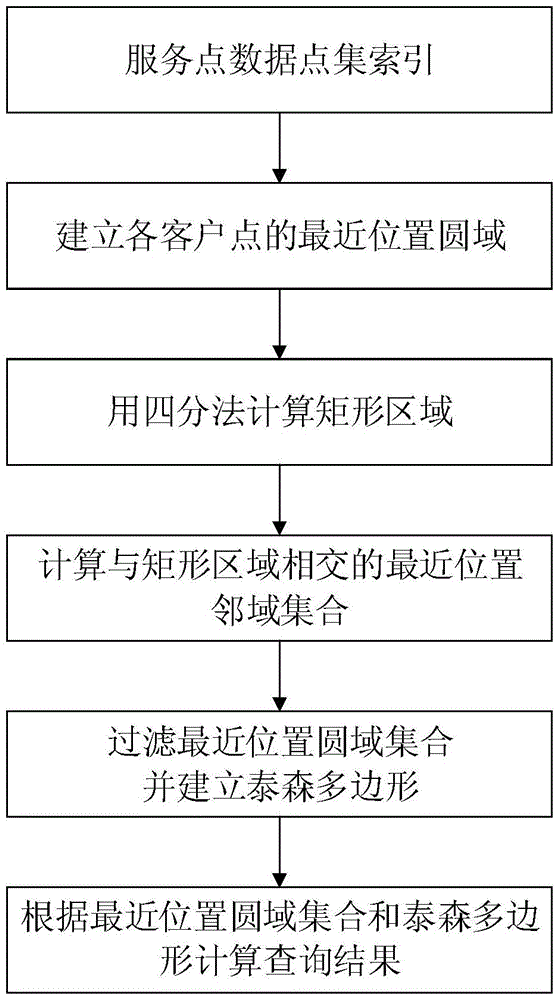

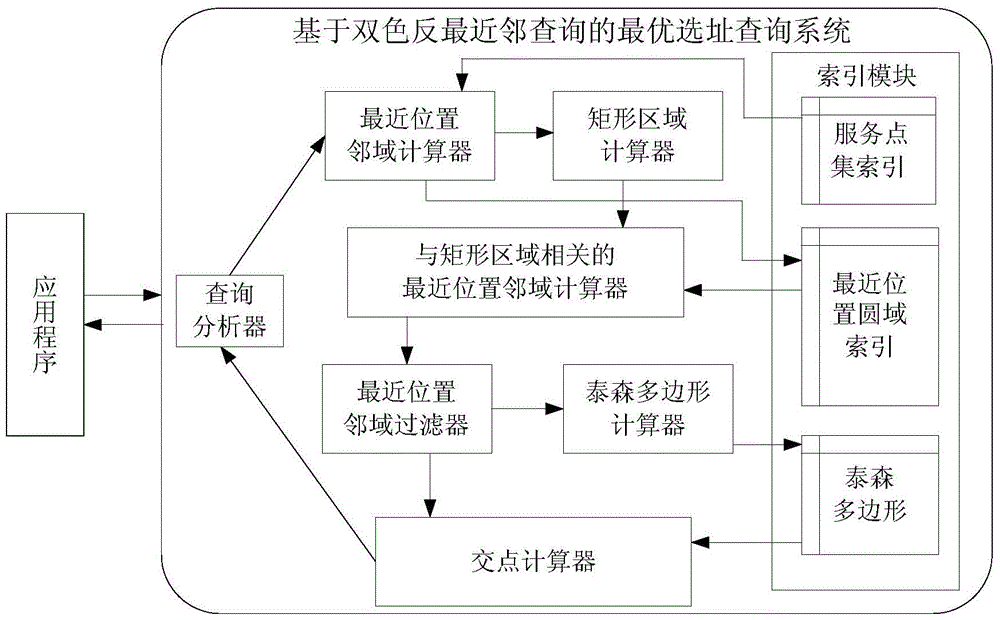

Optical location method based on double-color reverse nearest neighbor query

ActiveCN103778196AReduce overheadReduce CPU timeSpecial data processing applicationsPosition circleAlgorithm

The invention discloses an optical location method based on double-color reverse nearest neighbor query. The double-color reverse nearest neighbor query technology in a spatial database is used, the space quartering method and the Thiessen polygon are used in the optical location method, and it is guaranteed that query results have maximum reverse nearest neighbors so as to enable the minimum distances from the query results to the corresponding reverse nearest neighbors to be maximum. The optical location method includes the steps that firstly, nearest position circle domains of all client points are generated; secondly, the quartering method is used for finding out a rectangular region, and the rectangular region is made to fall in intersection sets of the nearest position circle domains as much as possible; thirdly, two effective pruning rules are used for pruning nearest position circle domain sets related to the rectangular region obtained in the former step; finally, an optical location point is find out according to the pruned nearest position circle domain sets and the Thiessen polygon. According to the optical location method, the searching space for query is greatly reduced, the query efficiency is obvious better than that of an existing method, and the optimal performance is provided.

Owner:ZHEJIANG UNIV

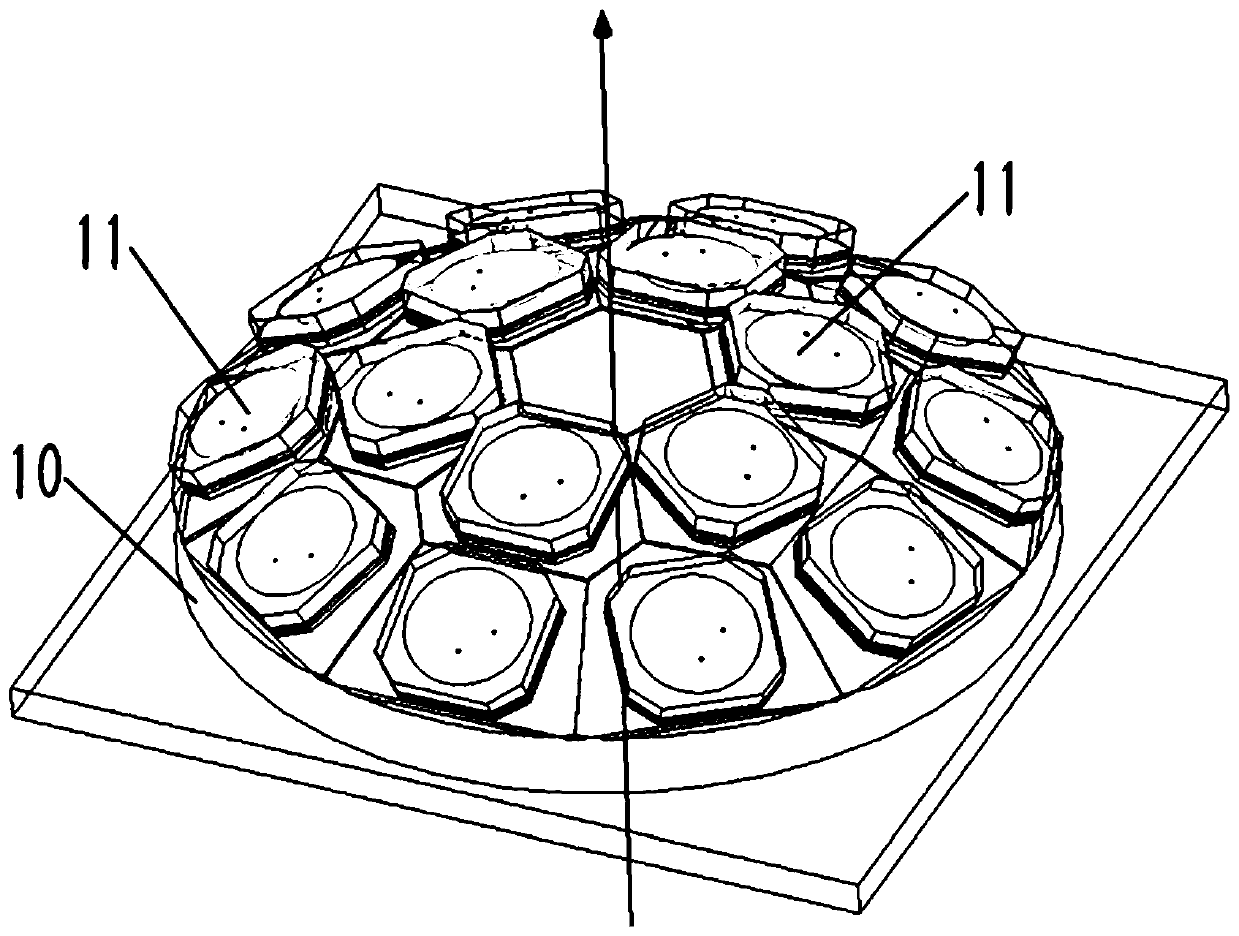

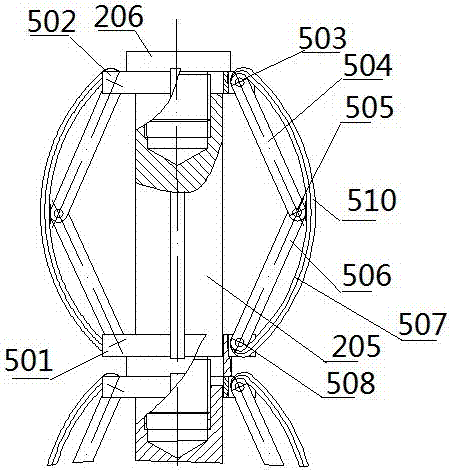

Satellite antenna and satellite navigation signal enhancement method

PendingCN110221318AIncrease landing powerFlexible deploymentSatellite radio beaconingPosition circleOrbit

The invention provides a satellite antenna. The satellite antenna comprises a spherical crown base, a plurality of positioning circles are defined on the spherical crown base, a plane where each positioning circle is located is parallel to the base surface of the spherical crown base, and a plurality of antenna units are uniformly distributed along the circumference of each positioning circle. Theinvention also provides another satellite antenna. The satellite antenna comprises a rectangular substrate, the rectangular substrate is provided with an array consisting of M*N antenna units, wherein M and N are positive integers. According to the satellite antenna and the satellite navigation signal enhancement method, the L-frequency-band direct-sending navigation signal with stronger power can be broadcast by the low-orbit satellite, the signal landing power is greatly improved, the navigation anti-interference capability is improved, multiple continuous coverage is formed for a target area through adoption of an antenna staring beam technology, and the local navigation enhancement service which can be flexibly deployed in the global range is achieved.

Owner:SHANGHAI ENG CENT FOR MICROSATELLITES

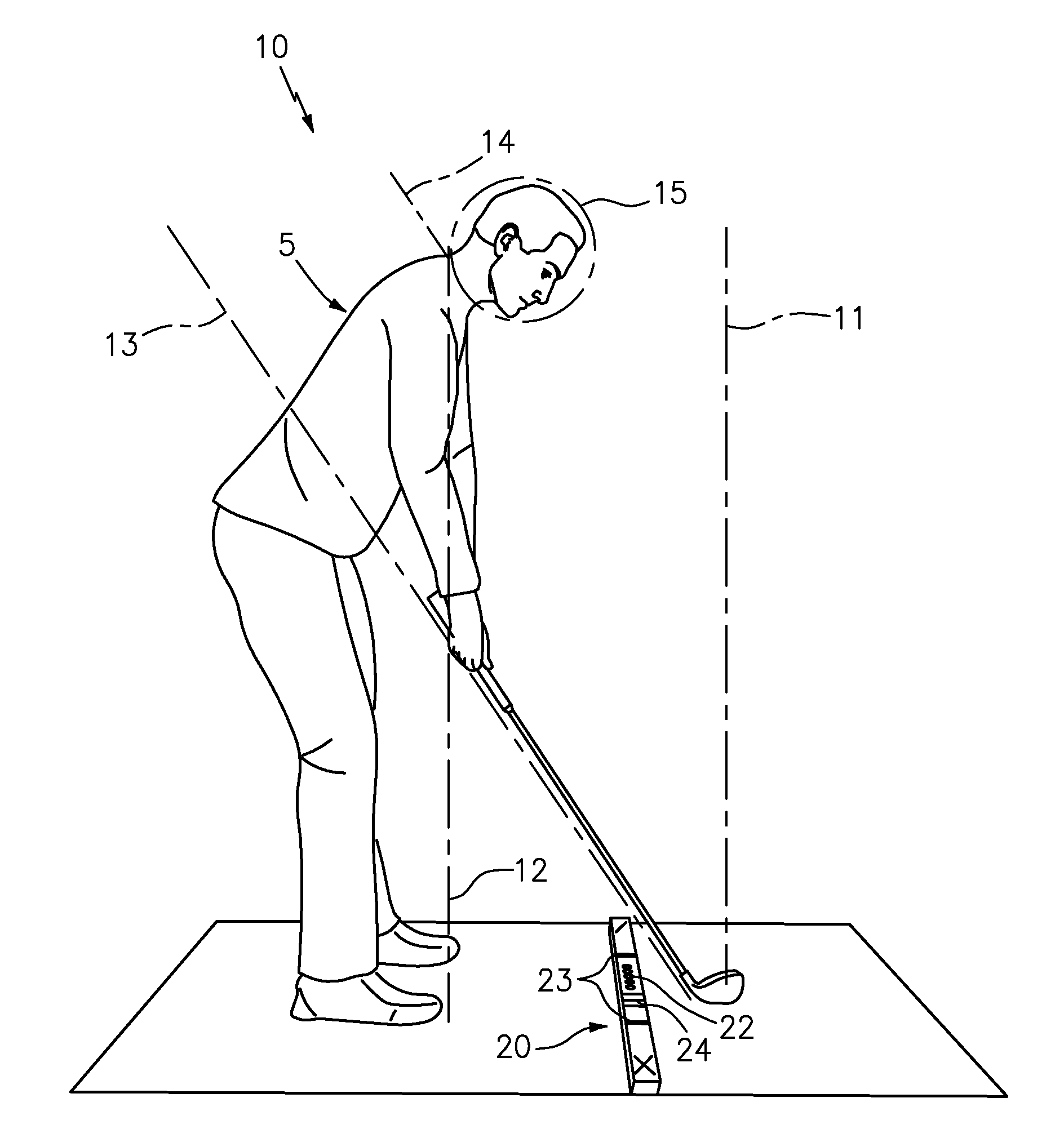

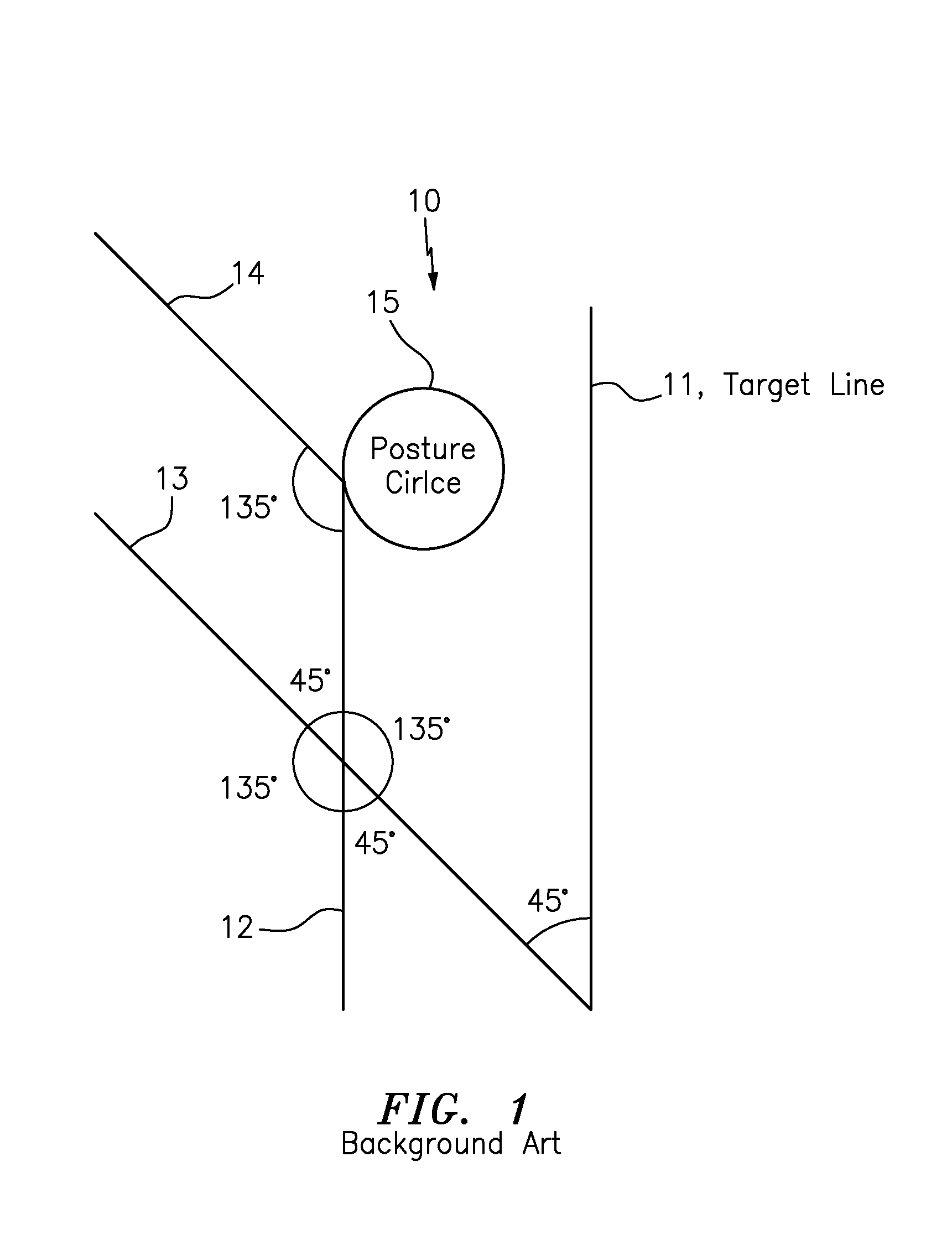

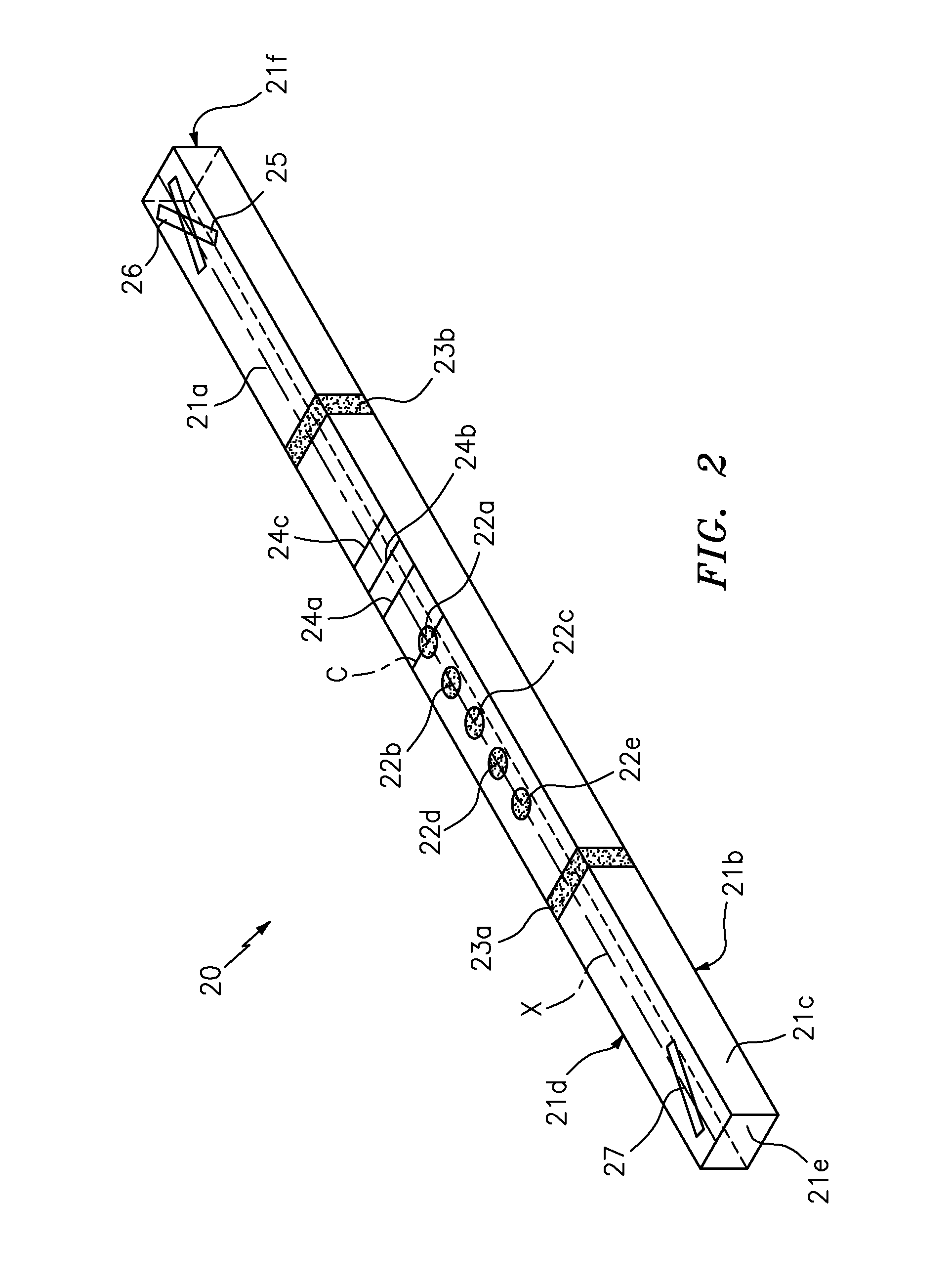

Golf swing instruction tool utilizing a motion training schematic

A golf swing instruction tool for positioning a golfer in accordance with a golf schematic representing a preferred golf swing includes an elongated shaft having a plurality of sides, a series of ball position circles, a pair of stance lines, a plurality of posture sight lines, a takeaway sight line, a downswing sight line, and a follow through sight line.

Owner:SCHEMATIC GOLF ENTERPRISES

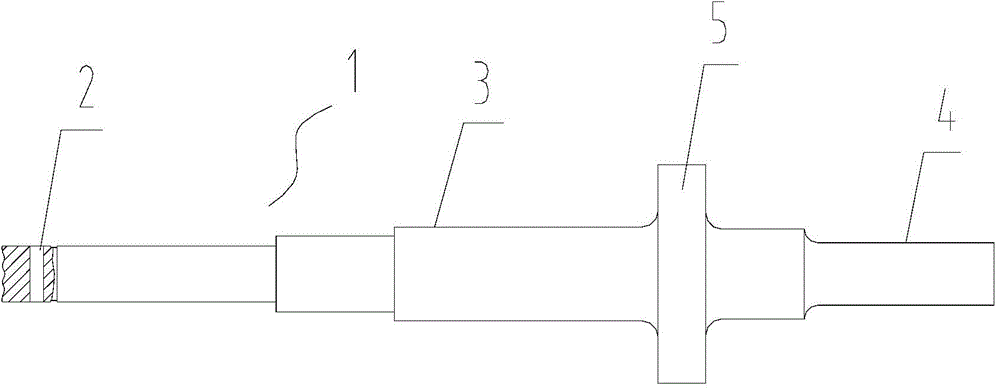

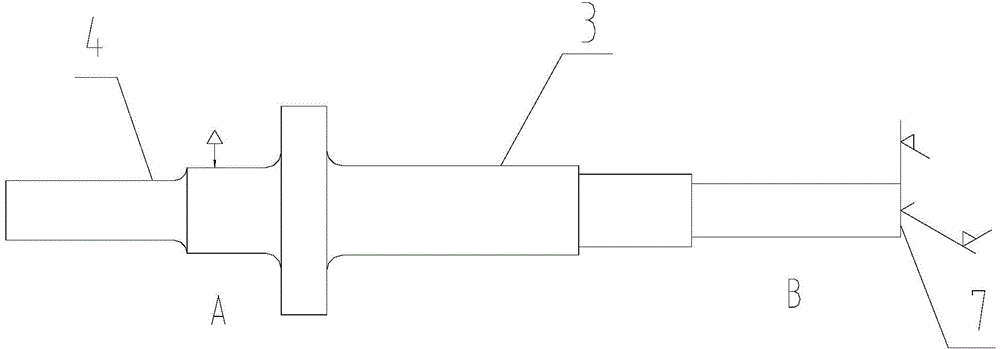

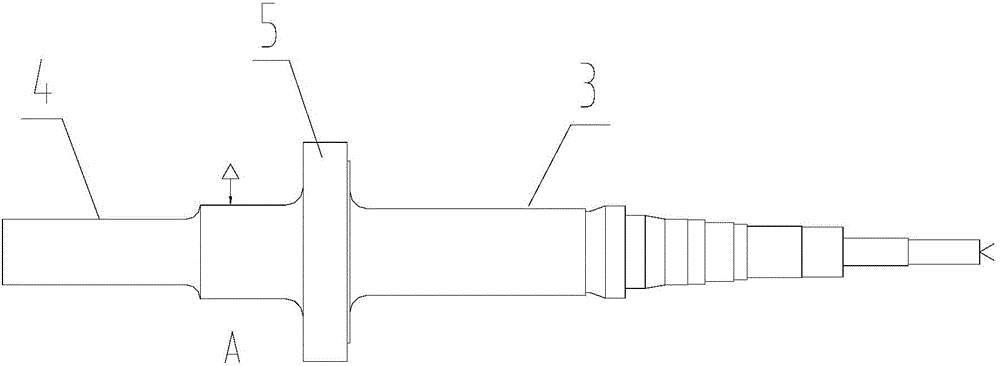

Machining method of turbine rotor

A machining method of a turbine rotor comprises the following processes of step a, performing rough turning on a pressure air end, a turbine disk and a turbine end of a turbine shaft; step b, performing drilling and heat treatment on a lifting hole; step c, performing heat treatment on the turbine shaft; step d, performing half-finished turning on the pressure air end, the turbine disk and the turbine end of the turbine shaft; step e, grinding outer circles and an end surfaces; step f, aligning the ground outer circles and end surfaces and performing finish turning on the pressure air end, the turbine disk and the turbine end of the turbine shaft; step g, grinding a tongue groove positioning circle and a key groove positioning circle; step h, aligning the tongue groove positioning circle and broaching a tongue groove; step i, aligning the key groove positioning circle and milling a key groove, an air guide wheel key groove and a pressure air impeller key groove; step j, performing finish turning an air sealing groove, an oil sealing groove and a center hole; step k, grinding stages of outer circles and end surfaces; step l, performing rounding on the key groove and performing deburring and chamfering on the tongue groove; step m, installing an air sealing ring on the turbine shaft; step n, performing finish turning on the end surface of the total length of the pressure air end and performing smooth transfer and polishing on the outer circles; step o, performing finish turning on the air sealing ring and performing smooth transfer and polishing on the outer circles; step p, performing appearance inspection. According to the machining method of the turbine rotor, the rotary accuracy of the turbine rotor is improved.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

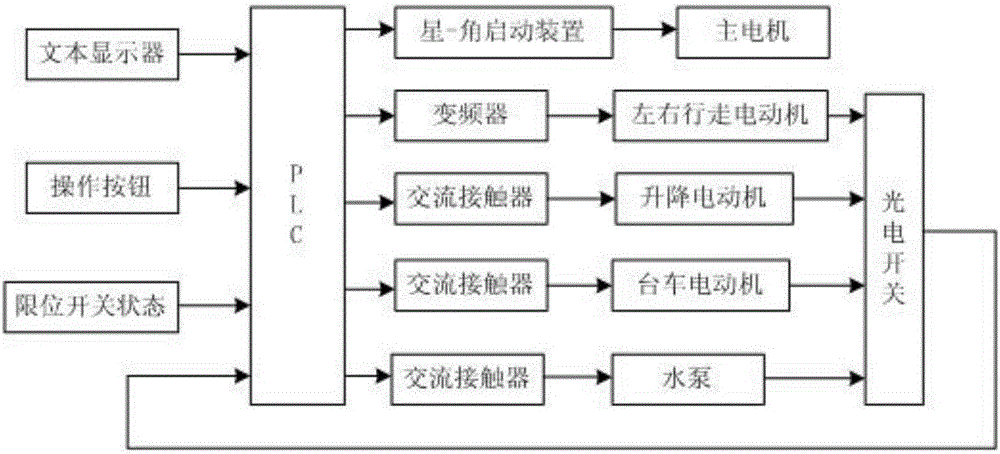

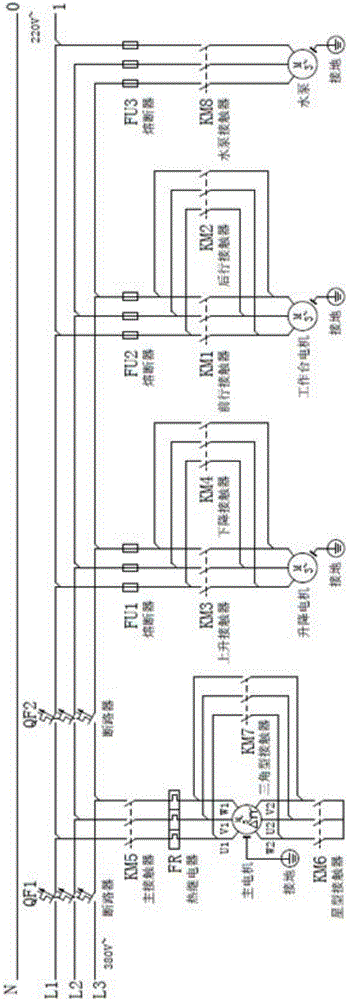

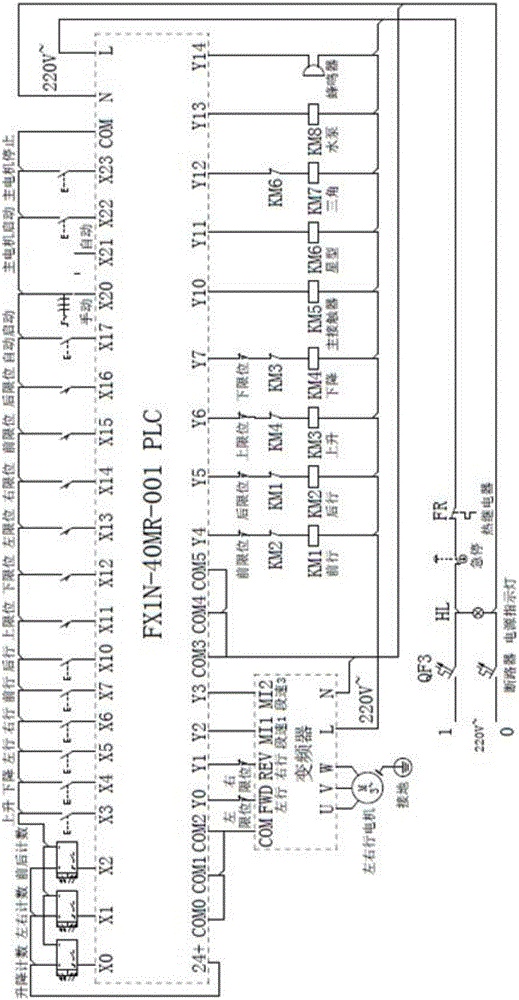

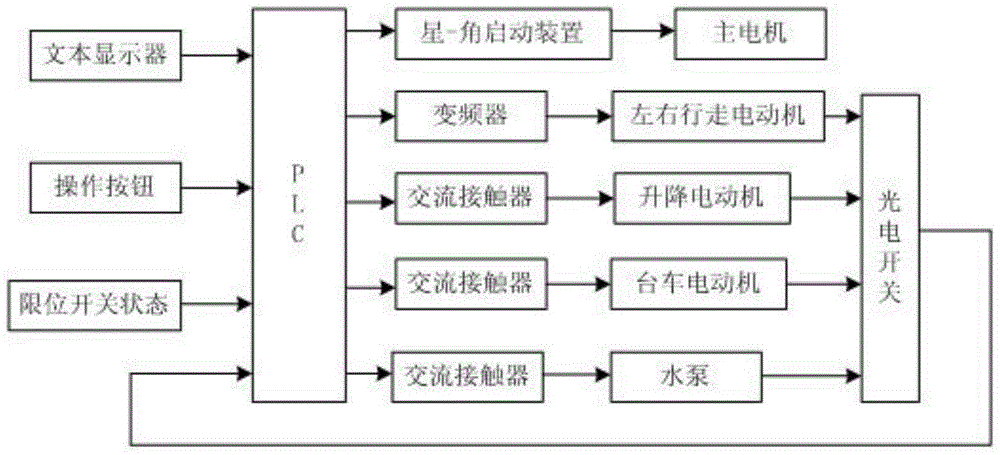

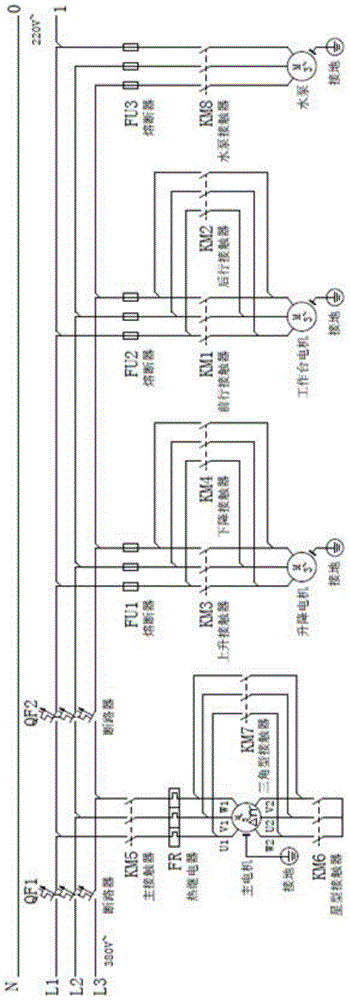

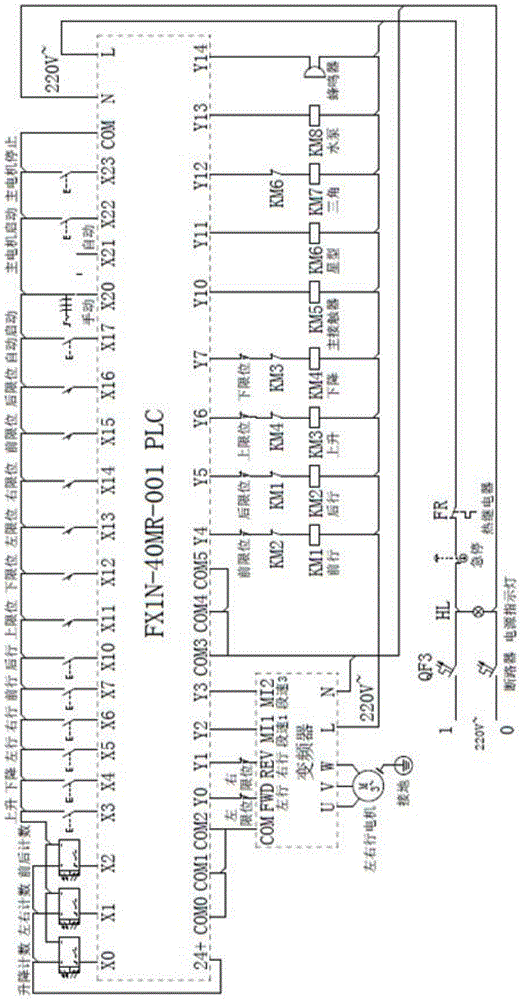

Control system and method for disc stone sawing machine

InactiveCN105058591AQuality improvementHigh degree of automationWorking accessoriesStone-like material working toolsCircular discPosition circle

The invention relates to a control system and method for a disc stone sawing machine. The control system comprises four portions of a power unit, an electrical control unit, a detection unit and a man-machine interaction part. Manual and automatic control modes are provided, the position of a first cutting disc saw can be determined according to the first cutting machining depth, stone size, the disc saw radius and the distance from the disc saw initial position circle center to a trolley, and accordingly the first cutting machining accuracy is guaranteed. By means of a left and right traveling mechanism, left and right traveling switching can be achieved through a stroke counting function, so that machining can be performed according to the actual stone width, and the problem of the idle running time process caused by switching of limit switches in the traditional method is solved; by means of the system, optimal matching of machining depth with machining speed is achieved, the main motor optimal operation efficiency is guaranteed, the system work efficiency is improved, and the energy-saving purpose of the system is reached; besides, the system safety and reliability are guaranteed.

Owner:BOHAI UNIV

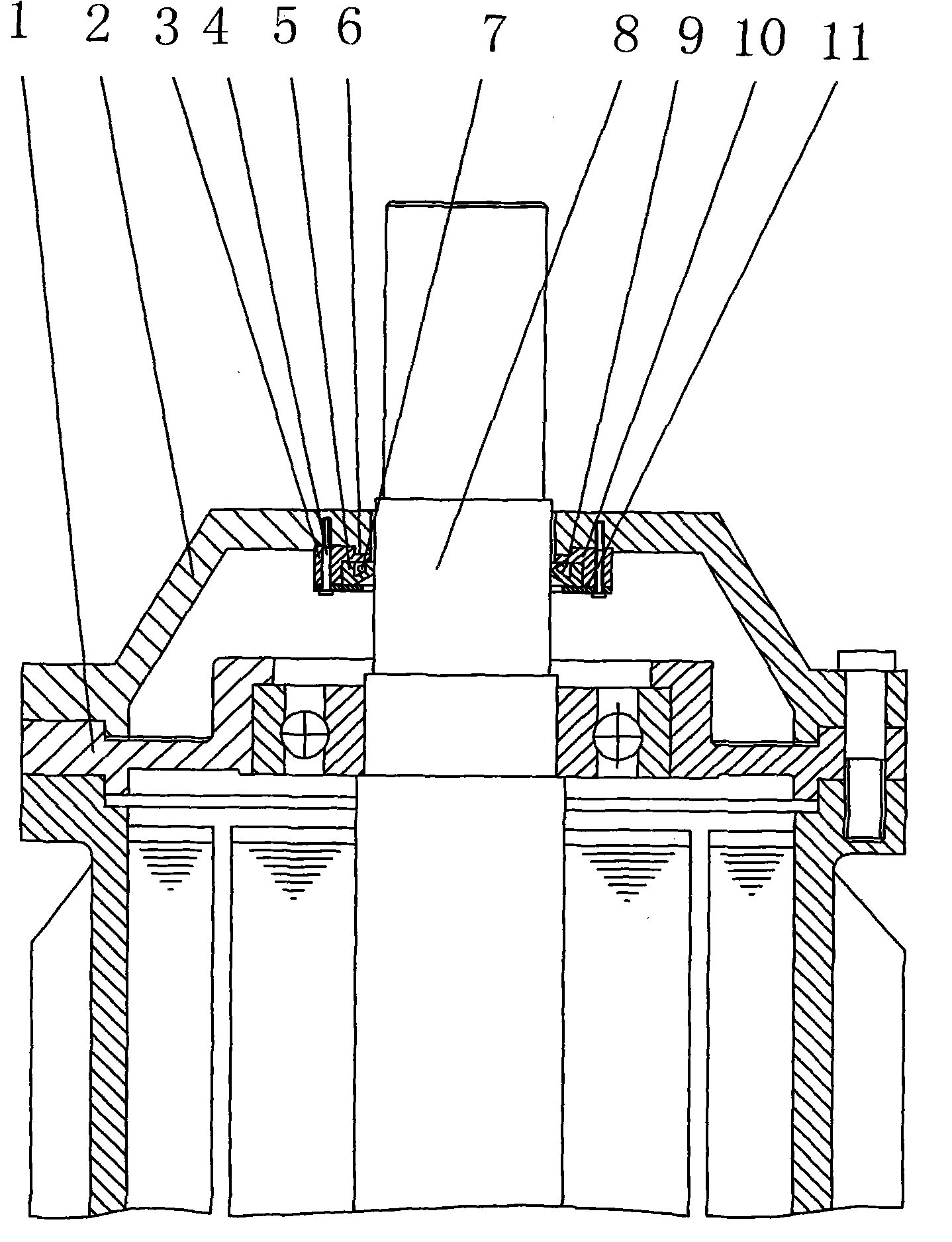

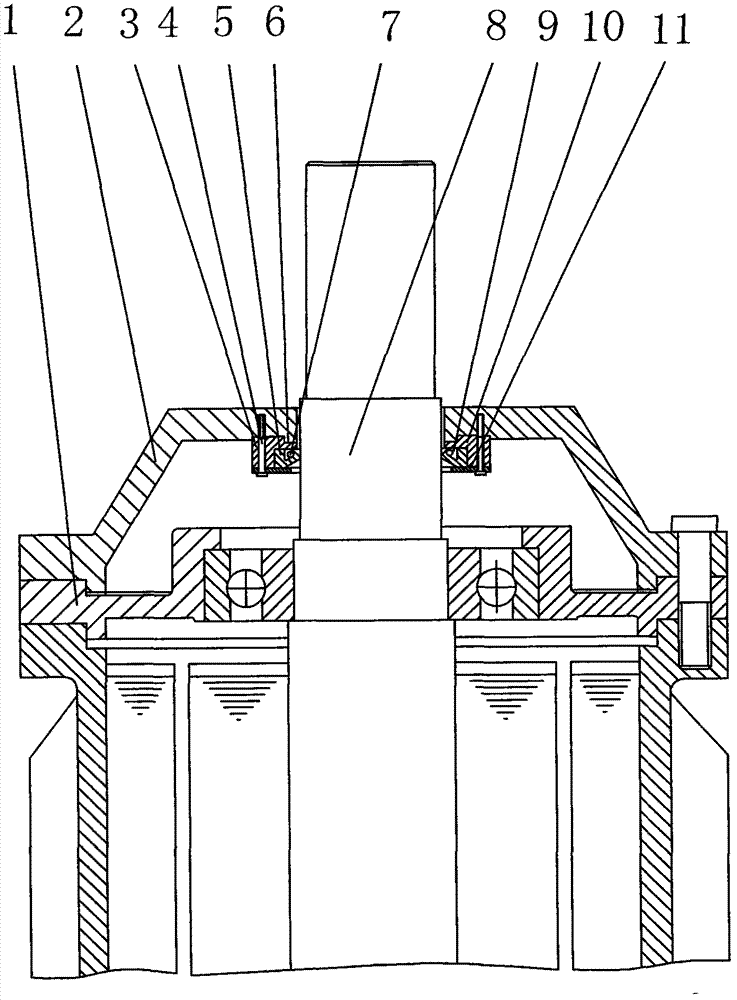

Motor end cover sealing device capable of preventing dust and sand from entering interior of motor

The invention relates to a motor end cover sealing device capable of preventing dust and sand from entering the interior of a motor. A plane and a positioning circle step are machined at the inner side of a motor end cover at the motor shaft extension end of the motor; a rubber oil seal seat is arranged on the positioning circle step; the rubber oil seal seat comprising a seat body and a cover plate is fixed on the motor end cover through bolts; a rubber oil seal is arranged in the rubber oil seal seat; a lip of the rubber oil seal faces to the motor end cover; the inner ring of the rubber oil seal closely clings to a motor shaft; and a tension spring ring is arranged in the groove lip of the rubber oil seal. The motor end cover sealing device can prevent dust and sand from entering the interior of the motor through a shaft hole gap of the motor end cover to damage a bearing part and burn out the motor and can also prolong the service life of the motor. The motor provided with the motor end cover sealing device is particularly suitable for occasions with more sand dust and dust.

Owner:KEHUA HLDG

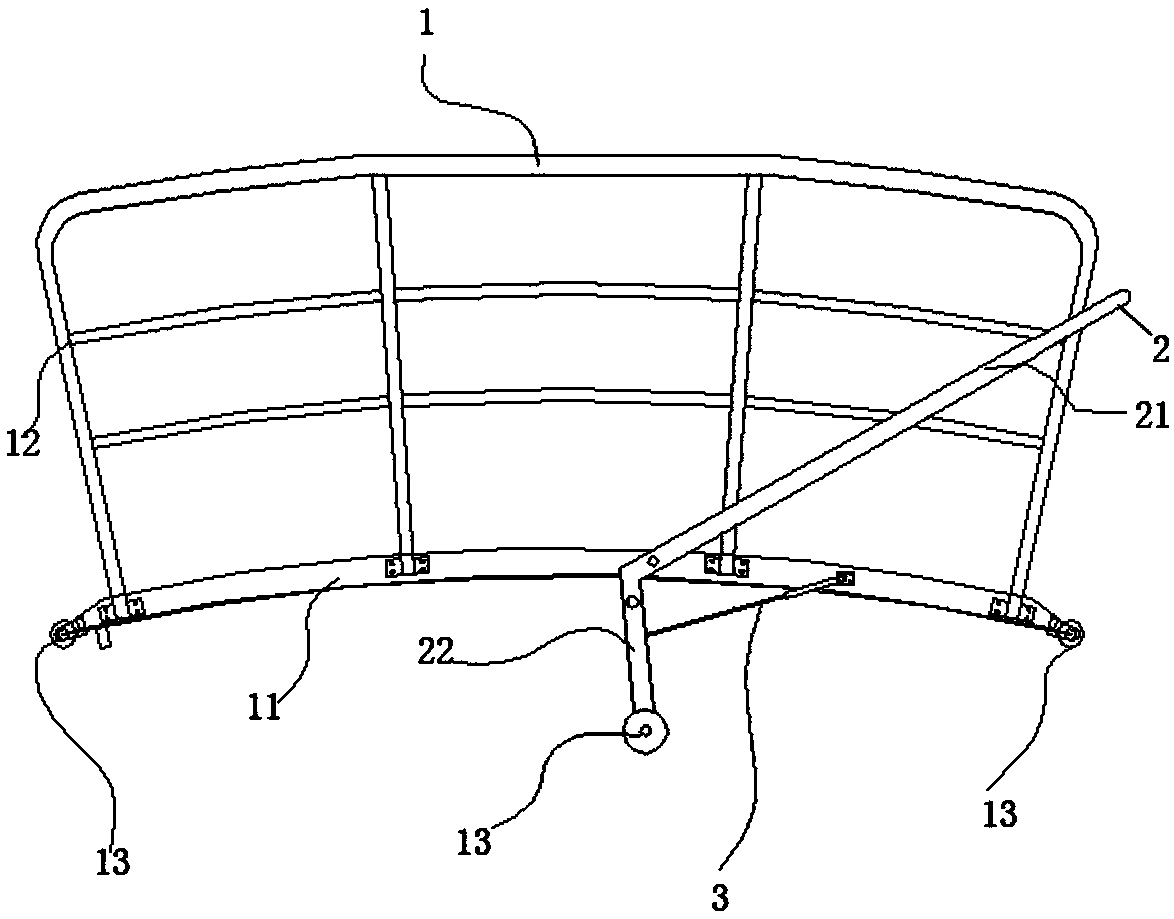

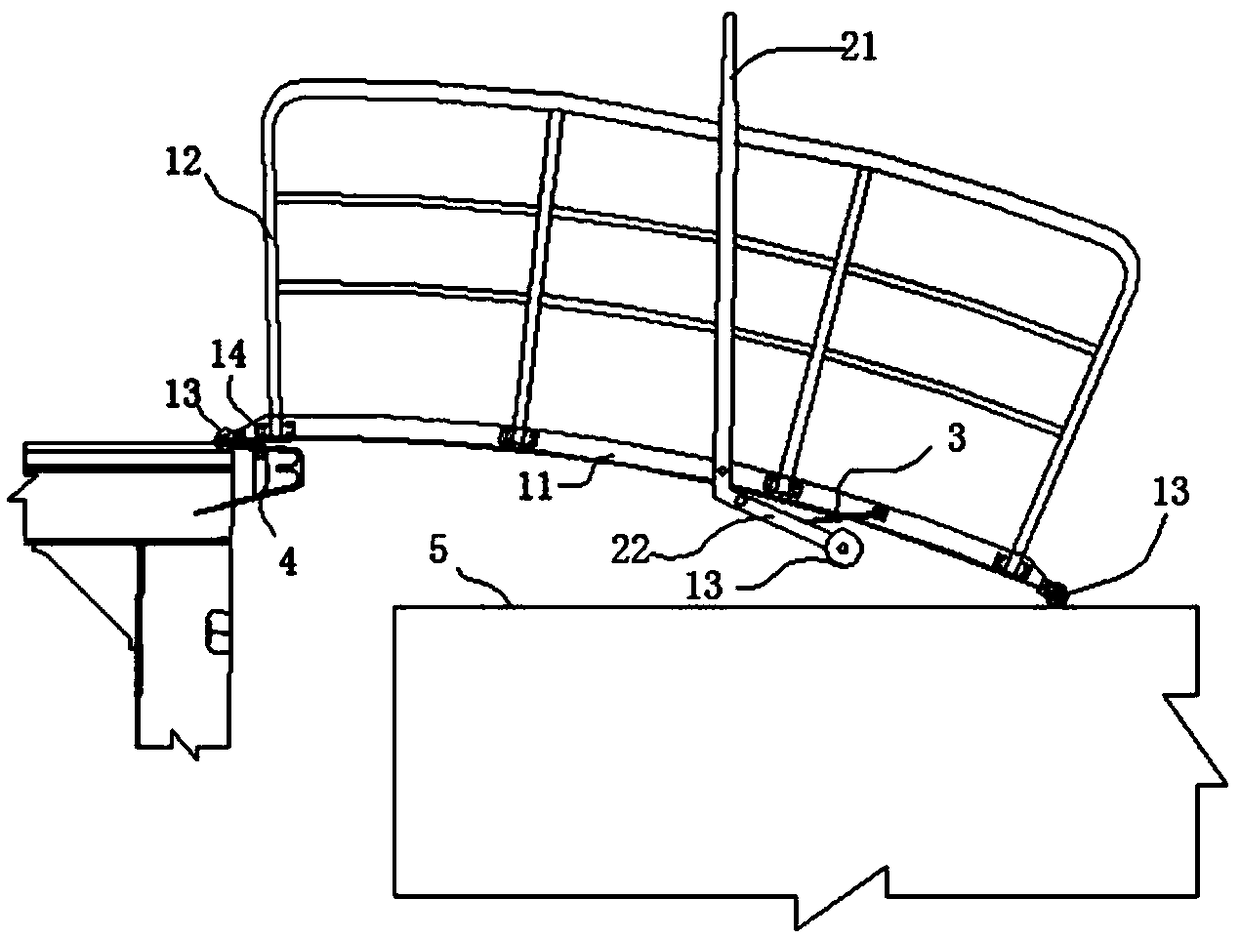

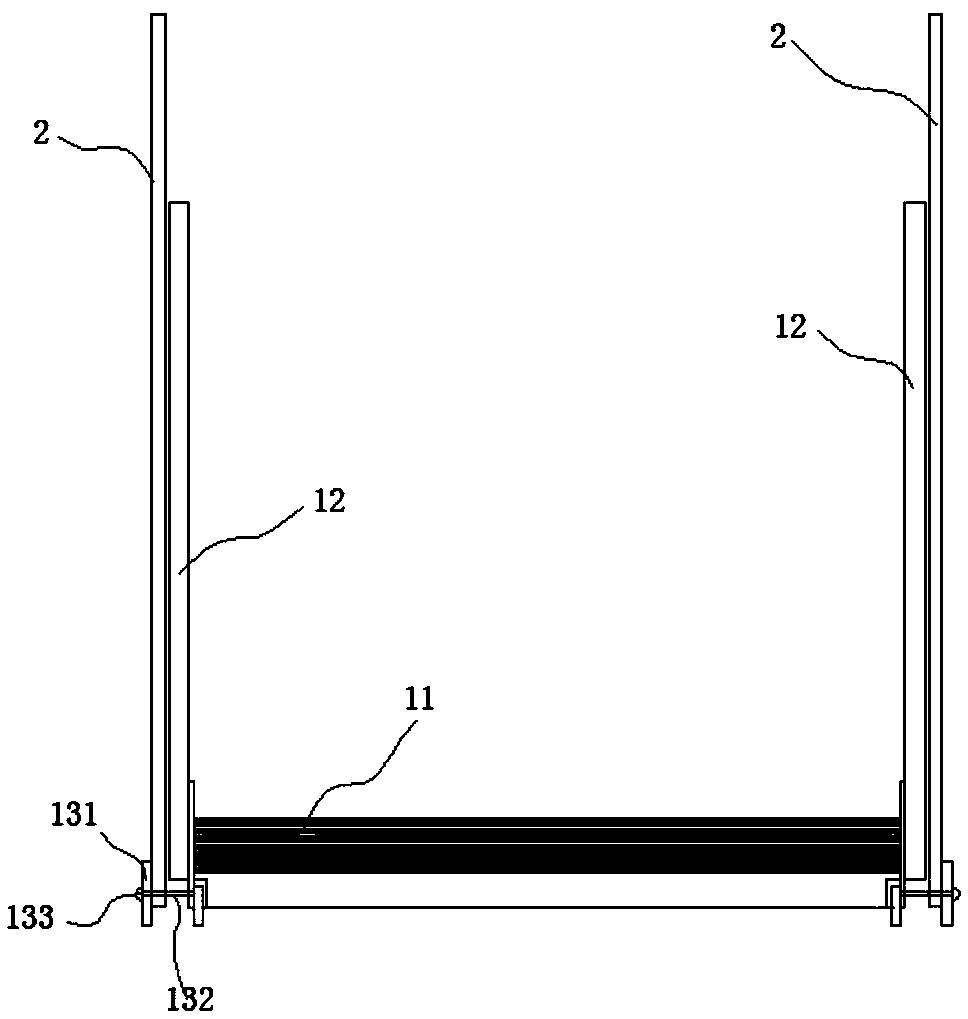

Boarding springboard

PendingCN109204710AWith removableAffiliate quicklyCargo handling apparatusPassenger handling apparatusPosition circleEngineering

Owner:澳龙船艇科技有限公司

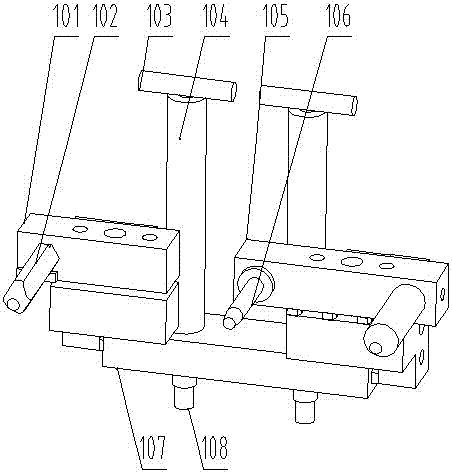

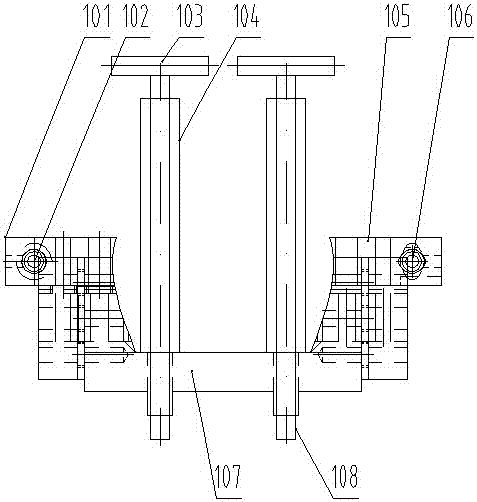

Workpiece clamping device with elastic sheet positioning reference

InactiveCN105234443AMeet each other parallelGuaranteed to be parallel to each otherChucksPosition circleEngineering

The invention discloses a workpiece clamping device with an elastic sheet positioning reference, and belongs to the technical field of tooling fixtures. The workpiece clamping device comprises a disc body and clamping jaws, wherein the clamping claws comprise a first clamping jaw and a second clamping jaw; a first positioning member is arranged on the first clamping jaw; the second clamping jaw is provided with a second positioning member; the first positioning member and the second positioning member perform are positioned in a cooperative manner; the first positioning member consists of a first positioning member body and an elastic sheet; an elastic sheet positioning opening is formed in the upper end part of the elastic sheet; a second positioning member positioning opening is formed in the upper end part of the second positioning member. The workpiece clamping device disclosed by the invention is simple in structure, convenient to use, and safe and reliable, and can meet drawing requirements. Through the adoption of the workpiece clamping device, a processing surface and the axis of a workpiece can be effectively guaranteed to be parallel to each other, so that the positioning circle of the workpiece does not deviate when the workpiece is fastened.

Owner:吉林博仁科技有限责任公司

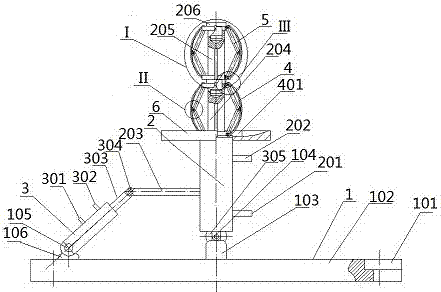

Electric control air pressure combined type drill fixture

InactiveCN107297527ASimple structureEasy to operateWork clamping meansPositioning apparatusPosition circleElectric power system

An electronically controlled pneumatic combined drilling jig, the main body is composed of six parts: base system, deflection system, power system, electric control system, positioning system and parts, and the positioning system includes tensioning system, tensioning and lengthening system, drill It is composed of a jig base plate, a tensioning extension system, a tensioning system and a conversion drill sleeve assembly, so that the drilling jig can be applied to the circumferential processing of center holes with different diameters or different heights. It can process round holes with different positioning circle diameters or different distributions or different apertures on the end face, and can also position and process holes with special angles on the end face or circumference through the deflection system. This product has simple structure, convenient operation and strong practicability. and other effects.

Owner:EASTERN LIAONING UNIV

Maglev rotary dining table

InactiveCN1883335ASecure central locationFlexible rotationServing tablesRevolvable tablesPosition circleElectrical polarity

A magnetic suspension type rotary dining table belongs to the product in the dining equipment field. The making method: make external magnetic field locating slot, internal external magnetic field locating slot and magnetic suspension slot on dining table body 1 and suspension table top 2, and then bind and solidify magnet steel 11 with them using binding and solidifying material 12. After completing making, the suspension table top is inversed so that its magnet steel face of the same polarity is corresponding with the dining table body's magnet steel face of the same polarity. Here, the suspension table top can be suspended by the expulsive force based on the principle of being repulsive for like polarities. Similarly, the objective of positioning is achieved under the mutual expulsive force of the permanent magnet steel inside the external magnetic field positioning circle and the internal magnetic field positioning circle.

Owner:陈少东

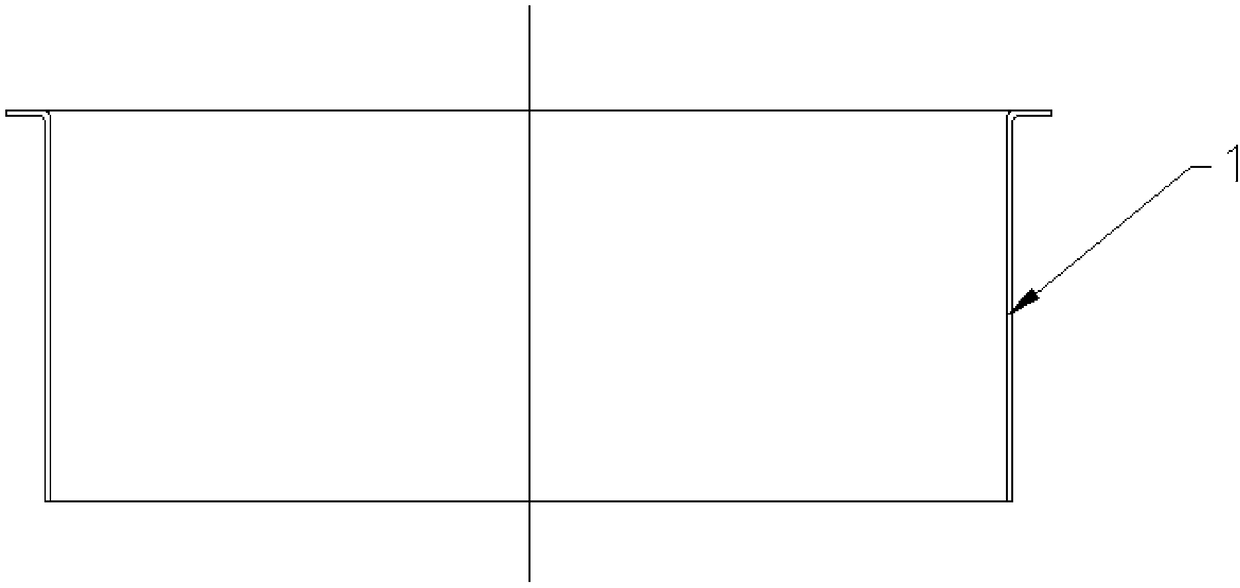

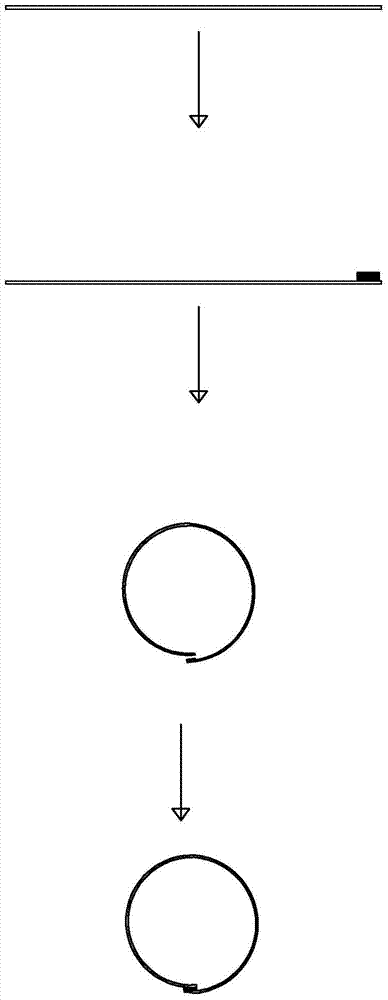

Lining plastic stainless steel ring processing production line

ActiveCN108381195AAvoid skewGuaranteed accuracyOther manufacturing equipments/toolsProduction linePosition circle

The invention provides a lining plastic stainless steel ring processing production line and belongs to the field of steel plate processing auxiliary equipment. The lining plastic stainless steel ringprocessing production line comprises a spheronization component, a welding component and a flanging component which are sequentially arranged; the flanging component comprises a fixed seat; a steel ring seat is arranged on the fixed seat, is rotationally connected with the fixed seat and comprises a positioning circle at the upper end and a positioning ring at the lower end; the outside diameter of the positioning circle is larger than the outside diameter of the positioning ring; and a flanging die is correspondingly arranged at the upper end of the positioning circle. The lining plastic stainless steel ring processing production line provided by the invention is formable and is high in accuracy and efficiency.

Owner:天津友发管道科技有限公司 +1

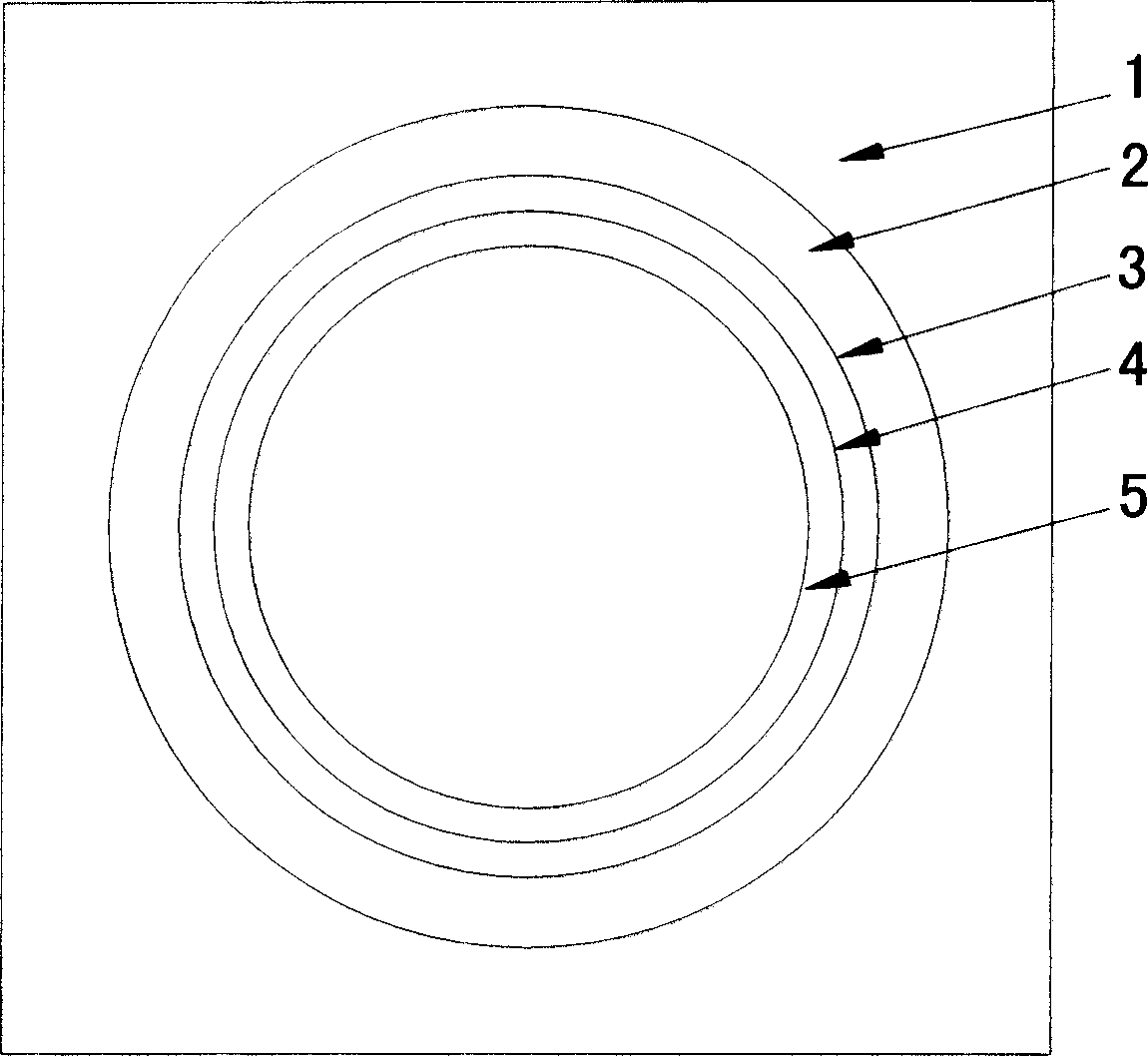

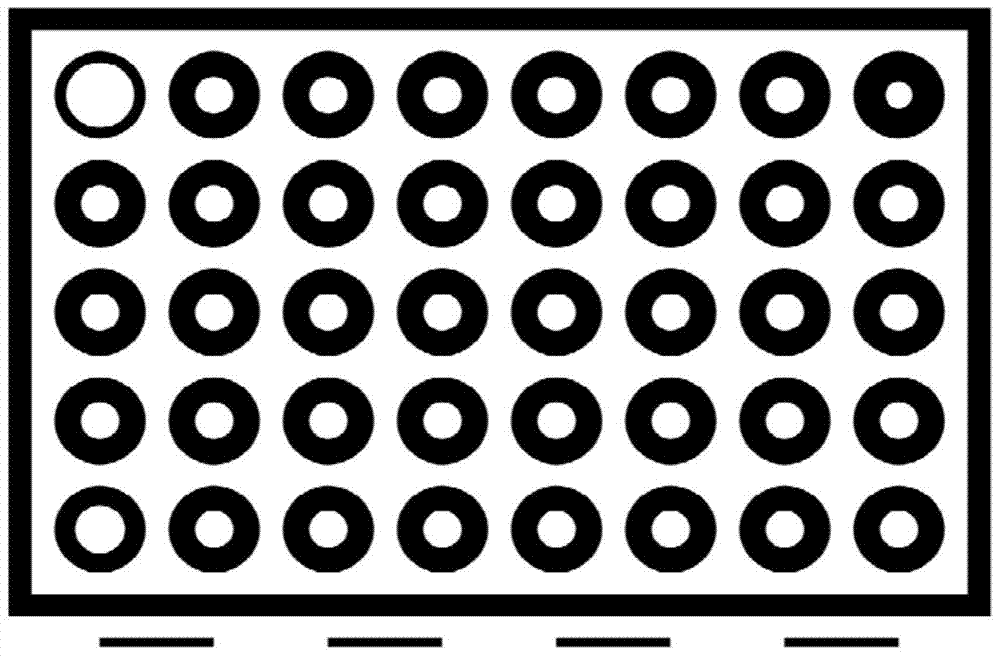

Non-checkerboard-pattern calibration plate for calibrating white light scanner

InactiveCN109186631AReduce in quantityImprove image qualityMeasurement devicesPosition circleCheckerboard pattern

The invention discloses a non-checkerboard-pattern calibration plate for a calibrating white light scanner. The non-checkerboard-pattern calibration plate comprises a backboard and a calibration plate, wherein a cavity with an opening is formed in the center of the backboard, a light-emitting plate is fixedly arranged in the cavity, the calibration plate is fixedly arranged at the opening of the cavity, marker circles with the same size are arranged on the surface of the calibration plate in an rectangular array manner, positioning circles are arranged in the marker circles, central circles are arranged in the centers of the positioning circles, and at least one auxiliary circle is arranged beside the central circles. According to the non-checkerboard-pattern calibration plate, positioningcircles are arranged in the rectangular-arrayed marker circles, and each positioning circle has unique parameter information, so that the calibration of the position is conveniently finished; the calibration plate is produced from a light-transmission material, and the marker circles are produced from a light-shading coating, so that a high-contrast calibration plate is formed, and errors are reduced; the positioning circles are few; and by aligning the scanner with any one positioning circle, coordinate information can be calculated, and the corresponding position calibration can be finished, so that the calibration plate has relatively strong operability and is relatively convenient.

Owner:宣城镐渭工业技术有限公司

Motor end cover sealing device capable of preventing dust and sand from entering interior of motor

The invention relates to a motor end cover sealing device capable of preventing dust and sand from entering the interior of a motor. A plane and a positioning circle step are machined at the inner side of a motor end cover at the motor shaft extension end of the motor; a rubber oil seal seat is arranged on the positioning circle step; the rubber oil seal seat comprising a seat body and a cover plate is fixed on the motor end cover through bolts; a rubber oil seal is arranged in the rubber oil seal seat; a lip of the rubber oil seal faces to the motor end cover; the inner ring of the rubber oil seal closely clings to a motor shaft; and a tension spring ring is arranged in the groove lip of the rubber oil seal. The motor end cover sealing device can prevent dust and sand from entering the interior of the motor through a shaft hole gap of the motor end cover to damage a bearing part and burn out the motor and can also prolong the service life of the motor. The motor provided with the motor end cover sealing device is particularly suitable for occasions with more sand dust and dust.

Owner:KEHUA HLDG

Intelligent counter product label structure and identification system

PendingCN109243061AEasy to identifyEasy to classifyCoin-freed apparatus detailsCash registersPosition circleComputer module

The invention discloses an intelligent counter product label structure and an identification system. The intelligent counter product label structure comprises a counter body and an input generation module which is connected with the counter body through a wireless network signal; an interior of the counter body is provided with a product and a scanning identification module; a surface of the product is provided with a label subassembly; the label subassembly includes an identification outer frame and an identification positioning circle disposed at an interior of the identification outer frame; the input generation module includes a cloud information string input module, a storage module and a checking module which are respectively connected with the cloud information string input module,and an information mapping module and a label generation module which are sequentially connected with the checking module; and the scanning identification module includes a mark positioning module, and a label correction module, a distance measurement module and an integrated scanning module which are sequentially connected with the mark positioning module. With the intelligent counter product label structure and the identification system, the problems in the prior art that an implementation cost of the intelligent vending counter identification mode is high and the information is unsafe due to the fact that the information is easily read by universal identification software are solved.

Owner:深圳市小村机器人智能科技有限公司

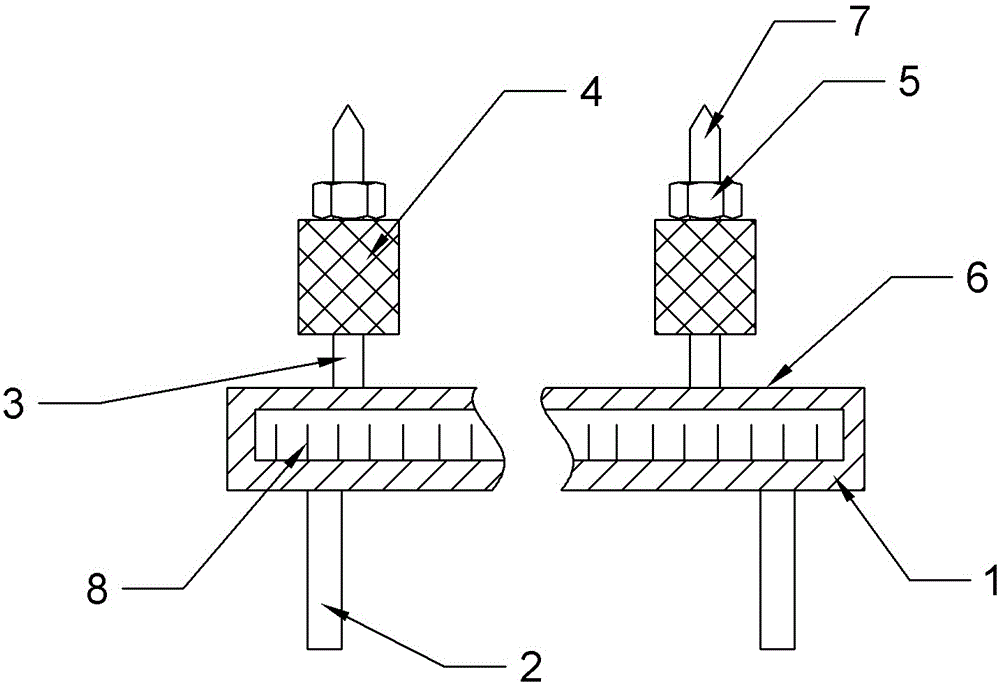

Automobile rear cantilever mounting hole distance detection measurement tool

The invention relates to the field of automobile detection, and particularly relates to an automobile rear cantilever mounting hole distance detection measurement tool, which comprises a measurement tool body. The overall measurement tool body is rectangular; a fixing rod and a sliding rod in sliding connection are arranged on the measurement tool body; top parts of the fixing rod and the sliding rod are conical; the fixing rod and the sliding rod are circumferentially sleeved with an elastic layer with a uniform thickness; the fixing rod and the sliding rod press the elastic layer via nuts; the side surface of the measurement tool body is provided with a scale reticle plate; and the starting point of the scale reticle plate is located at the place wherein a top rod at one side is connected with the measurement tool body. Through precisely positioning circle centers of two holes, the distance between the two hole centers is detected, and the mounting hole of the automobile rear cantilever and the corresponding mounting hole of a frame can be ensured to be fully coincident.

Owner:CHONGQING ZETIAN AUTO PARTS

Electroplating fixture

The invention provides an electroplating fixture, which has a clamping component that can elastically clamp and position a round conducting wire. The clamping assembly can shield the non-selective area of the clamped round conductive wire and expose the selective area of the clamped round conductive wire to contact with the electroplating solution, and can only treat the round conductive wire during the electroplating process. Electroplating is carried out on selective areas, so as to reduce the waste of electroplating materials in the electroplating solution, and can be used to reduce the waste of gold in the process of making conductive terminals of twisted pair connectors. In addition, it also has a jig shroud to slow down the flow rate of the plating solution inside the electroplating jig.

Owner:DONGGUAN SIWEB CONNECTORS

Linkage conductive system device

PendingCN107978467ARapid responseReasonable structureContact driving mechanismsContacts enclosures/screensPosition circleEngineering

The invention discloses a linkage conductive system device. The linkage conductive system device comprises a fixed contact and a moving contact, wherein the moving contact is mounted opposite to the static contact; one end of the moving contact is provided with a moveable arc-isolating piece, and the other end of the moving contact is provided with a conductive flexible connector, and one end of the conductive flexible connector is provided with a connecting plate; the moving contact is assembled on a rotating shaft, and the rotating shaft is provided with a rotating shaft positioning circle;the rotating shaft is provided with a connecting rod, and the connecting rod and the rotating shaft are fixedly connected with each other through a connecting rod shaft; one end of the connecting rodis provided with a connecting rod lower shaft, and one end of the connecting rod lower shaft is equipped with a baffle; and one side of the baffle is provided with a permanent magnet device body. According to the linkage conductive system device provided by the invention, when the permanent magnet device body is electrified instantly to work, the baffle moves to the closed limit and drives the connecting rod, so as to pull the rotating shaft to move around the rotating shaft positioning circle; the moving contact and the fixed contact are conducted and electrified, and otherwise, the moving contact and the fixed contact are disconnected and not electrified; and besides, the reaction is fast, the structure is reasonable and the stability is good.

Owner:上图电气有限公司

Quick change device shared by multiple stations

InactiveCN107498482APrecise positioningPositioning circular to achieve precise positioningWork holdersPosition circleEngineering

The invention discloses a quick change device shared by multiple stations. The device is characterized in that an external thread is arranged on the outer side of a lead crew; an internal thread is arranged on the inner side of a screw sleeve; the external thread of the lead screw is matched with the internal thread of the screw sleeve; a step is arranged at the lower part of the screw sleeve; the lower part of the screw sleeve penetrates through a round hole in a base plate; the screw sleeve is in plug-in connection with the round hole in the base plate; the upper end of the lead screw is connected with a handle; a left transfer block and a right transfer block are respectively fixed at the upper parts of the left and right ends of the base plate; a rhombic pin is fixed at the front part of the left transfer block; a positioning circle is fixed at the front part of the right transfer block; a connecting base is an L-shaped structure; the connecting base consists of a vertical molded plate and a horizontal molded plate; and a gap is formed between the connecting places between the vertical molded plate and the horizontal molded plate. The device has the advantages of convenience in use and high adaptability, and can effectively improve the production efficiency of vehicle part production enterprises.

Owner:WUHU CHANGRUI AUTO PARTS

Control system and control method of circular stone sawing machine

InactiveCN105058591BQuality improvementHigh degree of automationWorking accessoriesStone-like material working toolsPosition circleAutomatic control

The invention relates to a control system and method for a disc stone sawing machine. The control system comprises four portions of a power unit, an electrical control unit, a detection unit and a man-machine interaction part. Manual and automatic control modes are provided, the position of a first cutting disc saw can be determined according to the first cutting machining depth, stone size, the disc saw radius and the distance from the disc saw initial position circle center to a trolley, and accordingly the first cutting machining accuracy is guaranteed. By means of a left and right traveling mechanism, left and right traveling switching can be achieved through a stroke counting function, so that machining can be performed according to the actual stone width, and the problem of the idle running time process caused by switching of limit switches in the traditional method is solved; by means of the system, optimal matching of machining depth with machining speed is achieved, the main motor optimal operation efficiency is guaranteed, the system work efficiency is improved, and the energy-saving purpose of the system is reached; besides, the system safety and reliability are guaranteed.

Owner:BOHAI UNIV

A calibration template, template detection method, device and terminal

The present application discloses a calibration template, a template detection method, a device and a terminal. The calibration template includes at least one calibration circle group and at least three positioning circle groups, the centers of the at least three positioning circle groups are not located on the same straight line, each calibration circle group includes at least two calibration circles with the same center, and the same calibration circle At least two calibration circles in the group form a ring, and the color of the ring is different from that of the adjacent area; each positioning circle group includes at least two positioning circles with the same center, and at least two positioning circles in the same positioning circle group form Ring, the color of the ring is different from the adjacent area; each positioning circle group includes the first feature circle and the second feature circle, the radius of the first feature circle is not equal to the radius of the positioning circle in the positioning circle group, the second The radii of the two characteristic circles are not equal to the radii of the calibration circles in each calibration circle group. The calibration template disclosed in the present application is not easily disturbed by the external environment, which improves the accuracy of template detection.

Owner:江苏亿川机电有限公司

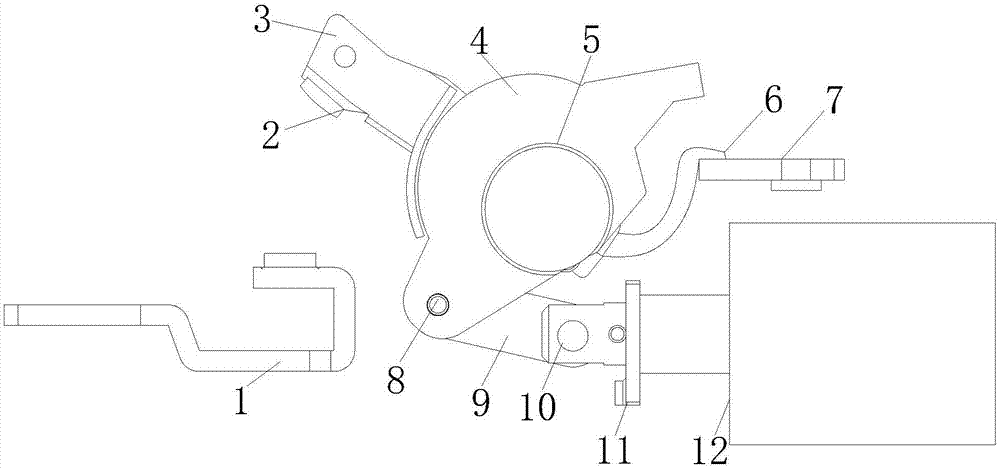

Automobile braking arm tool

InactiveCN108274044AImprove stabilityDrilling/boring measurement devicesDrill jigsPosition circleEngineering

The invention discloses an automobile braking arm tool. The automobile braking arm tool comprises a mold plate, a drill sleeve, a handle and a positioning block; the handle is arranged on the left ofthe mold plate, and the positioning block is arranged on the right of the mold plate; a positioning circle is arranged below the positioning block, and is provided with a positioning square block; andthe drill sleeve is arranged on the left side of the positioning square block. According to the automobile braking arm tool, according to the positioning block, positioning is performed through a first hole of a braking arm and a square groove and a pin penetrating hole is machined with the drill sleeve as the benchmark, the positions of the pin penetrating hole, the first hole and the square groove are made to meet the technical requirements, and stability is high.

Owner:凯瑞克(宁波)体育用品有限公司

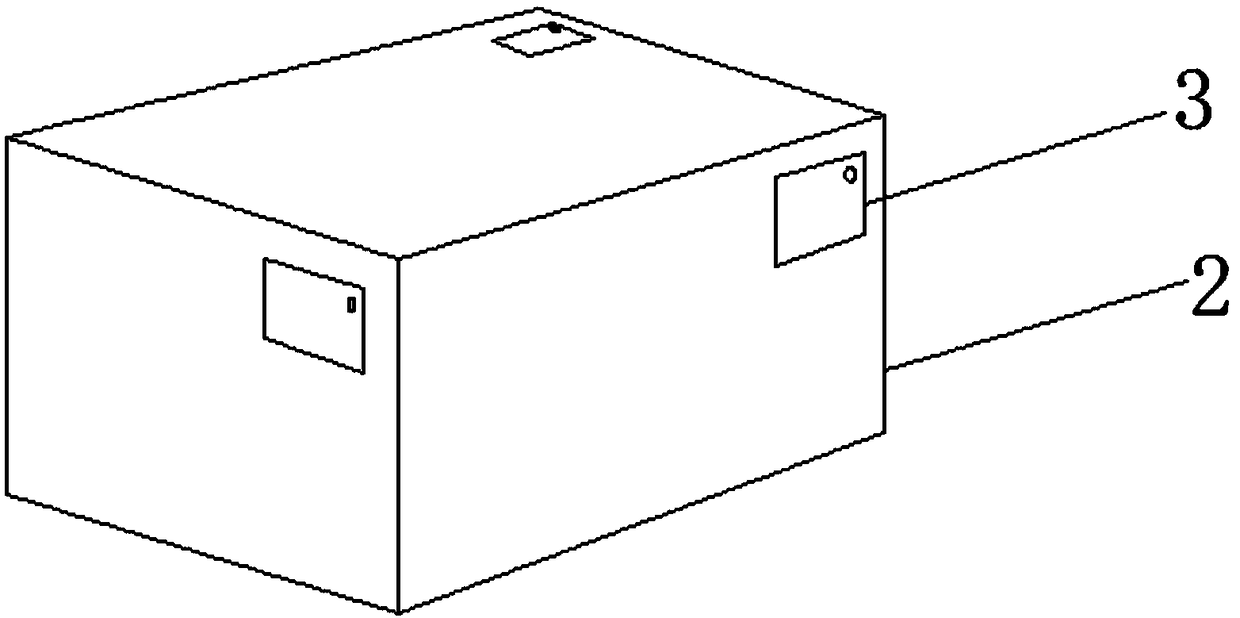

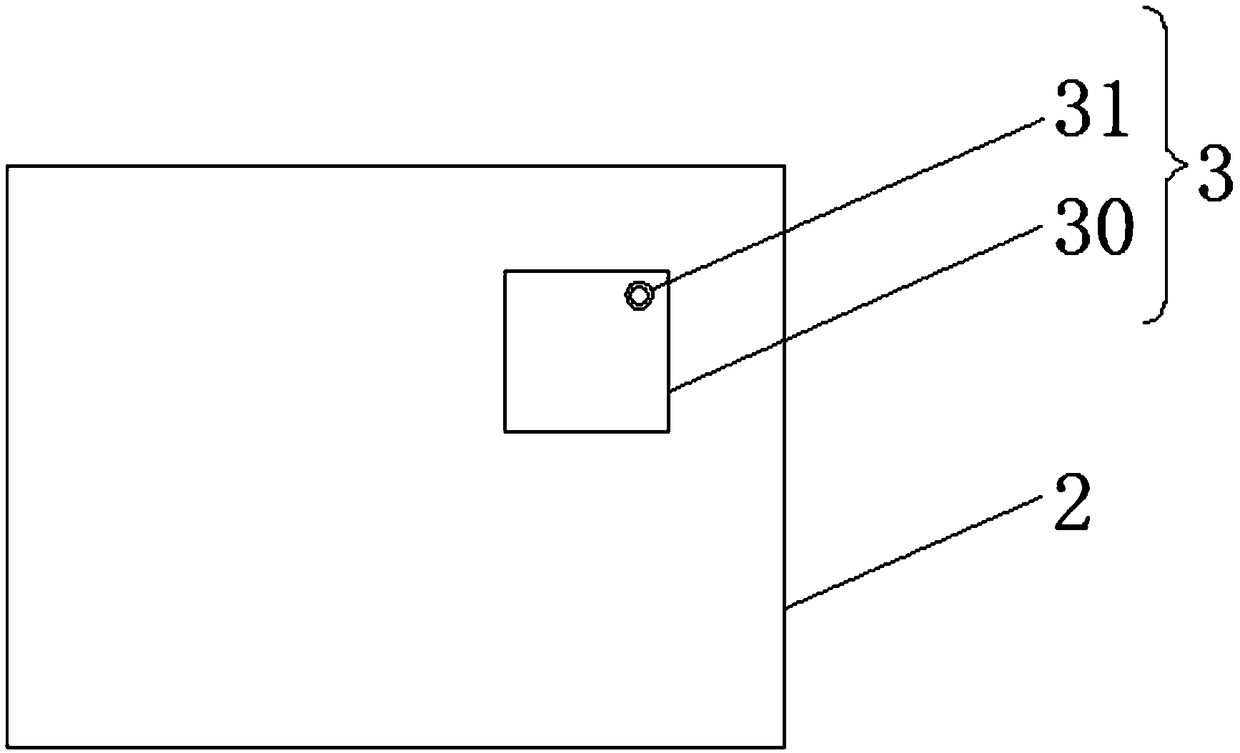

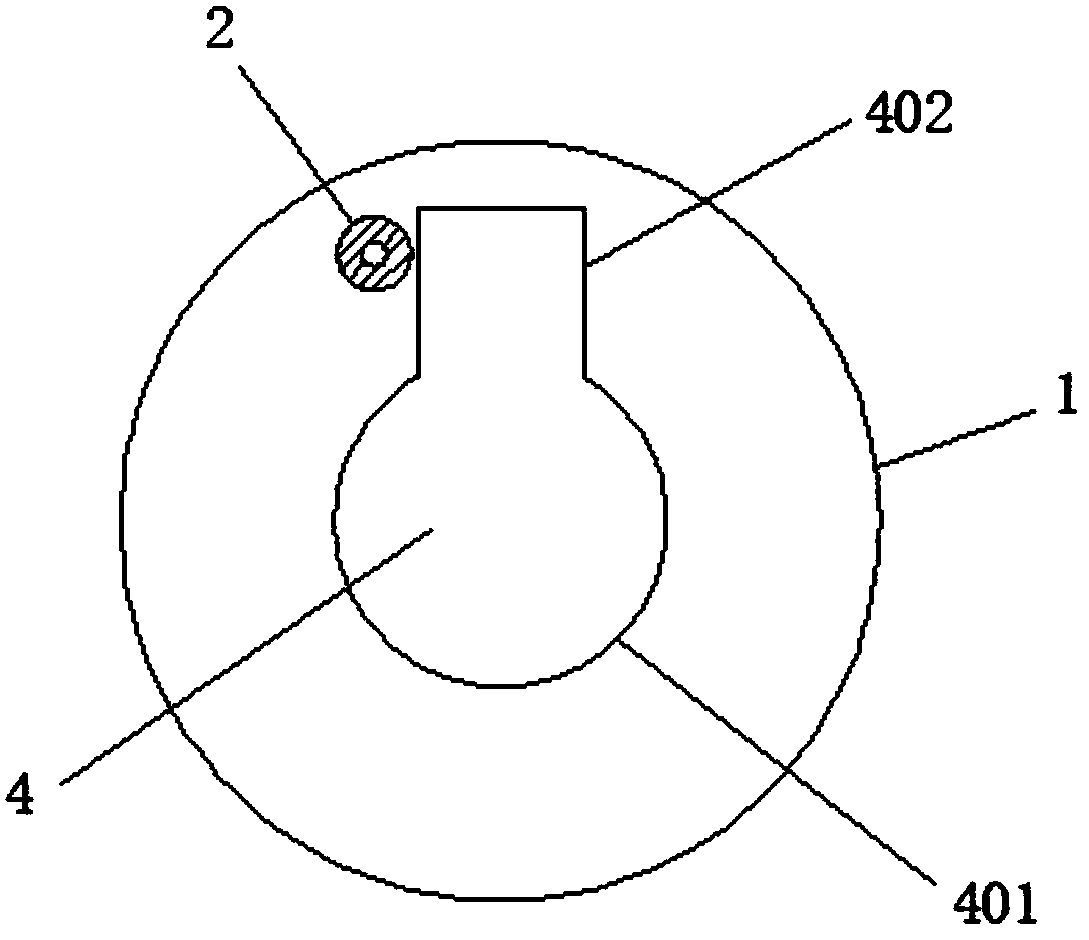

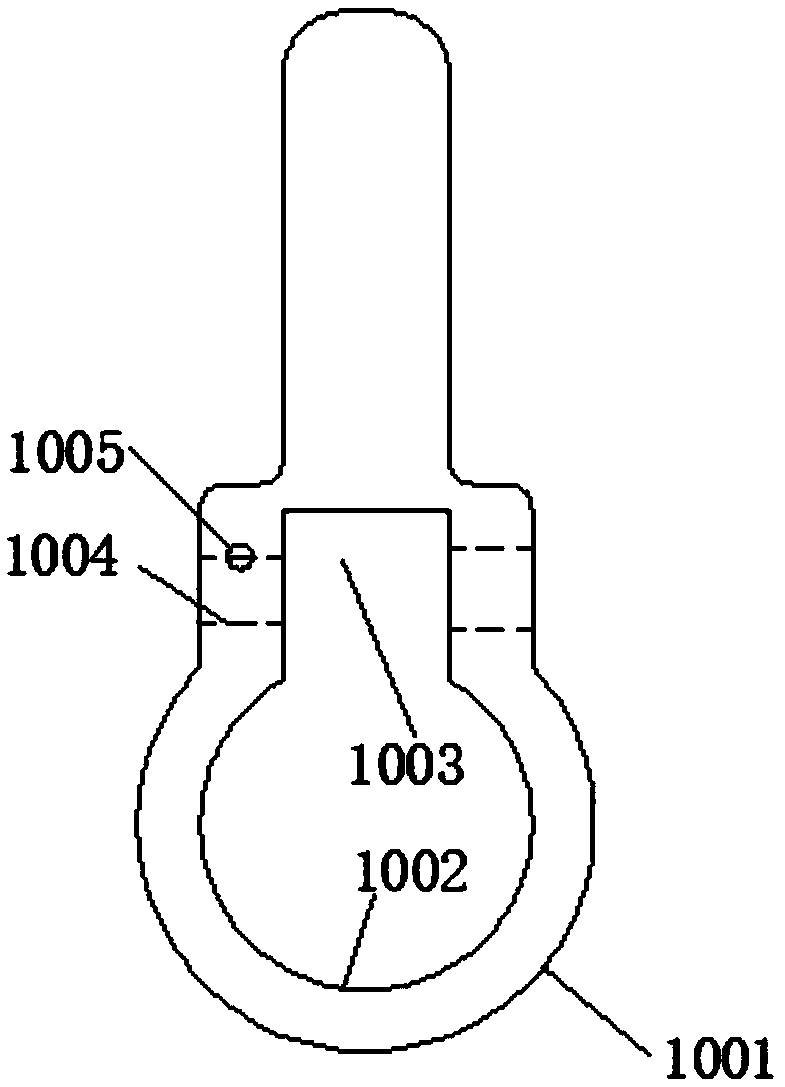

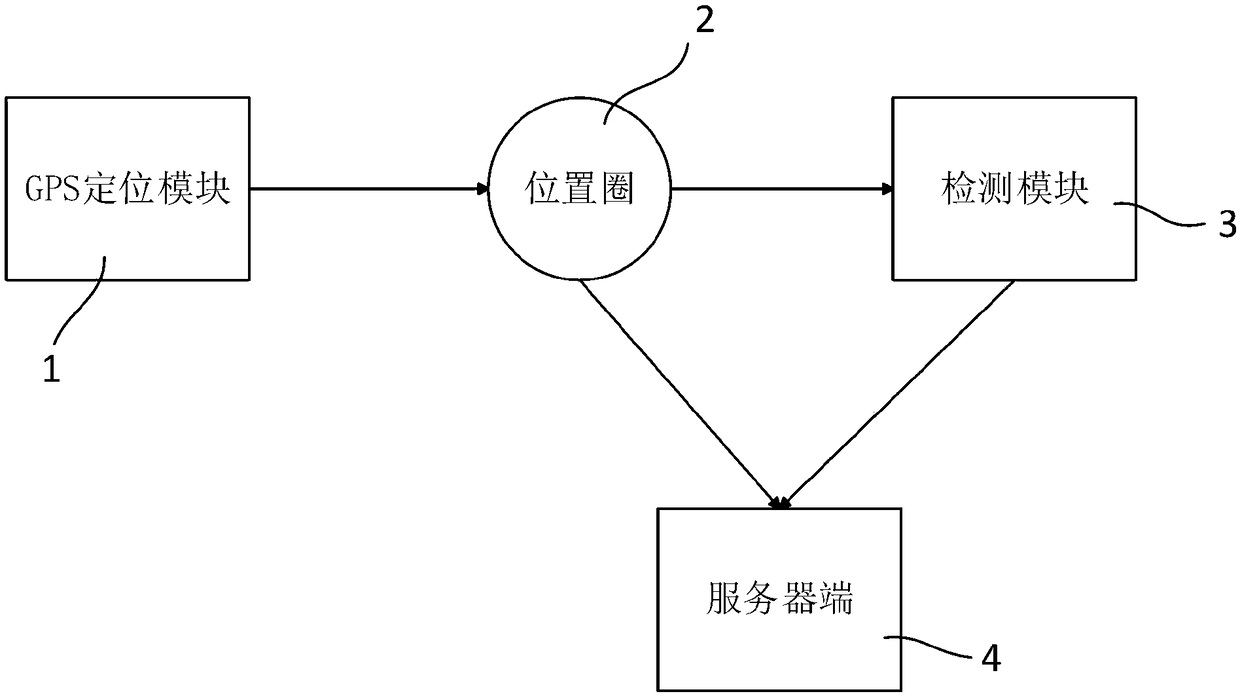

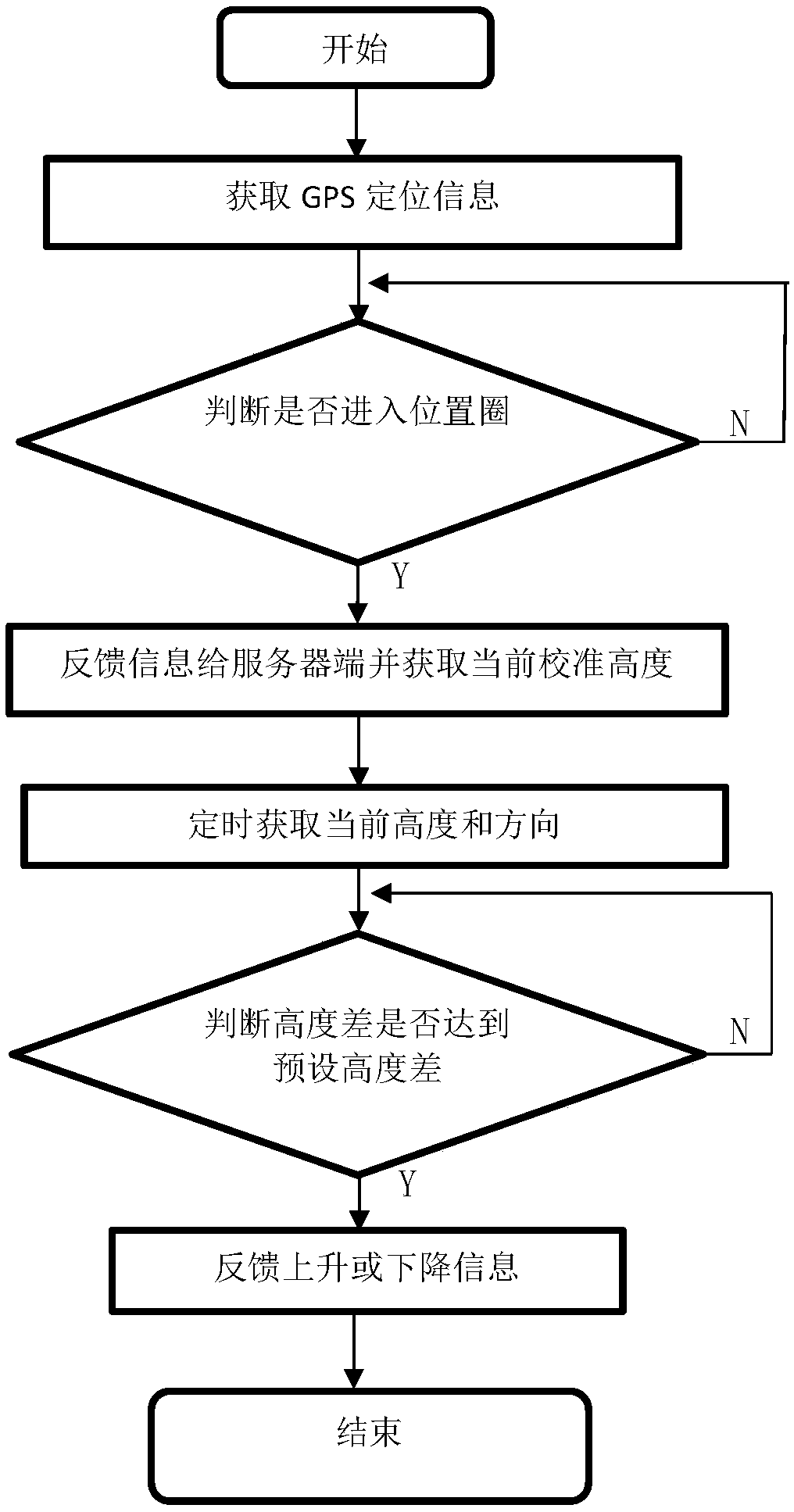

Container monitoring system

The invention provides a container monitoring system. A GPS positioning module determines the position of a container. When the container enters a position circle, the GPS positioning module feeds back information to a server side in time, a detecting module is started for starting to detect the ascending height or the descending height of the container and information of the ascending height or the descending height of the container is fed back to the server side. The monitoring system can remotely monitors the condition of the container in the transporting process and can monitor the unloading condition of the container at the fixed position, and monitoring of a logistics company for the container is facilitated. By setting the position circle, the ascending height or the descending height of the container is detected at the fixed point, and the phenomenon that in the transporting process, large errors of the detection height appear due to different air pressures at different placescan be avoided. Meanwhile, in the transporting process, the container height detection frequency becomes low, and electricity can be saved.

Owner:QUECLINK WIRELESS SOLUTIONS HF CO LTD

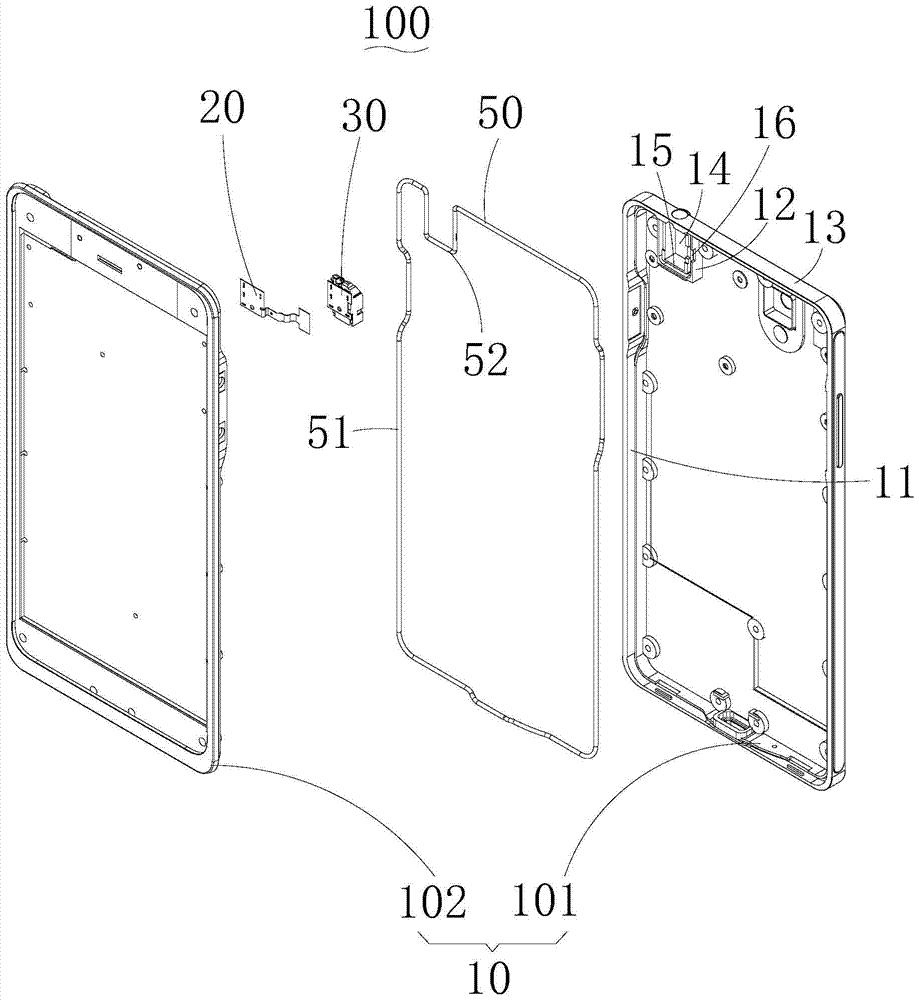

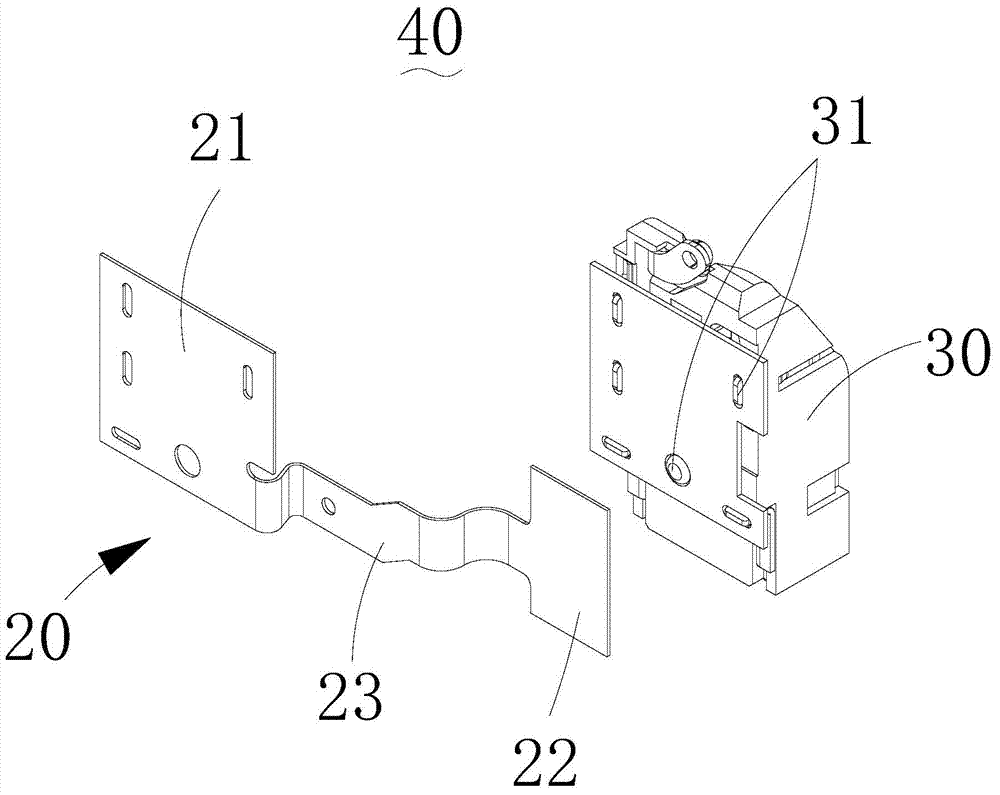

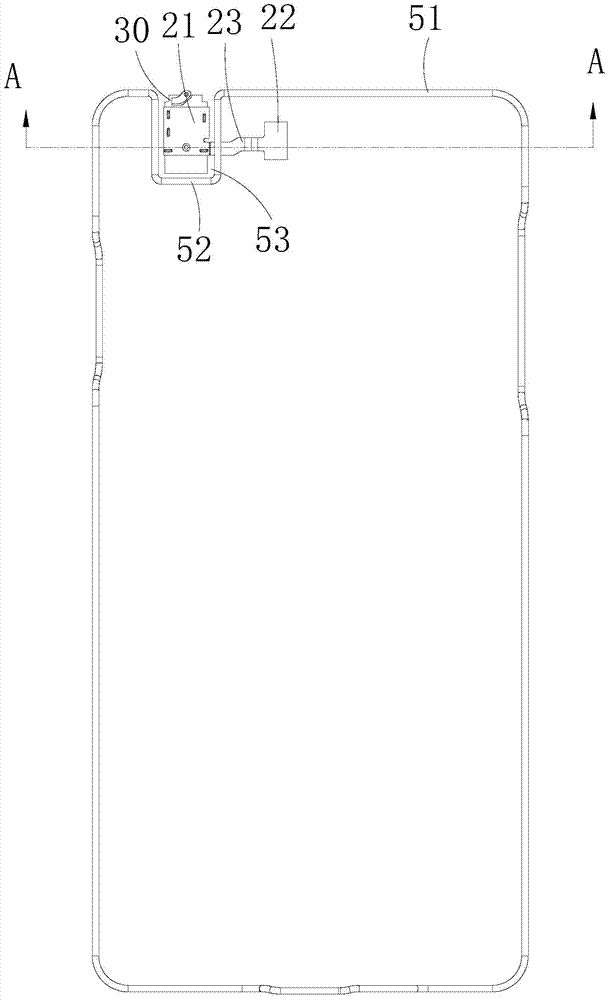

Electronic device with earphone holder and assembly method thereof

ActiveCN105006684BFirmly connectedWaterproofLine/current collector detailsCouplings bases/casesPosition circleFlexible circuits

The invention provides an electronic device with an earphone holder, which includes a housing, an earphone holder installed on the edge part of the housing, and a soft board located in the housing. The soft board includes a first board body, electrically connected to the main circuit board The connected second board and the transition board connecting the first and second boards, the headphone socket is surface-mounted on the first board of the soft board to jointly form the earphone socket assembly, which also includes in-mold injection molding on the earphone socket The sealing gasket on the component, the earphone holder and the first plate of the soft board are located outside the ring of the sealing gasket, the second board of the soft board is located in the circle of the sealing gasket, and the transition board of the soft board is fixed on the sealing gasket. The sealing gasket seals around the three side peripheries of the earphone holder and extends to the inner periphery of the housing. The present invention also provides an assembly method of the above-mentioned electronic device. The method of sealing around the earphone holder is used to waterproof the interior of the device. Not only is the product beautiful and easy to use, but the product can also be made very thin.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A New Spraying Machine with High Convenience for Automobiles

ActiveCN109013084BEasy to store and placeEasy to organizeLiquid spraying apparatusPosition circleAgricultural engineering

The invention discloses a high-convenience novel spraying machine for an automobile. The novel spraying machine comprises a machine body, wherein a storage frame is arranged on the machine body, a driving motor is arranged in the storage frame, and a first connecting bearing is coaxially arranged on an output shaft of the driving motor. A roller is arranged on the first connecting bearing, and anannular storage groove is formed in the roller. A connecting disc is coaxially fixed on the output shaft, and a connecting spring is fixedly arranged on the connecting disc. The position, close to theconnecting disc, of the output shaft is sleeved with a connecting sleeve, and the connecting sleeve is fixedly connected with the connecting spring. An electromagnet I is fixedly arranged in the connecting disc, and an electromagnet II is arranged on the outer circumferential surface of the roller. A limiting frame parallel to the output shaft is arranged on the storage frame, a limiting groove is formed in the limiting frame, and a pressing mechanism is arranged in the storage frame. A second connecting bearing is arranged in the storage frame, and a conical positioning cylinder is arrangedin the second connecting bearing. A positioning circle center hole is coaxially formed in the output shaft. The automatic winding of a water pipe can be realized by the spraying machine, and meanwhile, the water pipe can be firmly and compactly stored on the spraying machine.

Owner:江苏亚一智能装备有限公司

An Optimal Addressing Method Based on Two-color Inverse Nearest Neighbor Query

ActiveCN103778196BReduce overheadNarrow down the search spaceSpecial data processing applicationsPosition circleAlgorithm

The invention discloses an optical location method based on double-color reverse nearest neighbor query. The double-color reverse nearest neighbor query technology in a spatial database is used, the space quartering method and the Thiessen polygon are used in the optical location method, and it is guaranteed that query results have maximum reverse nearest neighbors so as to enable the minimum distances from the query results to the corresponding reverse nearest neighbors to be maximum. The optical location method includes the steps that firstly, nearest position circle domains of all client points are generated; secondly, the quartering method is used for finding out a rectangular region, and the rectangular region is made to fall in intersection sets of the nearest position circle domains as much as possible; thirdly, two effective pruning rules are used for pruning nearest position circle domain sets related to the rectangular region obtained in the former step; finally, an optical location point is find out according to the pruned nearest position circle domain sets and the Thiessen polygon. According to the optical location method, the searching space for query is greatly reduced, the query efficiency is obvious better than that of an existing method, and the optimal performance is provided.

Owner:ZHEJIANG UNIV

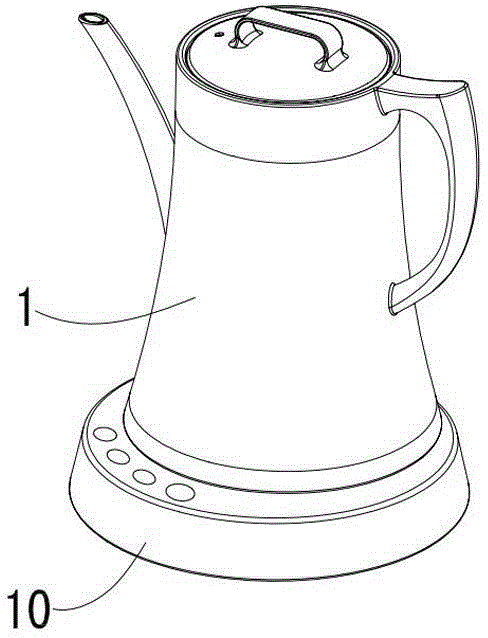

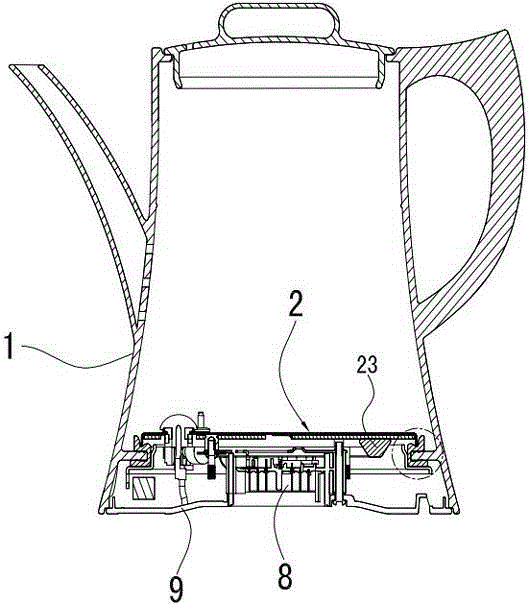

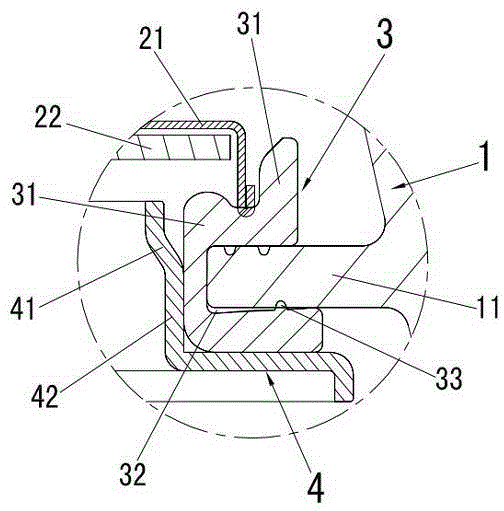

Heating disc positioning structure of kettle and manufacture method thereof

InactiveCN105476475AFull healthGive full play to textureWater-boiling vesselsWarming devicesPosition circleEngineering

The invention provides a heating disc positioning structure of a kettle, characterized by comprising a non-hardware kettle body, a heating disc assembly, a positioning ring or positioning sheet, a seal ring and nuts. The inner side of the lower portion of the non-hardware kettle body is provided with a positioning circle integrated to the non-hardware kettle body. The heating disc assembly is provided with a hardware bottom plate and positioning posts fixed to the hardware bottom plate. The hardware bottom plate and the positioning ring or the positioning sheet are located above and below the positioning circle, respectively. The hardware bottom plate and the positioning ring or the positioning sheet are connected together through the positioning posts and the nuts. The seal ring is located between the positioning circle and the hardware bottom plate or the positioning ring or the positioning sheet. The invention also provides a manufacture method for manufacturing the heating disc positioning structure of the kettle. The heating disc positioning structure of the kettle and the manufacture method thereof provide a solution to the technical problem that the non-hardware kettle body (particularly a kettle body of bone china) of the kettle and a heating disc assembly are difficult to seal and are unstably connected.

Owner:TOP ELECTRICAL APPLIANCES IND

Spark plug paper sleeve forming machine with video surveillance camera

ActiveCN105291488BAvoid hearing damageImprove processing efficiencyPaper/cardboard articlesVideo monitoringPosition circle

The invention discloses a spark plug paper cover molding machine with a video monitoring camera, which includes a frame, a feeding mechanism, an edge glue coating mechanism, a circle holding edge drying mechanism and a video monitoring camera; the feeding mechanism includes a feeding rail The plate and the feeding rail plate slide to drive the cylinder. The edge glue coating mechanism is arranged on the glued substrate above the feeding rail plate. The pressing plate, the clamping top plate, and the two circle-holding force assemblies arranged on the left and right sides of the circle-holding mold, the support plate is provided with a feeding hole, and the feeding hole is connected to the discharge end of the feeding mechanism. A hot air chamber is arranged inside the clamped top plate, and a plurality of hot air holes communicating with the hot air chamber are arranged on the top plate of the clamped top plate, and a hot air blower connected with the pipeline of the hot air chamber is also arranged on the support plate. The invention has the advantages of reasonable structural design, high processing efficiency and good product molding consistency.

Owner:TIANJIN JINHANG COMP TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com