Control system and control method of circular stone sawing machine

A technology of control system and circular saw, applied in the direction of manufacturing tools, stone processing tools, stone processing equipment, etc., can solve the problem of low degree of automation of the controller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with specific embodiment, the present invention is described in detail:

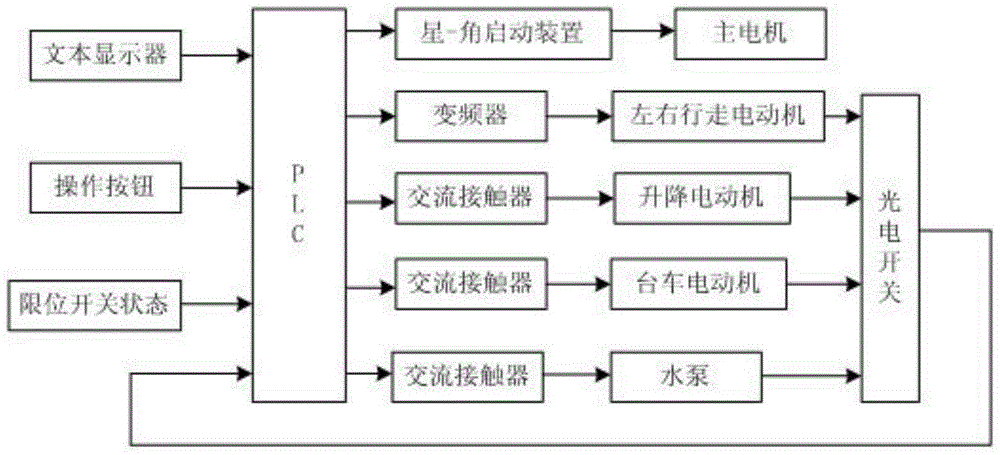

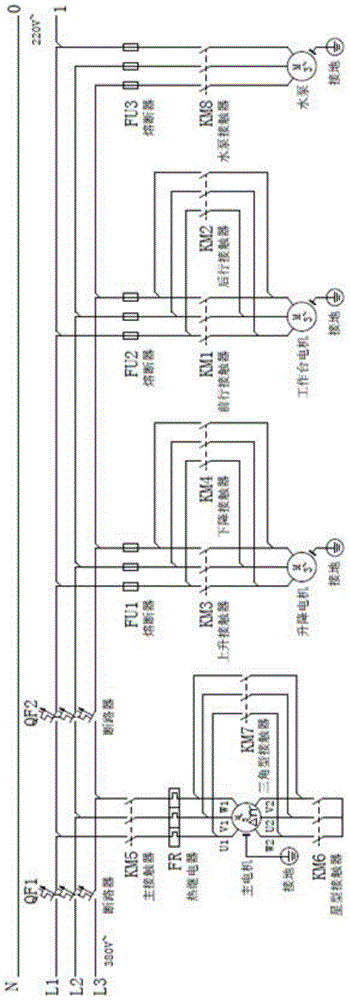

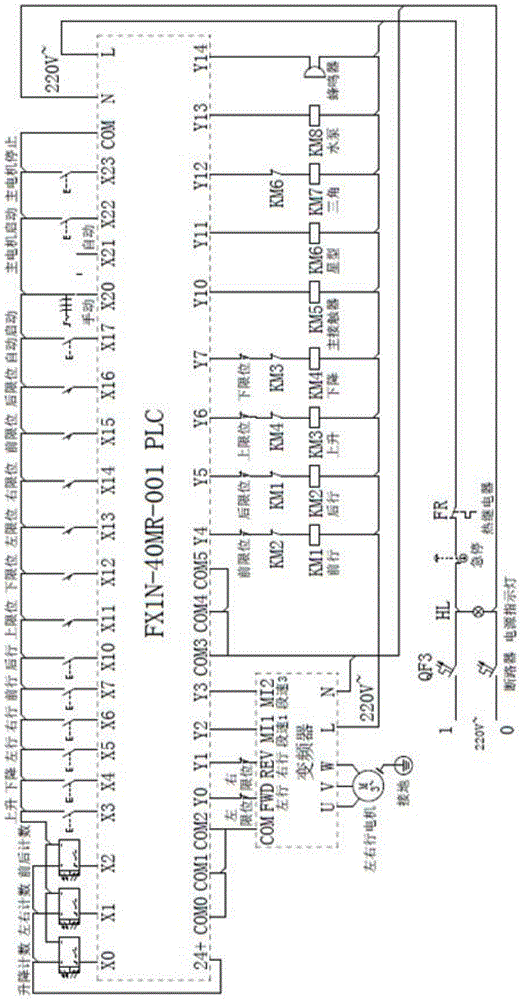

[0030] Such as figure 1 As shown, the control system of the circular stone sawing machine is composed of four parts: the power device, the electrical control device, the detection device and the human-computer interaction. The power device includes main motor, left and right travel motor, lifting motor, trolley motor, water pump; electrical control device includes AC contactor, frequency converter and PLC, of which the frequency converter adopts Kerun 1.5kW, and the PLC adopts Mitsubishi FX1N-40MR-001; The detection device includes a limit switch and a photoelectric switch; the human-computer interaction includes a text display and operation buttons, and the text display uses Haiwell TP300. The main motor is responsible for driving the cutterhead to rotate, and the left and right travel motor is responsible for driving the cutterhead to move left and right to achieve horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com