Patents

Literature

30results about How to "Avoid idle time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

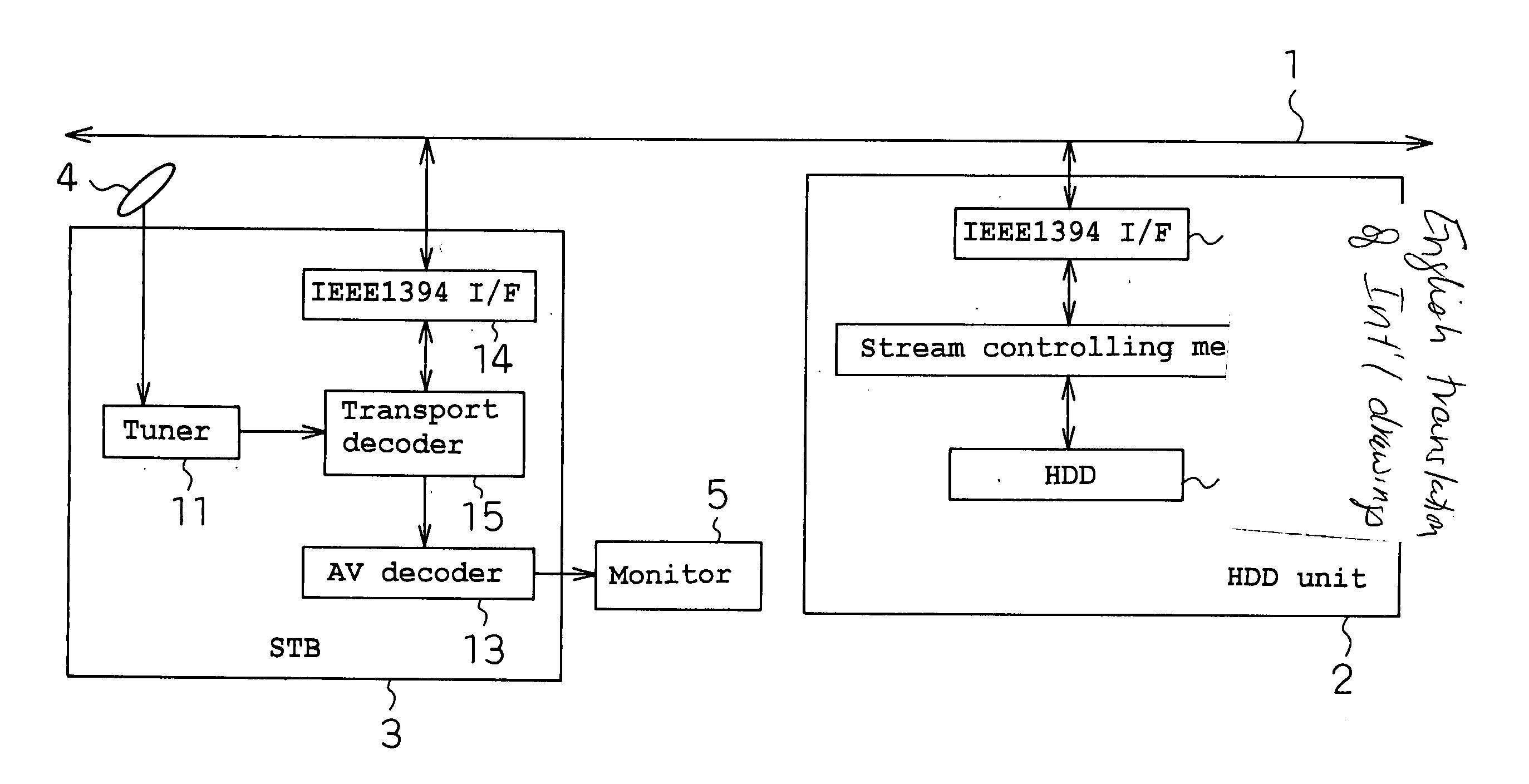

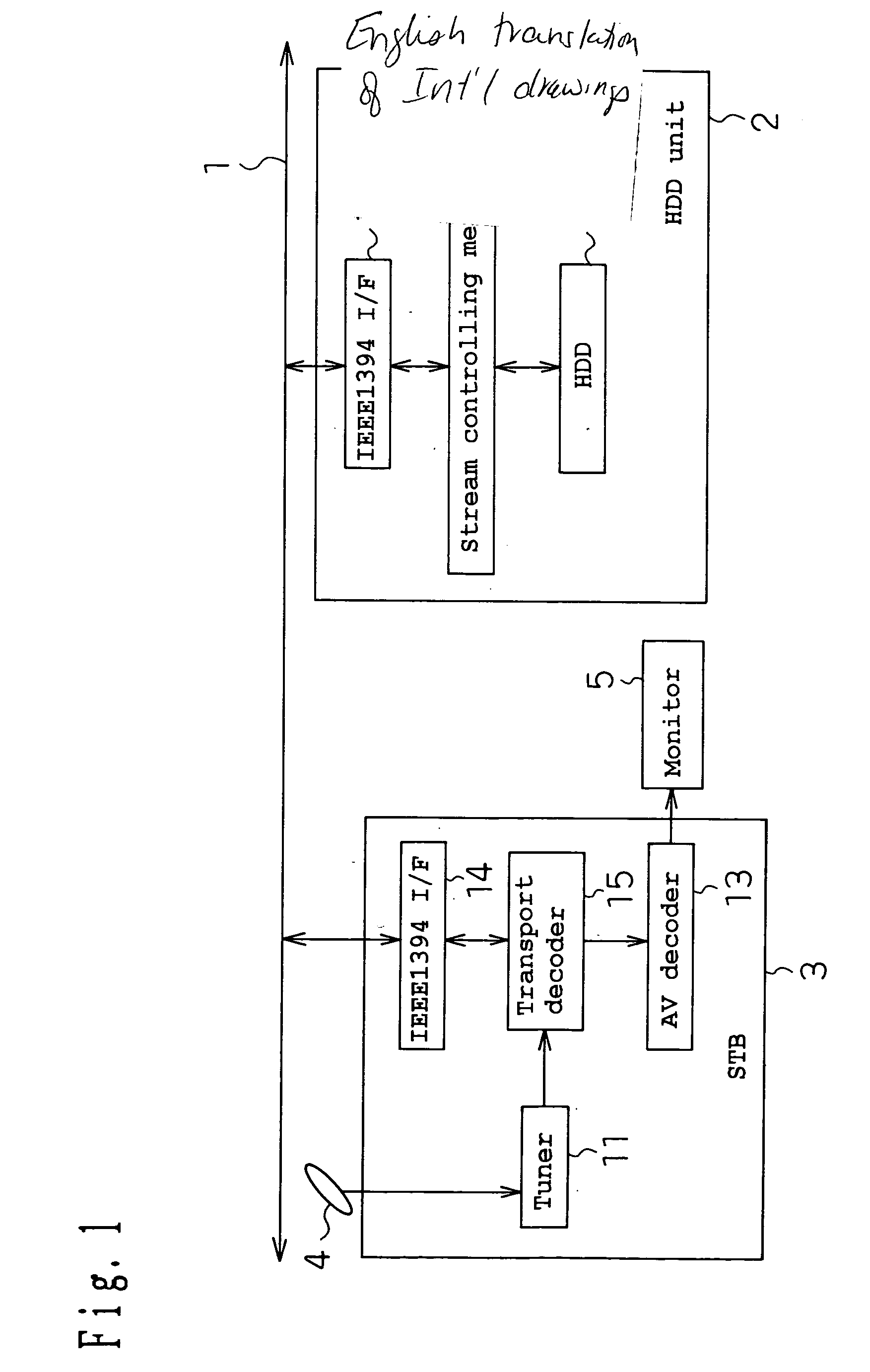

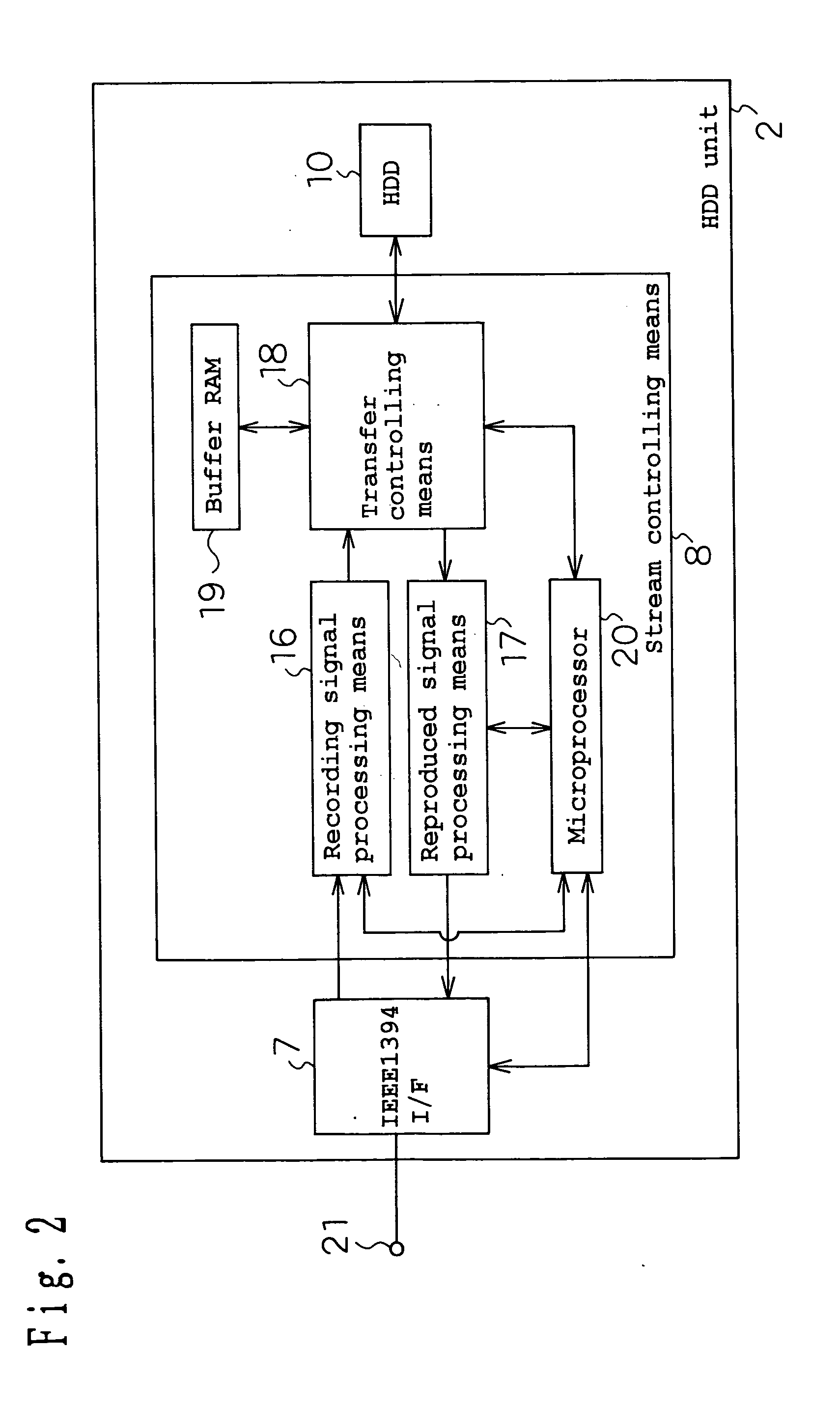

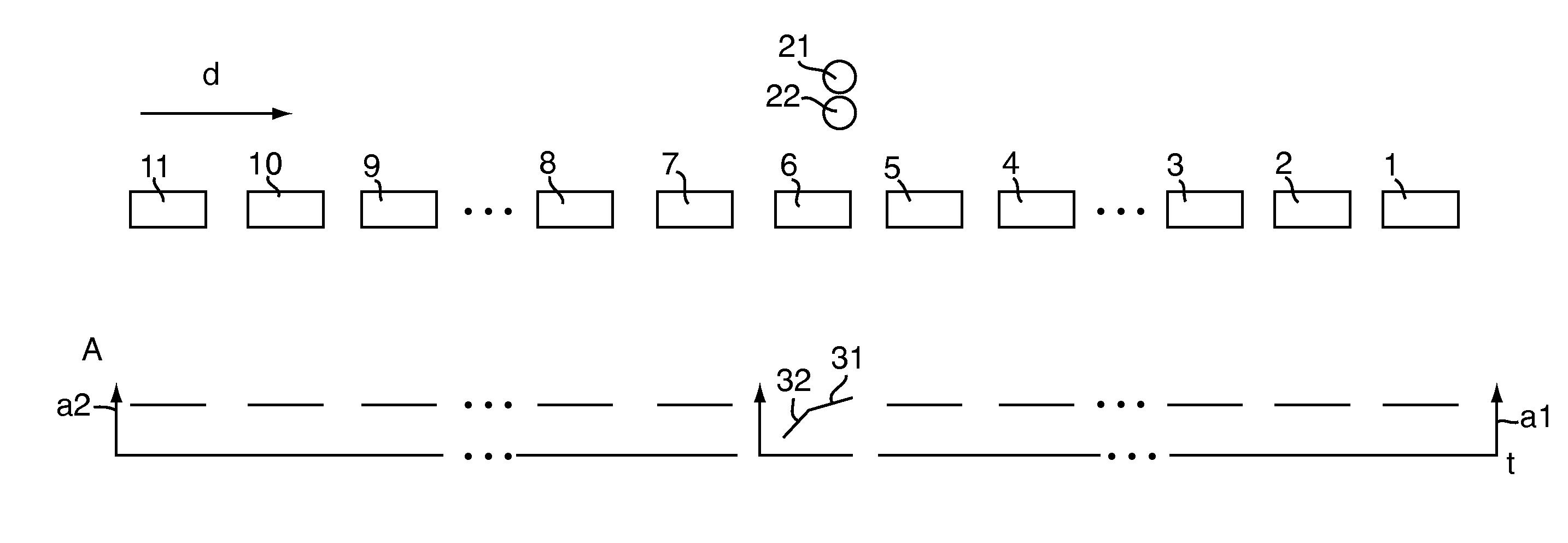

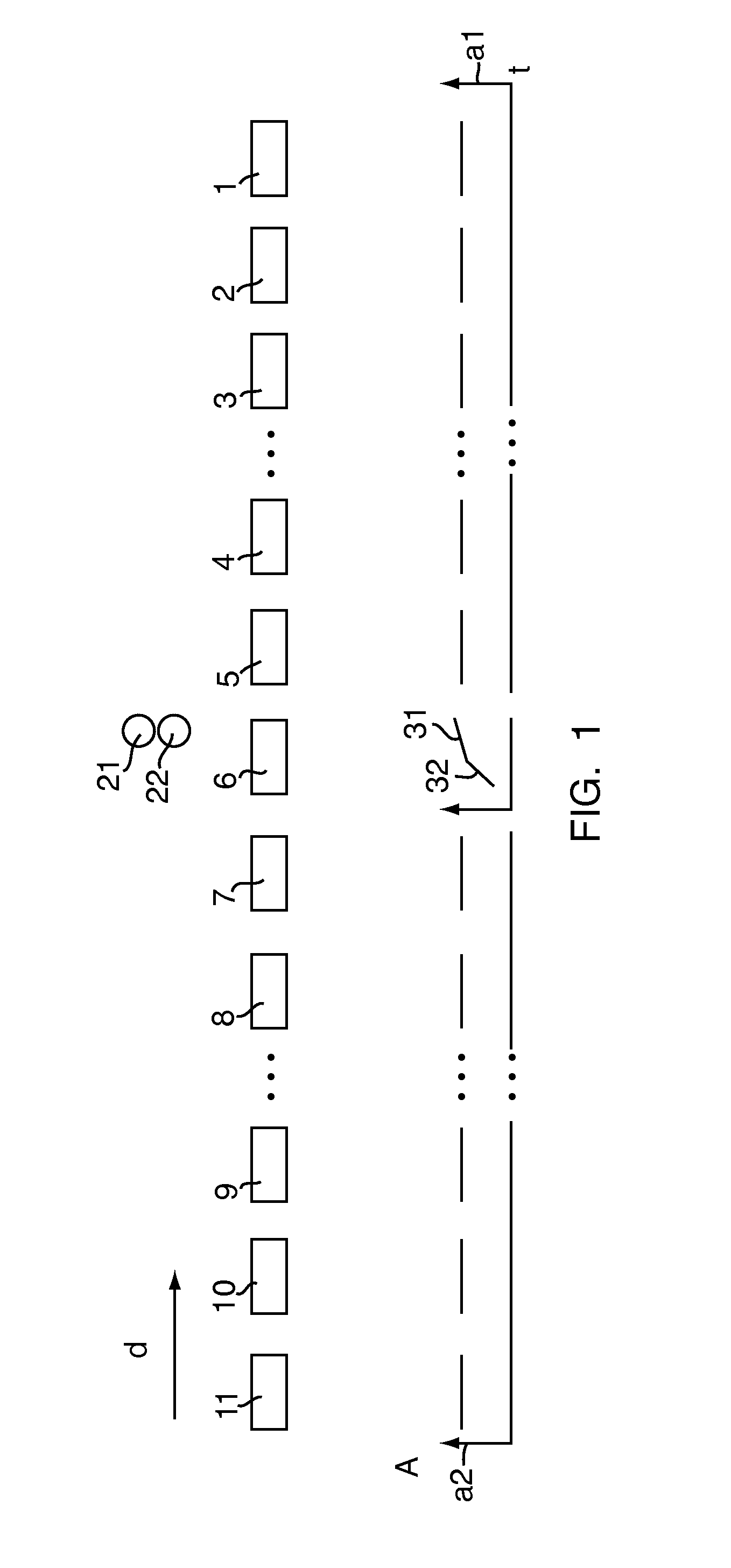

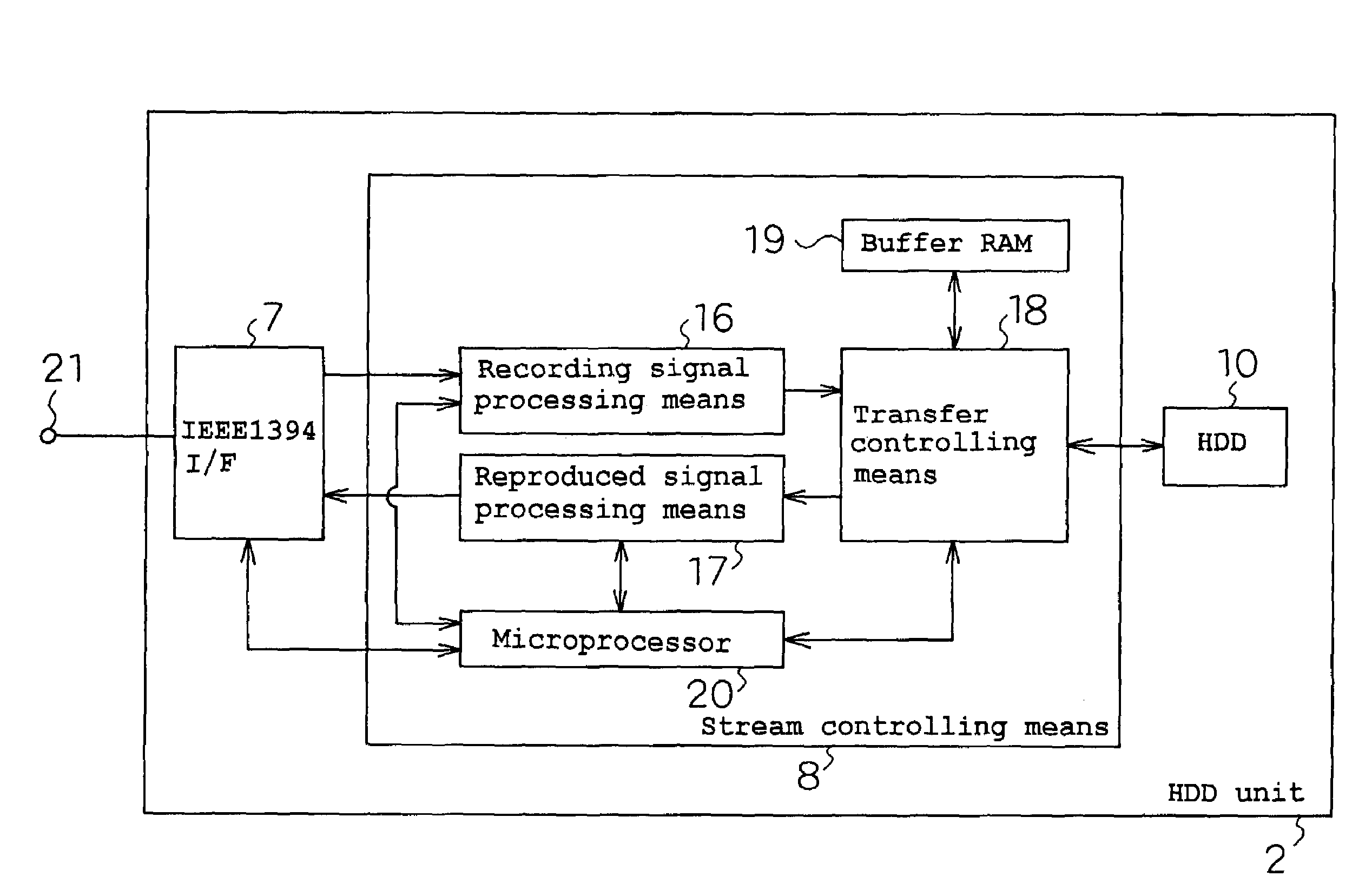

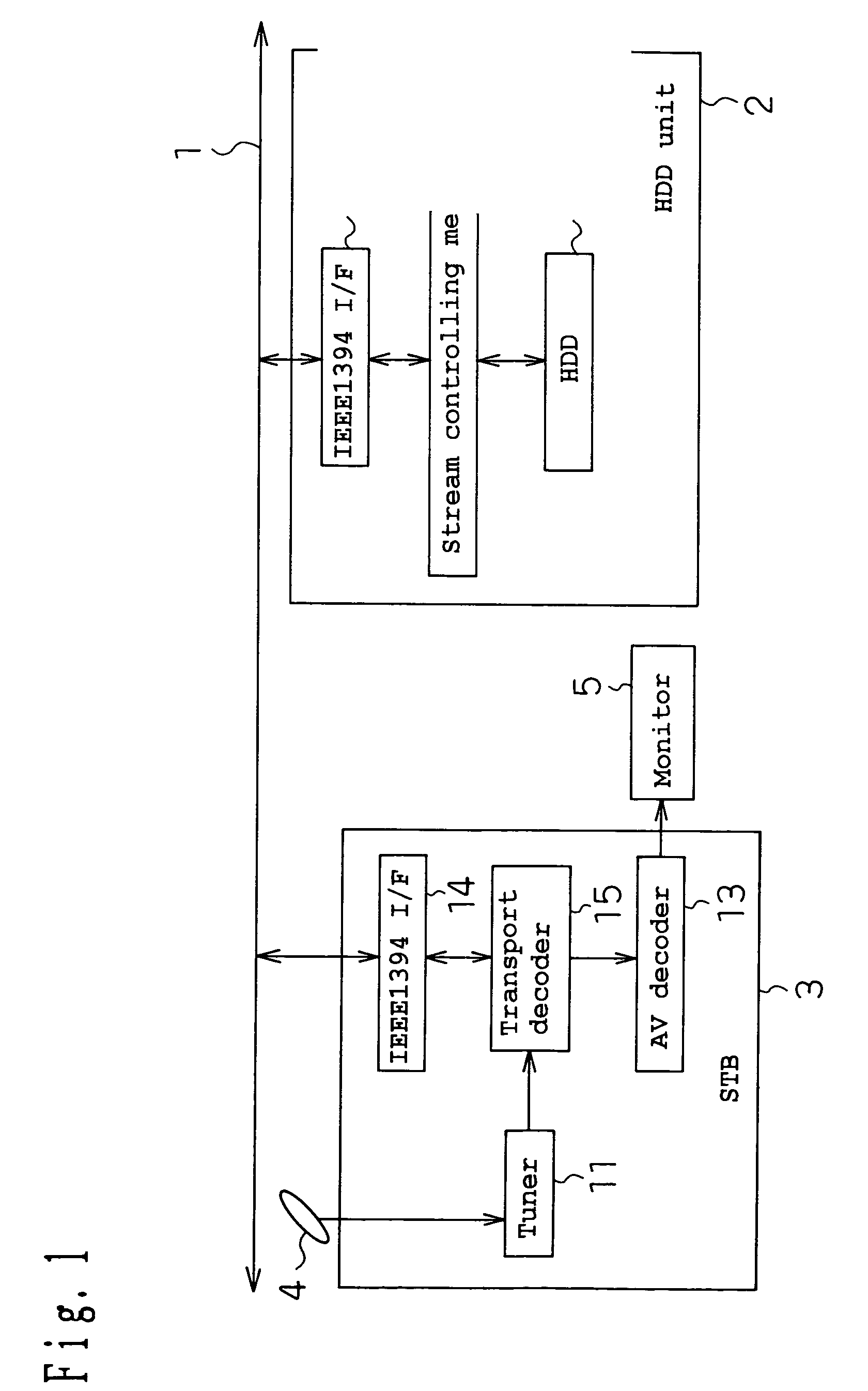

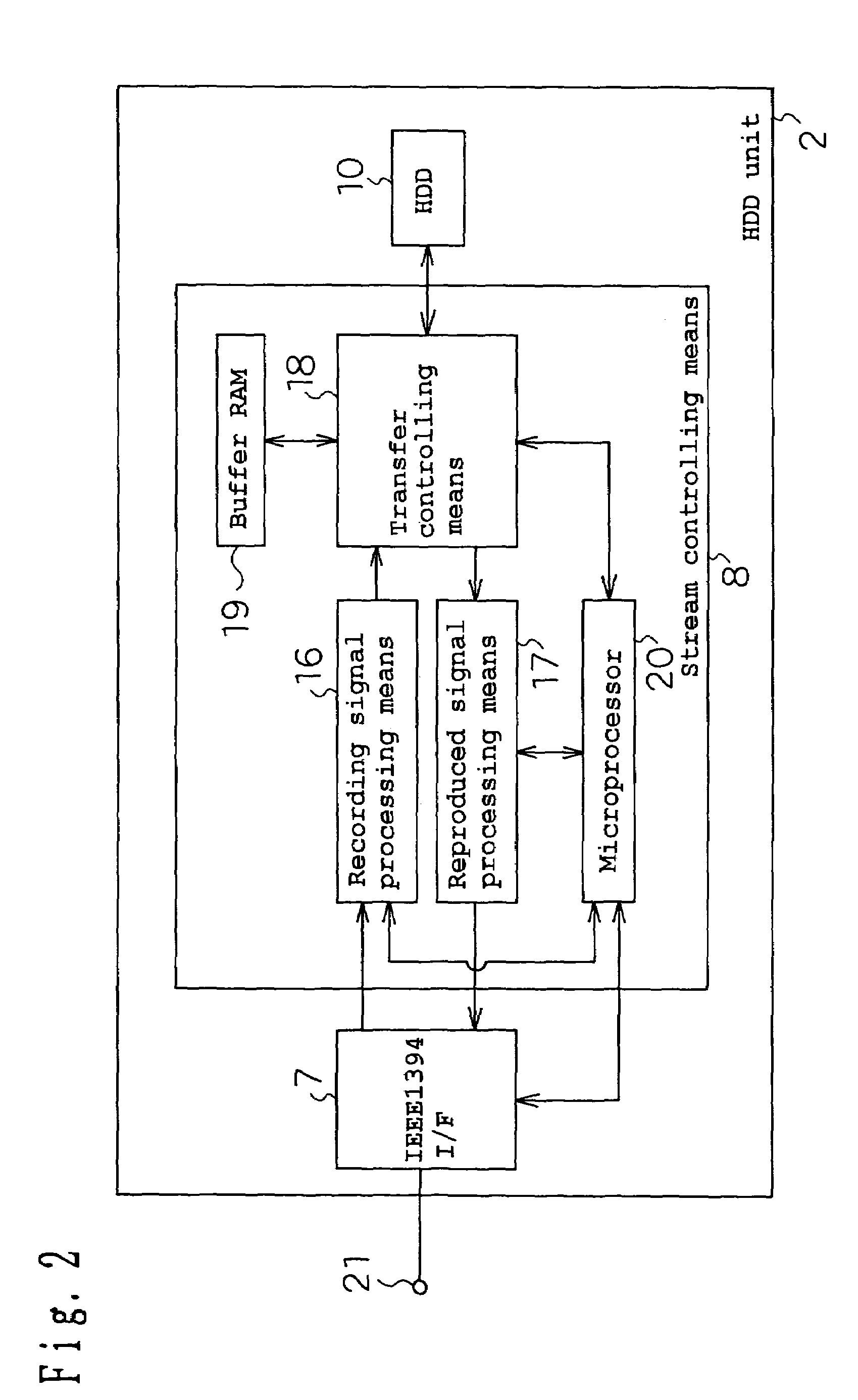

Hard disk apparatus, medium, and collection of information

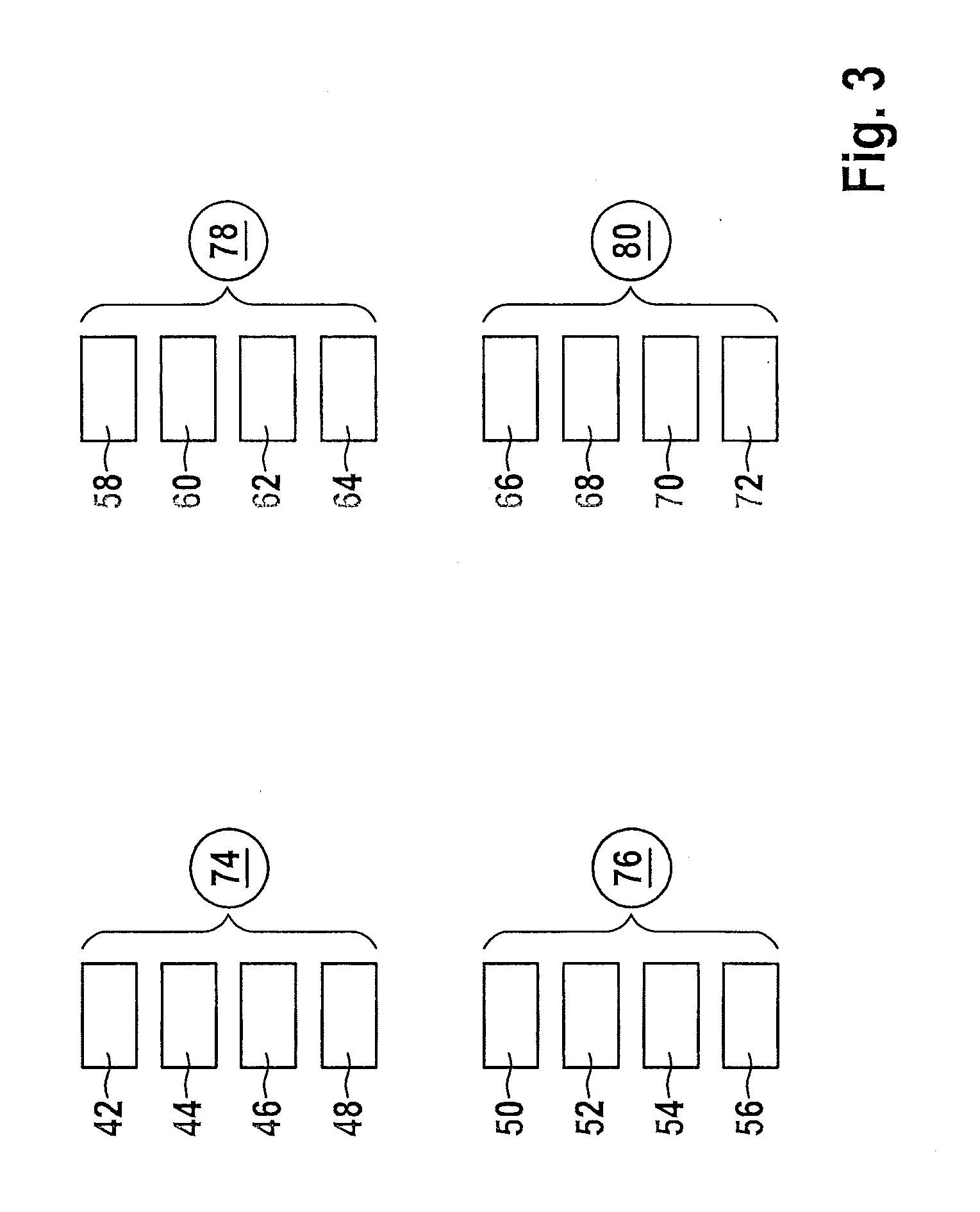

InactiveUS20040022526A1Increase the amount of dataAvoid idle timeTelevision system detailsDisc-shaped record carriersReproduction speedExecution unit

Alternation processes reduce the recording and reproducing speed of a hard disk apparatus. A hard disk apparatus comprising: an HDD 10 for recording AV data onto a hard disk; and stream controlling means 8 which is connected to the HDD 10 and thereby processes the signal of AV data transmitted from an IEEE1394 I / F 7 or the signal of AV data transmitted to the IEEE1394 I / F 7; whereby the hard disk apparatus can record and / or reproduce the AV data, wherein when AV data transfer is not normally completed for a disk access unit which is a minimum continuous unit in the access to the hard disk, an alternation process on a disk access unit basis is carried out so that another disk access unit is used hereafter in place of that disk access unit.

Owner:PANASONIC CORP

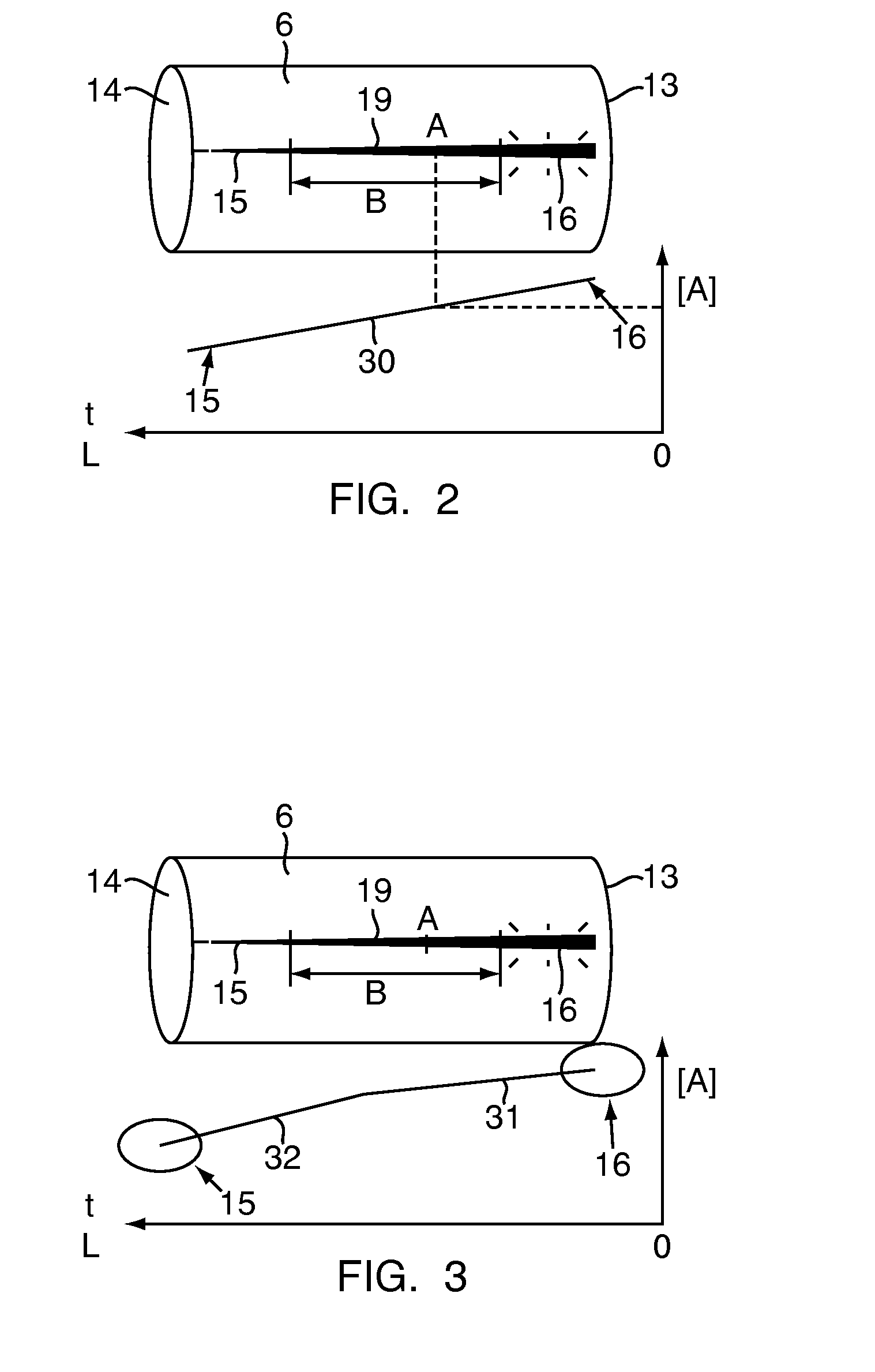

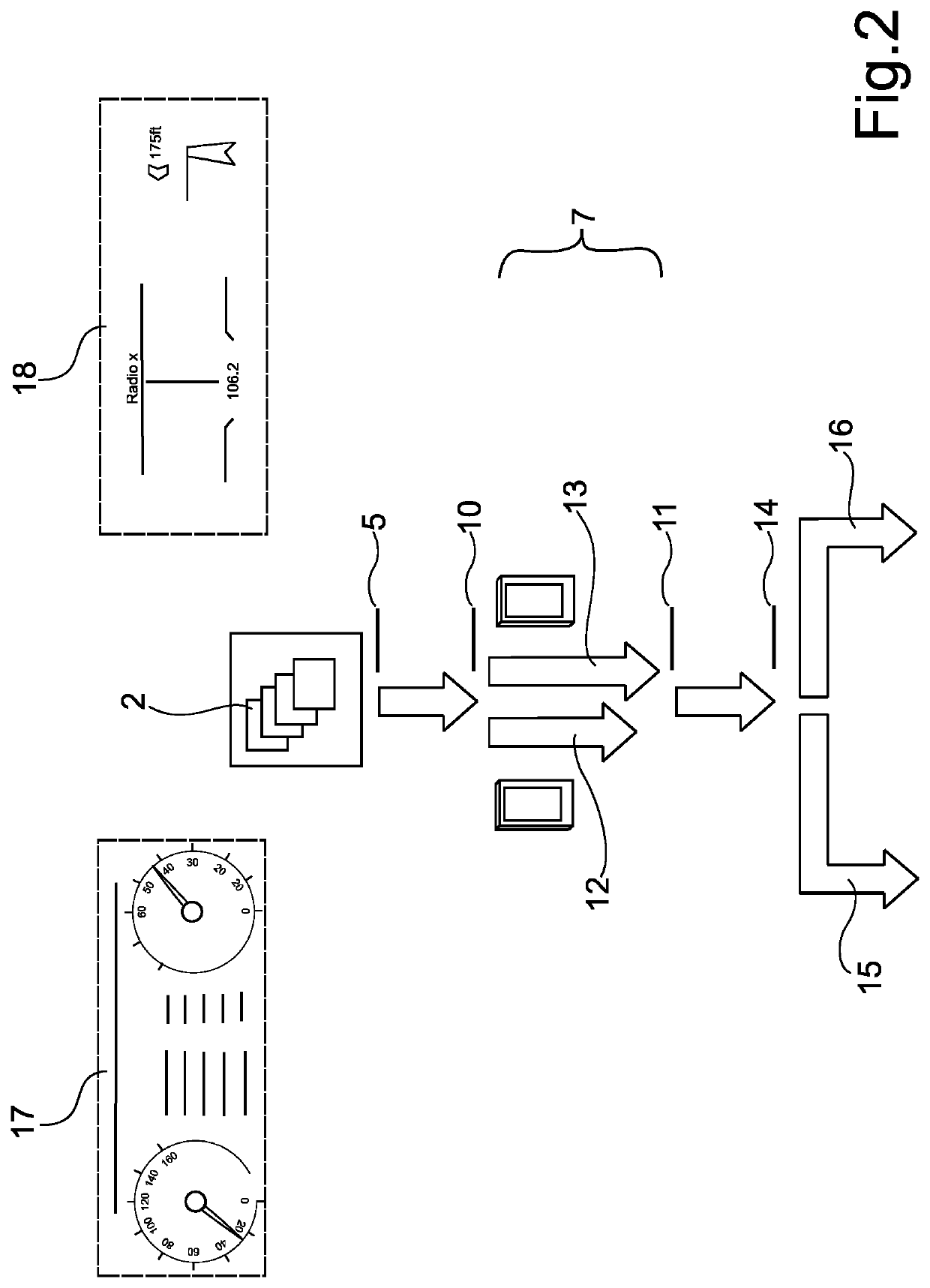

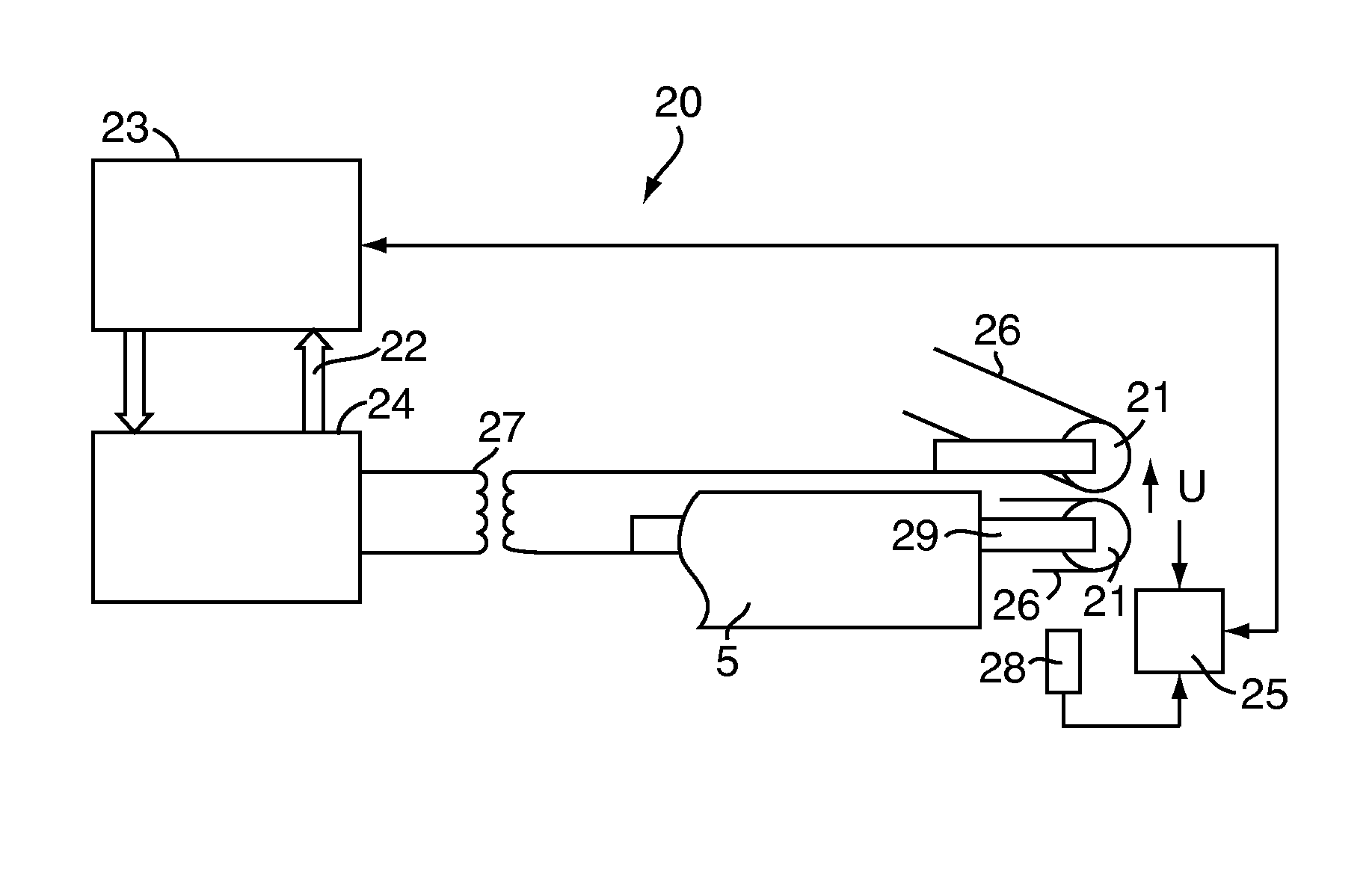

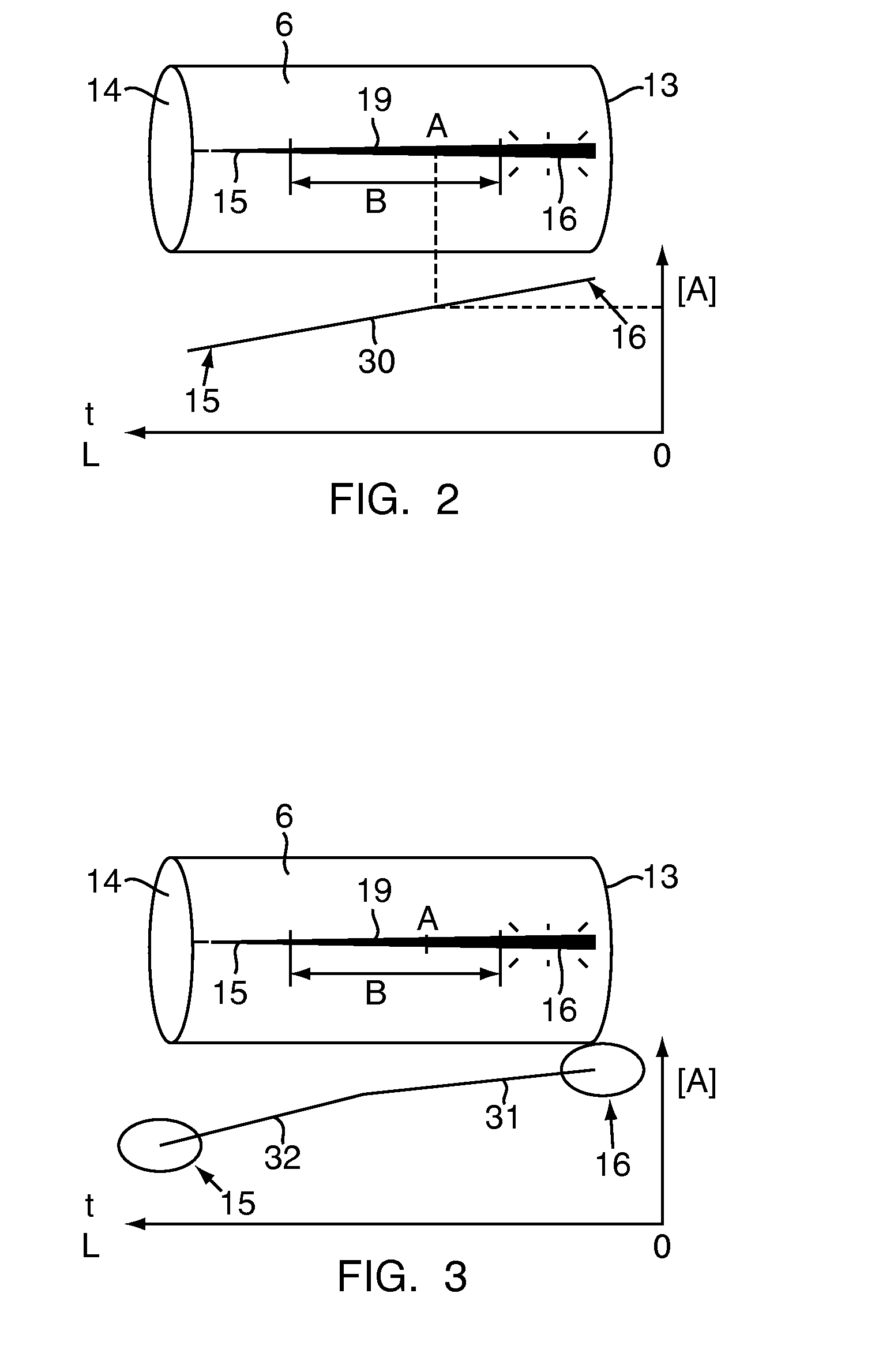

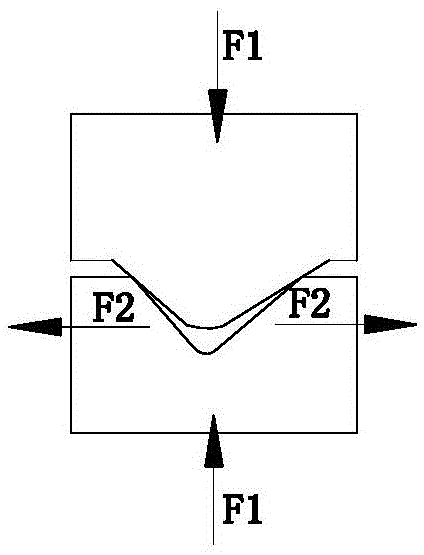

Method and welding device for the evaluation of the welding current intensity during the welding of container bodies

ActiveUS20110000892A1Compensate for changeManipulation errorSoldering apparatusElectrode supporting devicesSeam weldingElectric energy

In order to evaluate the welding current for the resistance seam welding of an overlap seam of container bodies, a welding with changing welding current intensity is carried out for a container body of the production series, resulting in a changing welding of the seam, ranging from the welding with a too high temperature to the welding with a too low temperature. The electric energy for this welding is determined several times during this welding and / or the temperature of the weld seam is determined several times and the welding current intensity is determined at which the welding of the individual container body is too cold and the welding current intensity at which the welding is too hot. This determination is based on the determined electric energy values and / or on the determined temperature values and based on this determination a preferred range for the welding current intensity within these limits of too hot and too cold is determined. By this, an evaluation if the welding current intensity is correct may take place in a simple way during the production. After the welding of the individual container bodies a changed welding current intensity lying between the welding current intensity of the too hot and of the too cold welding may optionally be set and used for the following series of container bodies of the production series.

Owner:SOUDRONIC

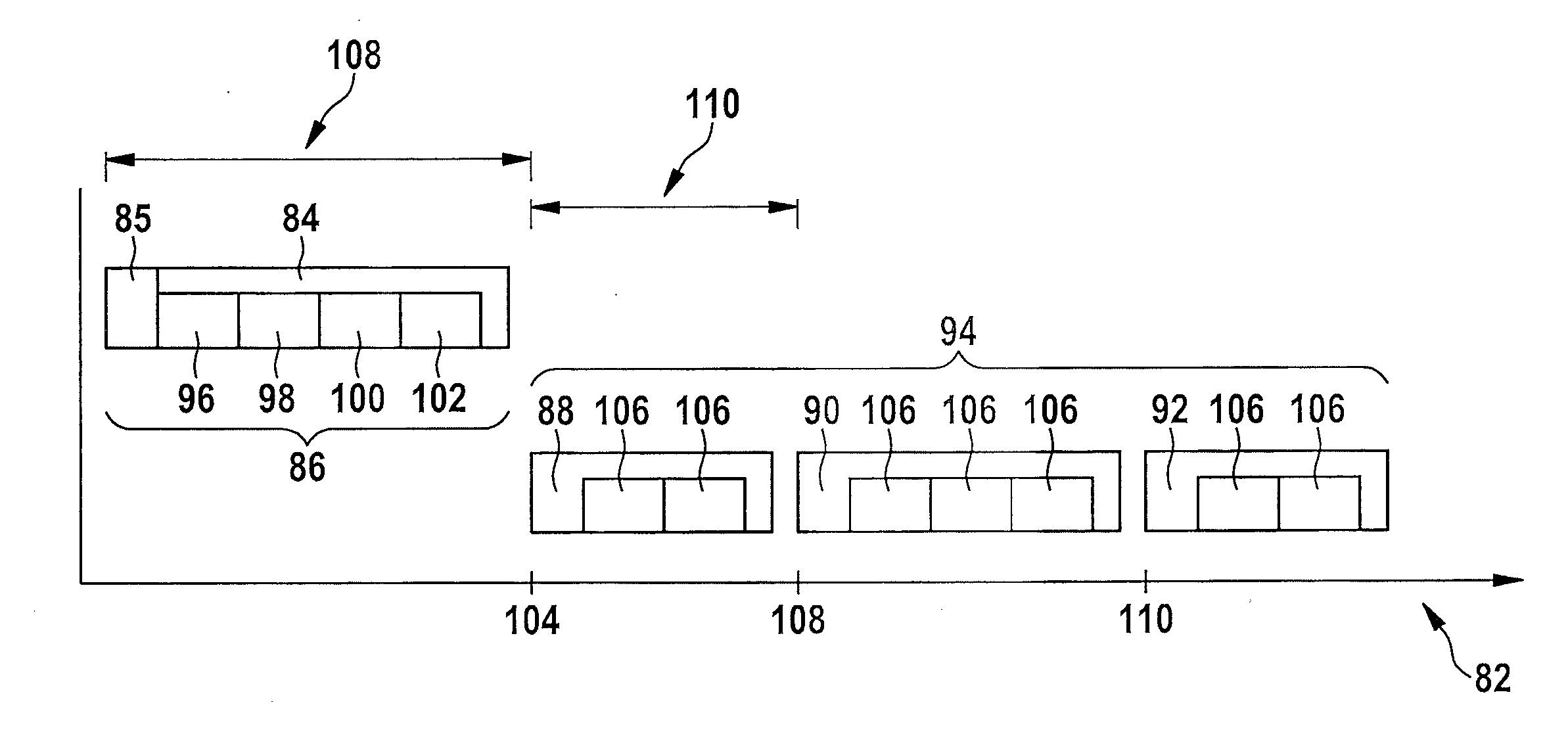

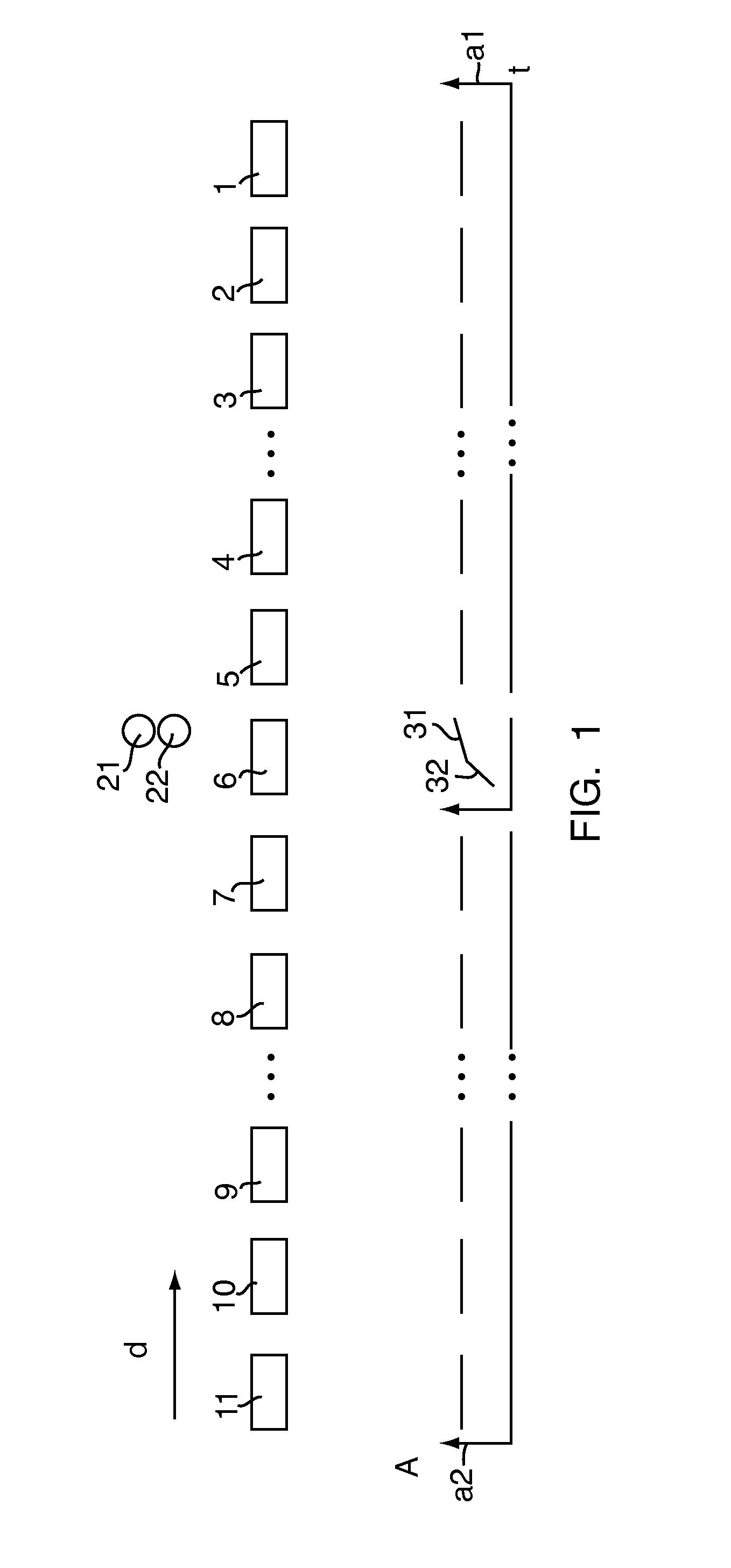

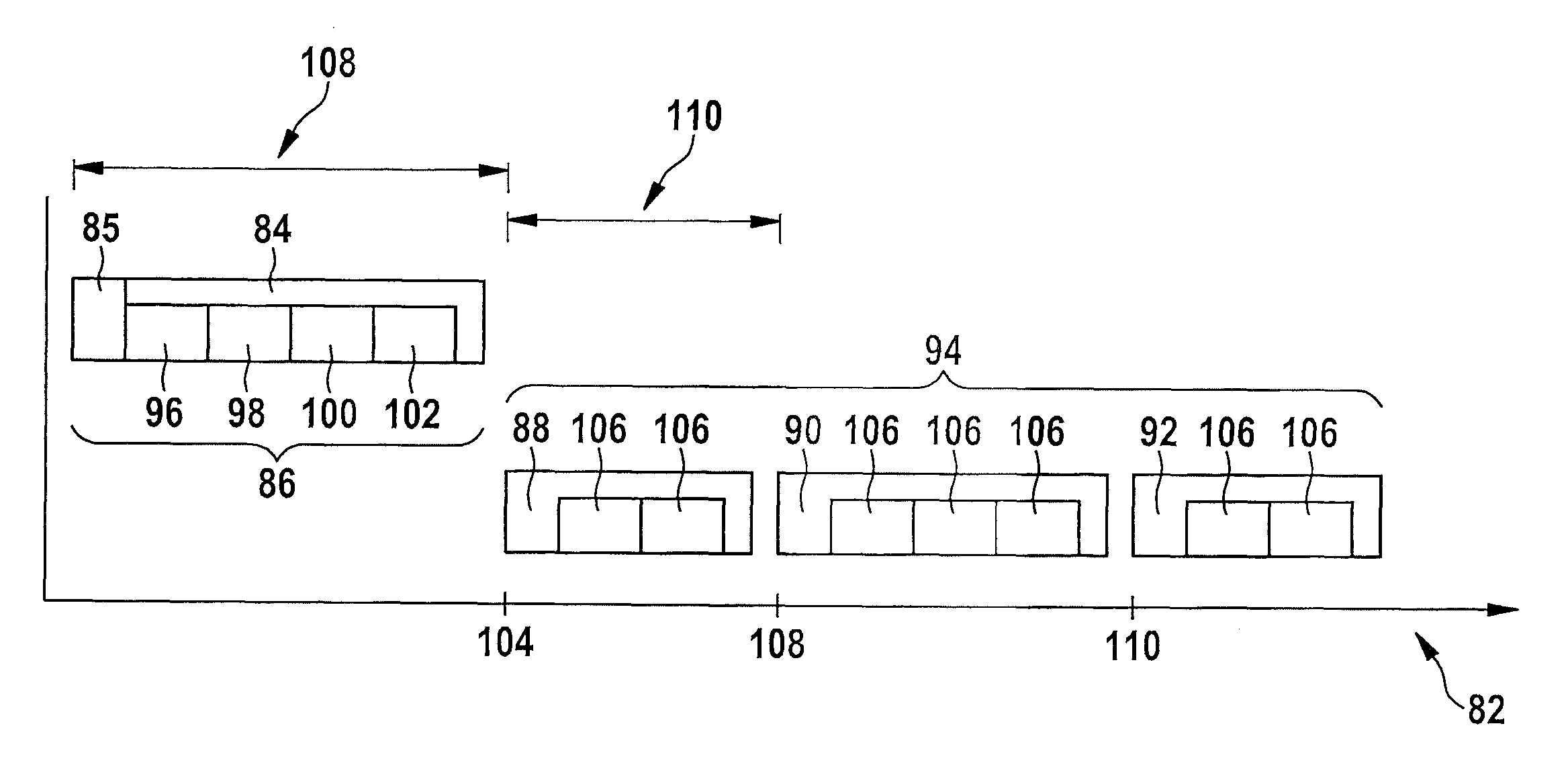

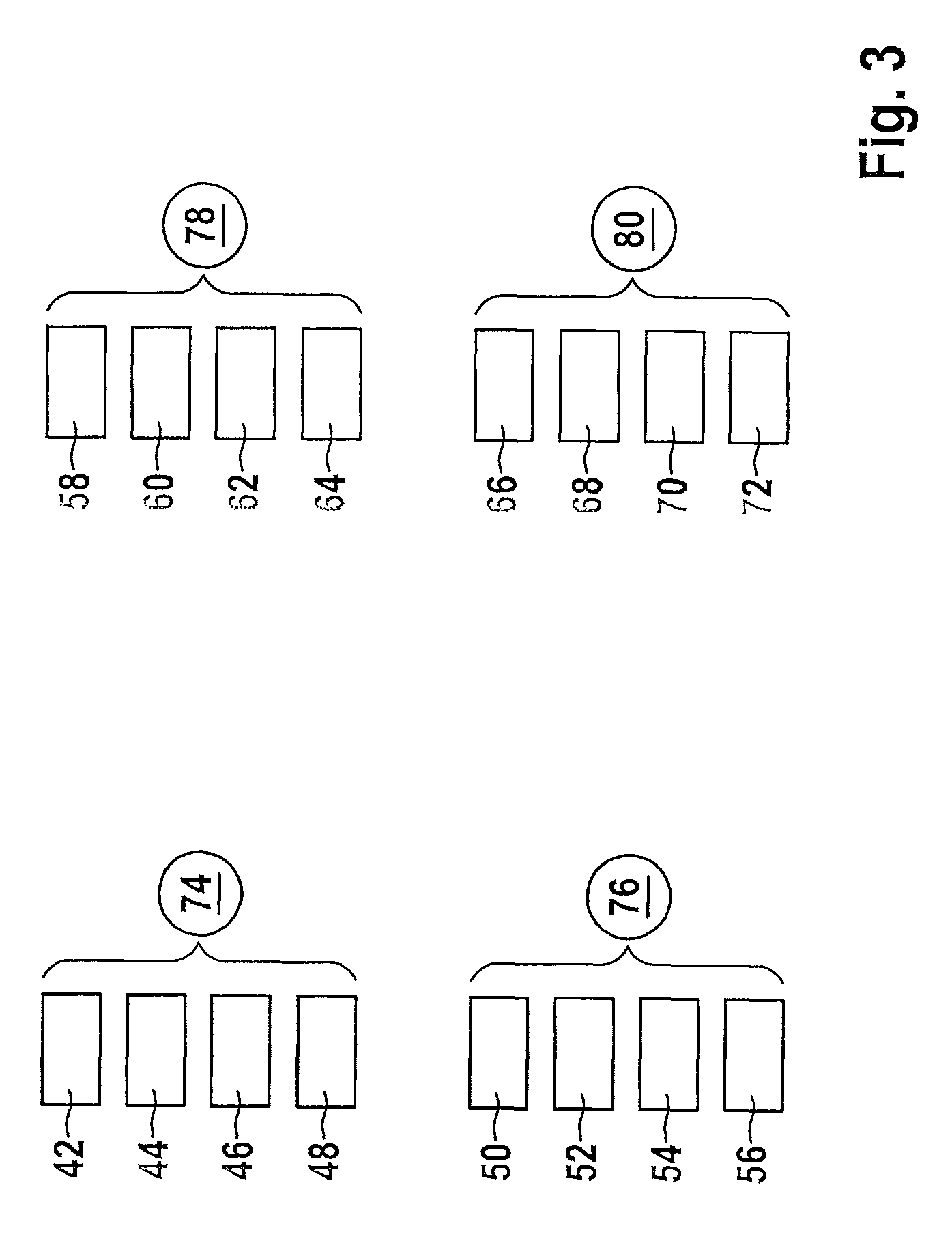

Method for operating a bus system

ActiveUS20130117483A1Avoid idle timeIncrease data transfer rateData switching networksElectric digital data processingTime scheduleEmbedded system

A method for operating a bus system, which includes a master and k slaves as users, where a header of an interrogation frame, which includes k information fields, is transmitted by the master to the slaves; in each instance, an mth slave being assigned an mth information field; an information item regarding the amount of data that is to be sent by the mth slave to the master being written by the mth slave to the mth information field assigned to it; the interrogation frame being transmitted to the master; and a time schedule, by which the amount of data to be sent is taken into account, being prepared by the master for transmitting the data.

Owner:ROBERT BOSCH GMBH

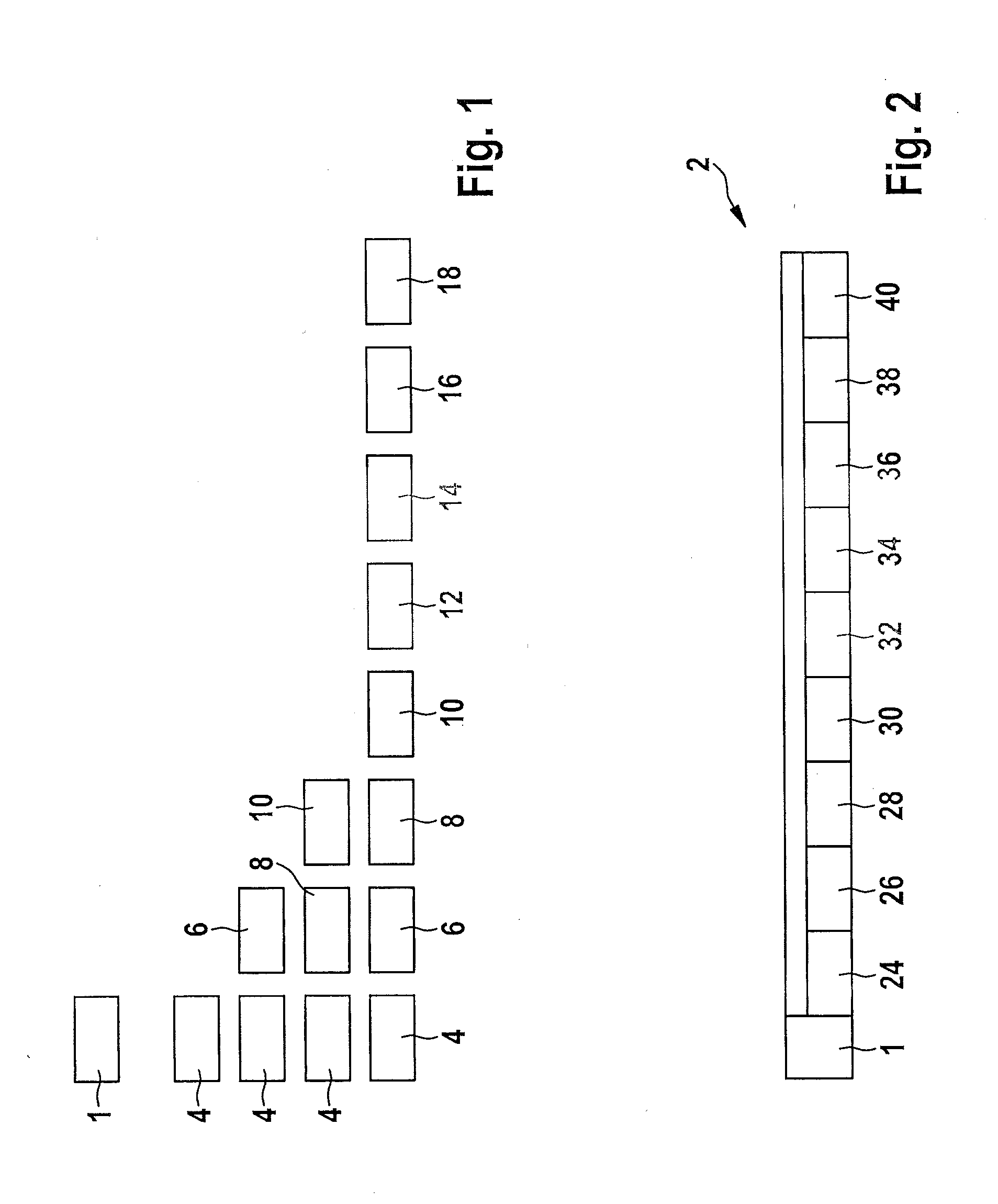

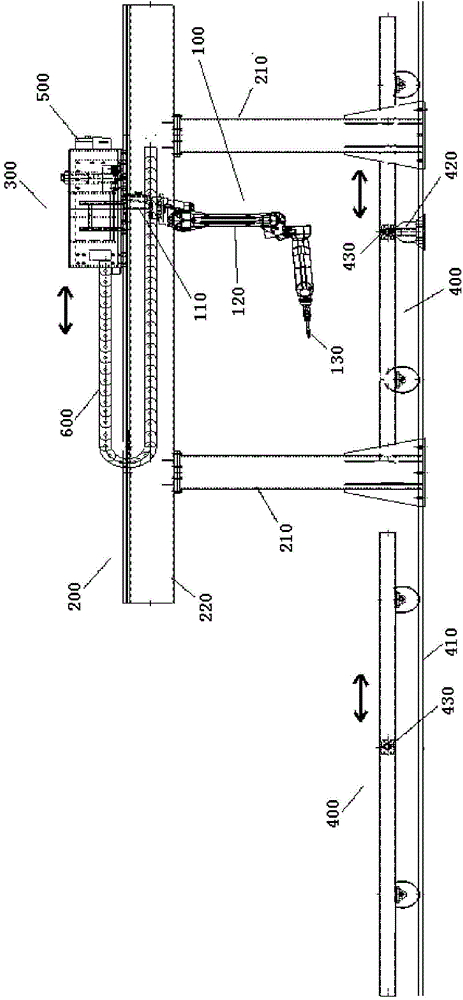

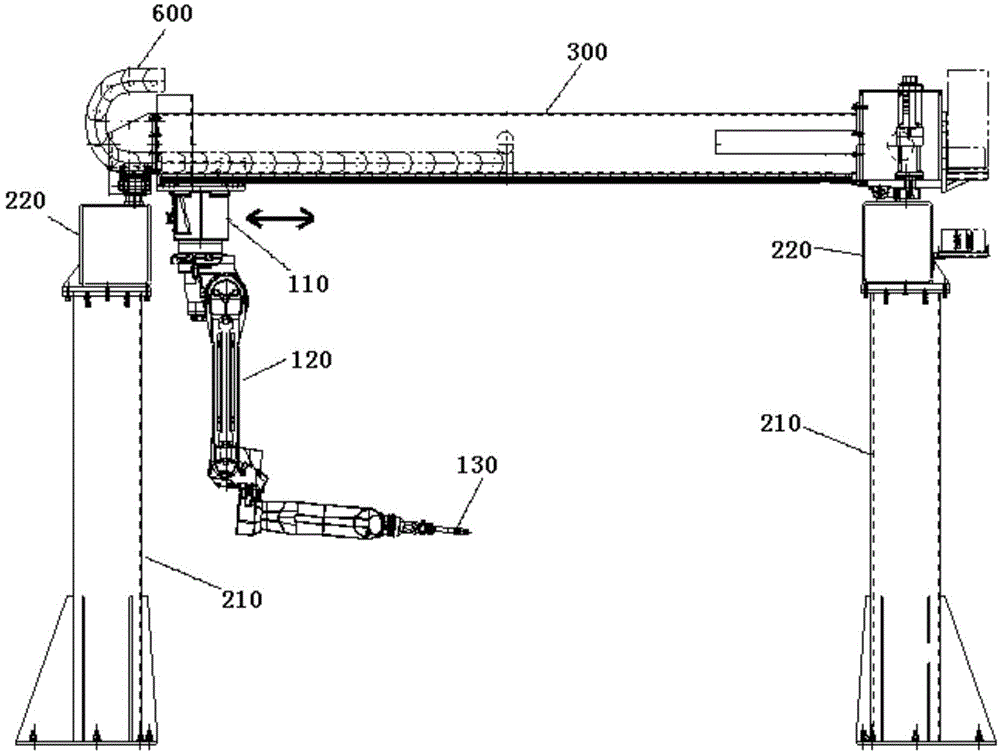

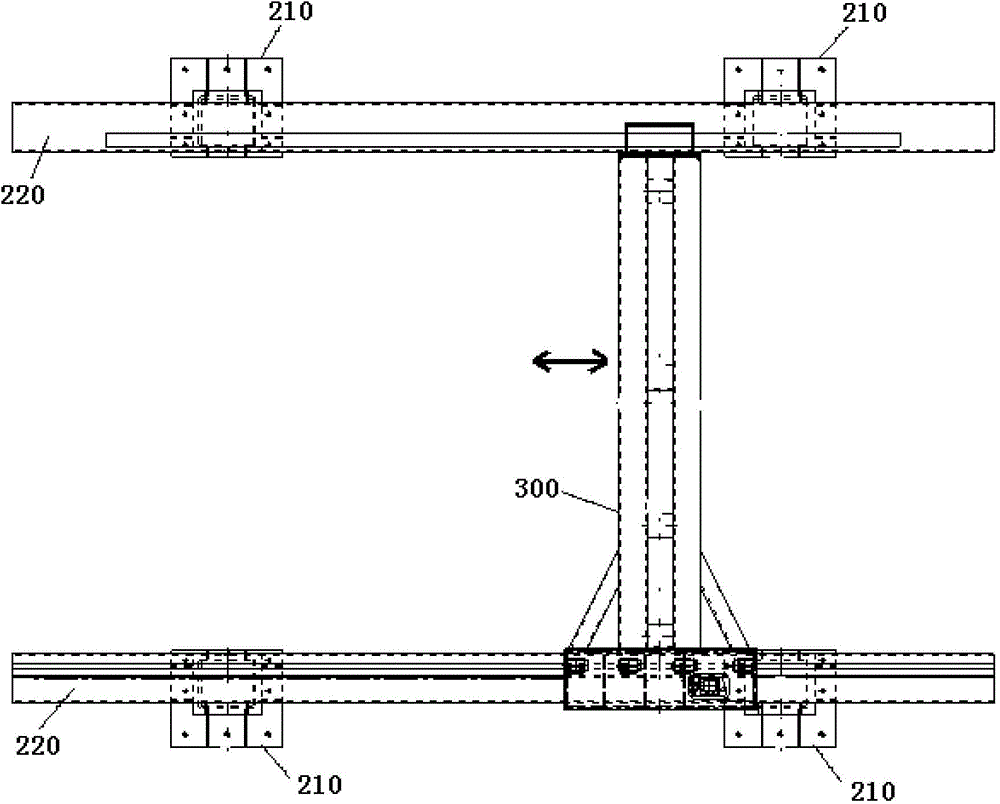

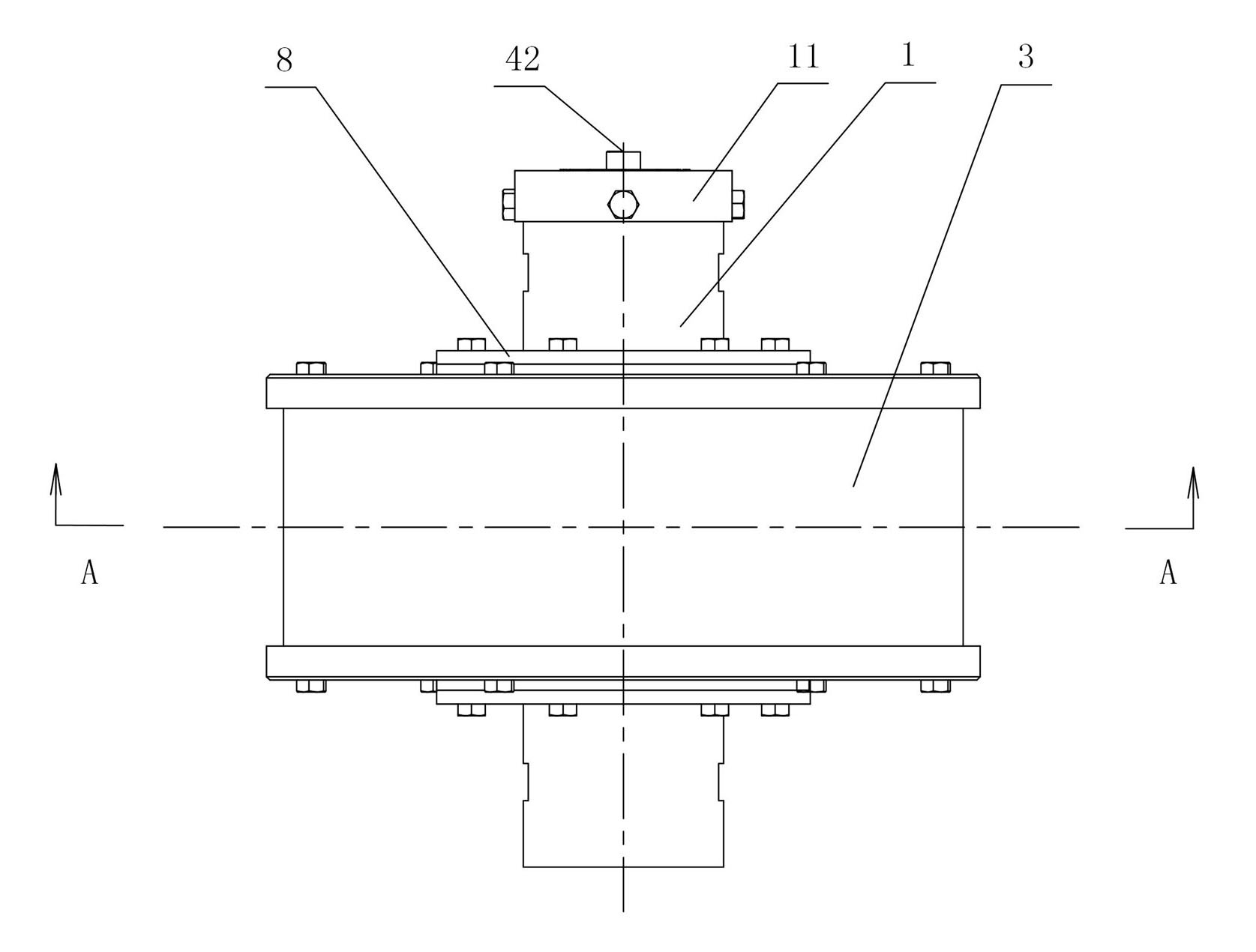

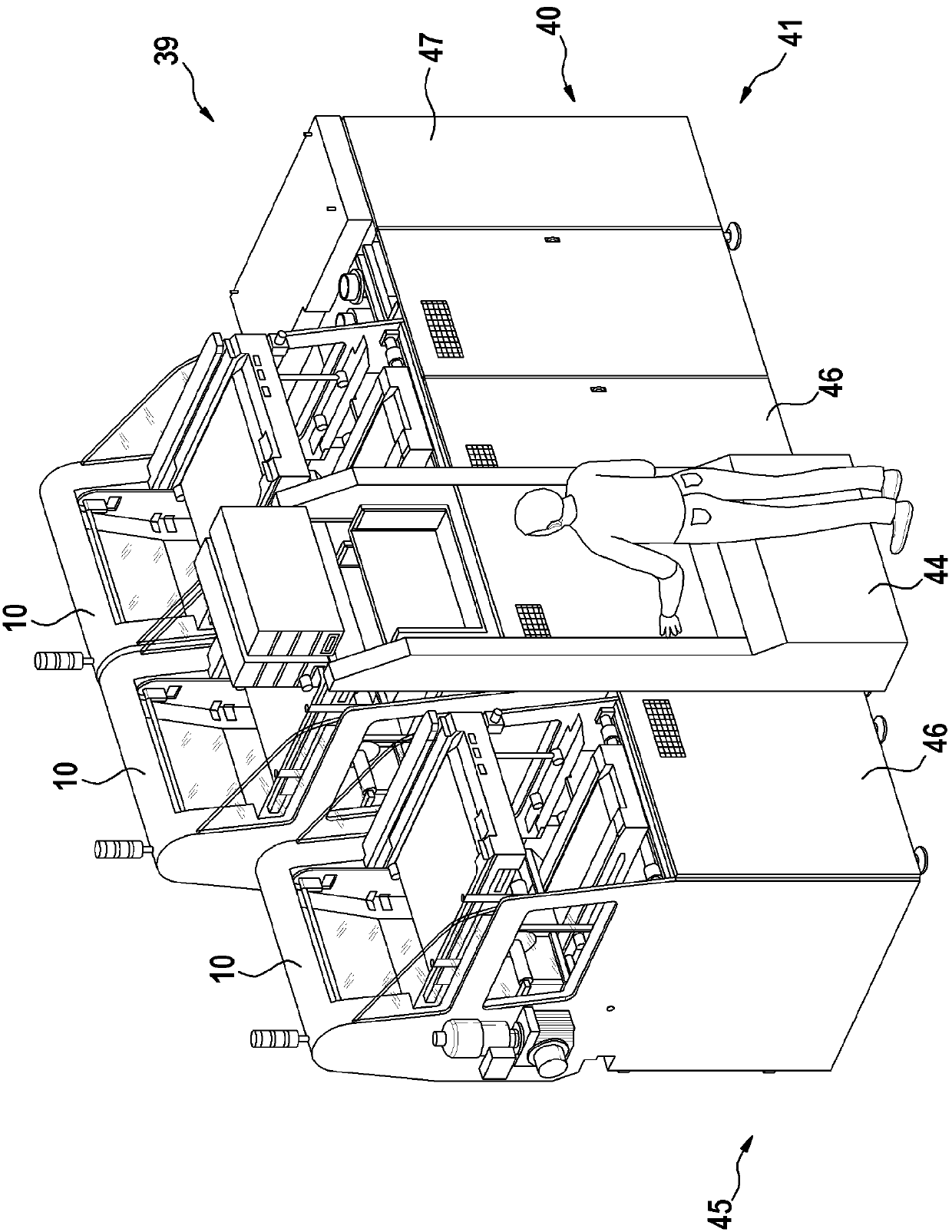

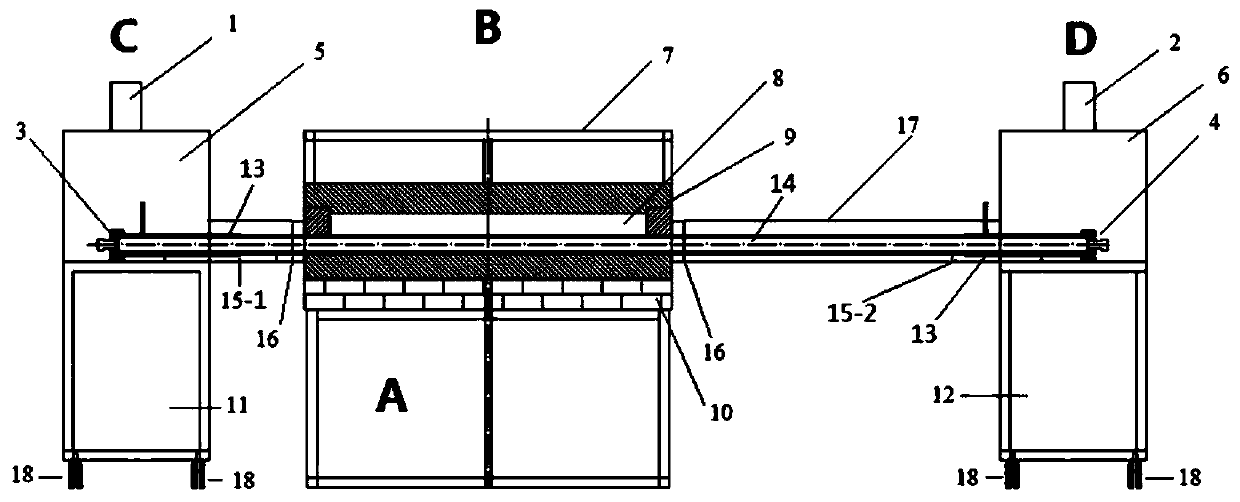

Automatic robot welding work station

InactiveCN103978326AAvoid idle timeImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWorkstation

The invention discloses an automatic robot welding work station. The work station comprises a robot welding unit, a gantry structural unit, a walking beam and two rolling work stations, wherein the walking beam is arranged on the gantry structural unit and can move reciprocally in a horizontal plane along the direction which is perpendicular to the axial direction of the walking beam; the robot welding unit is mounted on the walking beam in an inversely suspended way and can move reciprocally along the axial direction of the walking beam; the rolling work stations are used for clamping a piece to be welded, and can move reciprocally along the direction which is perpendicular to the axial direction of the walking beam, so that the two rolling work stations are positioned below the walking beam alternately; the robot welding unit welds continuously. The automatic robot welding work station provided by the invention is used for solving the technical problem that the conventional robot work station is low in welding efficiency.

Owner:肖宁

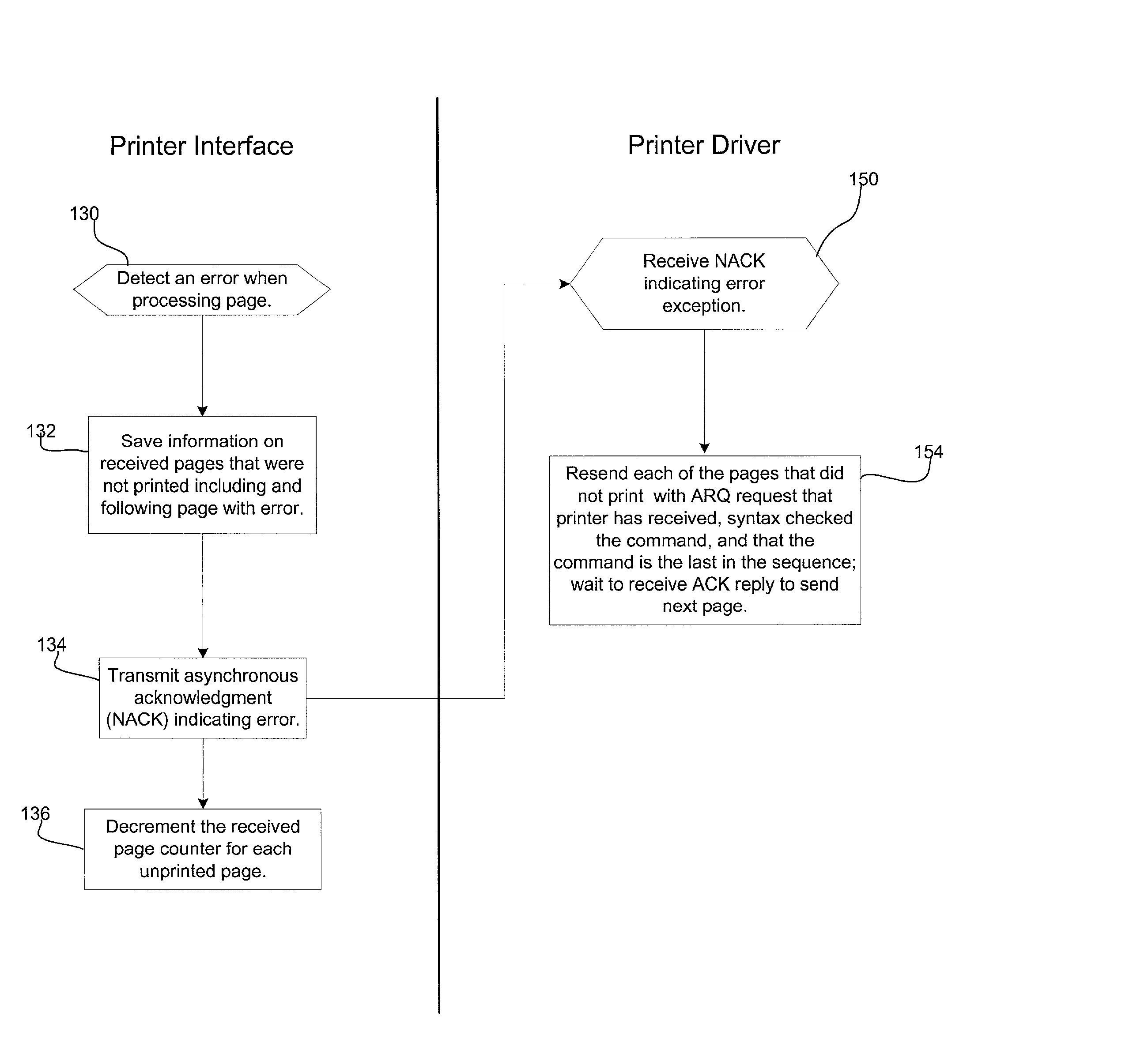

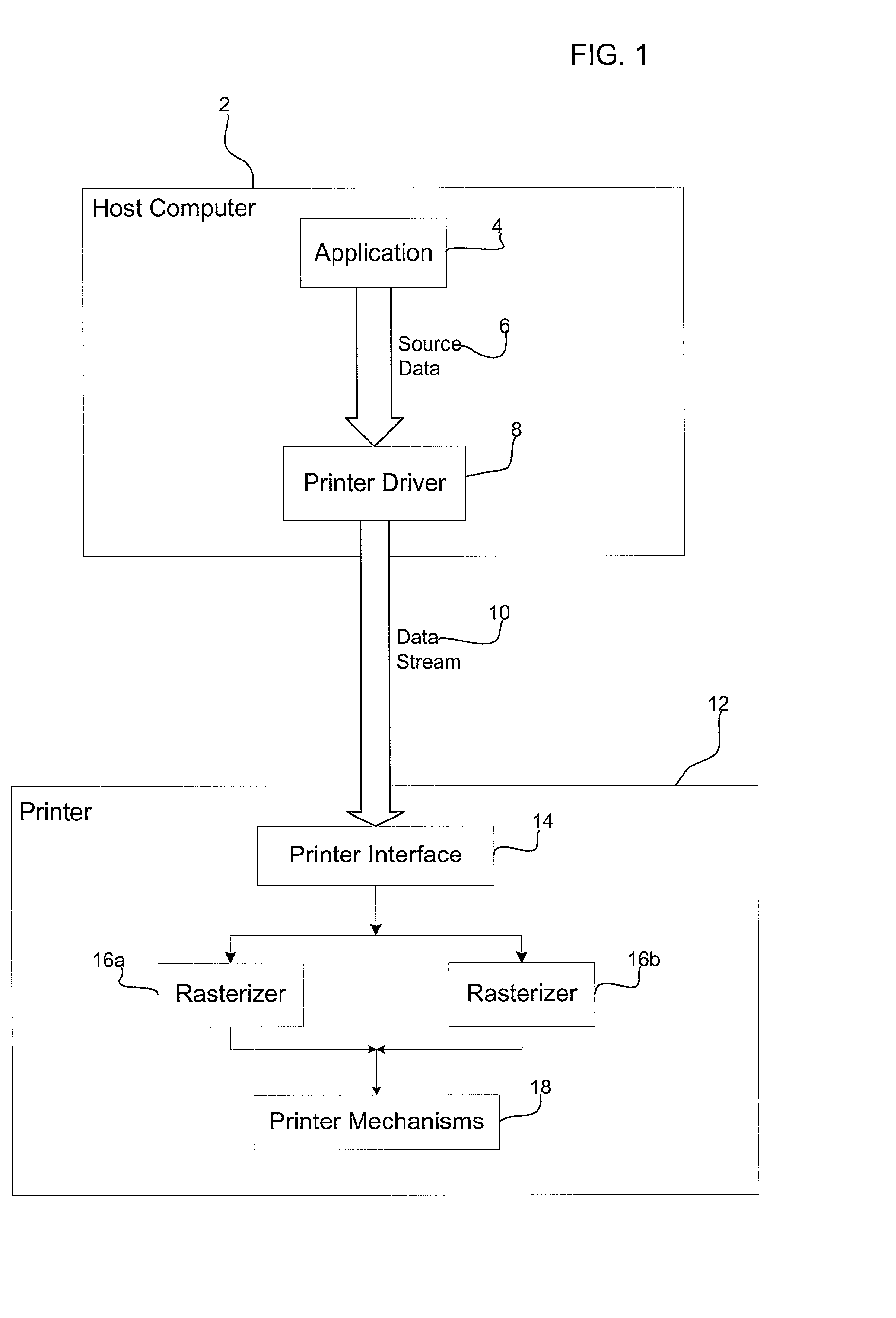

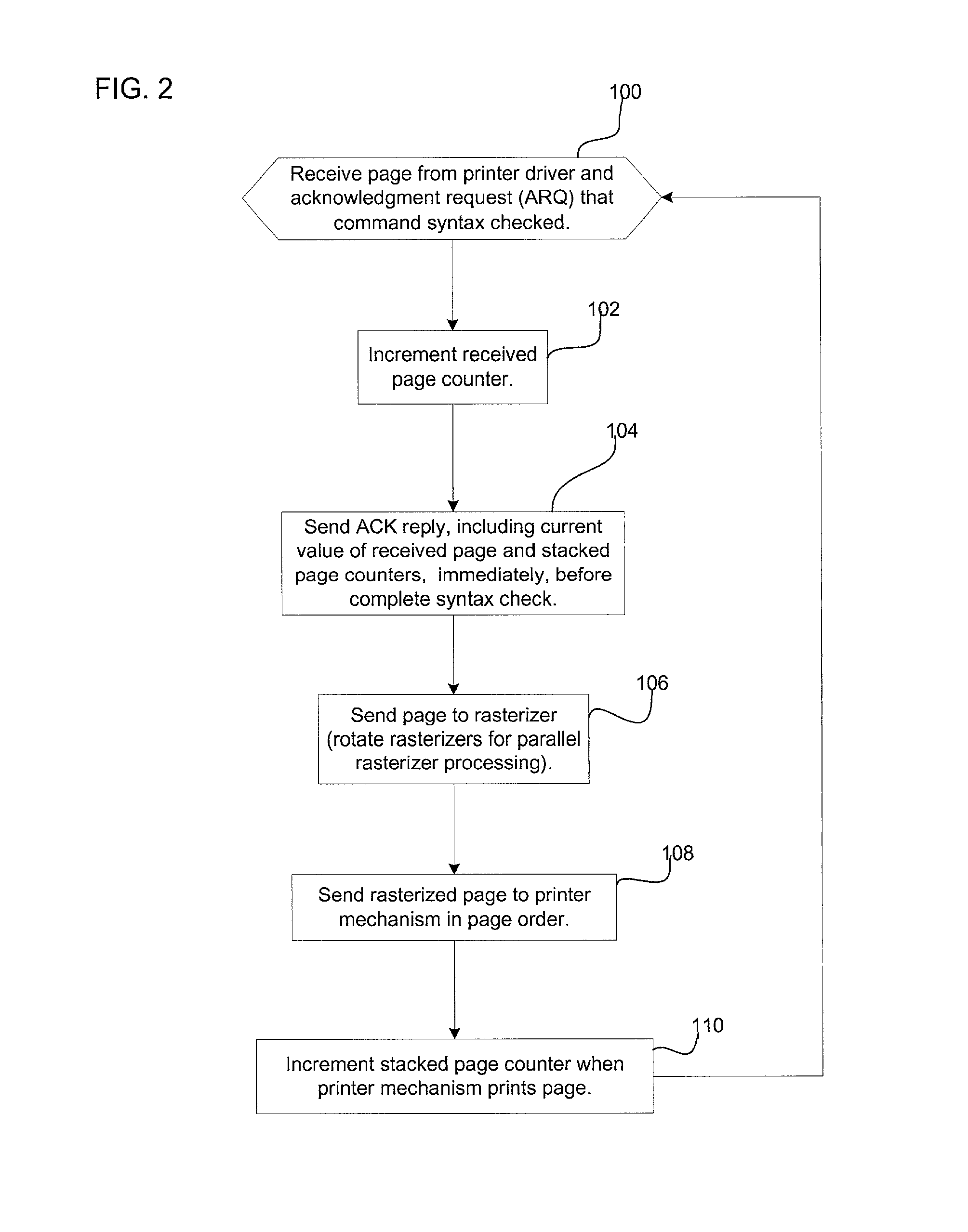

Method, system, and program for responding to an acknowledgment request from a printer driver

InactiveUS20020101601A1Improve performanceOptimizing throughputError prevention/detection by using return channelTransmission systemsComputer printingPrint processor

Provided is a method, system, and program for interfacing with a printer driver. Data and an acknowledgment request is received from the printer driver. The printer driver does not send further data to print until receiving an acknowledgment reply indicating that the transmitted data passed an initial check to improve printer performance. An acknowledgment reply is transmitted to the printer driver in response to the acknowledgment request before completing the initial check of the sent data to cause the printer driver to send further data. Data processing operations are resynchronized in response to detecting an error in the received data. The received data is rasterized and outputted.

Owner:RICOH KK

High-rise descent control device based on hydraulic damping

InactiveCN102068771AHydraulic damping force to slow down telescoping speedSlow down hydraulic damping forceBuilding rescueHydraulic cylinderEngineering

The invention discloses a high-rise descent control device based on hydraulic damping, which comprises a main shaft, a rope and an inner cam, wherein the inner cam is arranged at the main shaft, the rope is wound on the outer cylindrical surface of the inner cam, the inside of the inner cam is provided with a hydraulic cylinder, the piston rod of the hydraulic cylinder is driven by the cam wall of the inner cam to reciprocate, and the hydraulic cylinder is connected with a damping oil way which can adjust the reciprocating speed of the piston rod. The device of the invention has the advantages that the structure is simple and compact, the stability is good, the efficiency is high, the device is safe and reliable to use, the machining and assembly process is simple, the maintenance cost is low, the application range is wide, and the like.

Owner:NAT UNIV OF DEFENSE TECH

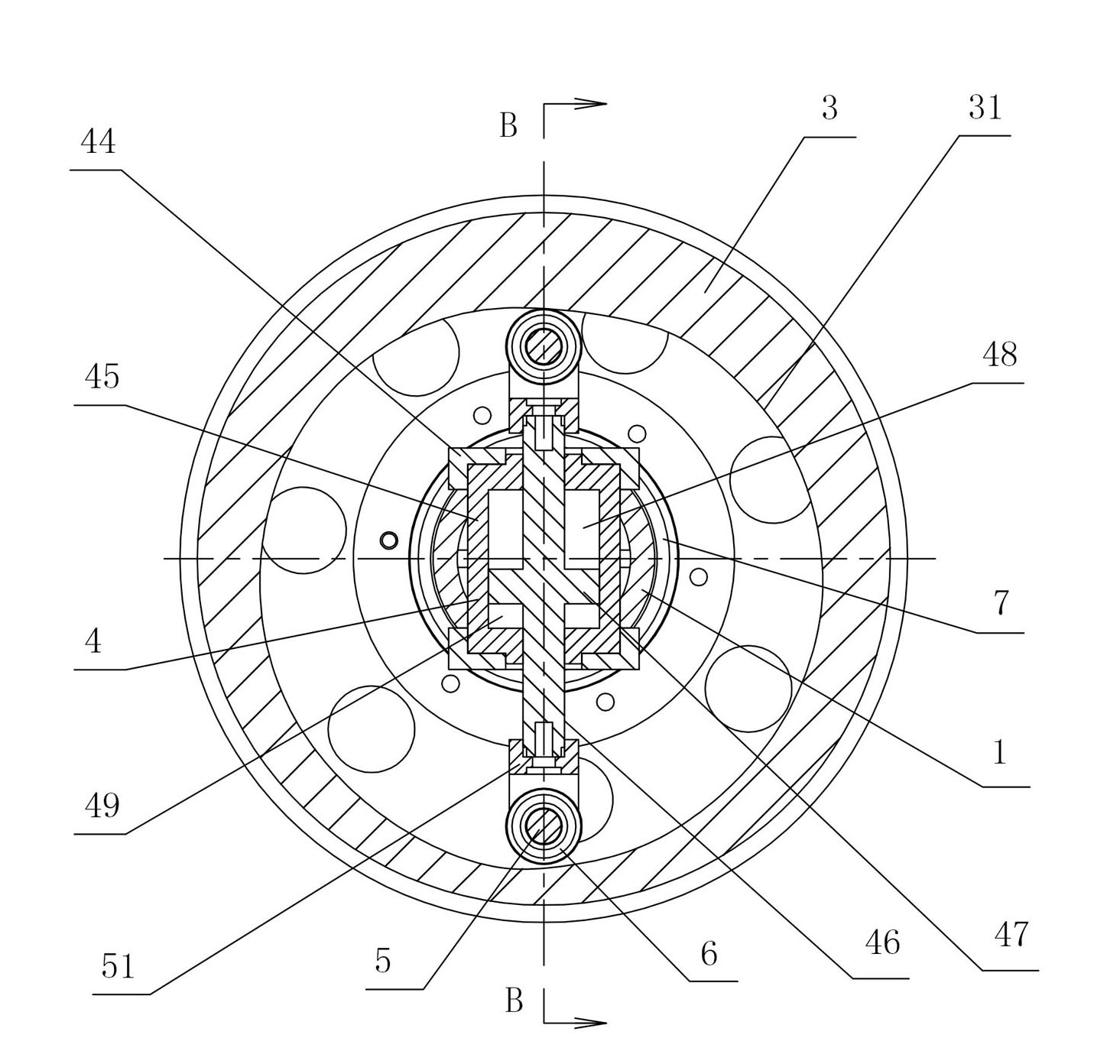

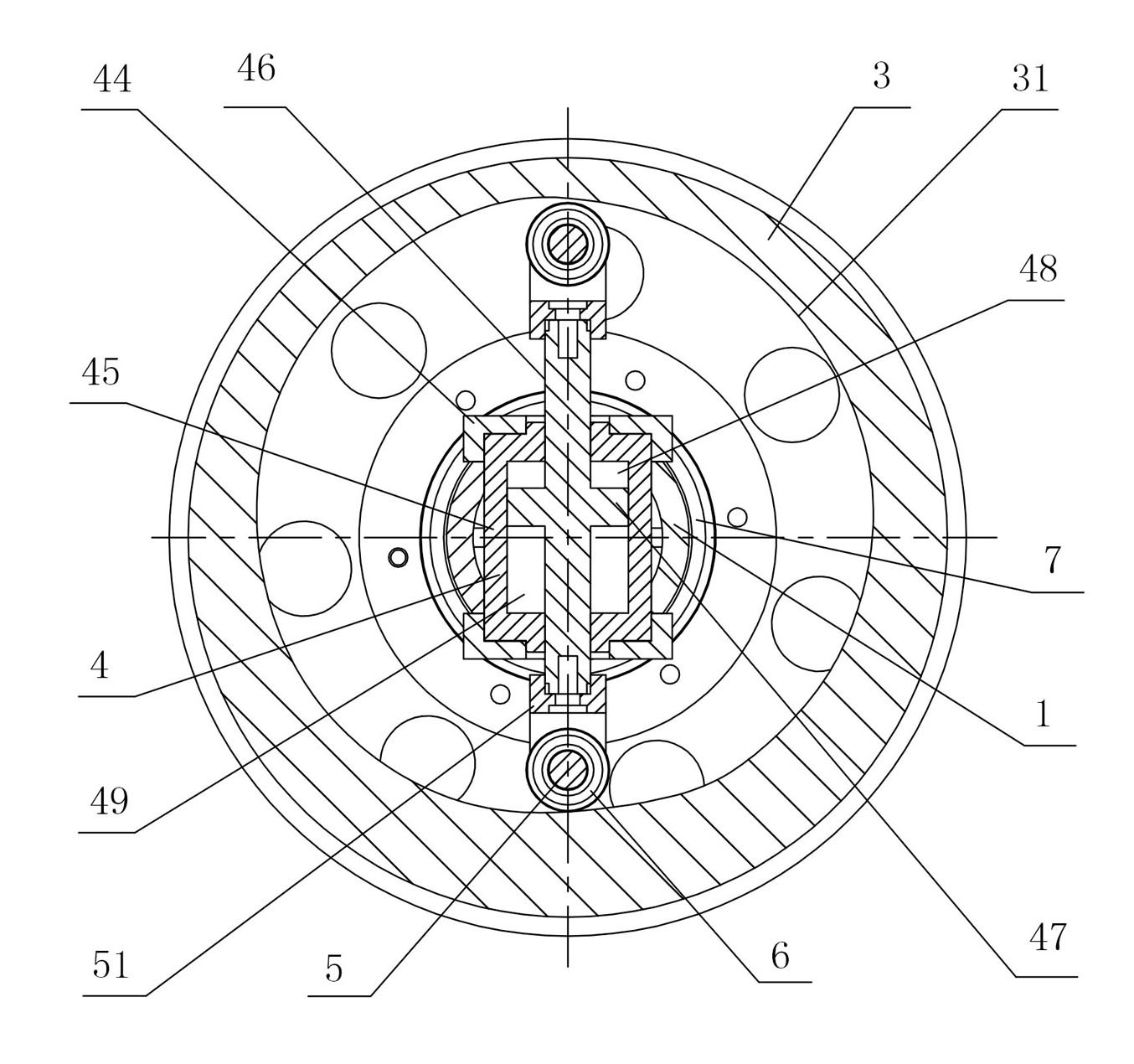

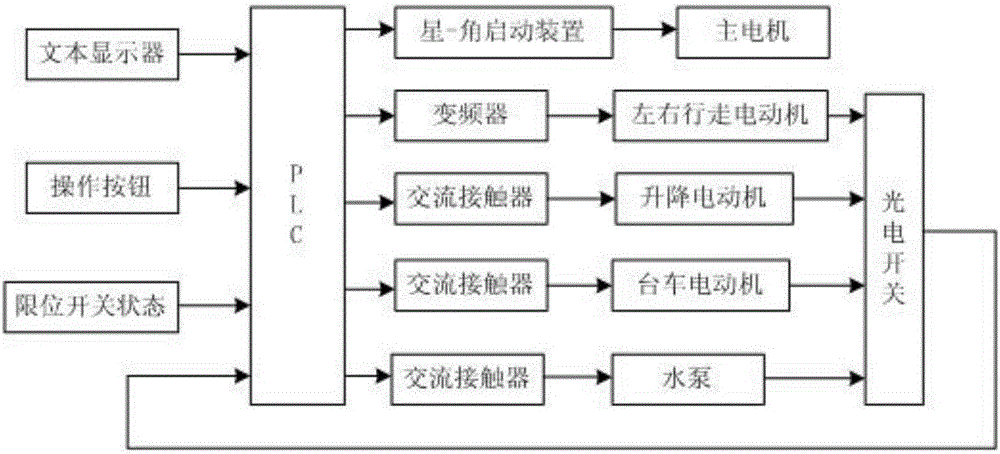

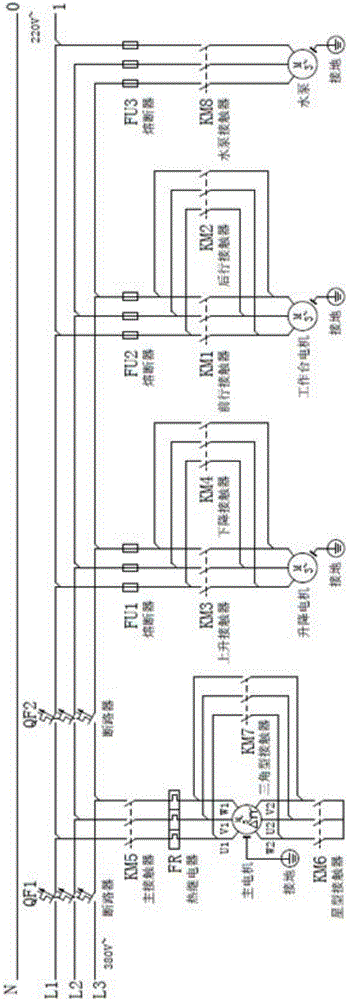

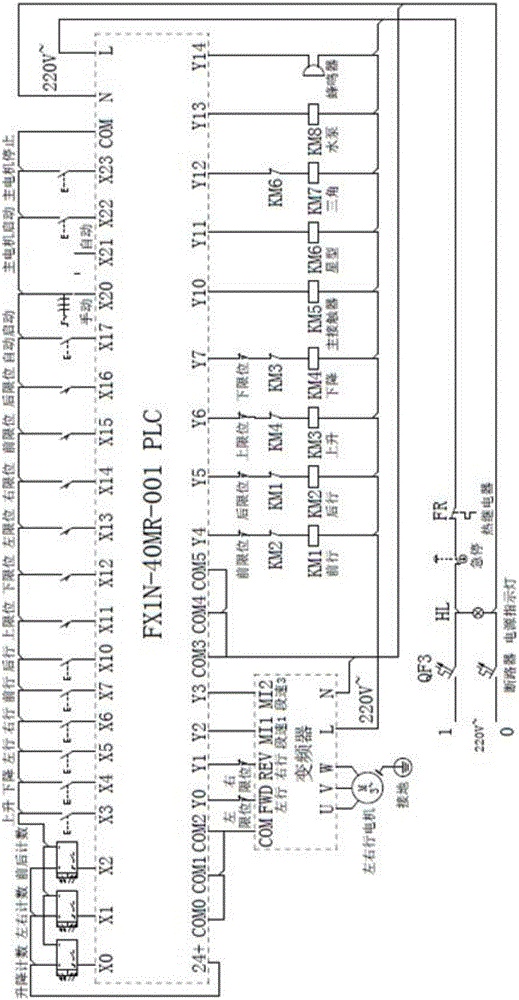

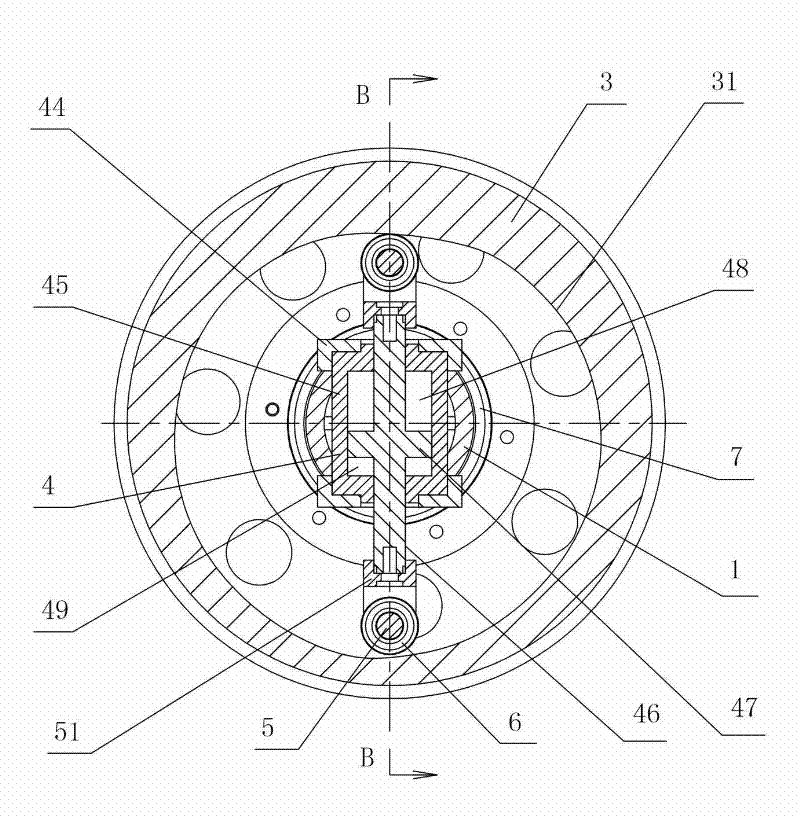

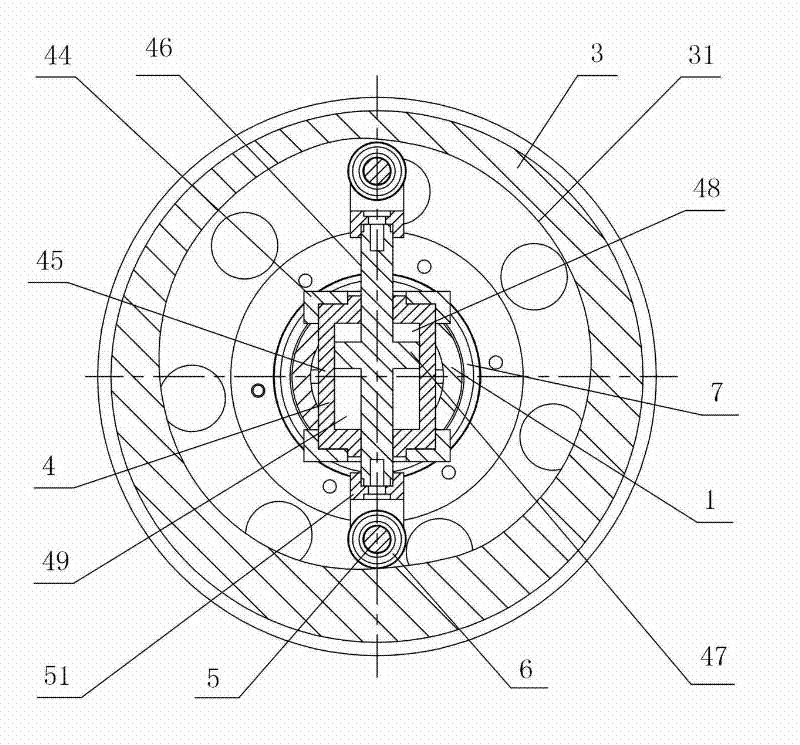

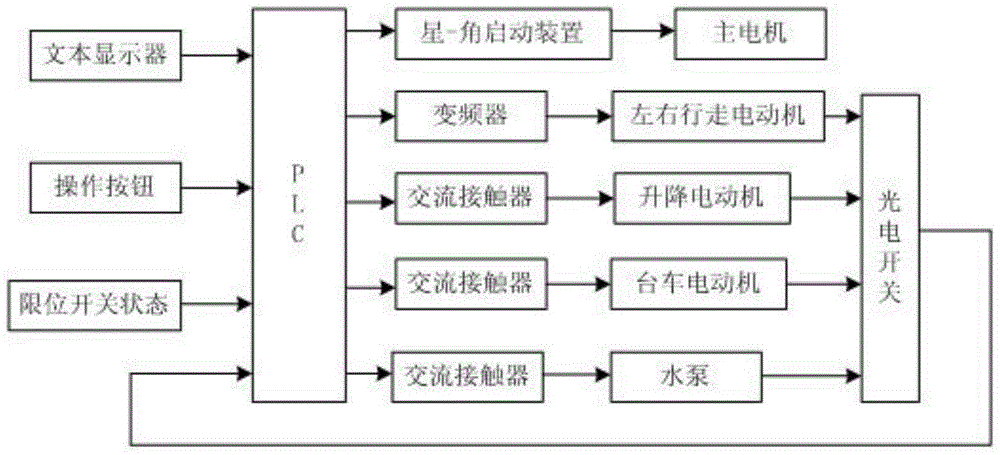

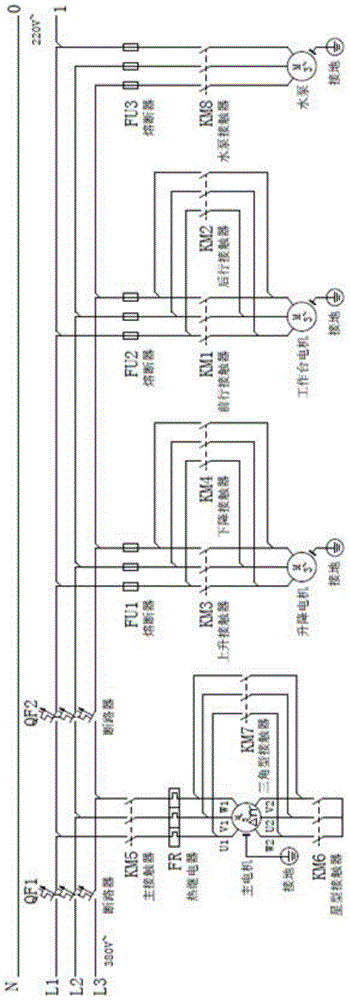

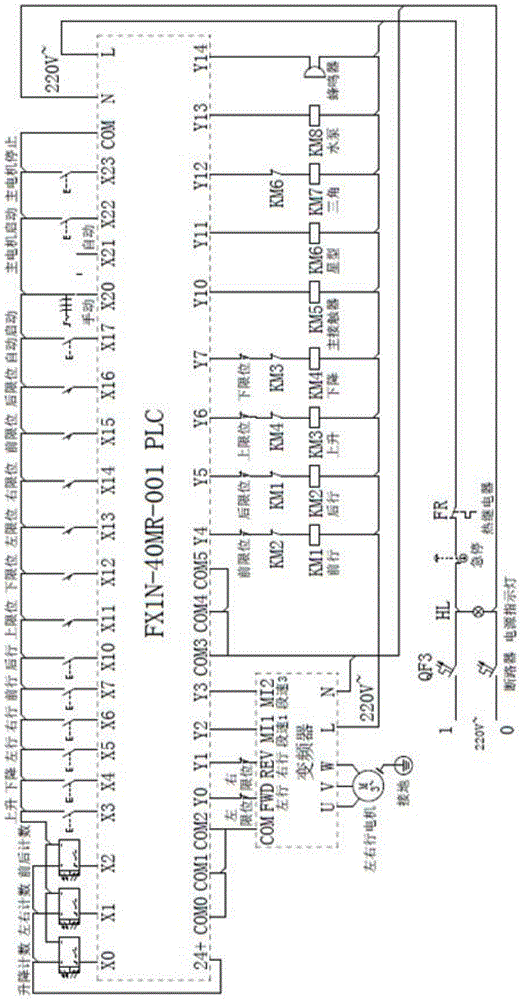

Control system and method for disc stone sawing machine

InactiveCN105058591AQuality improvementHigh degree of automationWorking accessoriesStone-like material working toolsCircular discPosition circle

The invention relates to a control system and method for a disc stone sawing machine. The control system comprises four portions of a power unit, an electrical control unit, a detection unit and a man-machine interaction part. Manual and automatic control modes are provided, the position of a first cutting disc saw can be determined according to the first cutting machining depth, stone size, the disc saw radius and the distance from the disc saw initial position circle center to a trolley, and accordingly the first cutting machining accuracy is guaranteed. By means of a left and right traveling mechanism, left and right traveling switching can be achieved through a stroke counting function, so that machining can be performed according to the actual stone width, and the problem of the idle running time process caused by switching of limit switches in the traditional method is solved; by means of the system, optimal matching of machining depth with machining speed is achieved, the main motor optimal operation efficiency is guaranteed, the system work efficiency is improved, and the energy-saving purpose of the system is reached; besides, the system safety and reliability are guaranteed.

Owner:BOHAI UNIV

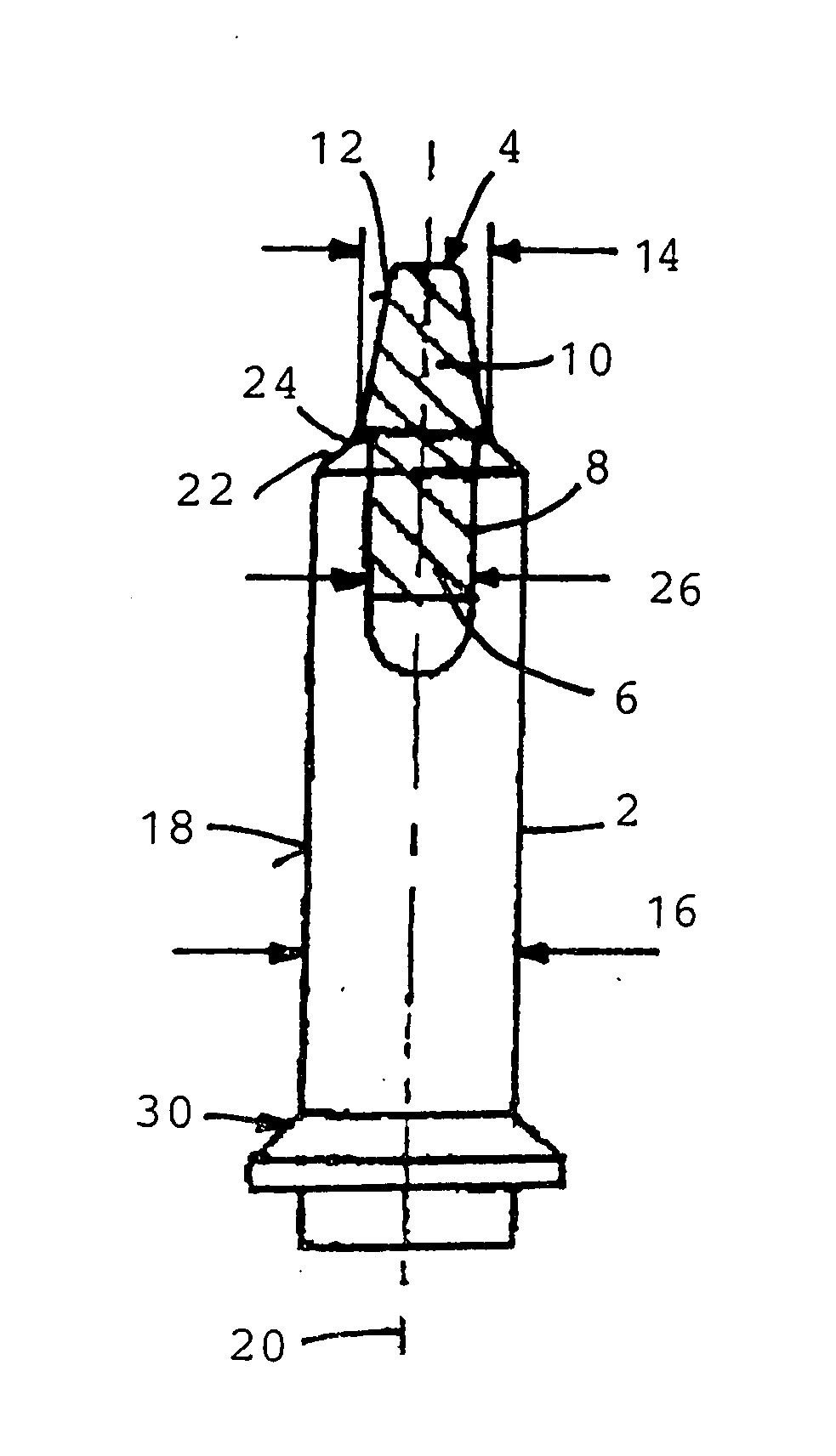

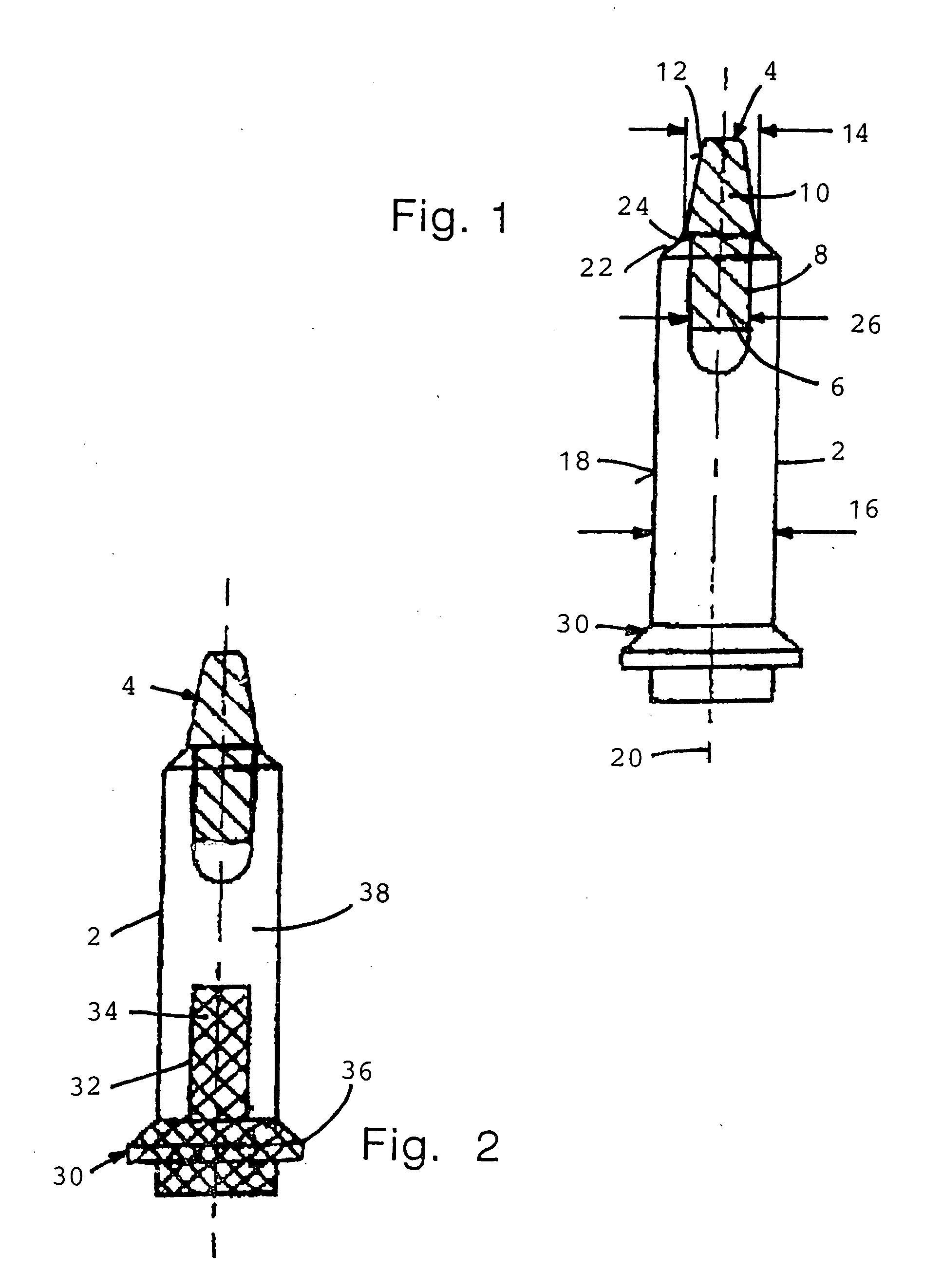

Centering pin

InactiveUS20070154278A1Avoid disadvantagesHigh degree of functional assurednessPrecision positioning equipmentNutsEngineeringHigh dimensional

A receiving element which can be introduced into a borehole of at least one component includes a bolt presenting an outer surface that is approximately parallel and advantageously coaxial to a longitudinal axis of the bolt. The receiving element requires few materials and can therefore be produced at a low constructional cost while being provided with high dimensional stability and positioning accuracy. The bold includes an abrasion-resistant sintered material, and a metal tip provided on the front end of the shaft. The end part of the tip is engageable in a recess of the bolt, and there is a direct connection between the end part and the recess in the connection region on the front end of the bolt.

Owner:FRIATEC AG DE

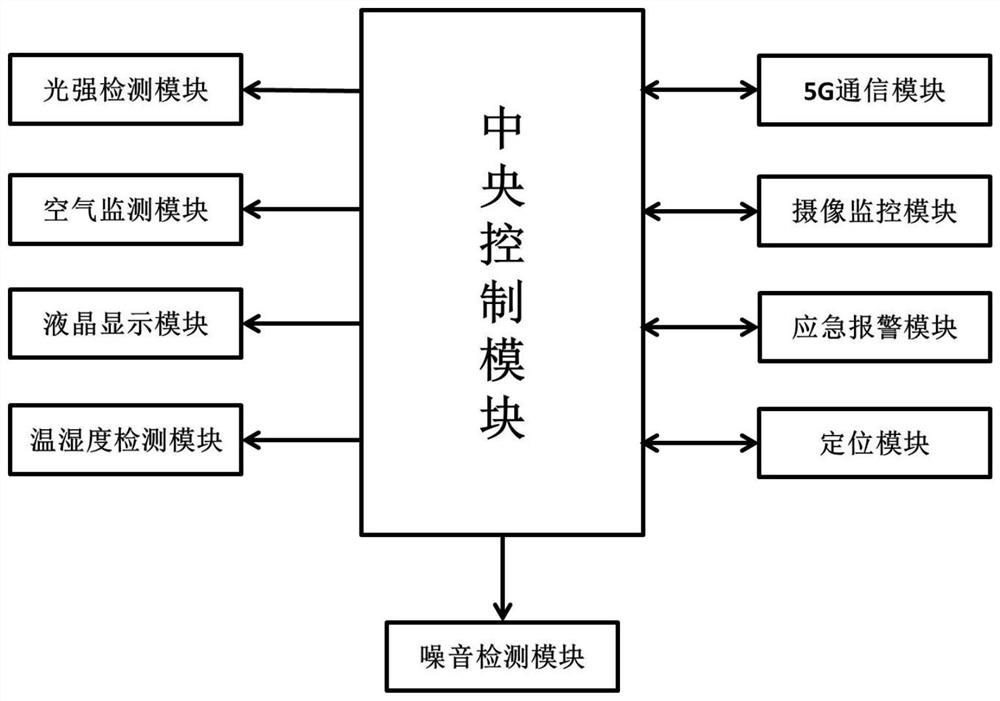

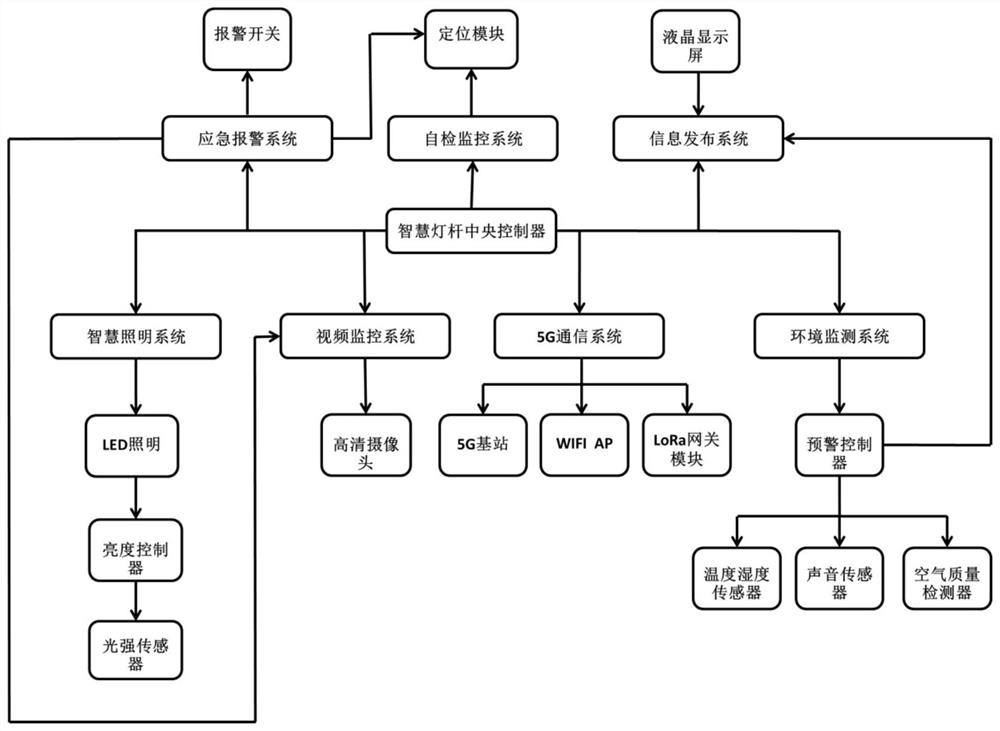

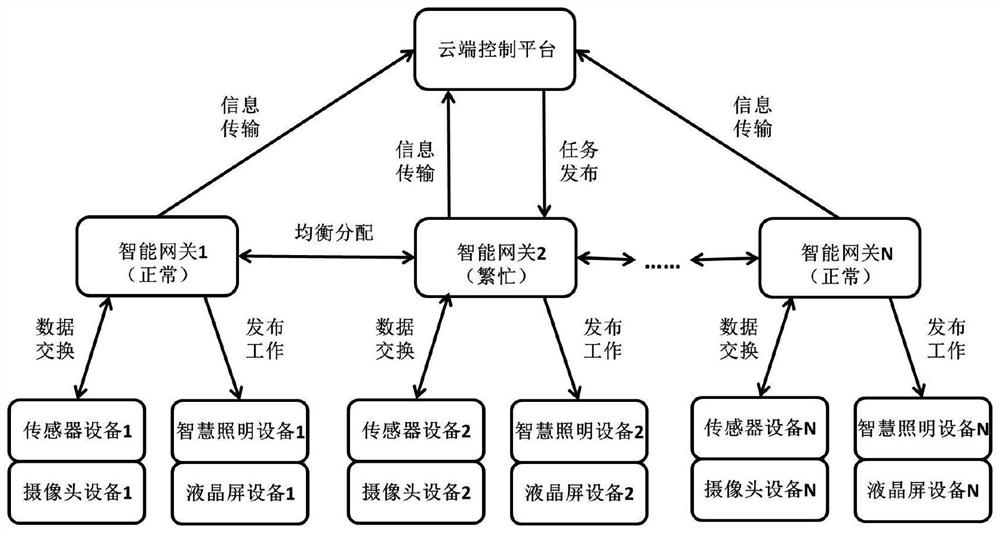

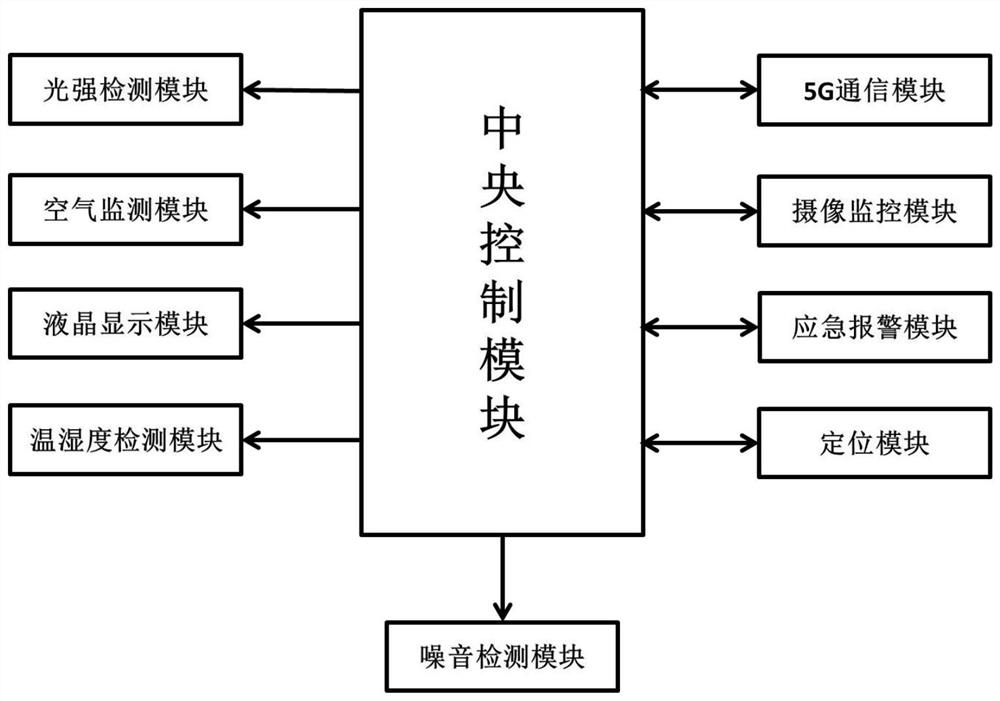

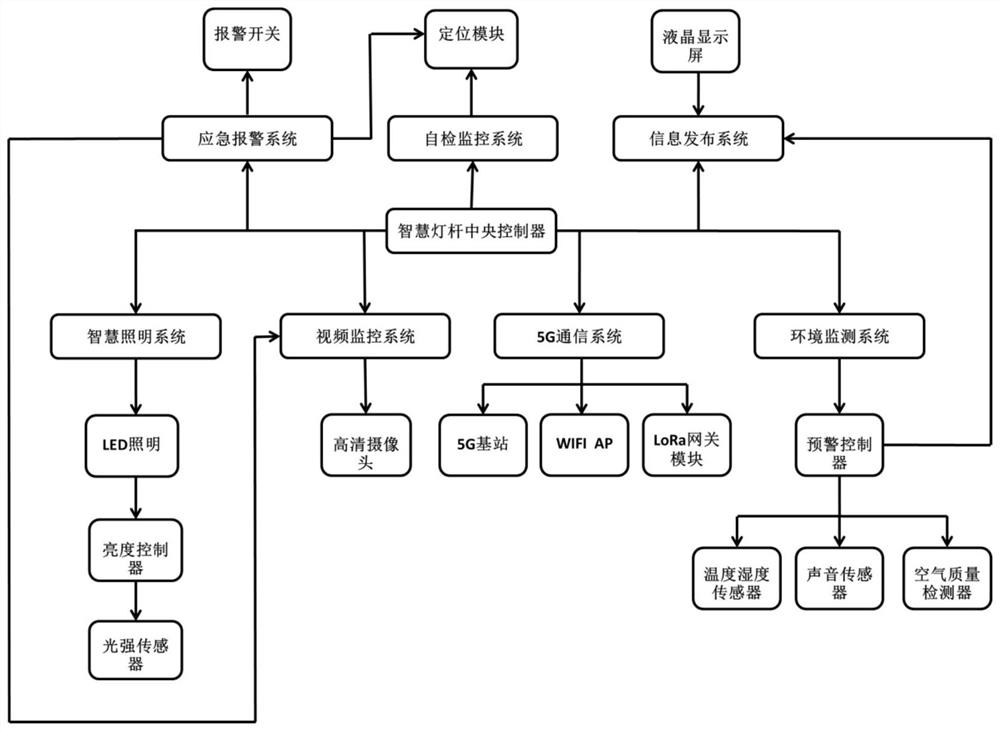

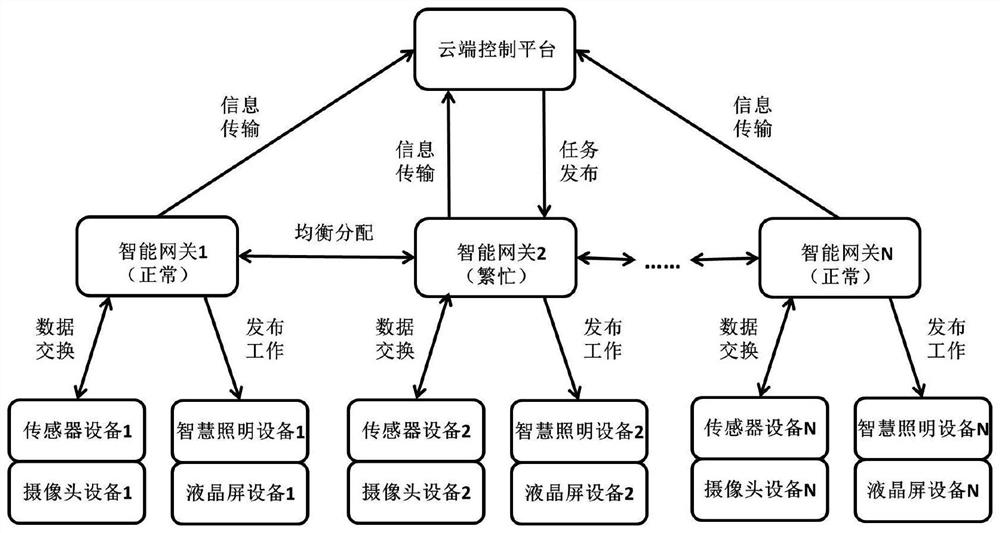

Intelligent lamp post integration device for 5G application and implementation method

ActiveCN112540557AImprove balanced allocation and scheduling capabilitiesEnsure smooth operationProgramme controlMeasurement devicesPhysicsLiquid-crystal display

The invention discloses an intelligent lamp post integration device for 5G application and an implementation method. The device comprises a central control module, a light intensity detection module,a 5G communication module, an air detection module, a camera monitoring module, a liquid crystal display module, an emergency alarm module, a temperature and humidity detection module, a noise detection module and a positioning module. The street lamp light control method based on fog computing is realized through 5G communication and a networking technology based on LoRa. According to the streetlamp light control method, some data processing does not need to be accessed to the Internet, so that the data processing time is shortened, and the cloud load is reduced. According to the light control method of the system, the light control model based on the regional position data does not depend on single lamp data for control, single lamps are associated but nearby data clusters, auxiliary calibration management is carried out through data of nearby street lamps, smooth operation of the whole network is guaranteed, and the whole system cannot be affected even if a single sensor breaks down. The problem of obtaining adjacent position points is solved.

Owner:HANGZHOU DIANZI UNIV

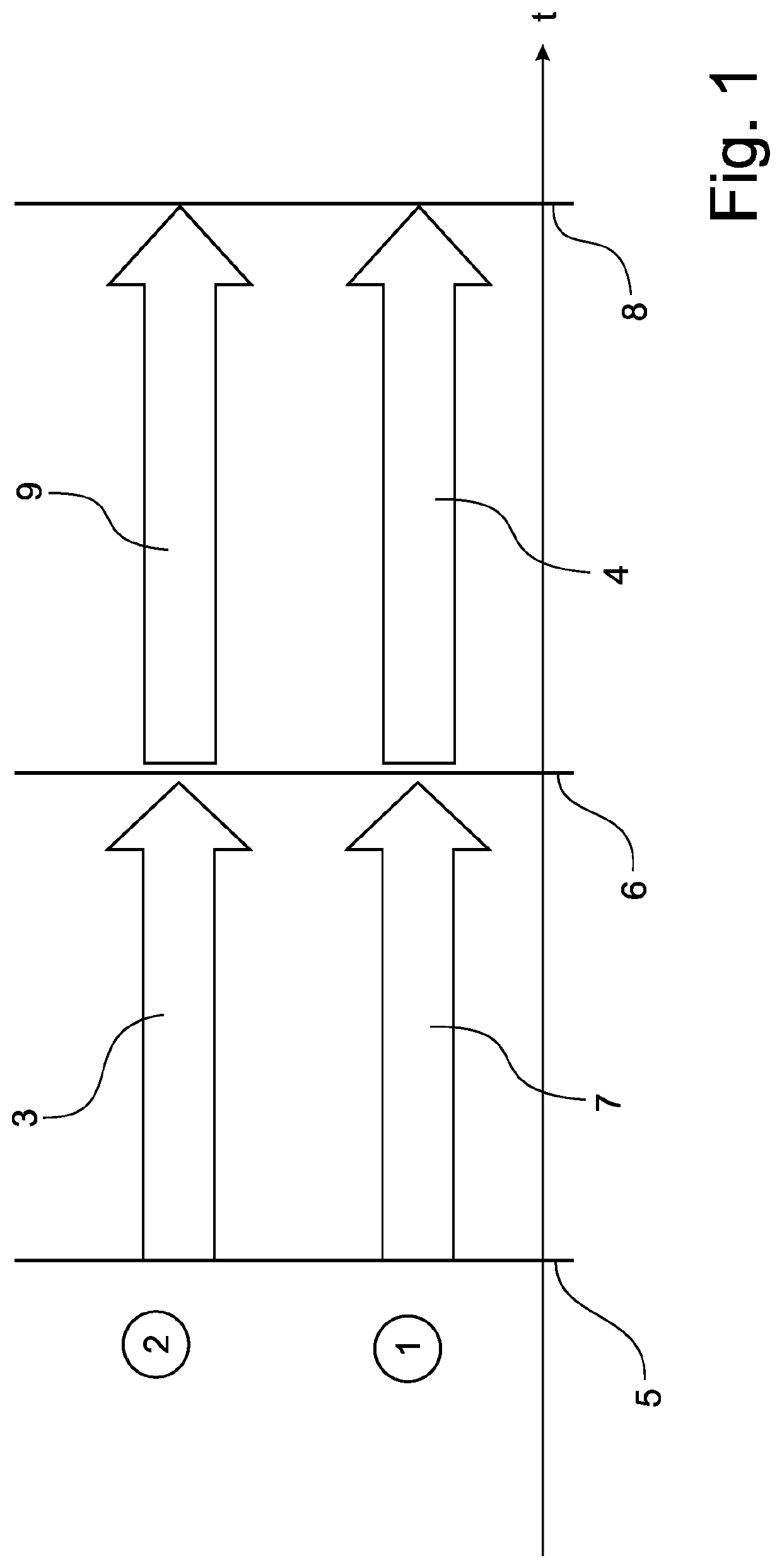

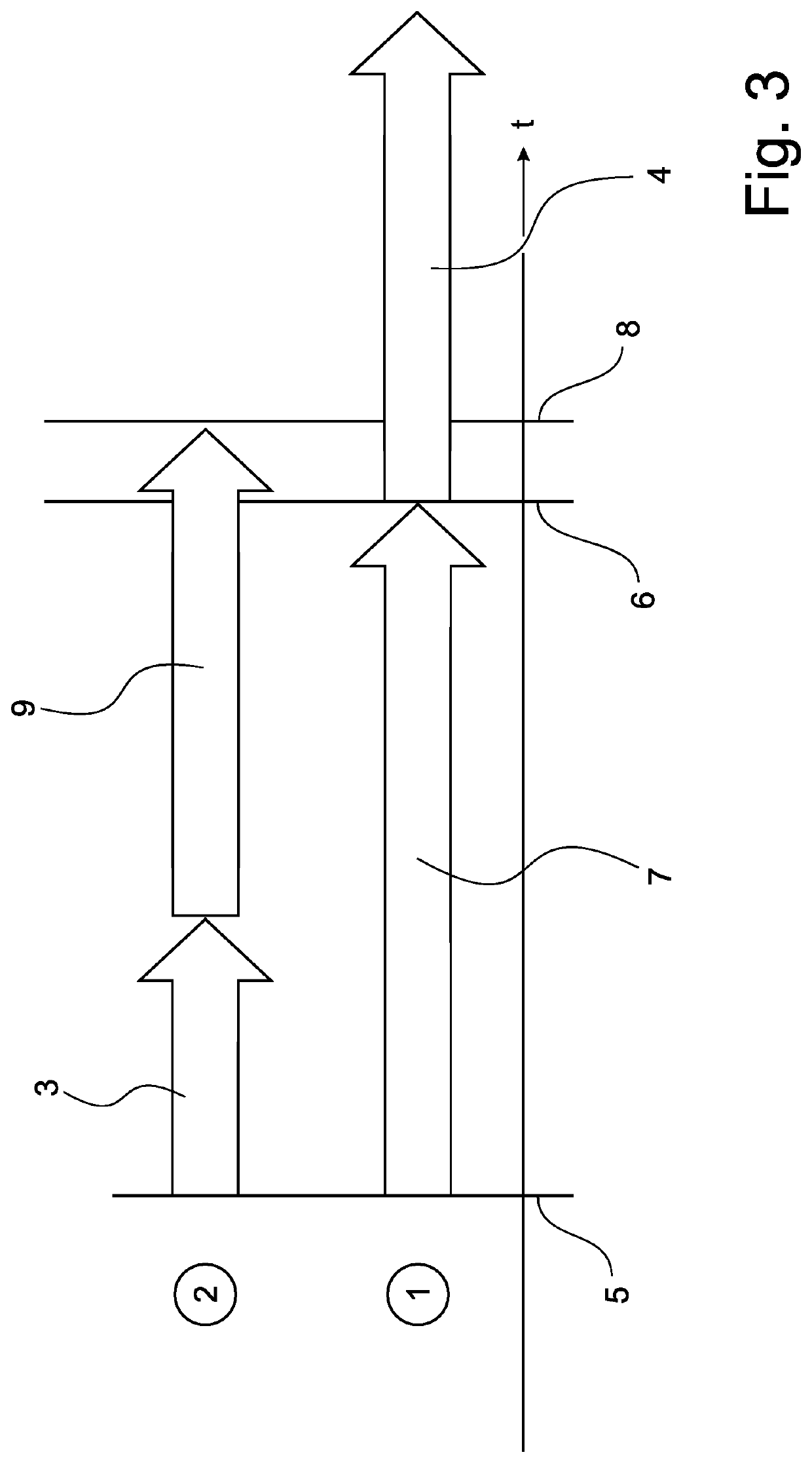

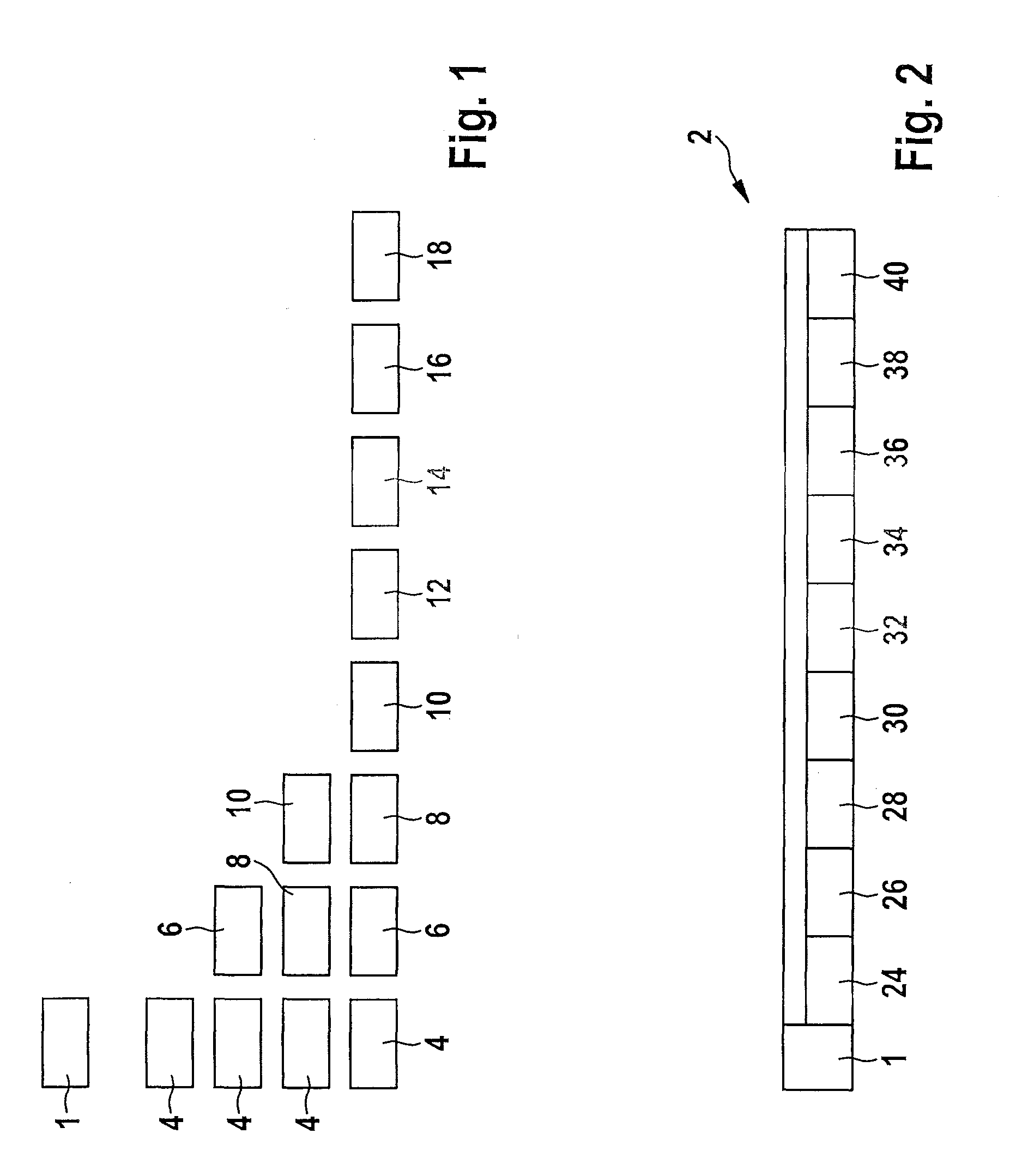

Method for starting an operating system

InactiveUS20190361710A1Avoid idle timeAvoid waiting timeMemory architecture accessing/allocationBootstrappingData processing systemParallel computing

A method for starting an operating system includes transferring, in response to starting an operating system in a data processing system, a first memory image that corresponds to a bootable storage medium to a working memory of the data processing system during a transfer of data. The method also includes processing, by a processor of the data processing system, instructions associated with the first memory image during a command execution process. The method also includes starting, by the processor, the command execution process for the instructions associated with the first memory image before transfer of the first memory image by the data transfer to the working memory of the data processing system is completed.

Owner:VISTEON GLOBAL TECH INC

Method and welding device for the evaluation of the welding current intensity during the welding of container bodies

ActiveUS8278583B2Manipulation errorIdle times of the production line are avoidedWelding/cutting auxillary devicesElectrode supporting devicesSeam weldingUltimate tensile strength

In order to evaluate the welding current for the resistance seam welding of an overlap seam of container bodies, a welding with changing welding current intensity is carried out for a container body of the production series, resulting in a changing welding of the seam, ranging from the welding with a too high temperature to the welding with a too low temperature. The electric energy for this welding is determined several times during this welding and / or the temperature of the weld seam is determined several times and the welding current intensity is determined at which the welding of the individual container body is too cold and the welding current intensity at which the welding is too hot. This determination is based on the determined electric energy values and / or on the determined temperature values and based on this determination a preferred range for the welding current intensity within these limits of too hot and too cold is determined. By this, an evaluation if the welding current intensity is correct may take place in a simple way during the production. After the welding of the individual container bodies a changed welding current intensity lying between the welding current intensity of the too hot and of the too cold welding may optionally be set and used for the following series of container bodies of the production series.

Owner:SOUDRONIC

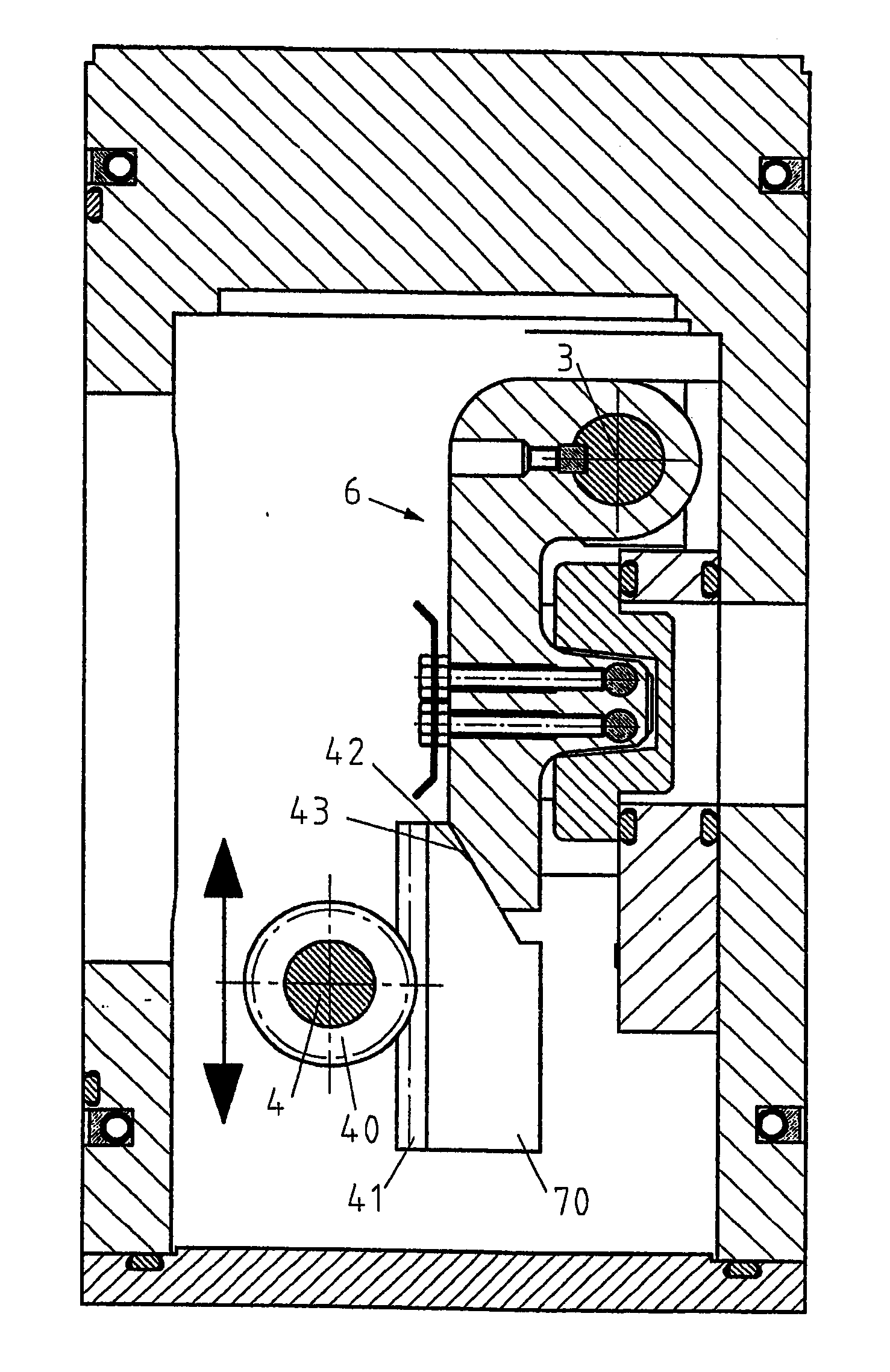

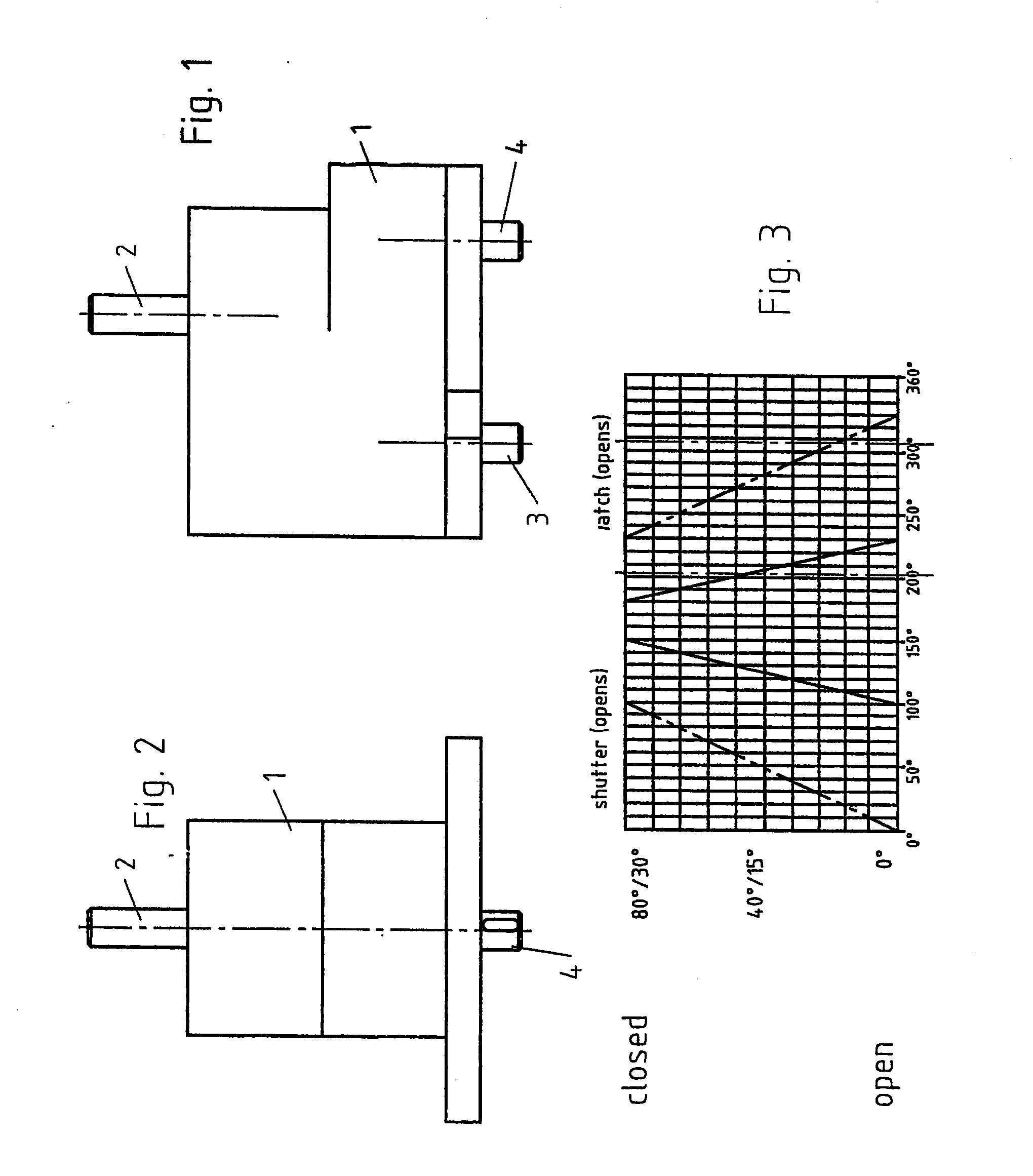

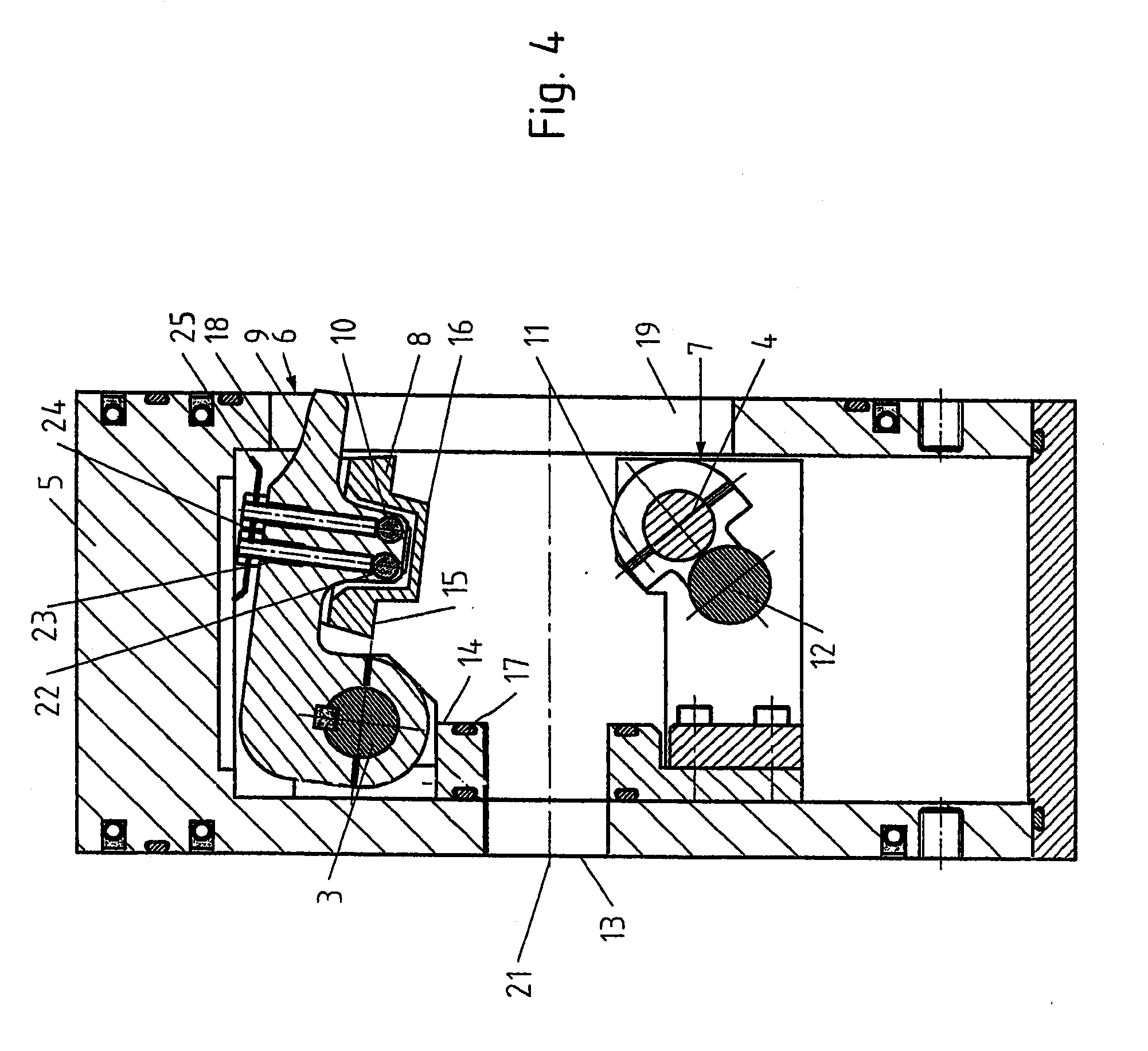

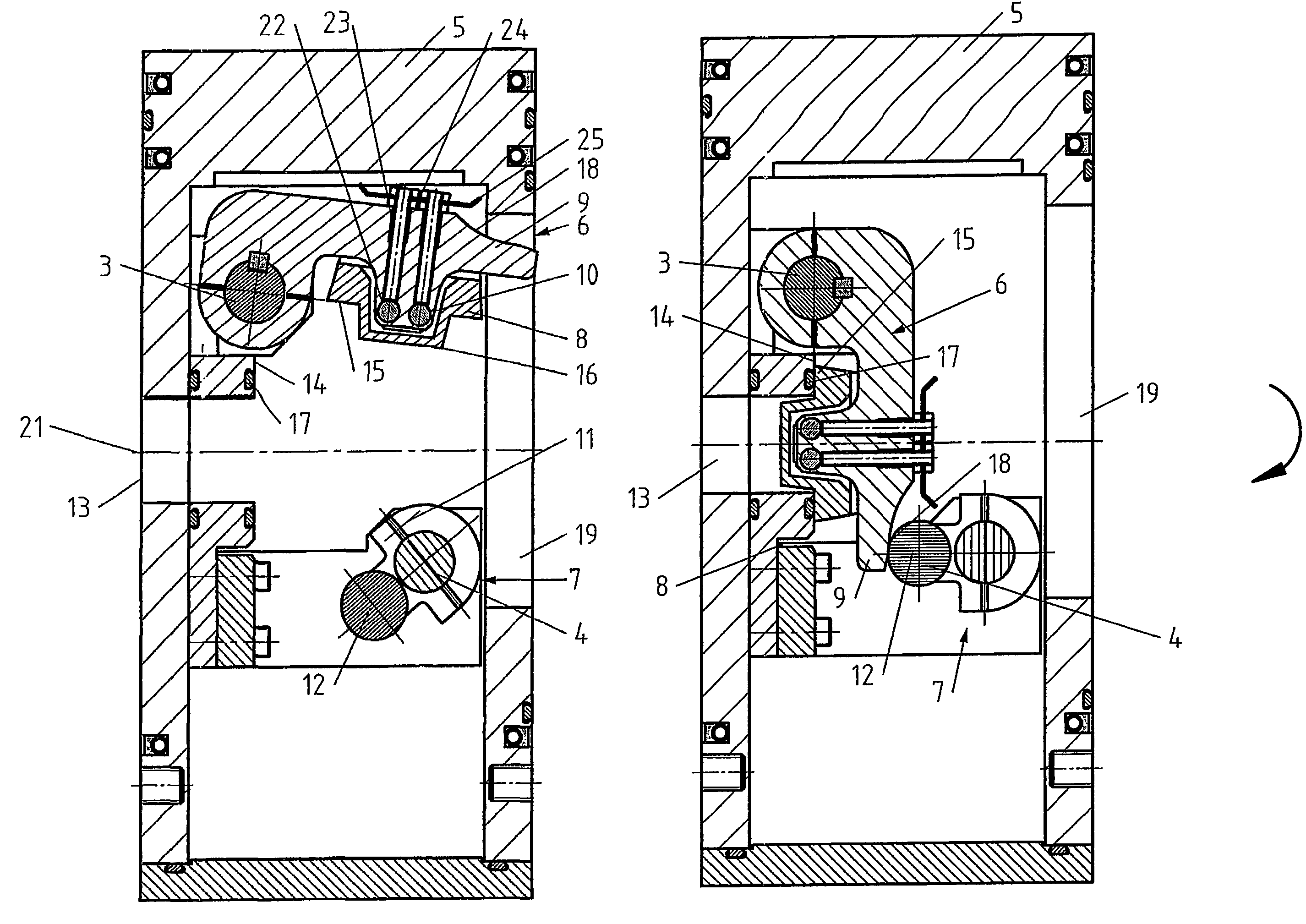

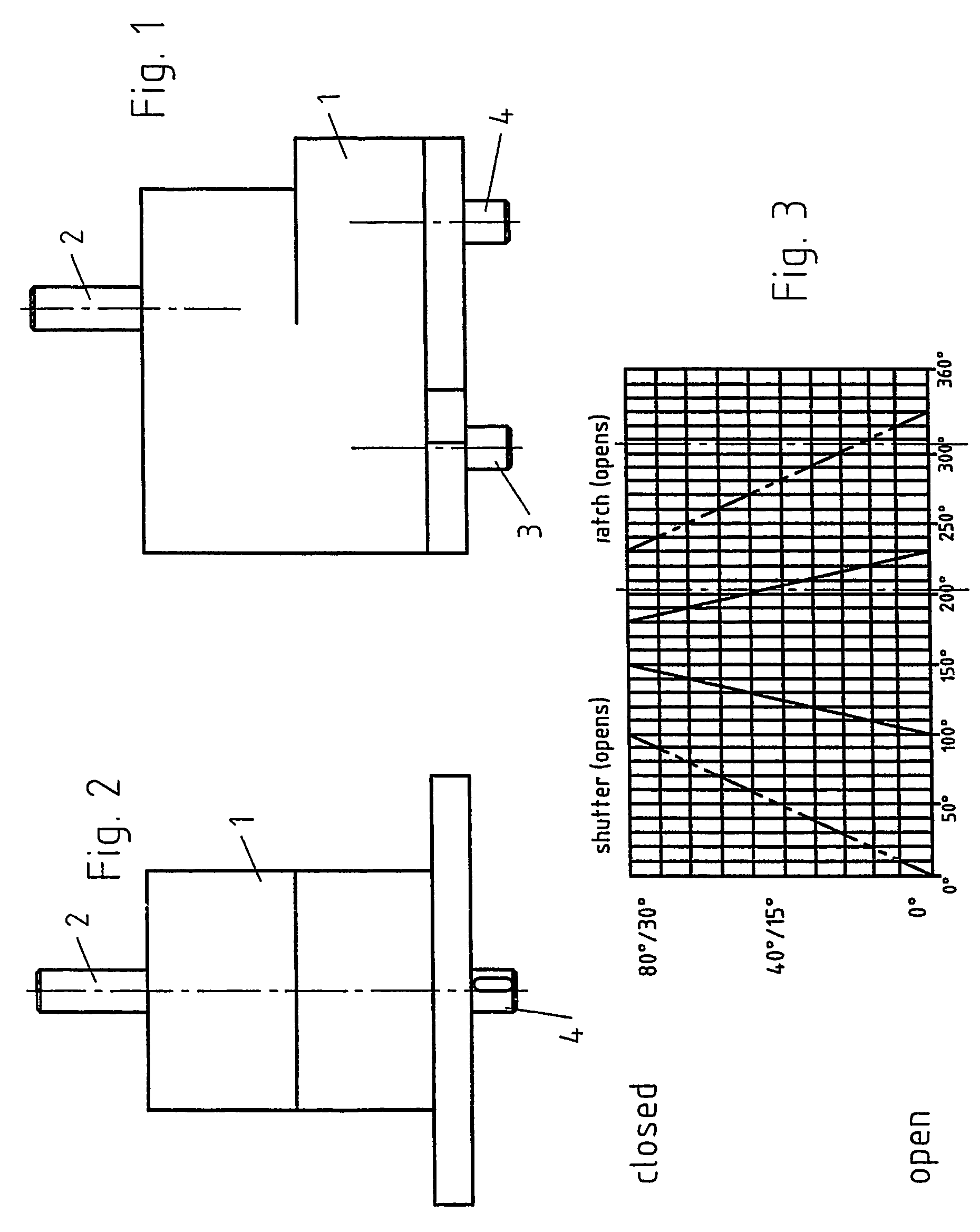

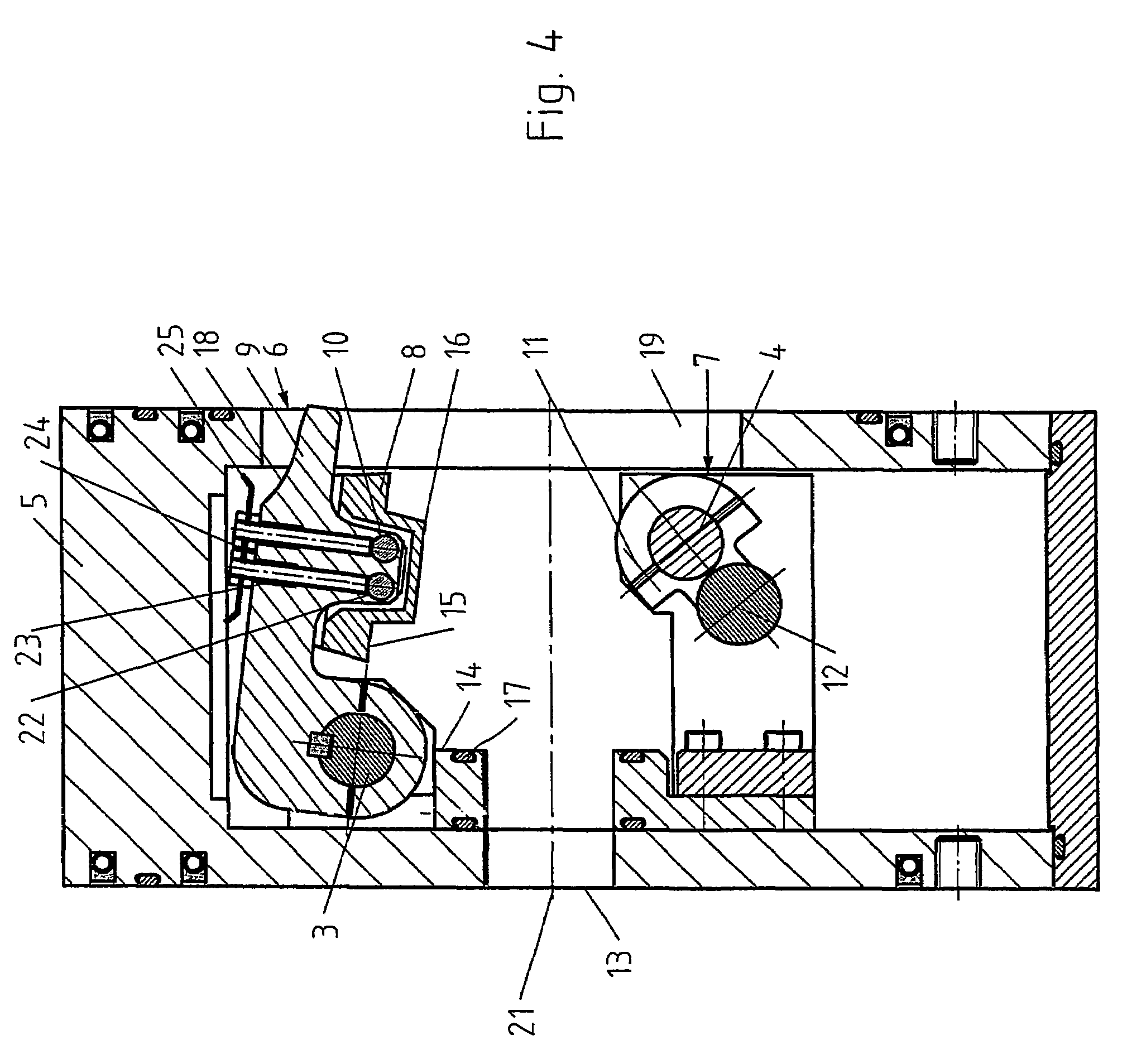

Coating plant with a charging lock and device therefor

InactiveUS20080086948A1Quick closureOpen fastMan-operated mechanismVacuum evaporation coatingWindow shutterEngineering

The present invention relates to a coating plant, especially a vacuum coating plant, with a charging lock, especially a rectangular vacuum lock for a coating chamber, with a lock aperture (13) having a length of at least 1000 mm that comprises a shutter (6) for closing and opening the lock aperture and a latch (7) to secure the shutter, wherein there are provided means for moving the shutter and the latch from a first open position to a second closed position, and vice versa, these means assuring also that the movements of the shutter (6) and the latch (7) will be coupled with each other in such manner that the shutter (6) will be automatically secured by the latch (7) after the shutter has been closed and will be released again before it is opened.

Owner:SCHUSSLER UWE +2

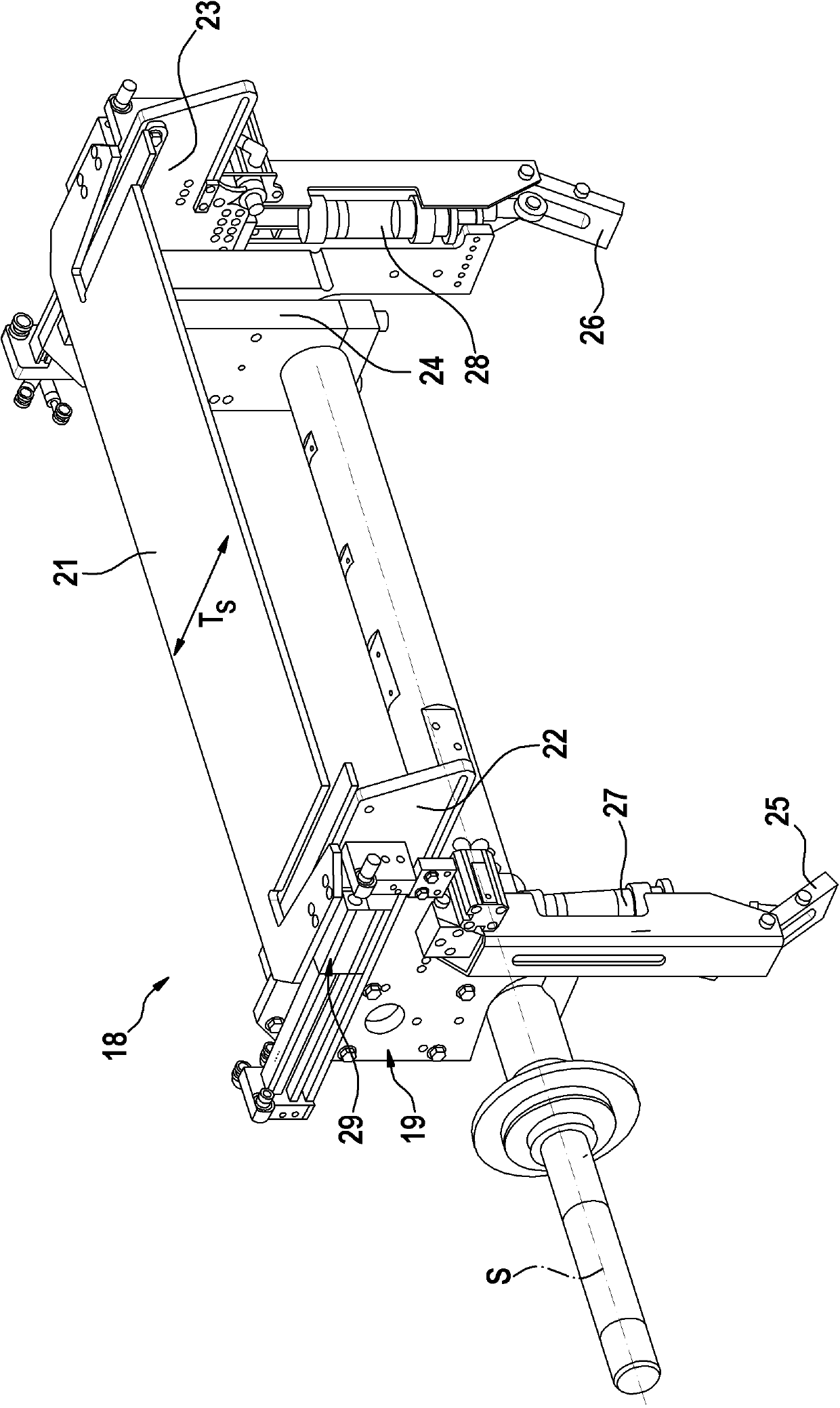

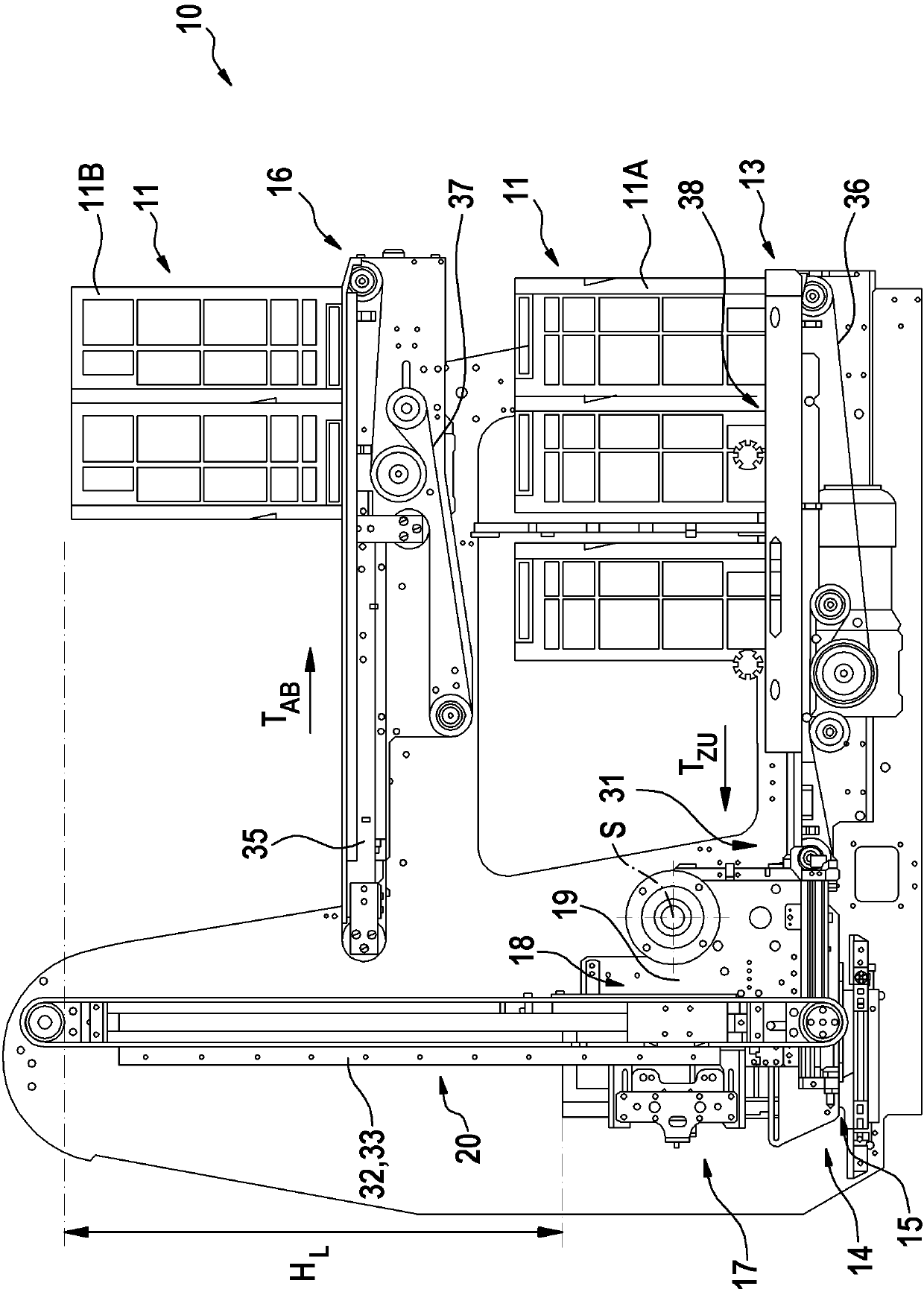

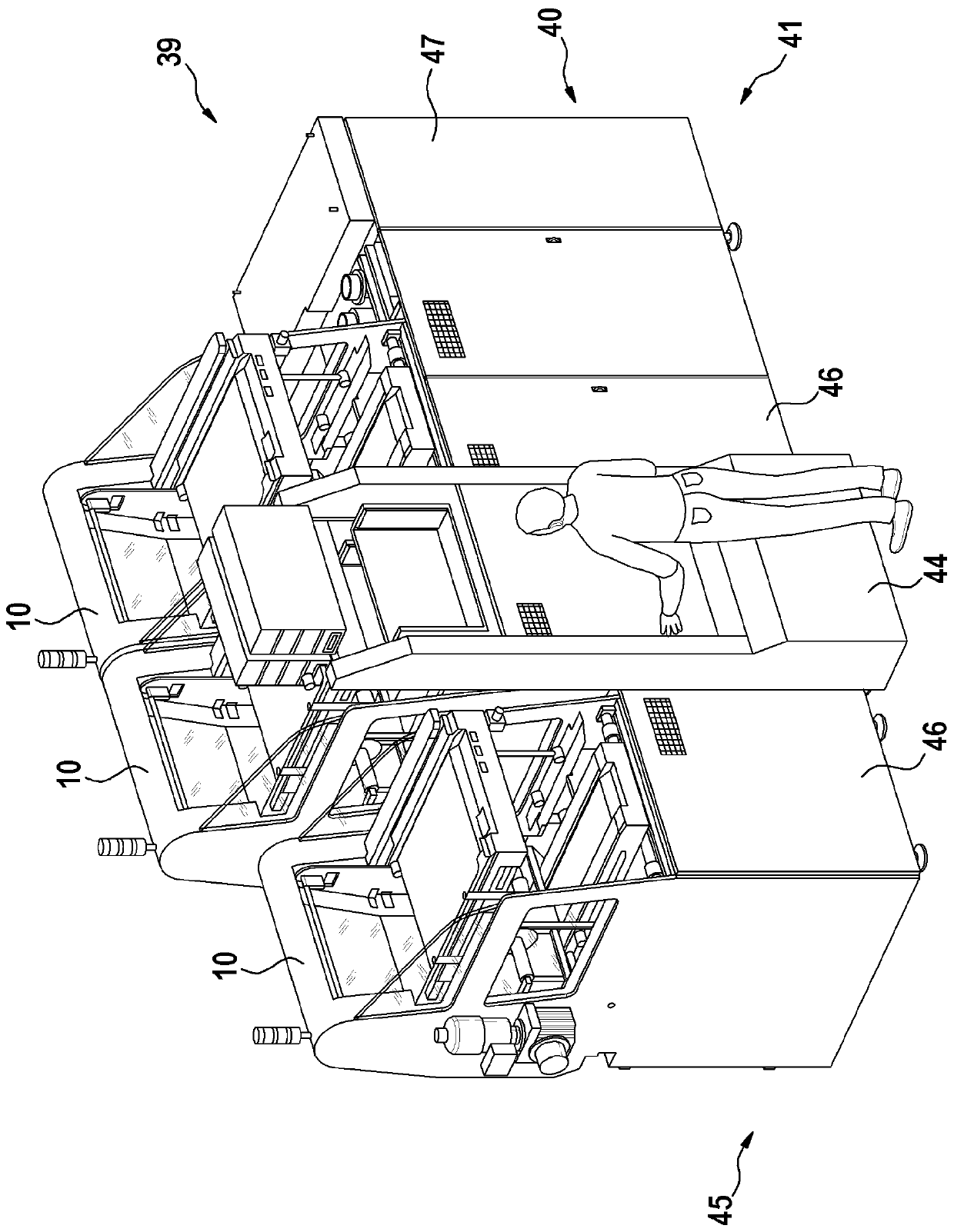

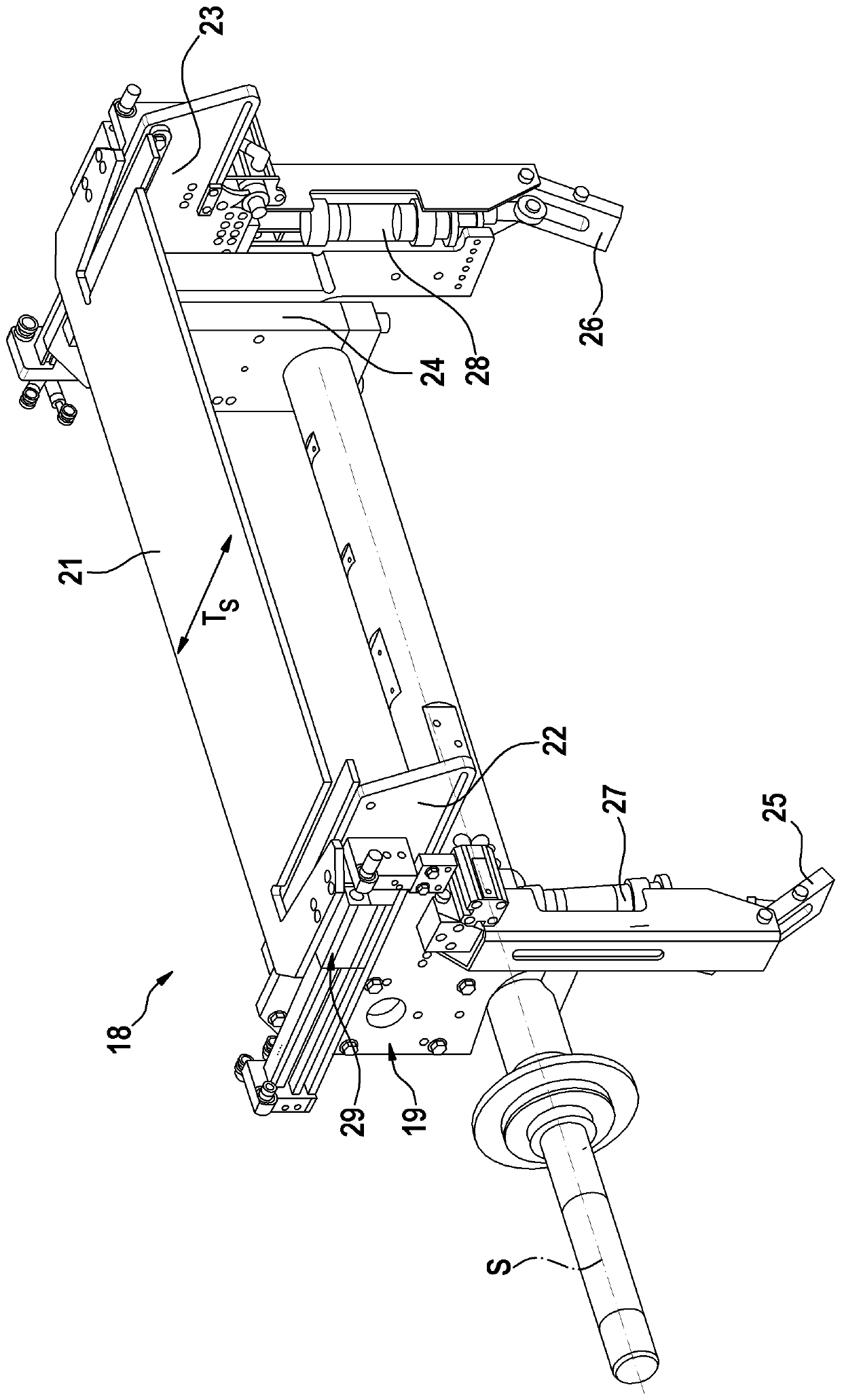

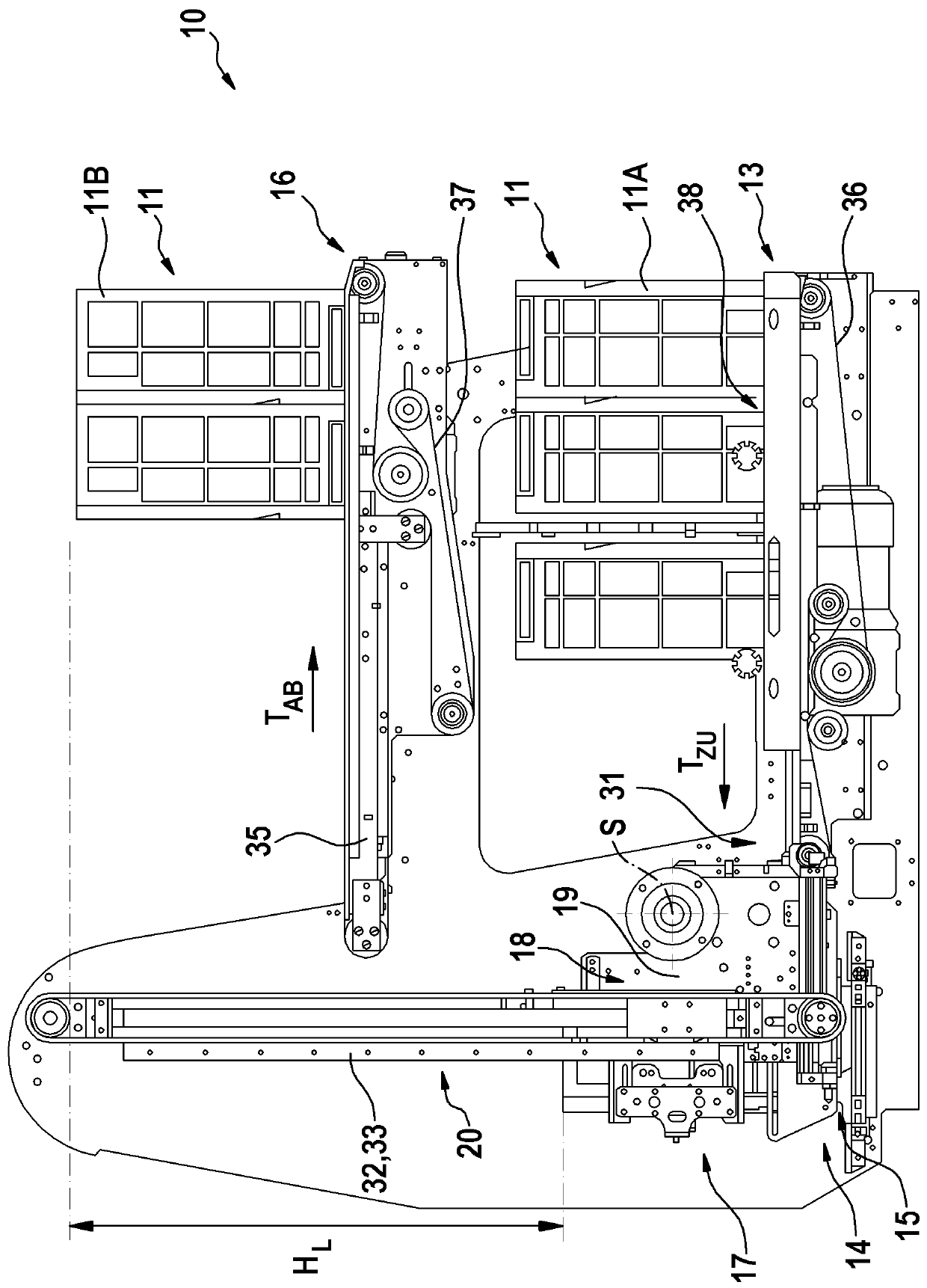

Chute Unloading Device And Method For Automatically Unloading Chutes And Production Assembly

ActiveCN103960777AEasy to transportReduce deliveryCigarette manufactureTobacco smoke filtersEngineeringMulti segment

The device has a feeding device for feeding filled articles and an upwardly open full tray in transport direction. A transport unit for transporting empty trays in transport direction, is arranged above feeding device. A transfer devicehas a pivot mechanism whose pivot motion is limited to 180 DEG about fixed pivot axis, a pivoting swivel cassette for fixing, panning and releasing full tray independently from the pivot mechanism and an acting lift device for fixing, linear processing and sharing empty trays. Independent claims are included for the following: a production arrangement; and a method for automatic emptying of containers with articles-filled trays in multi-segment filter manufacturing machine.

Owner:KOERBER TECH GMBH

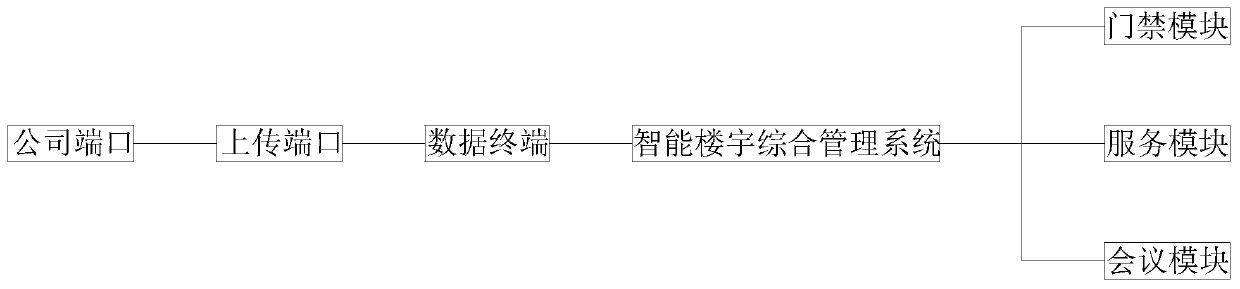

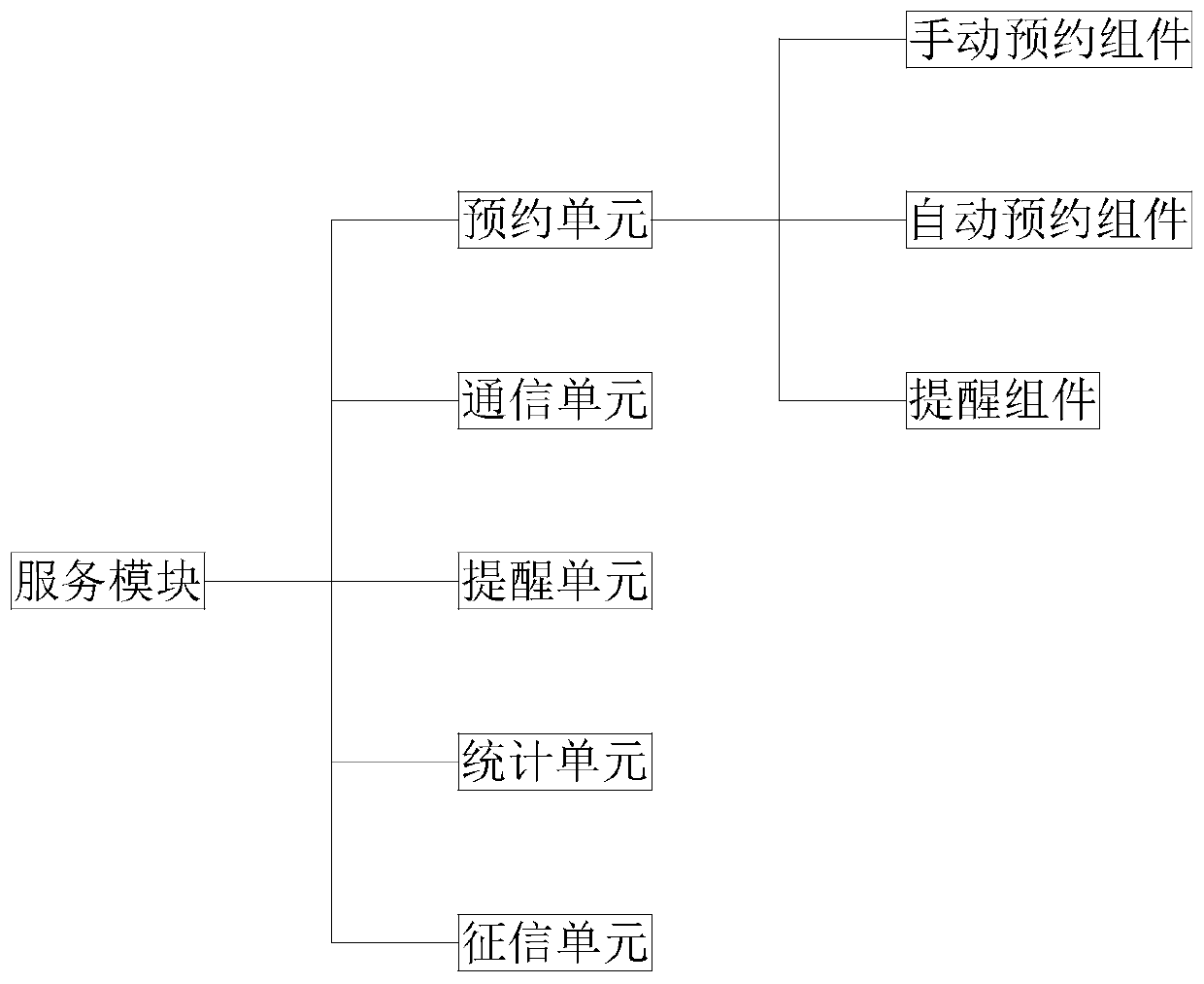

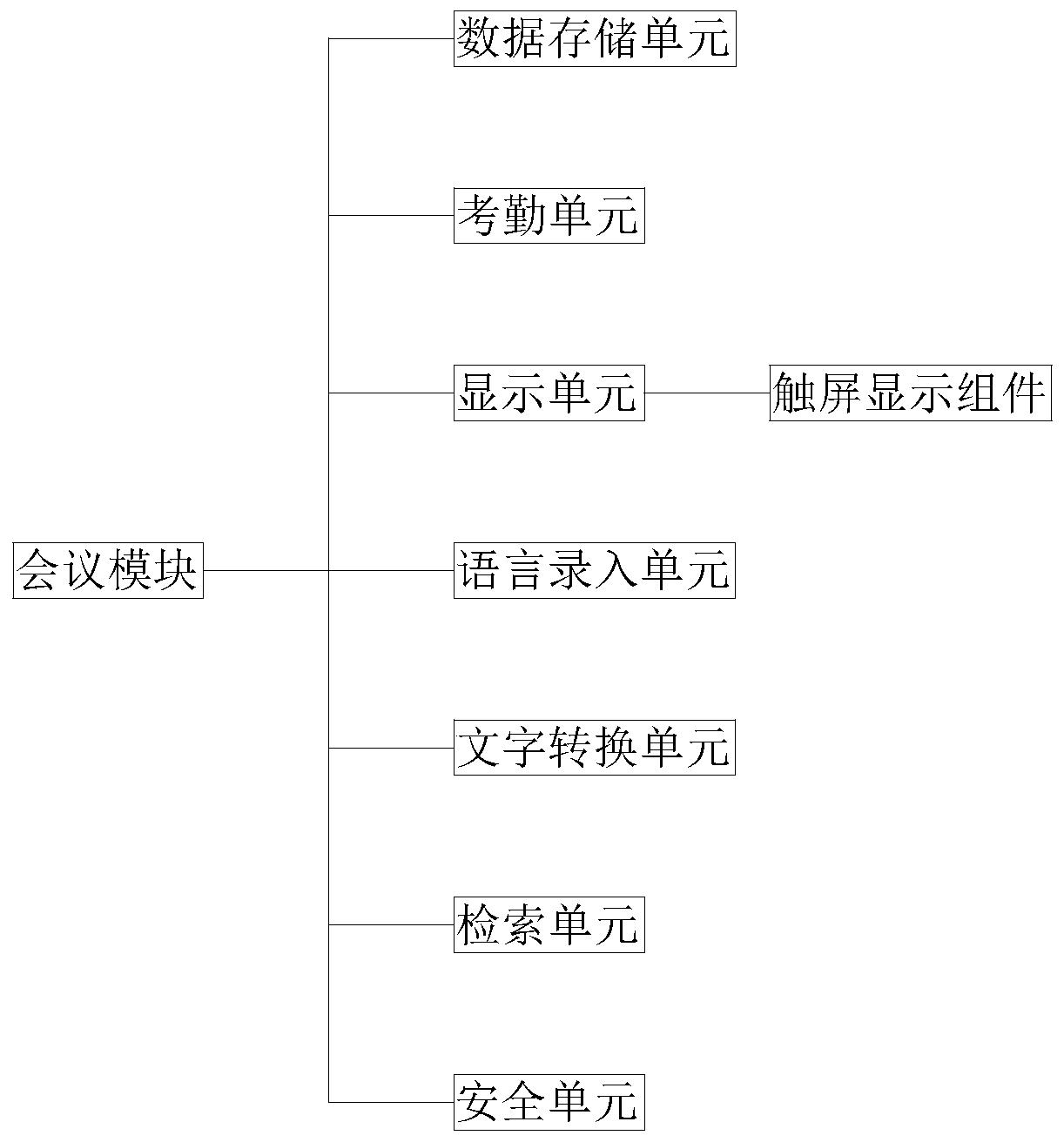

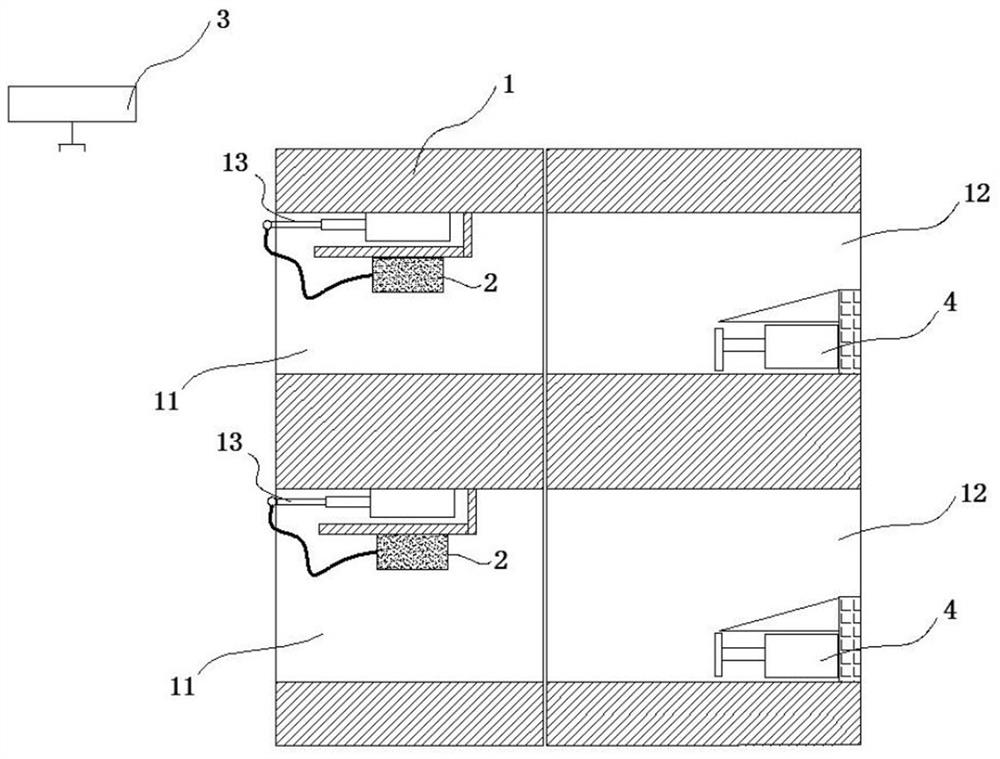

Intelligent building integrated management system based on mobile internet

PendingCN110033107AImprove securityAffect the progressRegistering/indicating time of eventsReservationsIntelligent lightingData terminal

The invention relates to the field of intelligent building management, in particular to an intelligent building integrated management system based on a mobile internet. The system comprises an accesscontrol module, a service module, a conference module, a data terminal and an uploading port, the service module comprises a reservation unit, a communication unit, a reminding unit, a statistics unitand a credit investigation unit, the appointment unit comprises a manual appointment assembly, an automatic appointment assembly and a reminding assembly, and the access control module, the service module, the conference module, the data terminal and the uploading port are matched with one another. When the authority is not obtained, other companies are prevented from entering the conference roomto influence the proceeding of the company conference in the conference room, so that the smooth proceeding of the company conference in the conference room is ensured, and the company conference content leakage caused by the fact that companies of the same type watch the conference content of the company in the conference room is prevented, and accordingly the security of the conference room isimproved.

Owner:合肥安知信息科技有限公司

Hard disk apparatus, medium, and collection of information

InactiveUS7321721B2Increase the amount of dataAvoid idle timeTelevision system detailsDisc-shaped record carriersReproduction speedExecution unit

Alternation processes reduce the recording and reproducing speed of a hard disk apparatus.A hard disk apparatus comprising: an HDD 10 for recording AV data onto a hard disk; and stream controlling means 8 which is connected to the HDD 10 and thereby processes the signal of AV data transmitted from an IEEE1394 I / F 7 or the signal of AV data transmitted to the IEEE1394 I / F 7; whereby the hard disk apparatus can record and / or reproduce the AV data, wherein when AV data transfer is not normally completed for a disk access unit which is a minimum continuous unit in the access to the hard disk, an alternation process on a disk access unit basis is carried out so that another disk access unit is used hereafter in place of that disk access unit.

Owner:PANASONIC CORP

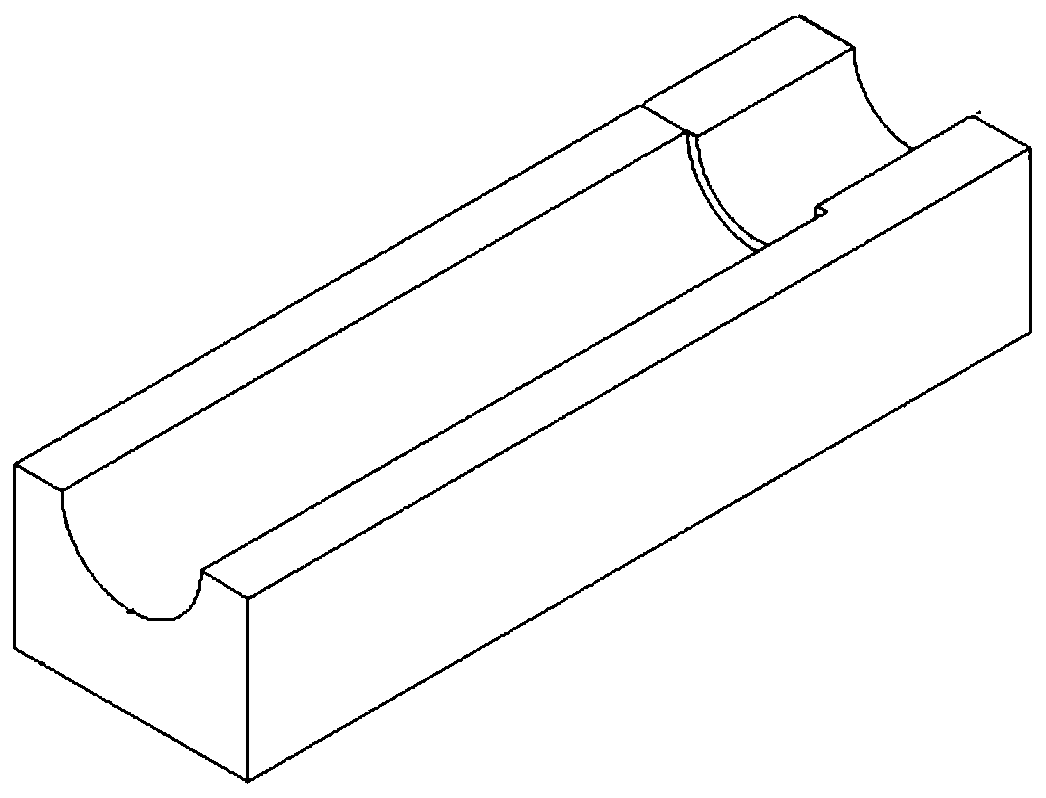

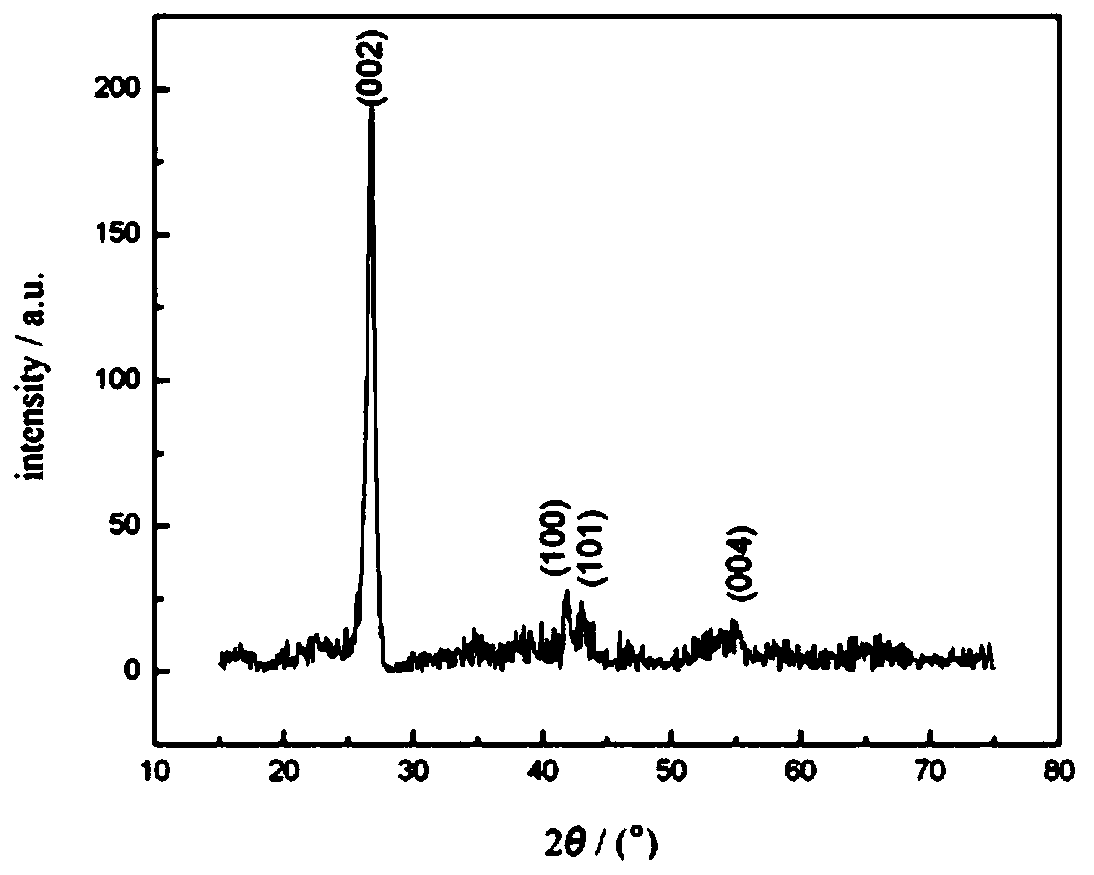

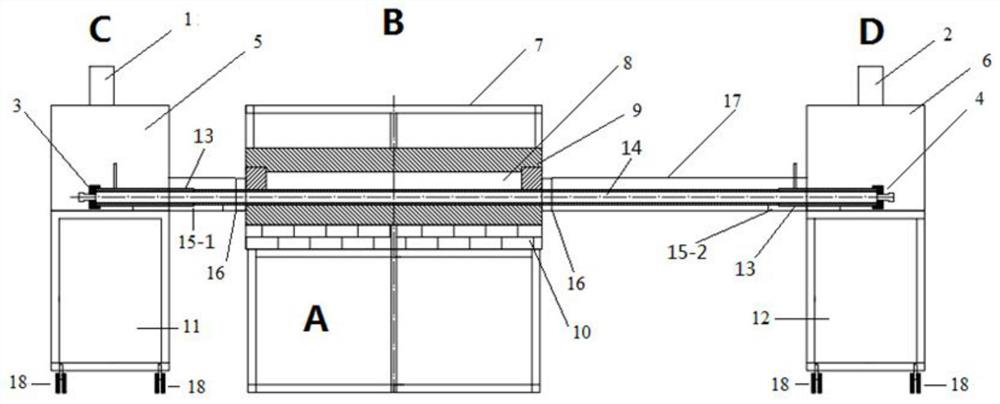

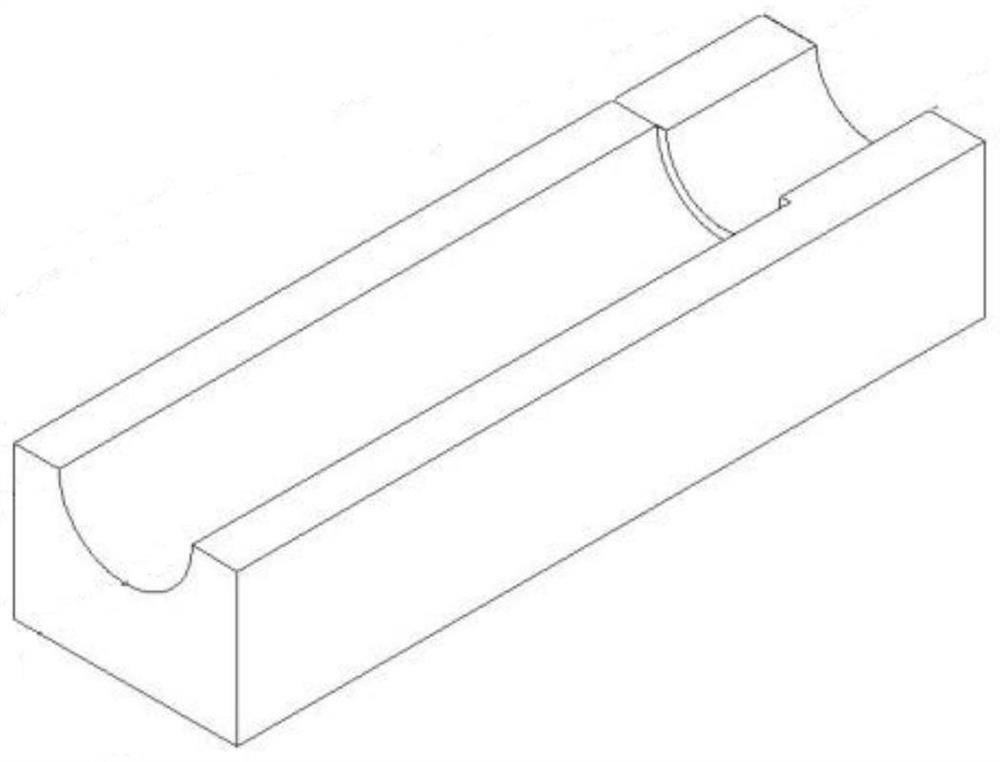

Push-boat-type semi-continuous boron nitride nanotube preparation furnace and application method thereof

ActiveCN109809374AEasy to operateRich and diverse product structureNitrogen compoundsBoron nitride nanotubeContinuous production

The invention relates to a push-boat-type semi-continuous boron nitride nanotube preparation furnace and an application method thereof. The set of device comprises an electric temperature control heating device A, a furnace body B, a furnace head C and a furnace tail D, wherein the electric temperature control heating device A is used for adjusting and controlling the temperature of the furnace body B, hearth in the furnace body B is communicated with the furnace head C and the furnace tail D at the two sides via furnace tubes, and circulation water trays for cooling are arranged on the outersurfaces of the furnace tubes. Raw materials are reacted with ammonia gas in the hearth in the furnace body B, and then transferred to the furnace tubes between the furnace body B and the furnace tailD for cooling, while the next batch of raw materials are conveyed to the hearth for reaction, and the cooled products are taken out from the furnace tail D, thereby achieving continuous production. The push-boat-type semi-continuous boron nitride nanotube preparation furnace has the advantages of convenient operation, rich product structures, particular suitability for industrial production applications, and high safety and stability, and a large scale of BNNTs (Boron Nitride Nanotubes) of different structures can be continuously synthesized.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

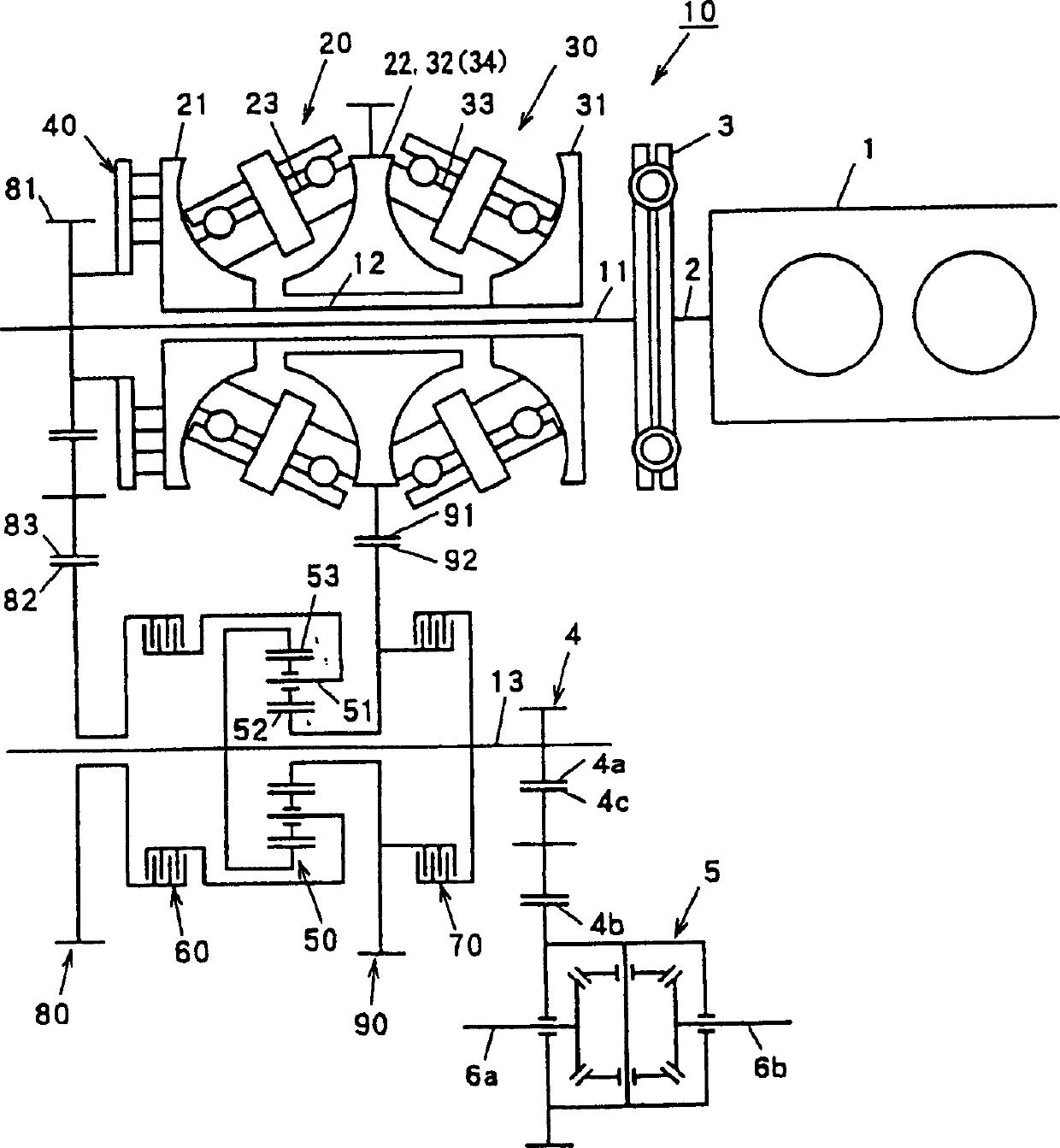

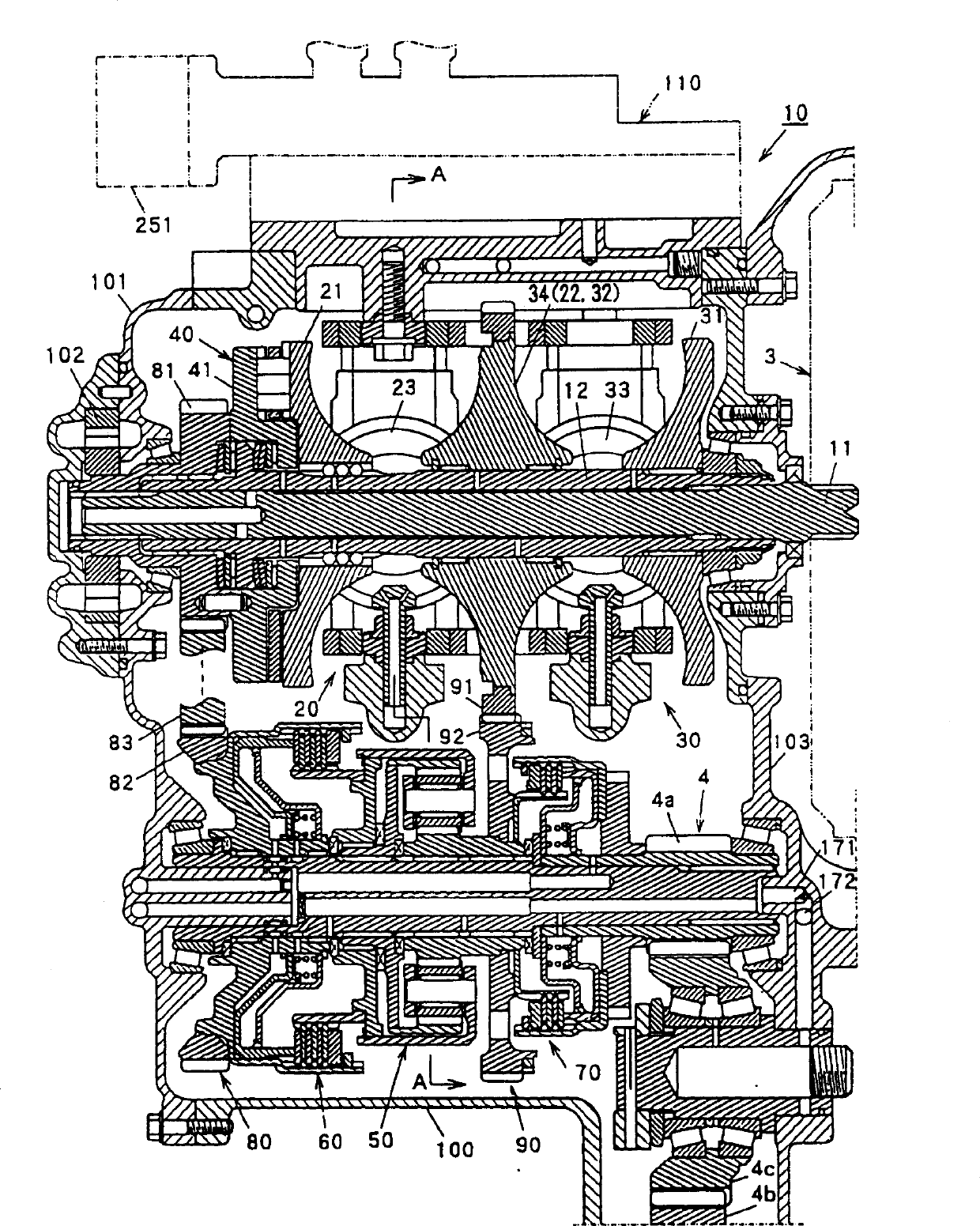

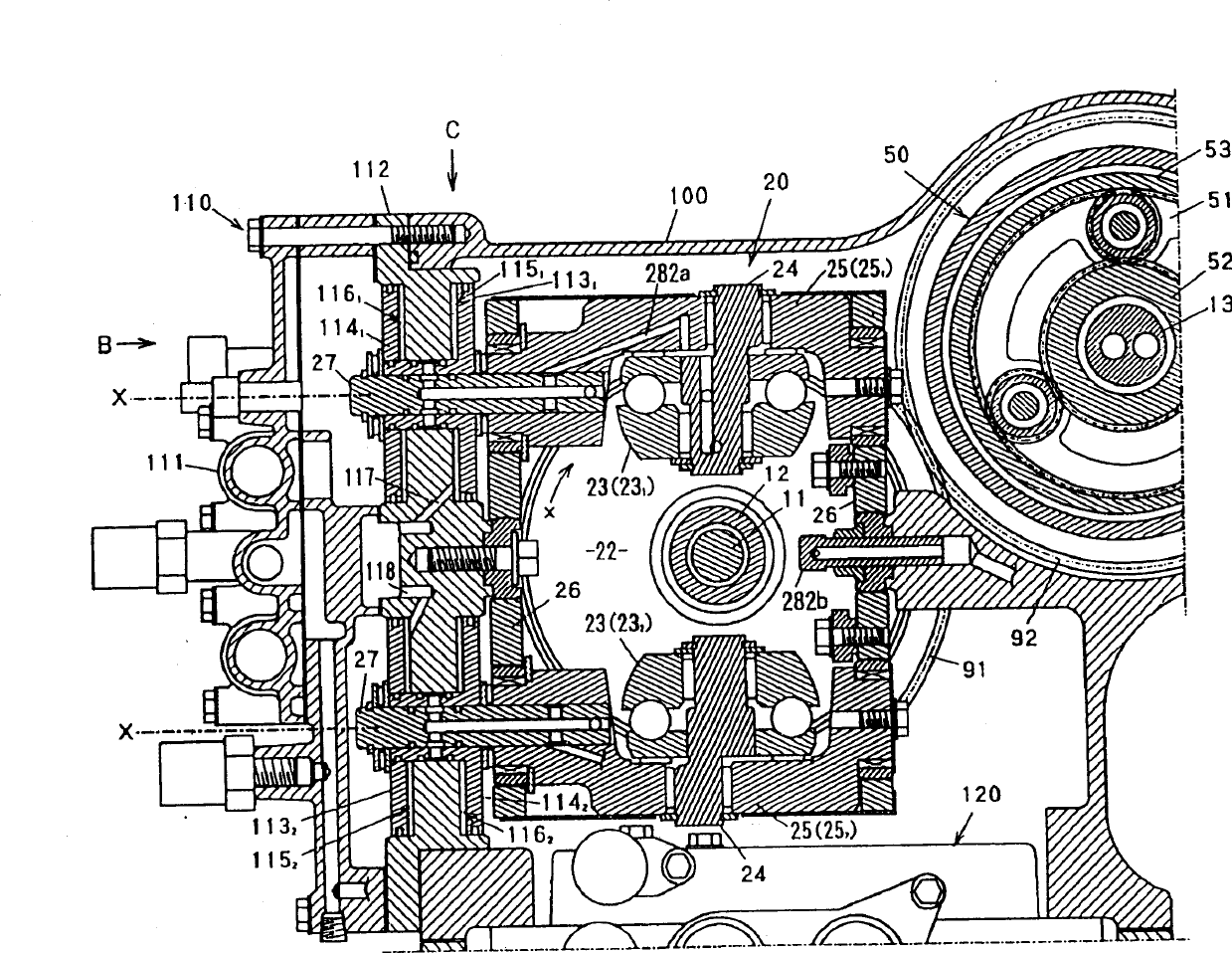

Toroidal continuously variable transmiision

InactiveCN1166878CAchieving an engaged neutral stateIncrease transmission speedGearing controlFriction gearingsEngineeringGear train

The object of the present invention is to provide compact toroidal type continuously variable transmission for a front engine front wheel drive vehicle, which employs geared neutral starting system. The toroidal type continuously variable transmission according to the present invention comprises an input shaft 11 whose one end is coupled with an engine, a primary shaft 12 into which said input shaft is fittingly inserted with play, a secondary shaft 13 which is disposed parallel with said shafts and whose engine side end is coupled with a differential gear unit 5, toroidal type continuously variable transmission mechanisms 20, 30 which are disposed on said primary shaft 12, a planetary gear mechanism 50 which is disposed on said secondary shaft 13, a low mode gear train 80 for coupling the input shaft 11 with a carrier 51 of the planetary gear mechanism 50, and a high mode gear train 90 for coupling a sun gear 52 with an output disk 34 of the continuously variable transmission mechanisms 20, 30, wherein said low mode gear train 80 is disposed on an opposite side end, with respect to the engine, of the input shaft 11.

Owner:MAZDA MOTOR CORP

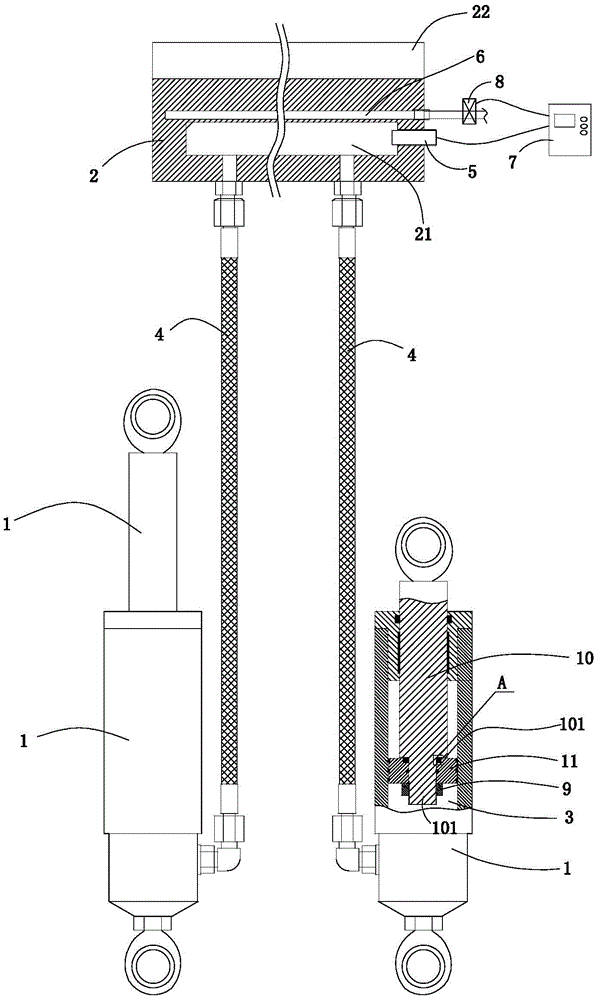

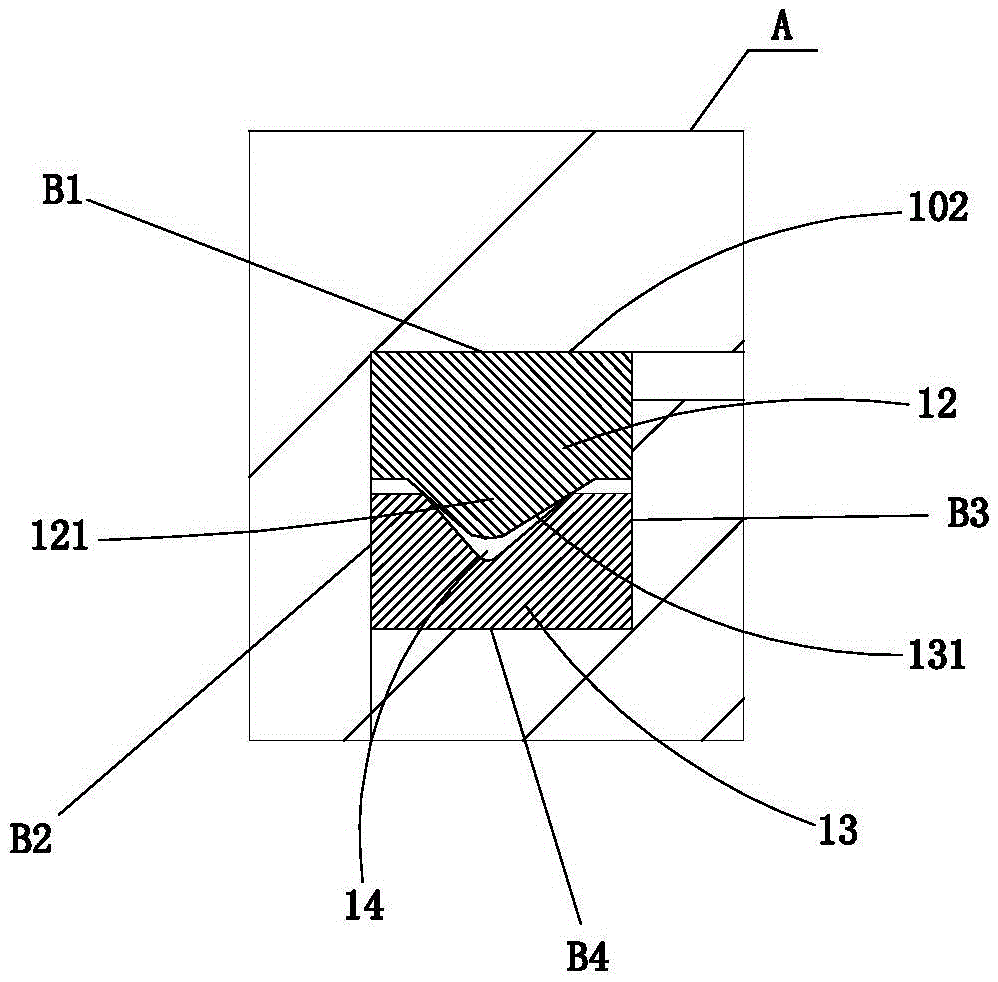

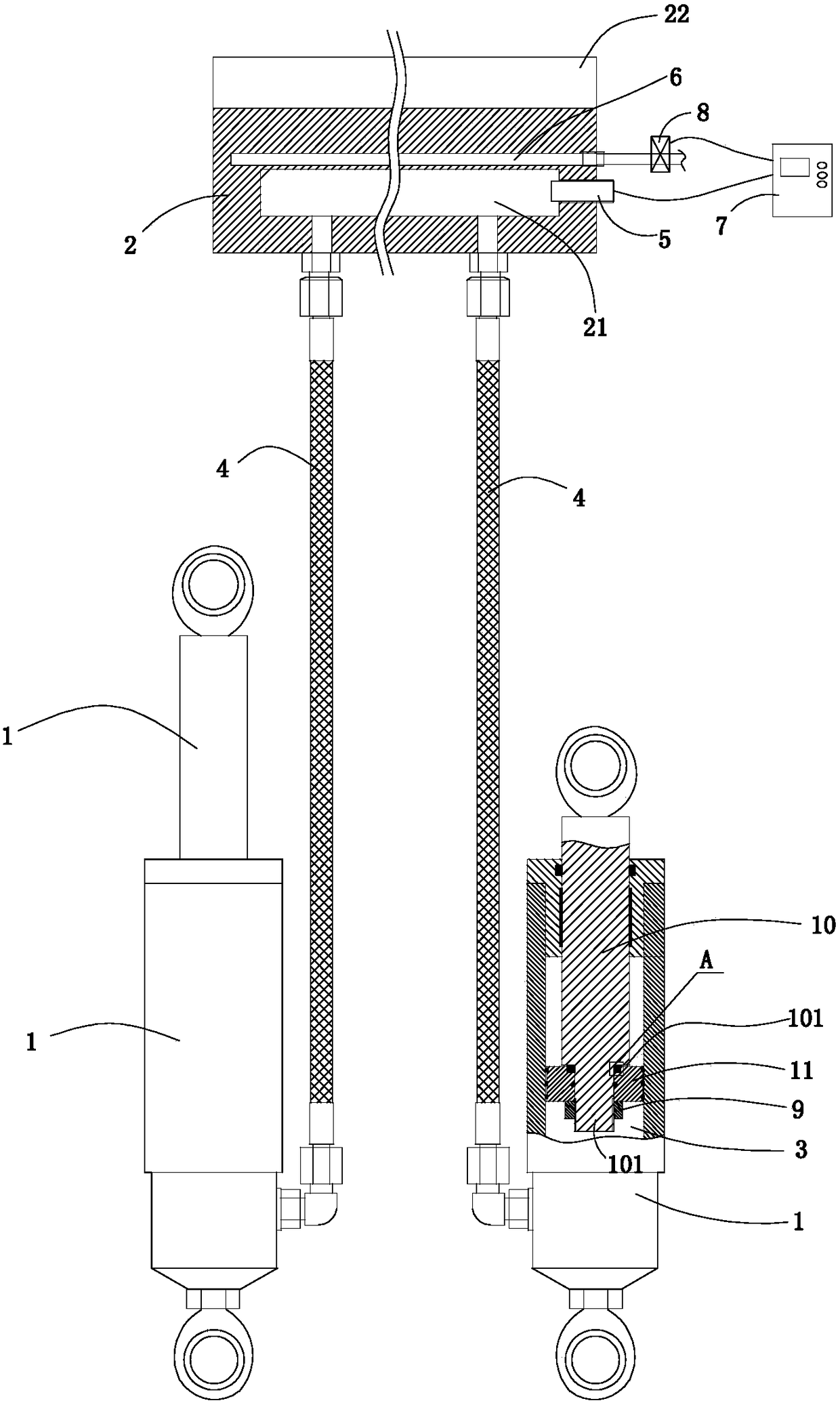

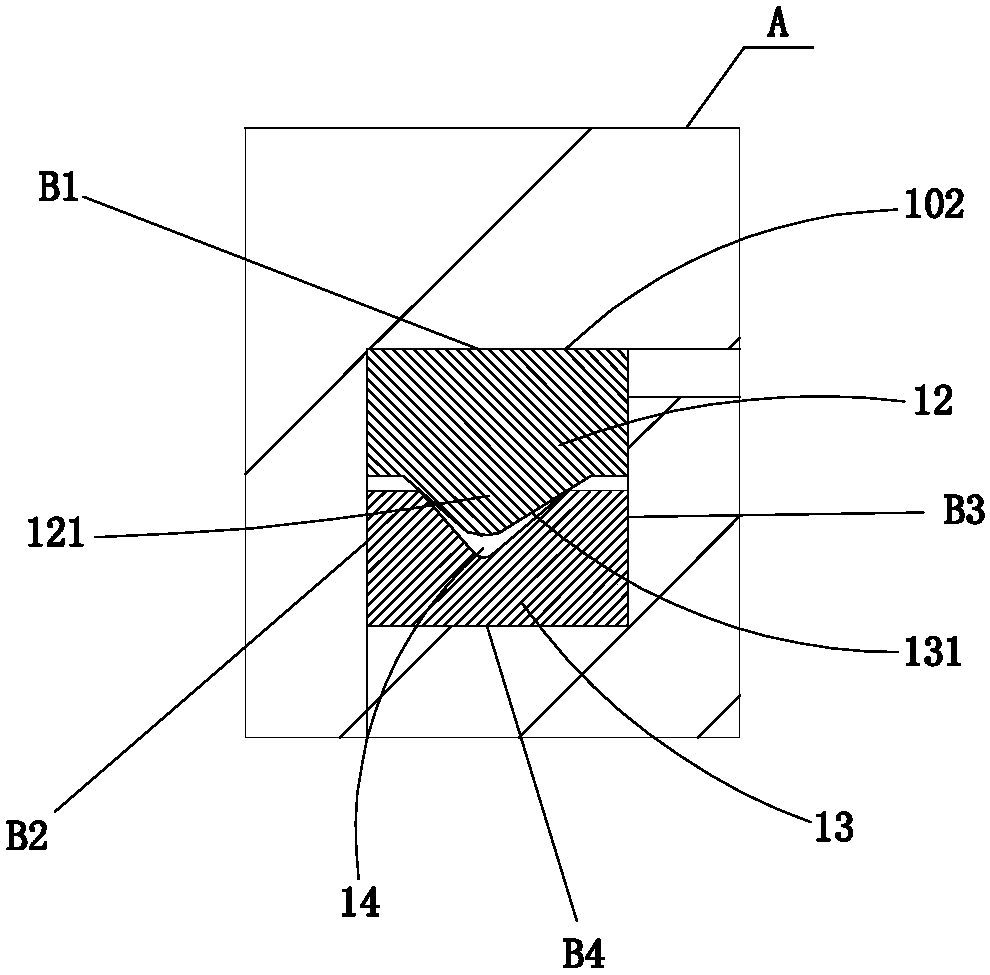

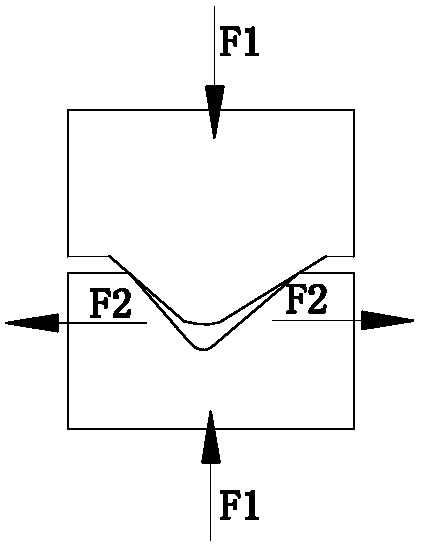

Oil cylinder device dissipating heat automatically

ActiveCN105673766AExtended service lifeDelay agingSpringsLiquid based dampersTemperature controlElectricity

The invention discloses an oil cylinder device dissipating heat automatically. The oil cylinder device dissipating heat automatically comprises two oil cylinders, a heat sink and a temperature control system, wherein each oil cylinder comprises an oil cavity arranged in the axial direction, a piston rod assembly movably arranged in the oil cavity in the axial direction, and an oil delivery tube communicating with the oil cavity; the heat sink is provided with a caching cavity; the oil cavities of the two oil cylinders communicate with the caching cavity through the oil delivery tubes; the temperature control system is used for regulating temperature of hydraulic oil, and comprises a temperature sensor, a refrigerating unit and a temperature controller; the temperature sensor is used for monitoring the temperature of the hydraulic oil; the refrigerating unit is used for further reducing the temperature of the hydraulic oil; the temperature controller is used for controlling the temperature of the hydraulic oil; the refrigerating unit is arranged on the heat sink; and a control switch which controls starting / closing of the refrigerating unit and the temperature sensor are electrically connected with the temperature controller. By the structure in the oil cylinder device dissipating heat automatically, the temperature of the hydraulic oil can be reduced quickly, and can be always below a set temperature, running stability of the oil cylinders is guaranteed, and the service lives of the oil cylinders are prolonged.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

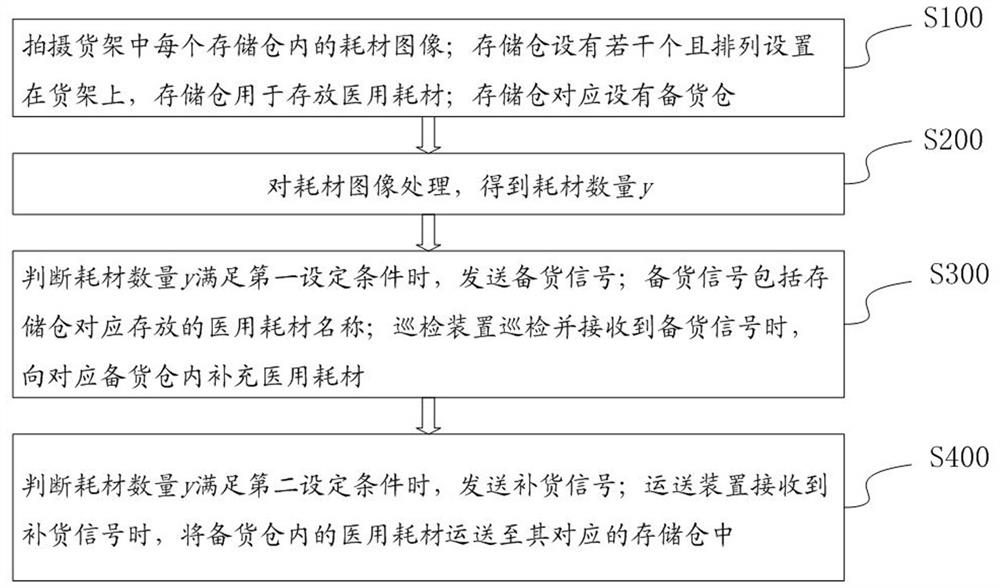

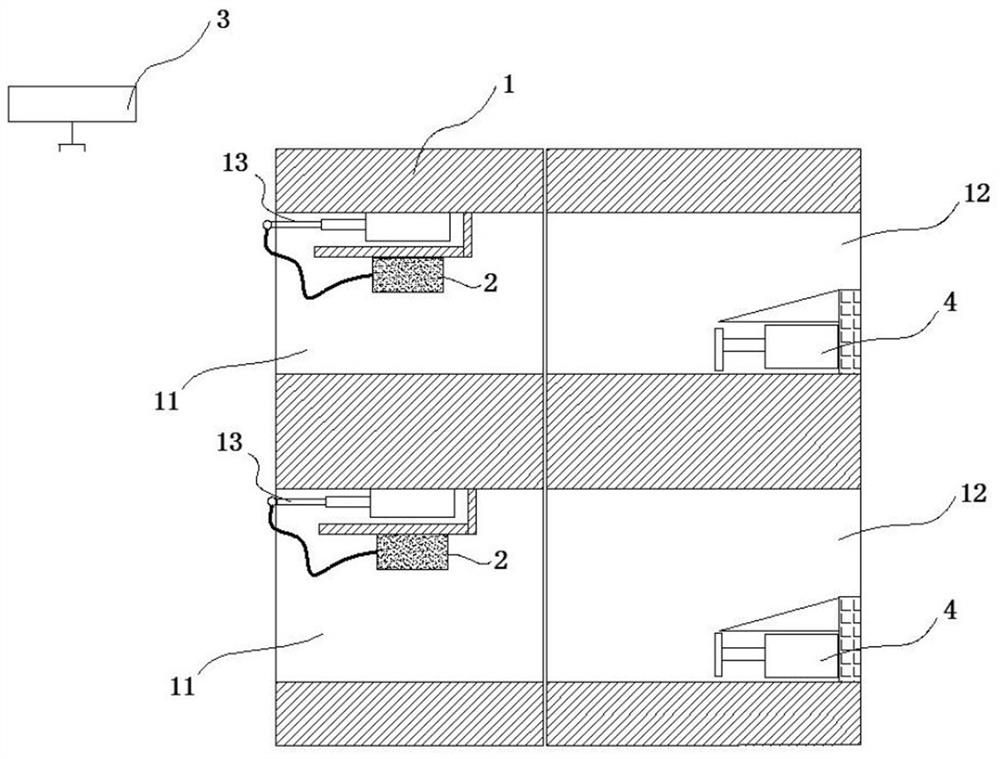

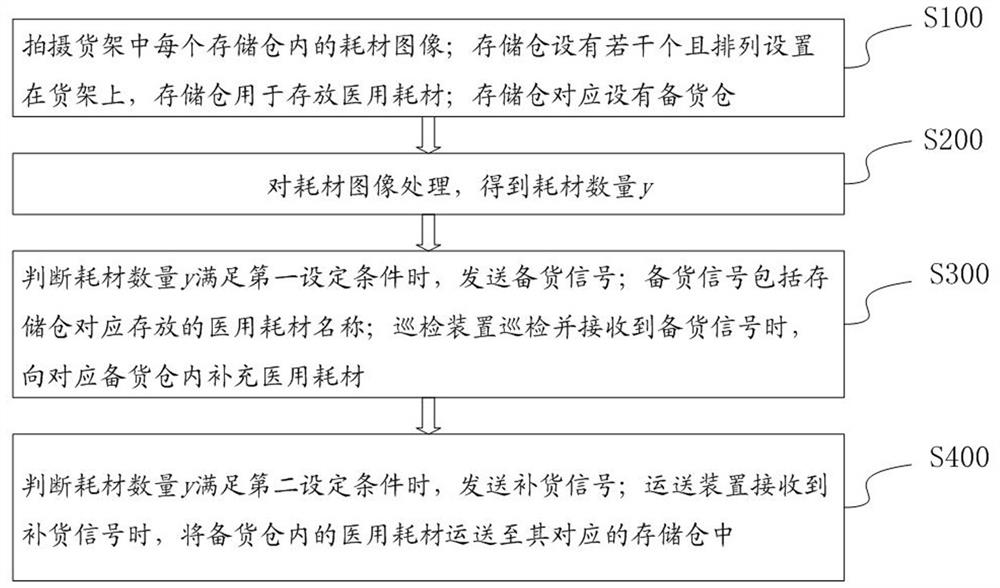

Intelligent inspection and replenishment method and system for warehouse

ActiveCN114004572AEasy replenishmentAvoid idle timeCharacter and pattern recognitionHealthcare resources and facilitiesIndustrial engineeringImage processing

The invention provides an intelligent inspection and replenishment method and system for a warehouse, and the method comprises the following steps: photographing the image of consumables in each storage bin in a goods shelf, and enabling each storage bin to be correspondingly provided with a stock bin; processing the consumable images to obtain the number y of consumables; when it is judged that the consumable number y meets a first set condition, sending a stock-up signal; when the inspection device inspects and receives the stock-up signal, supplementing the medical consumables into the corresponding stock-up bins; when it is judged that the consumable number y meets a second set condition, sending a replenishment signal; and when receiving the replenishment signal, enabling the conveying device to convey the medical consumables in the stock bin to the corresponding storage bin. By means of the method, replenishment can be conveniently conducted on the storage bins, the situation that no consumable is taken for use in the storage bins is avoided, and the situation that replenishment is not in time due to simultaneous replenishment of multiple storage bins is avoided; and occupation of data processing or control resources of the inspection device is reduced, and jamming of the inspection system caused by overlarge computation amount of the inspection device is avoided.

Owner:天津医药集团众健康达医疗器械有限公司

High-rise descent control device based on hydraulic damping

InactiveCN102068771BHydraulic damping force to slow down telescoping speedSlow down hydraulic damping forceBuilding rescueHydraulic cylinderEngineering

The invention discloses a high-rise descent control device based on hydraulic damping, which comprises a main shaft, a rope and an inner cam, wherein the inner cam is arranged at the main shaft, the rope is wound on the outer cylindrical surface of the inner cam, the inside of the inner cam is provided with a hydraulic cylinder, the piston rod of the hydraulic cylinder is driven by the cam wall of the inner cam to reciprocate, and the hydraulic cylinder is connected with a damping oil way which can adjust the reciprocating speed of the piston rod. The device of the invention has the advantages that the structure is simple and compact, the stability is good, the efficiency is high, the device is safe and reliable to use, the machining and assembly process is simple, the maintenance cost islow, the application range is wide, and the like.

Owner:NAT UNIV OF DEFENSE TECH

Control system and control method of circular stone sawing machine

InactiveCN105058591BQuality improvementHigh degree of automationWorking accessoriesStone-like material working toolsPosition circleAutomatic control

The invention relates to a control system and method for a disc stone sawing machine. The control system comprises four portions of a power unit, an electrical control unit, a detection unit and a man-machine interaction part. Manual and automatic control modes are provided, the position of a first cutting disc saw can be determined according to the first cutting machining depth, stone size, the disc saw radius and the distance from the disc saw initial position circle center to a trolley, and accordingly the first cutting machining accuracy is guaranteed. By means of a left and right traveling mechanism, left and right traveling switching can be achieved through a stroke counting function, so that machining can be performed according to the actual stone width, and the problem of the idle running time process caused by switching of limit switches in the traditional method is solved; by means of the system, optimal matching of machining depth with machining speed is achieved, the main motor optimal operation efficiency is guaranteed, the system work efficiency is improved, and the energy-saving purpose of the system is reached; besides, the system safety and reliability are guaranteed.

Owner:BOHAI UNIV

Method for scheduling bus system transmissions

ActiveUS9143348B2Shorten cycle timeReduce waiting timeElectric digital data processingBus networksTime scheduleEmbedded system

A method for operating a bus system, which includes a master and k slaves as users, where a header of an interrogation frame, which includes k information fields, is transmitted by the master to the slaves; in each instance, an mth slave being assigned an mth information field; an information item regarding the amount of data that is to be sent by the mth slave to the master being written by the mth slave to the mth information field assigned to it; the interrogation frame being transmitted to the master; and a time schedule, by which the amount of data to be sent is taken into account, being prepared by the master for transmitting the data.

Owner:ROBERT BOSCH GMBH

A 5G application-oriented smart light pole integrated device and its implementation method

ActiveCN112540557BAvoid the problem of switch hysteresis or even light sensor failureSolve the acquisition problemProgramme controlMeasurement devicesData setThe Internet

The invention discloses a 5G application-oriented smart light pole integration device and an implementation method. The invention includes a central control module, a light intensity detection module, a 5G communication module, an air detection module, a camera monitoring module, a liquid crystal display module, an emergency alarm module, a temperature and humidity detection module, a noise detection module and a positioning module. The present invention implements a street light control method based on fog computing through 5G communication and LoRa-based networking technology. The street light control method makes some data processing do not need to be connected to the Internet, speeds up the data processing timeliness and reduces cloud load. The light control method of this system makes the light control model based on the regional position data no longer rely on the data of a single lamp for control, and the single lamp is associated with the nearby data cluster, and the data of nearby street lamps is used for auxiliary calibration management to ensure the security of the entire network. Smooth operation, even if a single sensor fails, it will not affect the entire system. The invention solves the problem of acquiring adjacent position points.

Owner:HANGZHOU DIANZI UNIV

A method and system for warehouse intelligent inspection and replenishment

ActiveCN114004572BEasy replenishmentAvoid idle timeCharacter and pattern recognitionHealthcare resources and facilitiesComputer scienceIndustrial engineering

The present application provides a method and system for intelligent warehouse inspection and replenishment, wherein the method includes the following steps: taking images of consumables in each storage bin in the shelf, and each storage bin is correspondingly equipped with a stocking bin; processing the images of consumables, Get the number of consumables y ;Judging the number of consumables y When the first setting condition is met, a stocking signal is sent; when the inspection device inspects and receives the stocking signal, replenish medical consumables to the corresponding stocking warehouse; determine the quantity of consumables y When the second setting condition is satisfied, a replenishment signal is sent; when the delivery device receives the replenishment signal, it transports the medical consumables in the stocking bin to its corresponding storage bin. Through the above method, it is convenient to replenish the storage bins, avoiding the empty time when there is no consumables in the storage bins, and avoiding multiple storage bins replenishing goods at the same time, resulting in untimely replenishment; reducing the data processing of the inspection device Or control the occupancy of resources to avoid the excessive calculation of the inspection device and cause the inspection system to freeze.

Owner:天津医药集团众健康达医疗器械有限公司

Tray emptying device and method for emptying a tray into a manufacturing machine and manufacturing system

ActiveCN103960777BSimple and reliable acceptanceAvoid idle timeCigarette manufactureTobacco smoke filtersEngineeringMachine

The device (10) has a feeding device (13) for feeding filled articles and an upwardly open full tray (11A) in transport direction (TAB). A transport unit (16) for transporting empty trays (11B) in transport direction, is arranged above feeding device. A transfer device (17) has a pivot mechanism (18) whose pivot motion is limited to 180[deg] about fixed pivot axis, a pivoting swivel cassette (19) for fixing, panning and releasing full tray independently from the pivot mechanism and an acting lift device (20) for fixing, linear processing and sharing empty trays. Independent claims are included for the following: (1) a production arrangement; and (2) a method for automatic emptying of containers with articles-filled trays in multi-segment filter manufacturing machine.

Owner:KOERBER TECH GMBH

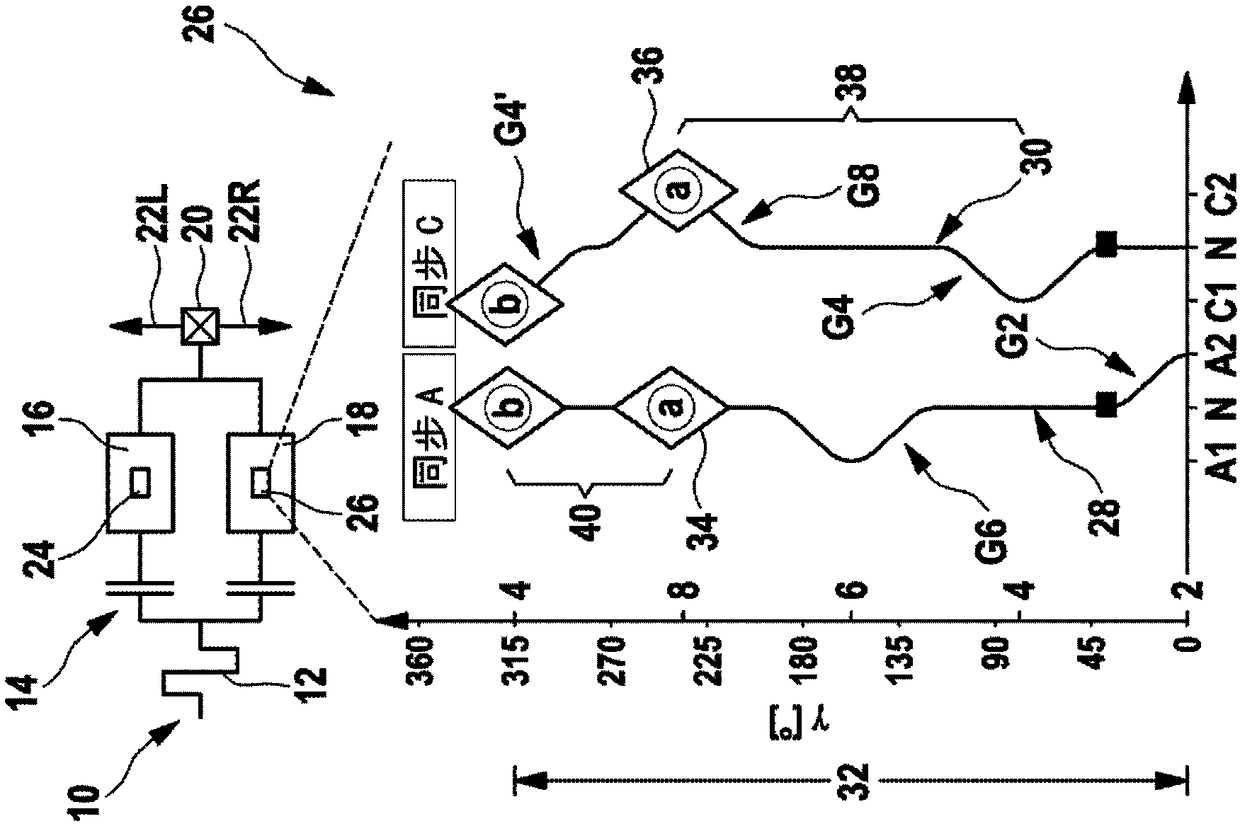

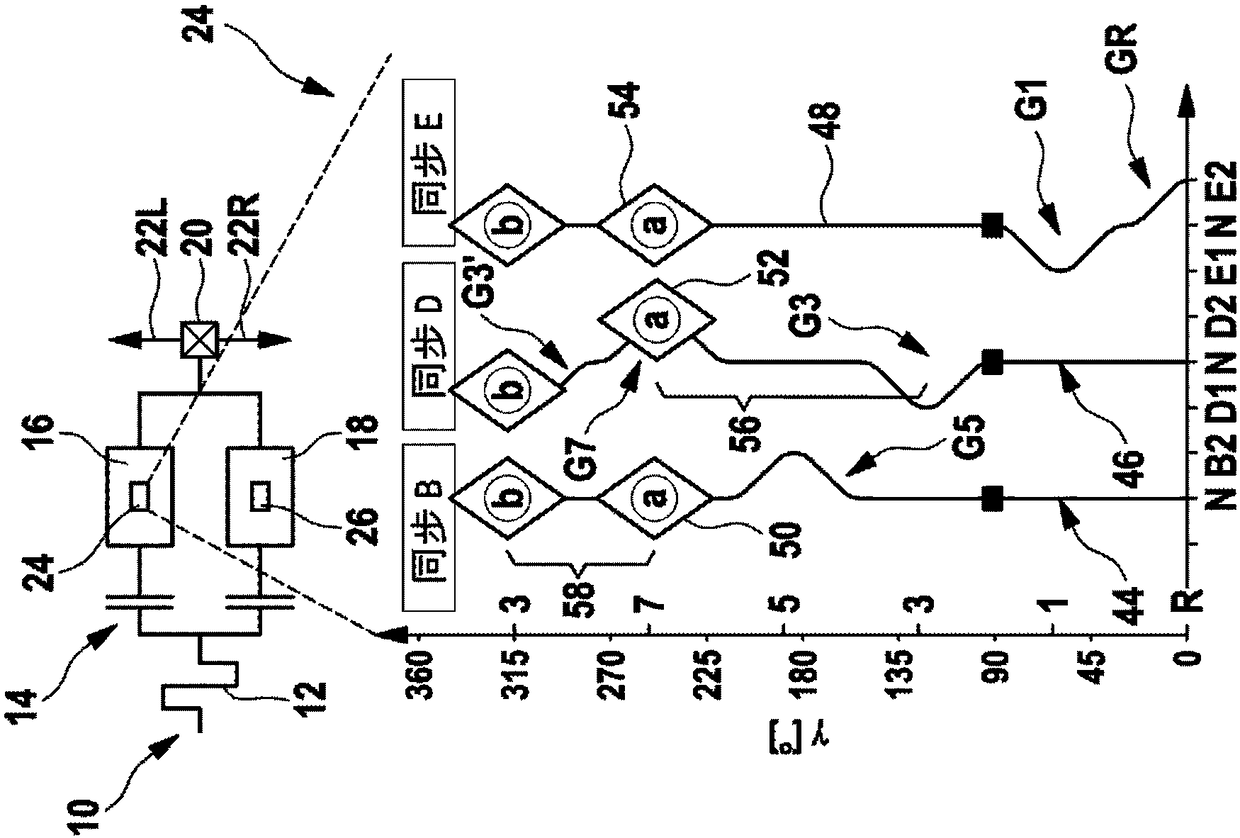

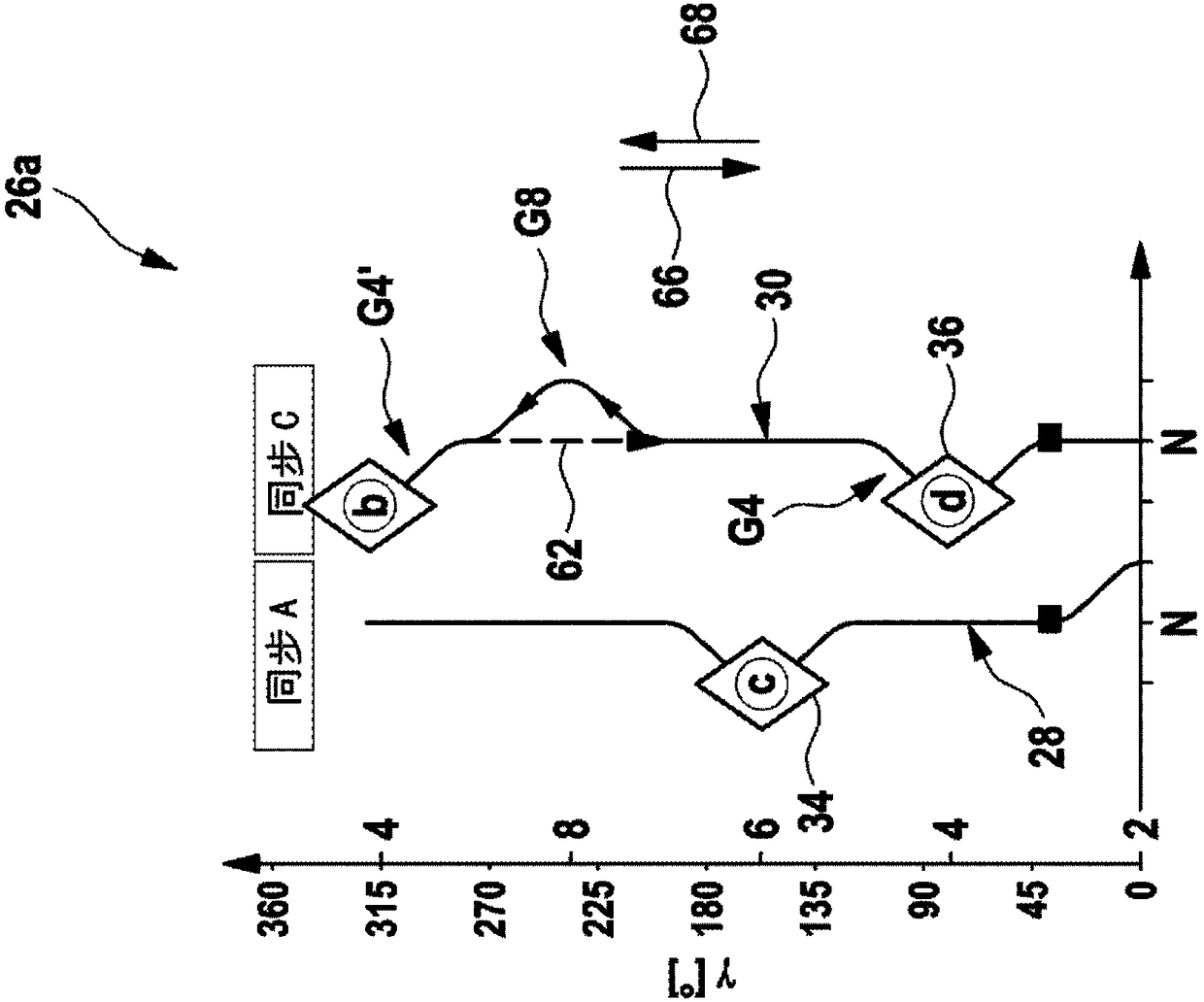

Shifting roll and shifting method

ActiveCN108223786AImprove drivabilityImprove operational reliabilityGearing controlAutomatic transmissionEngineering

Provided is a shifting roll used for an automatic transmission of a vehicle. The shifting roll has a shifting roll body rotating around the axis of a rotary shaft. At least one first shifting profileis formed on the shifting roll body. The first shifting profile extends on a circumferential section of the shifting roll body and a first synchronizing part can be joined on the first shifting profile. The first synchronizing part is folded correspondingly to a first shifting clutch of the transmission of the vehicle, wherein the first shifting profile has a first gear section and a second gear section. The first gear section corresponds to the position of the first shifting clutch folded by the first shifting clutch. The second gear section is spaced from the first gear section at the interval of a first circumference distance and corresponds to the position of a second shifting clutch folded by the first shifting clutch. The first shifting profile has a third gear section. The third gear section corresponds to the position of the first shifting clutch folded by the first shifting clutch and enables the second gear section to be arranged between the first gear section and the third gear section in the arrangement manner in the peripheral direction.

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

Coating plant with a charging lock and device therefor

InactiveUS7479189B2Quick closureOpen fastLiquid surface applicatorsVacuum evaporation coatingEngineeringMechanical engineering

The present invention relates to a coating plant, especially a vacuum coating plant, with a charging lock, especially a rectangular vacuum lock for a coating chamber, with a lock aperture (13) having a length of at least 1000 mm that comprises a shutter (6) for closing and opening the lock aperture and a latch (7) to secure the shutter, wherein there are provided means for moving the shutter and the latch from a first open position to a second closed position, and vice versa, these means assuring also that the movements of the shutter (6) and the latch (7) will be coupled with each other in such manner that the shutter (6) will be automatically secured by the latch (7) after the shutter has been closed and will be released again before it is opened.

Owner:APPLIED MATERIALS GMBH & CO KG

A kind of push boat type semi-continuous method boron nitride nanotube preparation furnace and using method thereof

ActiveCN109809374BEasy to operateRich and diverse structureNitrogen compoundsTemperature controlMetallurgy

Owner:WUHAN INSTITUTE OF TECHNOLOGY

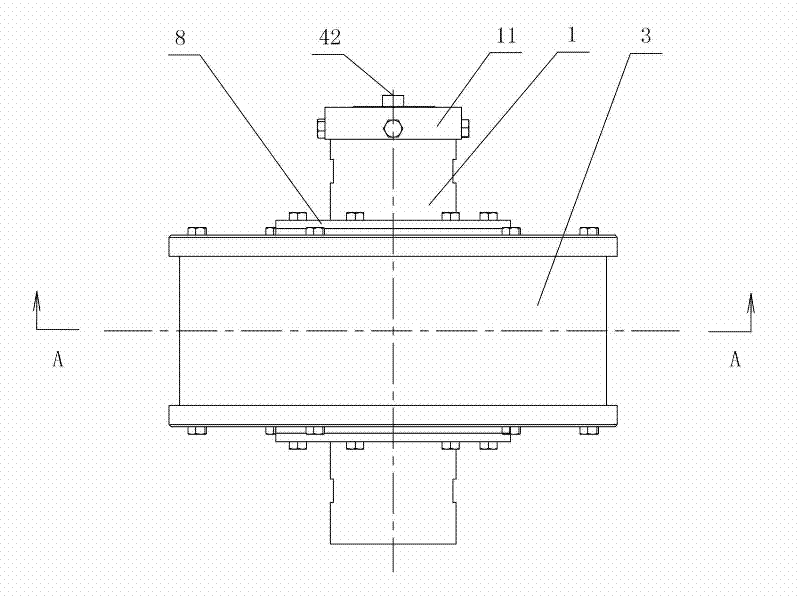

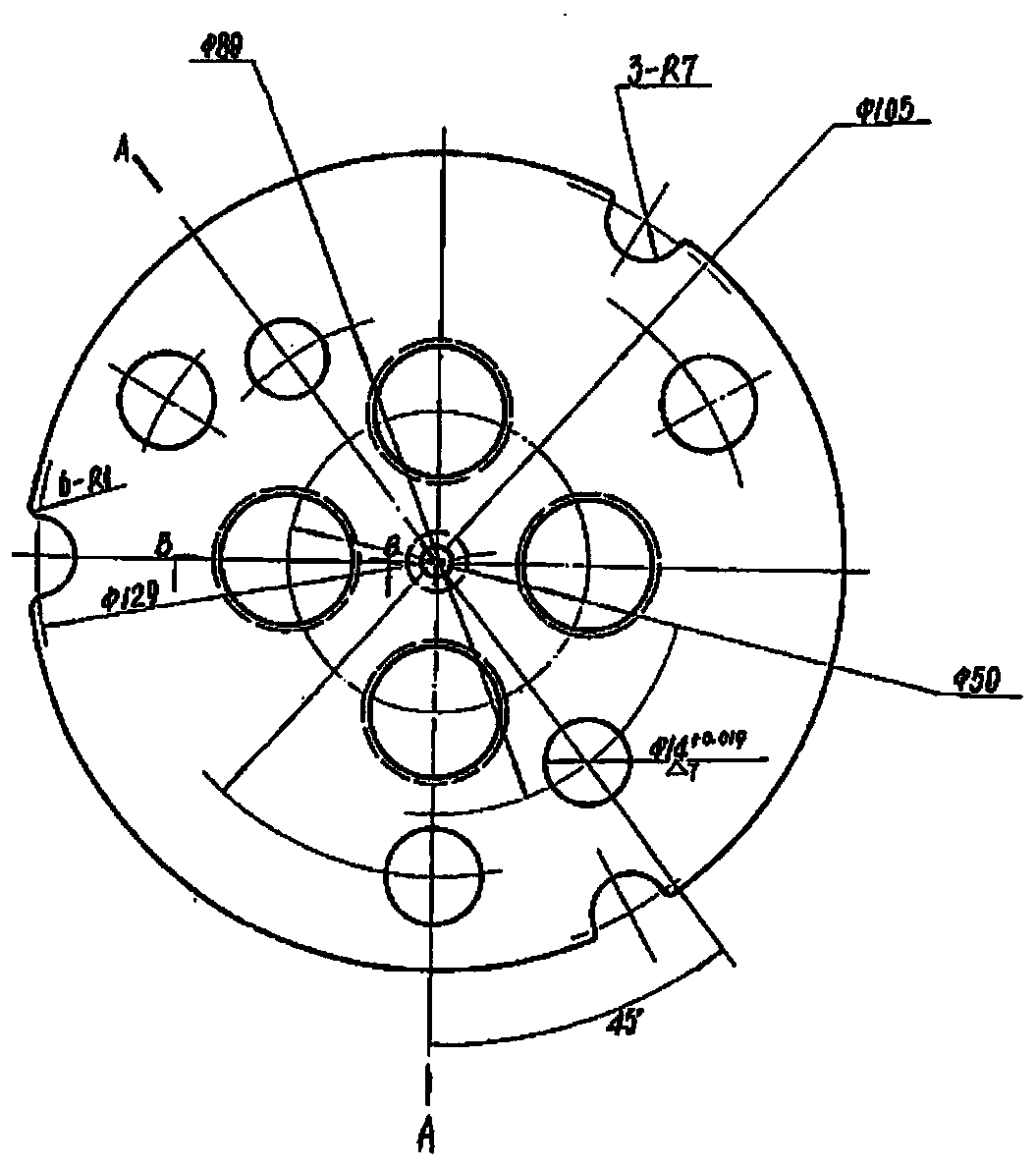

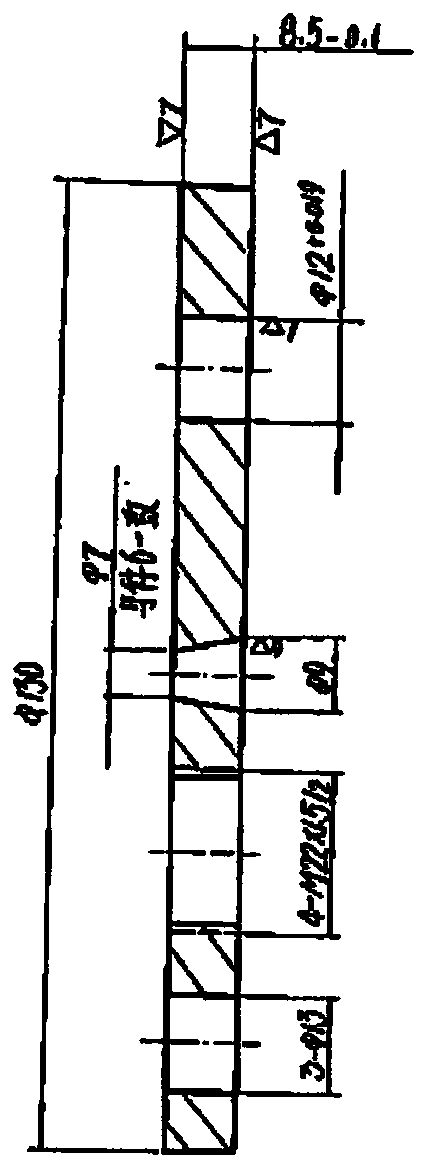

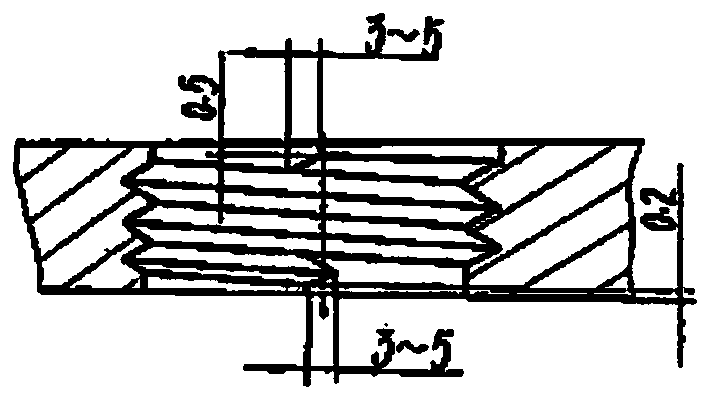

Branching device and branching method for processing high-precision multiple thread part

InactiveCN111014847AAvoid equipment idleGuarantee processing qualityPrecision positioning equipmentThread cutting machinesPhysicsEngineering

The invention belongs to the field of machine manufacturing and relates to a branching device and a branching method for processing a high-precision multiple thread part. The branching device comprises a base and a positioning plate. The base is parallel to the positioning plate and is fixedly connected to the positioning plate through a bolt; a positioning pin is arranged on the base; two or morepin holes matched with the shape structure of the positioning pin are formed in the positioning plate; the two or more pin holes are uniformly formed in the positioning plate; and a limiting screw for fixing a to-be-processed workpiece is arranged on the positioning plate. The invention provides the branching device and the branching method for processing the high-precision multiple thread part,wherein the branching device and the branching method are suitable for a common lathe, can branch precisely quickly and conveniently, are simple to operate and are not limited by screw pitch and stroke.

Owner:XIAN AERO ENGINE CONTROLS

Self-cooling cylinder device

ActiveCN105673766BExtended service lifeDelay agingSpringsLiquid based dampersTemperature controlElectricity

The invention discloses an oil cylinder device dissipating heat automatically. The oil cylinder device dissipating heat automatically comprises two oil cylinders, a heat sink and a temperature control system, wherein each oil cylinder comprises an oil cavity arranged in the axial direction, a piston rod assembly movably arranged in the oil cavity in the axial direction, and an oil delivery tube communicating with the oil cavity; the heat sink is provided with a caching cavity; the oil cavities of the two oil cylinders communicate with the caching cavity through the oil delivery tubes; the temperature control system is used for regulating temperature of hydraulic oil, and comprises a temperature sensor, a refrigerating unit and a temperature controller; the temperature sensor is used for monitoring the temperature of the hydraulic oil; the refrigerating unit is used for further reducing the temperature of the hydraulic oil; the temperature controller is used for controlling the temperature of the hydraulic oil; the refrigerating unit is arranged on the heat sink; and a control switch which controls starting / closing of the refrigerating unit and the temperature sensor are electrically connected with the temperature controller. By the structure in the oil cylinder device dissipating heat automatically, the temperature of the hydraulic oil can be reduced quickly, and can be always below a set temperature, running stability of the oil cylinders is guaranteed, and the service lives of the oil cylinders are prolonged.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com