Chute Unloading Device And Method For Automatically Unloading Chutes And Production Assembly

An emptying device and manufacturing system technology, which is applied in the manufacture of cigarettes, cigarettes, tobacco, etc., can solve the problems of increasing the load of products, and achieve the effects of compact structure, simple and saving transportation, and simple and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

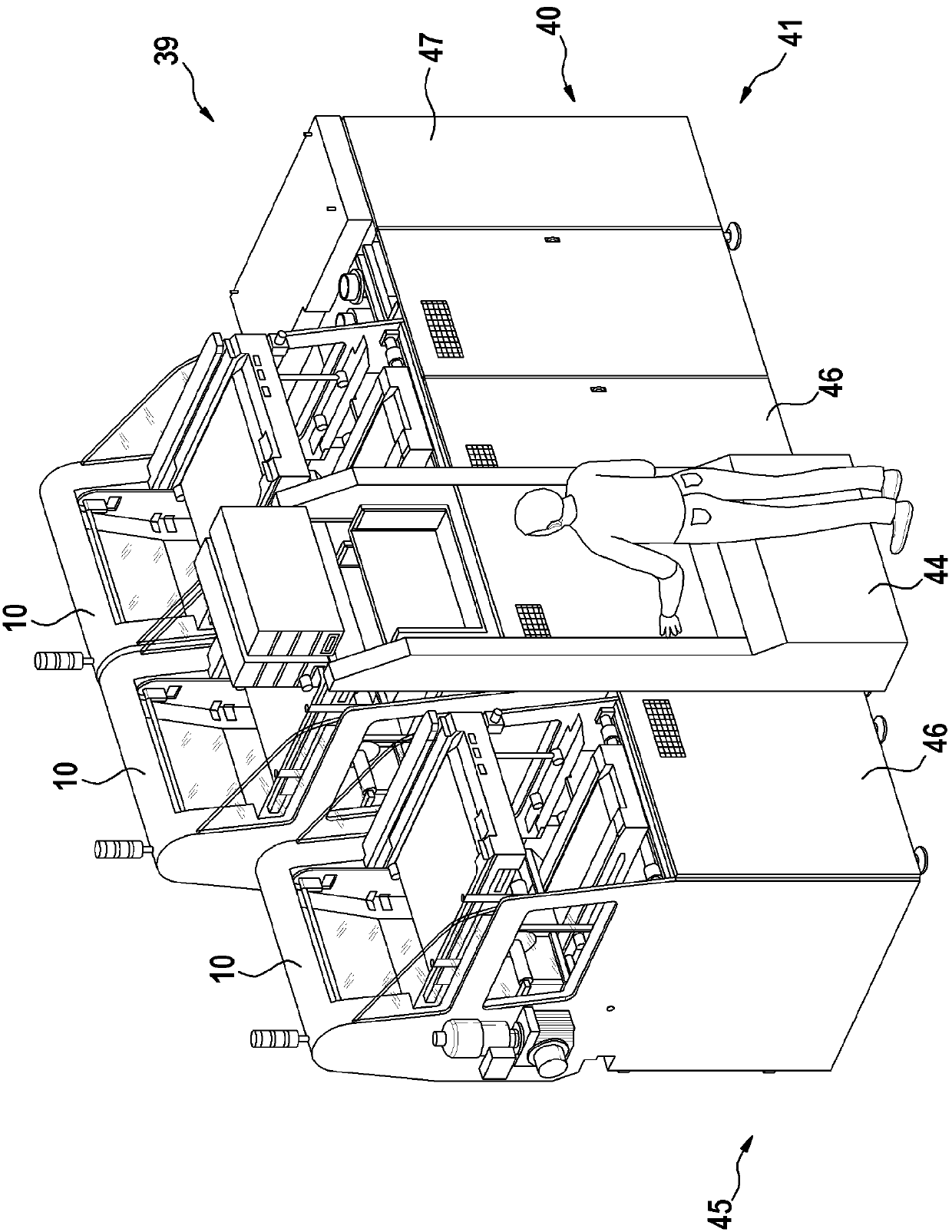

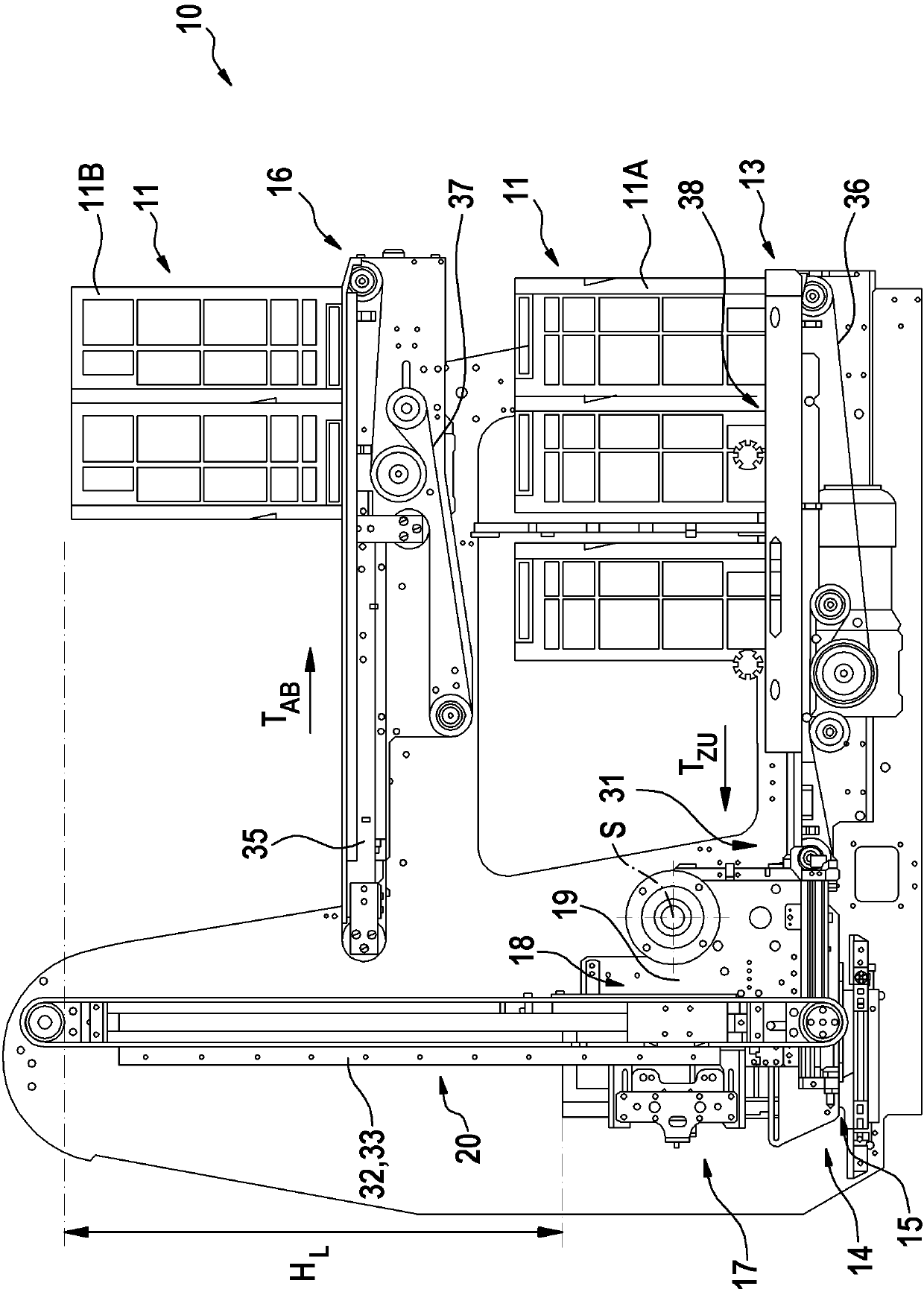

[0035] The invention is described on the basis of a diagram for a tray emptying device feeding a multi-segment filter making machine with rod-shaped products, ie filter (rod) segments. Of course, the invention also includes a tray emptying device designed and arranged for emptying further rod-shaped articles, such as filter rods, cigarettes, etc., to a further manufacturing machine, such as a filter fitting machine, cigarette making machine, etc. and Together, the manufacturing machines form the corresponding manufacturing system.

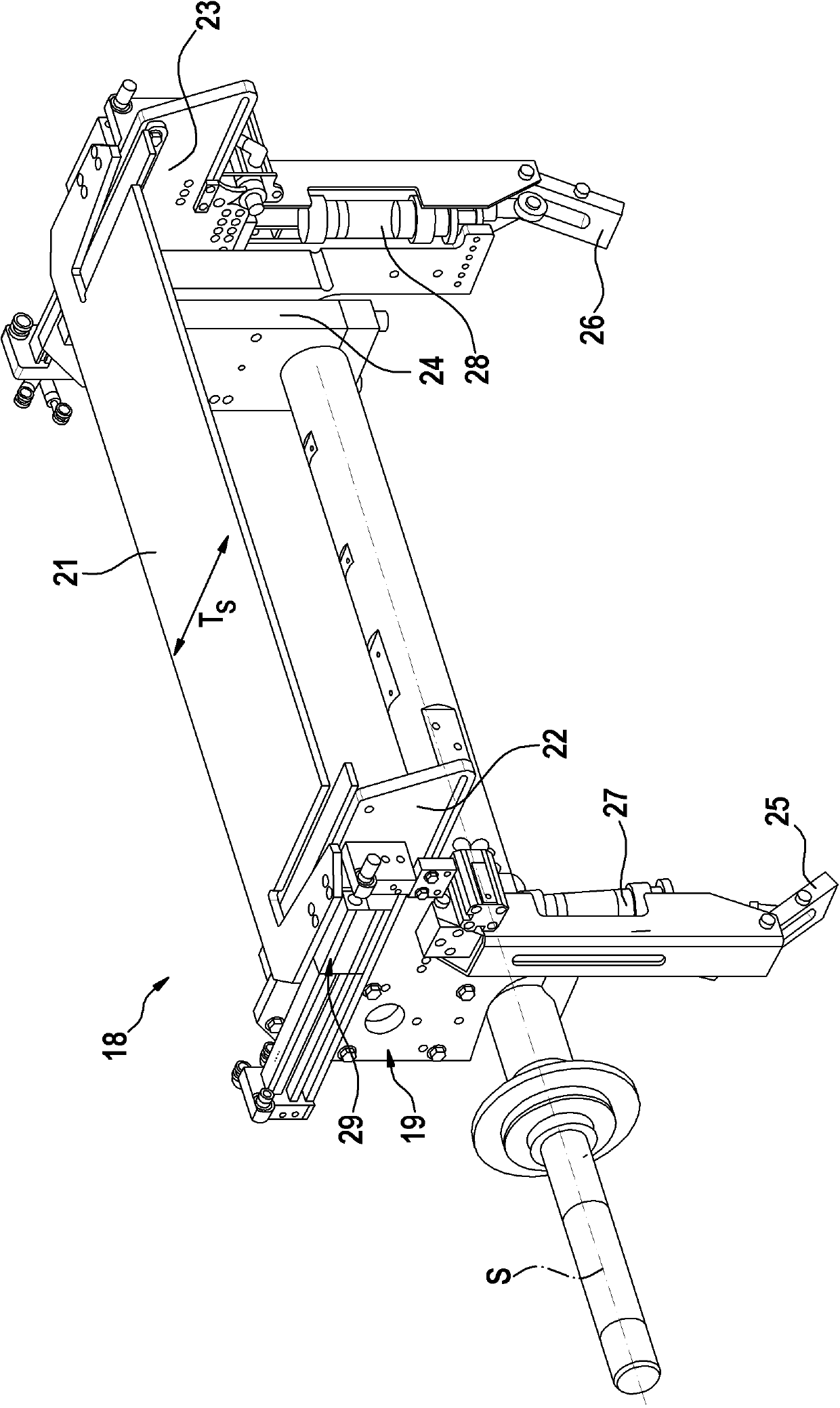

[0036] exist Figures 1 to 3 The tray emptying device 10 shown in is designed and arranged for automatically emptying a tray 11 filled with rod-shaped products into a manufacturing machine 12 in the tobacco processing industry and comprises: an input device 13 for transporting along the direction T ZU Feed full tray 11A filled with products and open upwards; emptying station 14 with emptying position 15 for emptying said full tray 11A upside down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com