Patents

Literature

31results about How to "Eliminate idle time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

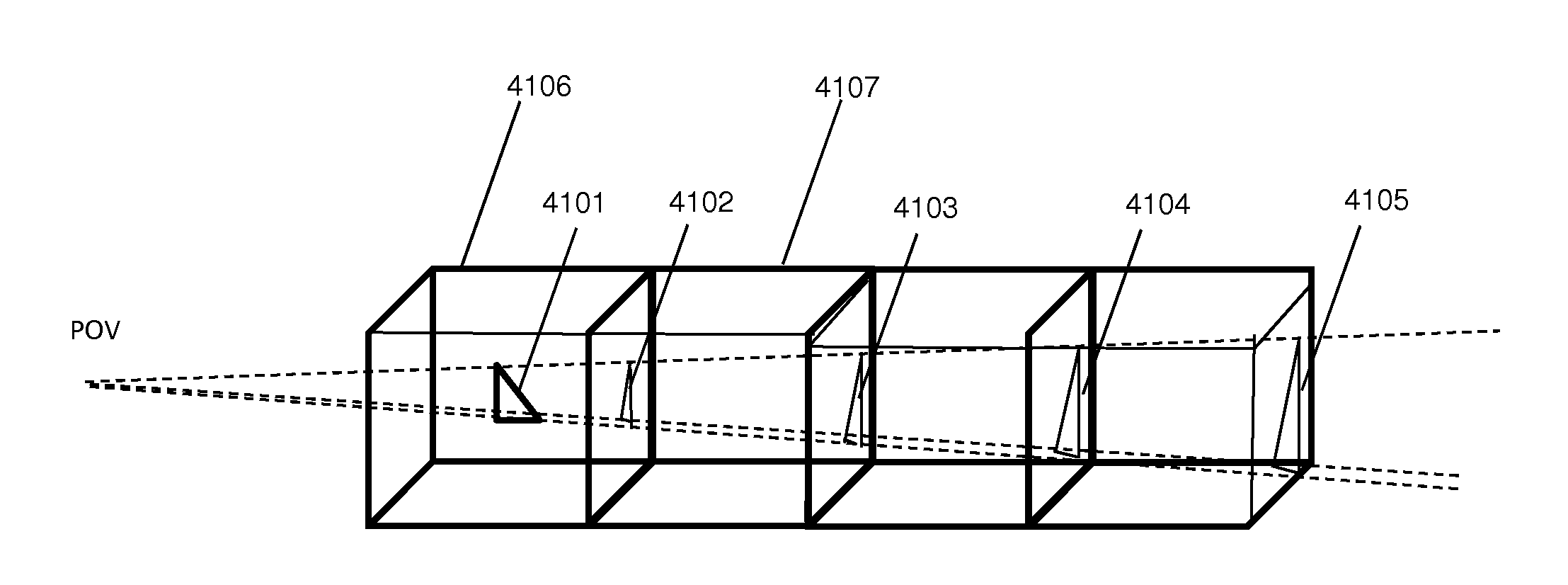

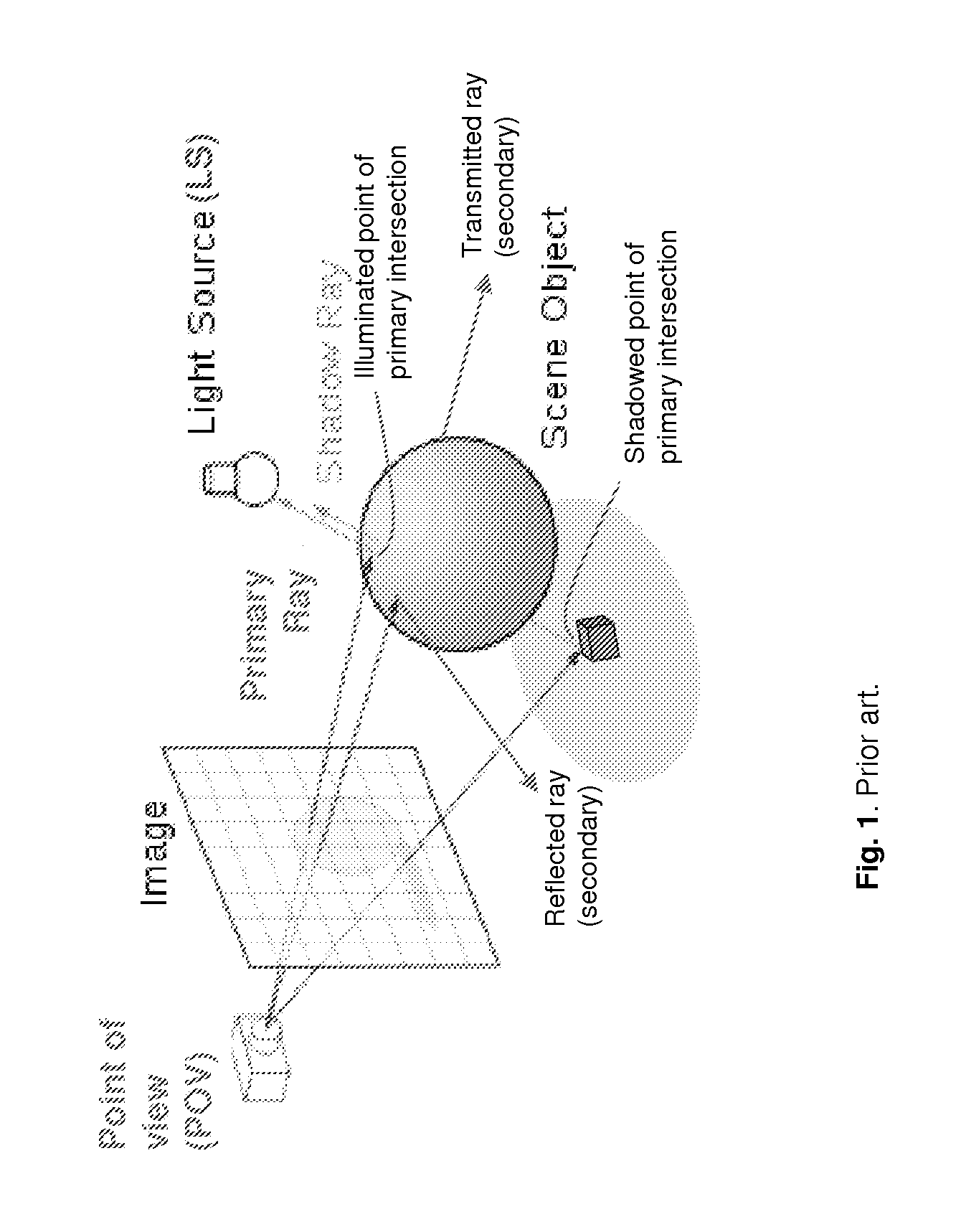

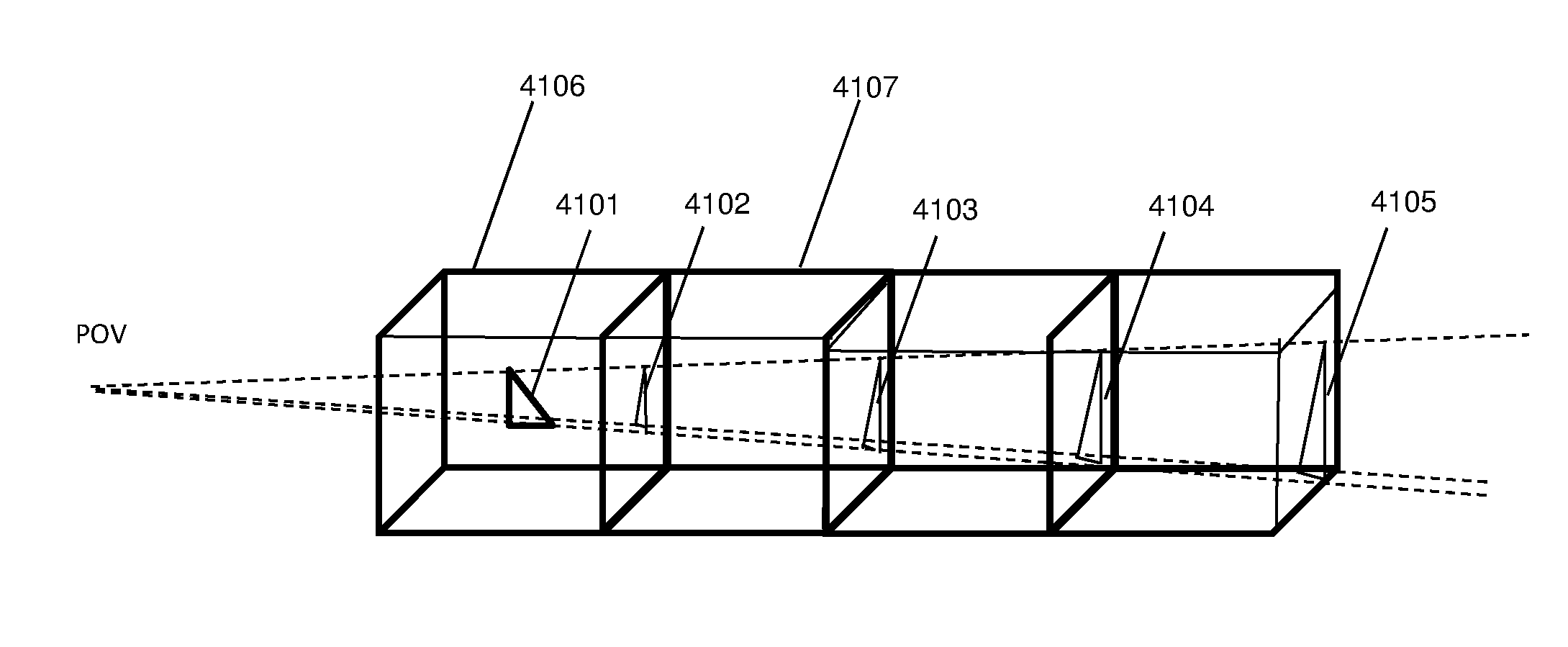

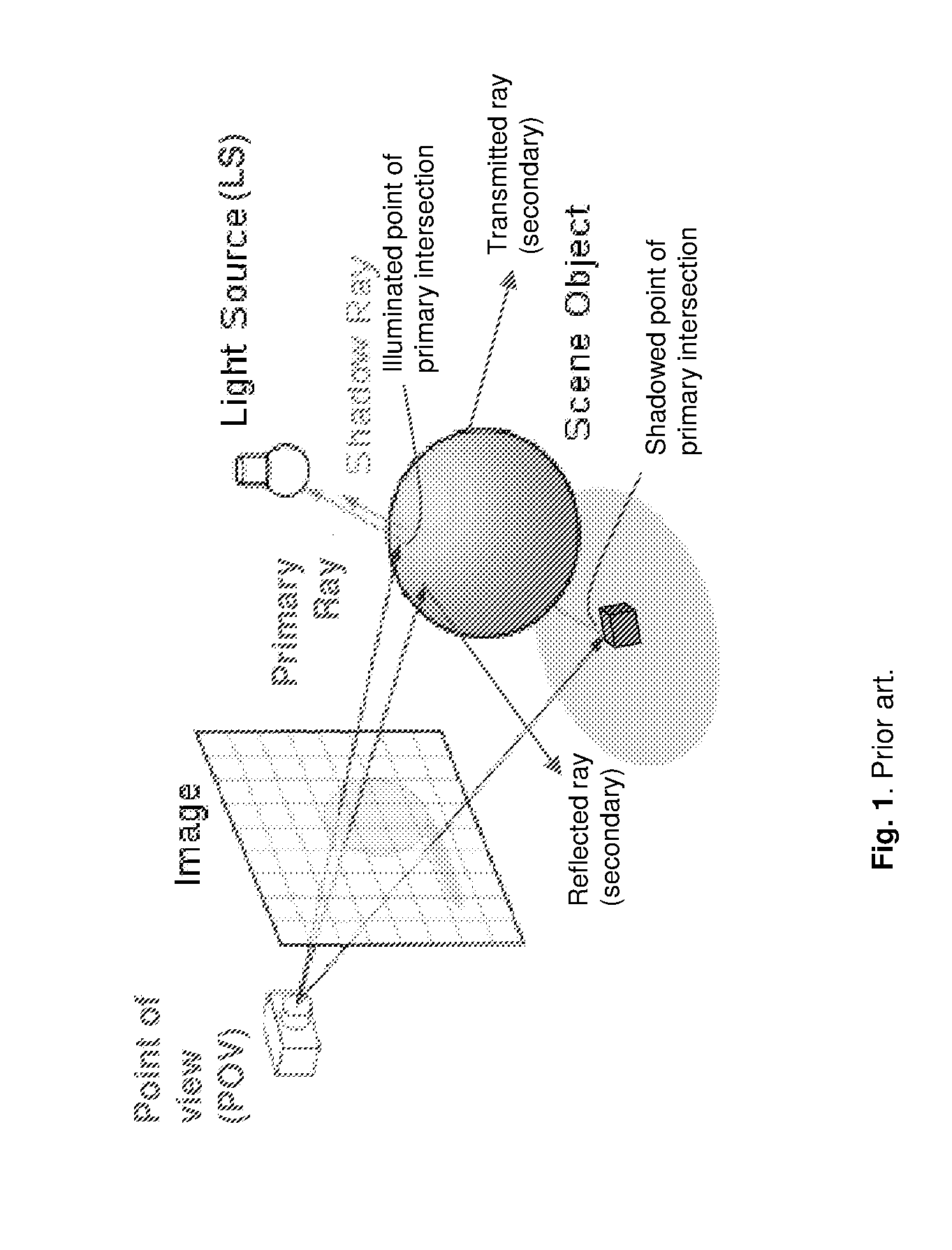

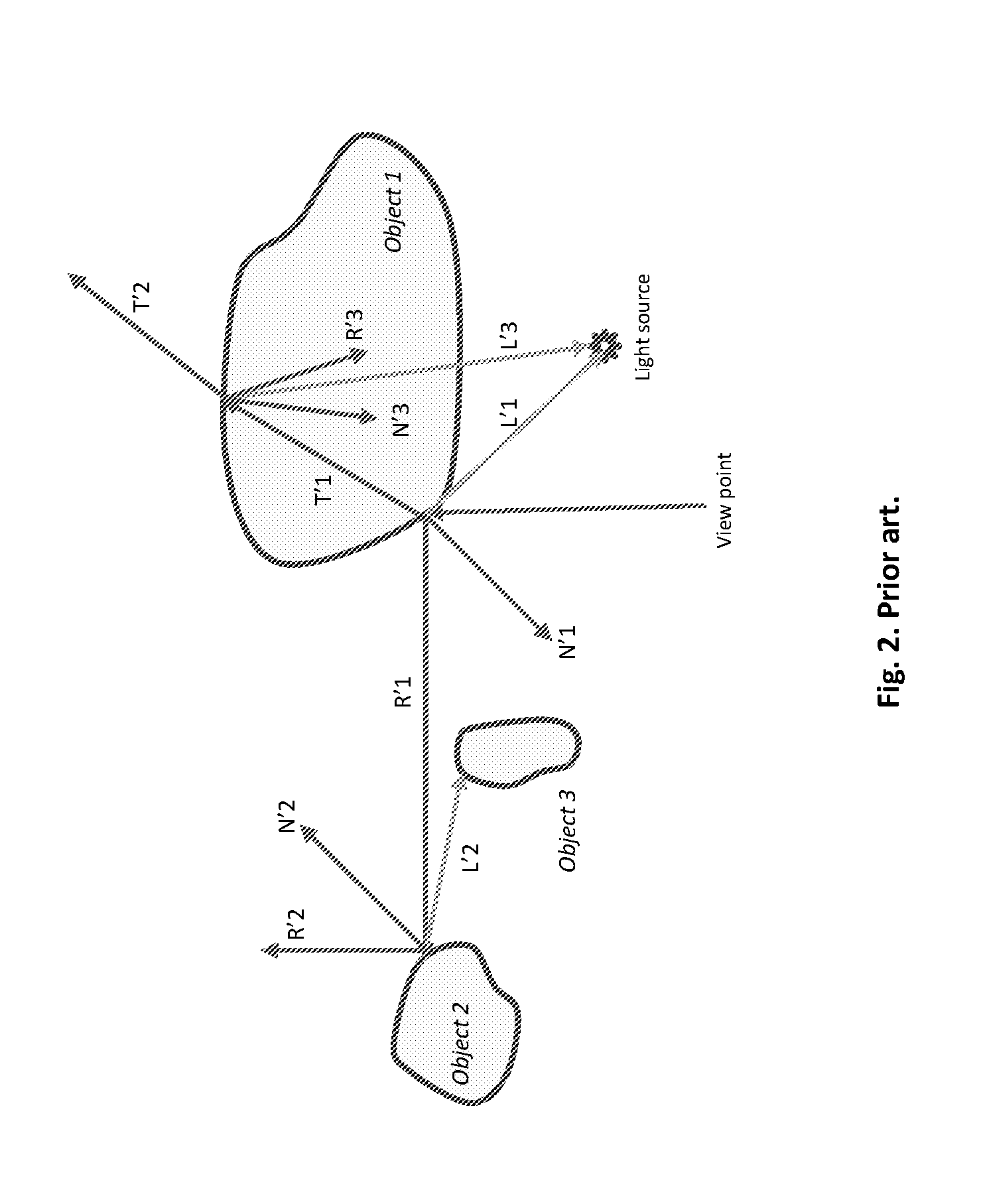

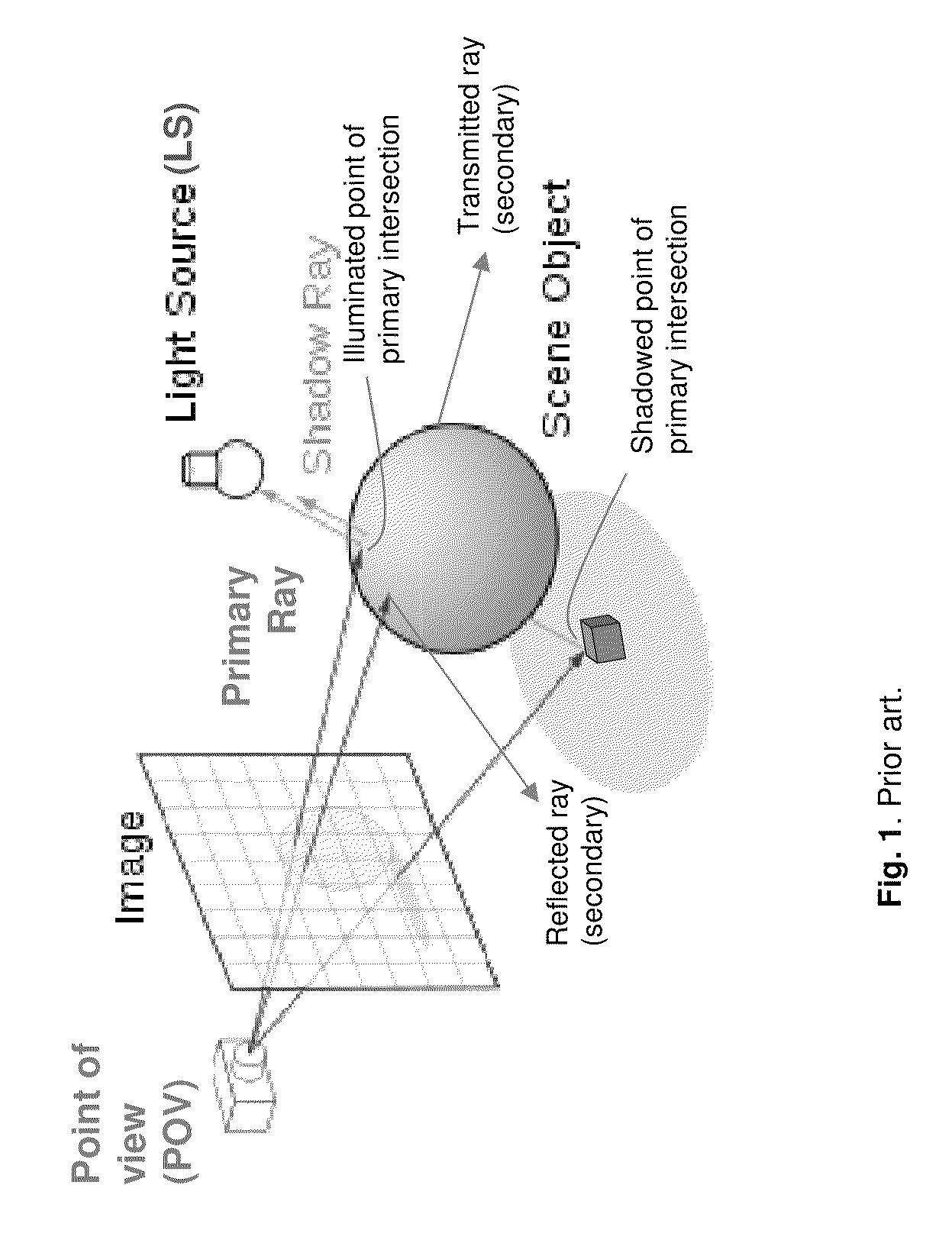

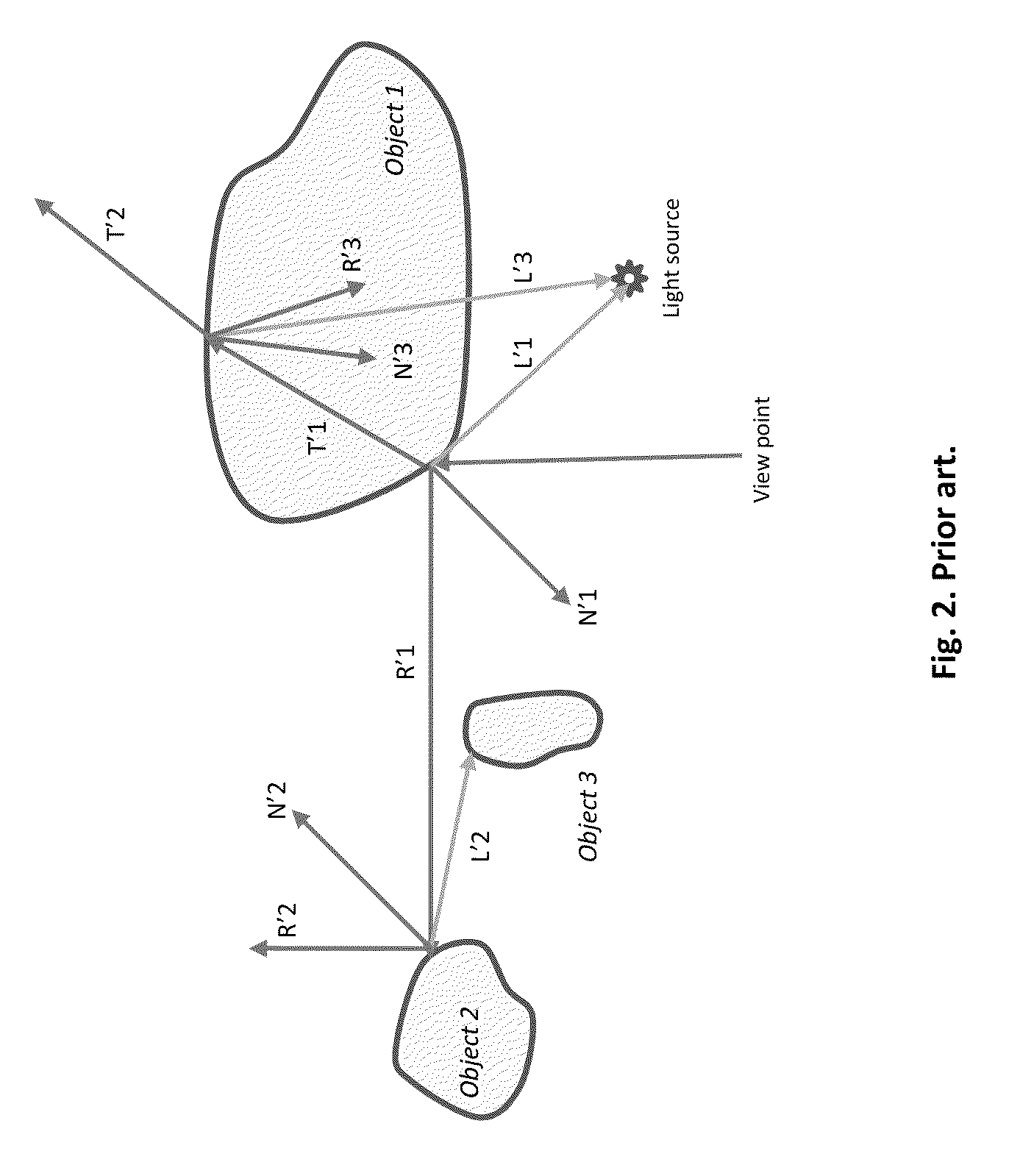

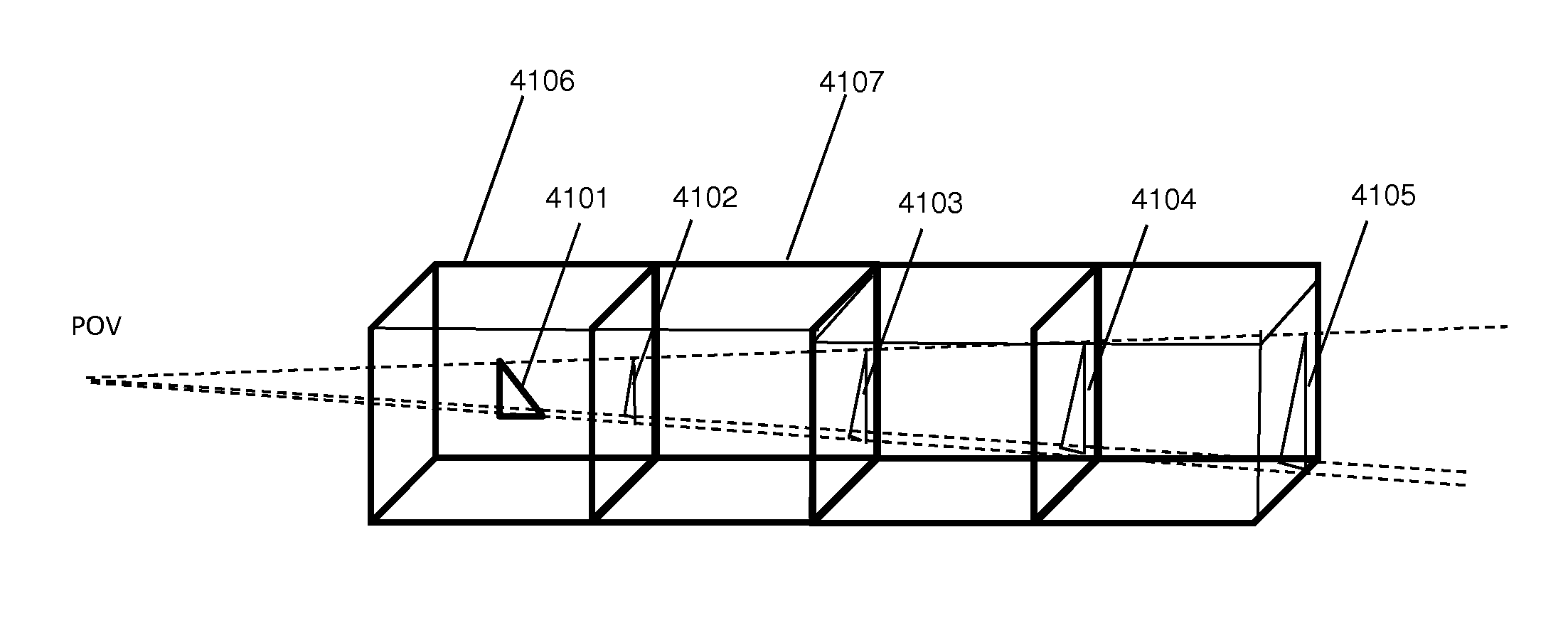

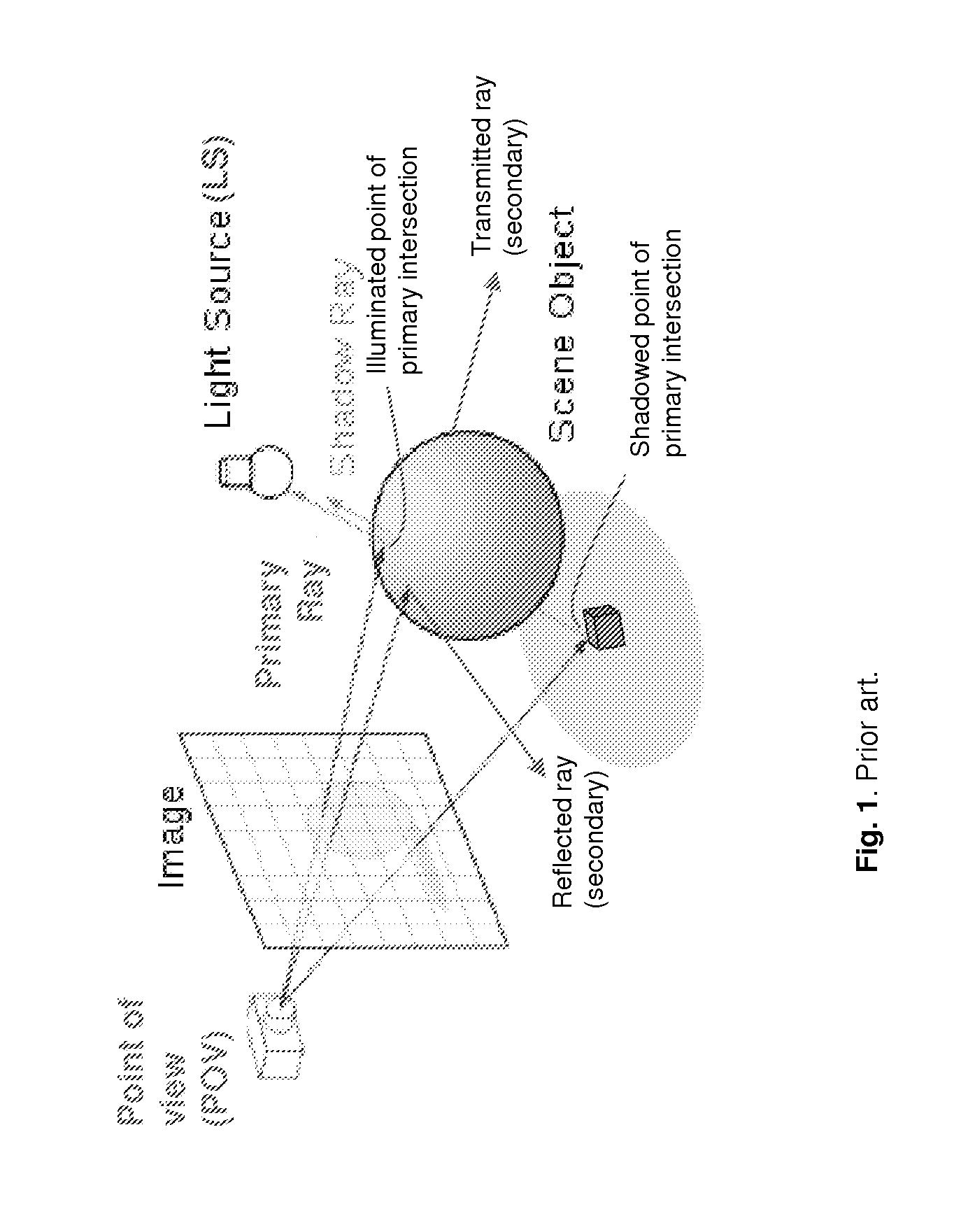

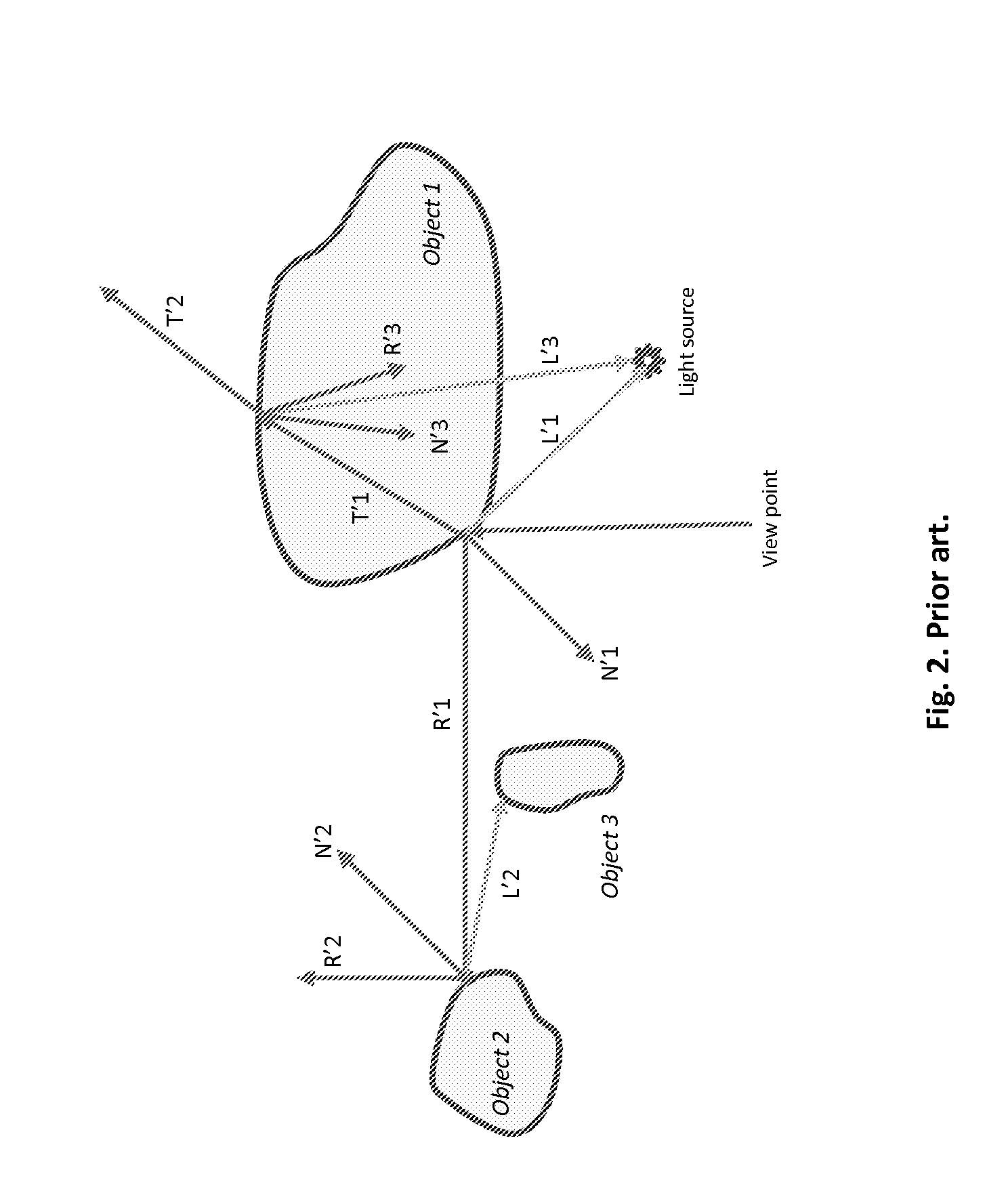

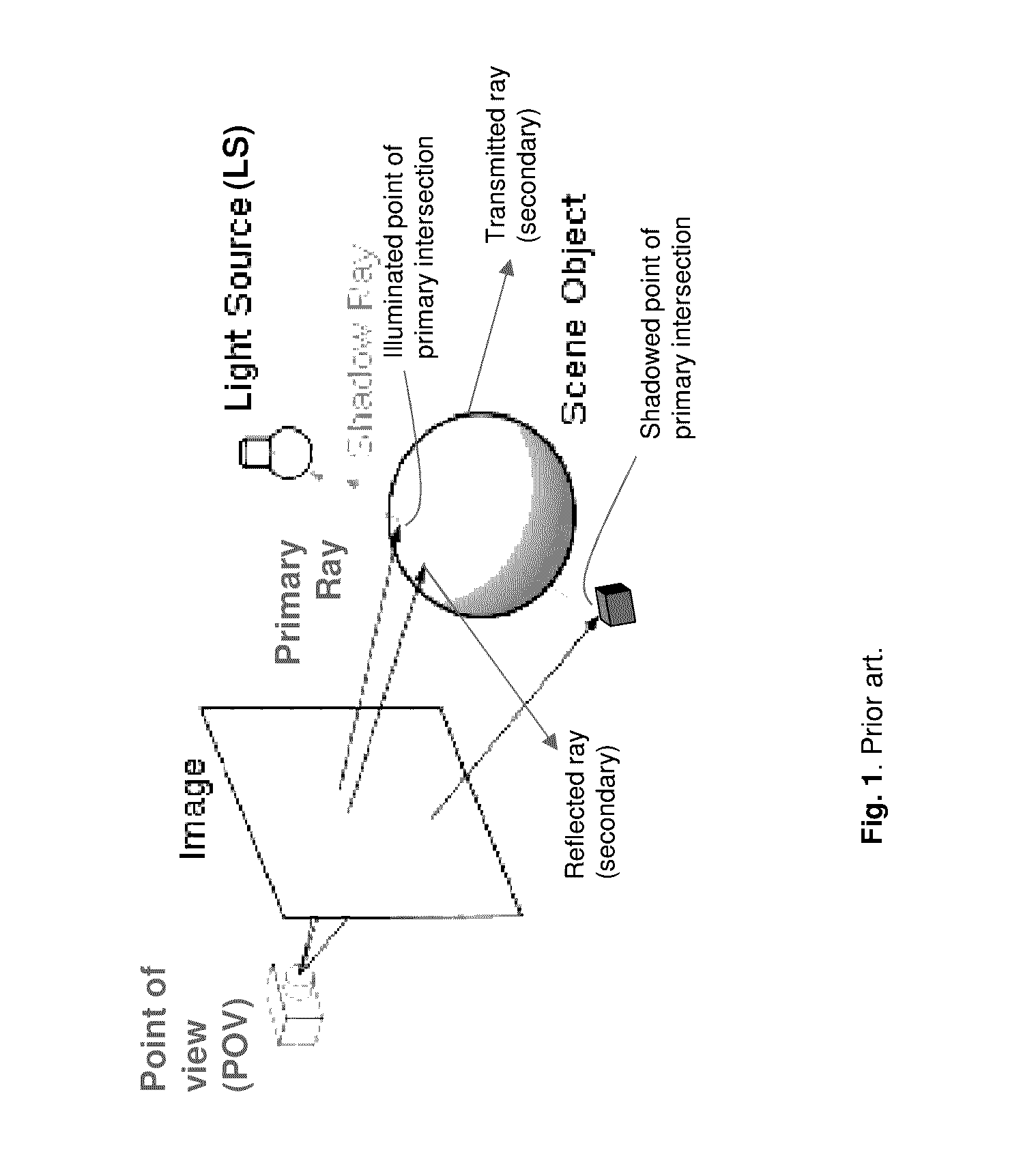

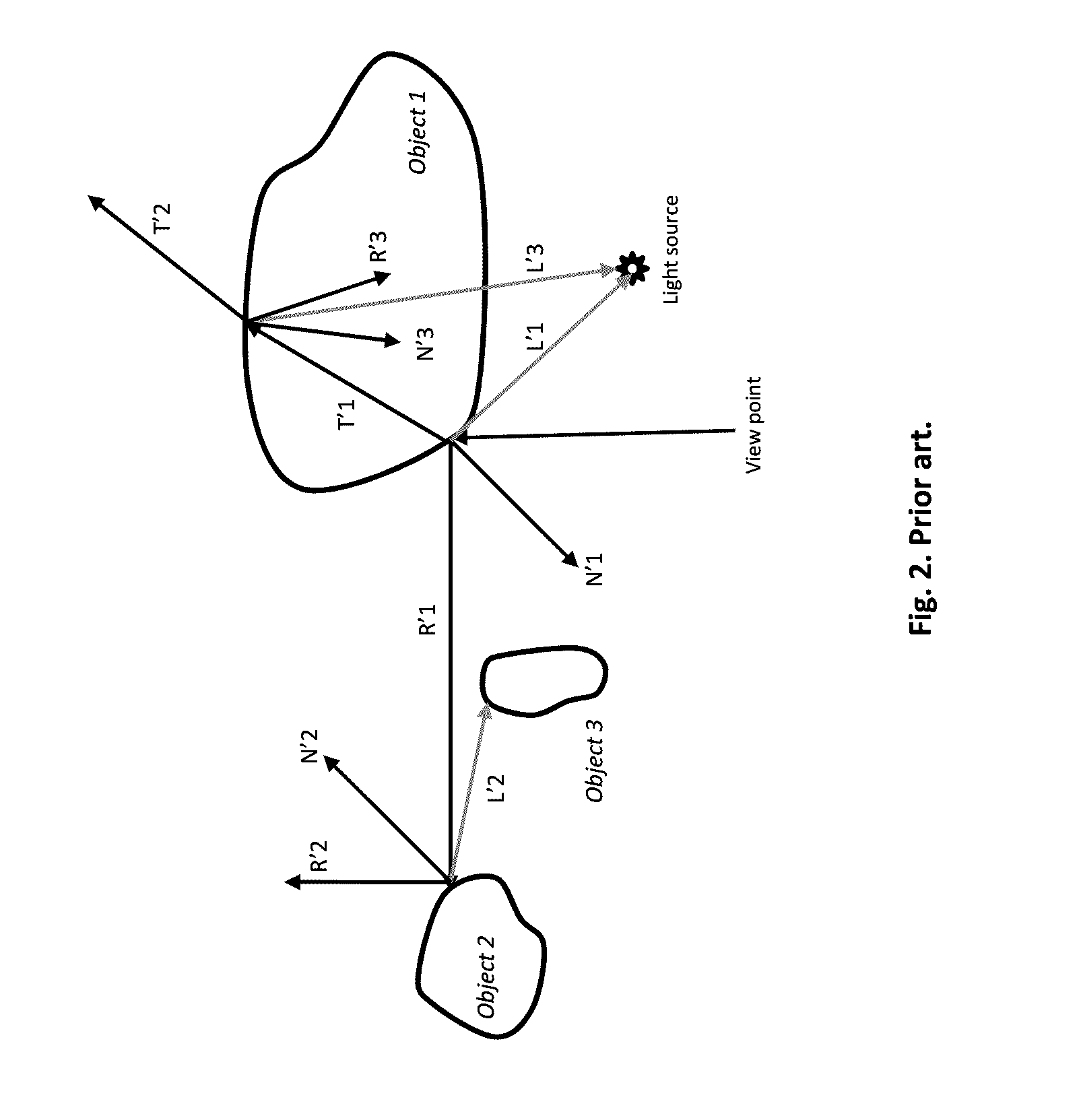

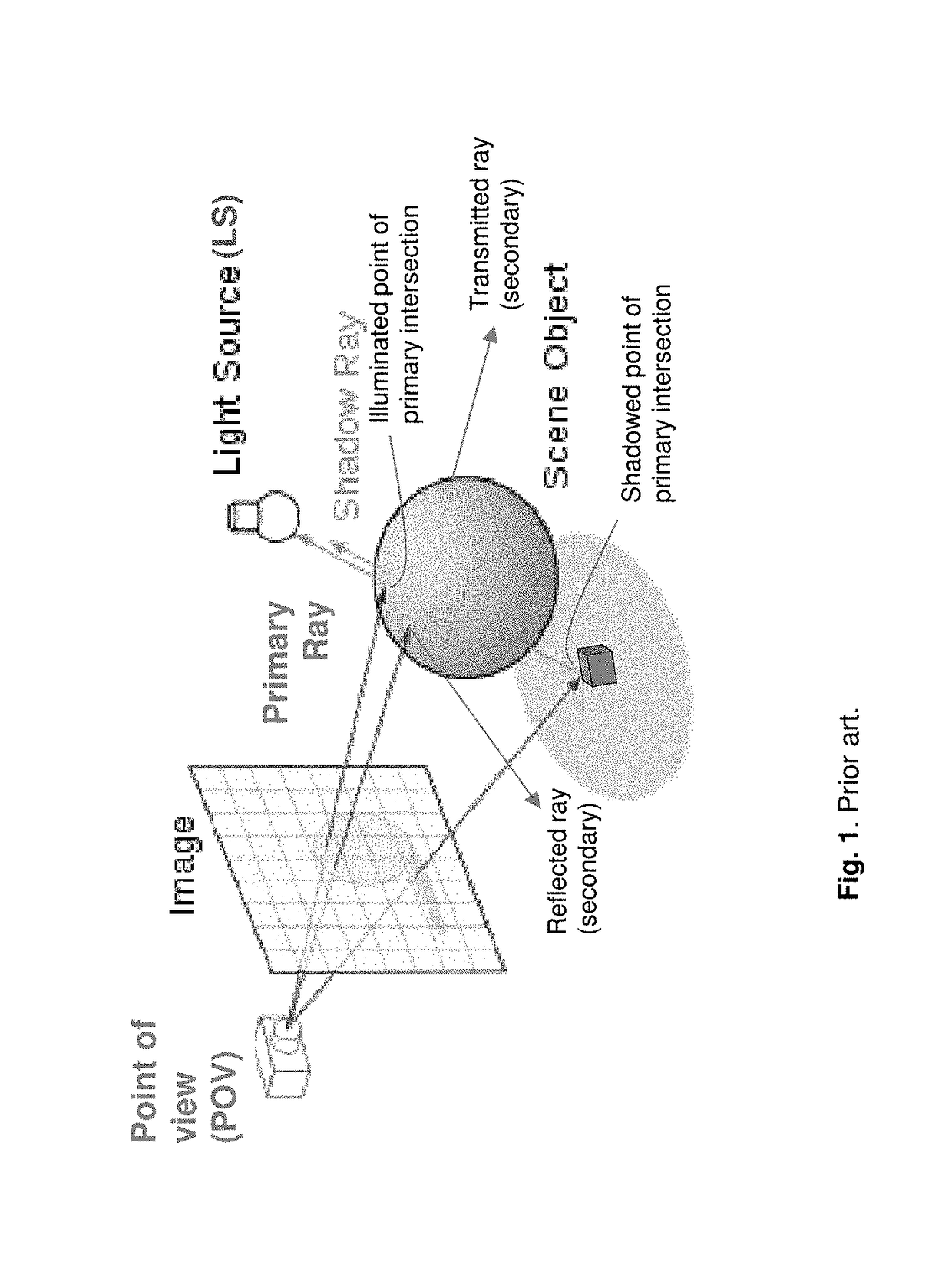

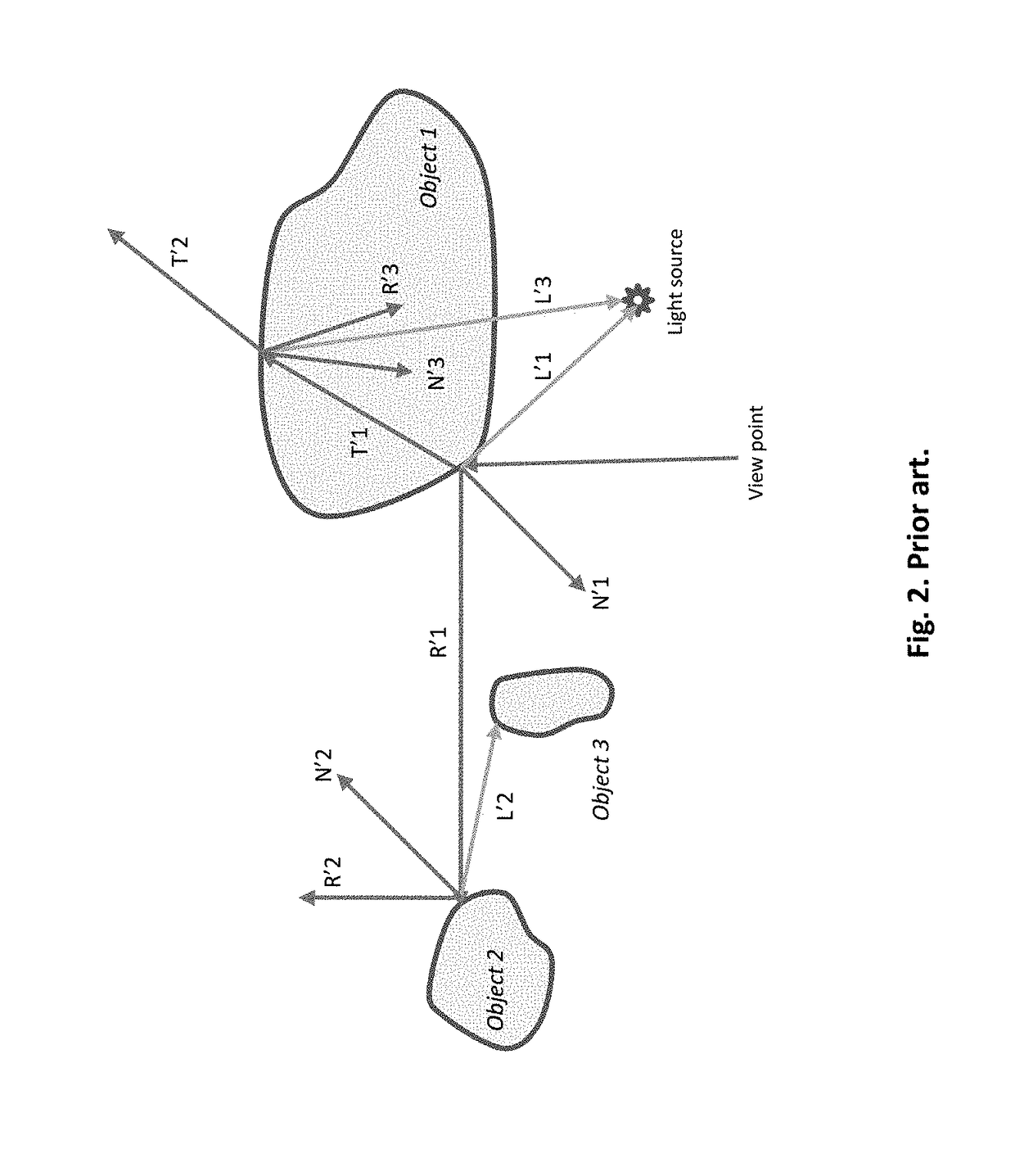

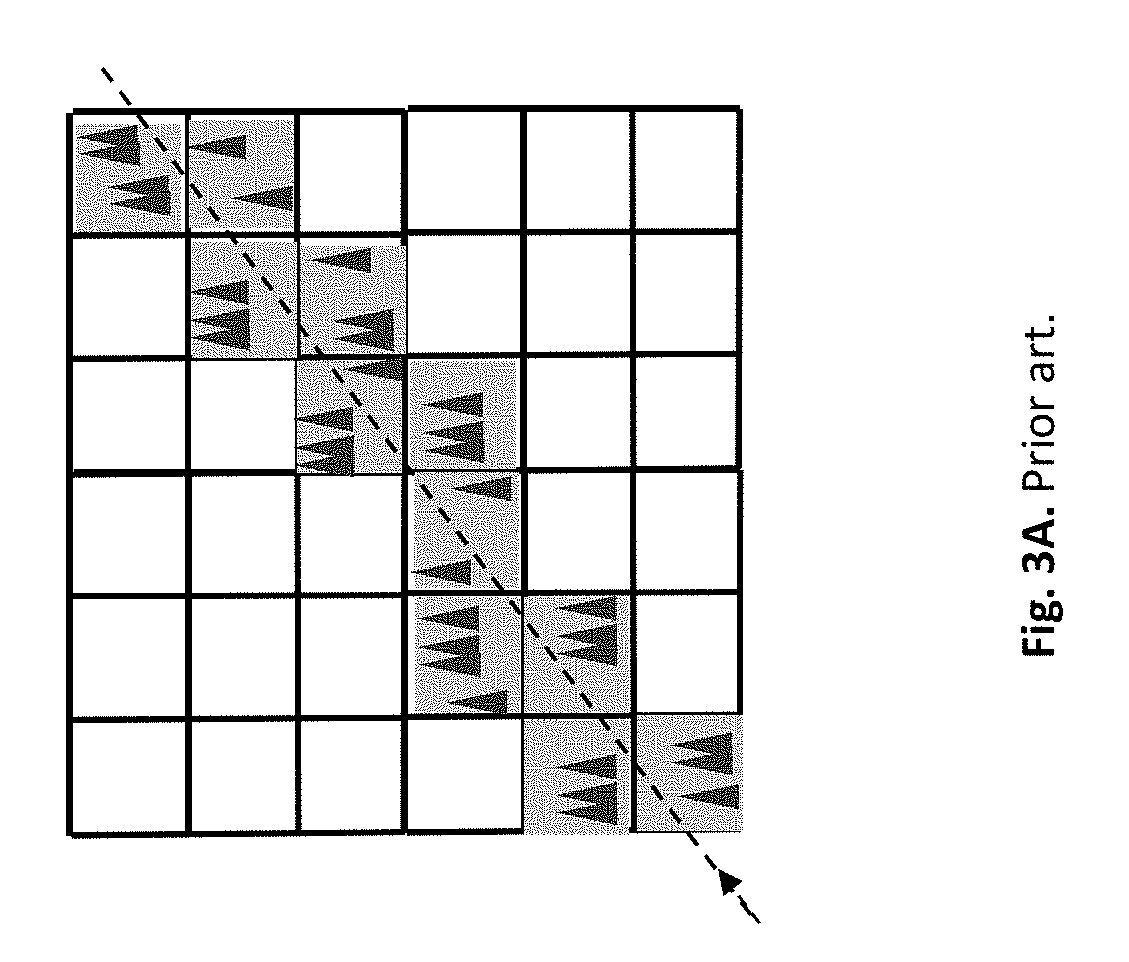

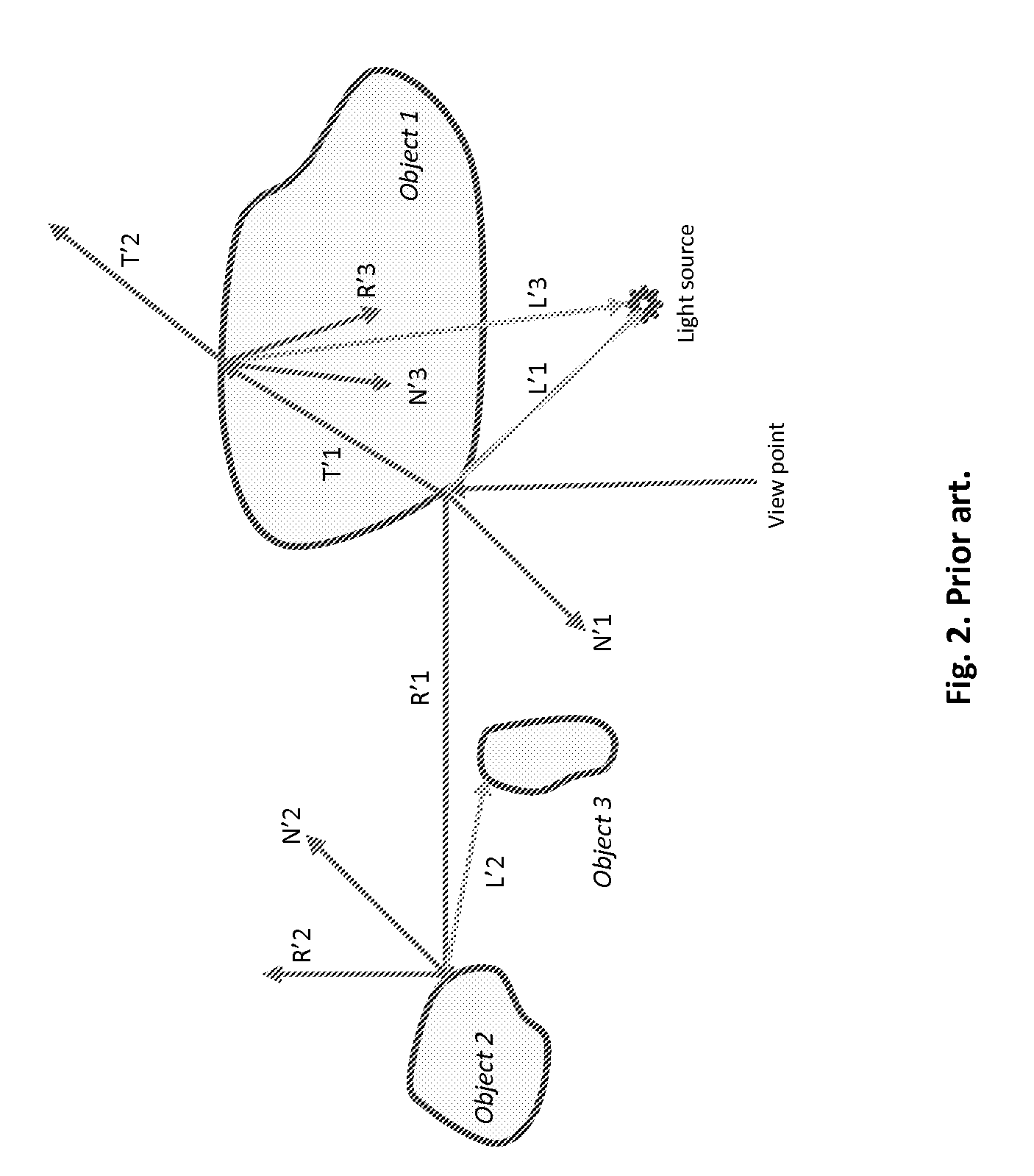

Ray shooting method utilizing geometrical stencils

ActiveUS20140375641A1Effective trackingCut down high traversalDetails involving 3D image dataProgram controlVisibilityViewpoints

Aspects comprise a ray shooting method based on the data structure of a uniform grid of cells, and on local stencils in cells. The high traversal and construction costs of accelerating structures are cut down. The object's visibility from the viewpoint and from light sources, as well as the primary workload and its distribution among cells, are gained in the preprocessing stage and cached in stencils for runtime use. In runtime, the use of stencils allows a complete locality at each cell, for load balanced parallel processing.

Owner:SNAP INC

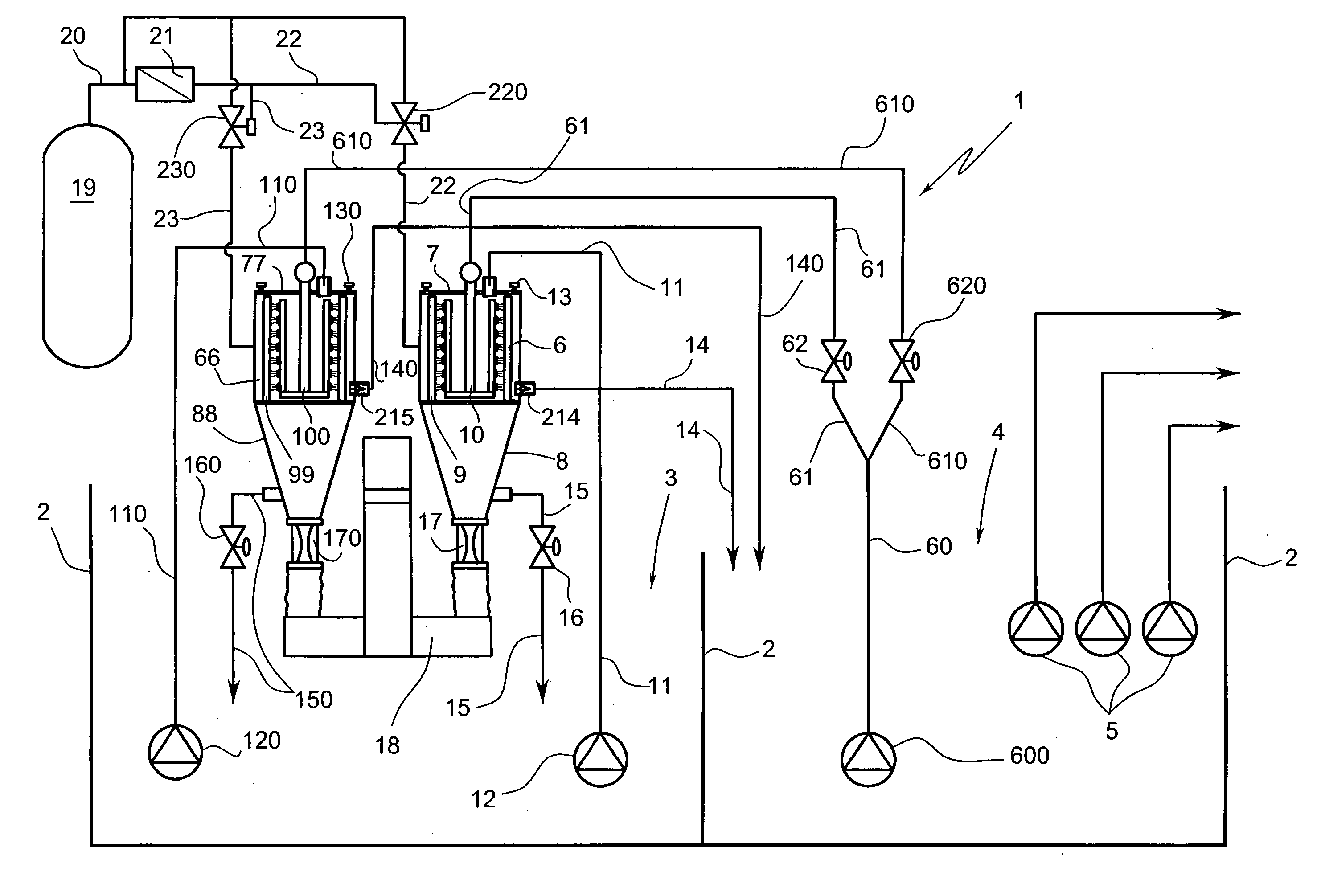

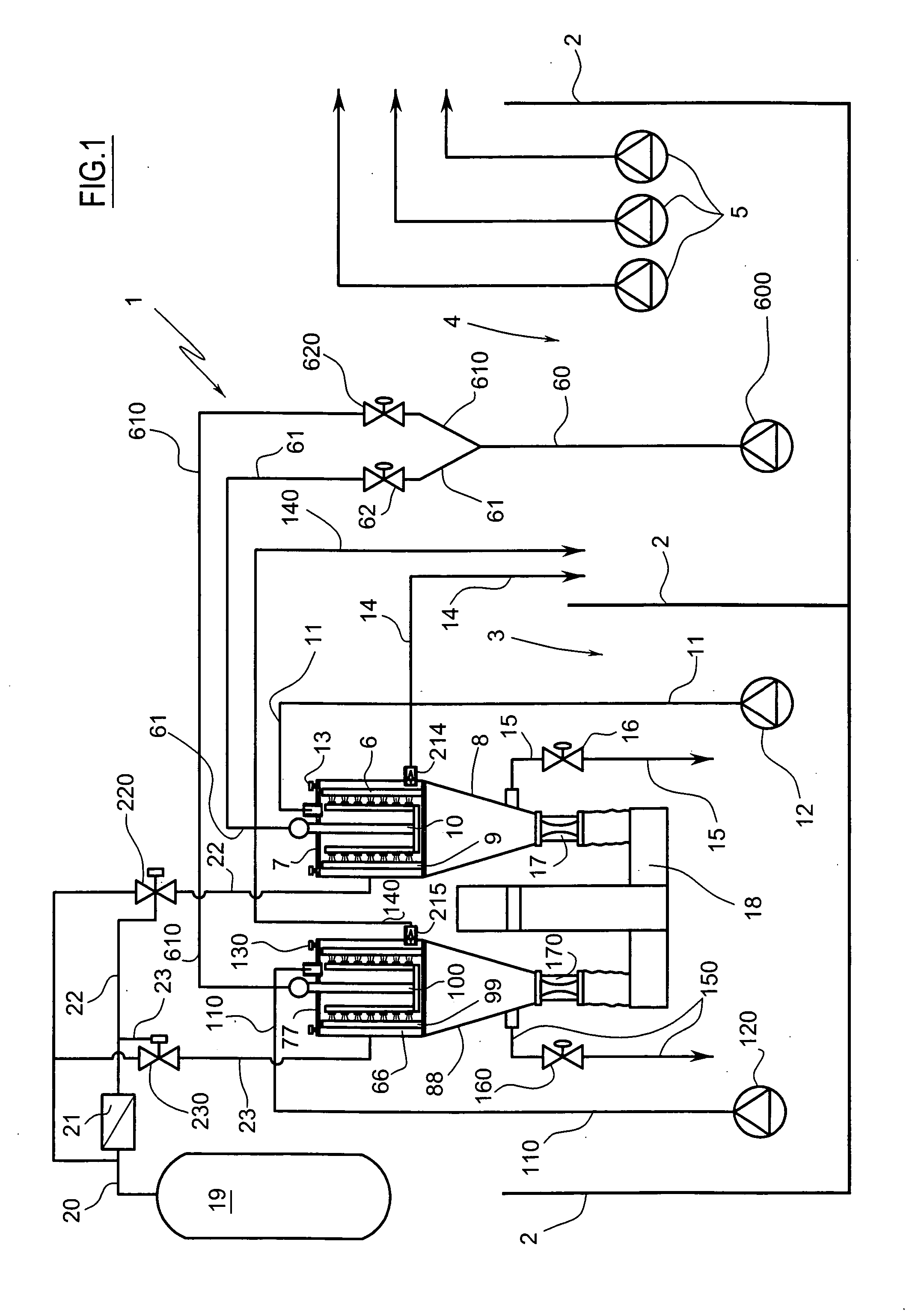

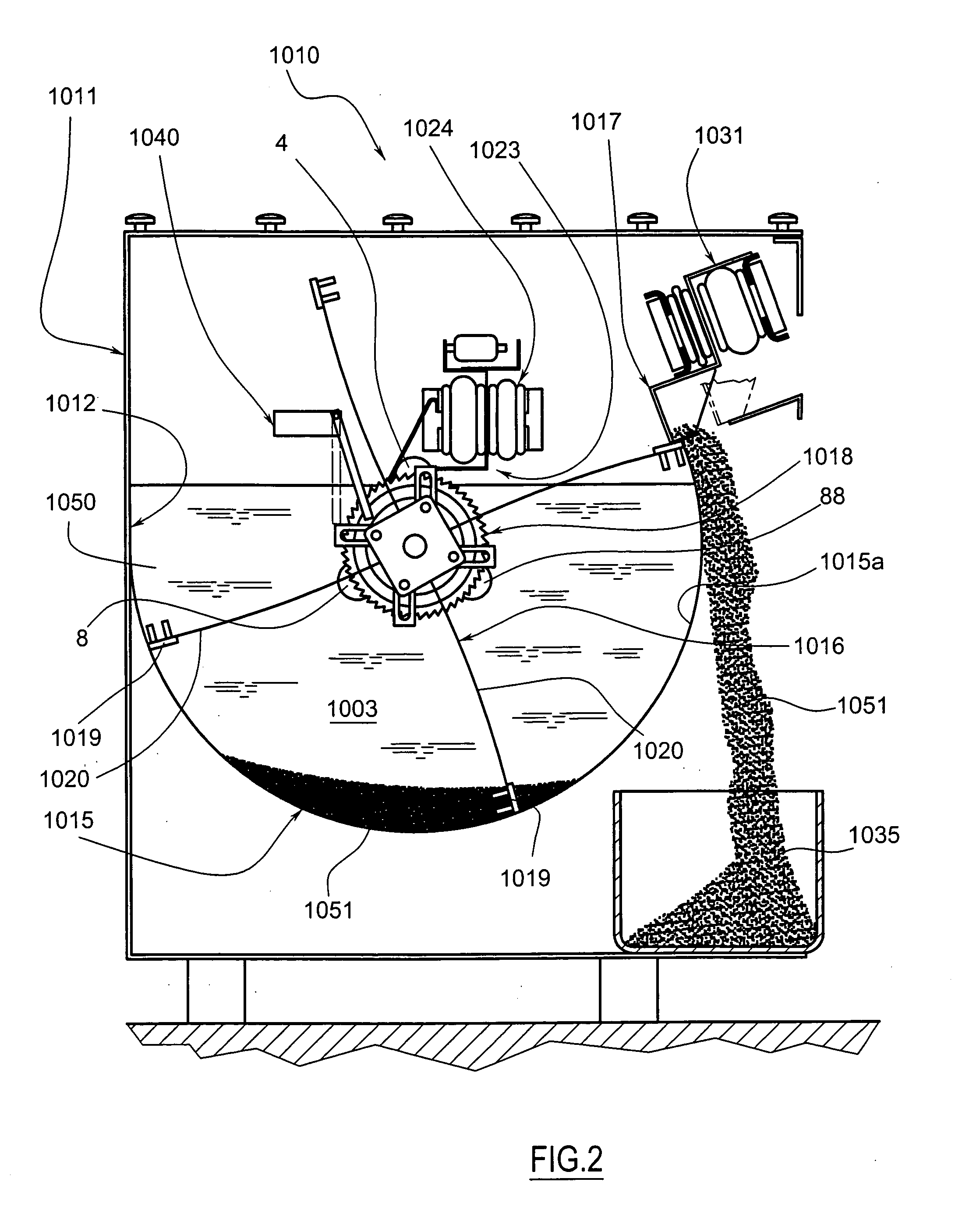

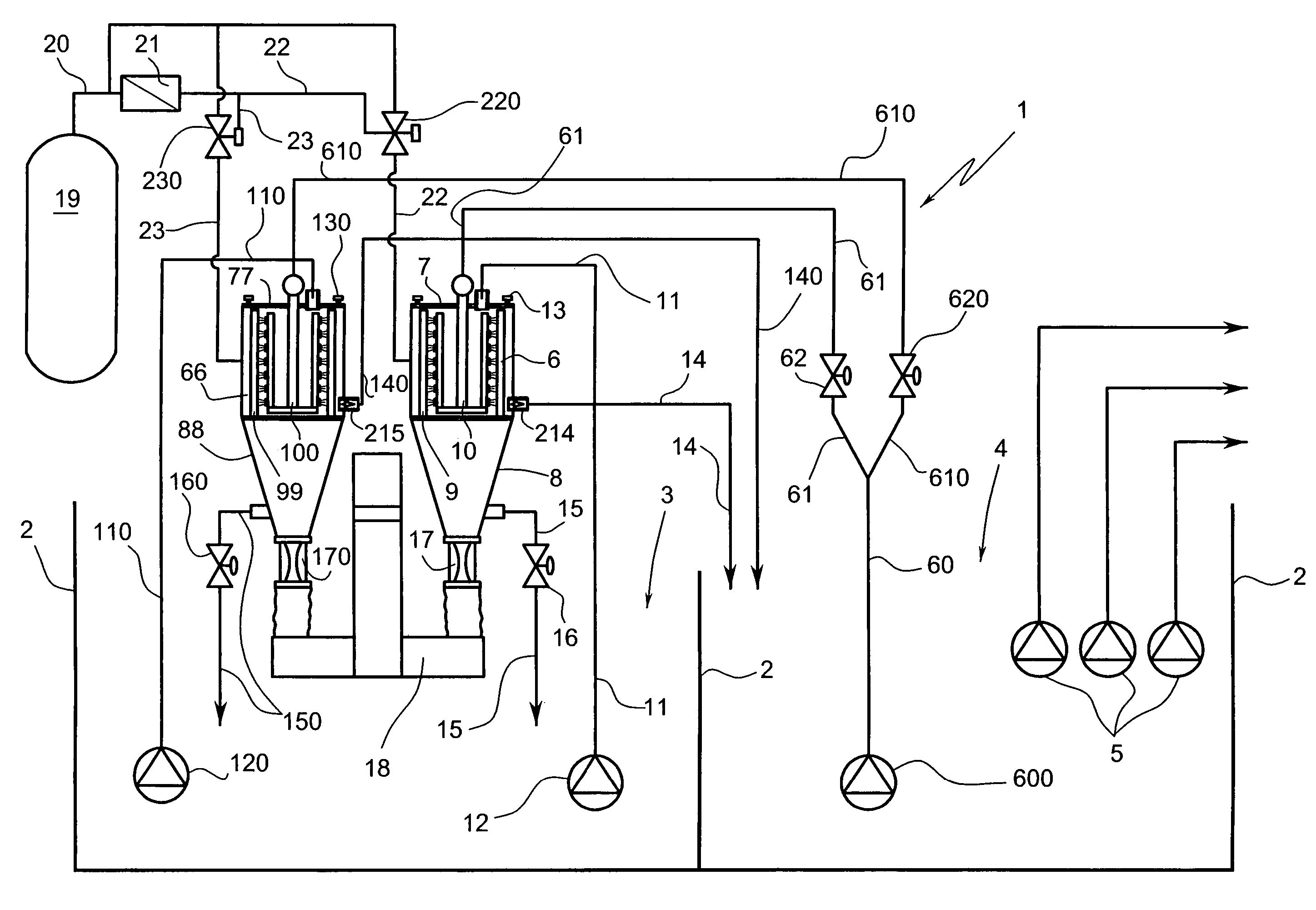

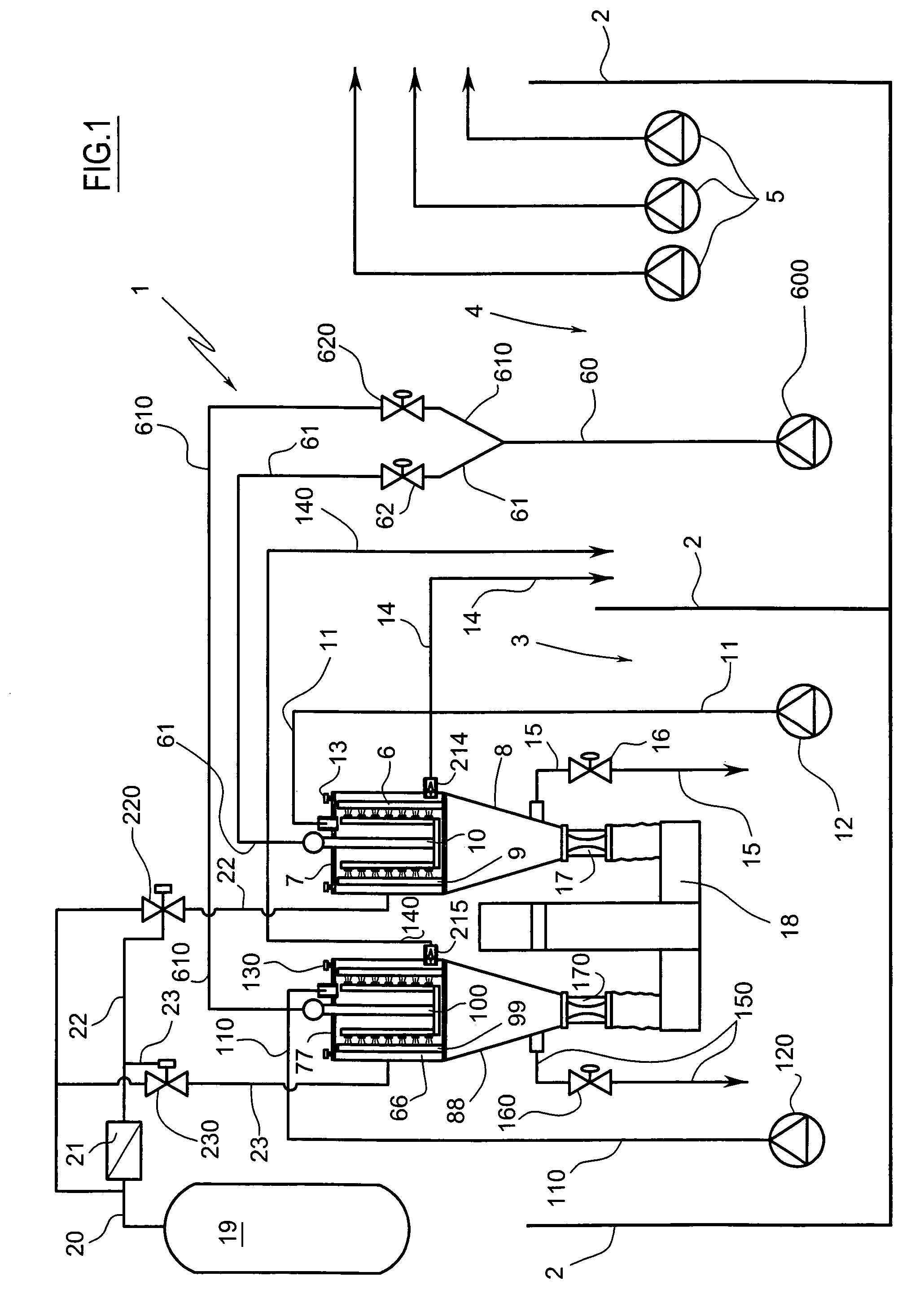

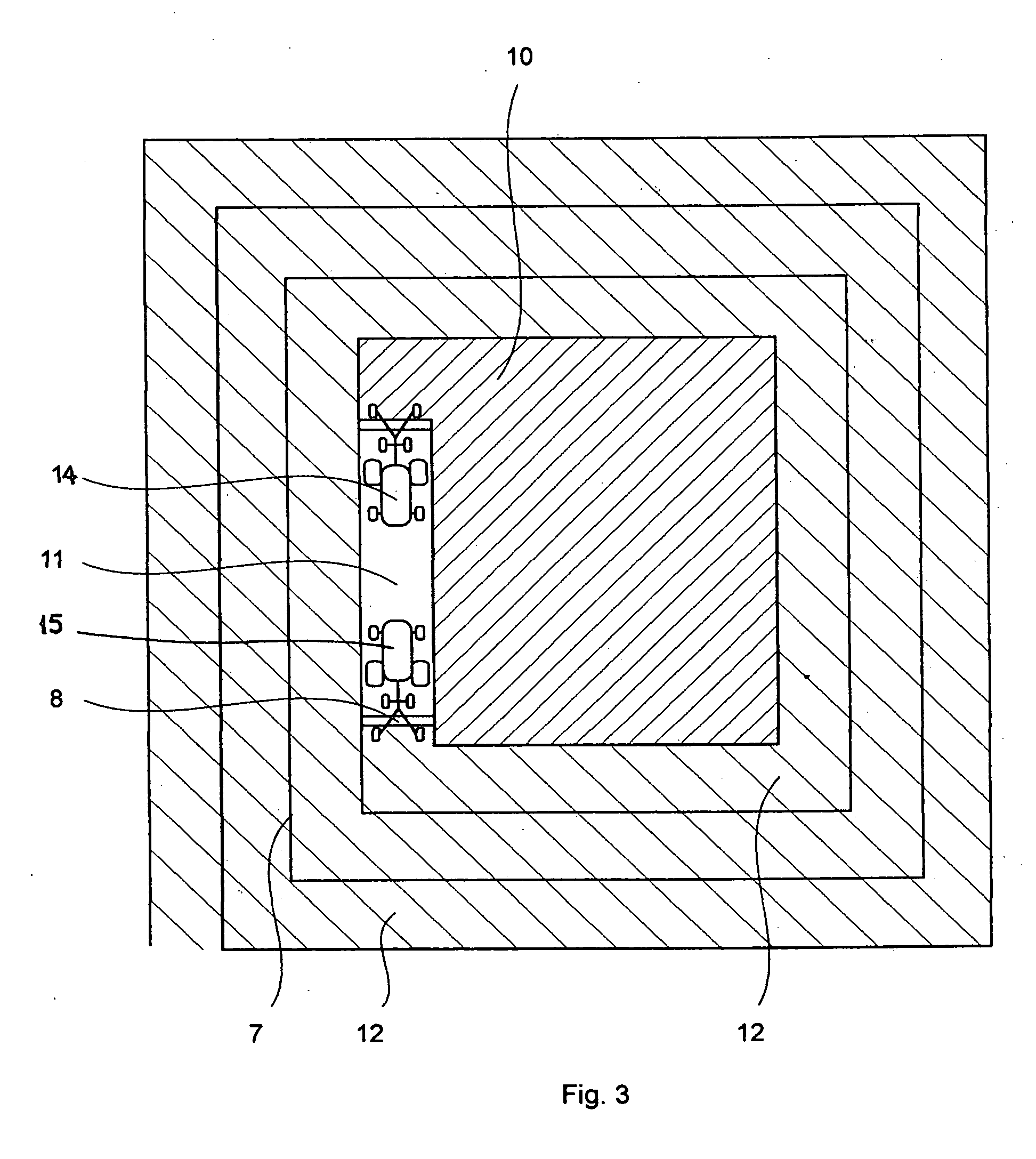

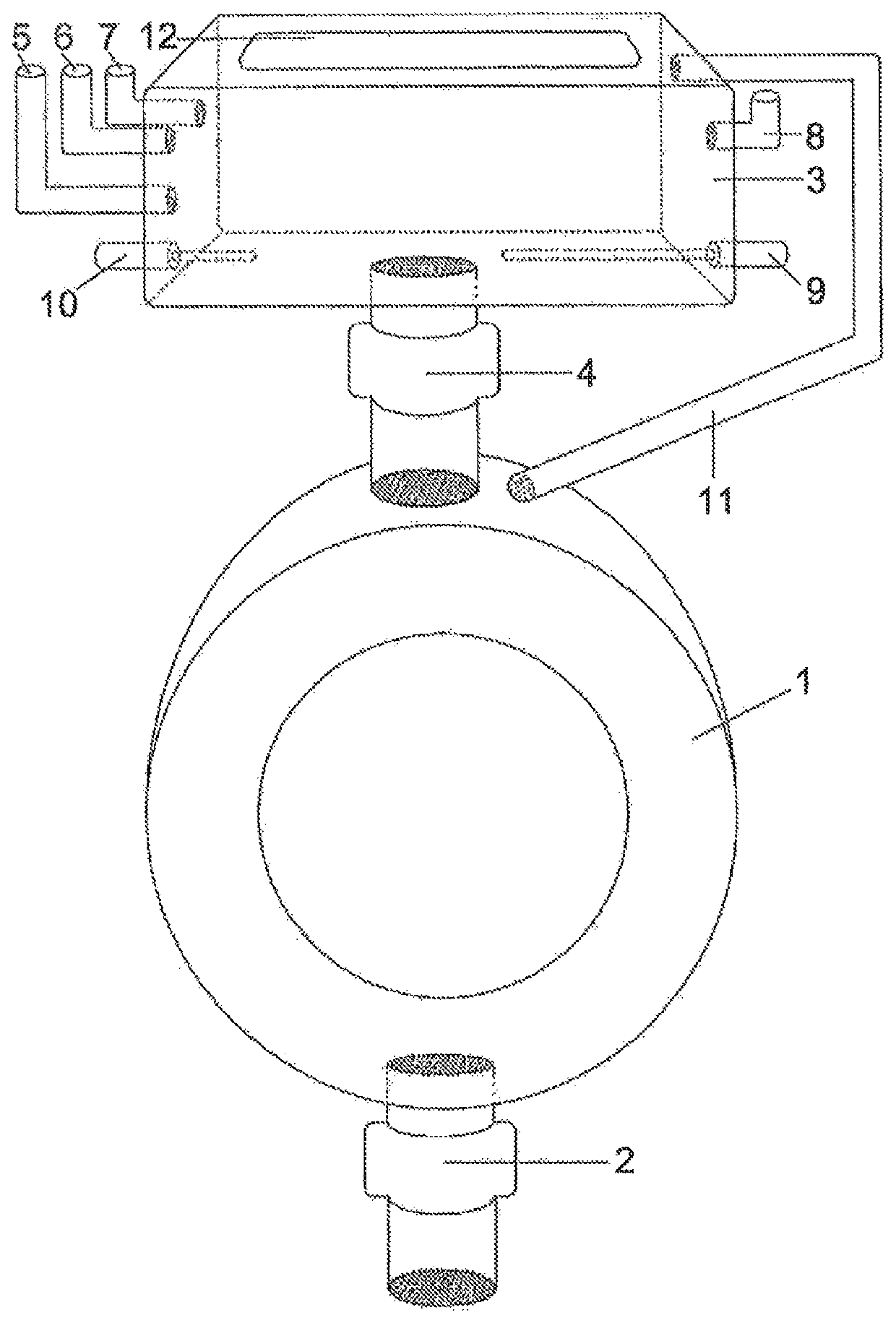

Plant and method for the treatment of the recovery cooling fluid in mechanical processing plants

ActiveUS20050167373A1Improve productivityEliminate idle timeSettling tanks feed/dischargeMembrane filtersFiltrationCooling fluid

Plant for treating the leftover liquids of mechanical processing, comprising a filtering partition (9) for filtration of the fluid and means for cleaning the partition by washing of the layer of mud deposited hereon, comprises vibratory means suitable for causing a generally fast and continuous vibratory state at least in the active portion of the partition. The plant comprises at least one chamber (6) that is divided into two parts by the filtering partition (9), one part being intended for the exit of the filtered fluid, means suitable for causing a generally fast and continuous vibratory state at least in the active portion of the partition are associated with said chamber. Method for treating the leftover fluids of mechanical processing, comprising filtration of the fluid through a filtering partition and periodic cleaning of the partition through washing of the layer of mud deposited here; it foresees that at least the surface of the partition on which the mud deposits is subjected to vibratory motion.

Owner:P M P O

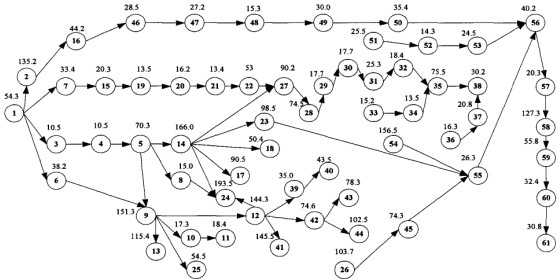

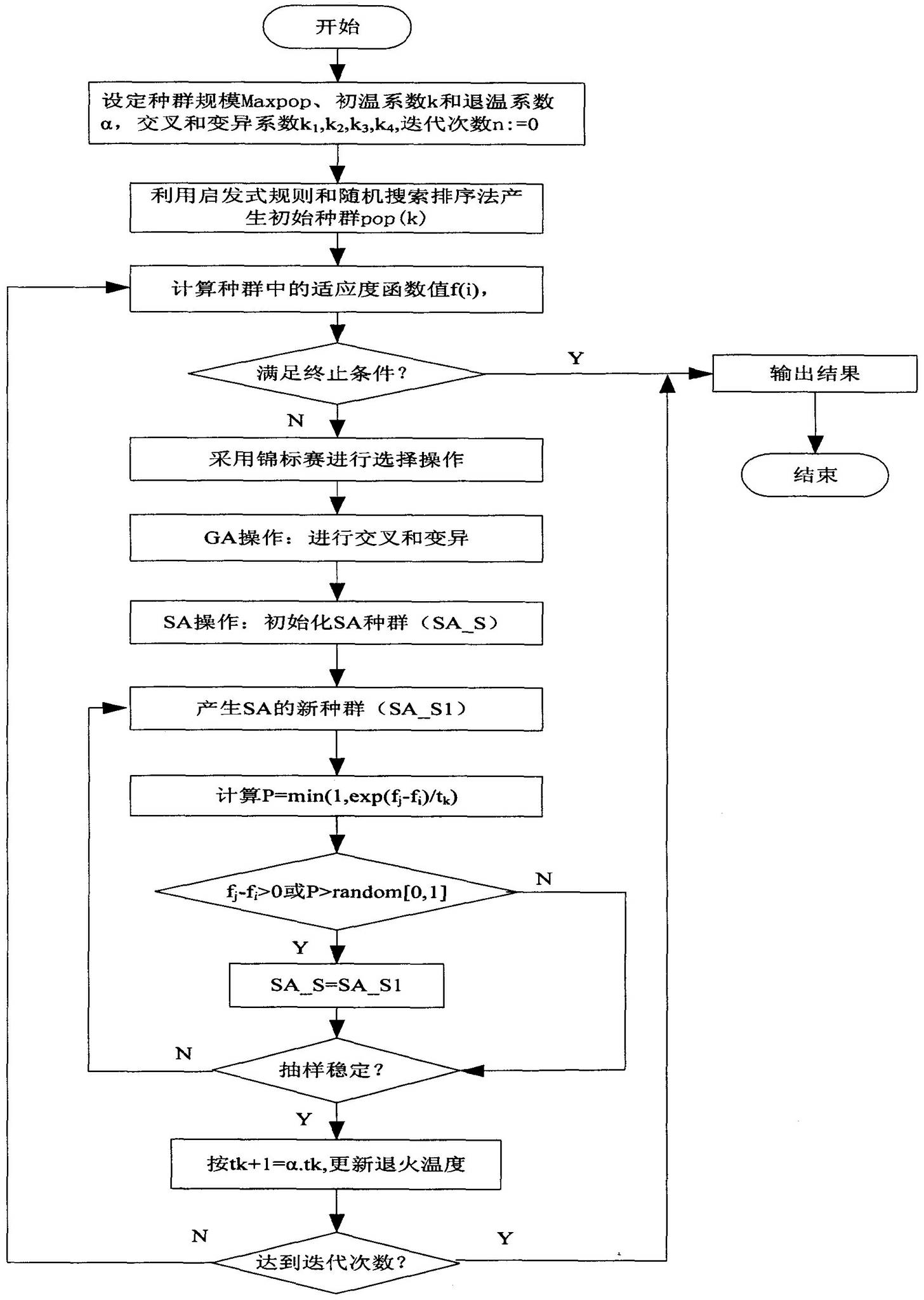

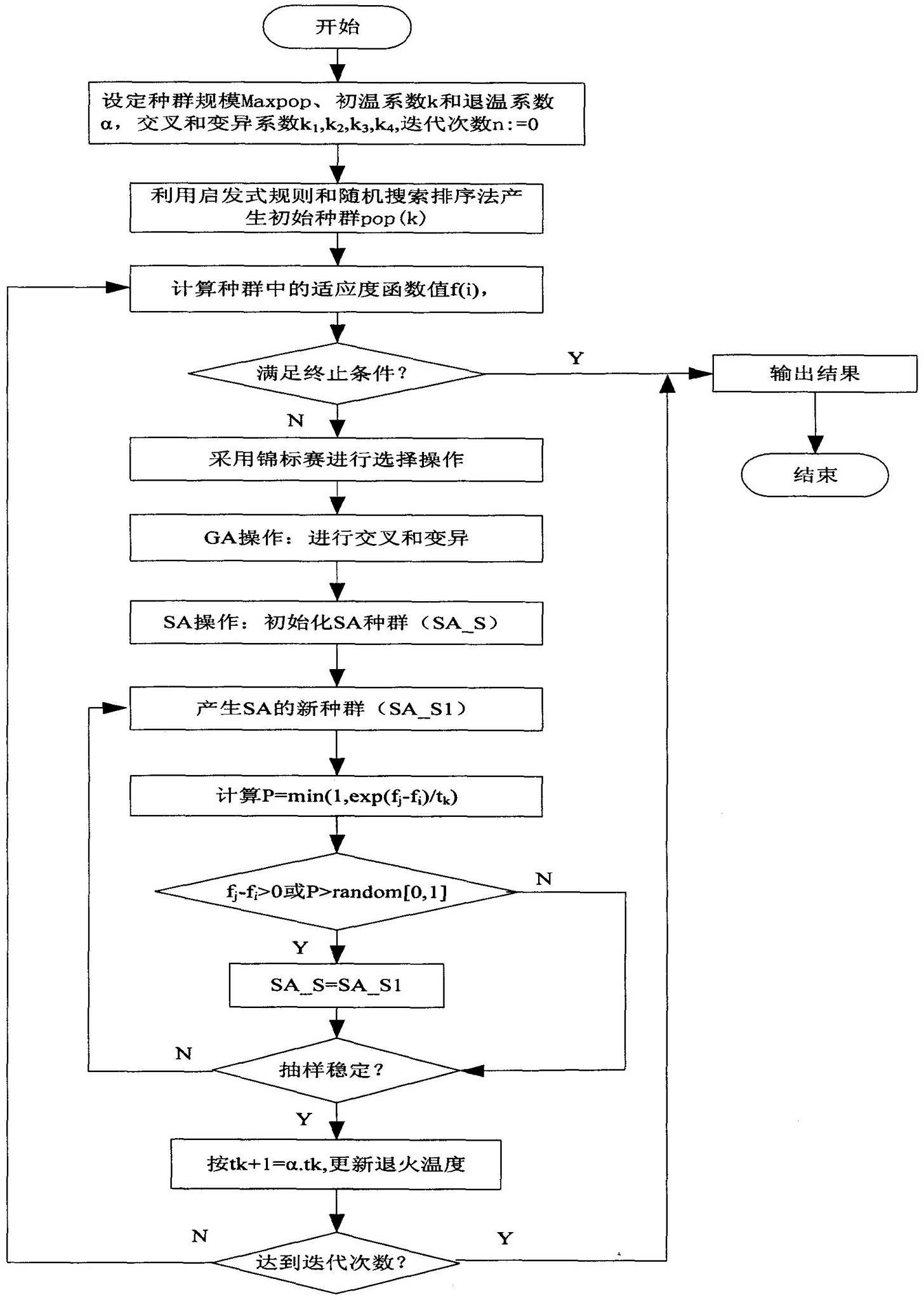

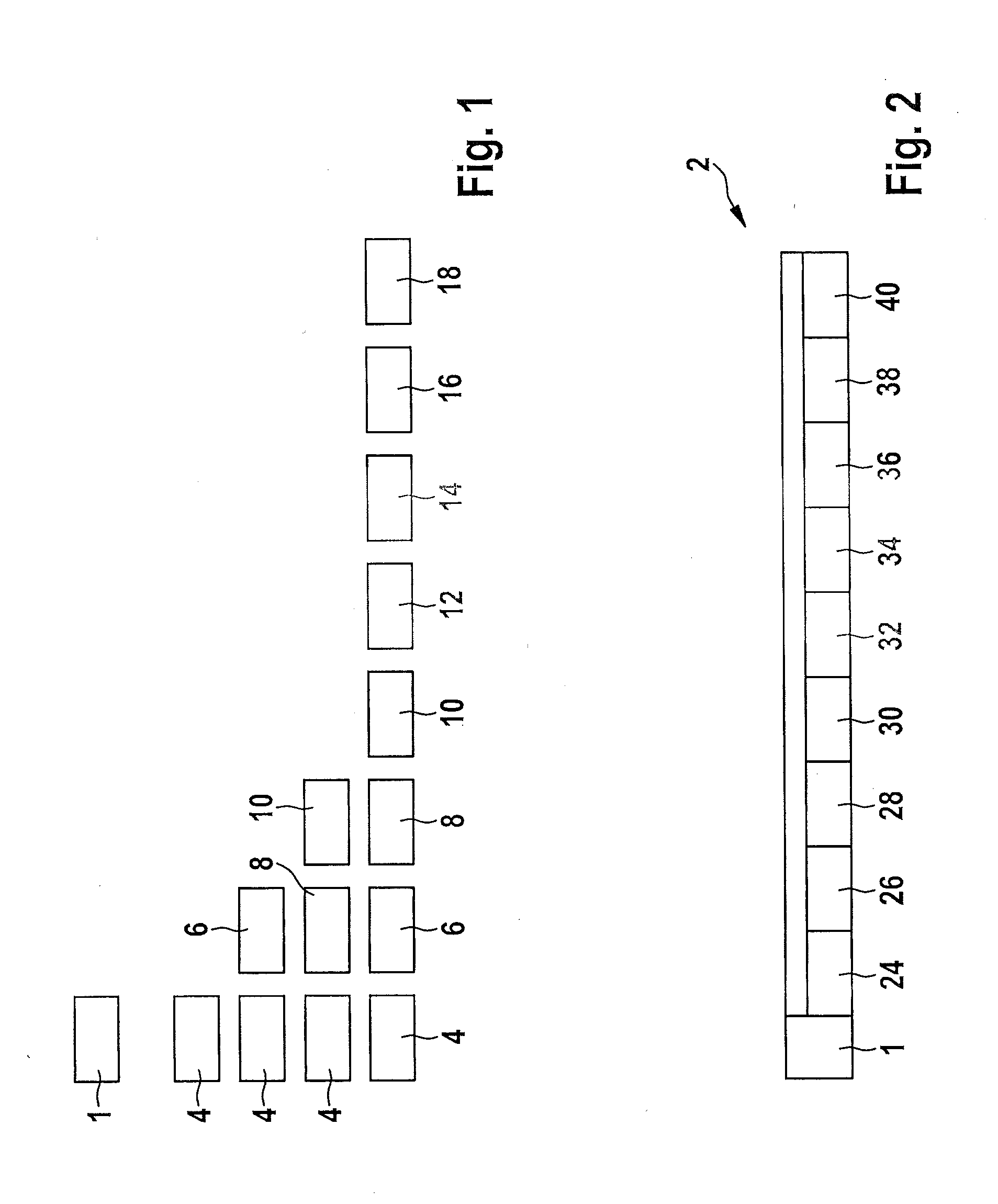

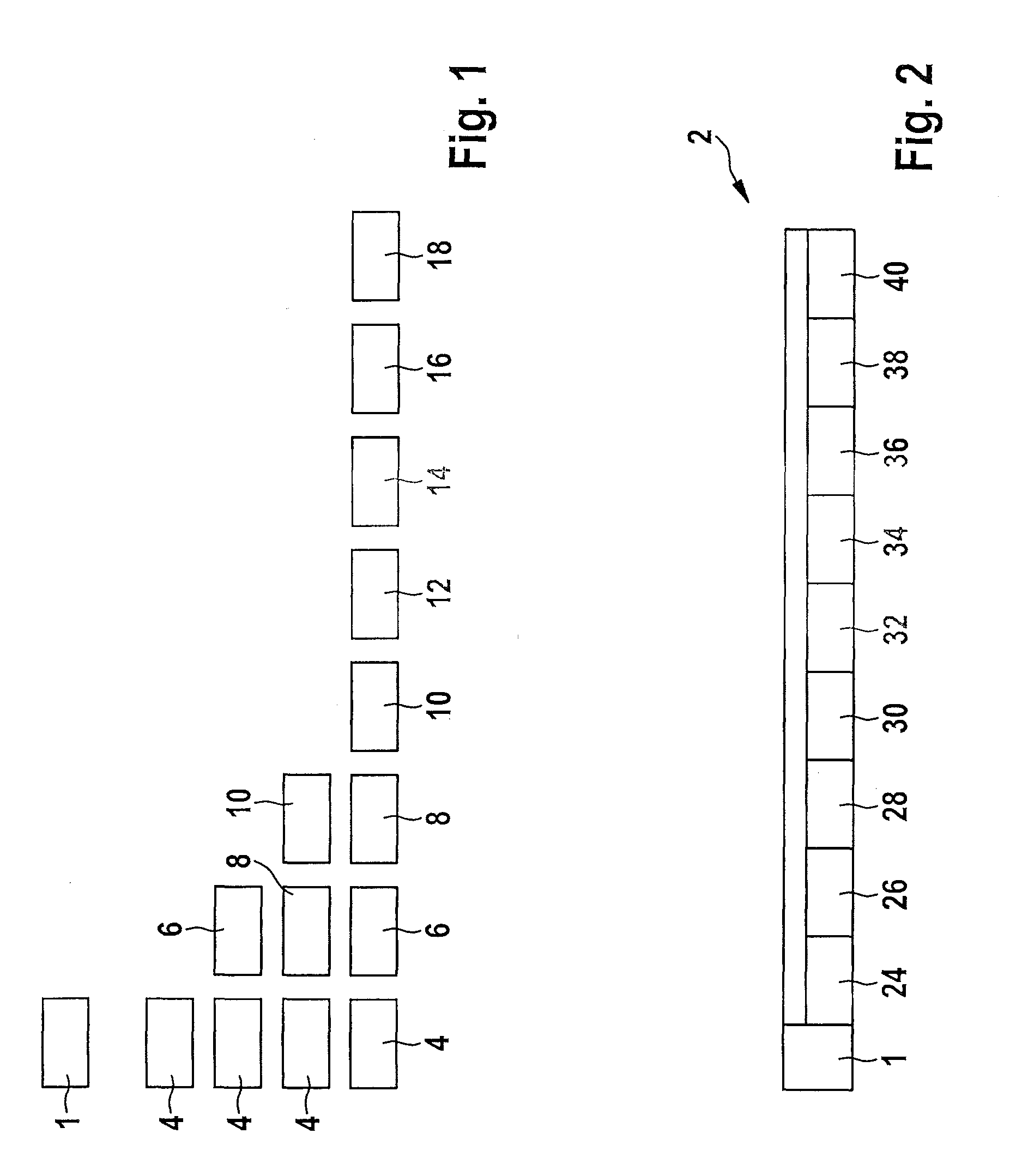

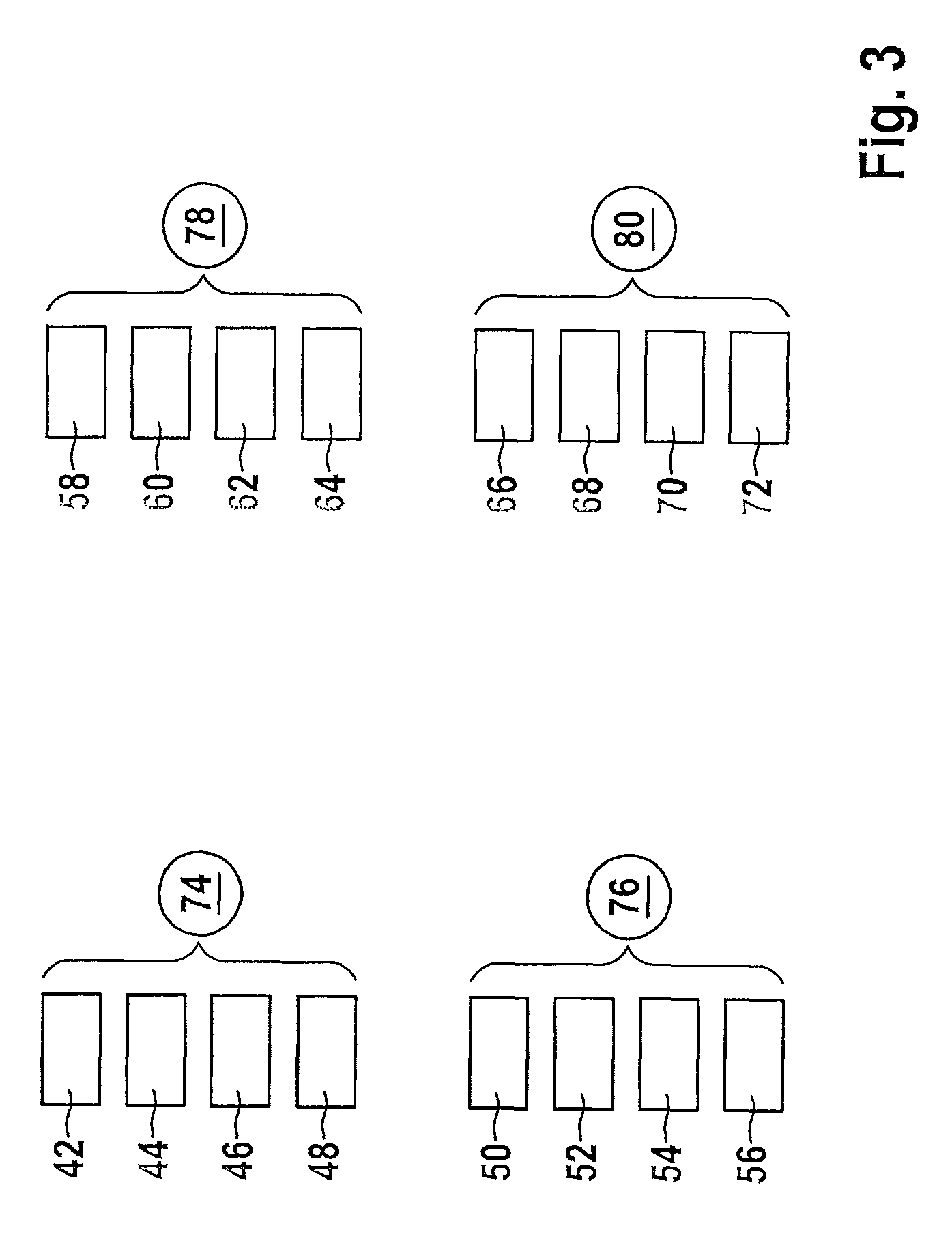

Balance method for reconfigurable assembly line customized on large scale

InactiveCN102354311AEliminate idle timeLow costGenetic modelsSpecial data processing applicationsSelf adaptiveAssembly line

The invention relates to a balance method for a reconfigurable assembly line customized on a large scale. The method comprises the following steps of: establishing a mathematical model for balancing the reconfigurable assembly line customized on a large scale, encoding genes, performing genetic operation, selecting initial temperature, annealing, iterating repeatedly and the like. By the method, the number and loads of workstations and the efficiency of the assembly line can be considered comprehensively, and idle time of each workstation can be eliminated as far as possible so as to fulfill the aim of minimizing cost or maximizing output. Simultaneously, the invention also provides a mixed genetic algorithm for optimizing the balance of the assembly line. In the algorithm, by combining a simulation annealing algorithm and a genetic algorithm and adopting a self-adaption reconfiguration strategy of cross probability and mutation probability, the defects of local searching, low convergence and the like of the genetic algorithm in actual application can be effectively avoided, and the problems that the conditions of integral searching space is not known much and operation efficiency is low in the simulation annealing algorithm can be solved.

Owner:HOHAI UNIV CHANGZHOU

Plant and method for the treatment of the recovery cooling fluid in mechanical processing plants

ActiveUS8361313B2Eliminate idle timeImprove productivityMachines/enginesLoose filtering material filtersFiltrationCooling fluid

Plant for treating the leftover liquids of mechanical processing, comprising a filtering partition (9) for filtration of the fluid and means for cleaning the partition by washing of the layer of mud deposited hereon, comprises vibratory means suitable for causing a generally fast and continuous vibratory state at least in the active portion of the partition.The plant comprises at least one chamber (6) that is divided into two parts by the filtering partition (9), one part being intended for the exit of the filtered fluid, means suitable for causing a generally fast and continuous vibratory state at least in the active portion of the partition are associated with said chamber.Method for treating the leftover fluids of mechanical processing, comprising filtration of the fluid through a filtering partition and periodic cleaning of the partition through washing of the layer of mud deposited here; it foresees that at least the surface of the partition on which the mud deposits is subjected to vibratory motion.

Owner:P M P O

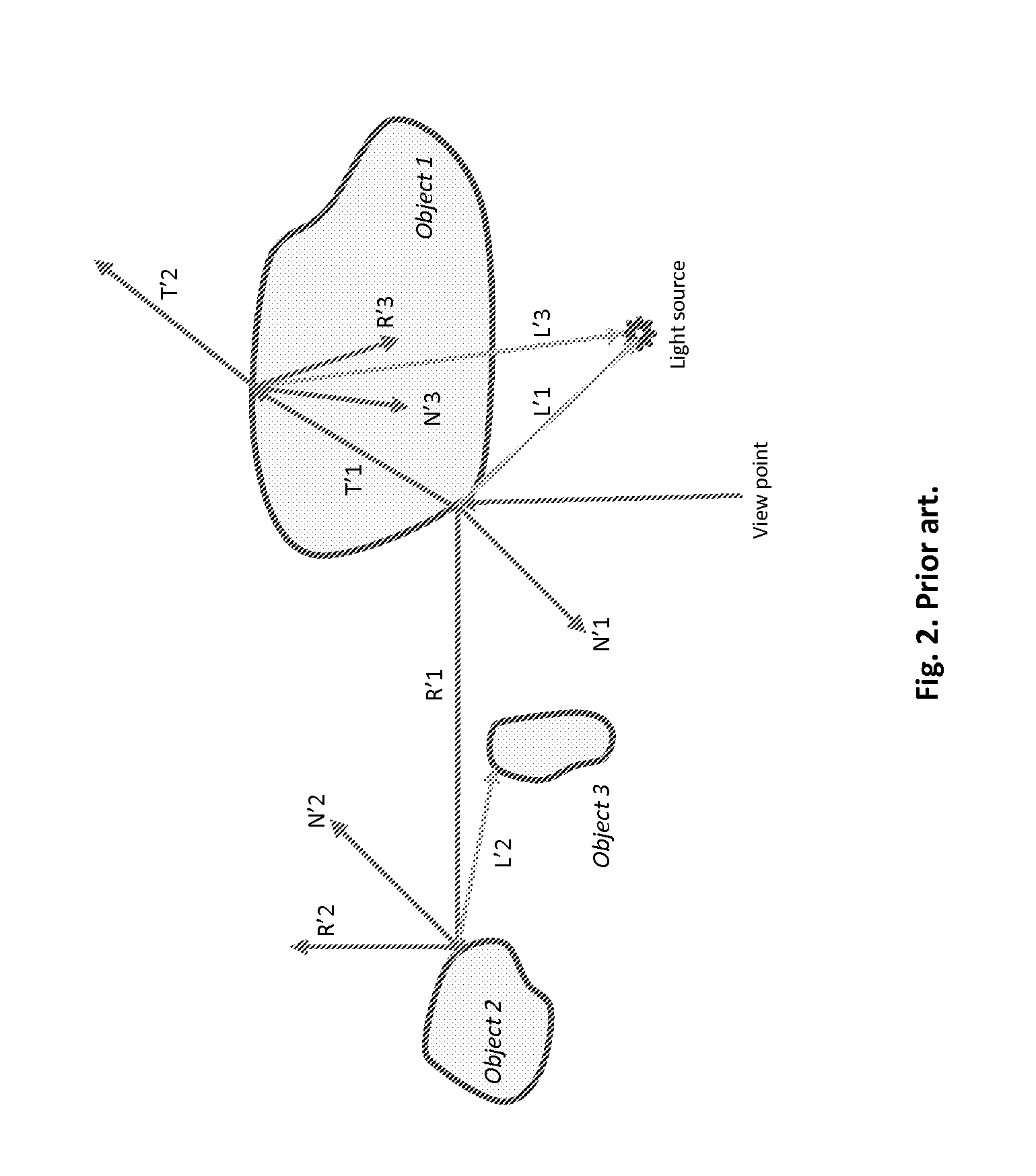

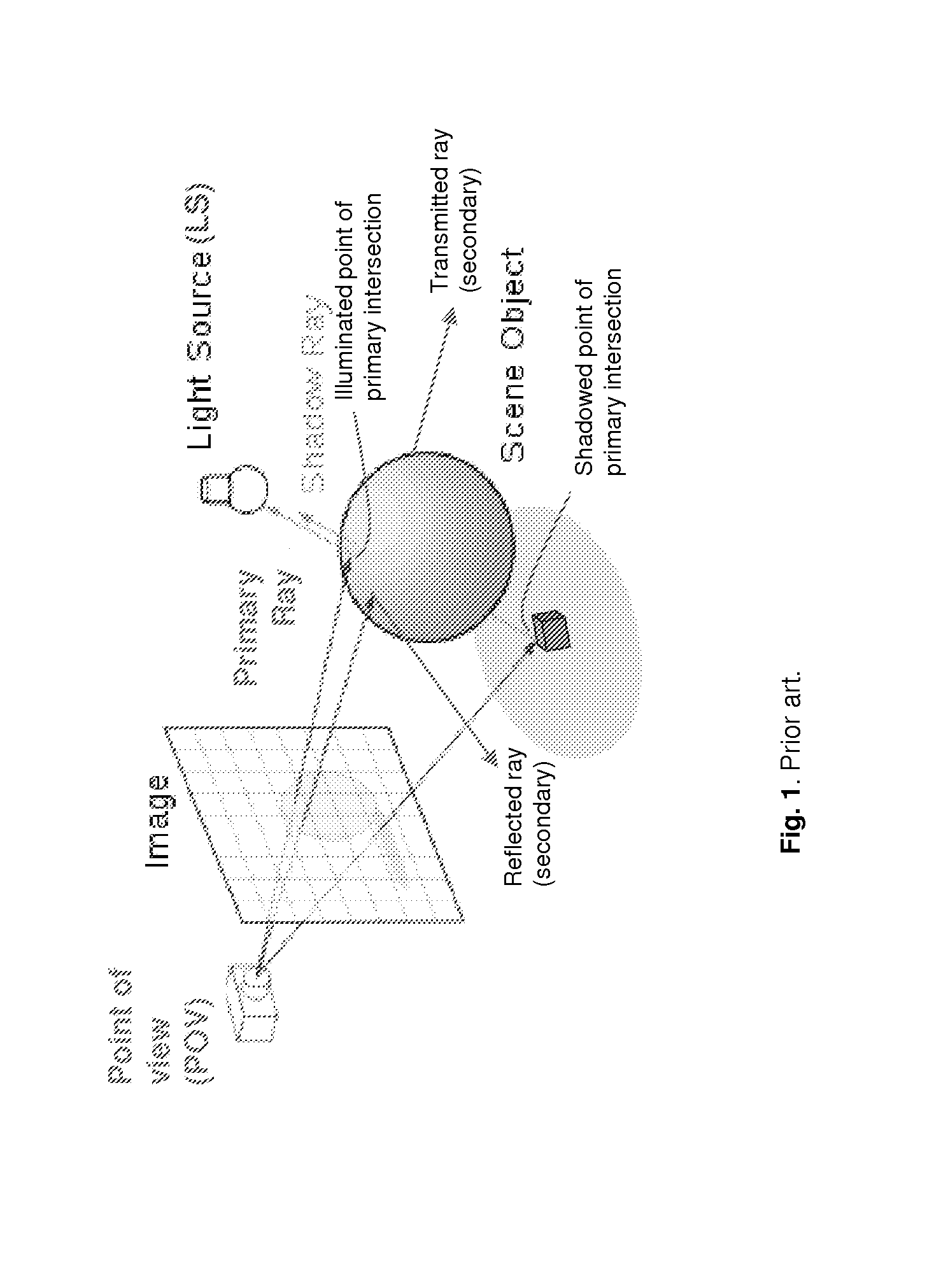

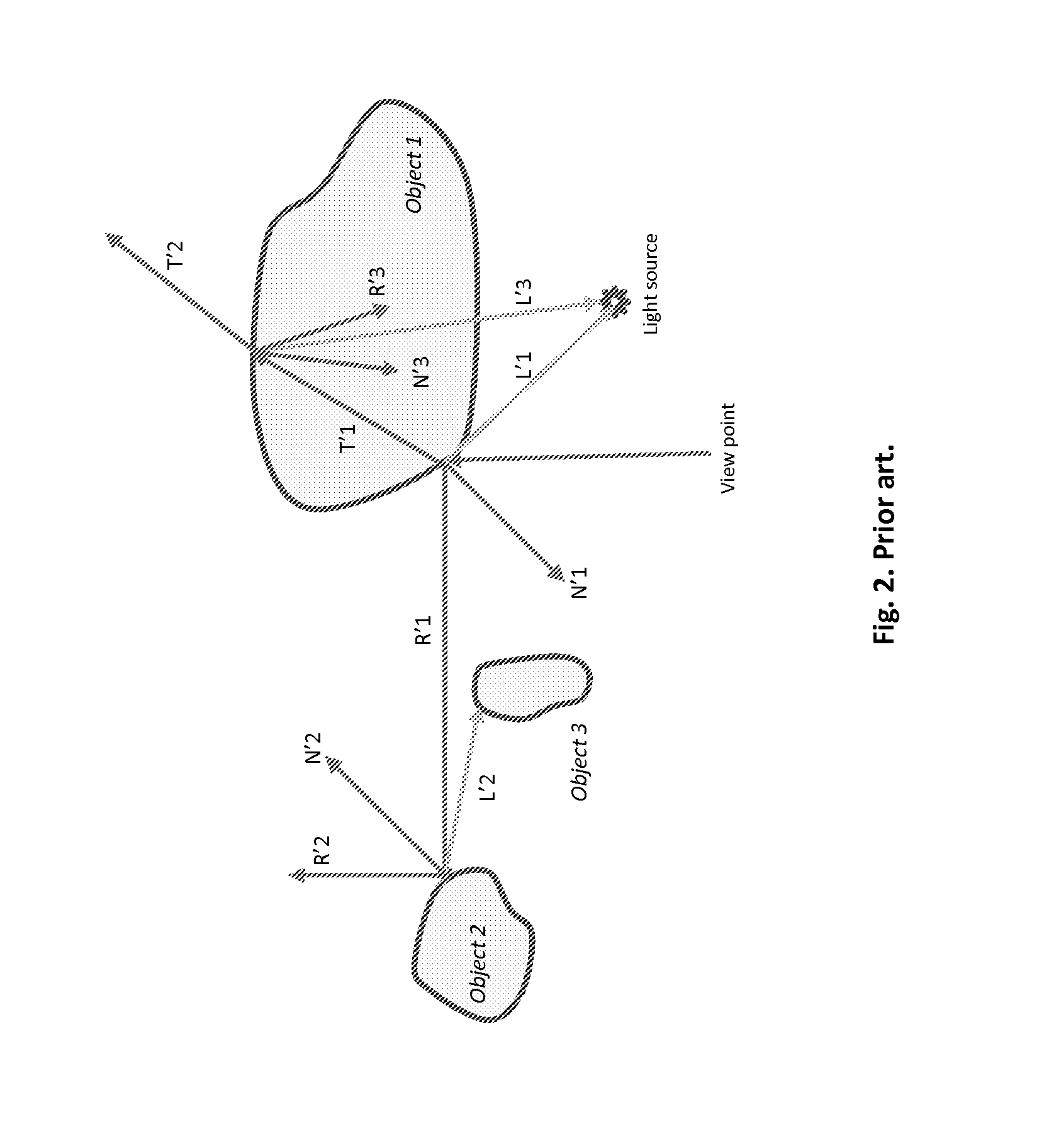

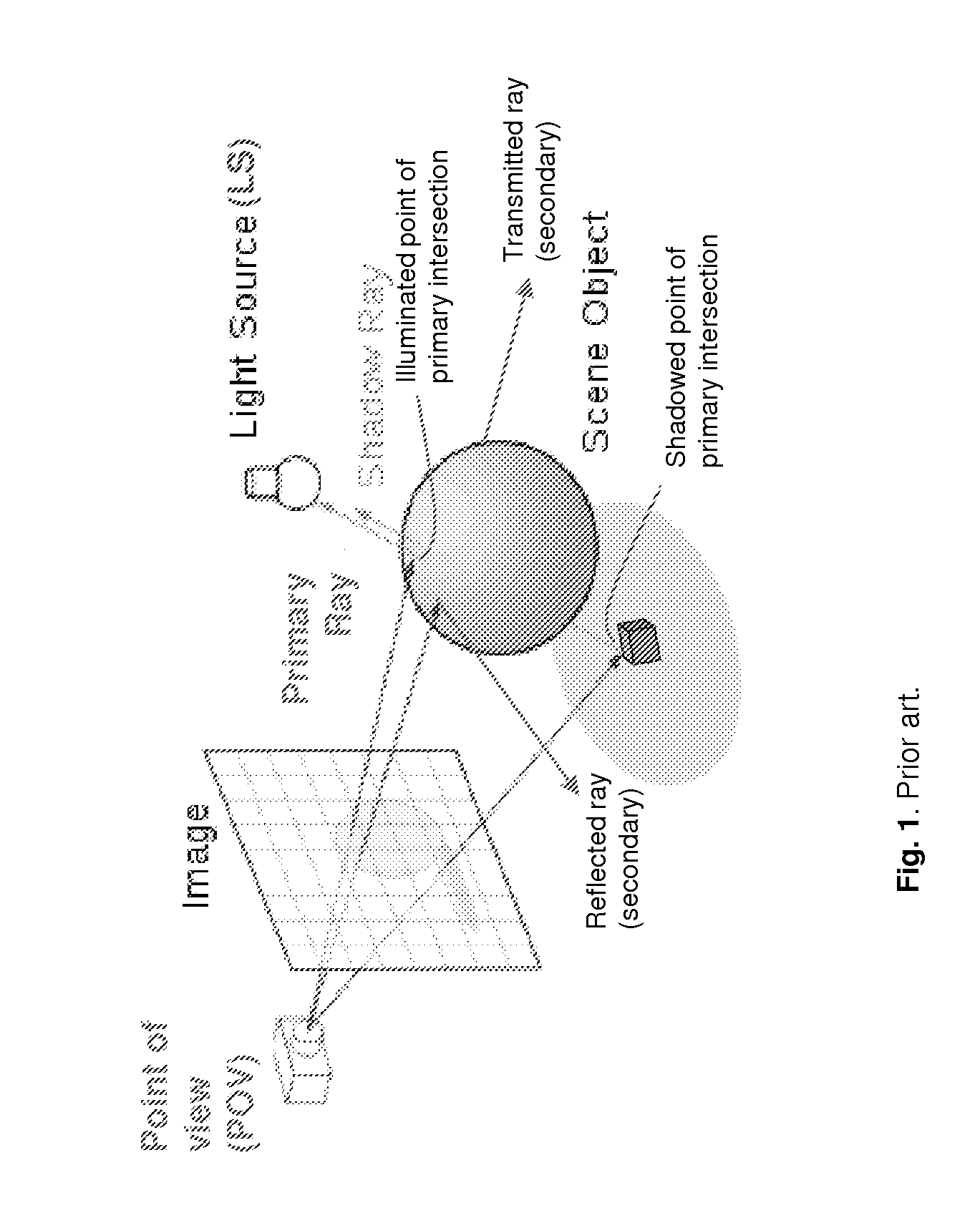

Shadowing Method for Ray Tracing Based on Geometrical Stencils

ActiveUS20160155258A1Effective trackingCut down high traversal and construction costProgram controlImage generationVisibilityViewpoints

Aspects comprise a ray tracing shadowing method based on the data structure of a uniform grid of cells, and on local stencils in cells. The high traversal and construction costs of accelerating structures are cut down. The object's visibility from the viewpoint and from light sources, as well as the primary workload and its distribution among cells, are gained in the preprocessing stage and cached in stencils for runtime use. In runtime, the use of stencils allows a complete locality at each cell, for load balanced parallel processing.

Owner:SNAP INC

Method for operating a bus system

ActiveUS20130117483A1Avoid idle timeIncrease data transfer rateData switching networksElectric digital data processingTime scheduleEmbedded system

A method for operating a bus system, which includes a master and k slaves as users, where a header of an interrogation frame, which includes k information fields, is transmitted by the master to the slaves; in each instance, an mth slave being assigned an mth information field; an information item regarding the amount of data that is to be sent by the mth slave to the master being written by the mth slave to the mth information field assigned to it; the interrogation frame being transmitted to the master; and a time schedule, by which the amount of data to be sent is taken into account, being prepared by the master for transmitting the data.

Owner:ROBERT BOSCH GMBH

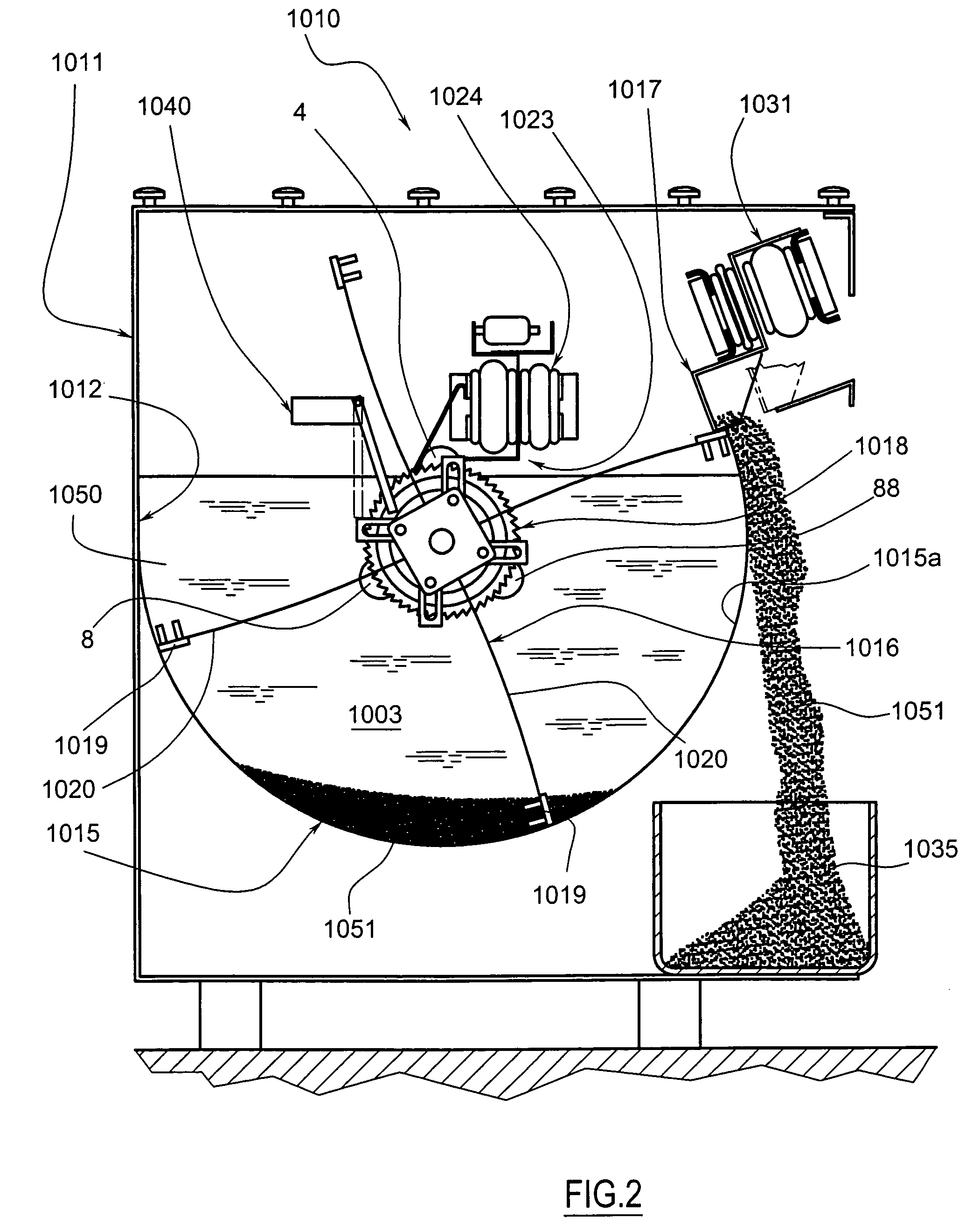

Washing Machine Fill Reservoir

ActiveUS20170191207A1Eliminate idle timeReduce processing timeOther washing machinesTextiles and paperBleachInlet valve

A Washing Machine Fill Reservoir comprising of a basin large enough to replenish the appropriate volume of water to adequately fill the wash drum of a washing machine.The shape of the Washing Machine Fill Reservoir configured to any dimensions desirable, as long as the capacity is sufficient to accommodate the appropriate amount of liquid required.Inlet valves allow the introduction of hot and cold water, additives including but not limited to soap, fabric softener, chlorine bleach and emulsifiers.A large orifice valve positioned between the Washing Machine Fill Reservoir and the washer drum enables prompt introduction of the fluid maintained in the Washing Machine Fill Reservoir to be conveyed into the washer drum.Fluid level in the Washing Machine Fill Reservoir may be either fixed volume or adjustable via an internal or external sensing device.A heating element and associated sensor may be incorporated to maintain or boost water temperature as desired.The overall advantage that the Washing Machine Fill Reservoir offers is a significantly reduced operating duration of the washing machine, without diminishing the quality of the laundering process. A significantly reduced operating time of the washing machine translates directly into increased laundry room efficiency and lower operating costs.

Owner:MCCLOY JOHN

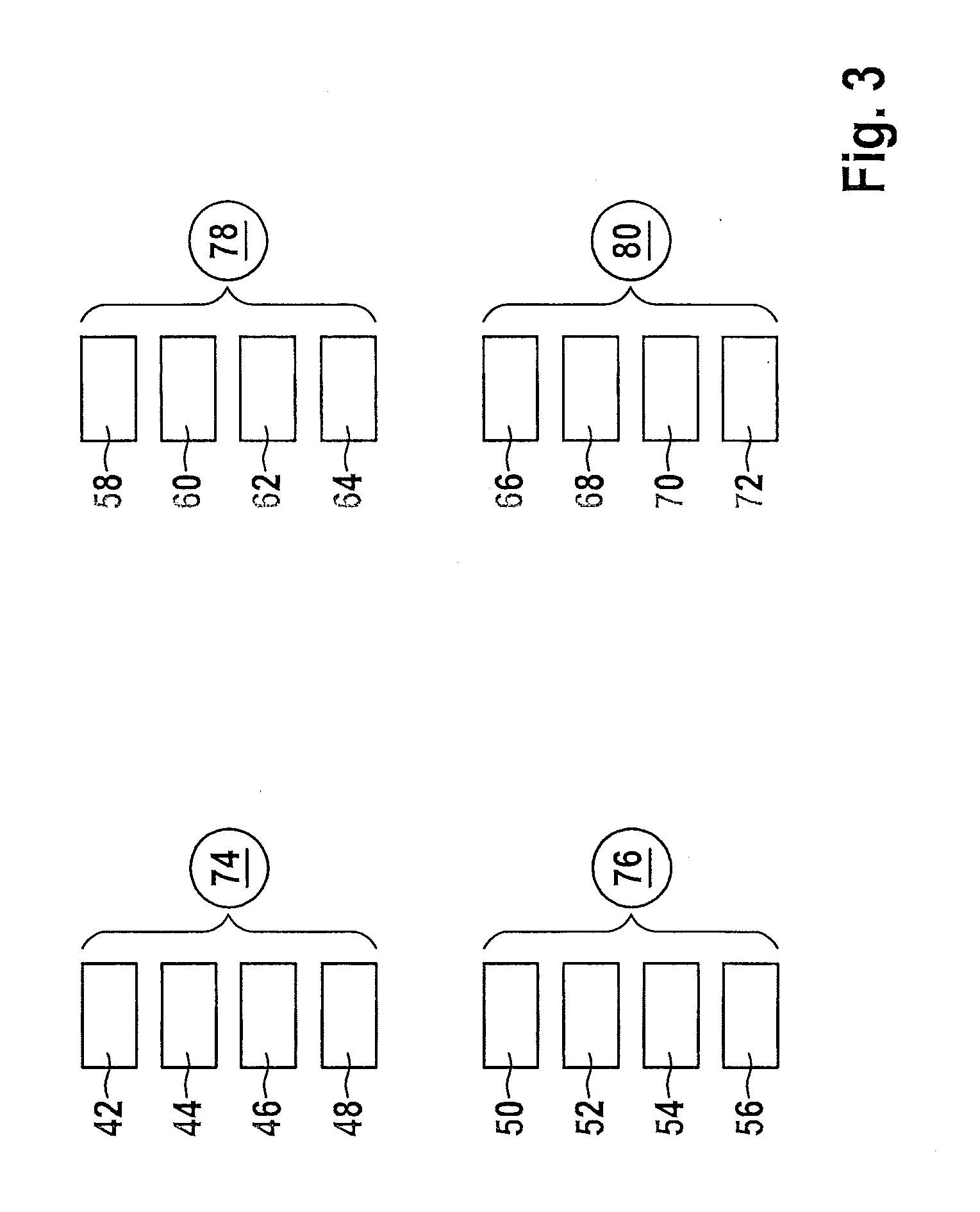

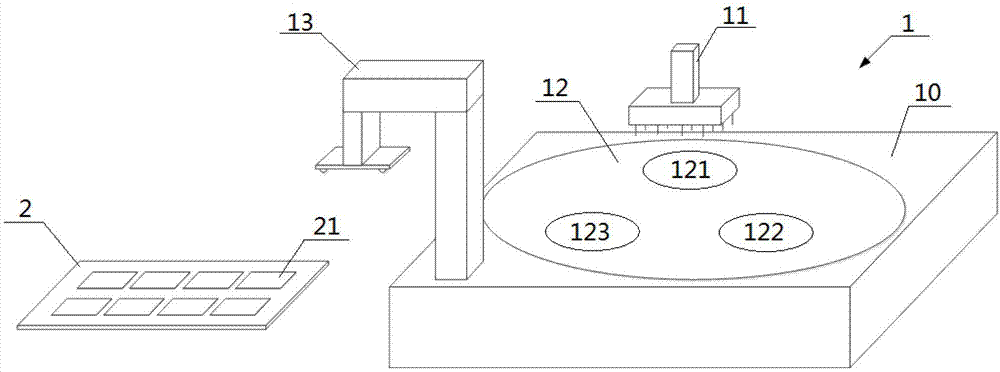

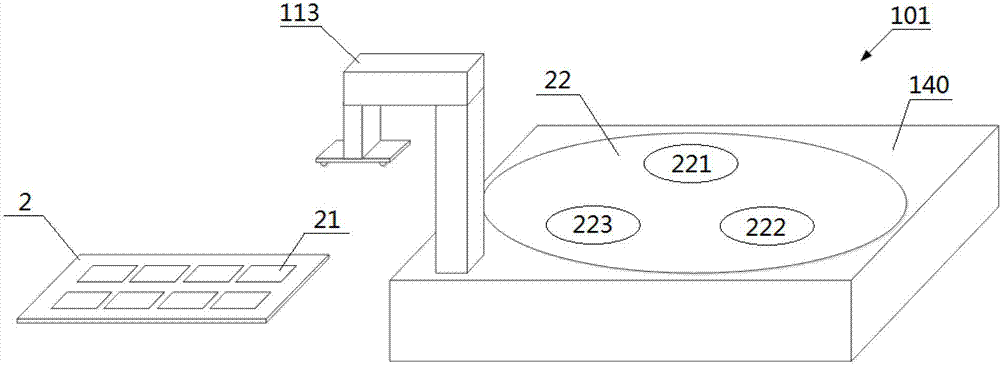

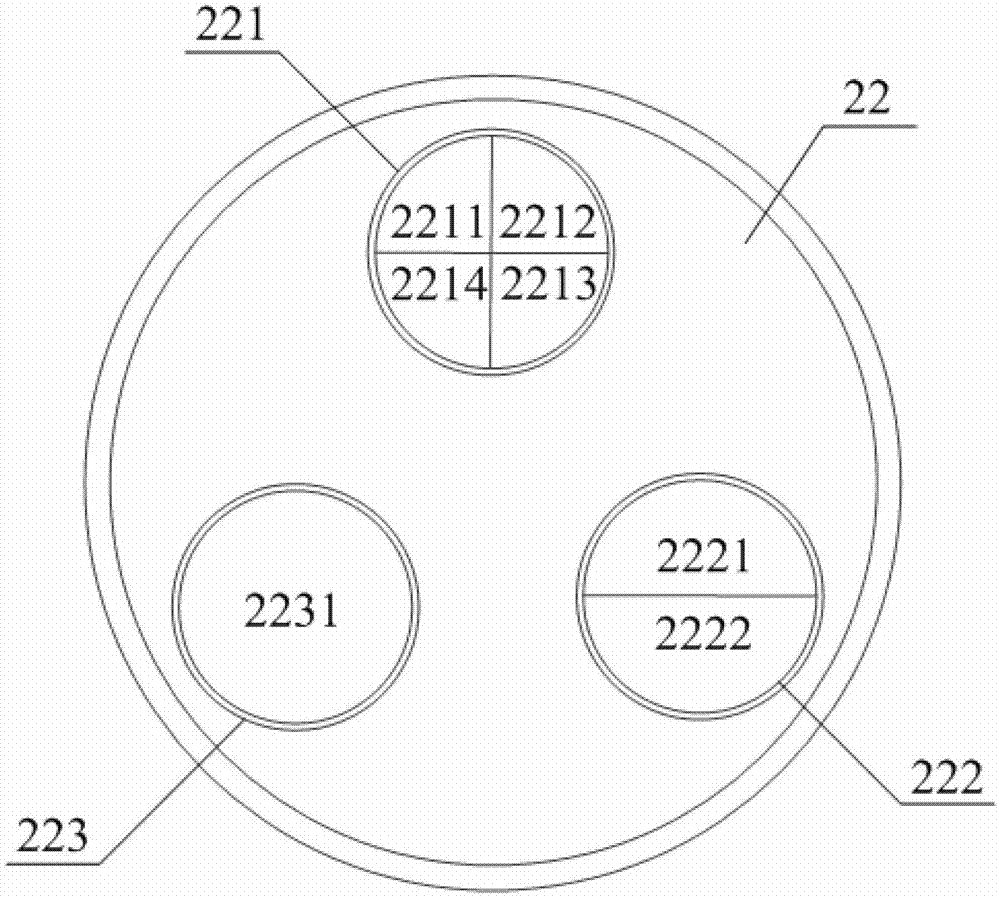

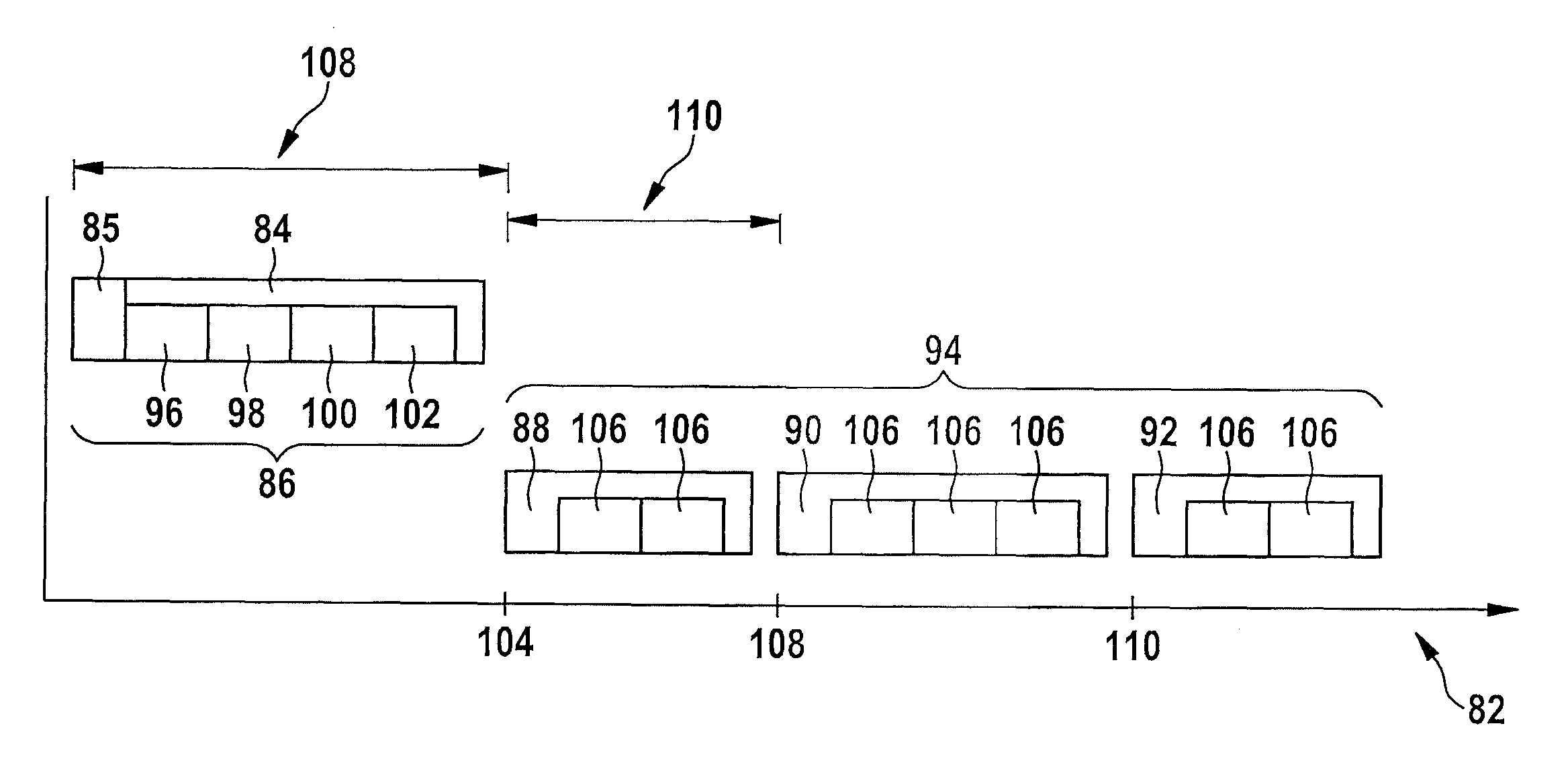

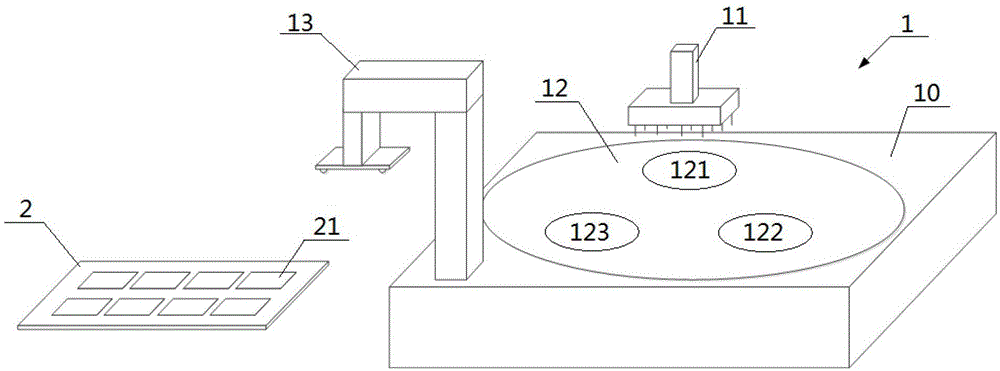

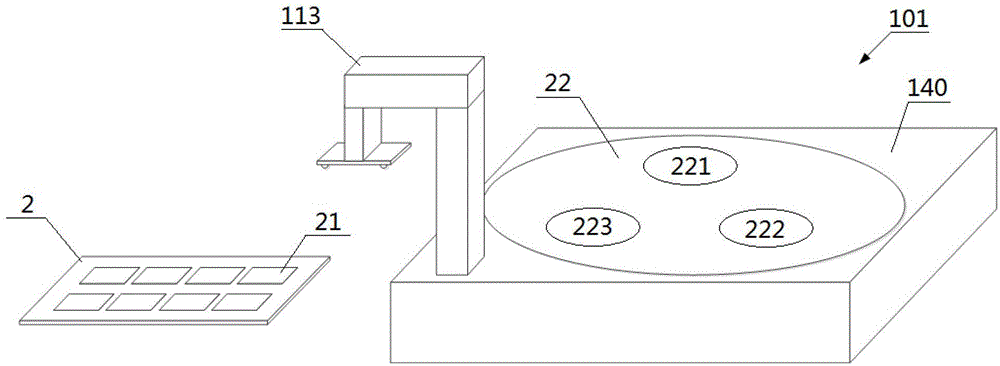

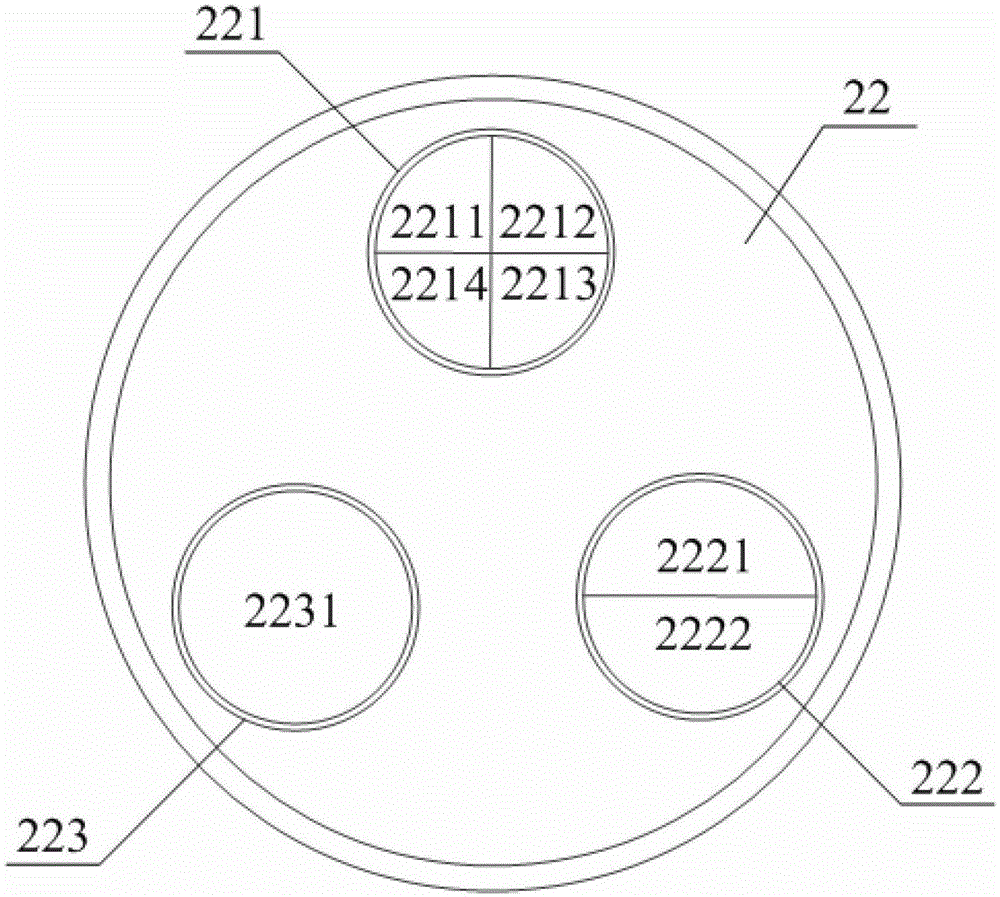

Entrance waiting time-free automatic test system for printed circuit board (PCB)

ActiveCN103048610AEliminate idle timeImprove test efficiencyElectronic circuit testingOptically investigating flaws/contaminationTest efficiencyEngineering

The invention discloses an entrance waiting time-free automatic test system for a printed circuit board (PCB). The system comprises a mechanical arm and a test bench. A rotatable station is arranged on the test bench. A plurality of rotatable sub-stations are arranged on the station. One or more working areas are arranged on each sub-station. A test device for sub-station test is arranged on each working area of each sub-station, and rotates synchronously with the corresponding sub-station. The number of the working areas on each sub-station is directly proportional to the test time of the sub-station. When the system is used, the PCB is sequentially transmitted to each sub-station to be tested on the sub-stations by rotating the station, and is sequentially transmitted to each working area by rotating the sub-stations. The working areas in a number which is directly proportional to the test time of each sub-station are arranged on the sub-station to eliminate entrance waiting time between the sub-stations, so that the test time of the PCB is saved, and the test efficiency of the PCB is improved.

Owner:SHANGHAI JINDONGTANG TECH CO LTD

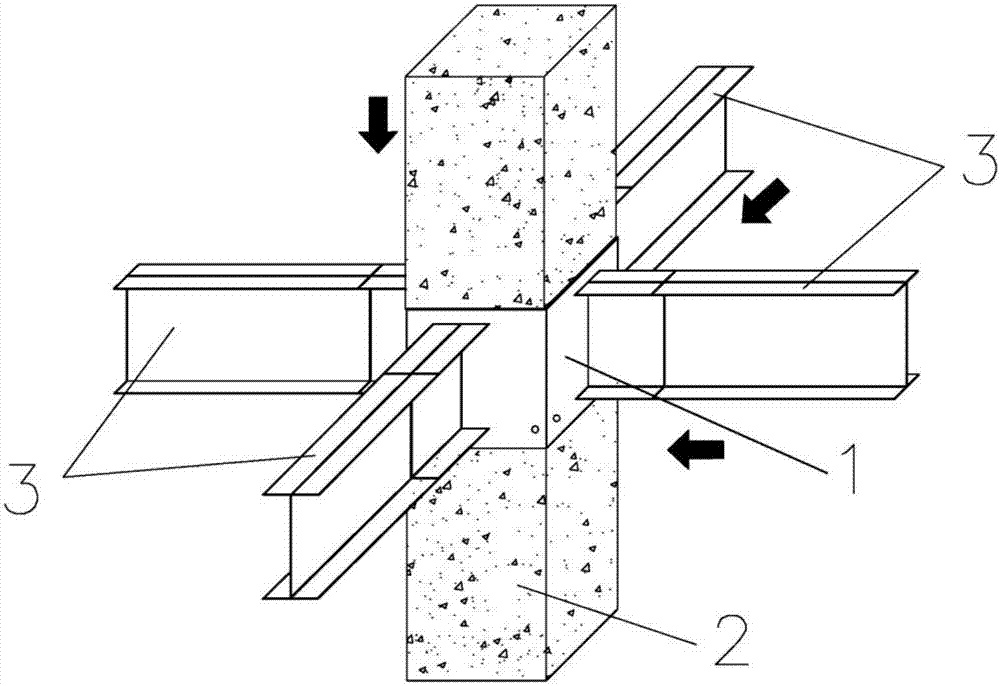

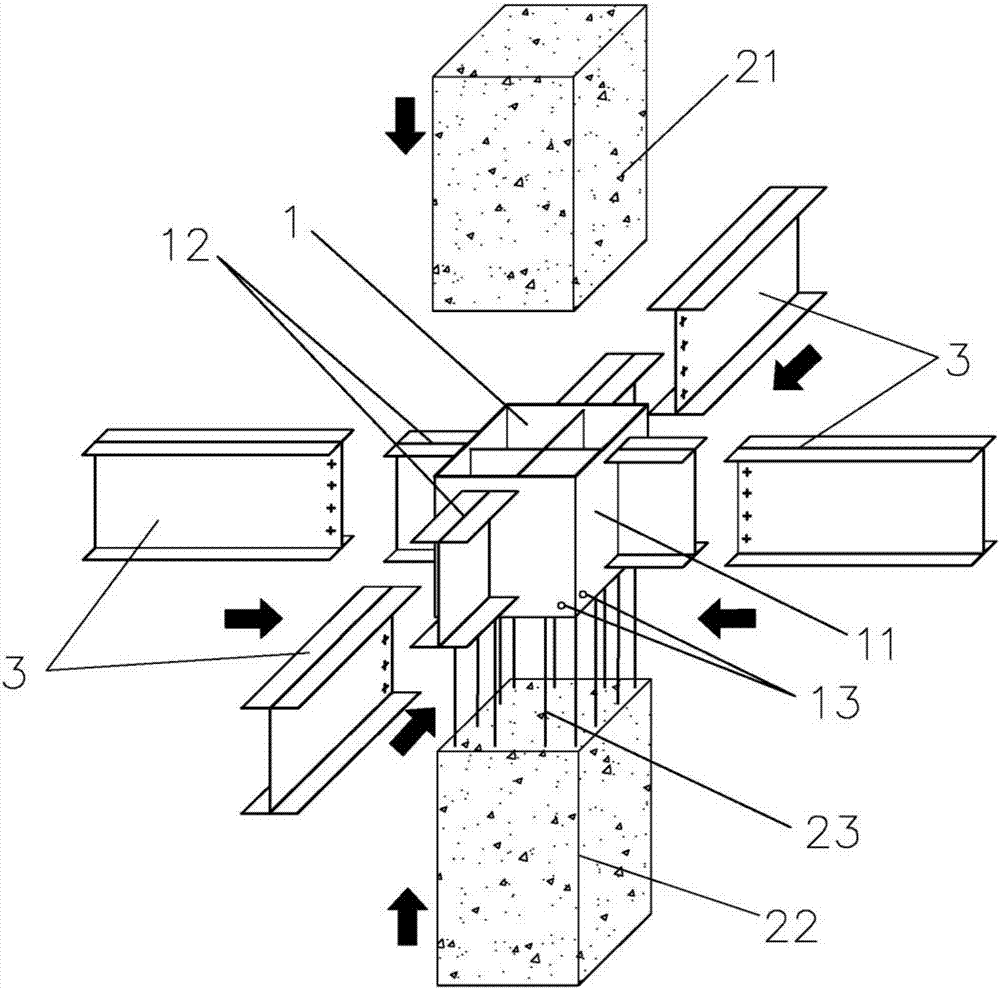

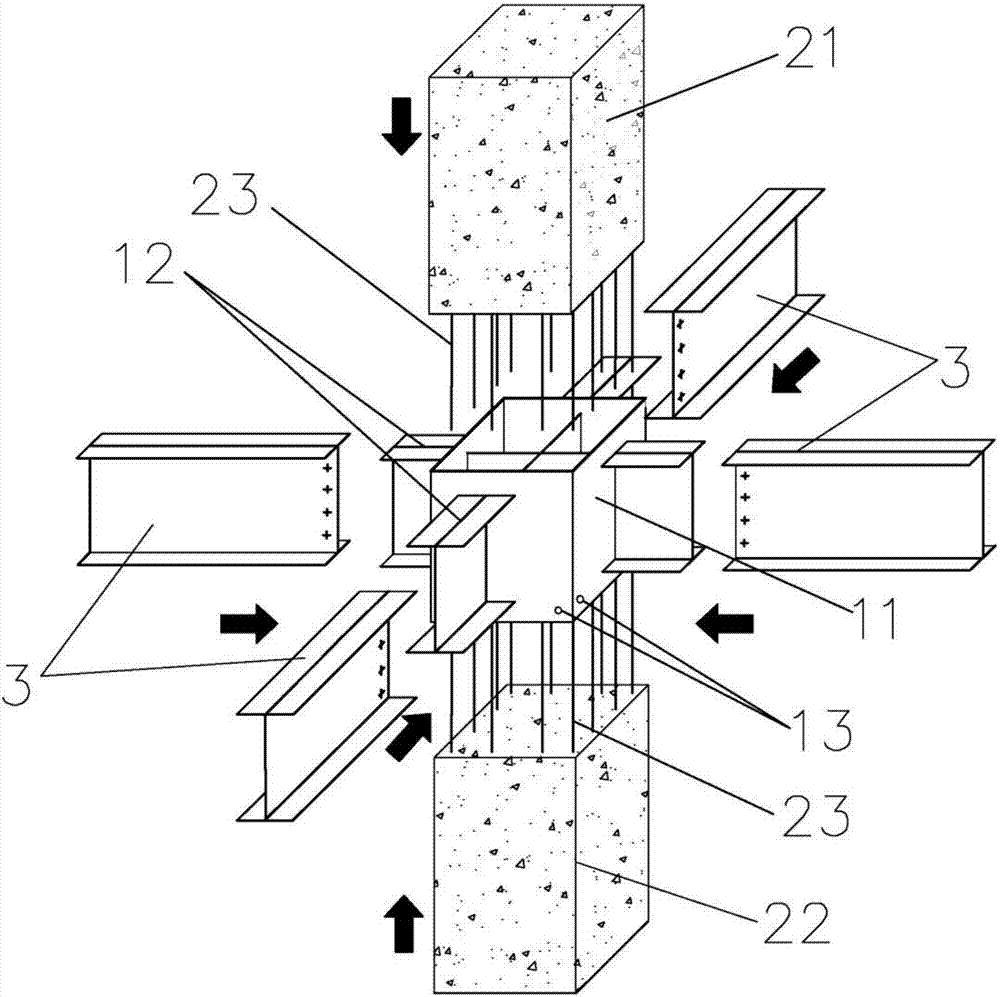

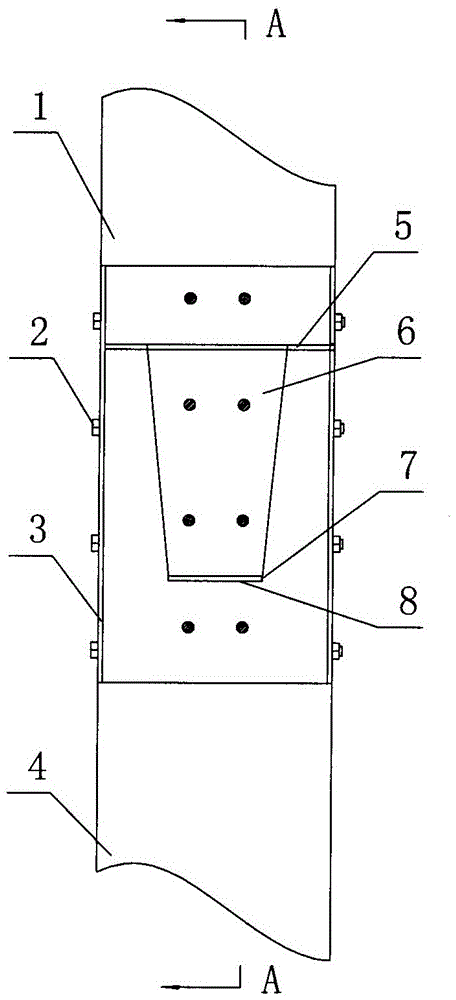

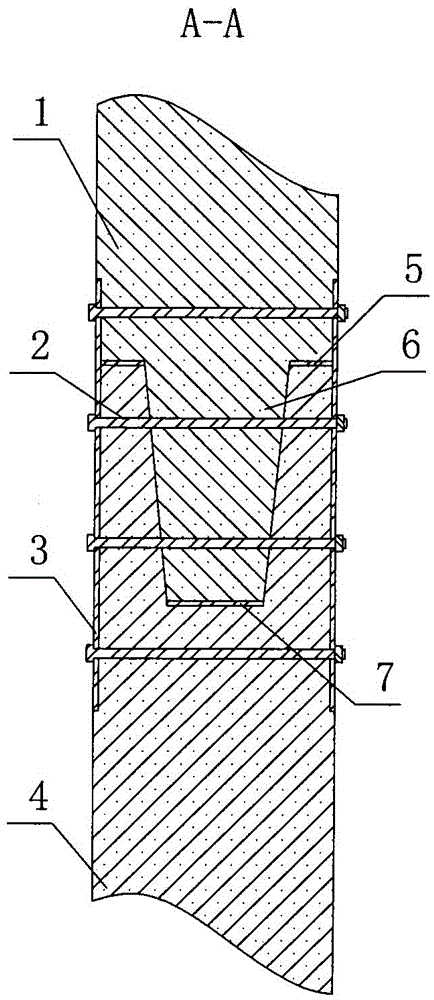

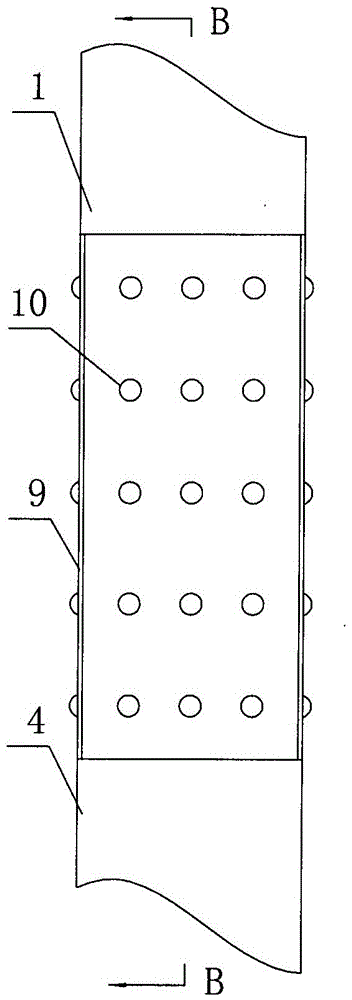

Prefabricated concrete column and steel beam joint

PendingCN107083808AOptimize volumeImprove the problem of difficult transportationBuilding constructionsCross connectionAgricultural engineering

The invention discloses a prefabricated concrete column and steel beam joint. The joint comprises a prefabricated joint unit, a prefabricated concrete column and a prefabricated steel beam. The prefabricated concrete column comprises an upper column body and a lower column body, the prefabricated joint unit comprises a box body and a short steel beam, the short steel beam comprises a cross-shaped end and an extending end, the cross-shaped end is located in the box body and is in cross connection, the extending end penetrates out of the box body, and the extending end is connected with the prefabricated steel beam; the lower portion of the box body is provided with a grouting hole, the prefabricated joint unit is arranged between the upper column body and the lower column body, and the prefabricated joint unit is connected between the upper column body and the lower column body through grouting. According to the prefabricated concrete column and the steel beam joint, a prefabricated part is divided into the prefabricated concrete column, the prefabricated steel beam and the prefabricated joint unit, all the parts can be prefabricated in a prefabricating factory, the construction progress can be accelerated, and the construction quality can be improved; in addition, the size of the divided prefabricated part becomes small, and the problems that an existing prefabricated part is large in size and difficult to transport and assemble are solved.

Owner:CHONGQING UNIV

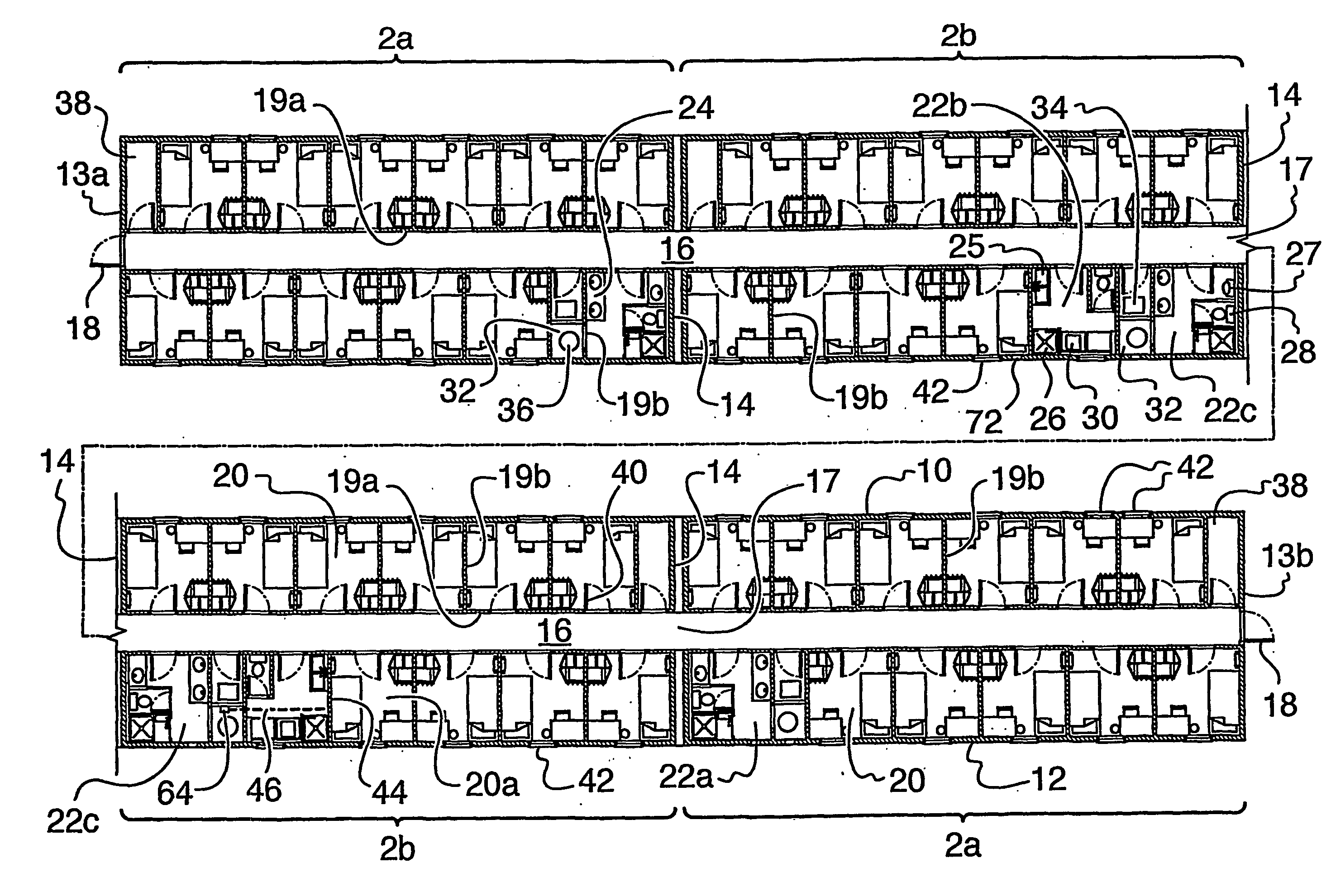

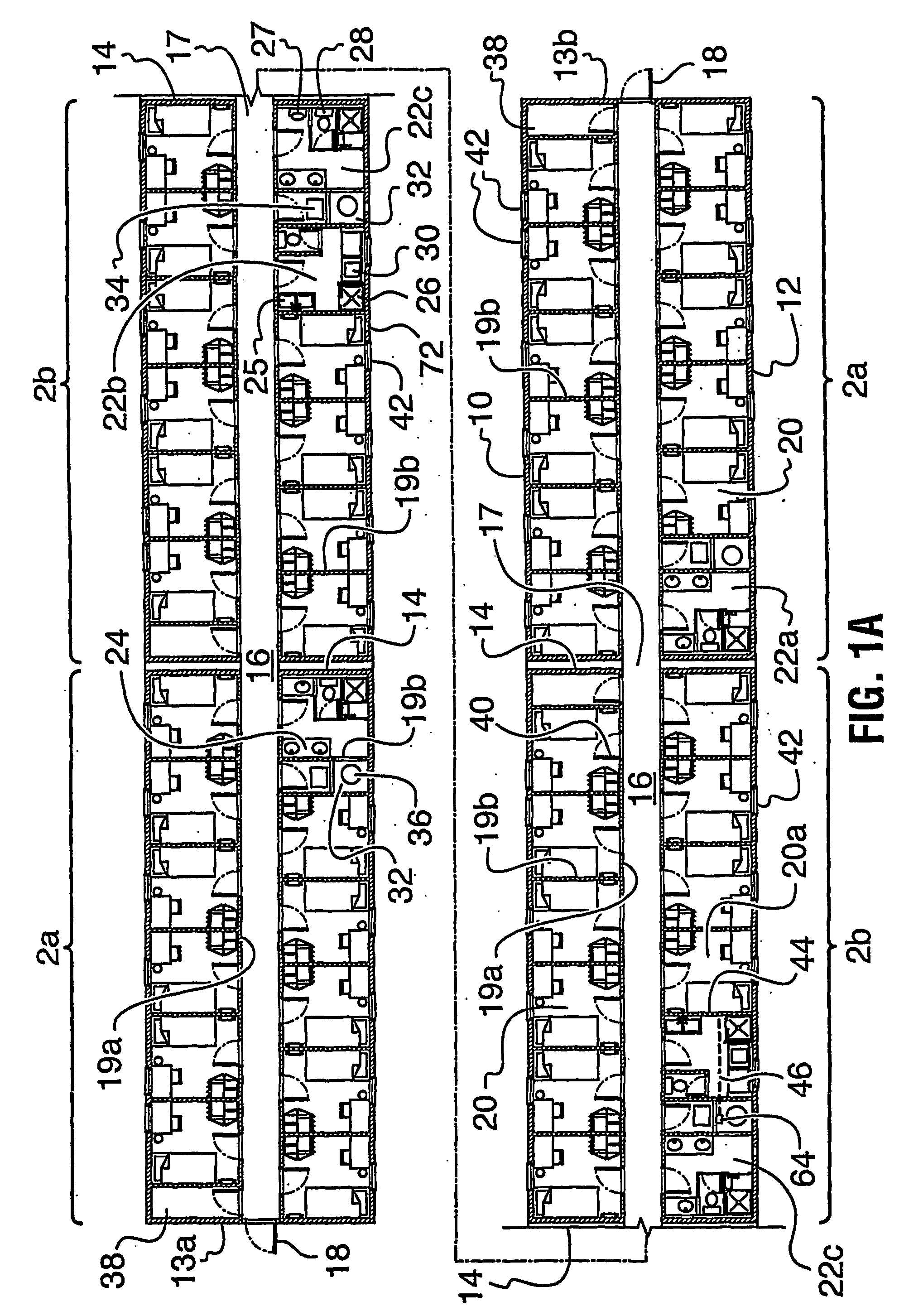

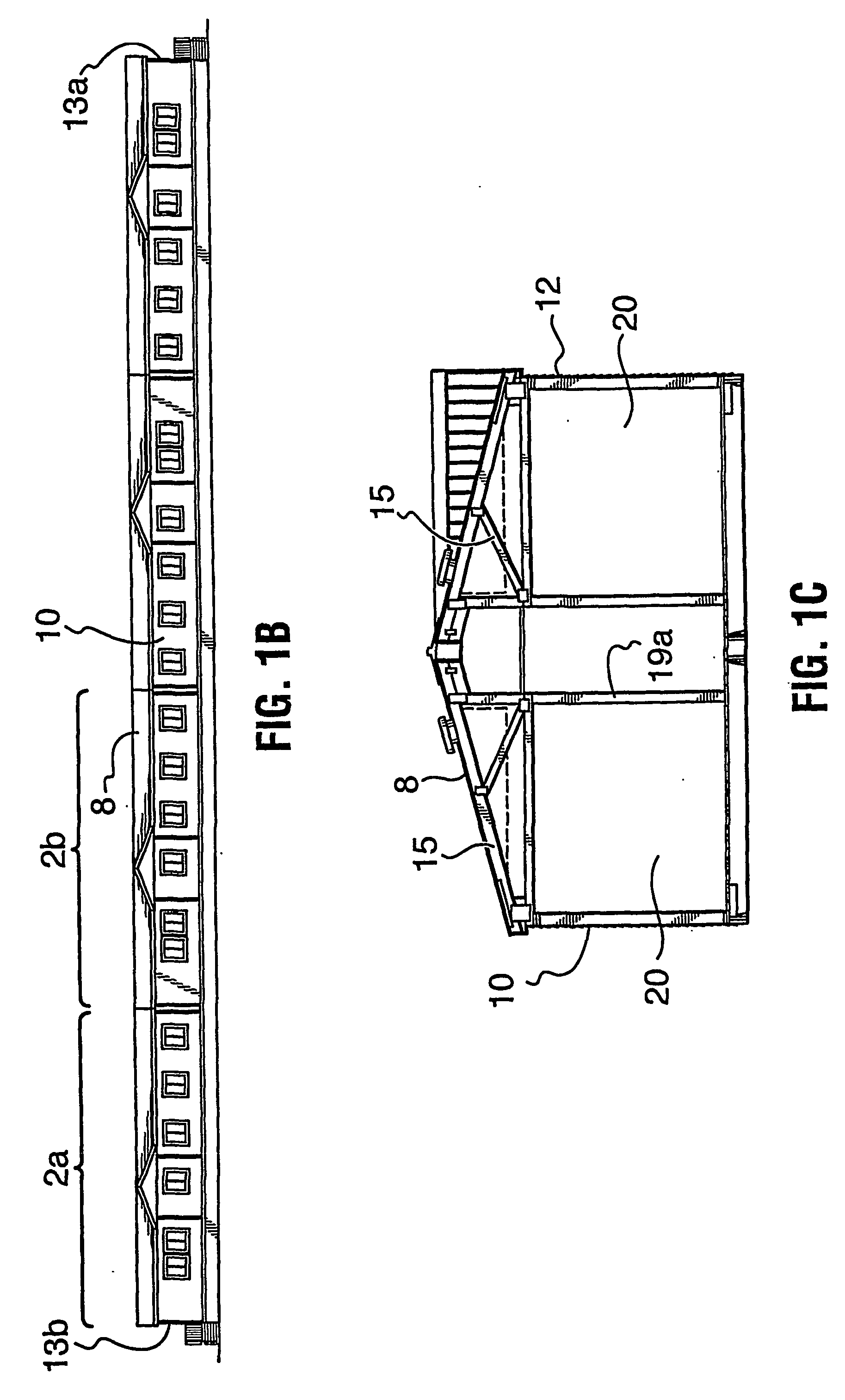

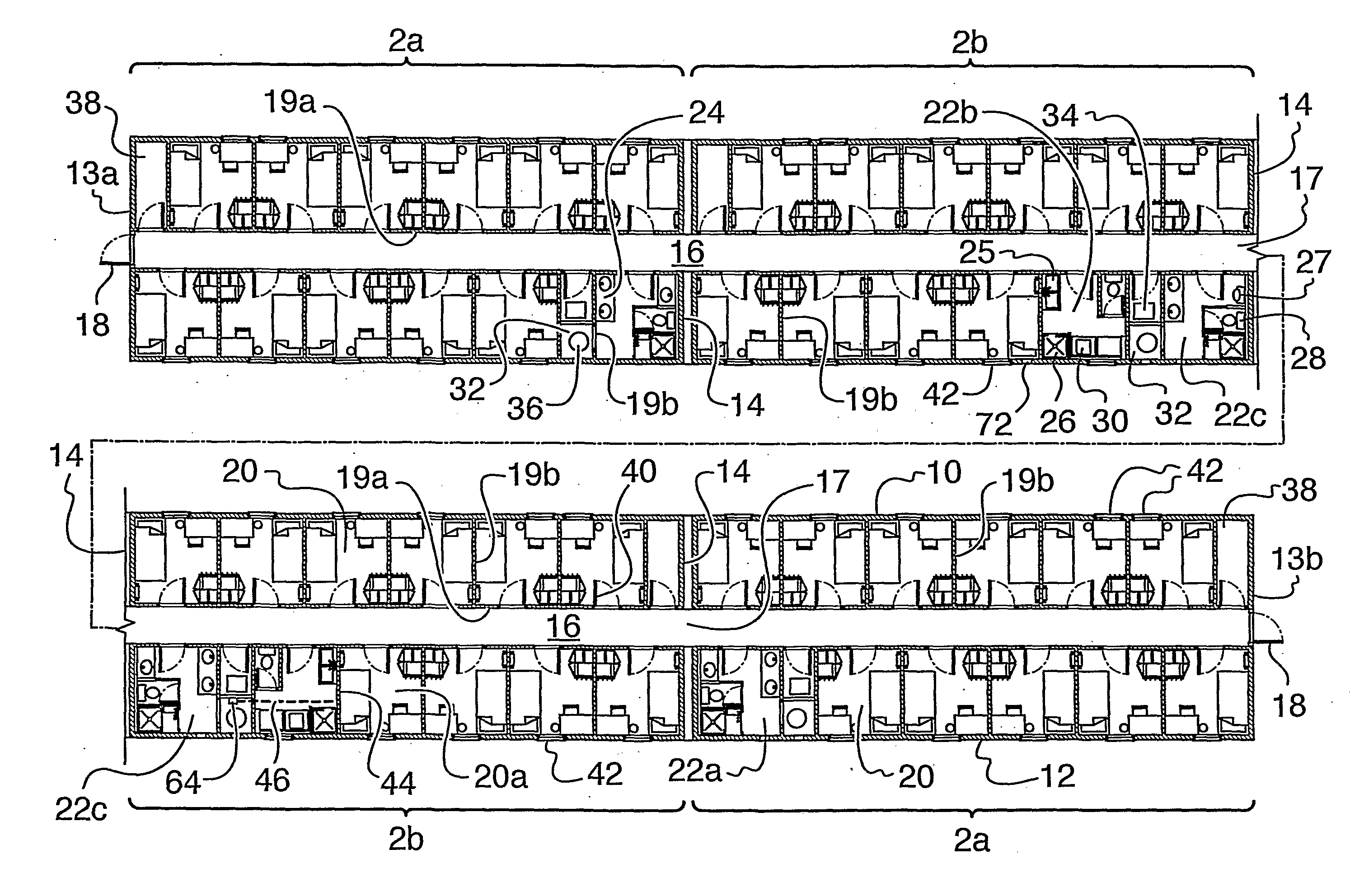

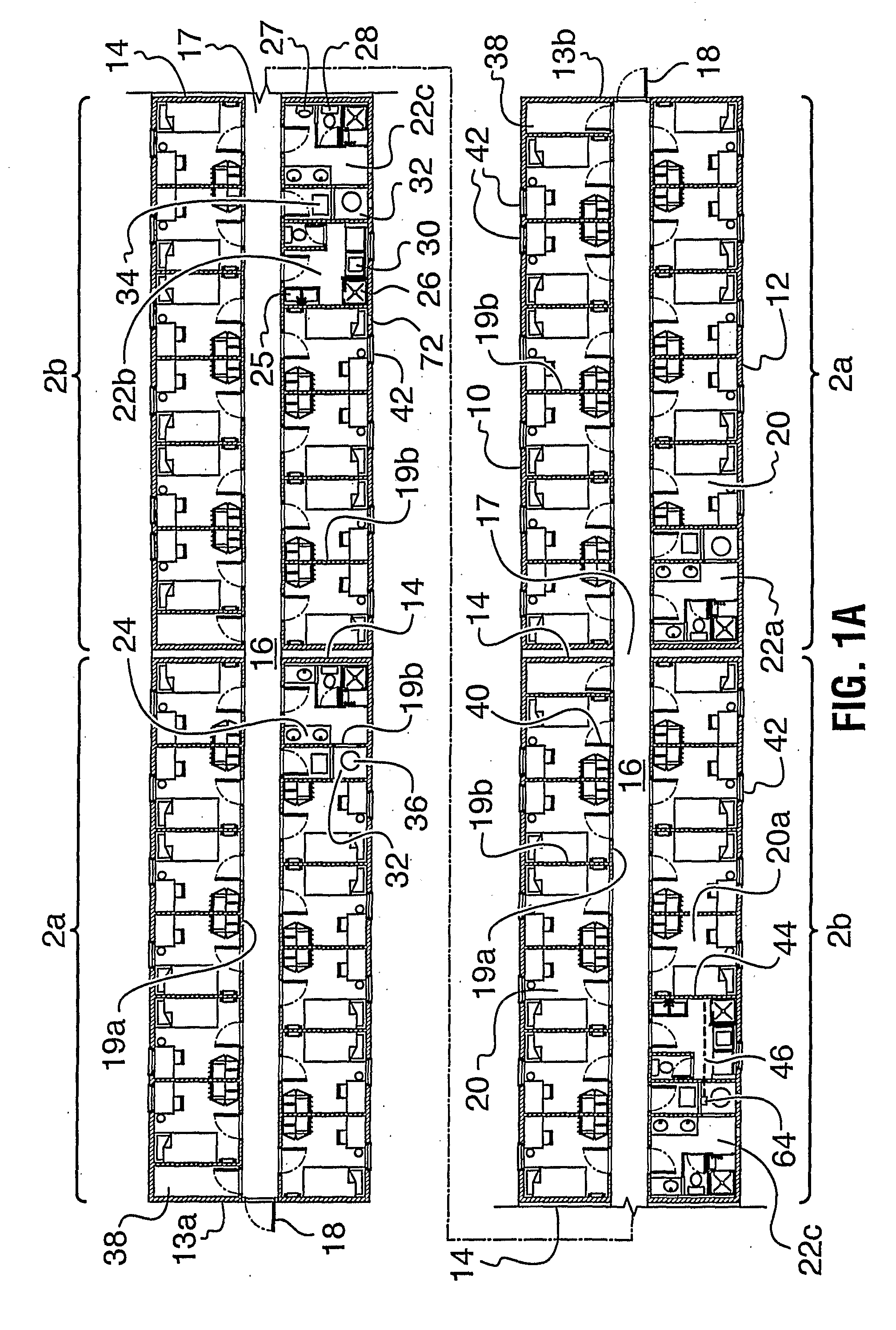

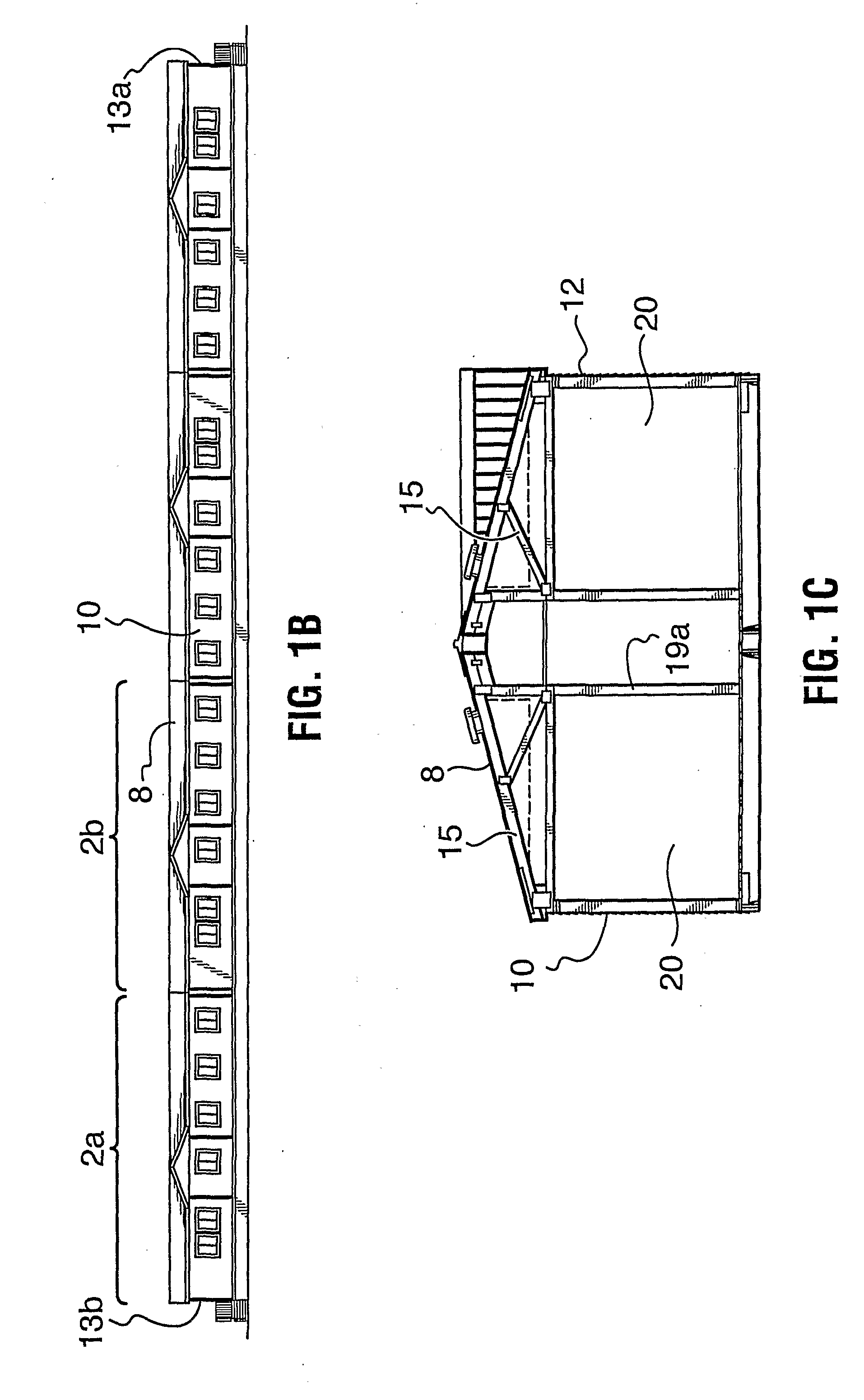

Reusable worker housing and methods relating thereto

InactiveUS20060096198A1Significant comprehensive benefitsReduce shipping costsHotelsSpecial buildingResidenceEngineering

Owner:ATCO STRUCTURES & LOGISTICS

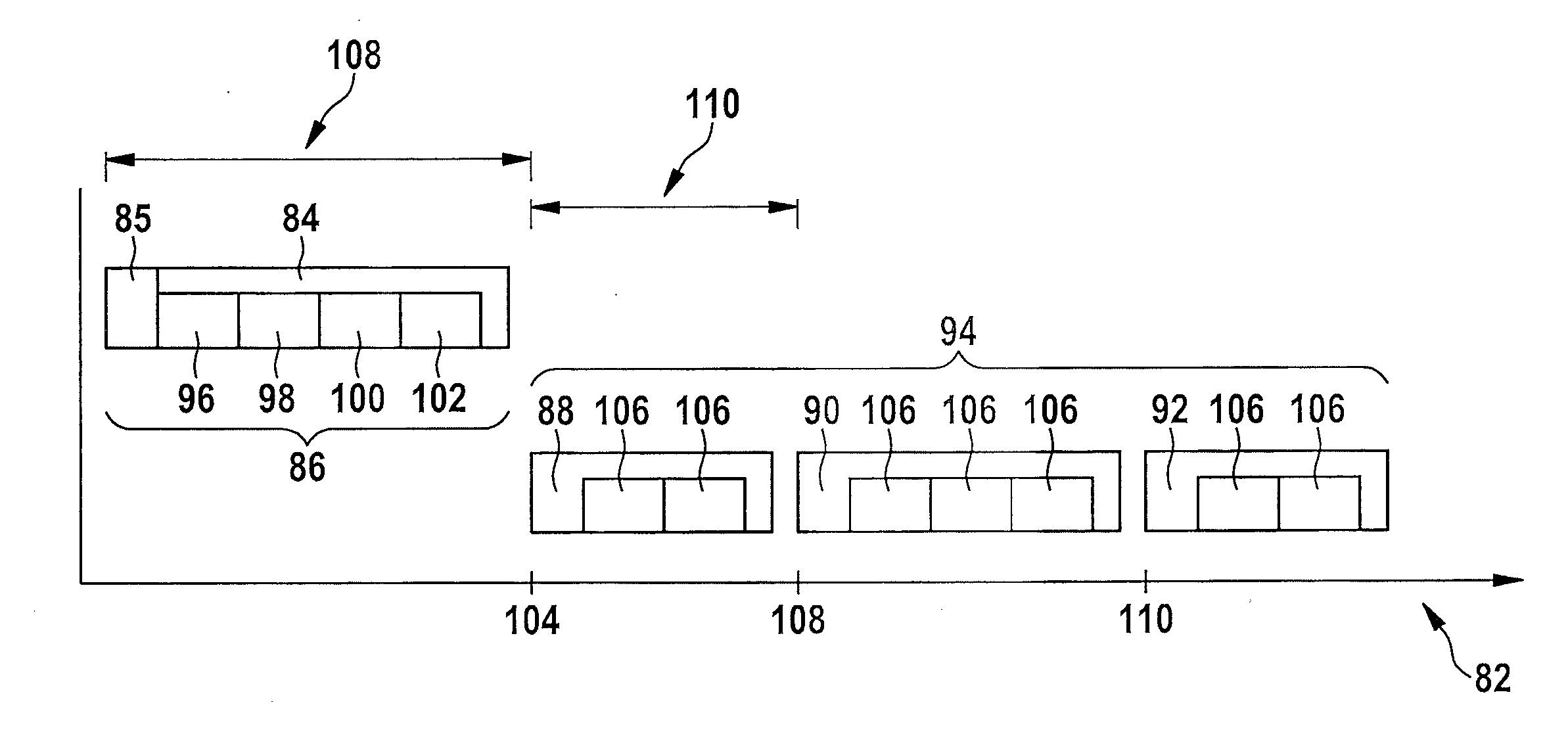

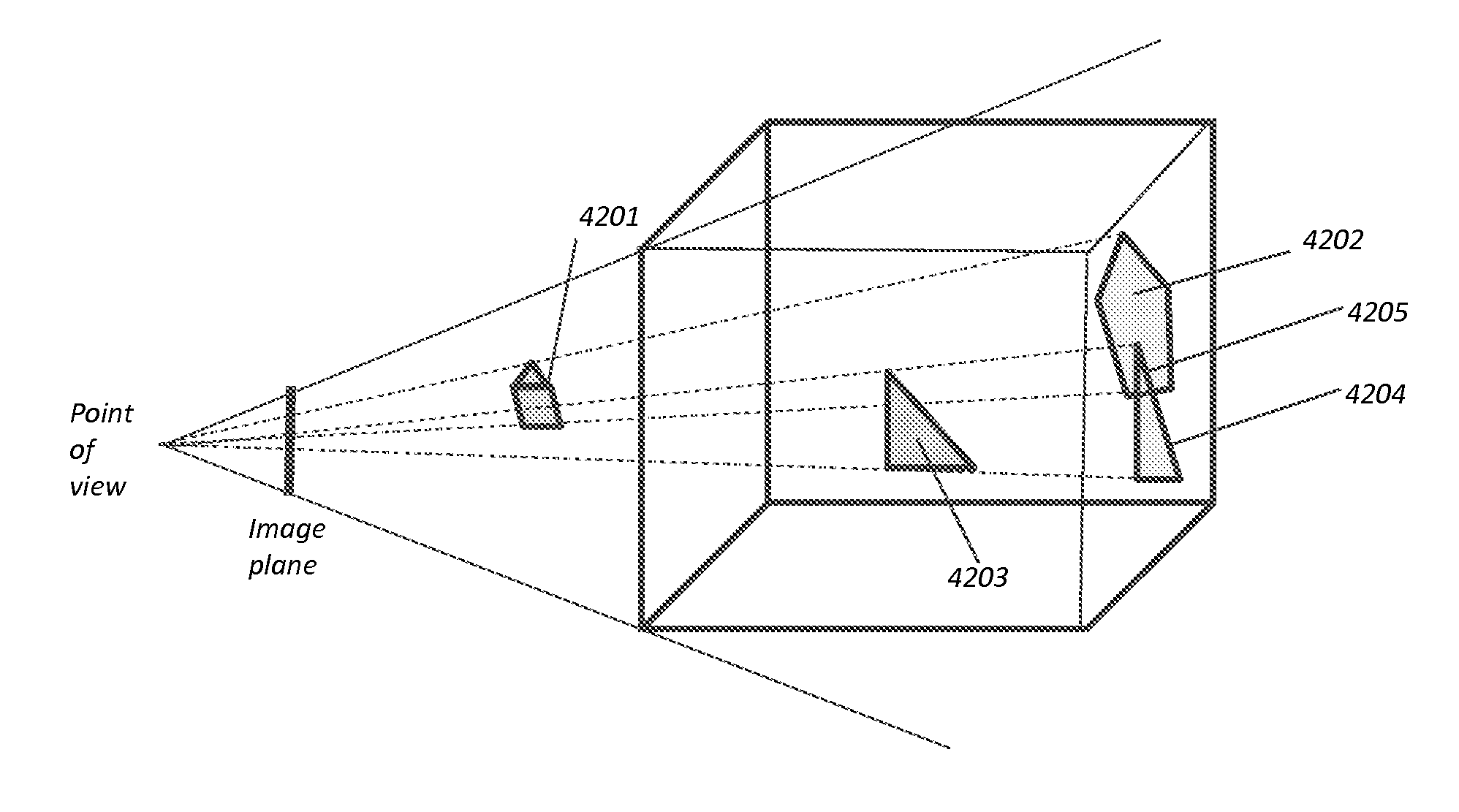

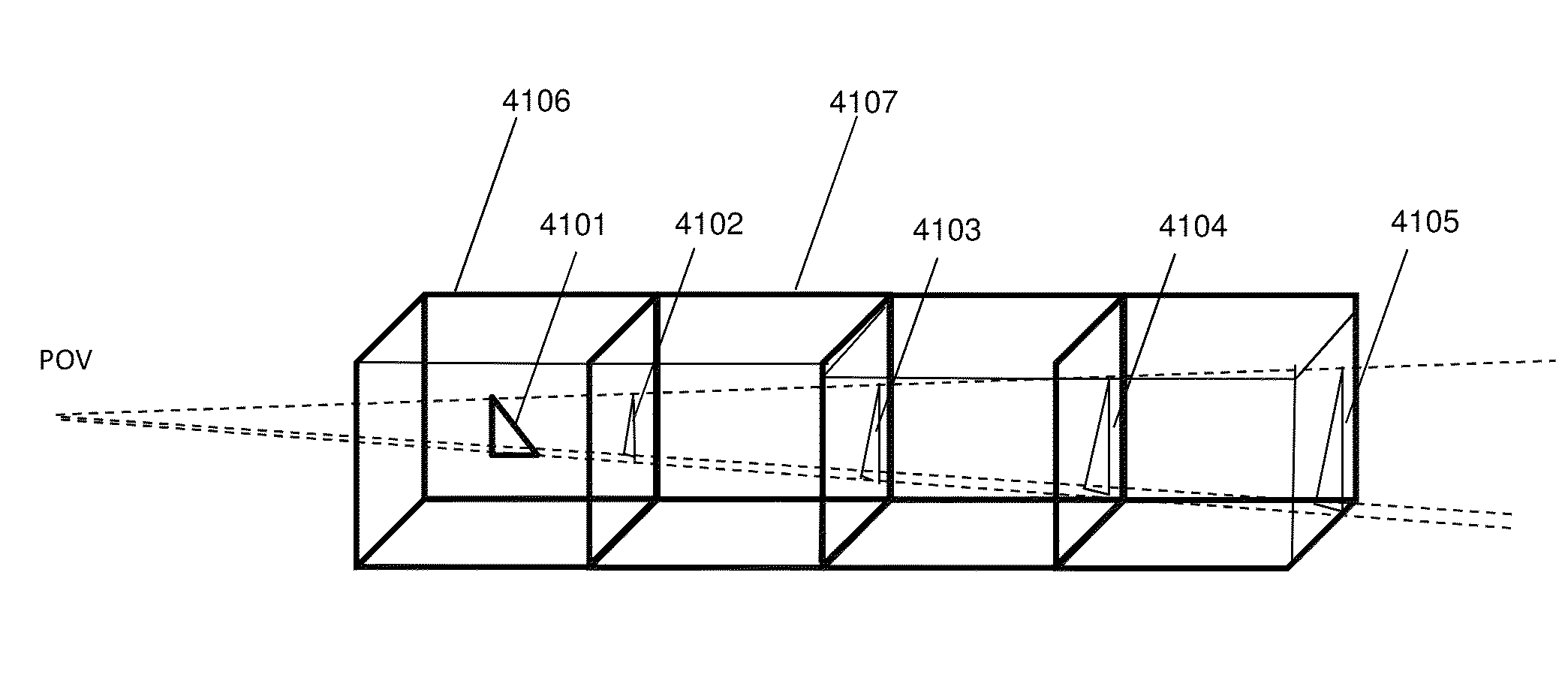

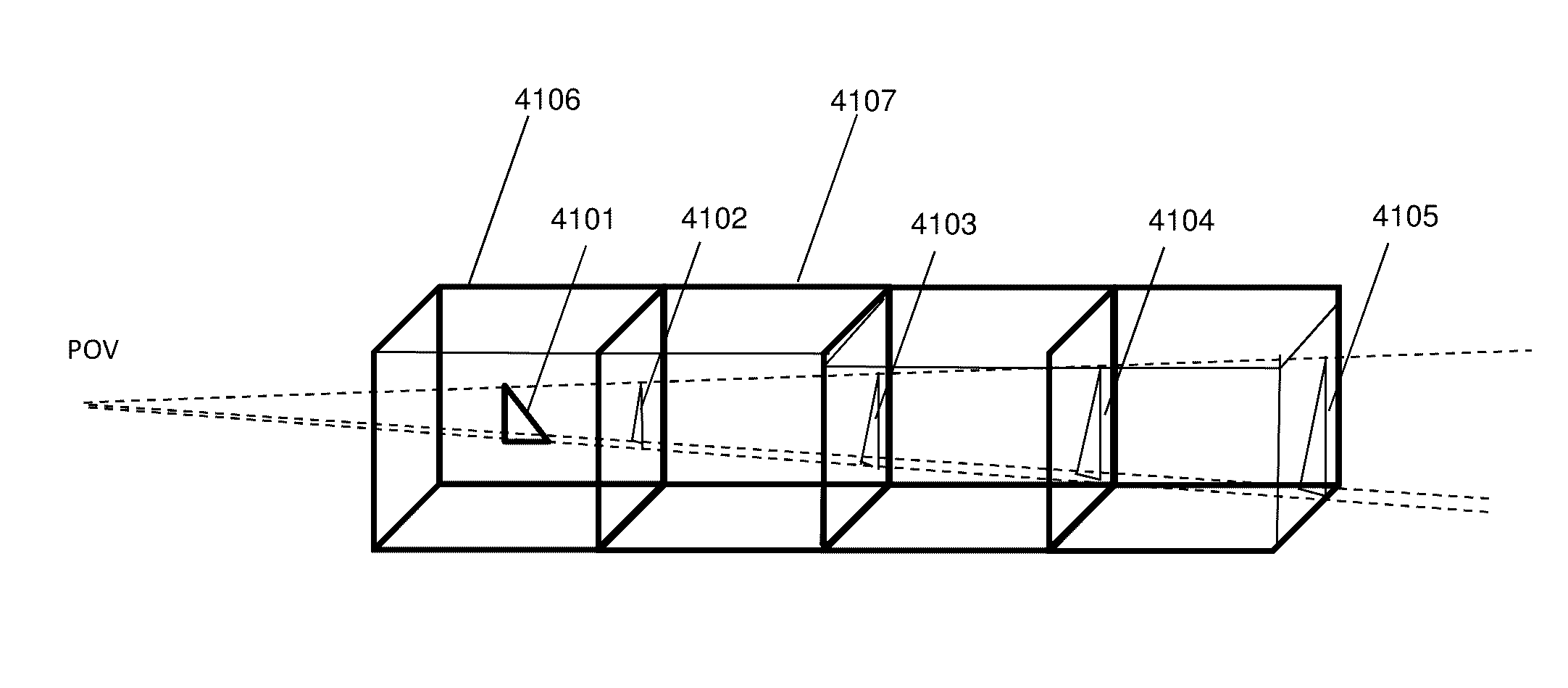

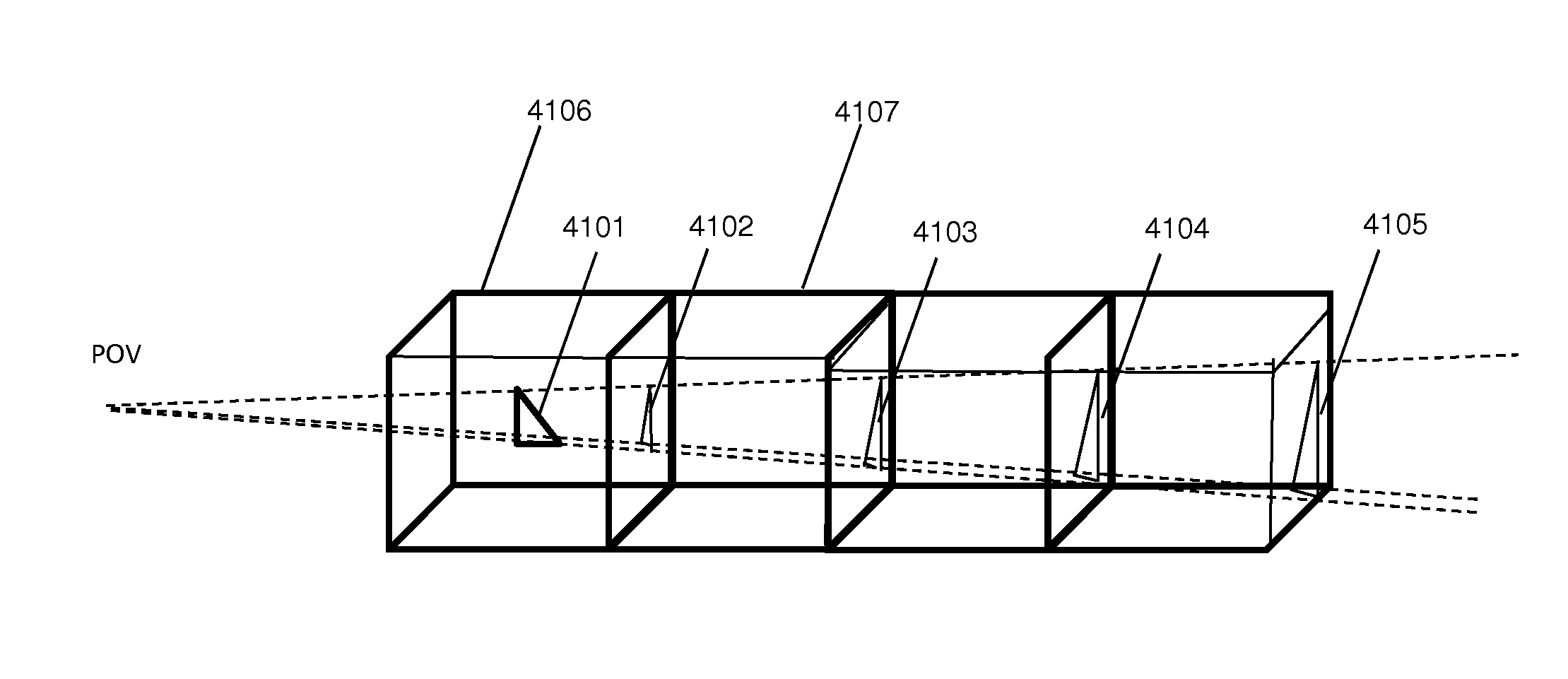

System for primary ray shooting having geometrical stencils

ActiveUS20140375643A1Effective trackingCut down high traversalProgram controlImage generationVisibilityViewpoints

Aspects comprise ray shooting system based on the data structure of a uniform grid of cells, and on local stencils in cells. The high traversal and construction costs of accelerating structures are cut down. The object's visibility from the viewpoint and from light sources, as well as the primary workload and its distribution among cells, are gained in the preprocessing stage and cached in stencils for runtime use. In runtime, the use of stencils allows a complete locality at each cell, for load balanced parallel processing.

Owner:SNAP INC

Reusable worker housing and methods relating thereto

InactiveUS20080313974A1Significant comprehensive benefitsReduce shipping costsHotelsSpecial buildingResidenceComputer module

Owner:ATCO STRUCTURES & LOGISTICS

System for primary ray shooting having geometrical stencils

ActiveUS9007372B2Effective trackingCut down high traversal and construction costProgram controlImage generationVisibilityViewpoints

Aspects comprise ray shooting system based on the data structure of a uniform grid of cells, and on local stencils in cells. The high traversal and construction costs of accelerating structures are cut down. The object's visibility from the viewpoint and from light sources, as well as the primary workload and its distribution among cells, are gained in the preprocessing stage and cached in stencils for runtime use. In runtime, the use of stencils allows a complete locality at each cell, for load balanced parallel processing.

Owner:SNAP INC

Ray shadowing method utilizing geometrical stencils

InactiveUS20140375640A1Effective trackingCut down high traversalDetails involving 3D image dataProgram controlVisibilityViewpoints

Aspects comprise a ray tracing shadowing method based on the data structure of a uniform grid of cells, and on local stencils in cells. The high traversal and construction costs of accelerating structures are cut down. The object's visibility from the viewpoint and from light sources, as well as the primary workload and its distribution among cells, are gained in the preprocessing stage and cached in stencils for runtime use. In runtime, the use of stencils allows a complete locality at each cell, for load balanced parallel processing.

Owner:ADSHIR LTD

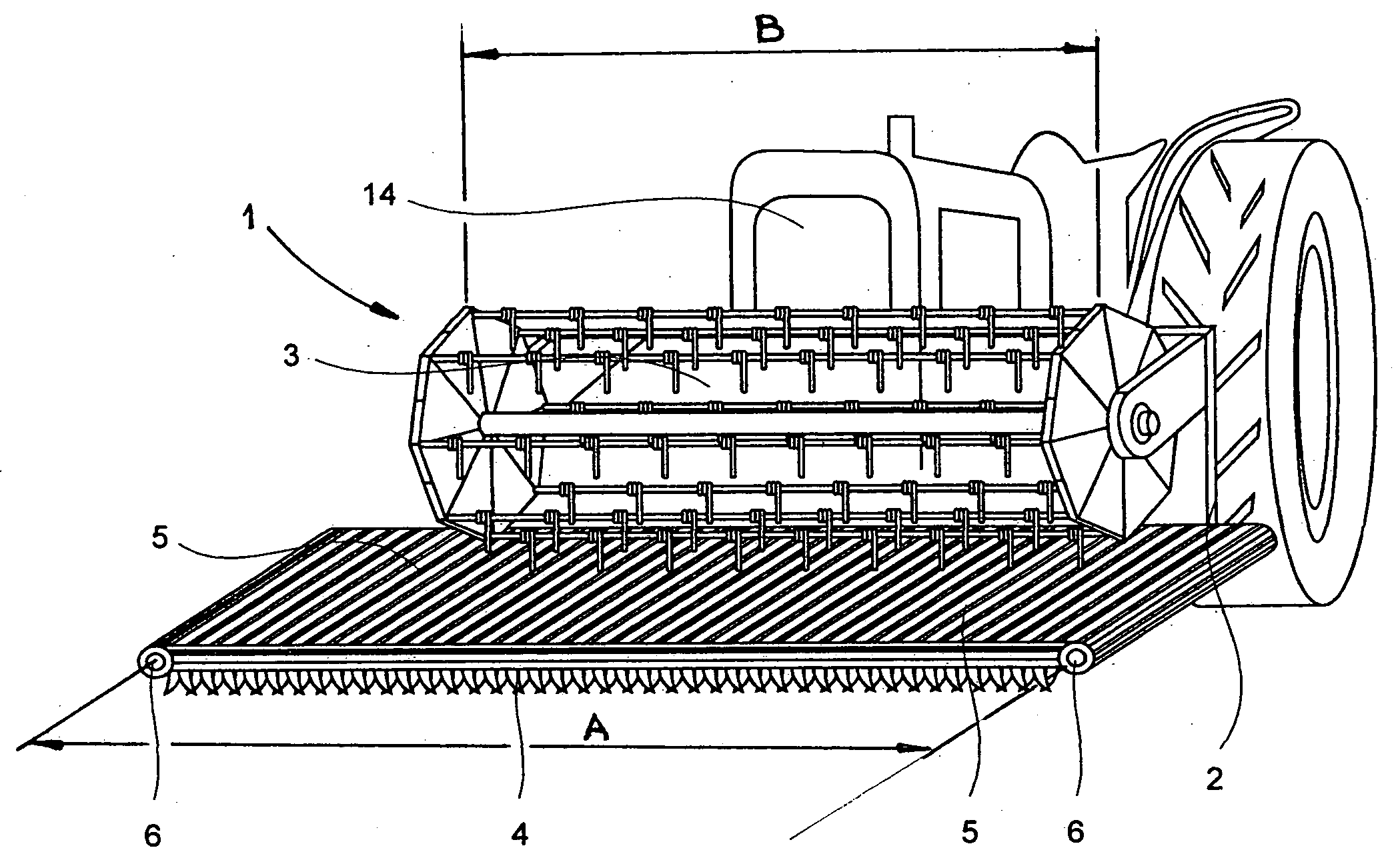

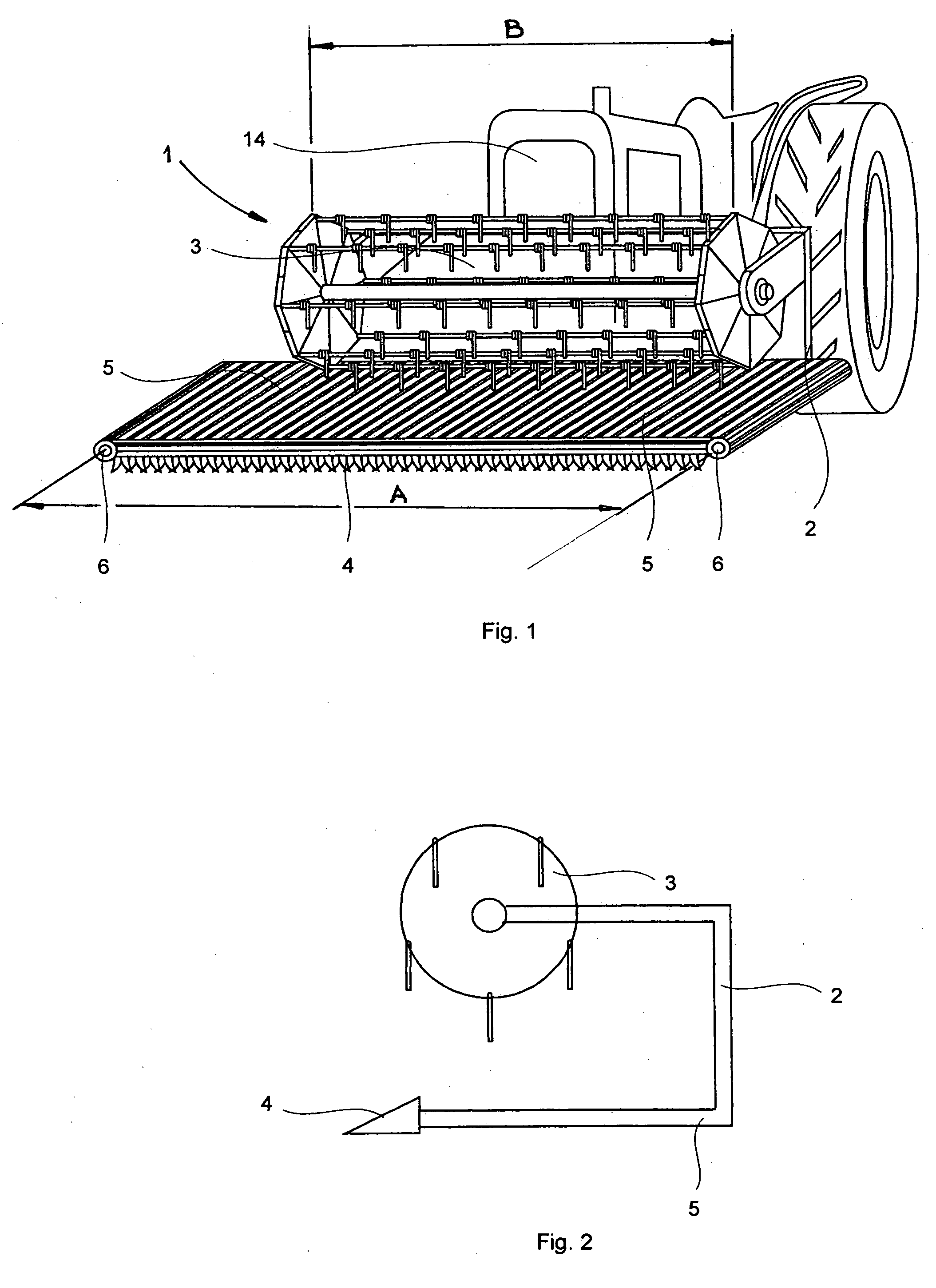

Windrow machine and harvesting method

InactiveUS20050050874A1Extend incubation timeEliminate idle timeTill seedingClimate change adaptationEngineeringCrop cultivation

A farming windrow machine and method for sowing a second crop before the first crop is harvested. The windrow machine is preferably hitched to a tractor and is followed by an agricultural machine to sow a field immediately after the crop nearly ready for harvested is cut. The machine omprises a frame supporting means for aligning crop upstanding in the field and mower means for cutting the aligned crop. The machine further comprises a conveyor belt mounted on a pair of spaced rollers, the conveyor belt cantilevered over a side of the windrow machine for transporting and piling the cut crop over and away from one side of the machine, such that a sower machine may follow the windrow machine to sow a second crop in the wake of the first cut crop, thereby increasing crop cultivation days and improving farm turnover.

Owner:PAILHE HORACIO ALBERTO

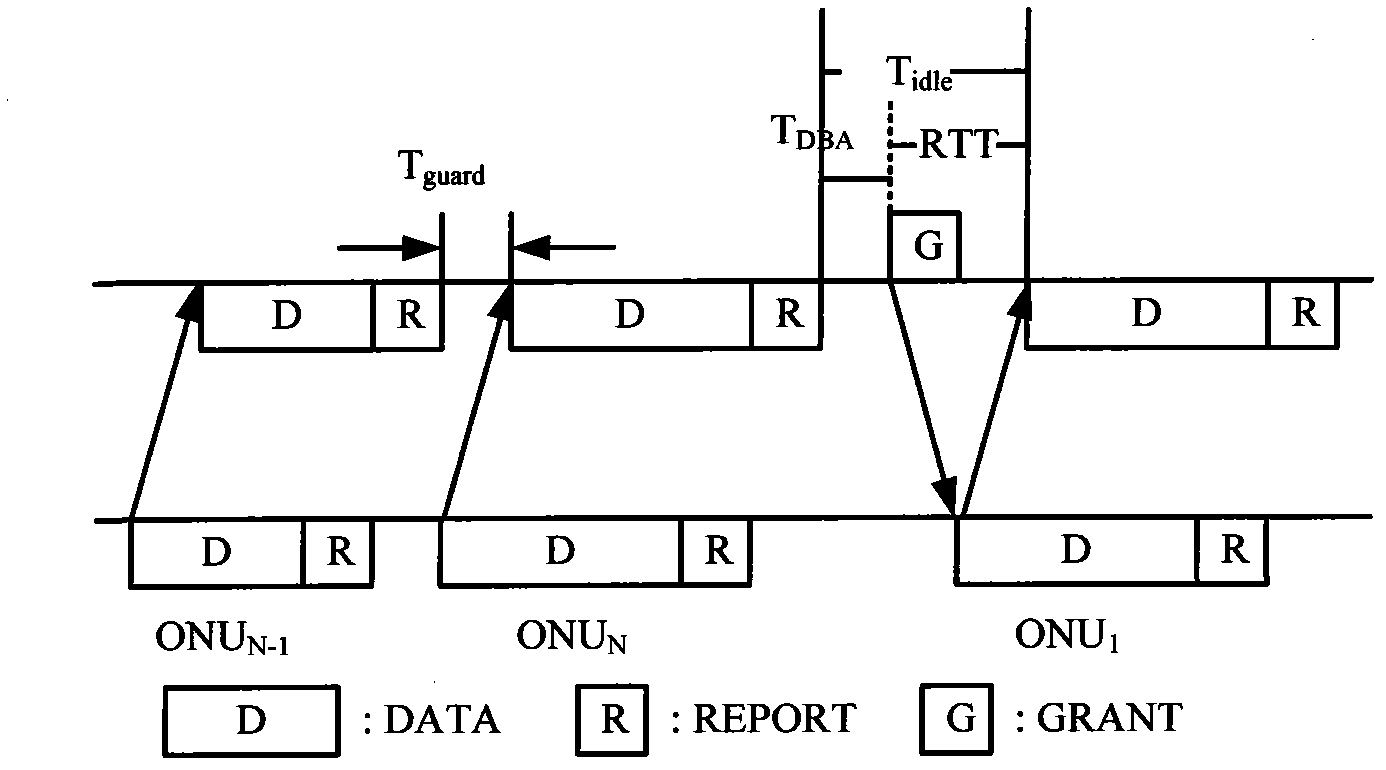

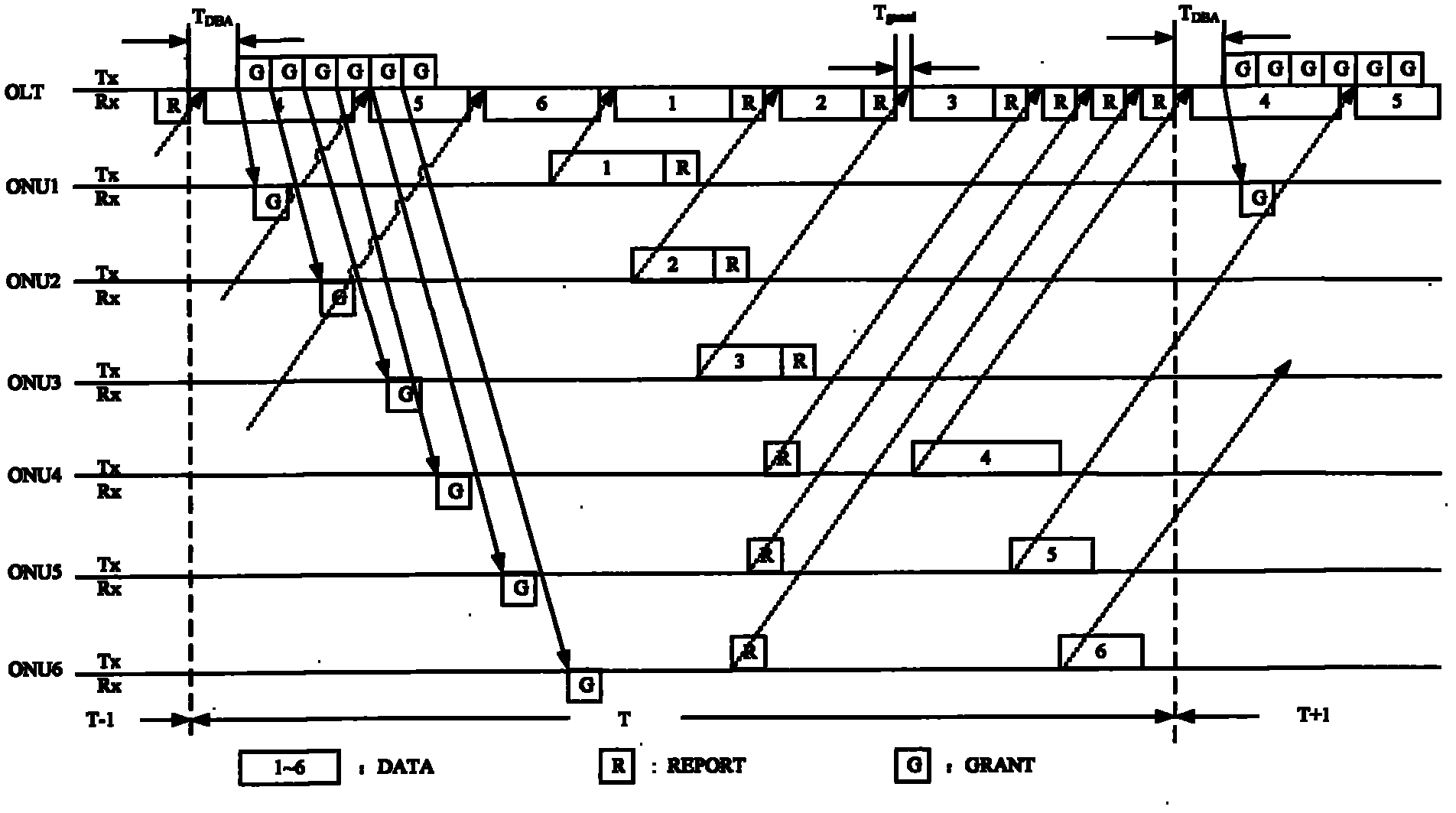

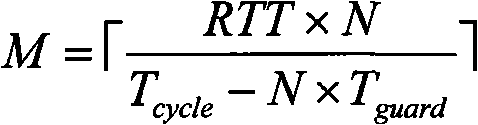

EPON channel transmission method for eliminating idle time

InactiveCN101931834AImprove bandwidth utilizationGuaranteed Bandwidth UtilizationMultiplex system selection arrangementsFibre transmissionAccess networkStart stop

The invention discloses an Ethernet passive optical network (EPON) channel transmission method for eliminating idle time, and relates to the technical field of optical communication and optical access networks. The method comprises the following steps of: dividing optical network units (ONU) into a common ONU and an alternative ONU; transmitting a REPORT frame and a DATA frame of the common ONU together; transmitting the REPORT frame and the DATA frame of the alternative ONU separately; and taking the time when an optical line terminal (OLT) starts to perform bandwidth allocation as a start-stop movement of a polling cycle, in each polling cycle, first, uploading the DATA frame of the alternative ONU, then, uploading the REPORT frame and the DATA frame of the common ONU, and finally, uploading the REPORT frame of the ONU. The method uploads the data frame of the alternative ONU at the idle time of waiting the arrival of the authorization of the OLT in the mode of transmitting the REPORT frame and the DATA frame separately so as to eliminate the idle time under a conventional cycle polling mechanism and improve the bandwidth utilization rate of an uplink of an EPON system.

Owner:NANJING UNIV OF POSTS & TELECOMM

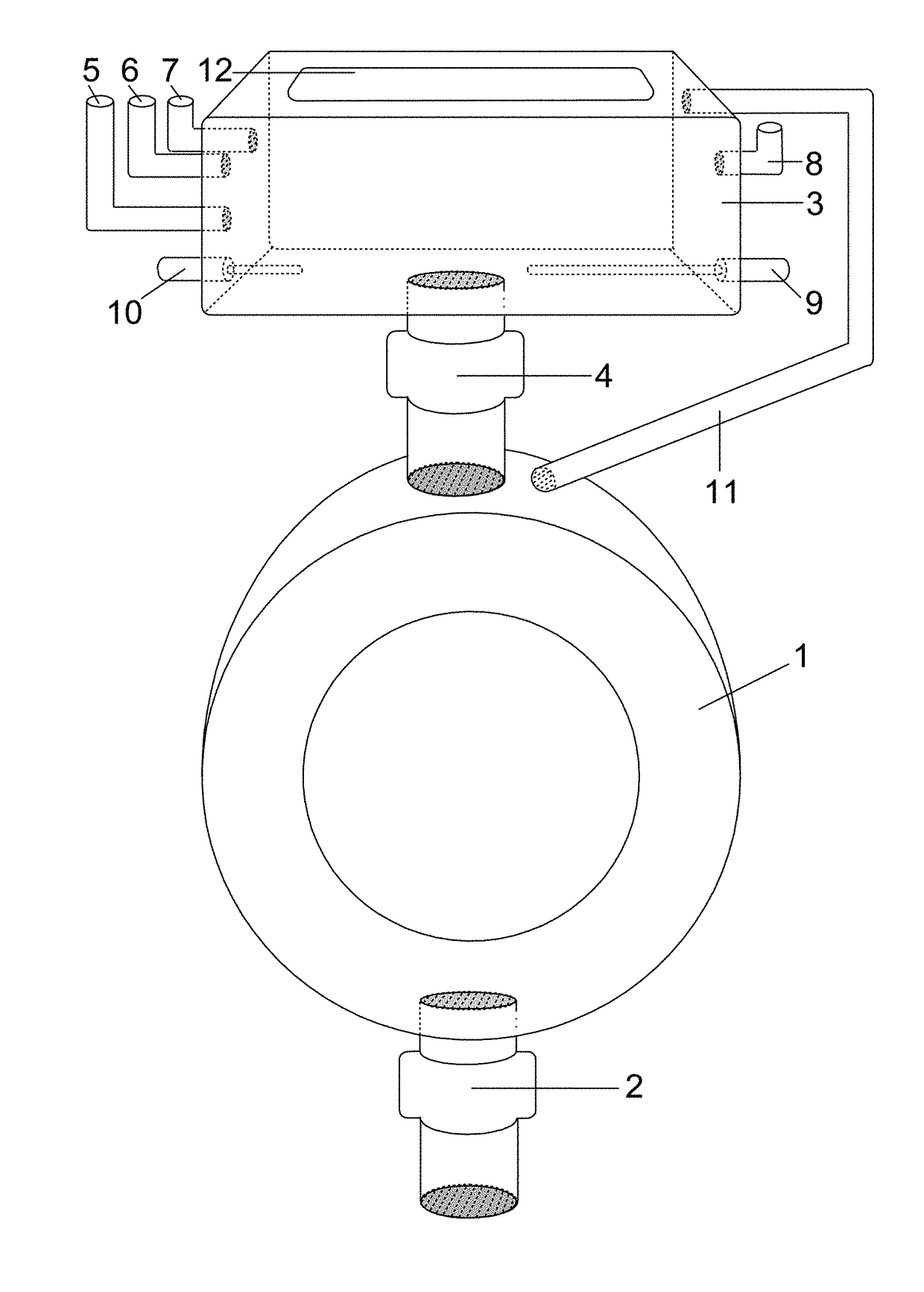

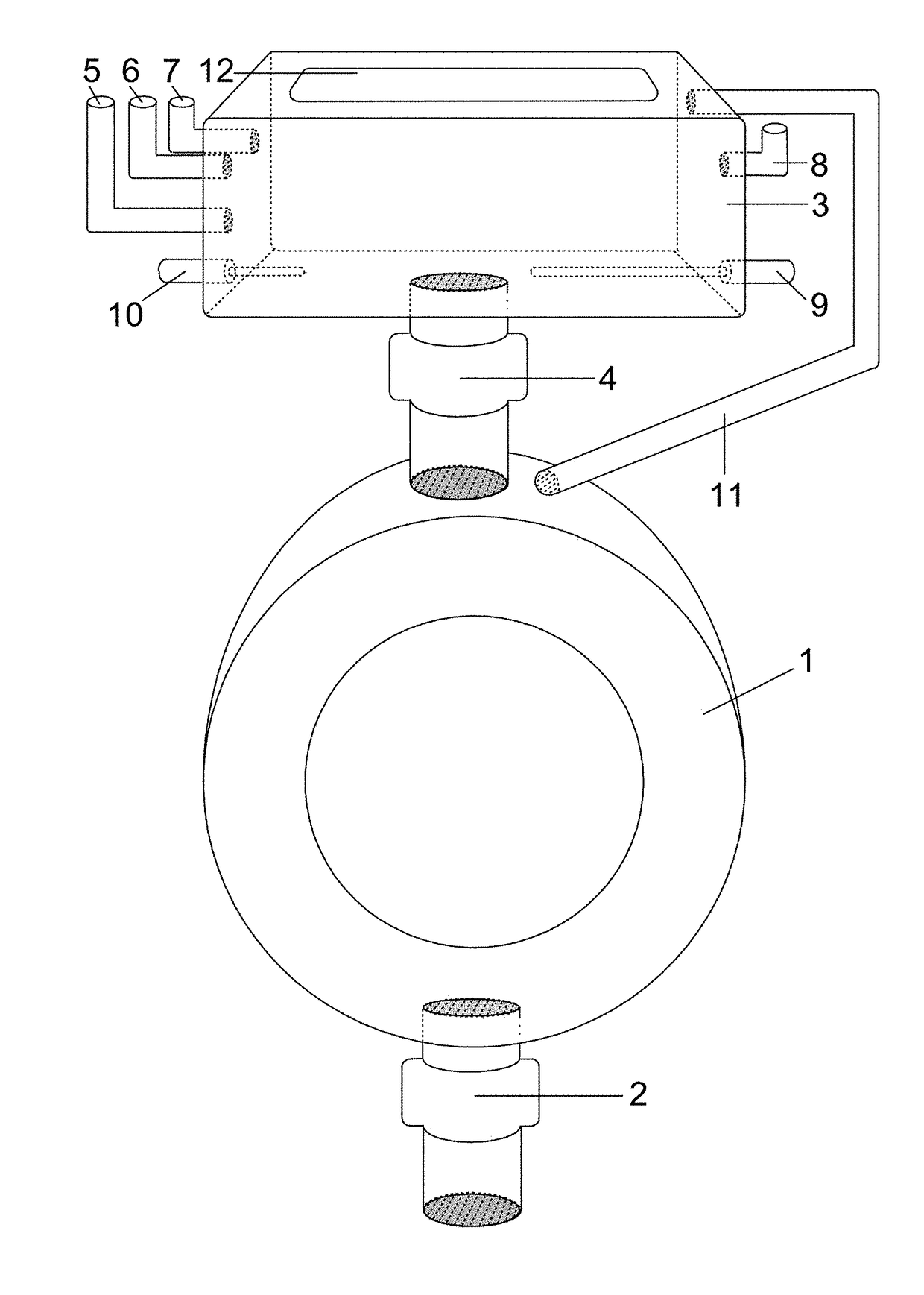

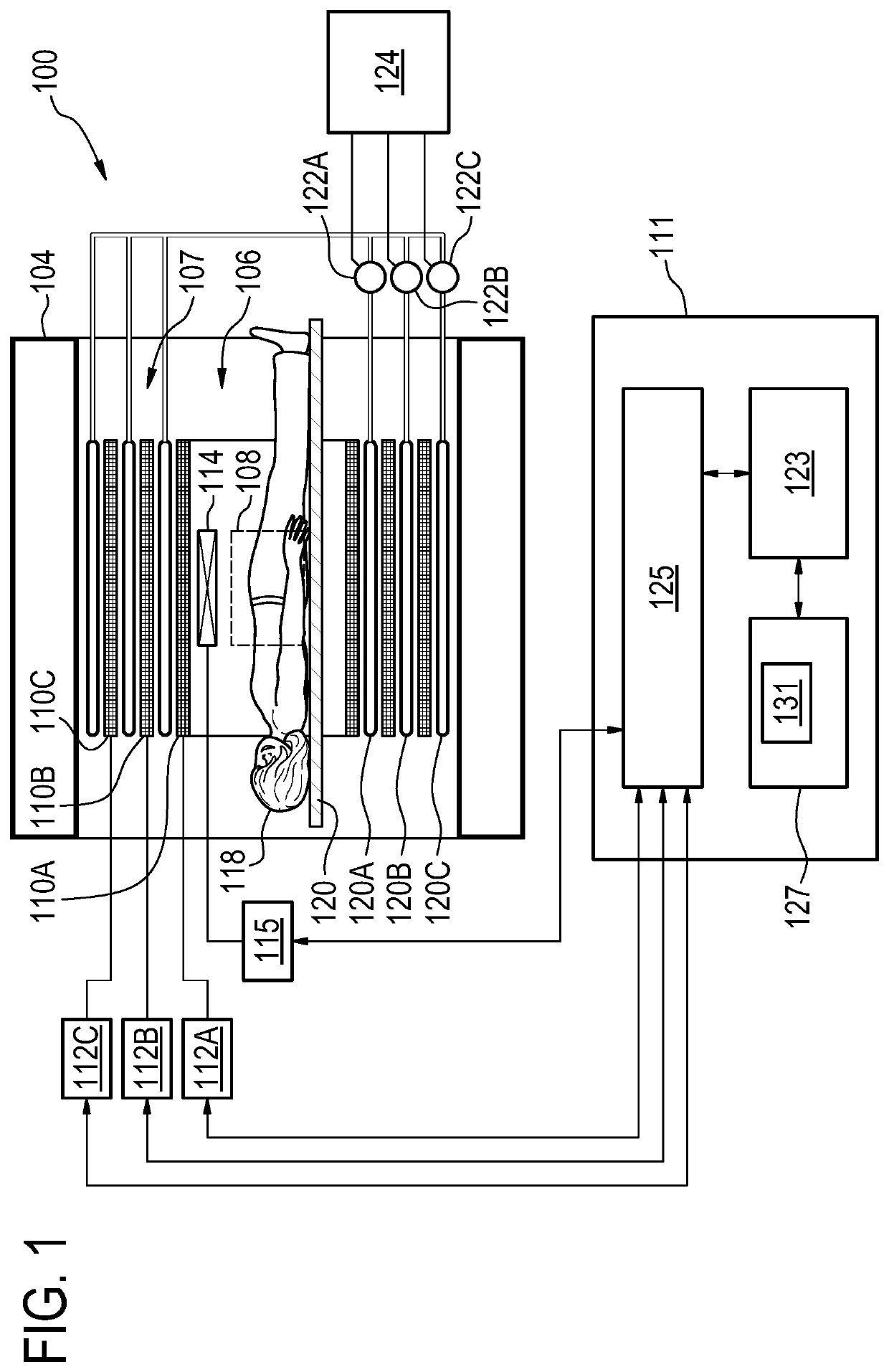

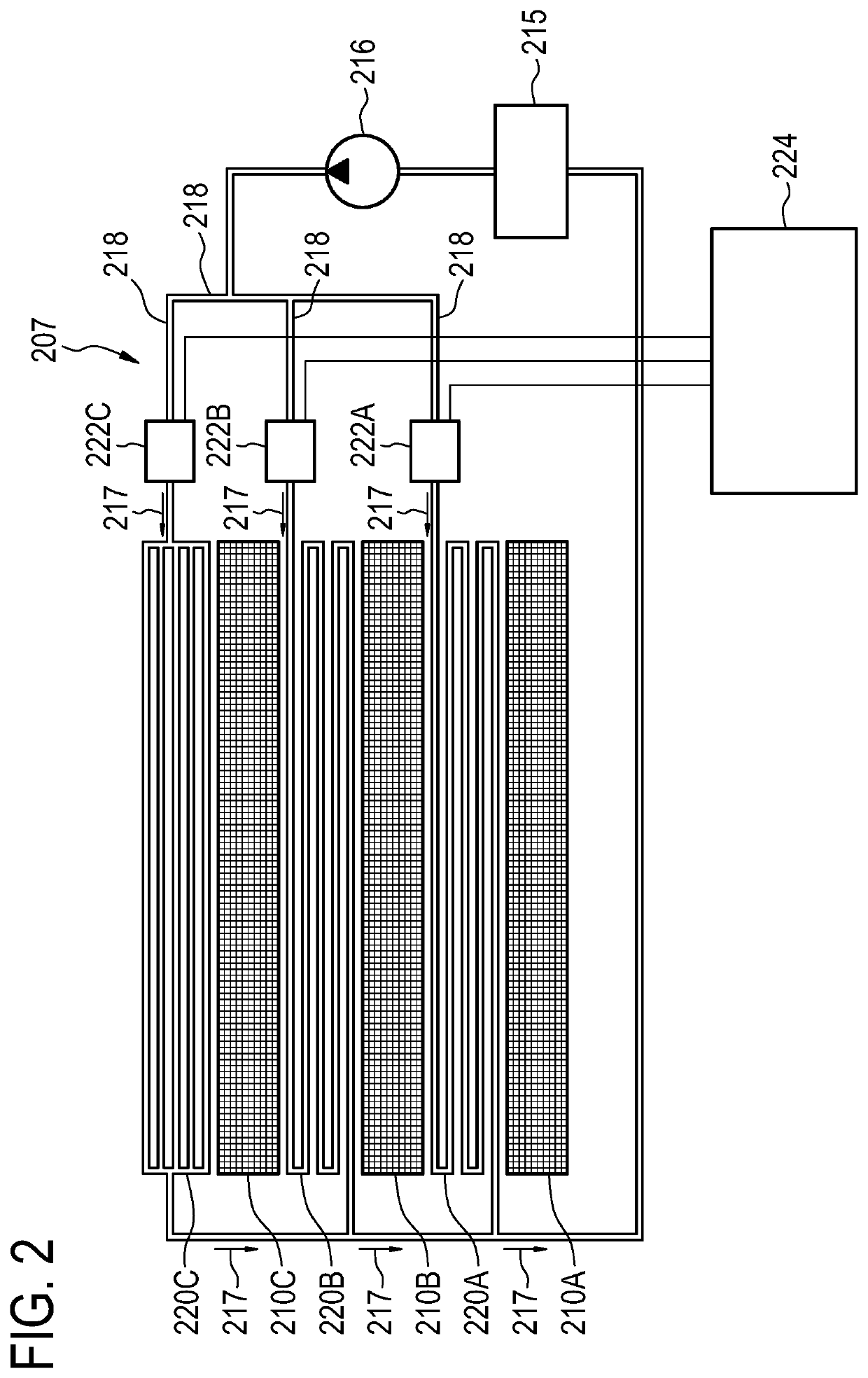

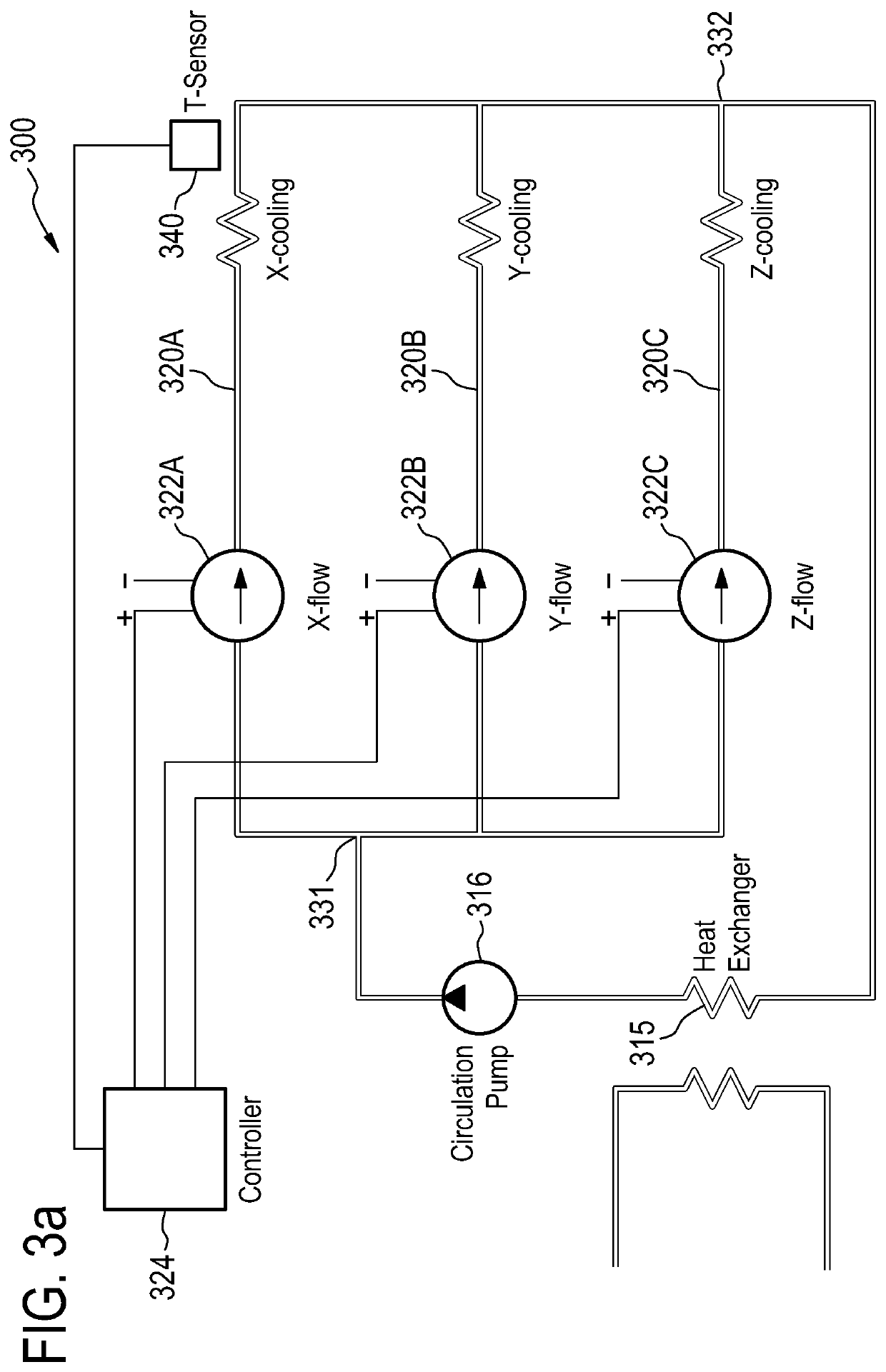

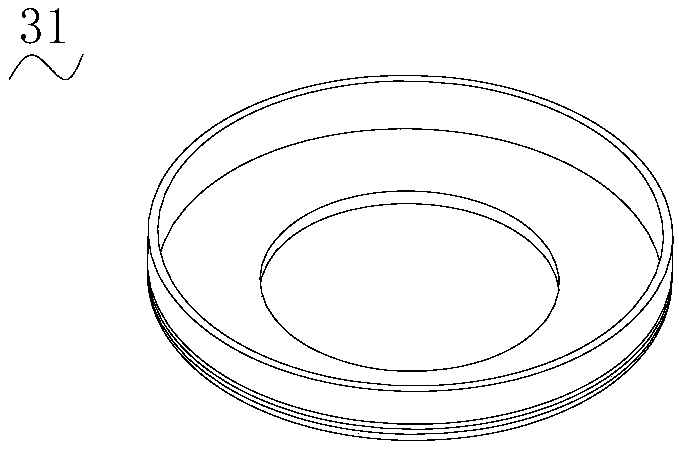

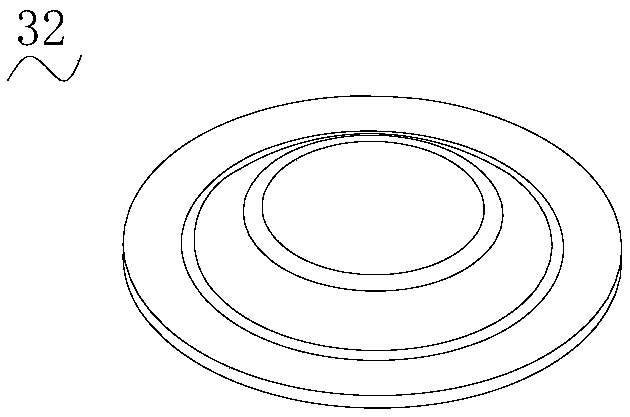

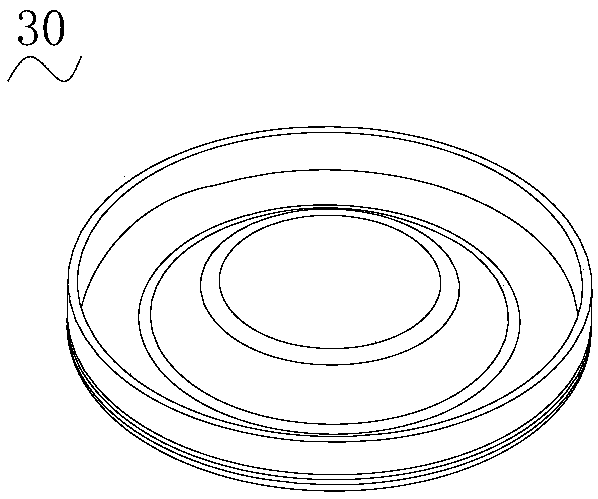

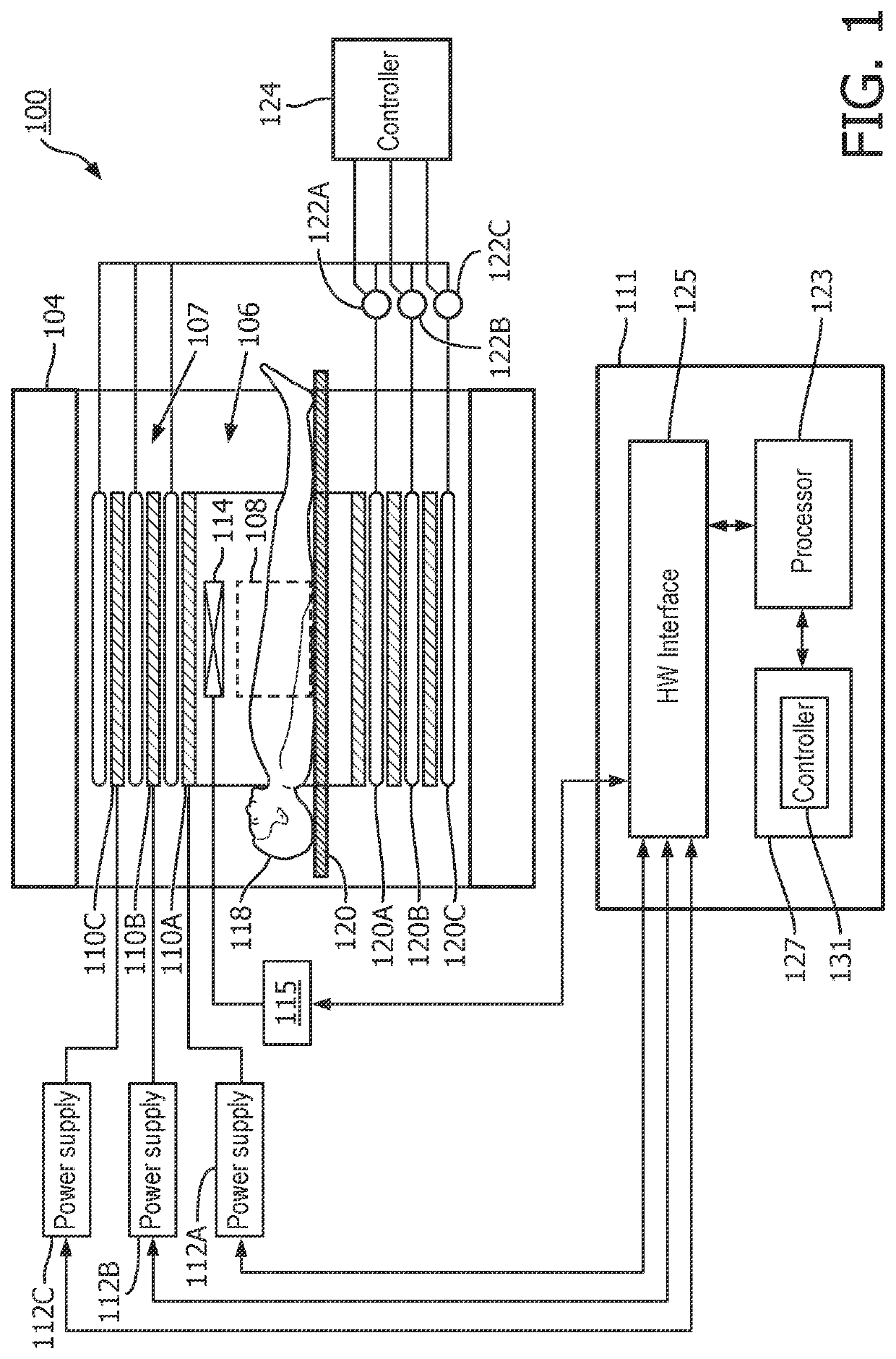

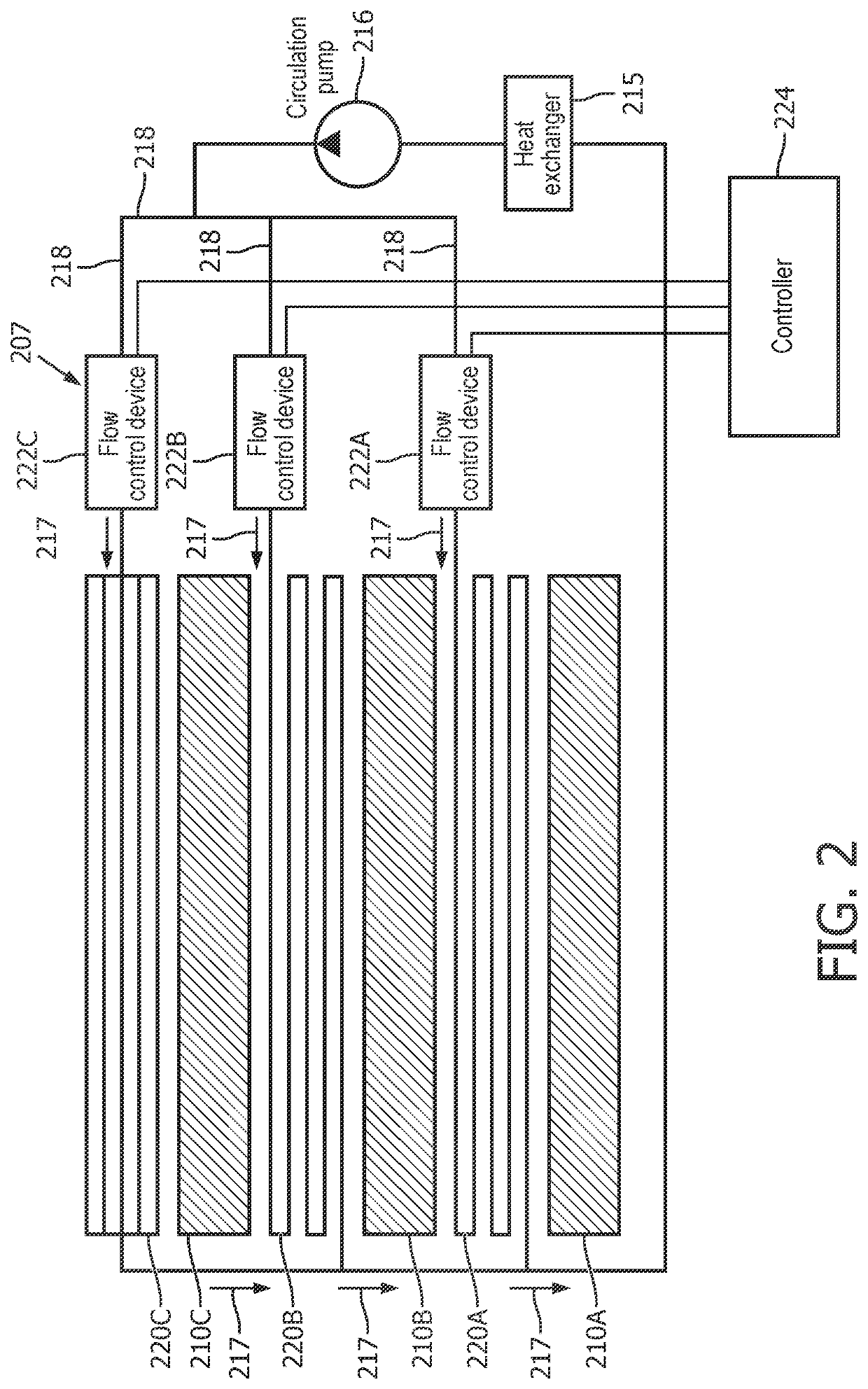

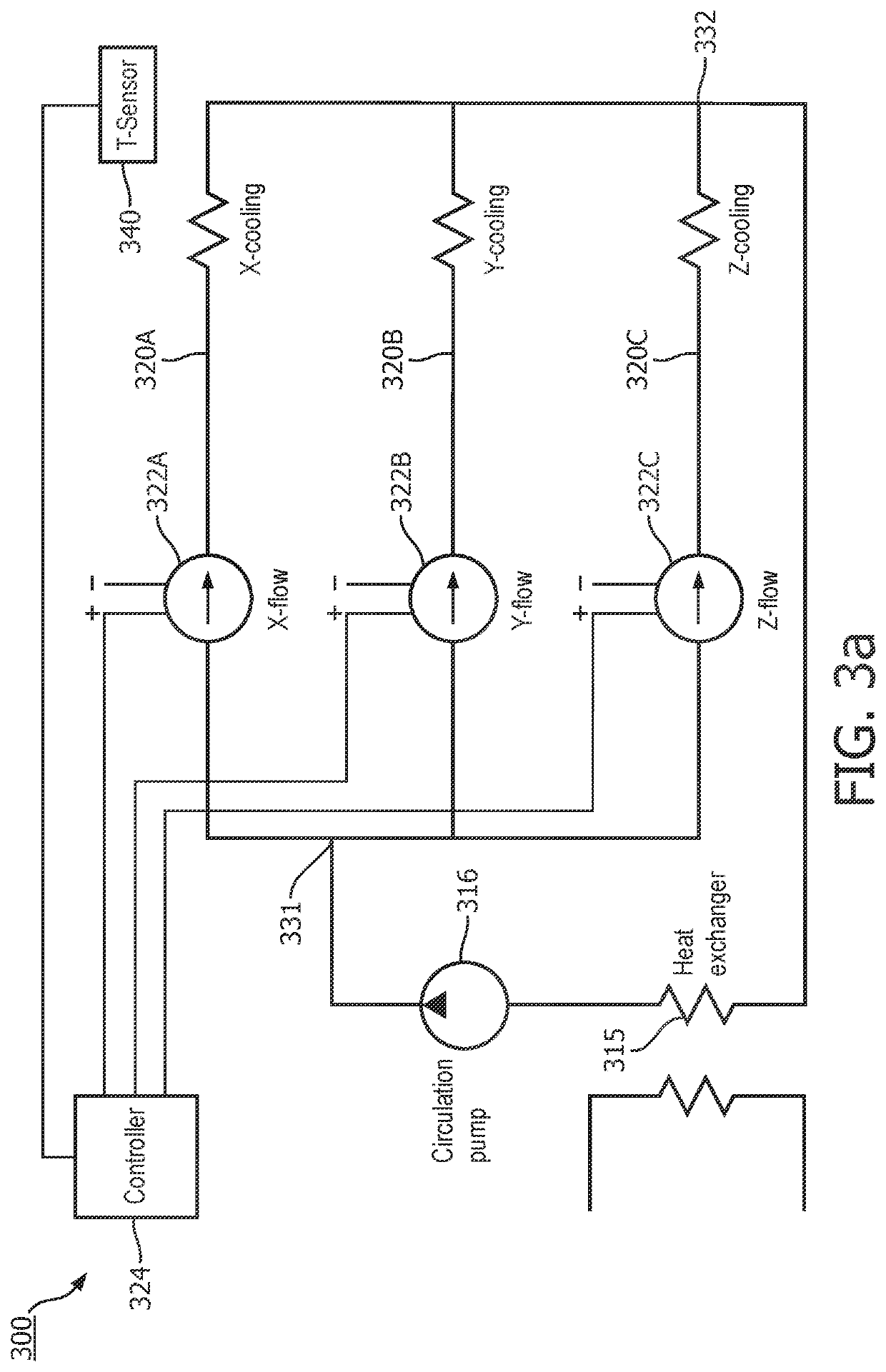

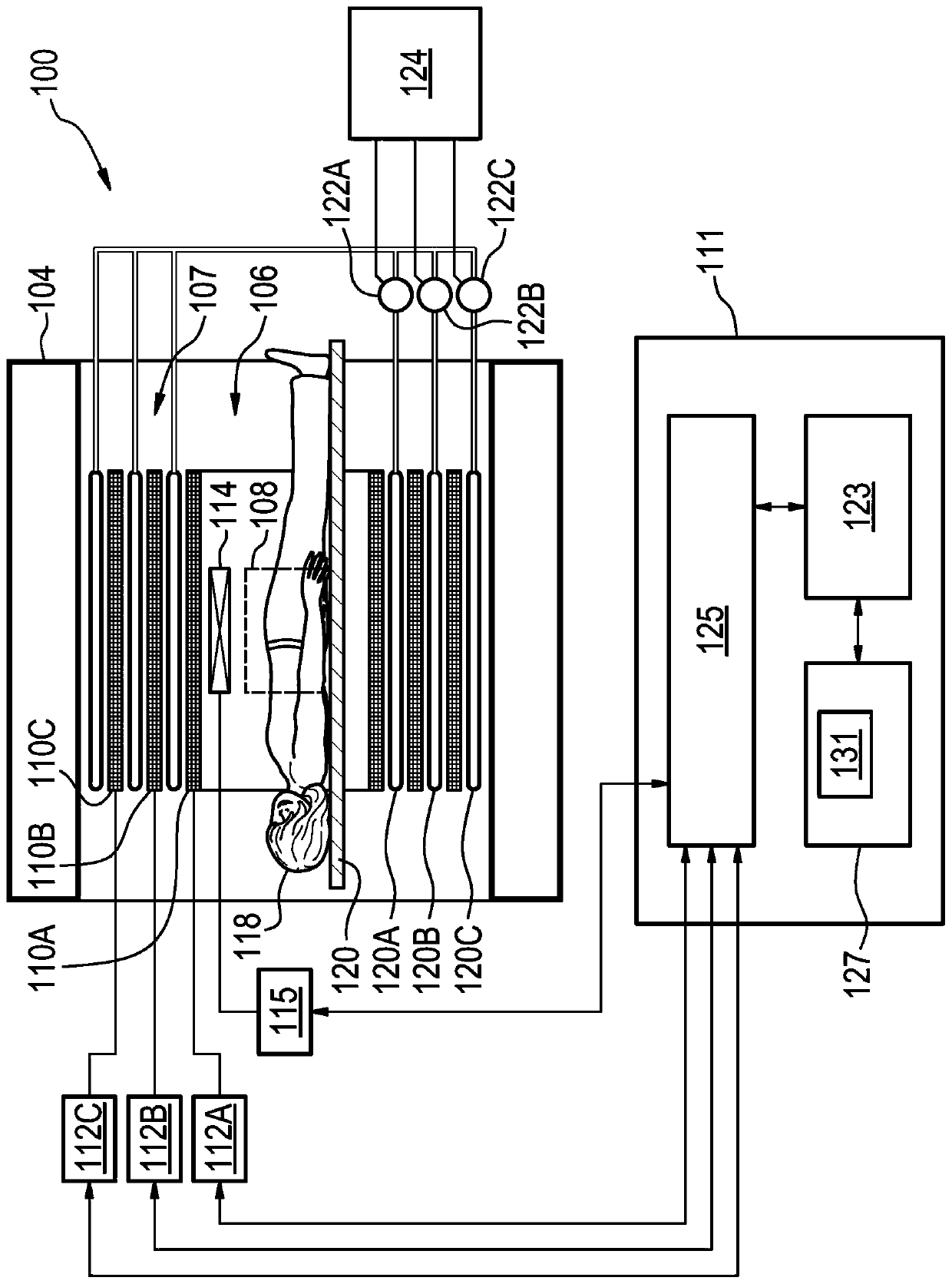

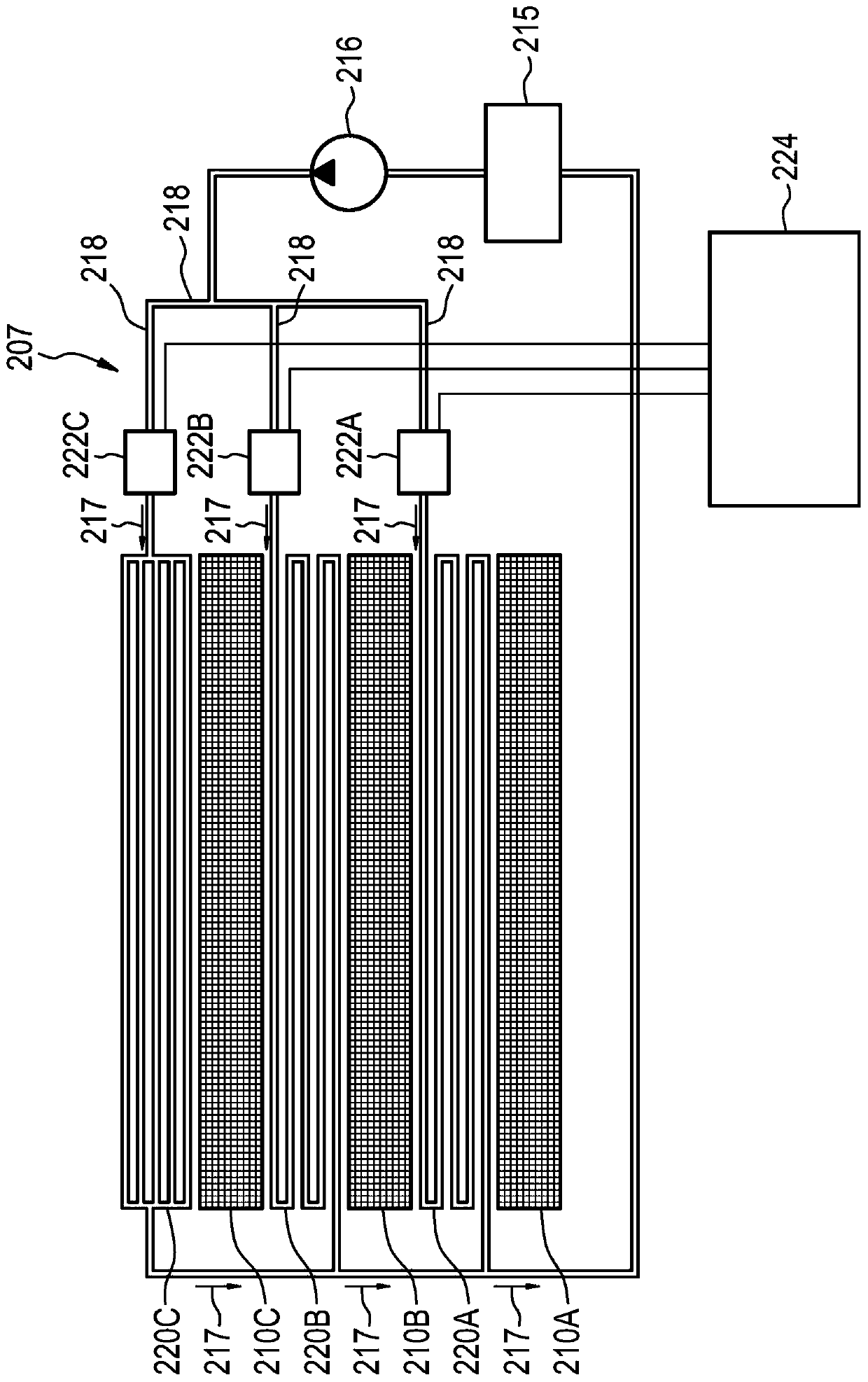

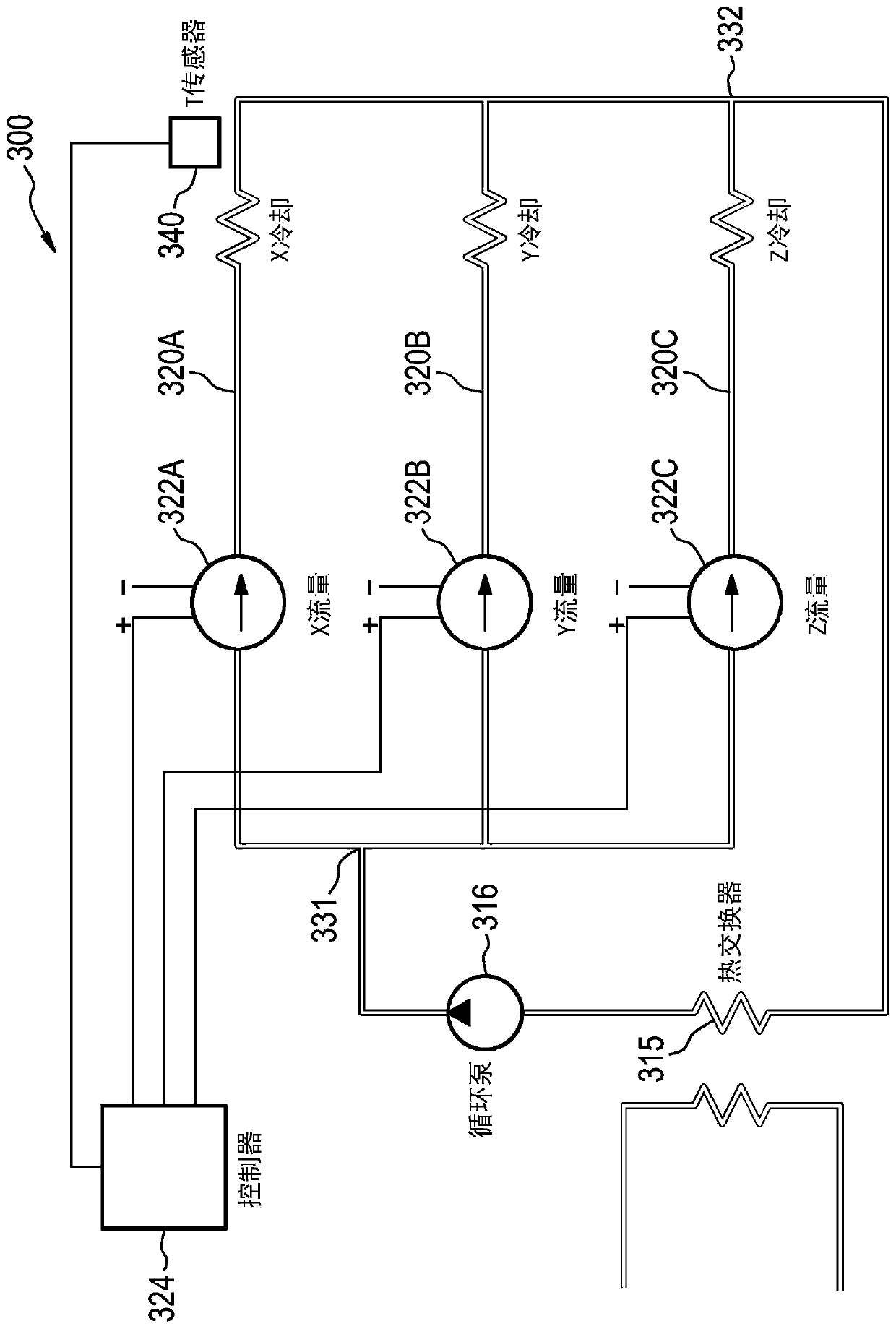

Gradient system with controlled cooling in the individual gradient channels

ActiveUS20200049779A1Compact designEasy to useMeasurements using NMR imaging systemsMagnet resonance imagingCooling fluid

The present disclosure relates to a gradient coil system (107, 207) for a magnetic resonance imaging, MRI, system (100). The gradient coil system (107, 207) comprises: a plurality of gradient coils (110A-C, 210A-C) for applying a gradient magnetic field to a target volume (108); at least one coolant tube (120A-C, 220A-C, 320A-C) per gradient coil (110A-C, 210A-C) for cooling the gradient coil (110A-C, 210A-C), the coolant tubes (120A-C, 220A-C, 320A-C) being connected to respective flow control devices (122A-C, 222A-C, 322A-C); a controller (124, 224, 324) coupled to the coolant tubes (120A-C, 220A-C, 320A-C) configured to control each flow control device of the flow control devices (122A-C, 222A-C, 322A-C) for adjusting the flow of a coolant in the respective coolant tube (120A-C, 220A-C, 320A-C), wherein the controller (124, 224, 324) is configured to control the flow control device (122A-C, 222A-C, 322A-C) on the basis of heat load caused by the respective gradient coil (110A-C, 210A-C).

Owner:KONINKLJIJKE PHILIPS NV

Ray shooting method utilizing geometrical stencils

ActiveUS9483865B2Effective trackingCut down high traversal and construction costResource allocationImage generationLoad SheddingVisibility

Aspects comprise a ray shooting method based on the data structure of a uniform grid of cells, and on local stencils in cells. The high traversal and construction costs of accelerating structures are cut down. The object's visibility from the viewpoint and from light sources, as well as the primary workload and its distribution among cells, are gained in the preprocessing stage and cached in stencils for runtime use. In runtime, the use of stencils allows a complete locality at each cell, for load balanced parallel processing.

Owner:SNAP INC

Battery cap welding device

PendingCN110369869AImprove welding process efficiencyFit closelyLaser beam welding apparatusEngineeringAutomation

The invention belongs to the technical field of battery production equipment, and particularly relates to a battery cap welding device. The battery cap welding device comprises a machine frame, a feeding device, an assembly device, a welding device, a conveying device and a discharging device. The feeding device comprises a first feeding mechanism for conveying top covers, and a second feeding mechanism for conveying explosion-proof covers. The assembly device is used for carrying out assembly on the explosion-proof covers conveyed by the second feeding mechanism and the top covers conveyed bythe first feeding mechanism to form caps. The welding device comprises a jig and a galvanometer welding machine which are arranged on the machine frame. The jig is provided with multiple welding stations for containing assembled caps. The conveying device is arranged between the assembly device and the welding device, and is used for conveying the assembled caps to the welding stations. The galvanometer welding machine is used for welding the caps in the welding stations. The battery cap welding device is low in processing cost, high in automation degree and high in processing efficiency.

Owner:深圳市通则新能源科技有限公司

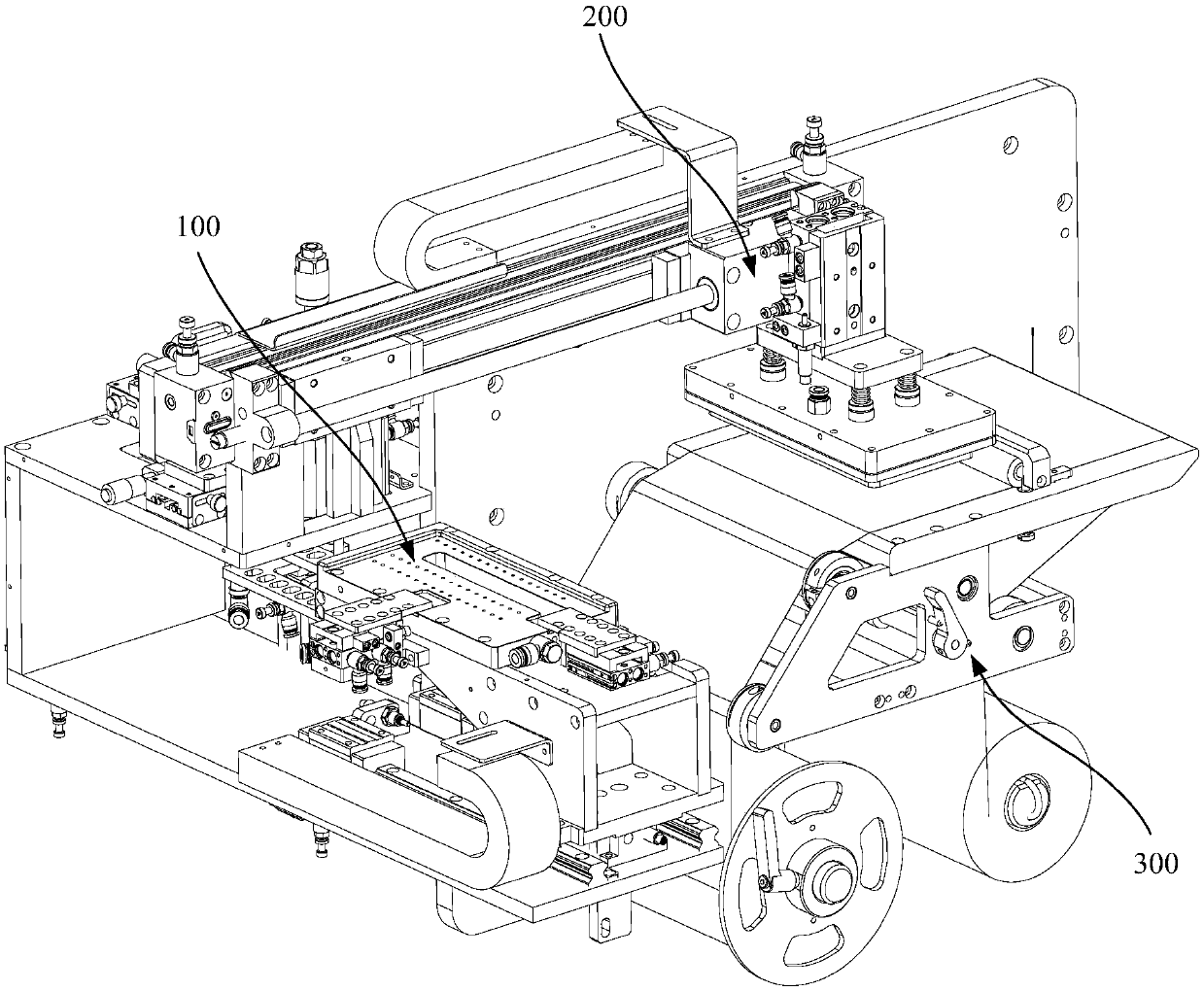

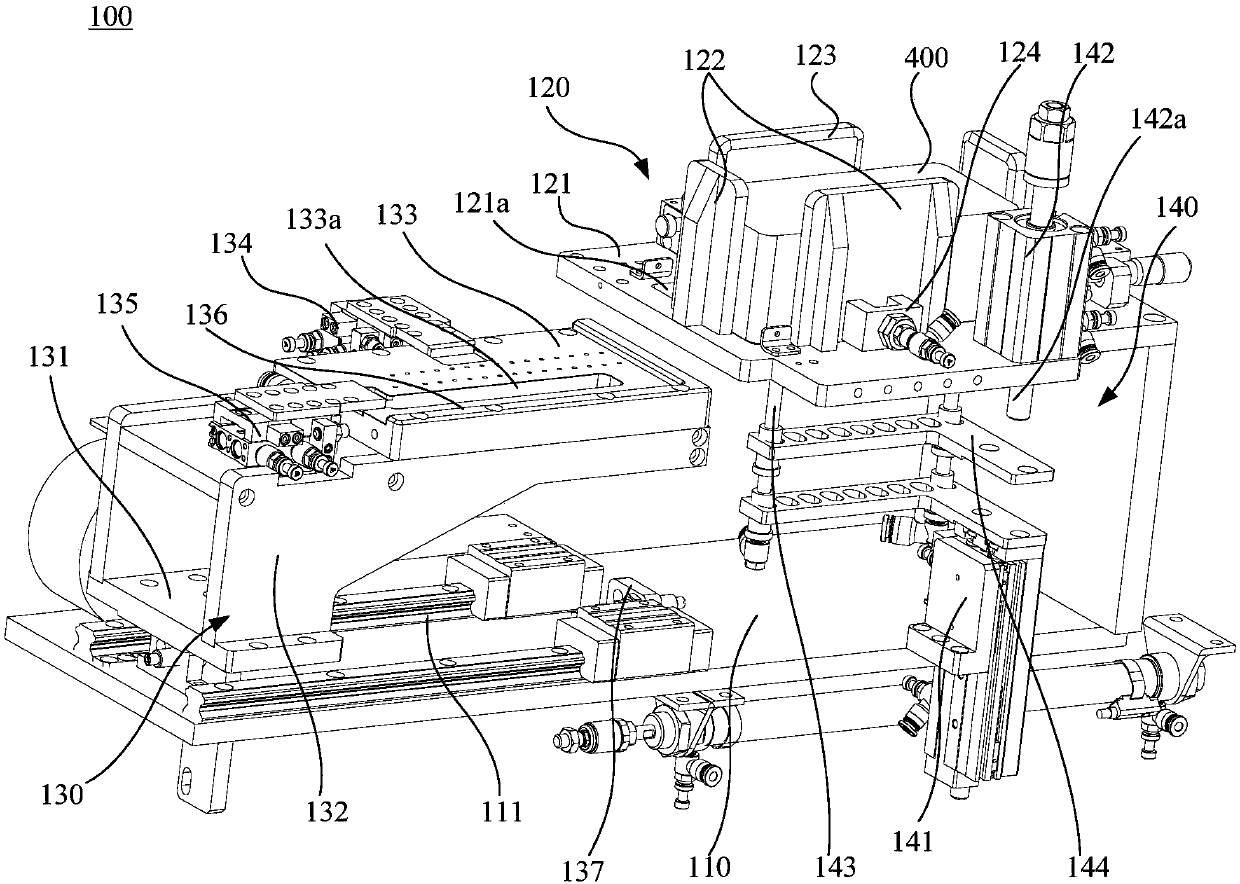

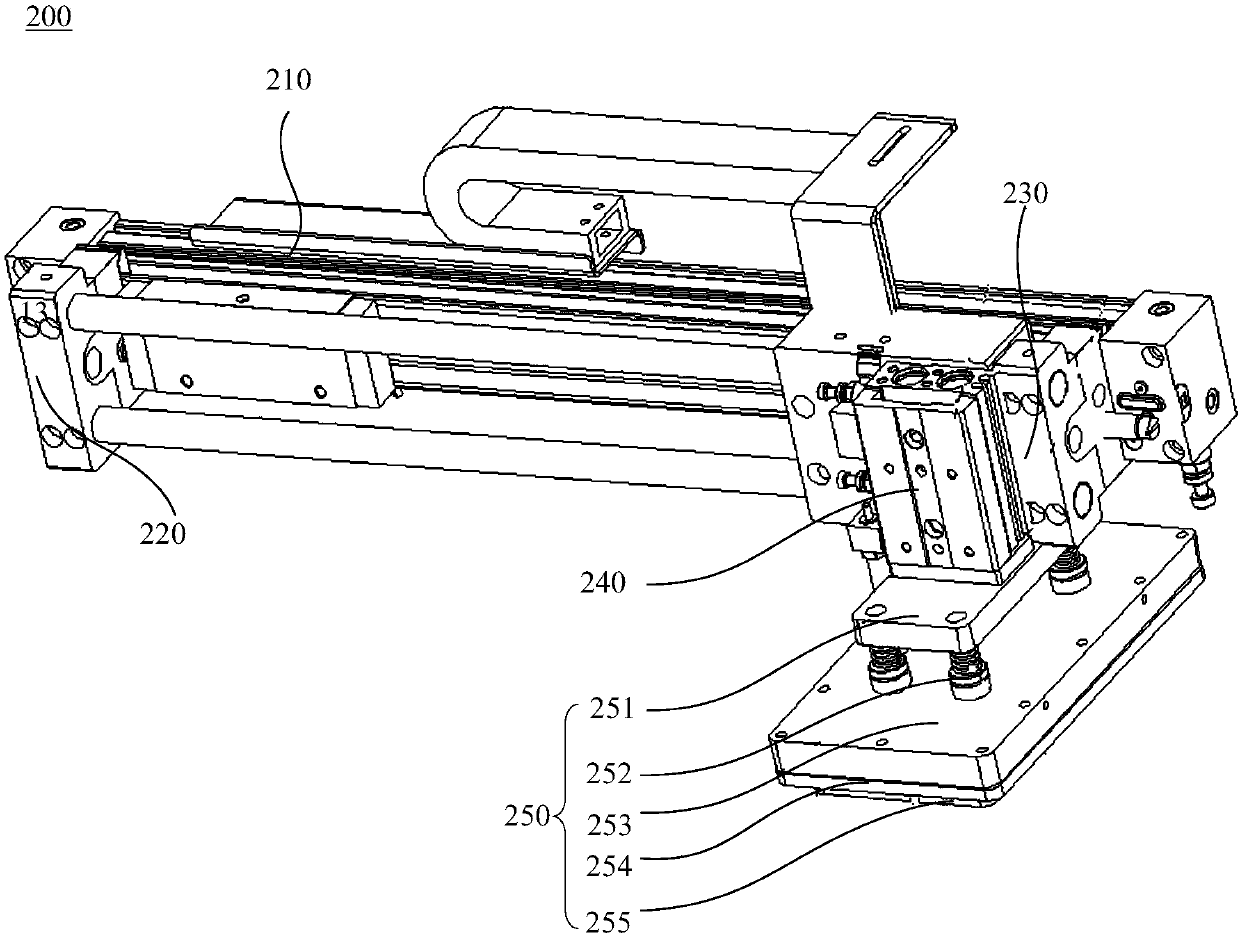

Automatic stripping machine

ActiveCN106541686BImprove work efficiencyPrevent static electricityLamination ancillary operationsLaminationEngineeringWaiting time

Owner:SHENZHEN ZOWEE TECH +1

Gradient system with controlled cooling in the individual gradient channels

ActiveUS10989777B2Easy to useReduce the temperatureMeasurements using NMR imaging systemsEngineeringMagnet resonance imaging

A gradient coil system for a magnetic resonance imaging system includes a plurality of gradient coils for applying a gradient magnetic field to a target volume; at least one coolant tube per gradient coil for cooling the gradient coil (110A-C, 210A-C). The coolant tubes are connected to respective flow control devices and a controller, which is configured to control each flow control device of the flow control devices for adjusting the flow of a coolant in the respective coolant tube. The controller is configured to control the flow control device on the basis of heat load caused by the respective gradient coil.

Owner:KONINKLJIJKE PHILIPS NV

Method for scheduling bus system transmissions

ActiveUS9143348B2Shorten cycle timeReduce waiting timeElectric digital data processingBus networksTime scheduleEmbedded system

A method for operating a bus system, which includes a master and k slaves as users, where a header of an interrogation frame, which includes k information fields, is transmitted by the master to the slaves; in each instance, an mth slave being assigned an mth information field; an information item regarding the amount of data that is to be sent by the mth slave to the master being written by the mth slave to the mth information field assigned to it; the interrogation frame being transmitted to the master; and a time schedule, by which the amount of data to be sent is taken into account, being prepared by the master for transmitting the data.

Owner:ROBERT BOSCH GMBH

Assembling a monolithic laminated frame structure

InactiveCN103758208BGuaranteed stabilityGuaranteed continuityBuilding constructionsEngineeringUltimate tensile strength

The invention discloses an assembled monolithic overlapping type frame structure. The assembled monolithic overlapping type frame structure solves the problems that according to a post-cast monolithic concrete structure, the connection method is not standard and the amount of wet construction is large during construction. The assembled monolithic overlapping type frame structure comprises a first prefabricated part, a second prefabricated part and a fixing and connecting assembly, wherein the first prefabricated part and the second prefabricated part are overlapped and are integrated through the fixing and connecting assembly. The assembled monolithic overlapping type frame structure is characterized in that the first prefabricated part is provided with a boss, a groove which is matched with the boss is formed in the position where the first prefabricated part and the second prefabricated part are overlapped, and the fixing and connecting assembly is an integrated connecting assembly which is composed of an integrated connecting piece, a connecting bolt and a locking nut or is a split type connecting assembly which is composed of a split type connecting piece and a pre-buried locking piece. The assembled monolithic overlapping type frame structure has the advantages that the structural stress is reasonable, the connecting joints of the prefabricated parts are standard, the strength is high, requirements of the bearing capacity and deformation are met, the stability of the overall structure is guaranteed, the application range is widened, field connection is stable, firm, reliable, fast and convenient, working efficiency is improved, and green construction is guaranteed.

Owner:沈阳赫声装备科技有限公司 +1

Ray Shooting Based on Geometrical Stencils

InactiveUS20190012823A1Effective trackingCut down high traversal3D-image renderingVisibilityPre treatment

Aspects comprise a ray tracing system based on data structure of a uniform grid of cells, and on local stencils in cells. The high traversal and construction costs of accelerating structures, typical to the prior art ray tracing, are greatly reduced. The stencils, generated in a preprocessing phase, hold visibility information, for a runtime use. Each cell achieves high locality, allowing improved parallel processing.

Owner:ADSHIR LTD

pcb automatic test system without carry waiting time

ActiveCN103048610BEliminate idle timeImprove test efficiencyElectronic circuit testingOptically investigating flaws/contaminationTest efficiencyTested time

The invention discloses an entrance waiting time-free automatic test system for a printed circuit board (PCB). The system comprises a mechanical arm and a test bench. A rotatable station is arranged on the test bench. A plurality of rotatable sub-stations are arranged on the station. One or more working areas are arranged on each sub-station. A test device for sub-station test is arranged on each working area of each sub-station, and rotates synchronously with the corresponding sub-station. The number of the working areas on each sub-station is directly proportional to the test time of the sub-station. When the system is used, the PCB is sequentially transmitted to each sub-station to be tested on the sub-stations by rotating the station, and is sequentially transmitted to each working area by rotating the sub-stations. The working areas in a number which is directly proportional to the test time of each sub-station are arranged on the sub-station to eliminate entrance waiting time between the sub-stations, so that the test time of the PCB is saved, and the test efficiency of the PCB is improved.

Owner:SHANGHAI JINDONGTANG TECH CO LTD

Gradient system with controlled cooling in the individual gradient channels

InactiveCN110325870AEfficient use of cooling capacityUse cooling capacityMeasurements using NMR imaging systemsMagnet resonance imagingMaterials science

The present disclosure relates to a gradient coil system (107, 207) for a magnetic resonance imaging, MRI, system (100). The gradient coil system (107, 207) comprises: a plurality of gradient coils (110A-C, 210A-C) for applying a gradient magnetic field to a target volume (108); at least one coolant tube (120A-C, 220A-C, 320A-C) per gradient coil (110A-C, 210A-C) for cooling the gradient coil (110A-C, 210A-C), the coolant tubes (120A-C, 220A-C, 320A-C) being connected to respective flow control devices (122A-C, 222A-C, 322A-C); a controller (124, 224, 324) coupled to the coolant tubes (120A-C,220A-C, 320A-C) configured to control each flow control device of the flow control devices (122A-C, 222A-C, 322A-C) for adjusting the flow of a coolant in the respective coolant tube (120A-C, 220A-C,320A-C), wherein the controller (124, 224, 324) is configured to control the flow control device (122A-C, 222A-C, 322A-C) on the basis of heat load caused by the respective gradient coil (110A-C, 210A-C).

Owner:KONINKLIJKE PHILIPS NV

Washing machine fill reservoir

ActiveUS10640909B2Eliminate idle timeReduce processing timeOther washing machinesTextiles and paperLaundry washing machineInlet valve

A washing machine fill reservoir includes a basin large enough to replenish a volume of water to adequately fill a washing machine drum of a washing machine. Inlet valves allow for introduction of hot and cold water and additives such as-soap, fabric softener, chlorine bleach and emulsifiers. A large orifice valve positioned between the washing machine fill reservoir and the washer drum enables prompt introduction of the fluid maintained in the washing machine fill reservoir to be conveyed into the washer drum. Fluid level in the washing machine fill reservoir may be either fixed volume or adjustable via an internal or external sensing device. The washing machine fill reservoir offers a significantly reduced operating duration of the washing machine, without diminishing the quality of the laundering process.

Owner:MCCLOY JOHN

Ray shadowing system utilizing geometrical stencils

InactiveUS20140375642A1Effective trackingCut down high traversalDetails involving 3D image dataDigital computer detailsVisibilityViewpoints

Aspects comprise ray tracing shadowing system based on the data structure of a uniform grid of cells, and on local stencils in cells. The high traversal and construction costs of accelerating structures are cut down. The object's visibility from the viewpoint and from light sources, as well as the primary workload and its distribution among cells, are gained in the preprocessing stage and cached in stencils for runtime use. In runtime, the use of stencils allows a complete locality at each cell, for load balanced parallel processing.

Owner:ADSHIR LTD

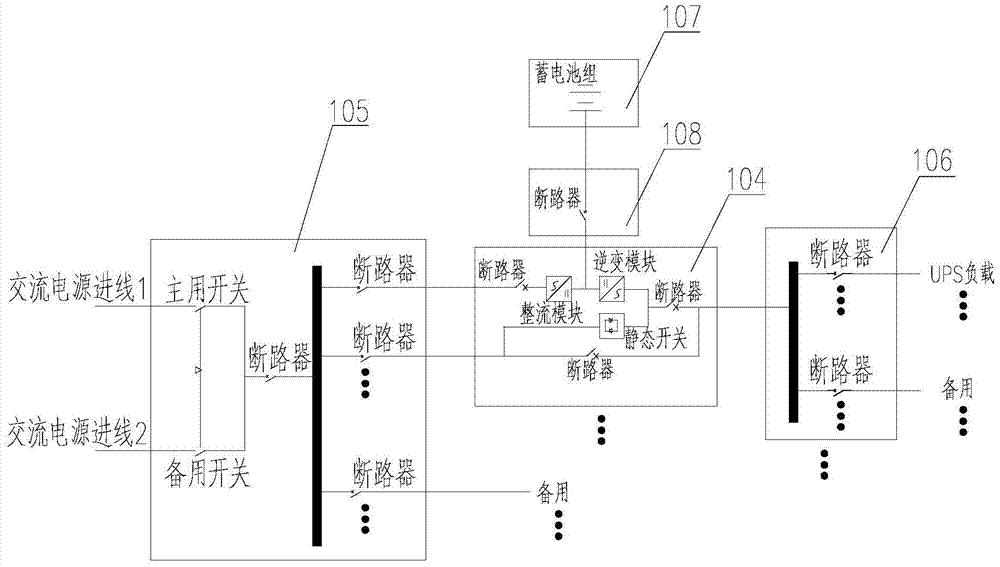

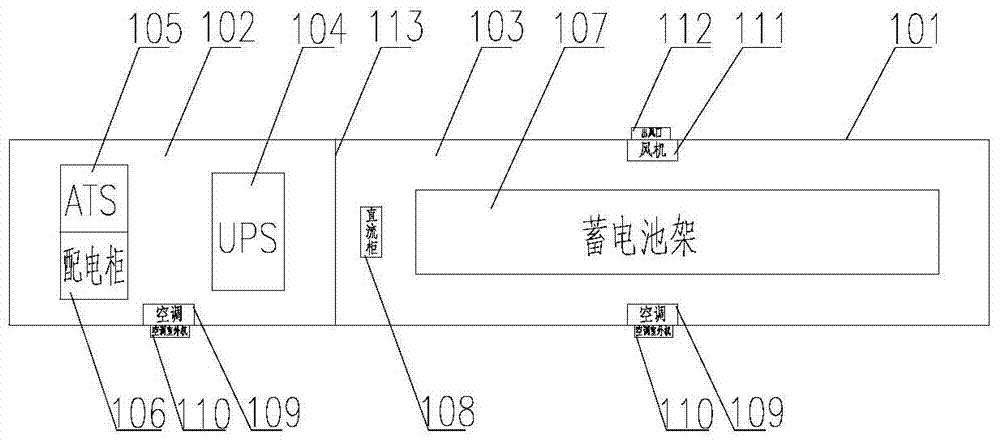

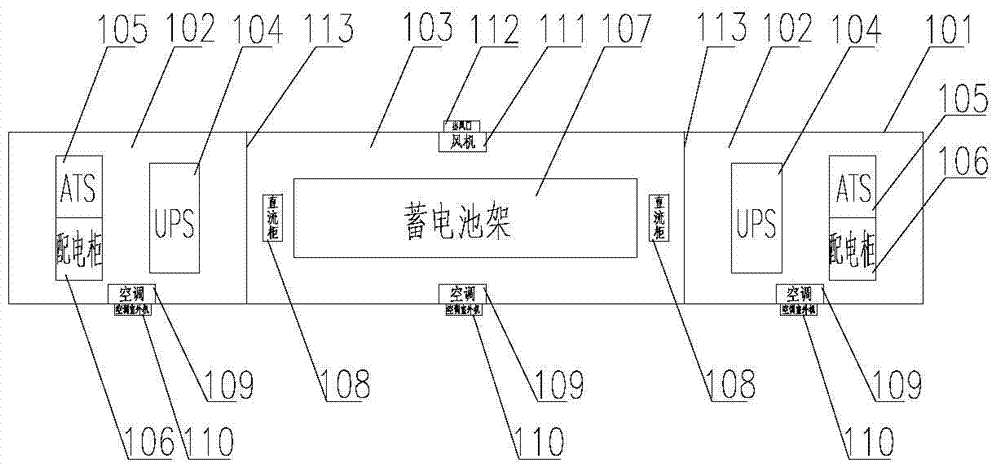

A prefabricated uninterruptible power supply system

ActiveCN104362733BAchieve pollutionReduce pollutionBatteries circuit arrangementsElectric powerSystem integrationCommunication interface

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST CO LTD

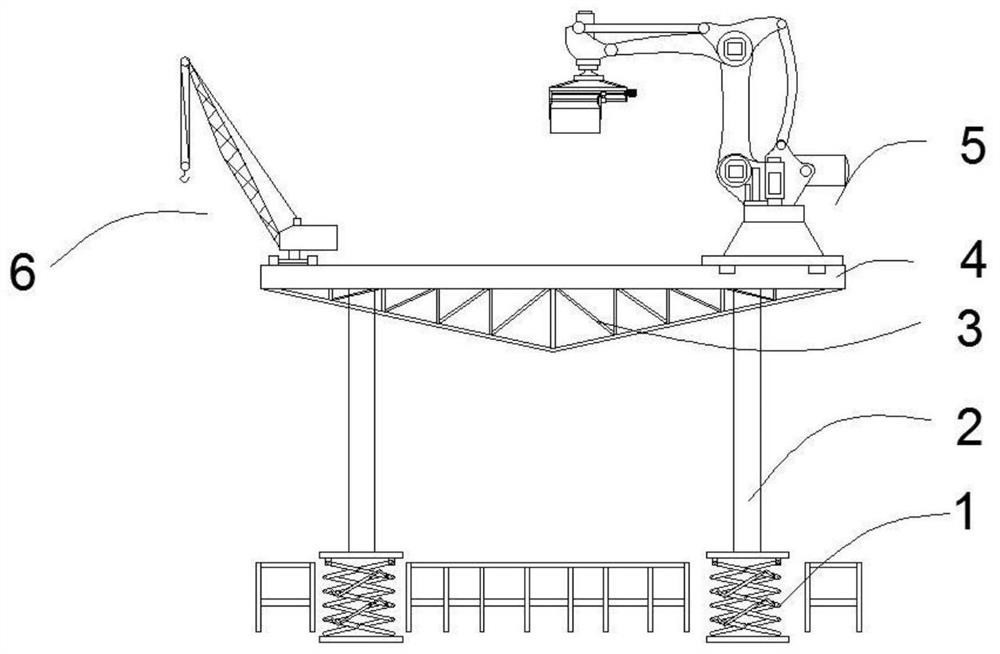

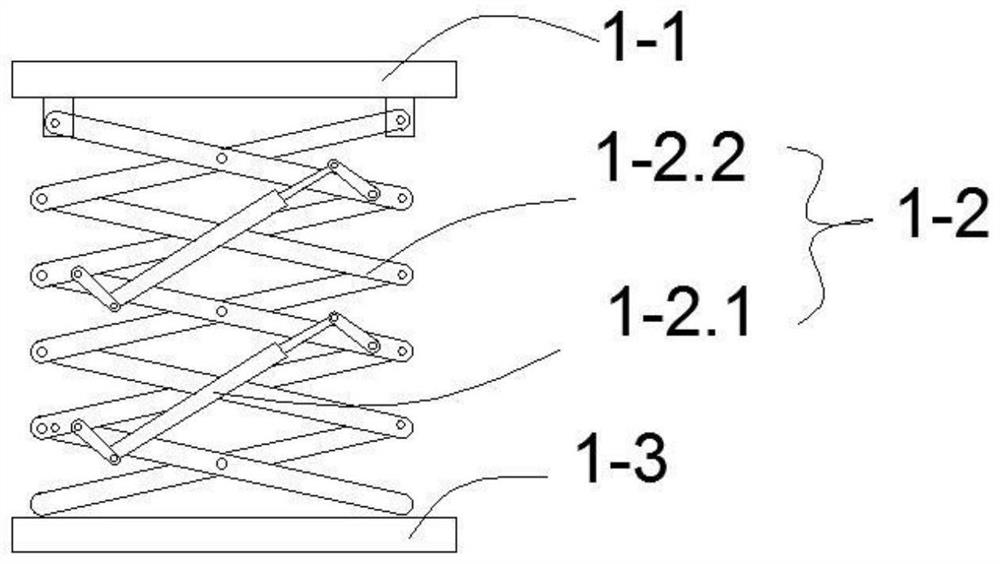

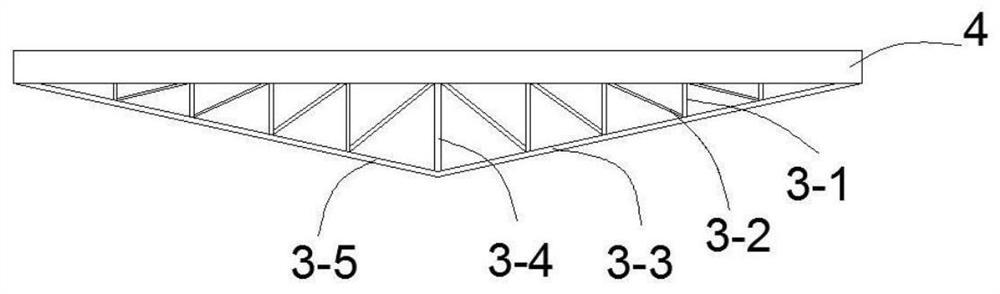

Hoisting equipment for prefabricated part of fabricated building

InactiveCN112239149AEasy to moveImprove positioning accuracyBuilding material handlingCranesReciprocating motionArchitectural engineering

The invention discloses hoisting equipment for a prefabricated part of a fabricated building, and relates to the technical field of hoisting of prefabricated building parts. The hoisting equipment comprises a plurality of lifting rods which are vertically arranged at intervals and a composite guide rail beam arranged at the tops of the multiple lifting rods; a stable lifting mechanism for drivingthe lifting rods to ascend and descend is arranged at the bottom of each lifting rod; and the composite guide rail beam is provided with a prefabricated part crane and a rotary clamping robot capableof doing reciprocating motion along the composite guide rail beam. The hoisting equipment for the prefabricated part of the fabricated building has the advantages of being simple in structure, accurate in positioning, high in efficiency and small in manual labor intensity.

Owner:徐辉设计股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com