Hoisting equipment for prefabricated part of fabricated building

A technology of prefabricated components and hoisting equipment, applied in building construction, processing of building materials, construction, etc., can solve the problems of increasing coordination work and low degree of automation, so as to increase coordination work, eliminate process connection, and improve positioning accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

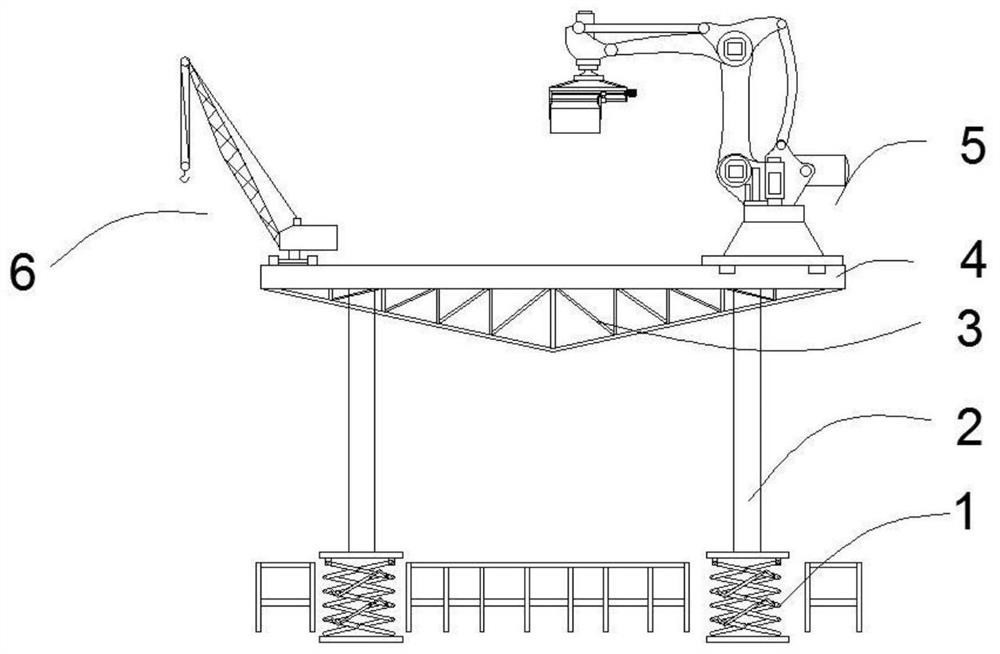

[0029] Such as Figures 1 to 6 As shown, this embodiment provides a hoisting device for prefabricated building components, including a number of vertically spaced elevating rods 2 and composite guide rail beams arranged on top of several elevating rods 2, each elevating rod 2 bottom is A stable lifting mechanism 1 is provided to drive the lifting rod 2 up and down, and the composite guide rail beam is provided with a preset member crane 6 and a rotary clamping robot 5 that can reciprocate along the composite guide rail beam.

[0030] The rotary clamping robot 5 includes a rotary robotic arm 5-1 and a combined clamping gripper 5-2 that is movably connected to the end of the rotary robotic arm 5-1 and has an adjustable grasping size. The rotary robotic arm The end of 5-1 is also consolidated with a drive mechanism 5-3 that drives the combined clamping handle 5-2 to rotate.

[0031] The combined clamping handle 5-2 includes a connection seat A5-2.1, a connection seat B5-2.2, an ...

Embodiment 2

[0036] This embodiment is further optimized on the basis of embodiment 1, specifically:

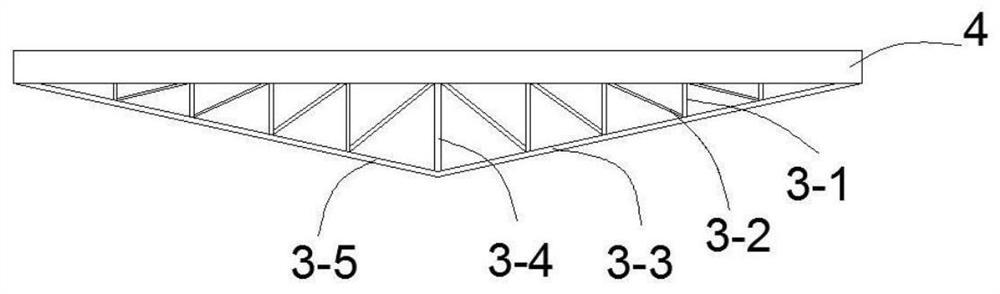

[0037] The composite guide rail beam includes a horizontally arranged crossbeam 4, an auxiliary support mechanism 3 is arranged below the crossbeam 4, and the auxiliary support mechanism 3 includes a lower support rod 3-4 arranged at the middle of the bottom surface of the crossbeam 4, two ends of the lower support rod 3-4 The sides are inclined with inclined tie rod A3-3 and inclined tie rod B3-5, one end of the inclined tie rod A3-3 and the inclined tie rod B3-5 is welded to the end of the lower support rod 3-4, and the inclined tie rod A3-3 and the inclined tie rod B3-5 The other end of the other end is welded with two ends of crossbeam 4 respectively, and in the area that inclined tie rod A3-3 and inclined tie rod B3-5 and crossbeam 4 are formed, be provided with some vertical reinforcing rods 3-1 and inclined reinforcing rod 3-2.

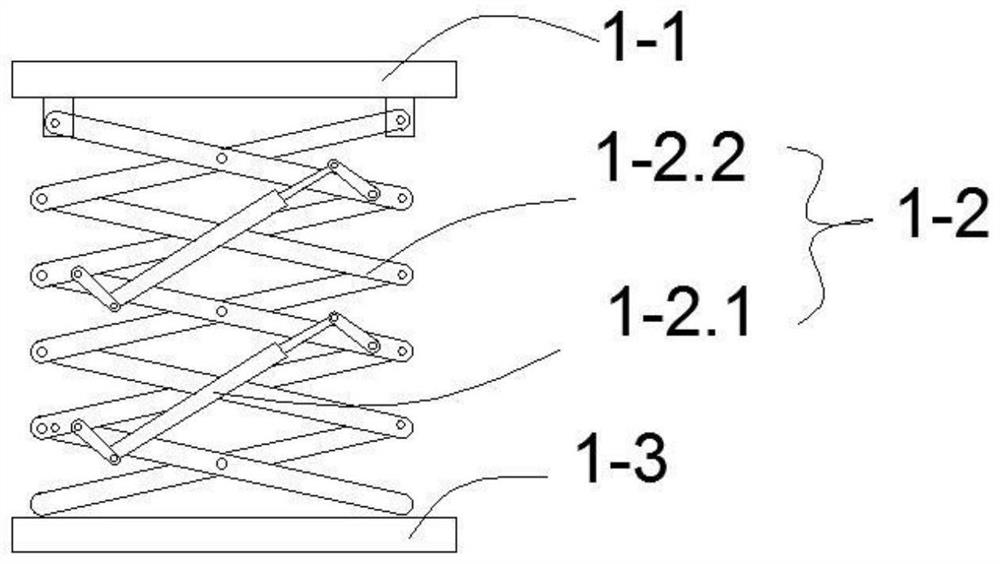

[0038] Described stable lifting mechanism 1 comprise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com