pcb automatic test system without carry waiting time

An automatic testing system and waiting time technology, applied in the direction of electronic circuit testing, optical testing flaws/defects, measuring electricity, etc., to achieve the effect of eliminating idle time, improving testing efficiency, and saving testing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

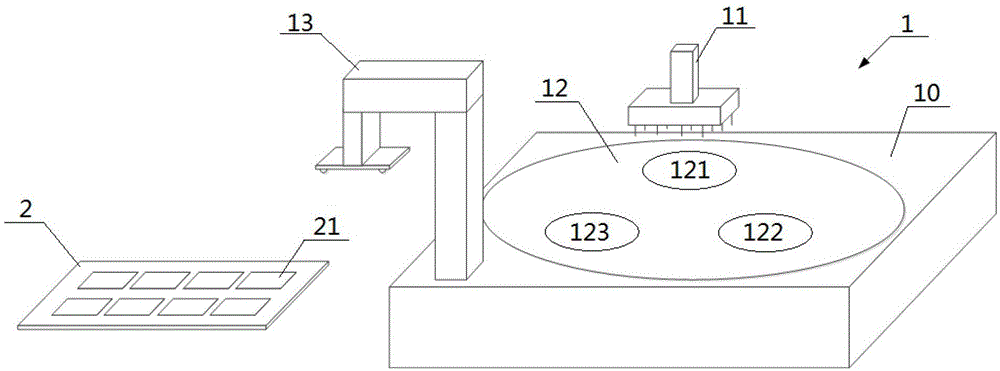

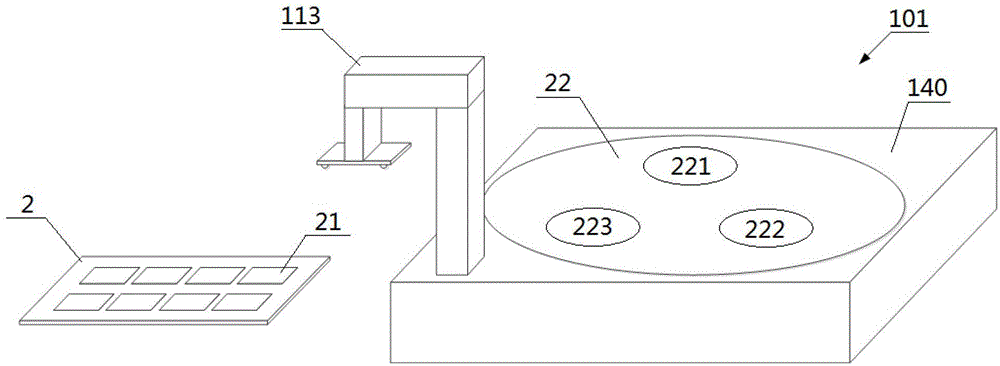

[0026] In the first embodiment, the PCB automatic test system 101 without carry waiting time of the present invention is as figure 2 As shown, a test bench 140 and a robot arm 113 are included, and the test bench 140 has a station 22 on it. Eight single-piece PCB boards 2 such as single-piece 21 are grasped and placed on the station 22 of the test bench 110 by the mechanical arm 113 of the PCB automatic test system 101 without carry waiting time of the present invention to accept different tests.

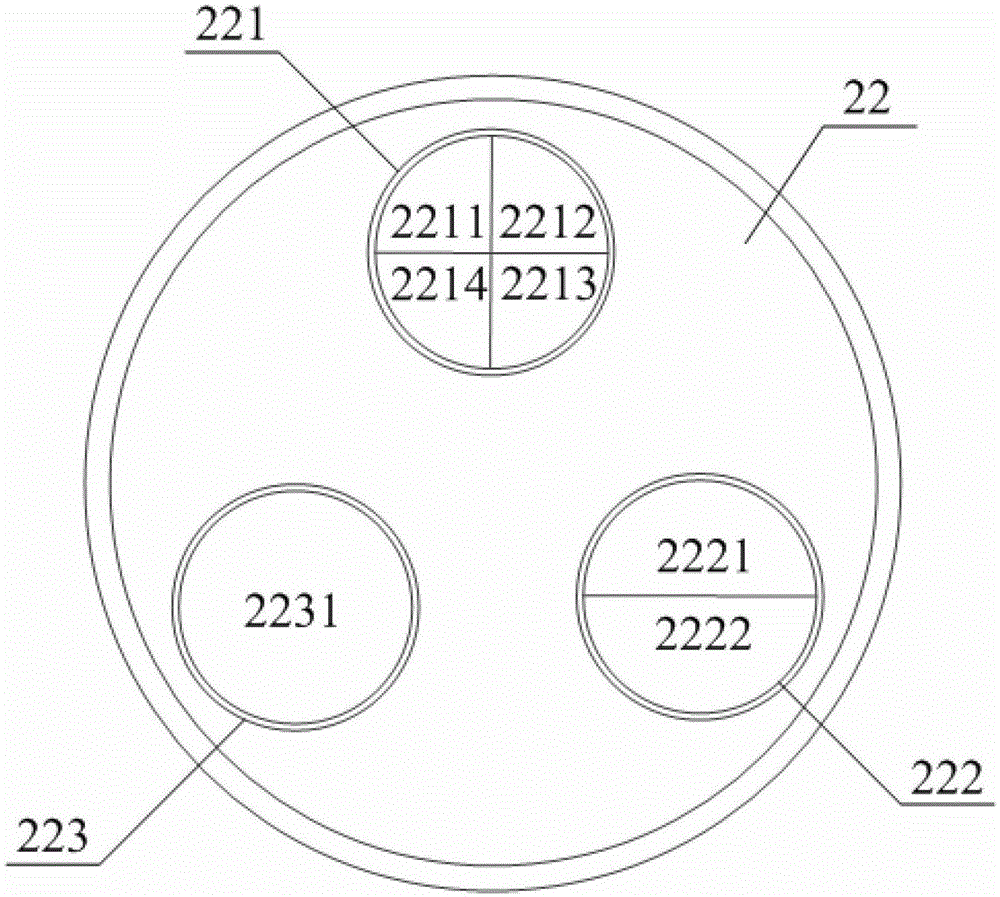

[0027] image 3 show figure 2 Shown in station 22. Station 22 is a rotating disk-shaped station that rotates about its central axis. There are three rotatable disc-shaped sub-stations on the station 22, which are respectively the first sub-station 221, the second sub-station 222 and the third sub-station 223, and each sub-station surrounds its respective The central axis rotates. Wherein, the test of the first sub-station 221 is a bending process, and the test time of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com