Balance method for reconfigurable assembly line customized on large scale

An assembly line, high-volume technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low computational efficiency, difficulty in optimal solution of requirements, local search and poor convergence of algorithms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

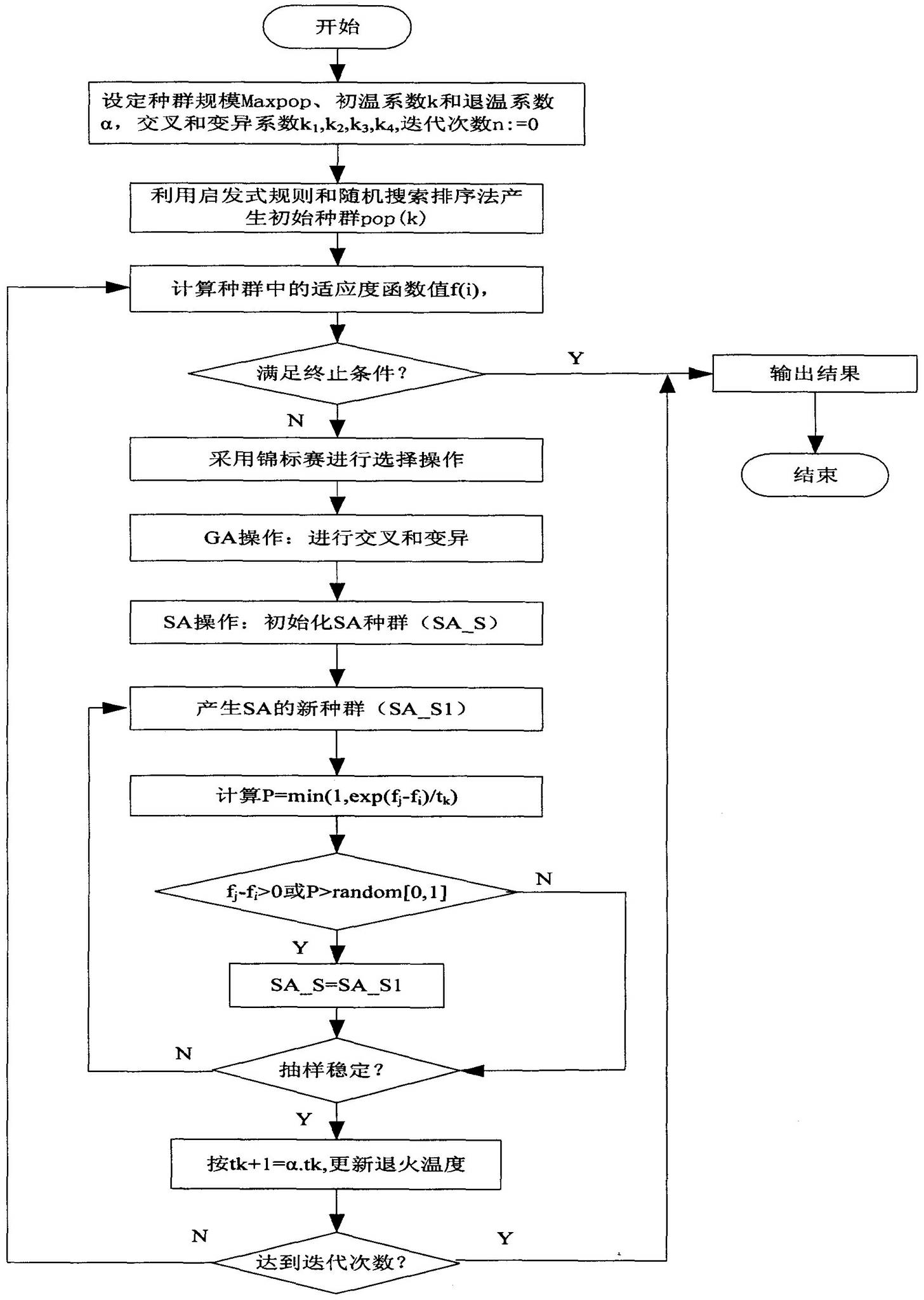

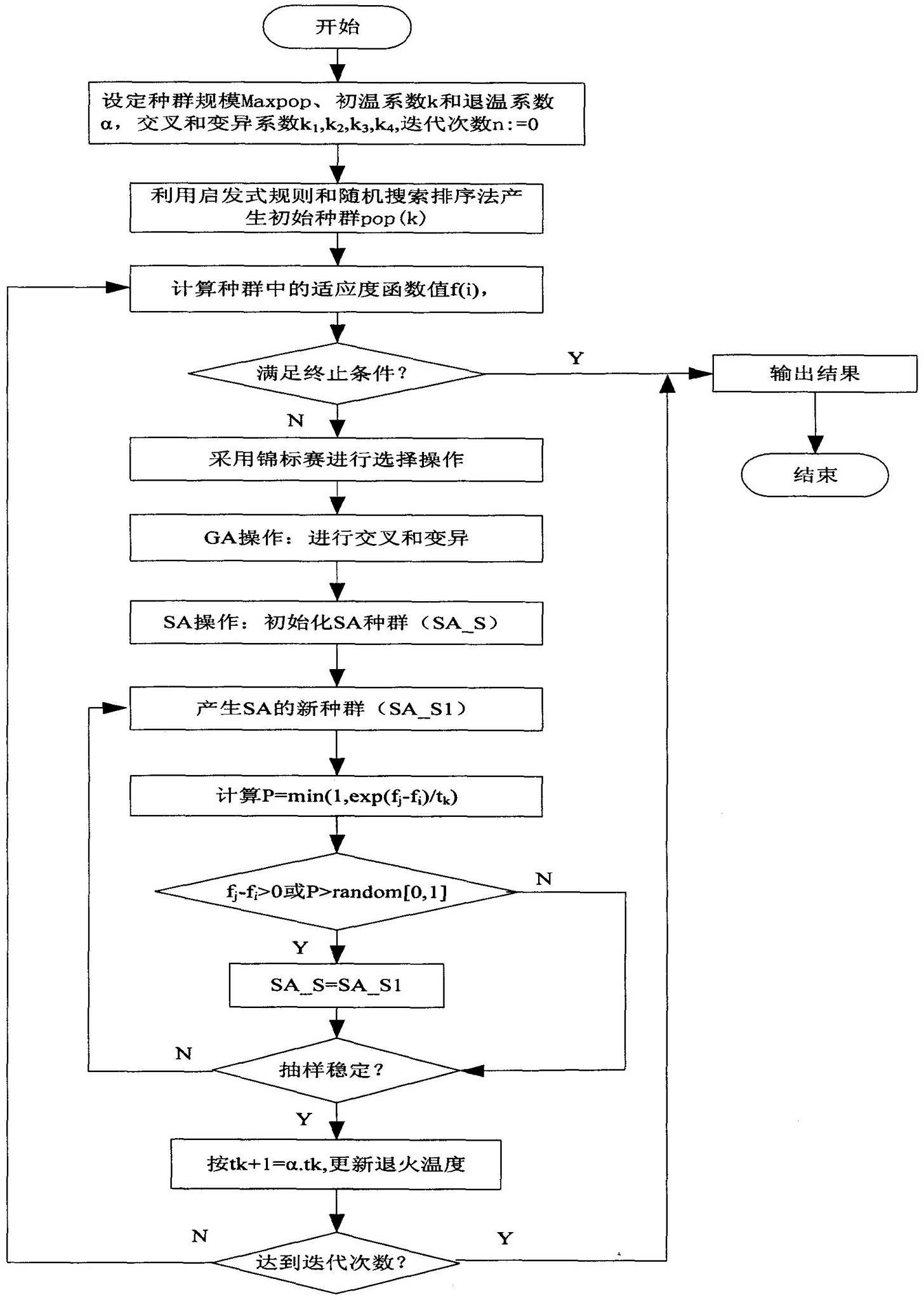

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

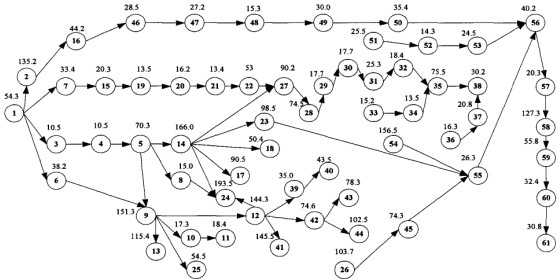

[0051] Taking a special vehicle assembly line of a special vehicle manufacturing enterprise as an example, the assembly line mainly completes the general assembly of a special vehicle chassis. Rear axle assembly, engine assembly, fuel tank, auxiliary assemblies, wheel assembly, cab, rotating shaft assembly, seat installation, etc. The current order requires the assembly of three products. The basic functional modules of these three products are the same, but they have different requirements in some aspects. Therefore, it can be regarded as mass customization and realized through reconfigurable assembly lines.

[0052] The joint assembly priority diagram of the three products, as attached figure 2 shown. The production cycle of the order is 3 days, calculated as 8 hours per day, the order quantity of the three products is A=5 pieces, B=10 pieces, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com