Prefabricated concrete column and steel beam joint

A concrete column, prefabricated assembly technology, applied in the direction of architecture, building structure, etc., can solve the problems of large volume, difficult assembly, etc., achieve the effects of strong ductility and deformation recovery ability, reduce the connection of steel joints, and simplify the structure of the joint area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

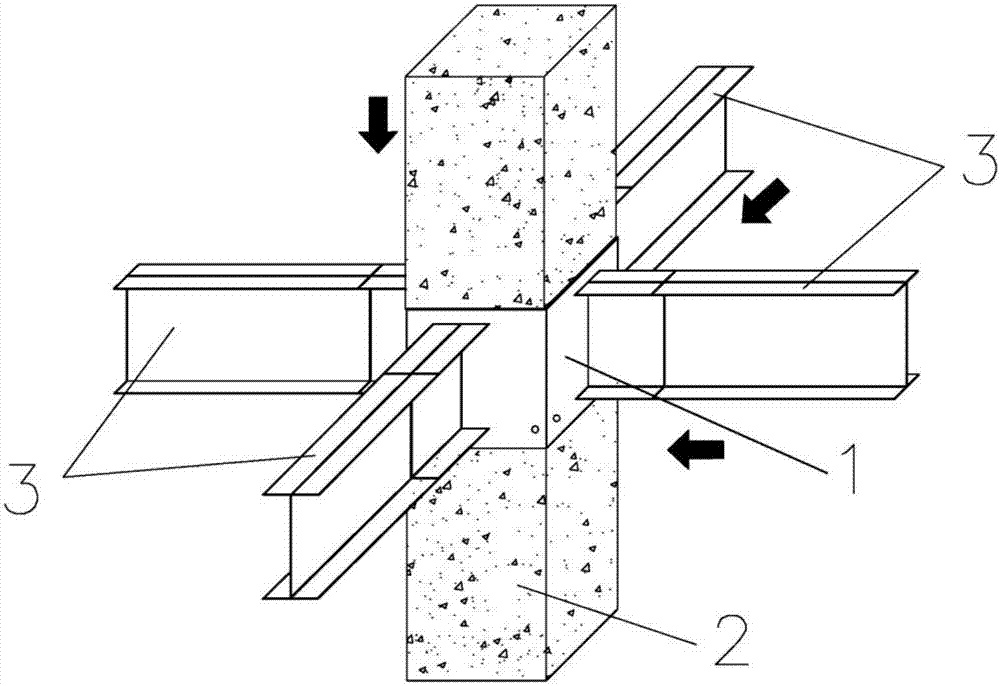

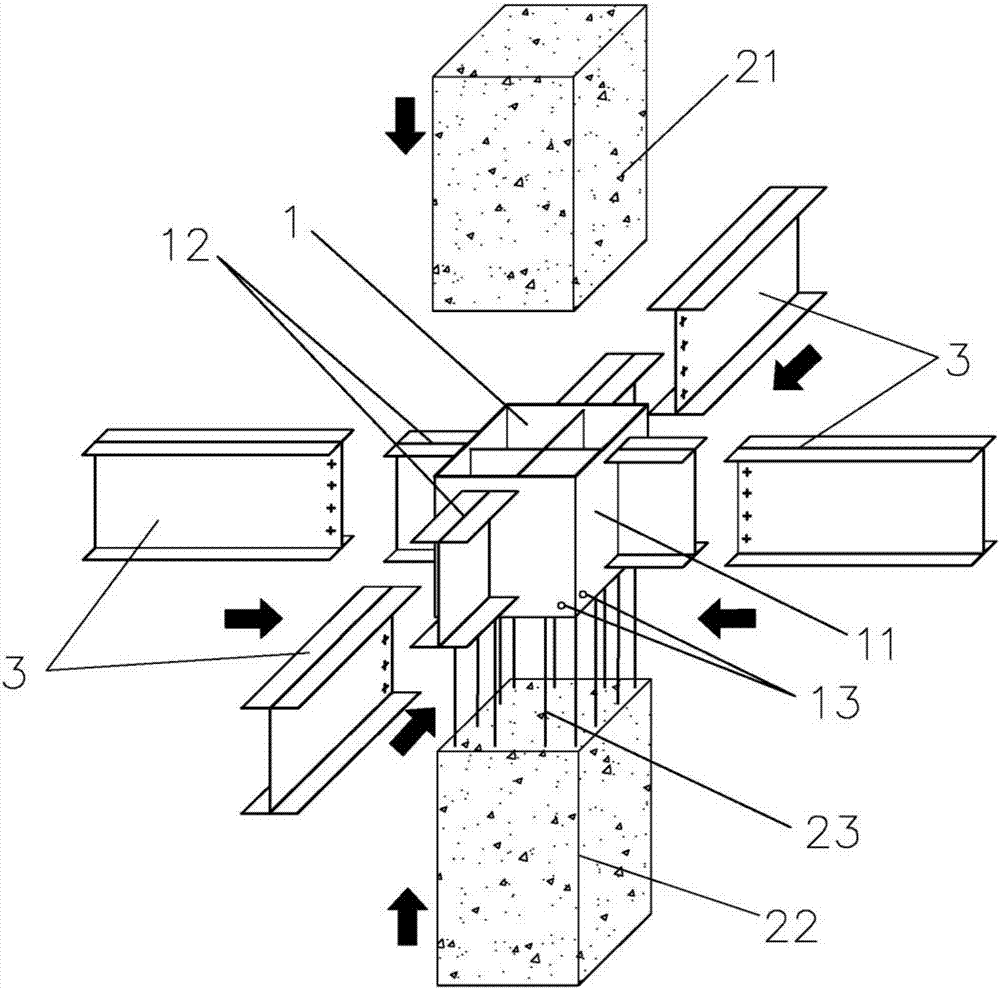

[0032] Such as figure 1 and figure 2 As shown, a prefabricated concrete column-steel beam node includes a prefabricated node unit 1, a prefabricated concrete column 2 and a prefabricated steel beam 3, the prefabricated concrete column 2 includes an upper column 21 and a lower column 22, and the prefabricated node The unit 1 includes a box body 11 and a short steel beam 12. The short steel beam 12 includes a cross end inside the box body that is connected as a cross and an extended end that penetrates and extends out of the box body. The extended end is connected to the box body. The prefabricated steel beams 3 are connected, the lower part of the box body 11 is provided with a grouting hole 13, the prefabricated node unit 1 is connected between the upper column 21 and the lower column 22, and the prefabricated node unit 1 is connected to the upper column 21, The lower columns 22 are connected by grouting.

[0033] In this embodiment: vertical longitudinal ribs 23 are reserv...

Embodiment 2

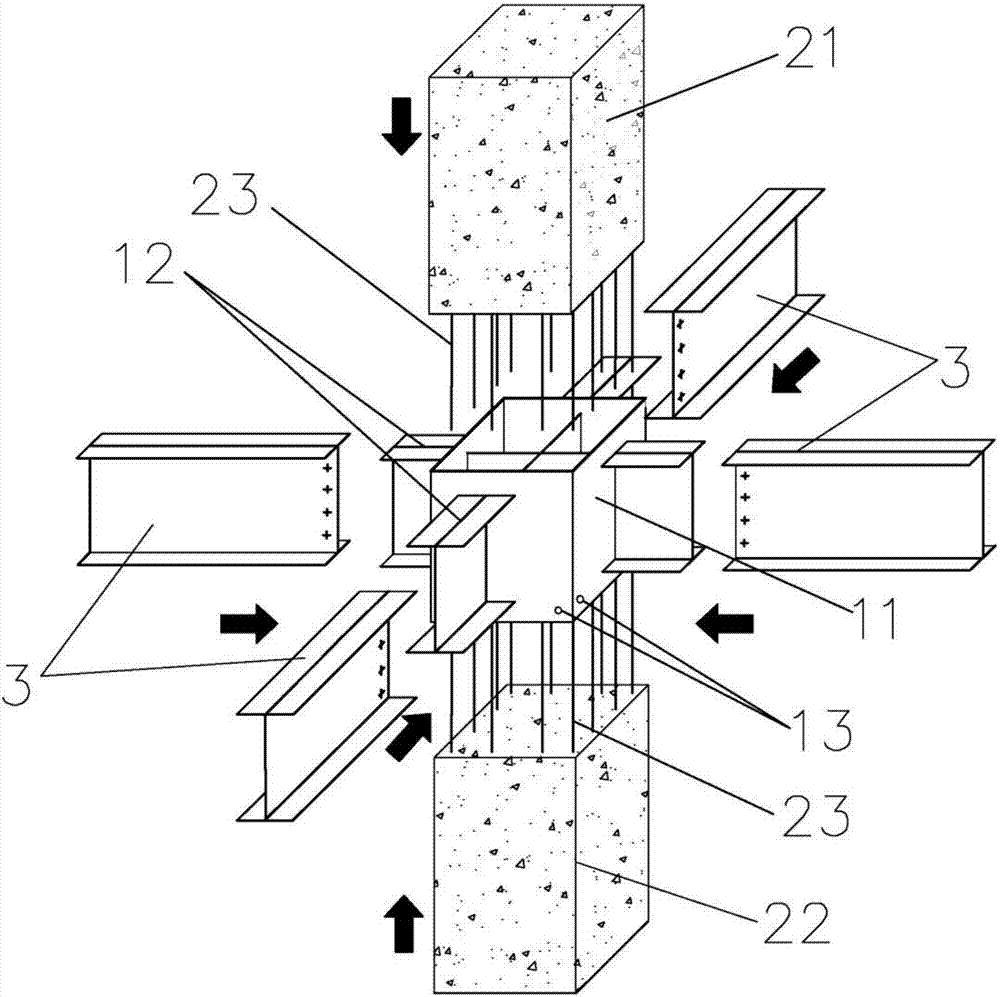

[0038] Such as image 3 As shown, the difference between Embodiment 2 and Embodiment 1 is that: the top of the lower column 22 and the bottom of the upper column 21 are reserved vertical longitudinal ribs 23, and they are overlapped in the prefabricated node unit 1, And connected into a whole by grouting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com