Assembling a monolithic laminated frame structure

A frame structure, integral technology, applied in the direction of building structure, construction, etc., can solve the problems of large wet work volume and non-standard connection methods, and achieve the effect of ensuring continuity, standardizing connection nodes, and improving operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

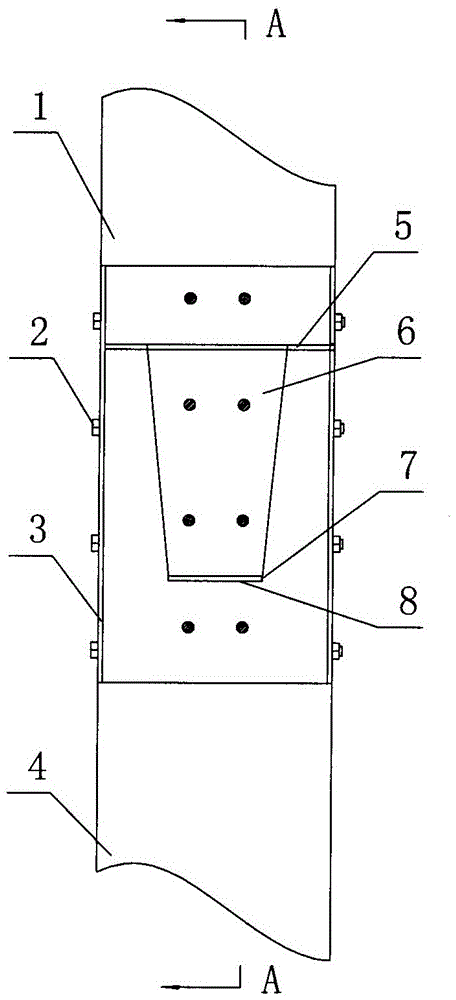

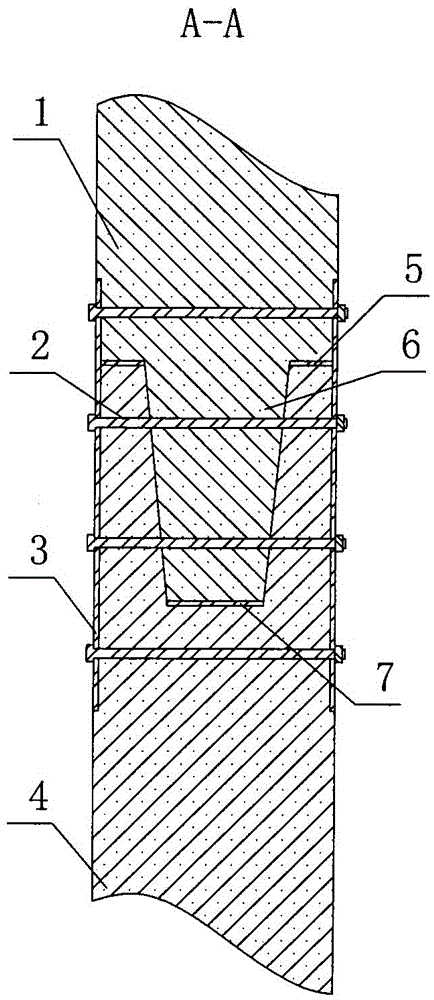

[0032] Embodiment 1: The first prefabricated component 1 and the second prefabricated component 4 are produced and processed by the prefabricated factory. The reinforcement arrangement of the two is the same as that of the existing prefabricated components, and the assembly joint method adopts the usual rigid node processing technology. Before inserting the boss 6 at the superposition into the groove 8, insert the integral connector 3 first, and then use the connecting bolt 2 to pass through the through holes of the first and second prefabricated components 1, 4 and the integral connector 3 , and securely connected by lock nuts. The prefabricated component in this embodiment does not reserve a cavity.

Embodiment approach 2

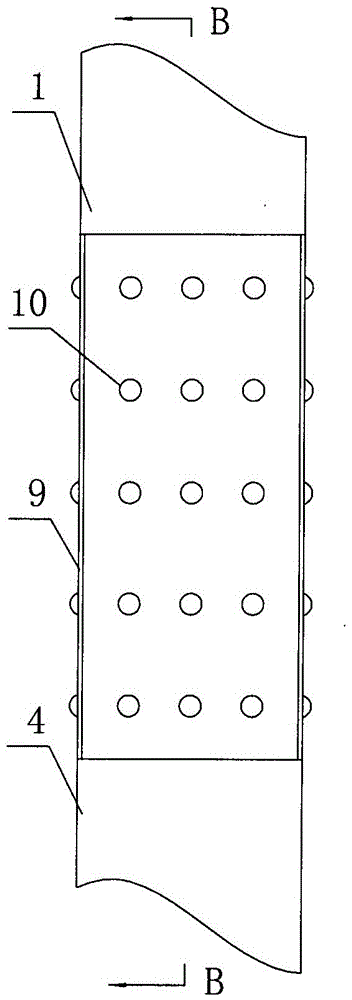

[0033] Embodiment 2: The first prefabricated component 1 and the second prefabricated component 4 are provided with a reserved pipeline cavity 11 for pre-embedding various pipelines in the building structure, and the first and second prefabricated components 1 and 4 are produced and processed by the prefabricated factory. And the reinforcement layout is the same as that of the existing prefabricated components. Its assembly joint method adopts the usual rigid node processing technology. Insert the boss 6 at the superposition into the groove 8, and then surround and fix the four symmetrically structured steel plates of the split connector 9 on the four joint surfaces of the prefabricated components one by one, so that the first and second The pre-embedded locking parts 10 on the two prefabricated components 1 and 4 pass through the through holes on the split connector 9 respectively, and the end of the pre-embedded locking part 10 protruding from the through hole is thickened w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com