Toroidal continuously variable transmiision

A continuously variable transmission, transmission system technology, applied in transmission, friction transmission, transmission control, etc., can solve the difficulty of increasing the size of the transmission mechanism along the axial direction, the installation of the size of the axis direction, and the layout design of the engine and transmission mechanism, etc. problem, to avoid interference and shorten the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

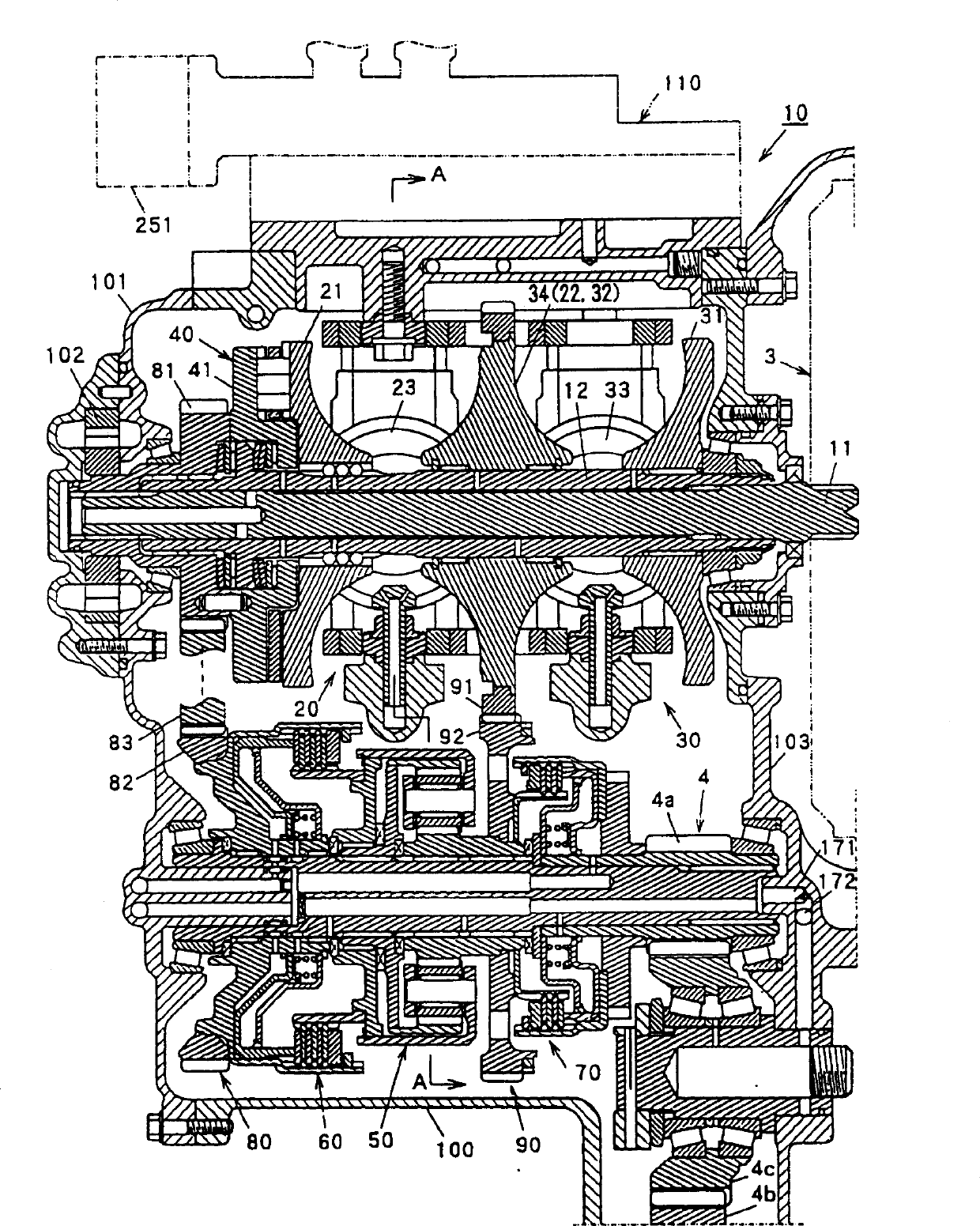

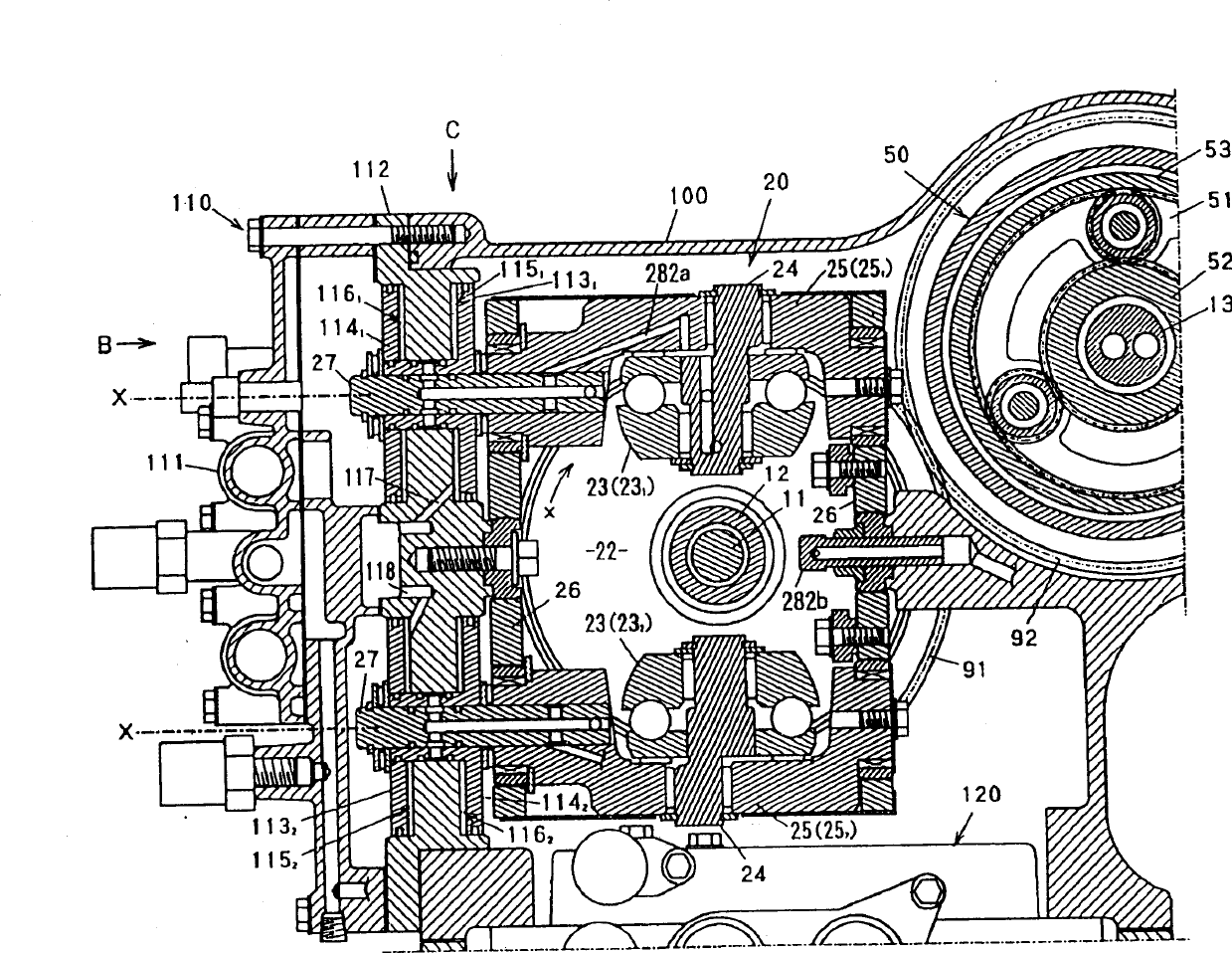

[0076] The following will describe the mechanical structure of the continuously variable transmission of the present invention, the structure of the hydraulic control circuit and the specific operation of the transmission control.

[0077] Mechanical structure

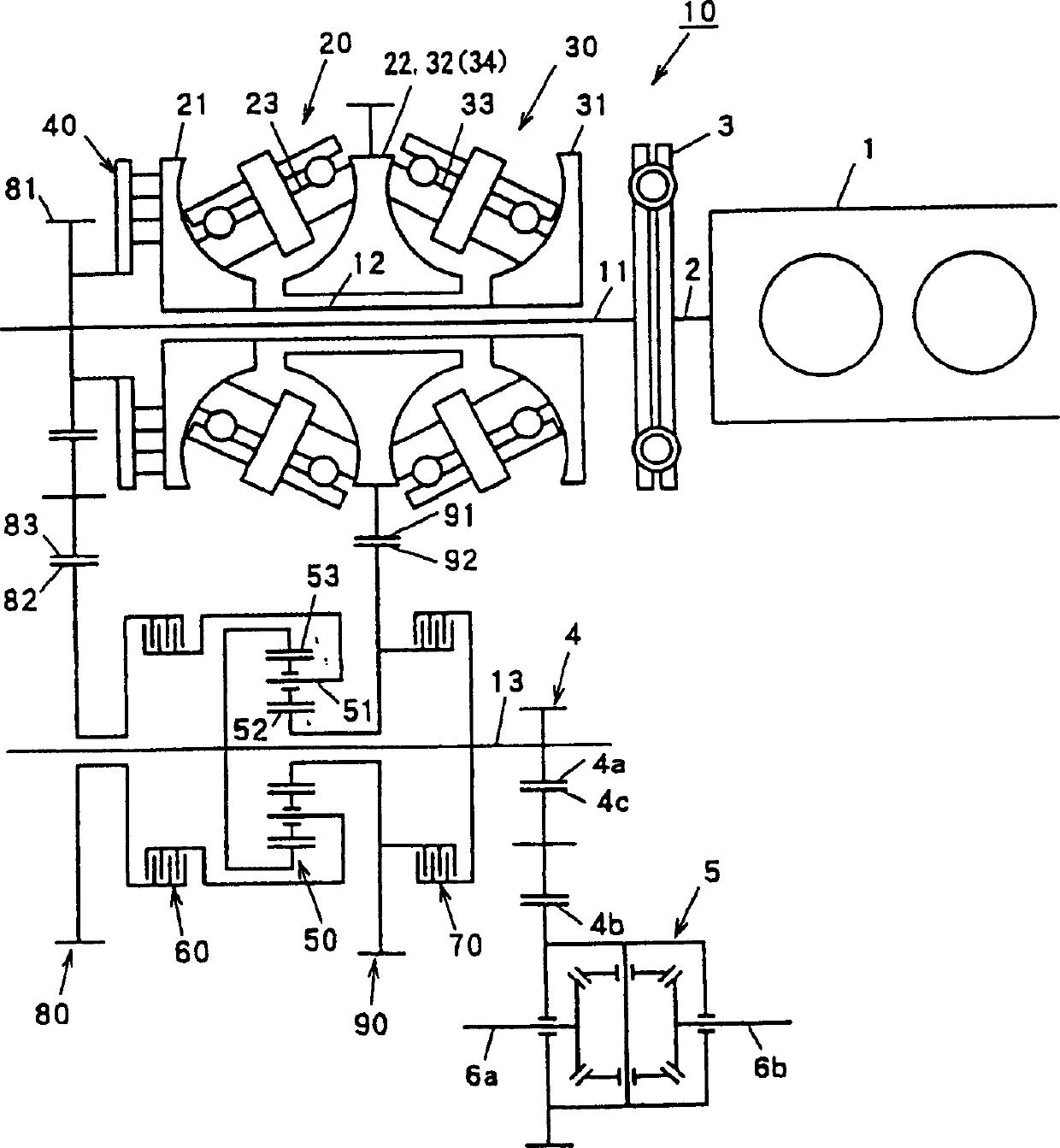

[0078] 1 is a schematic view showing the mechanical structure of the toroidal continuously variable transmission system of the present invention, wherein the transmission system 10 includes an input shaft (first shaft) 11 connected to the output shaft 2 of the engine 1 through a torsional damper 3, A main shaft (third shaft) 12 having a through hole in which the shaft 11 is inserted, an auxiliary shaft (second shaft) 13 arranged in parallel with the shafts 11 and 12, wherein the shafts 11 to 13 are all arranged at extending laterally of the vehicle.

[0079] In addition, in the transmission system 10, the annular first continuously variable transmission mechanism 20, the annular second continuously variable transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com