Coating plant with a charging lock and device therefor

a technology of charging lock and coating plant, which is applied in the direction of ion implantation coating, coating, lifting valve, etc., can solve the problems affecting the cycle time of coating in the coating plant, and achieve the effect of quick closure and opening of the lock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

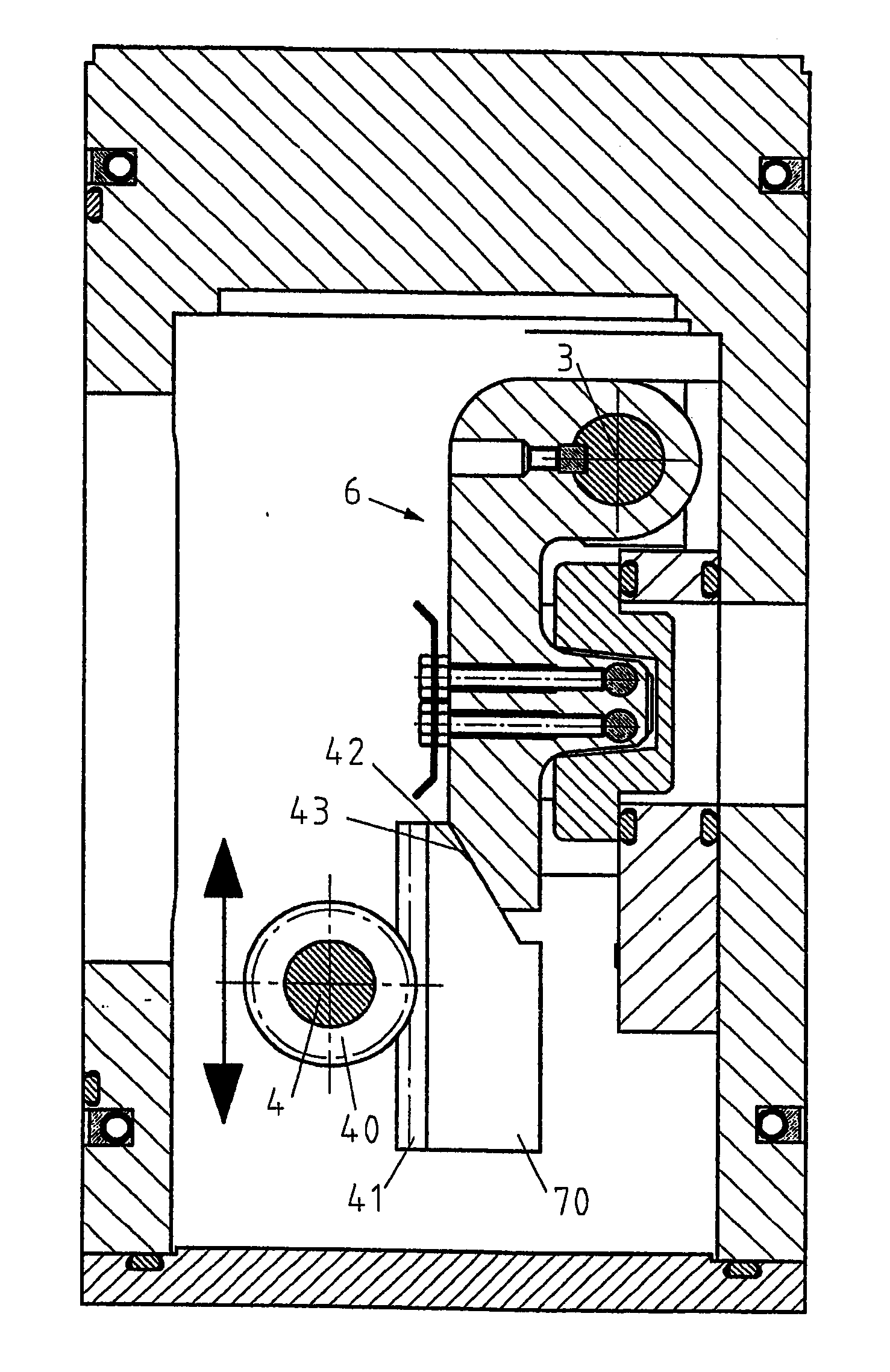

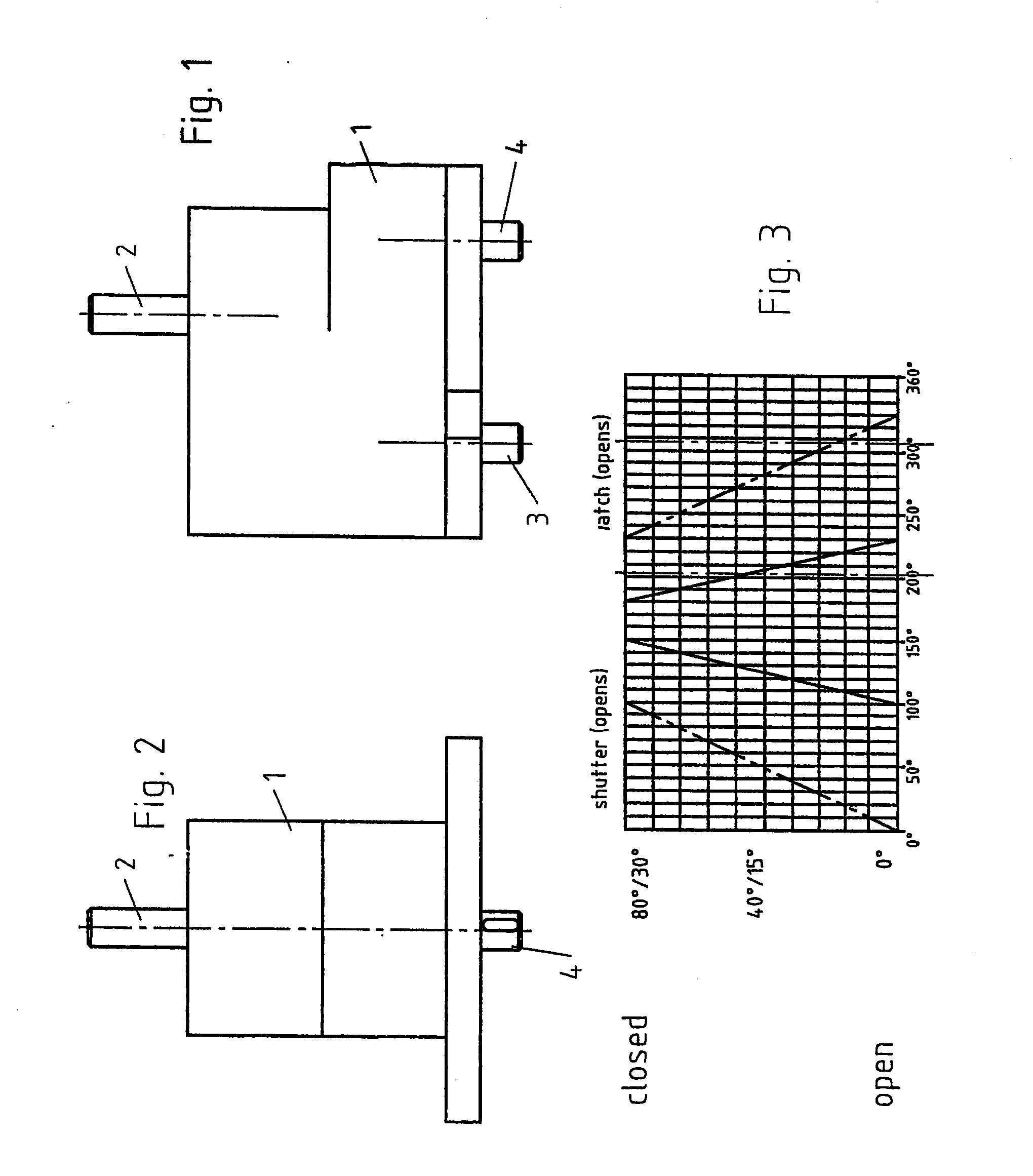

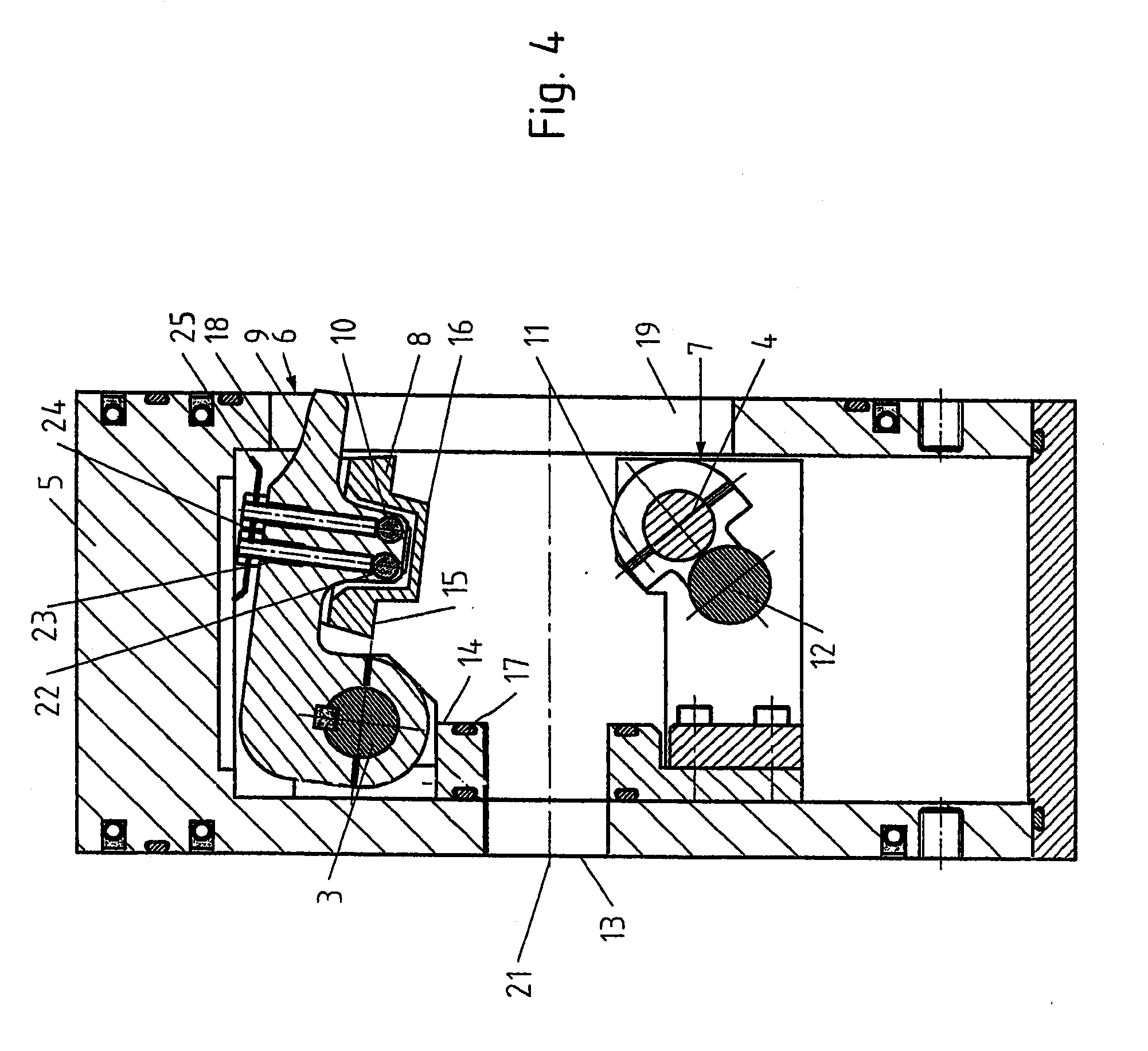

[0029]FIG. 1 shows a lateral view of a transmission gear, especially a reciprocating or swinging cam drive, with one driving shaft 2 and two driven shafts 3 and 4, the latter performing an interdependent movement. While the driving shaft 2 is effectively connected to a drive, an electric motor for example, the driven shafts are connected for operating purposes to the shutter 6 and the latch 7 of the lock (see FIG. 4). Accordingly, both the driving shaft 2 and the driven shafts 3 and 4 comprise coupling means to connect them to the drive, the shutter 6 and the latch 7, as can best be seen, for example, in FIG. 2 for the shaft 4.

[0030] The transmission gear couples the driven shafts 3 and 4 to each other in such a manner that both the shafts 3 and 4 will be automatically rotated or swiveled when the driving shaft 2 is driven by means of a drive or motor. In particular, the coupled movement of the shafts 3 and 4 is phase-staggered, as can be seen from the motion diagram of FIG. 3. Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com