Poor-quality surrounding rock concrete wet-spraying method

A technology of surrounding rock and inferior quality, which is applied in the field of shotcrete surrounding rock of roadway and wet shotcrete of inferior surrounding rock, can solve the problems of poor supporting effect of dry shotcrete, and achieve good integrity and cohesion, stable performance, spraying fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The wet shotcrete method for inferior surrounding rock comprises the following steps:

[0020] The gravel and sand are sieved with a special standard sieve for gravel and a special standard sieve for sand respectively, and then the cement, gravel and sand are mixed by a batching machine in a ratio of 1:1.5:3 by mass;

[0021] The prepared mixture is transported to the mixer by an explosion-proof transport vehicle;

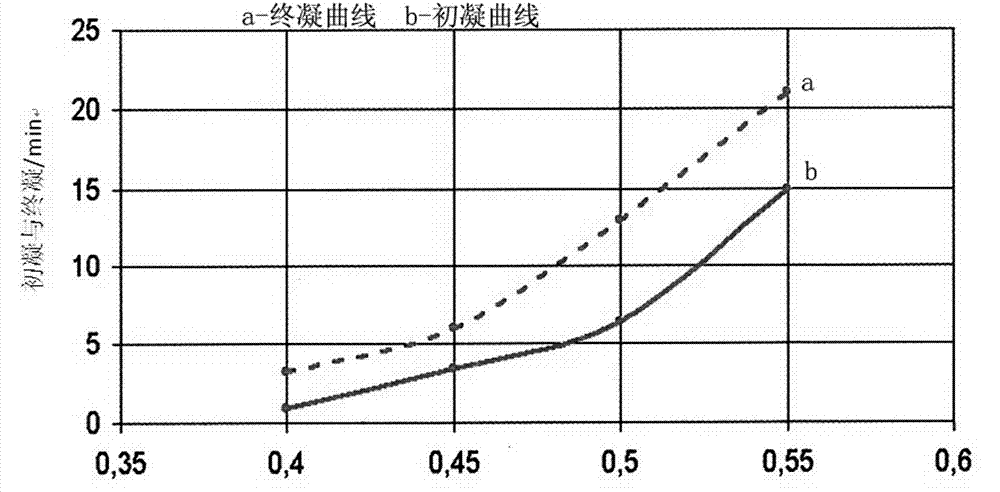

[0022] Add water to the mixer at a mass ratio of 0.4:1 to cement, and stir to obtain concrete. Add water reducer and hydration agent to the concrete. The amount of water reducer added is 0.8% of the cement mass, and hydration agent The additive amount is 0.3% of the cement mass, the water reducer is RHEOPLUS 26 water reducer, and the hydration agent is Delvo hydration agent;

[0023] Use explosion-proof tanker to transport the concrete to the wet spraying machine installed in the underground;

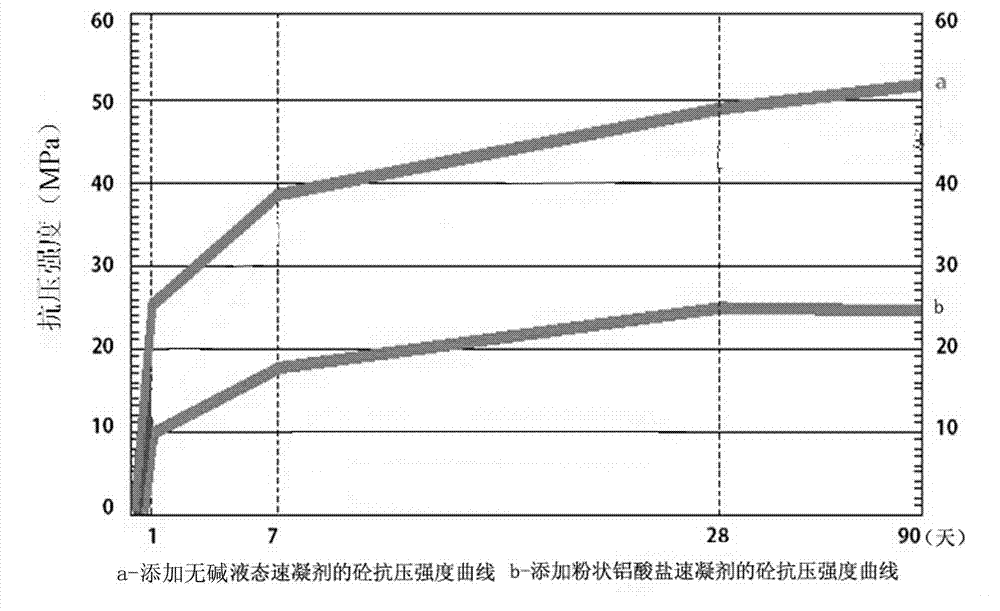

[0024] At the nozzle of the wet spraying machine, the peristal...

Embodiment 2

[0026] The wet shotcrete method for inferior surrounding rock comprises the following steps:

[0027] The gravel and sand are sieved with a special standard sieve for gravel and a special standard sieve for sand respectively, and then the cement, gravel and sand are mixed by a batching machine in a mass ratio of 1:2:1.5;

[0028] The prepared mixture is transported to the mixer by an explosion-proof transport vehicle;

[0029] Add water to the mixer at a mass ratio of 0.5:1 to cement, and stir to obtain concrete. Add water reducer and hydration agent to the concrete. The amount of water reducer added is 1% of the cement mass, and hydration agent The additive amount is 1% of the cement mass, the water reducer is RHEOPLUS 26 water reducer, and the hydration agent is Delvo hydration agent;

[0030] Use explosion-proof tanker to transport the concrete to the wet spraying machine installed in the underground;

[0031]At the nozzle of the wet spraying machine, a peristaltic pump i...

Embodiment 3

[0033] The wet shotcrete method for inferior surrounding rock comprises the following steps:

[0034] The gravel and sand are sieved with a special standard sieve for gravel and a special standard sieve for sand respectively, and then the cement, gravel and sand are mixed by a batching machine in a ratio of 1:3:2 by mass;

[0035] The prepared mixture is transported to the mixer by an explosion-proof transport vehicle;

[0036] Add water to the mixer at a mass ratio of 0.43:1 to cement, and stir to obtain concrete. Add water reducer and hydration agent to the concrete. The amount of water reducer added is 0.85% of the cement mass, and hydration agent The additive amount is 1.5% of the cement mass, the water reducer is RHEOPLUS 26 water reducer, and the hydration agent is Delvo hydration agent;

[0037] Use explosion-proof tanker to transport the concrete to the wet spraying machine installed in the underground;

[0038] At the nozzle of the wet spraying machine, the peristal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com