Push-boat-type semi-continuous boron nitride nanotube preparation furnace and application method thereof

A boron nitride nanotube, semi-continuous technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problem that the synthesis of BNNTs is not too large, the effective utilization rate of reducing gas is not high, and the exhaust gas cannot be effectively treated. and other problems, to achieve the effect of continuous large-scale synthesis, rich and diverse product structure, avoiding repeated opening times and idle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

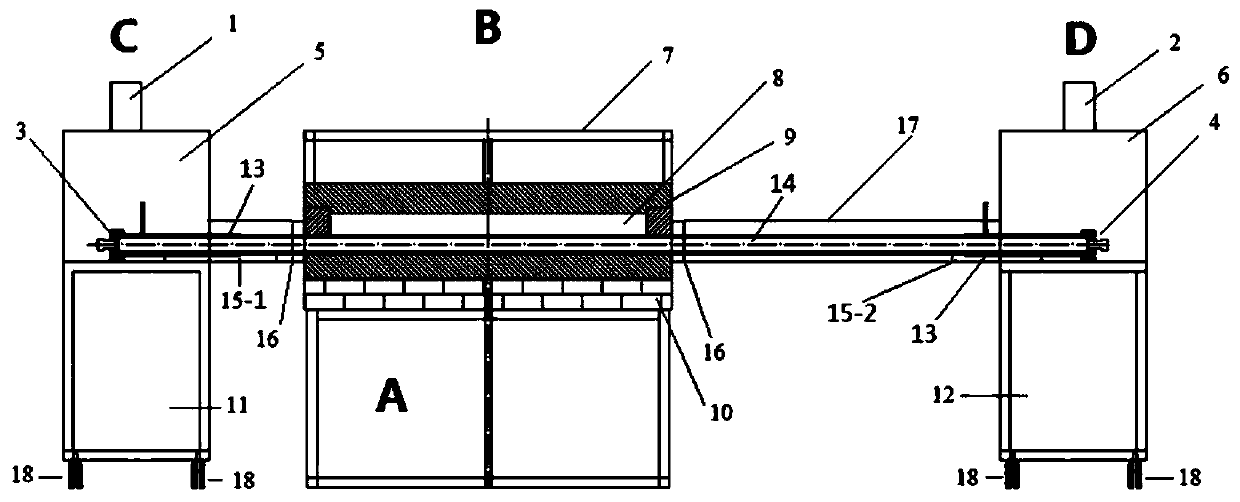

[0030] Utilize the present invention to provide such as figure 1 The method for synthesizing boron nitride nanotubes with smooth inner walls by the shown equipment is as follows:

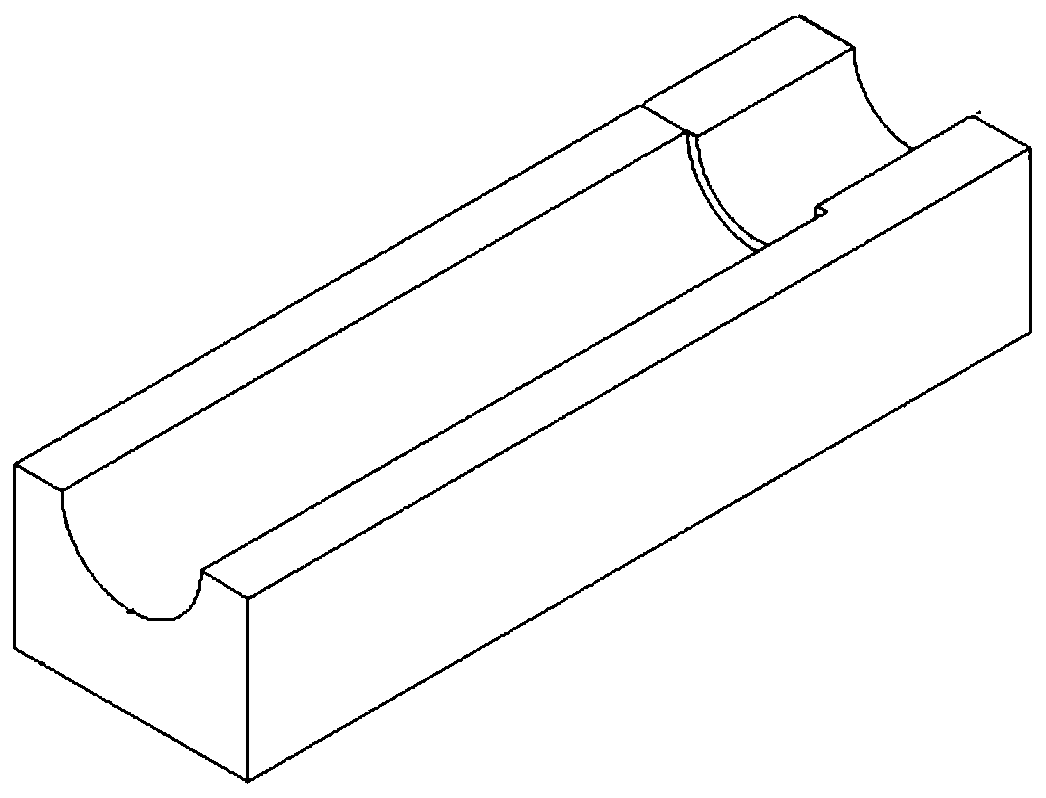

[0031] Check ahead of time to make sure the overall equipment is in good working order. Start the electric heating device A, set the temperature to heat the furnace 8, and the heating rate is 4-8°C / min. Close the furnace door 3 at the furnace head and the furnace tail door 4, open the exhaust pipe 1 at the furnace head and the inlet pipe 2 at the furnace tail, vacuumize and exhaust the furnace 8, and then continuously transport Ammonia gas, the flow rate of ammonia gas is controlled at 0.4-1.0L / min, and the pipeline gas cycler is kept in the working state. Then put the ceramic boat covered with superfine boron carbide powder into the hearth 8 of the furnace body B to carry out heat preservation reaction, the reaction temperature is 900-1350°C, and the heat preservation time is 10-15h. After the r...

Embodiment 2

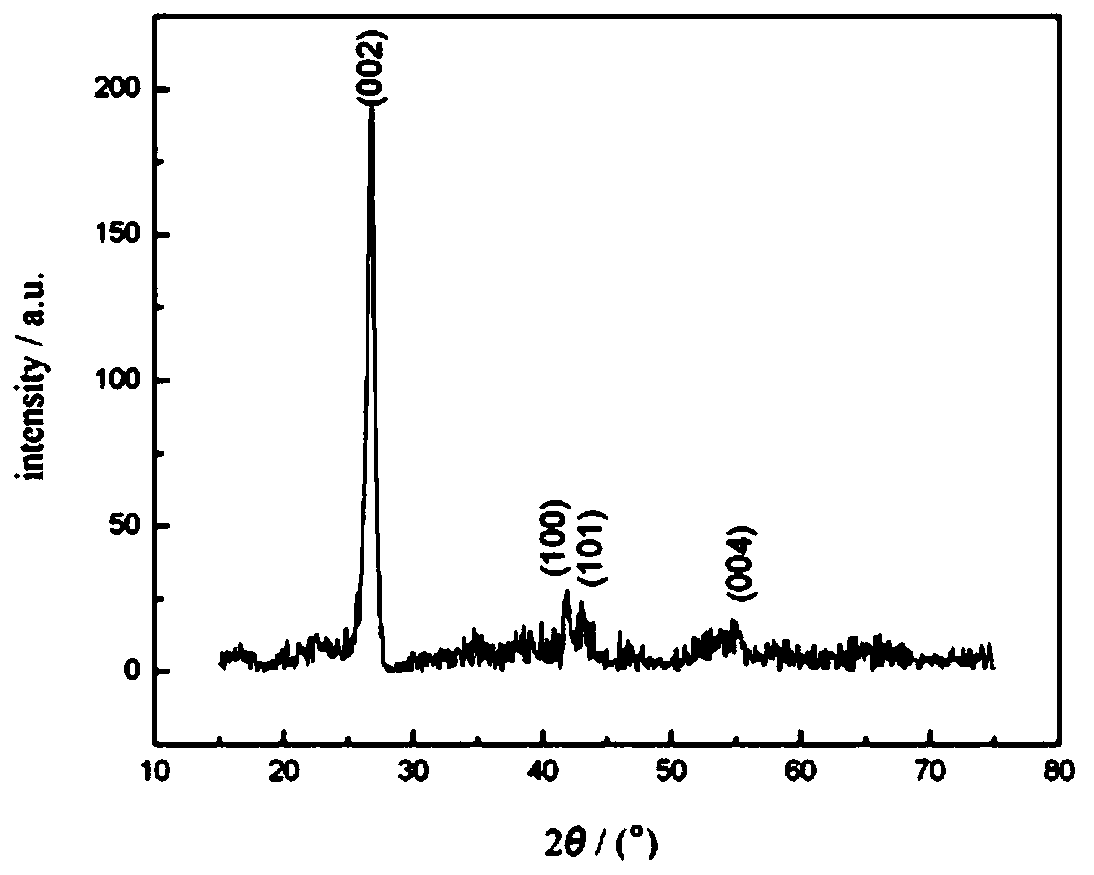

[0033] Utilize the present invention to provide such as figure 1 The method for synthesizing bamboo-shaped boron nitride nanotubes with the shown equipment is basically similar to that of Example 1, except that the heating rate is 6-10°C / min, the flow rate of ammonia gas is 0.6-1.2L / min, and the holding temperature is 900°C. -1400℃, holding time 3-6h. The bamboo-shaped BNNTs that embodiment 2 makes has carried out XRD, Raman spectrum, TEM analysis, and the result is as follows Figure 3-5 shown.

[0034] from image 3 It can be seen in the characteristic XRD diffraction spectrum of the BNNTs sample that the characteristic diffraction peaks are very clear, indicating that the sample has a good degree of crystallization. The d values of the characteristic diffraction peaks are at 0.33492, 0.21843, 0.20786 and 0.16693 nm, corresponding to (002), (100), (101) and (004) crystal planes of hexagonal boron nitride, respectively. From this, the unit cell constants of the product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com