Intelligent inspection and replenishment method and system for warehouse

A technology of intelligent inspection and replenishment method, applied in the field of warehouse replenishment, can solve the problems of waste of human resources, inaccurate acquisition quantity, system jam, etc., to reduce the occupation of data processing or control resources, and to reduce the shooting angle. Restriction and avoid the effect of excessive computation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

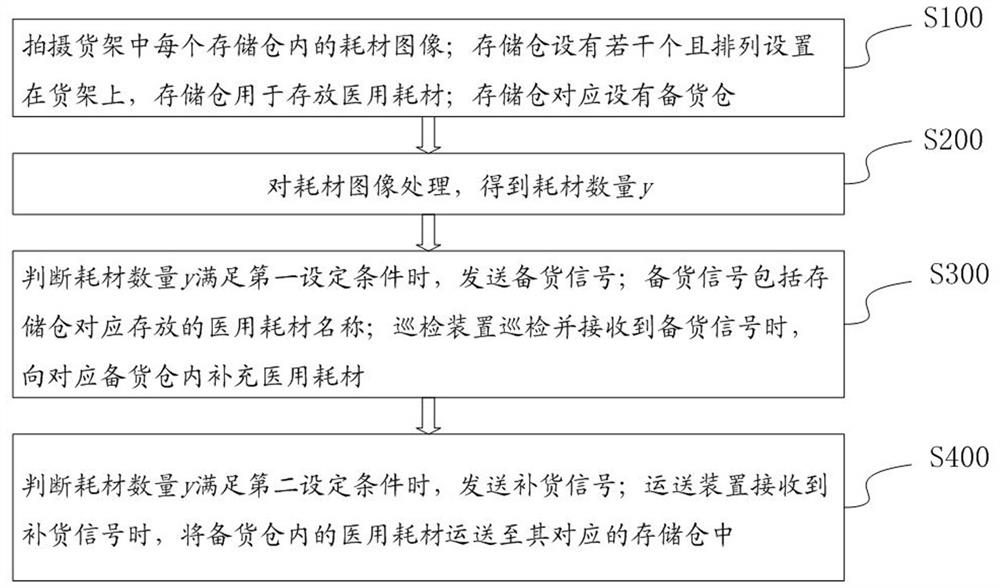

[0058] Please refer to figure 1 A warehouse intelligent inspection and replenishment method provided for this application includes the following steps:

[0059] S100: Take images of consumables in each storage bin in the shelf; there are several storage bins arranged on the shelf, and the storage bins are used to store medical consumables; the storage bins are correspondingly equipped with stocking bins ;

[0060] Specifically, the images of the consumables are captured by the processing device;

[0061] Specifically, the storage warehouse is used to store medical consumables for use by various medical departments; the stocking warehouse is used to temporarily store medical consumables, so as to replenish the storage warehouse in time.

[0062] Specifically, the storage bin and the stocking bin have a maximum storage capacity, for example, both the storage bin and the stocking bin can store a maximum of 100 A consumables.

[0063] S200: Process the image of the consumable t...

Embodiment 2

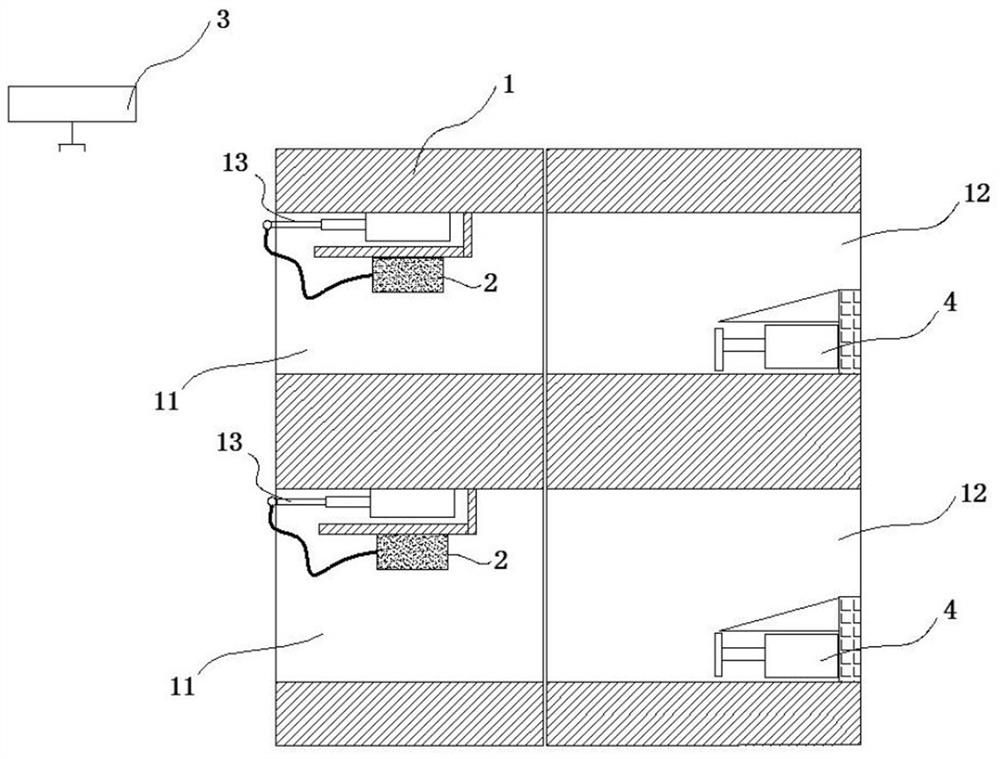

[0091] This embodiment provides a warehouse intelligent patrol replenishment system, such as figure 2 shown, including:

[0092] A shelf 1, on which a number of storage bins 11 are arranged; the storage bins 11 are used to store medical consumables; the storage bins 11 are correspondingly equipped with a stocking bin 12;

[0093] A processing device 2, said processing device 2 being installed in each of said storage bins 11, configured for:

[0094] taking images of consumables in the storage bin 11;

[0095] Processing the image of the consumable to obtain the quantity of the consumable;

[0096] When it is judged that the quantity of the consumables satisfies the first set condition, a stocking signal is sent;

[0097] When it is judged that the quantity of the consumables satisfies the second set condition, a replenishment signal is sent;

[0098] Patrol device 3, described patrol device 3 is configured for:

[0099] Inspecting and receiving the stocking signal; the s...

Embodiment 3

[0127] On the basis of Embodiment 2, in this embodiment, the storage bin 11 has a loading port and a stocking port; the stocking bin 12 is arranged near the stocking port; the delivery device 4 is installed on the stocking port 12 within, making the number of supplies y When the second set condition is satisfied, it is convenient to transport the pre-prepared medical consumables in the stocking warehouse 12 to the storage warehouse 11 through the delivery device 4 .

[0128] Specifically, the picking port and the stocking port are respectively arranged at both ends of the storage bin 11;

[0129] In a preferred embodiment, the stocking warehouse 12 is arranged on the stocking shelf, and the storage bin 11 and the stocking warehouse 12 are arranged along the horizontal direction; both ends of the stocking warehouse have an input port and an output port, and the stocking port communicating with the output port;

[0130] In a preferred embodiment, the conveying device 4 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com