Patents

Literature

101results about How to "Improve replenishment efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-speed photocuring 3D printing device and printing method

ActiveCN105014974AInhibition of attachmentTroubleshoot disruptive technical issuesAdditive manufacturing apparatusEngineeringGlass sheet

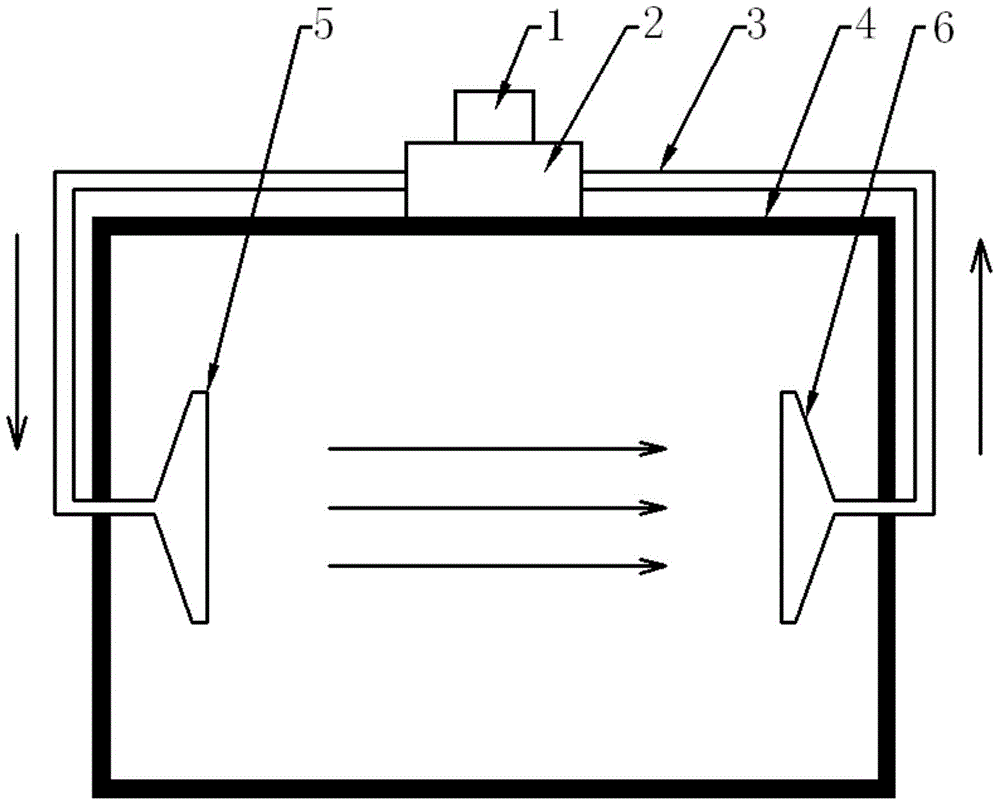

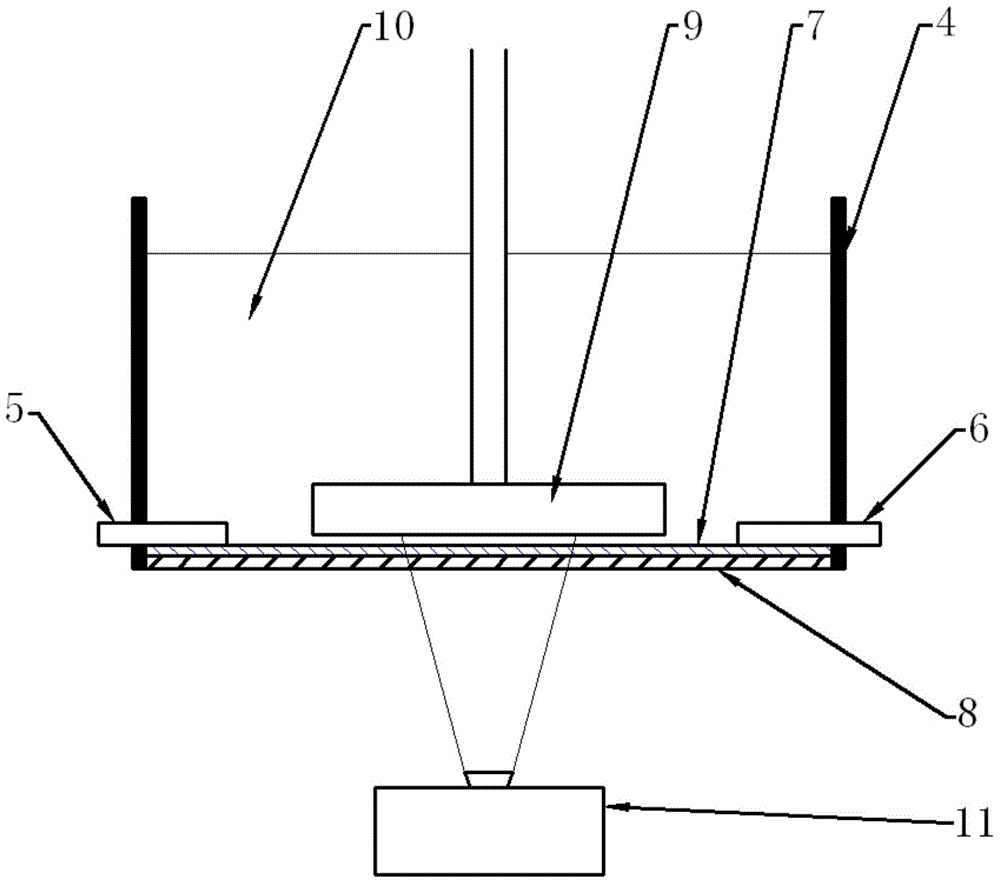

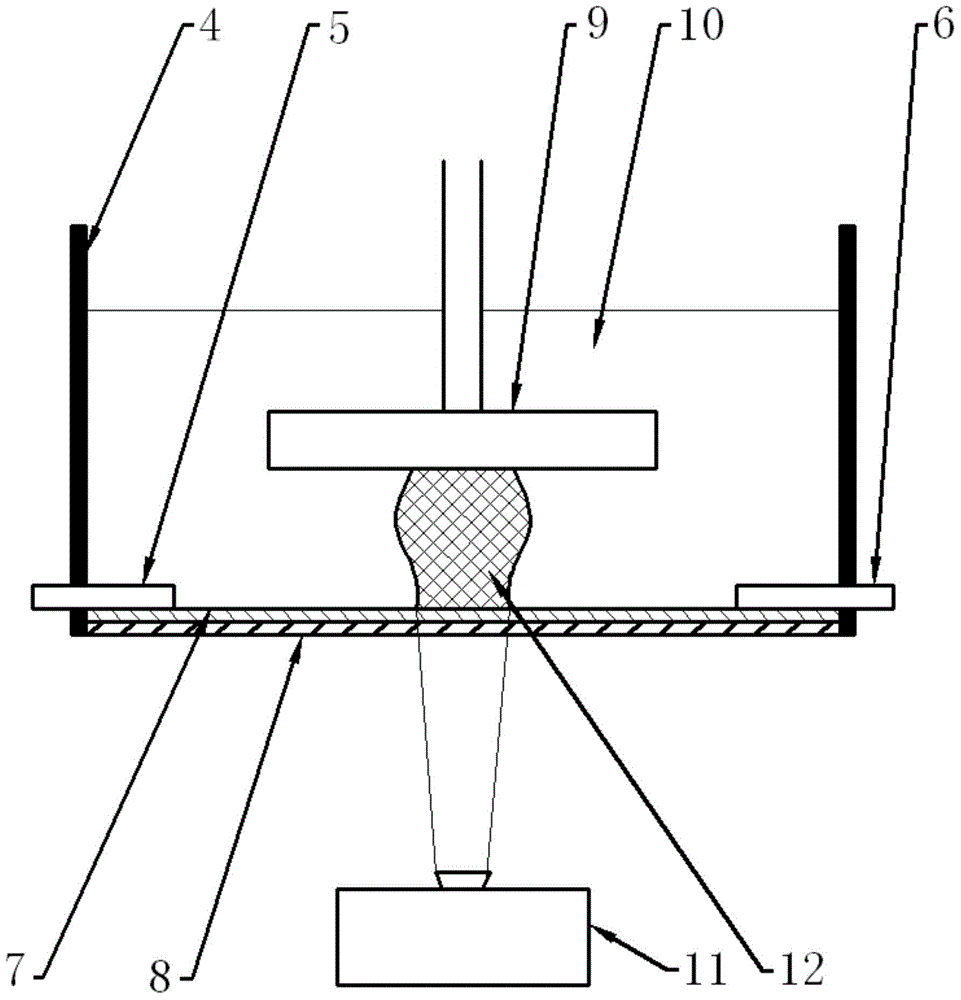

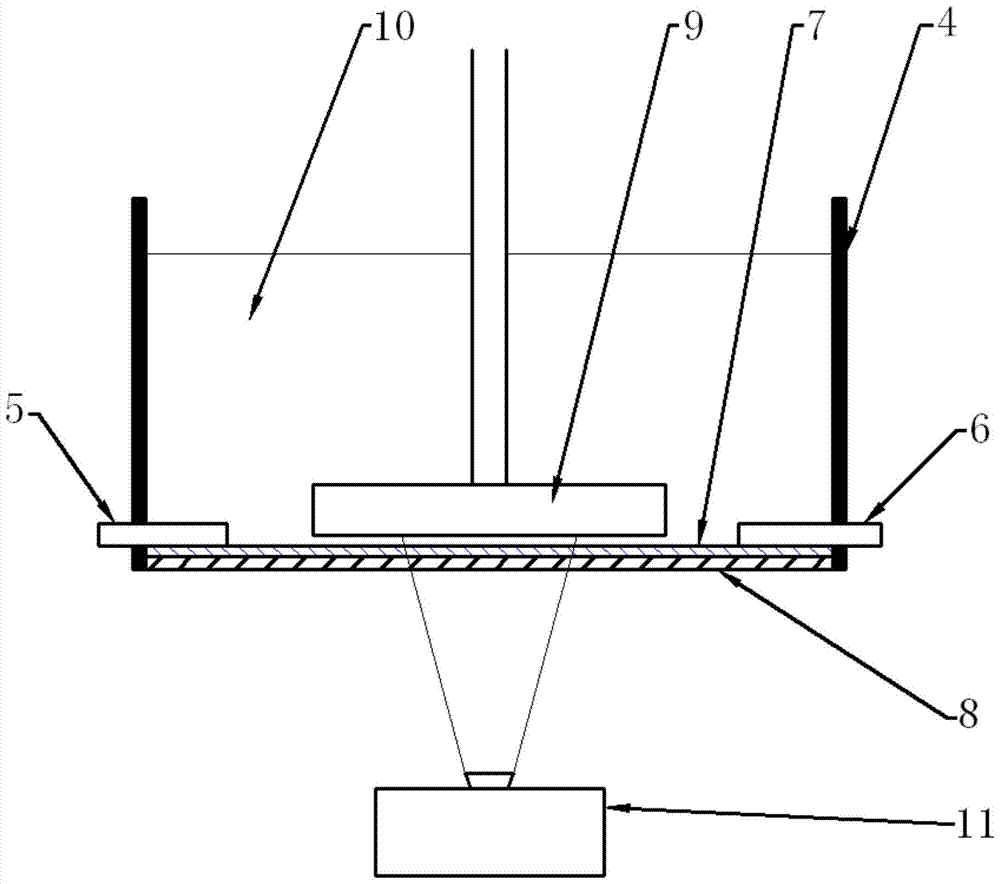

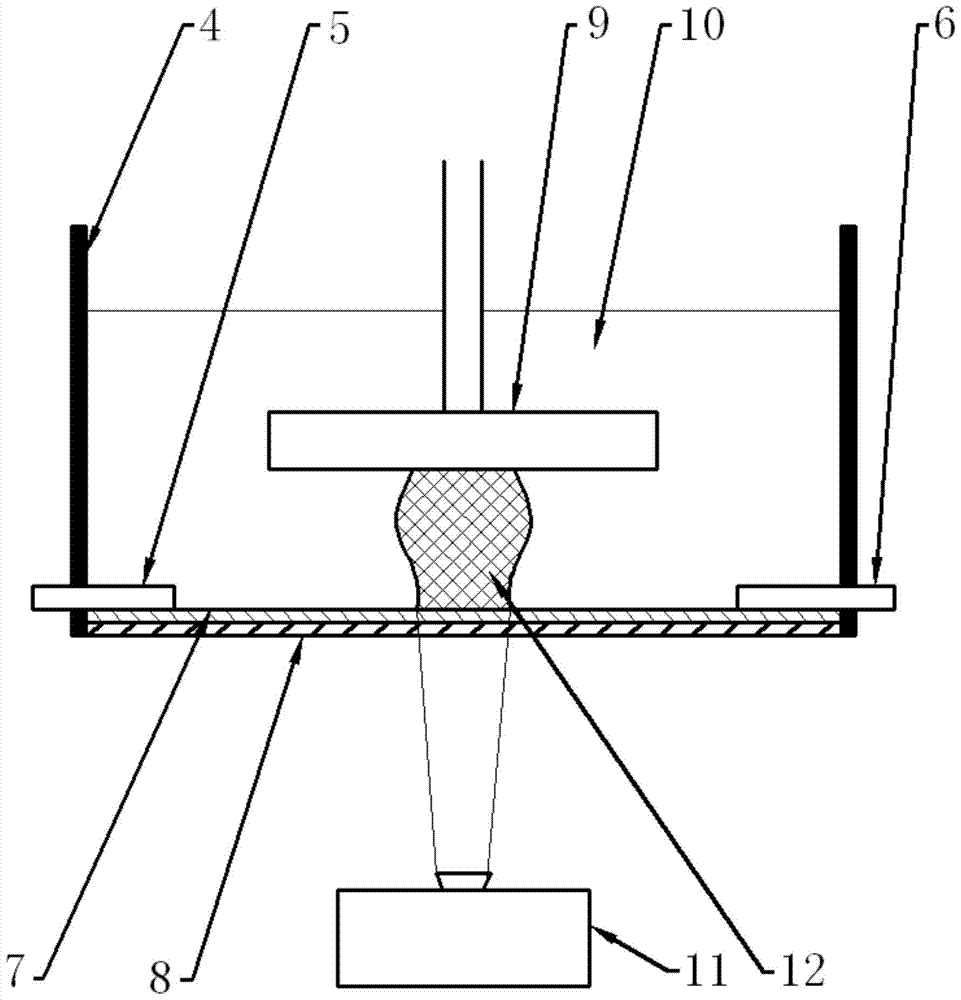

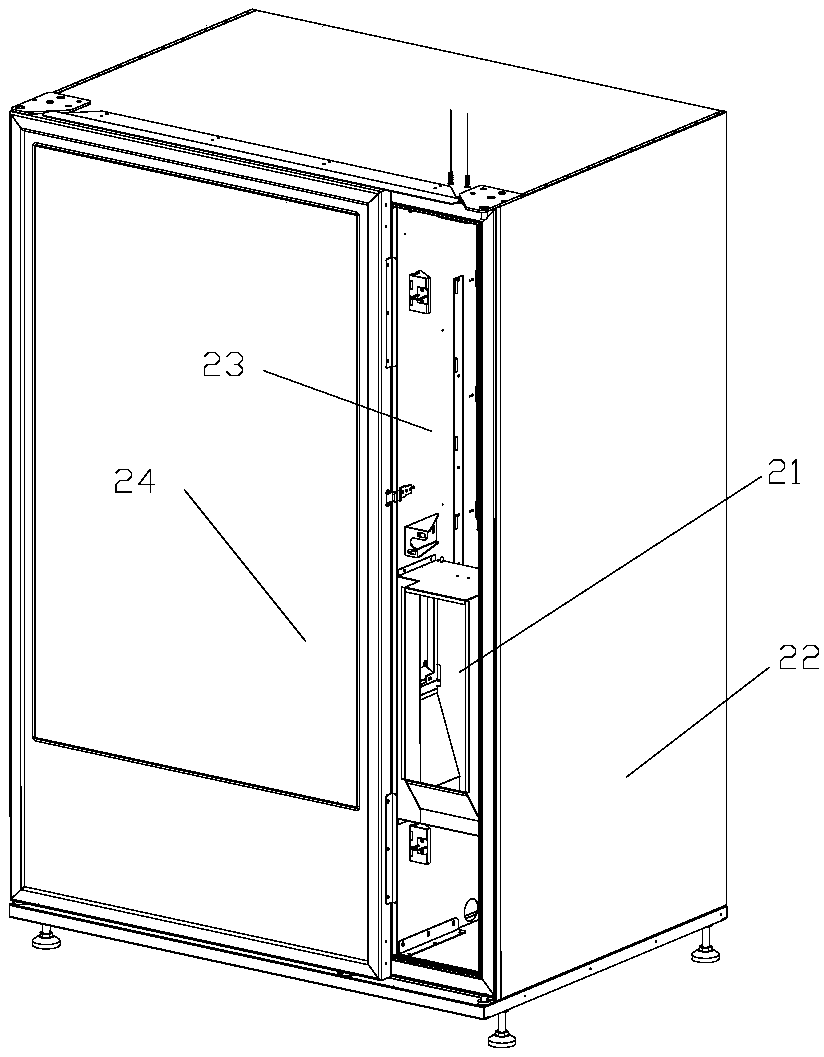

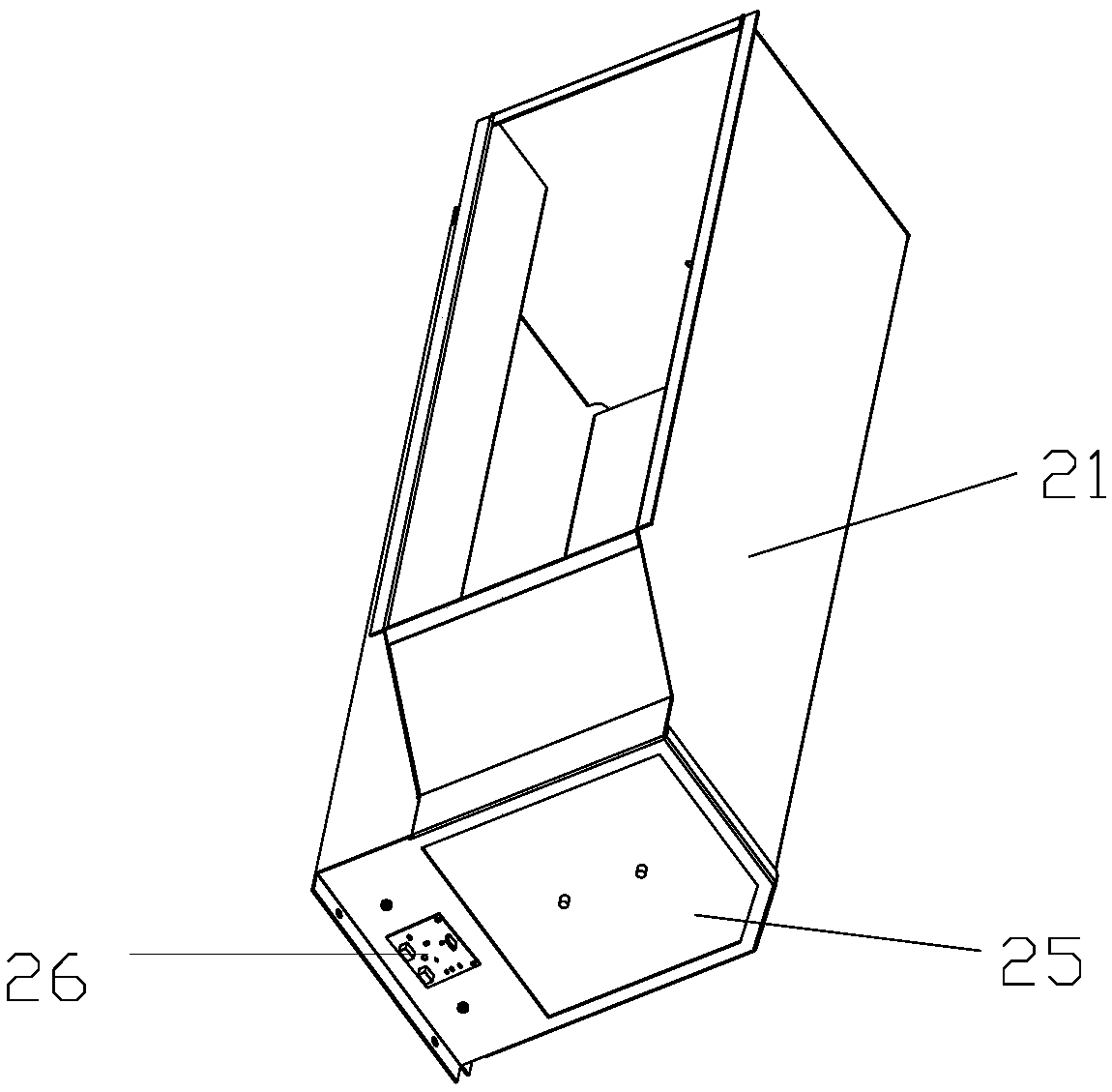

The invention discloses a high-speed photocuring 3D printing device and method. The device comprises a liquid pool filled with liquid photosensitive resin, a printing platform and a radiation source. A transparent plate corresponding to the printing platform and the radiation source is arranged at the bottom of the liquid pool. The side, facing the printing platform, of the transparent plate is covered with a transparent anti-bonding coating. The device further comprises a liquid outlet and a liquid inlet which are formed in the side wall of the liquid pool, a pipeline connecting the liquid outlet and the liquid inlet, and a drive unit which is arranged on the pipeline and used for driving the liquid photosensitive resin to flow among the liquid outlet, the liquid inlet and the pipeline. A curing window is coated with the transparent anti-bonding coating, and therefore the problem that the curing photosensitive resin is bonded and attached to a glass plate due to excessively fast laser radiation is avoided. Pipelines promoting flowing of the liquid photosensitive resin are arranged on the two sides of a printing area, the mobility of the photosensitive resin near the printing area is improved, supplementing of the photosensitive resin is accelerated, and rapid printing of the SLA is achieved.

Owner:苏州智能制造研究院有限公司

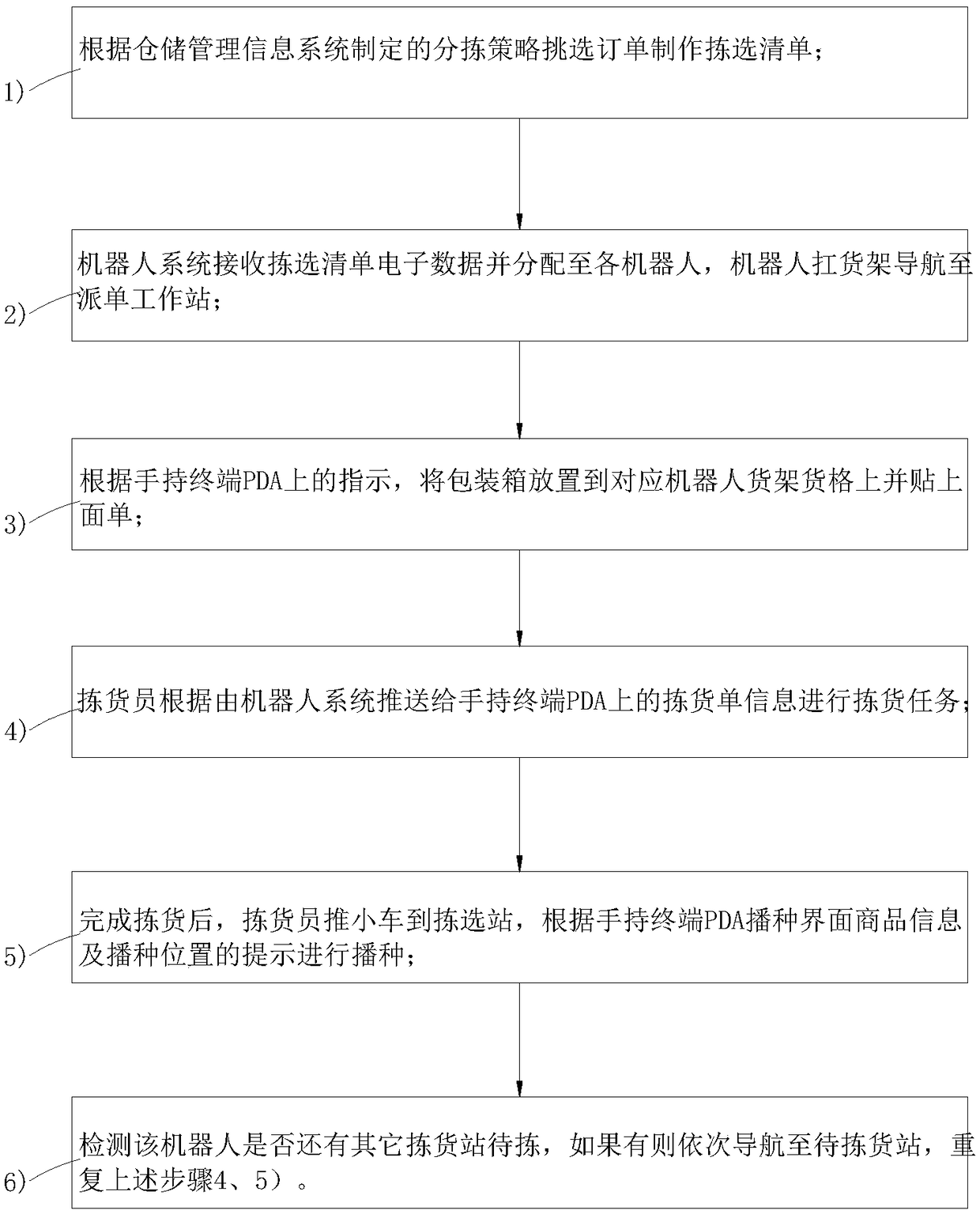

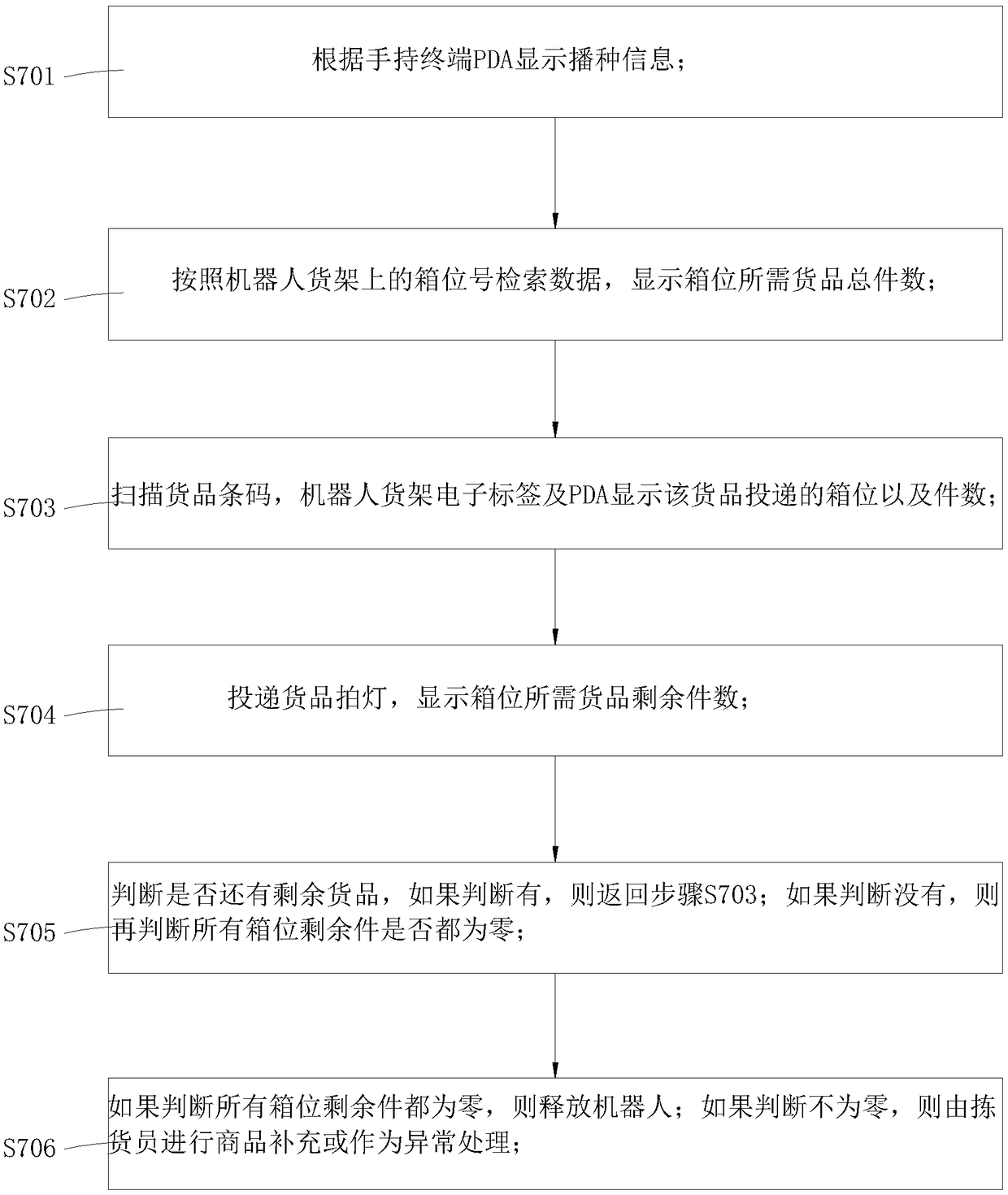

Robot automatic sorting method and system based on simultaneous picking and sorting

PendingCN109160163AHigh sorting hit rateImprove picking efficiencyStorage devicesIndustrial engineeringReal-time computing

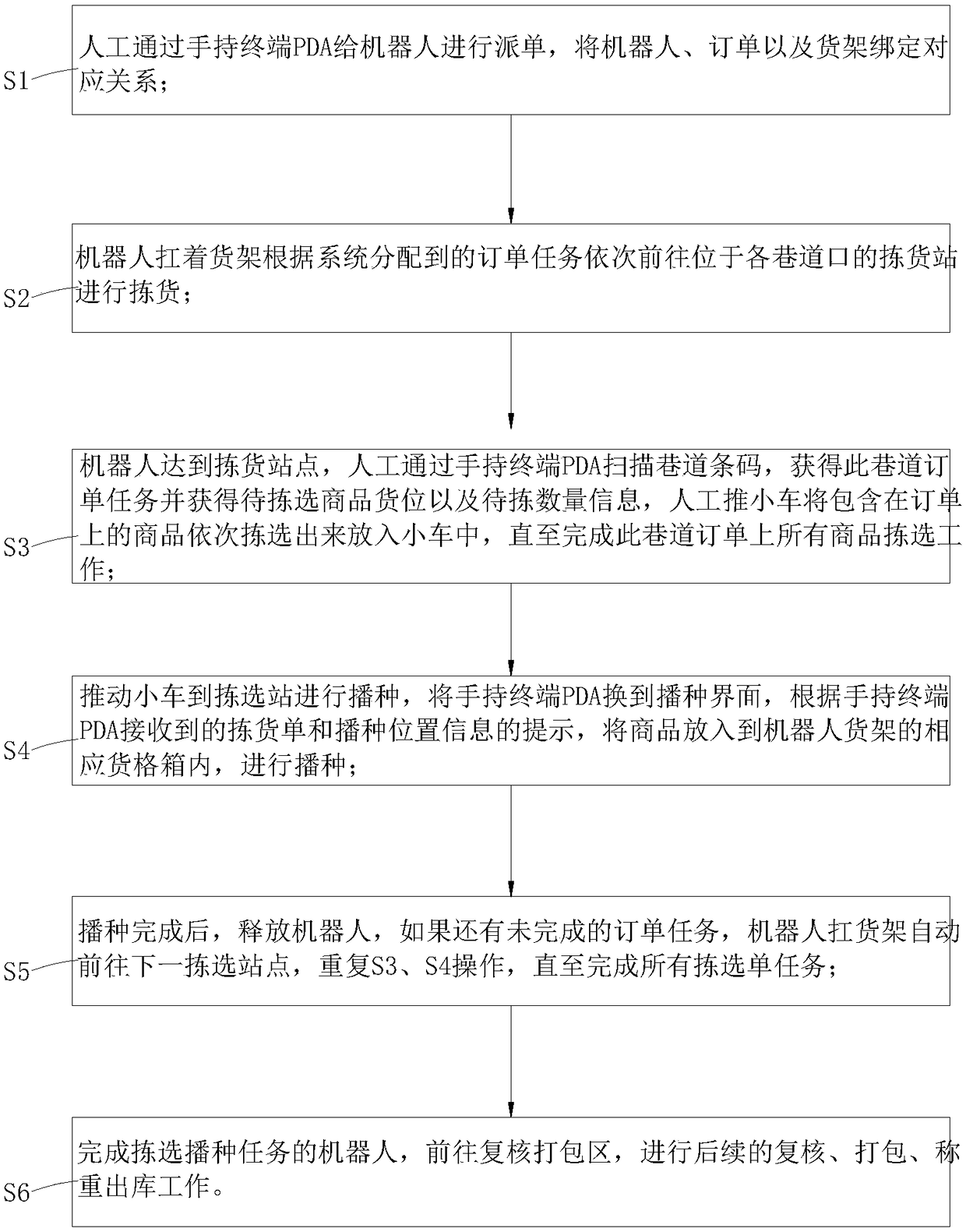

The invention discloses a robot automatic sorting method and system based on simultaneous picking and sorting. The robot automatic sorting method comprises the following steps that a robot is dispatched by manually operating a handheld terminal PDA; S2, the robot carries a goods shelf to leave for a sorting station to conduct sorting according to distributed dispatching information; S3, the robotarrives at the corresponding laneway sorting station to acquire a laneway order task until completing all commodity sorting work on a laneway order; S4, a trolley is pushed to the sorting station to conduct seeding and puts commodities into corresponding goods grids of the goods shelf of the robot to conduct seeding; S5, after completion of seeding, the robot is released; if there is uncompleted order tasks, the robot carries the good shelf to automatically leave for the next sorting station to repeat operations in the steps S3 and S4 until completing all the sorting order tasks. Through the robot automatic sorting method, manpower participates in sorting; sorting and seeding tasks are completed simultaneously at the sorting station; as sorting and seeding are completed at the sorting station simultaneously, the number of seeding personnel is reduced while the procedures are reduced, and the labor cost is reduced.

Owner:BEIJING IT LOGISTICS CO LTD

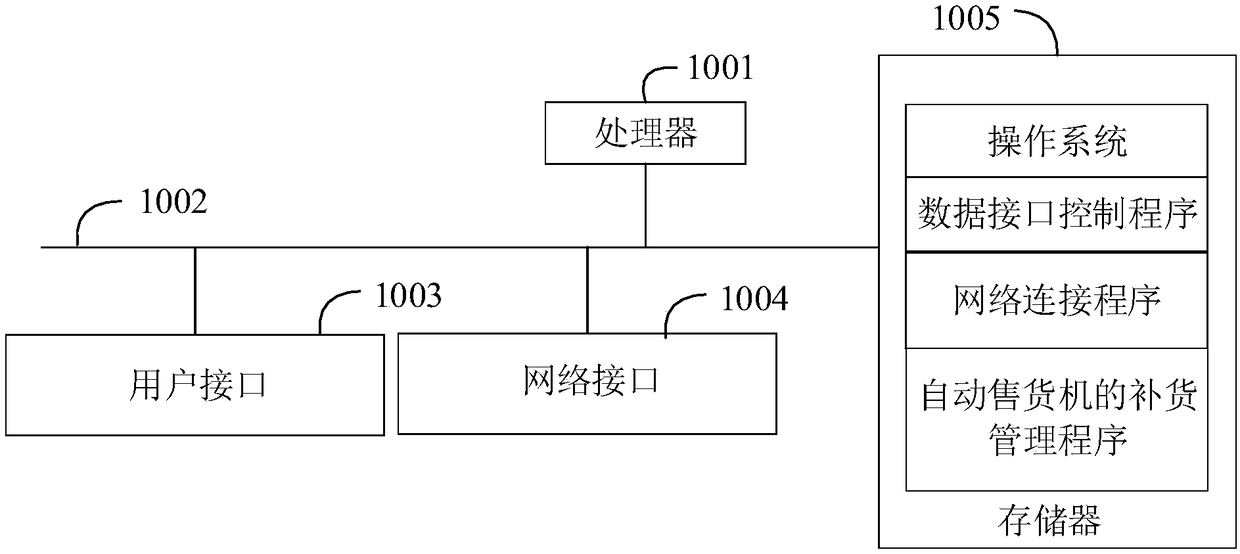

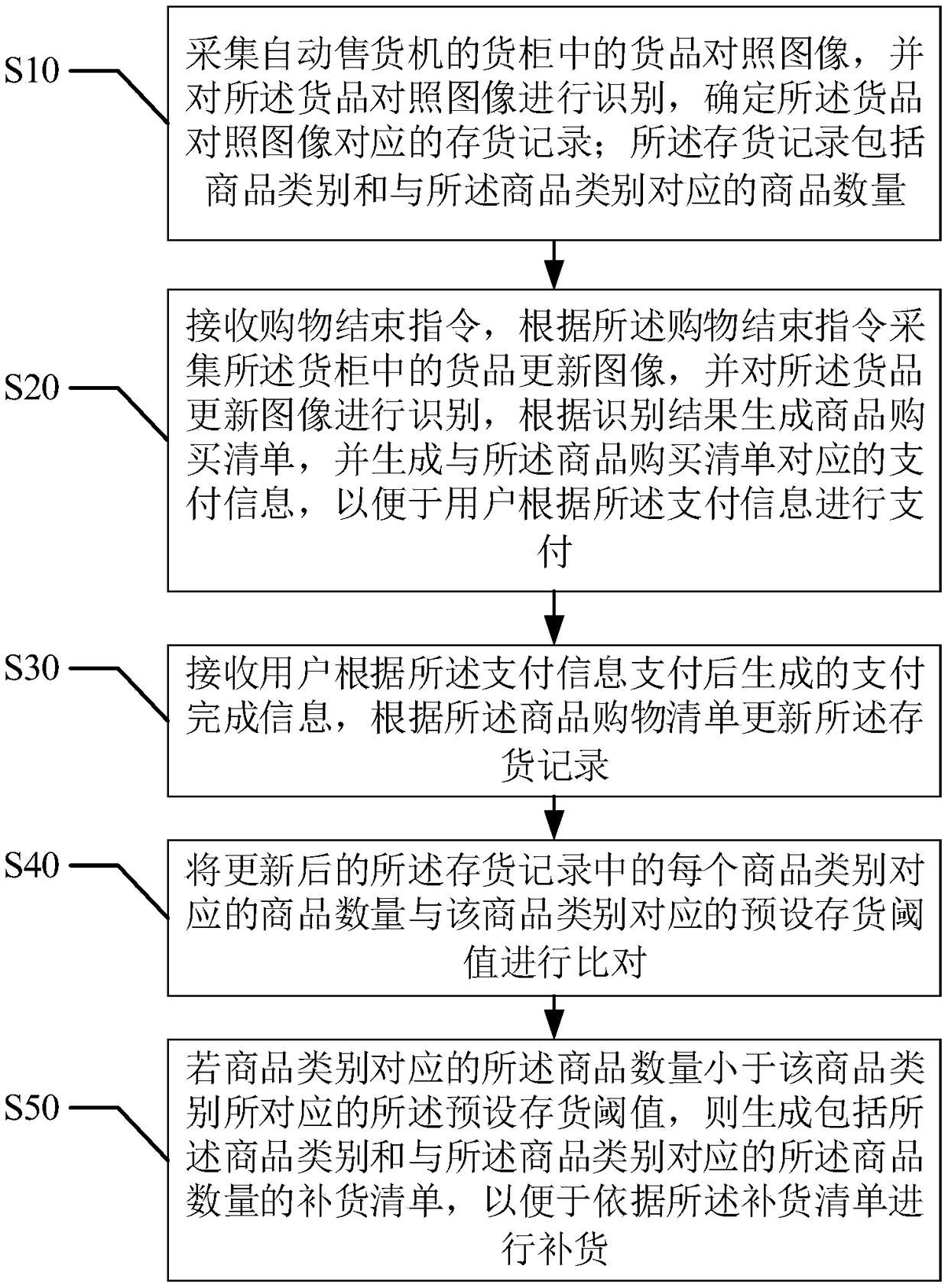

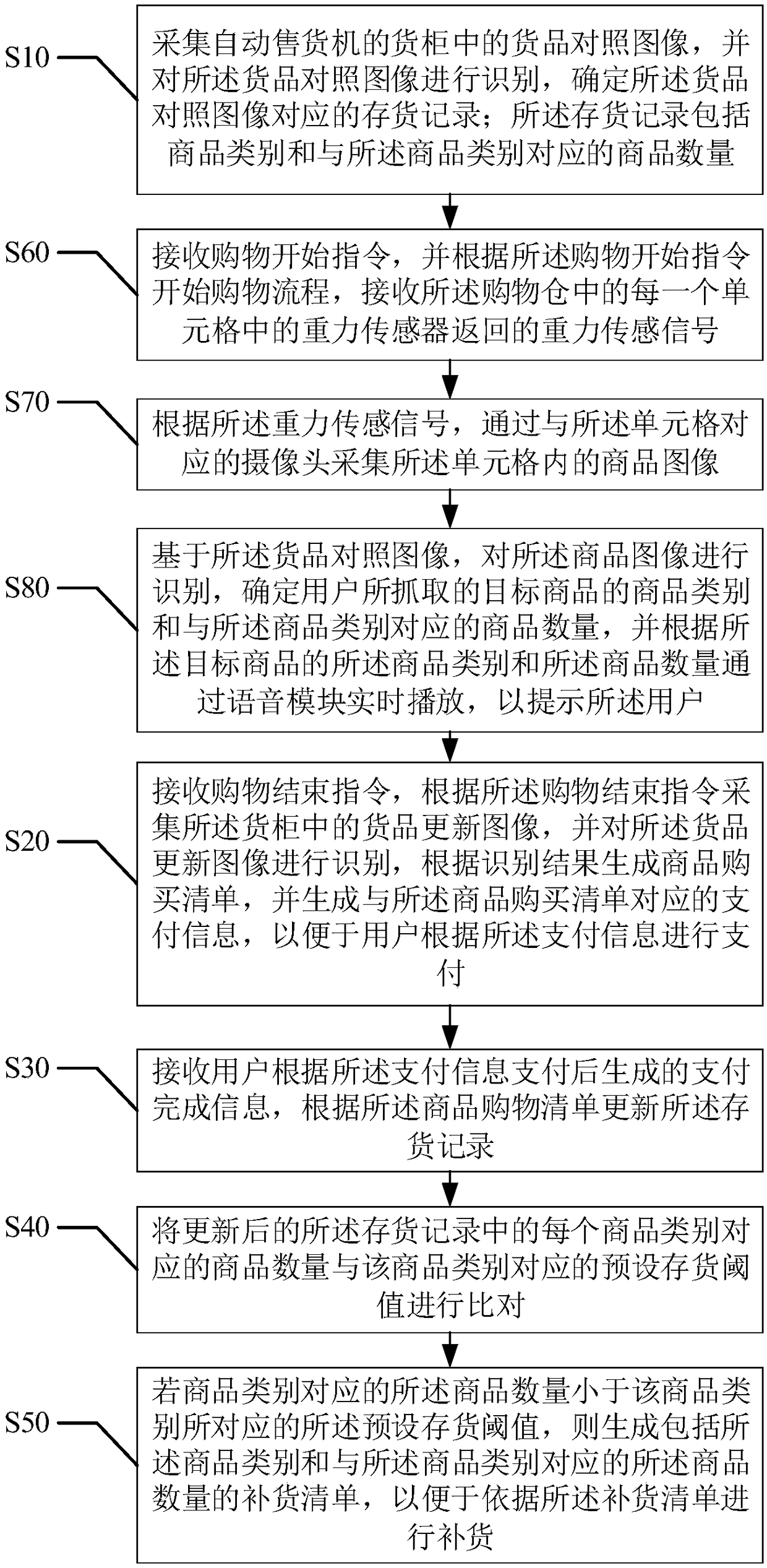

Replenishment management method and apparatus of vending machine and user terminal

ActiveCN108922026AImprove experienceConvenient paymentCoin-freed apparatus detailsCharacter and pattern recognitionImage identificationComputer science

The invention provides a replenishment management method and apparatus of a vending machine and an user terminal . The method comprises the following steps: updating an inventory record according to agoods shopping list; comparing the quantity of goods corresponding to each goods category in the updated inventory record with a preset inventory threshold corresponding to the goods category; if thequantity of goods corresponding to the goods category is less than the preset inventory threshold corresponding to the goods category, generating a replenishment list including the goods category andthe quantity of goods corresponding to the goods category. After a user finishes shopping, an image recognition technology is used to compare the identified inventory record with the preset thresholdto intelligently determine goods needing to be replenished, thereby allowing image recognition to intelligently determine the goods needing to be replenished during the goods replenishment process. The method is simple, the replenishment efficiency is high, and the user experience is good.

Owner:SHANGHAI YUEPU INVESTMENT CENT (LLP)

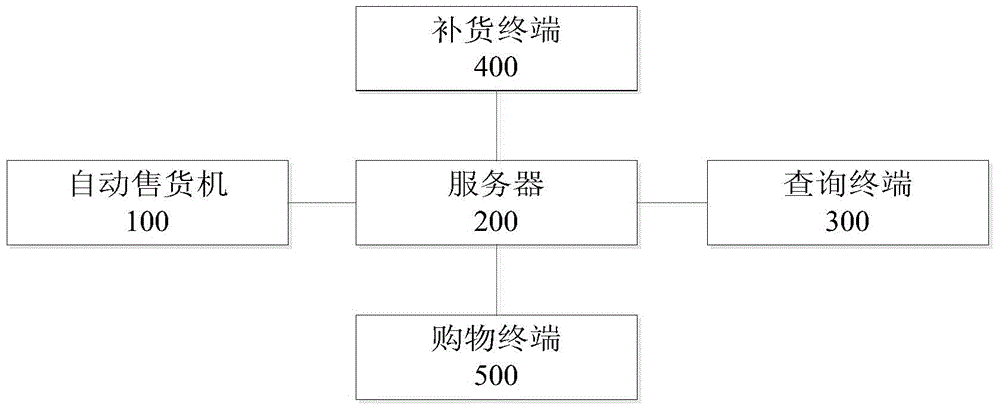

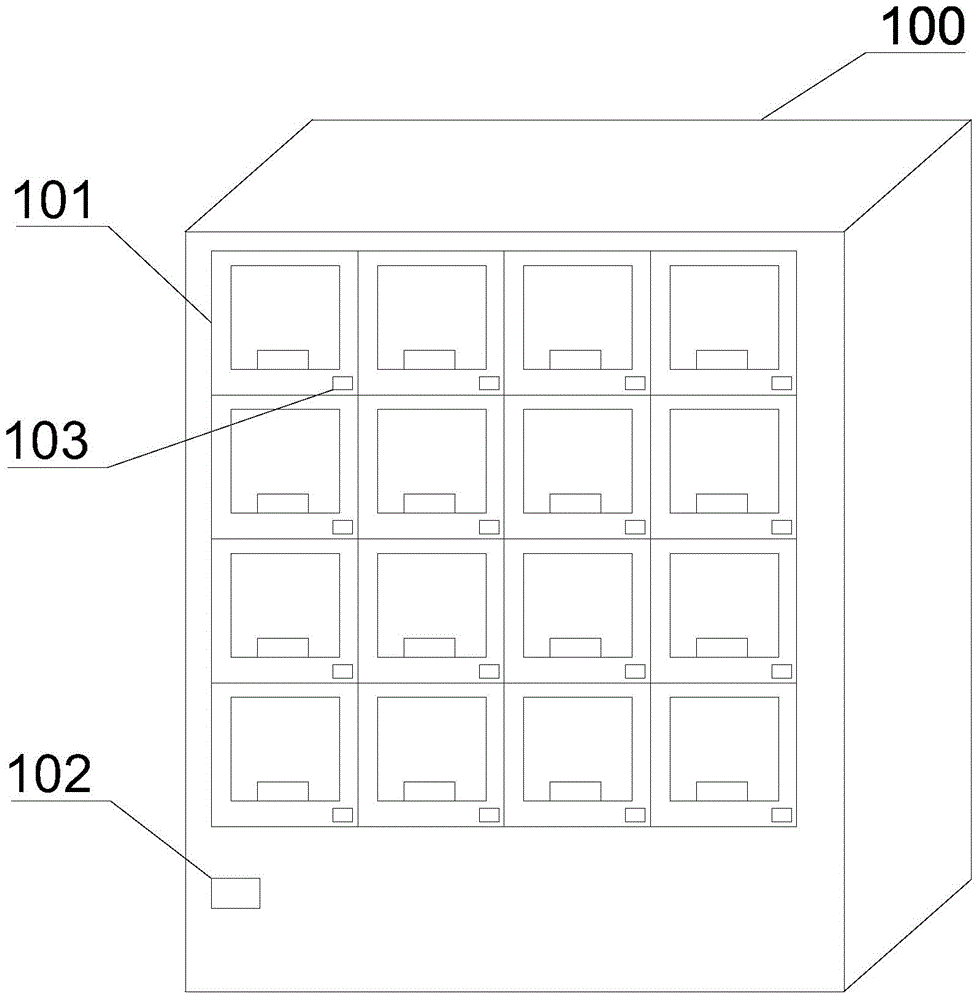

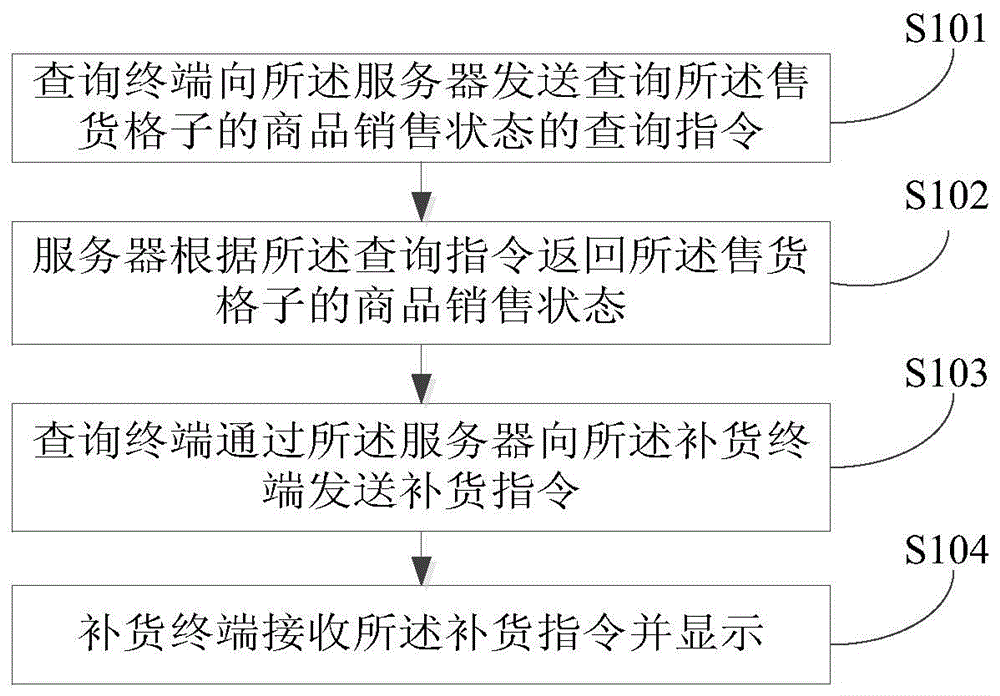

Automatic replenishing method and device

ActiveCN105205926AImprove replenishment efficiencyCoin-freed apparatus detailsApparatus for dispensing discrete articlesSoftware engineeringAutomation

The invention provides an automatic replenishing method and device applied to an automatic replenishing system, relating to the field of automation. The automatic replenishing system comprises an automatic selling machine, a server, an inquiring terminal and a replenishing terminal, wherein the automatic selling machine comprises a plurality of selling grids for containing commodities, and the commodity selling state of the selling grids is stored in the server. The automatic replenishing method comprises the following steps: the inquiring terminal sends an inquiring instruction for inquiring the commodity selling state of the selling grids to the server; the server returns the commodity selling state of the selling grids according to the inquiring instruction; the inquiring terminal sends an replenishing instruction to the replenishing terminal through the server; and the replenishing terminal receives and displays the replenishing instruction. According to the automatic replenishing method and device provided by the embodiment, a supplier can inquire the commodity selling state of the automatic selling machine through the server in real time and informs a replenishing person of replenishing the automatic selling machine, so that the operation is very convenient and rapid, and the replenishing efficiency is improved.

Owner:新加法成都智能科技有限责任公司

Replenishment method and device, computer readable storage medium and electronic equipment

ActiveCN108596540ASolve the shortage of resourcesReduce transportation pressureLogisticsWorkstationComputer science

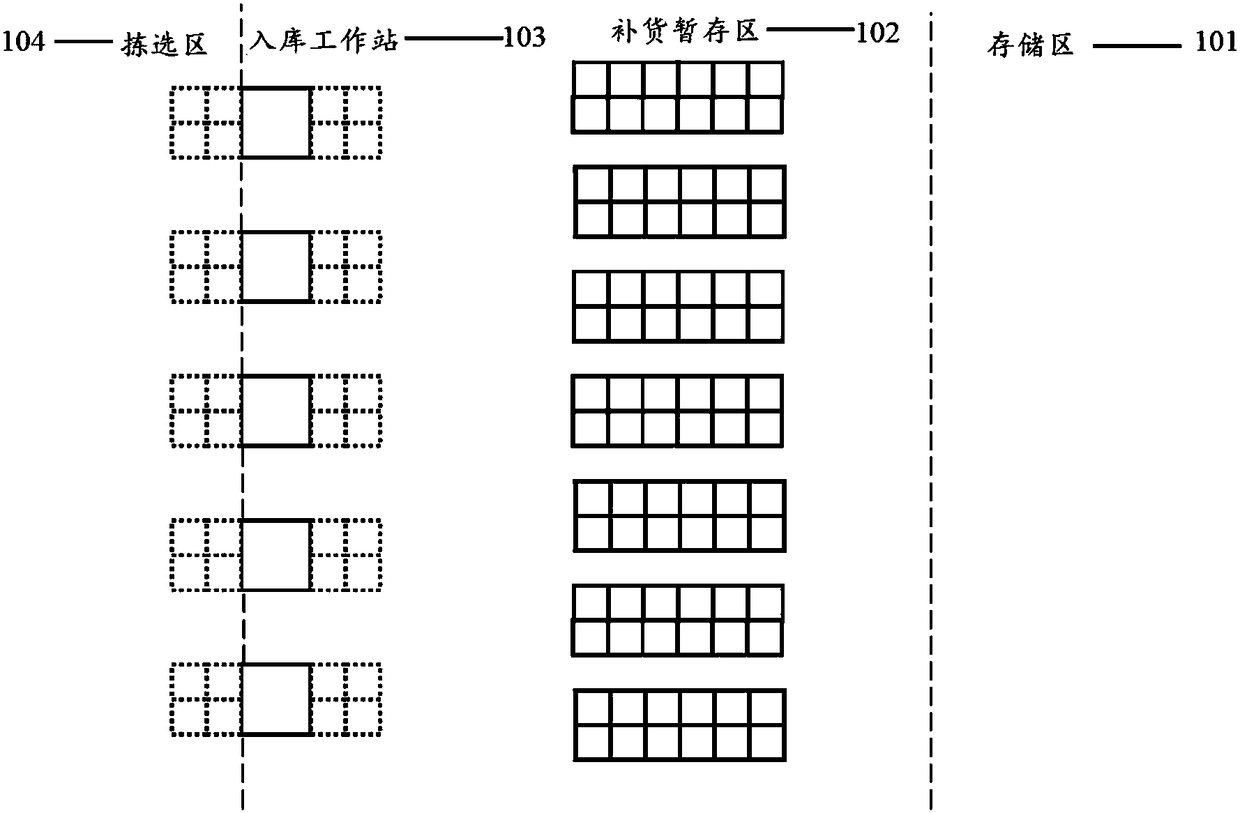

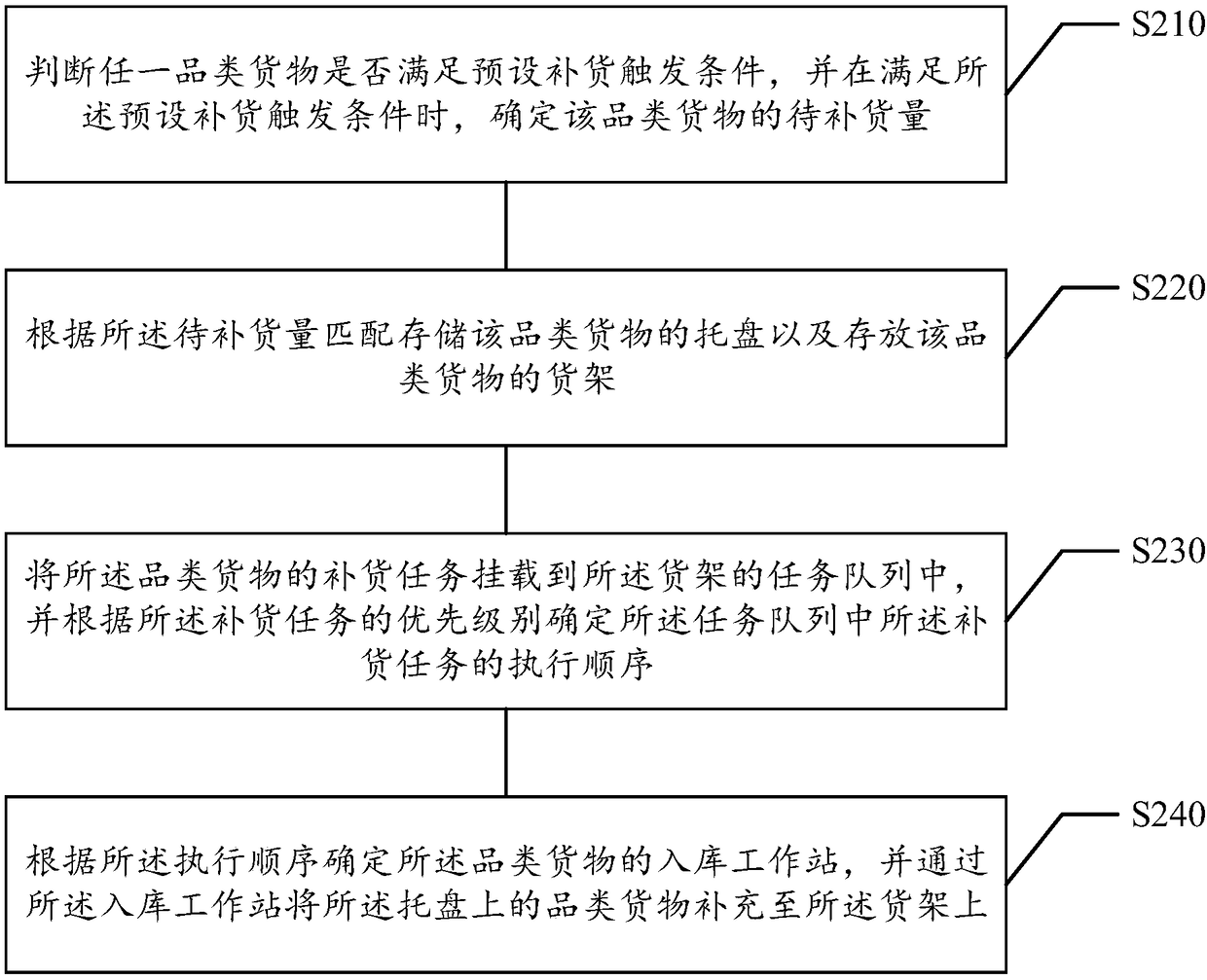

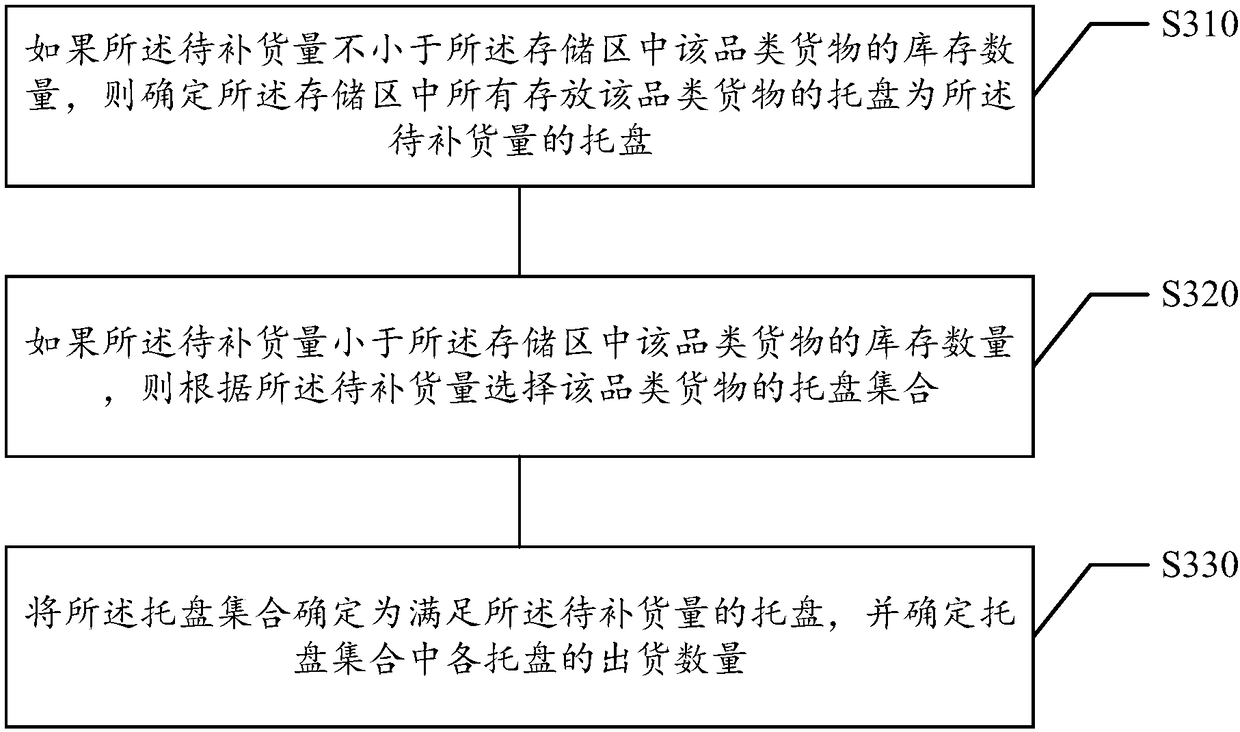

The invention relates to a replenishment method and device, and belongs to the technical field of warehousing. The replenishment method comprises the following steps of: judging whether any category of cargos satisfies a preset replenishment triggering condition or not, and determining a to-be-replenished amount of the category of cargos when the preset replenishment triggering condition is satisfied; matching a tray and a shelf for storing the category of cargos according to the to-be-replenished amount; mounting a replenishment task of the category of cargos into a task queue of the shelf and determining an execution sequence of the replenishment task in the task queue; and determining an in-storage workstation of the category of cargos according to the execution sequence and replenishing the category of cargos on the tray onto the shelf. According to the method, transportation chain shortage caused by centralized planning and execution of replenishment tasks is avoided, the transportation pressure of transportation chains is reduced and the replenishment efficiency is improved at the same time.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

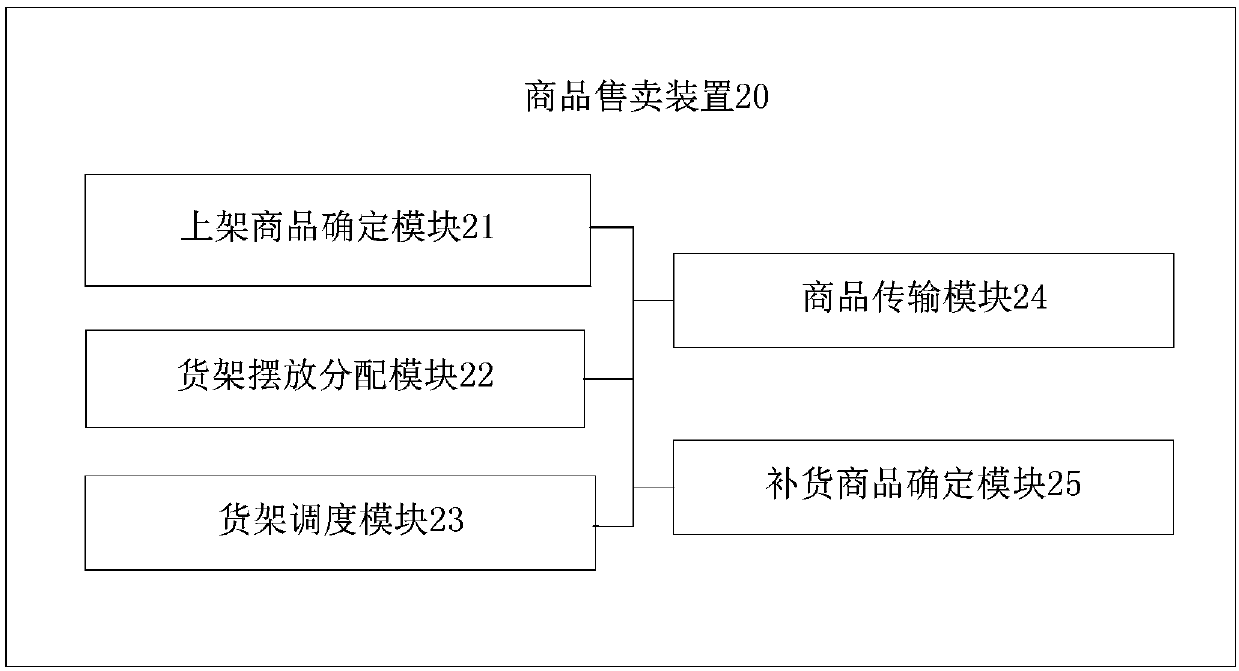

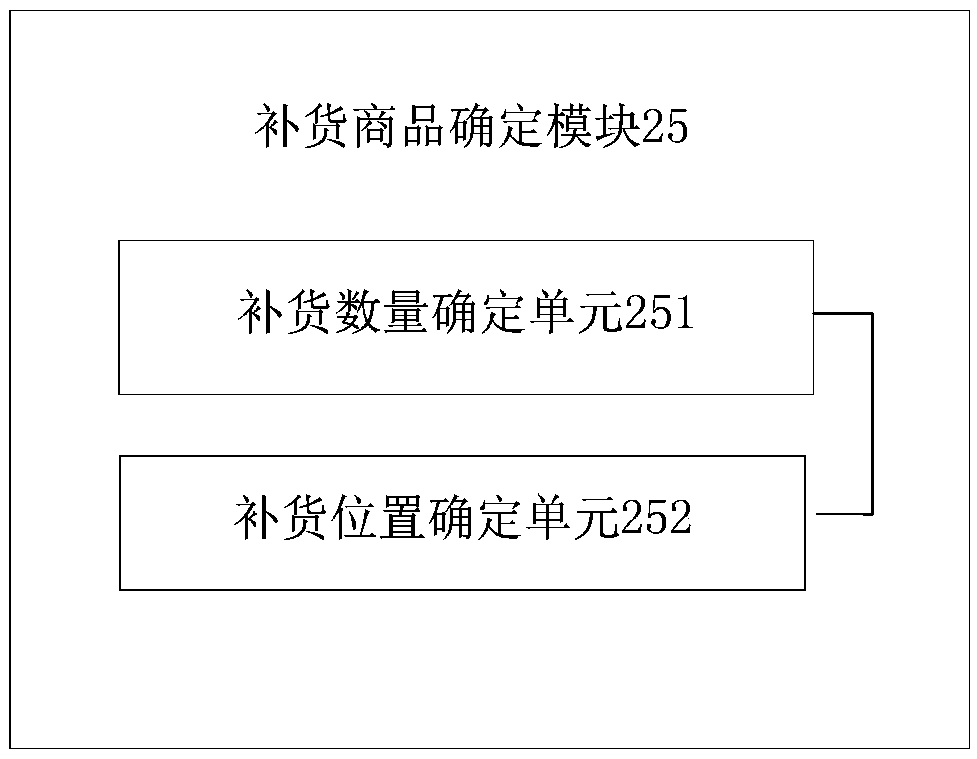

Commodity selling method and device

PendingCN110689290ARealize automatic operationReduce operating costsBuying/selling/leasing transactionsLogisticsDelivery systemOperations research

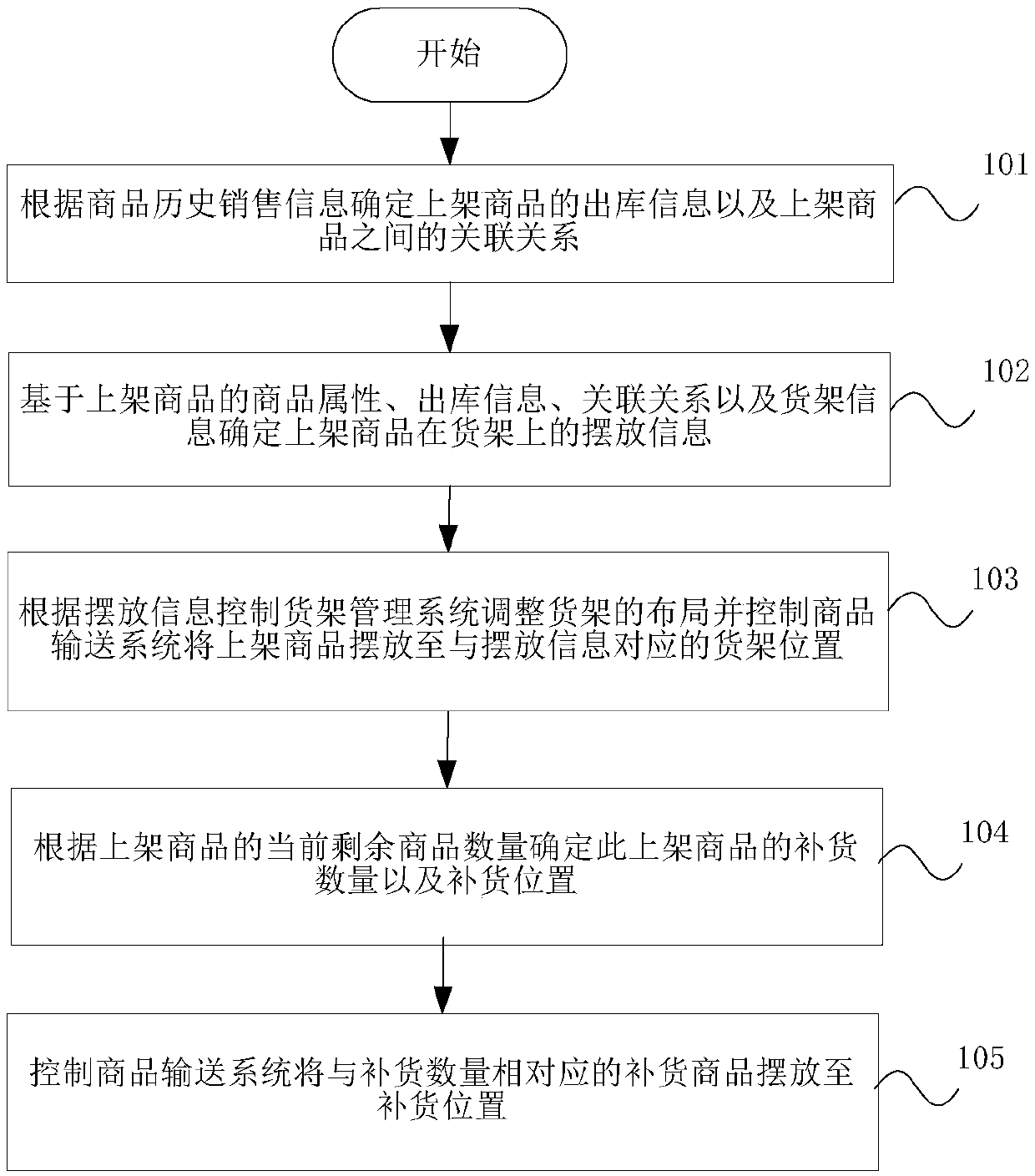

The invention provides a commodity selling method and device, and relates to the technical field of intelligent shopping, and the method comprises the steps: determining the warehouse-out informationand association relation of shelving commodities according to the historical sales information of commodities, and determining the placement information of the shelving commodities on a shelf based onthe attributes of the commodities, the warehouse-out information, the association relation and the shelf information; controlling the shelf management system to adjust the shelf layout according to the placement information; and determining the replenishment quantity and the replenishment position of the shelving commodity according to the current residual commodity quantity of the shelving commodity, and controlling the commodity conveying system to place the replenishment commodity to the replenishment position. According to the commodity selling method and device, full-flow automatic operation of goods on the shelf can be realized, operations such as loading and unloading of goods, automatic determination of goods placement positions, full-automatic goods replenishment and the like canbe carried out, the goods loading and replenishment efficiency is improved, workers in shopping places can be reduced, the operation cost of supermarkets can be reduced, the customer experience is improved, and the sales volume can also be improved.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

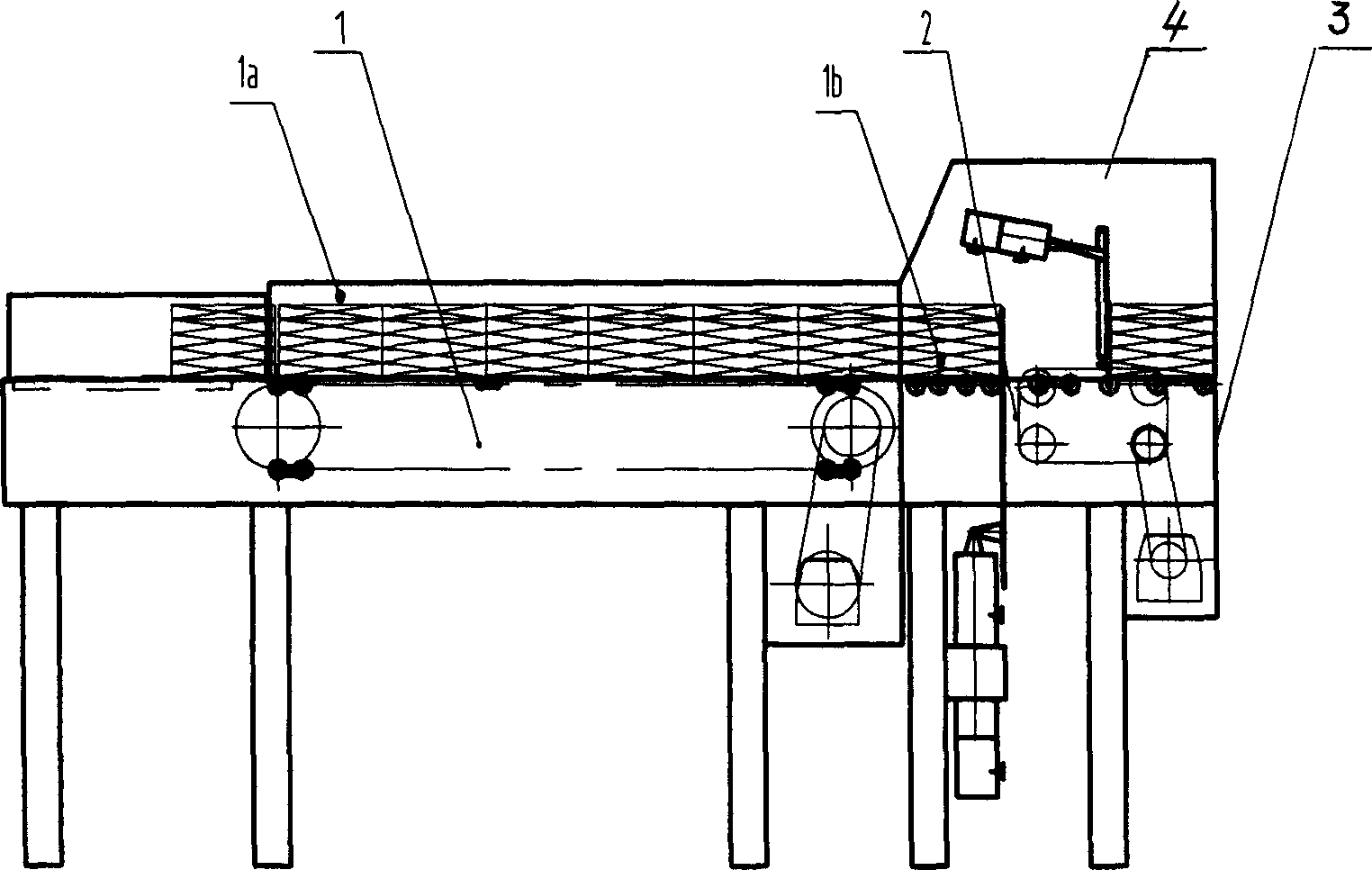

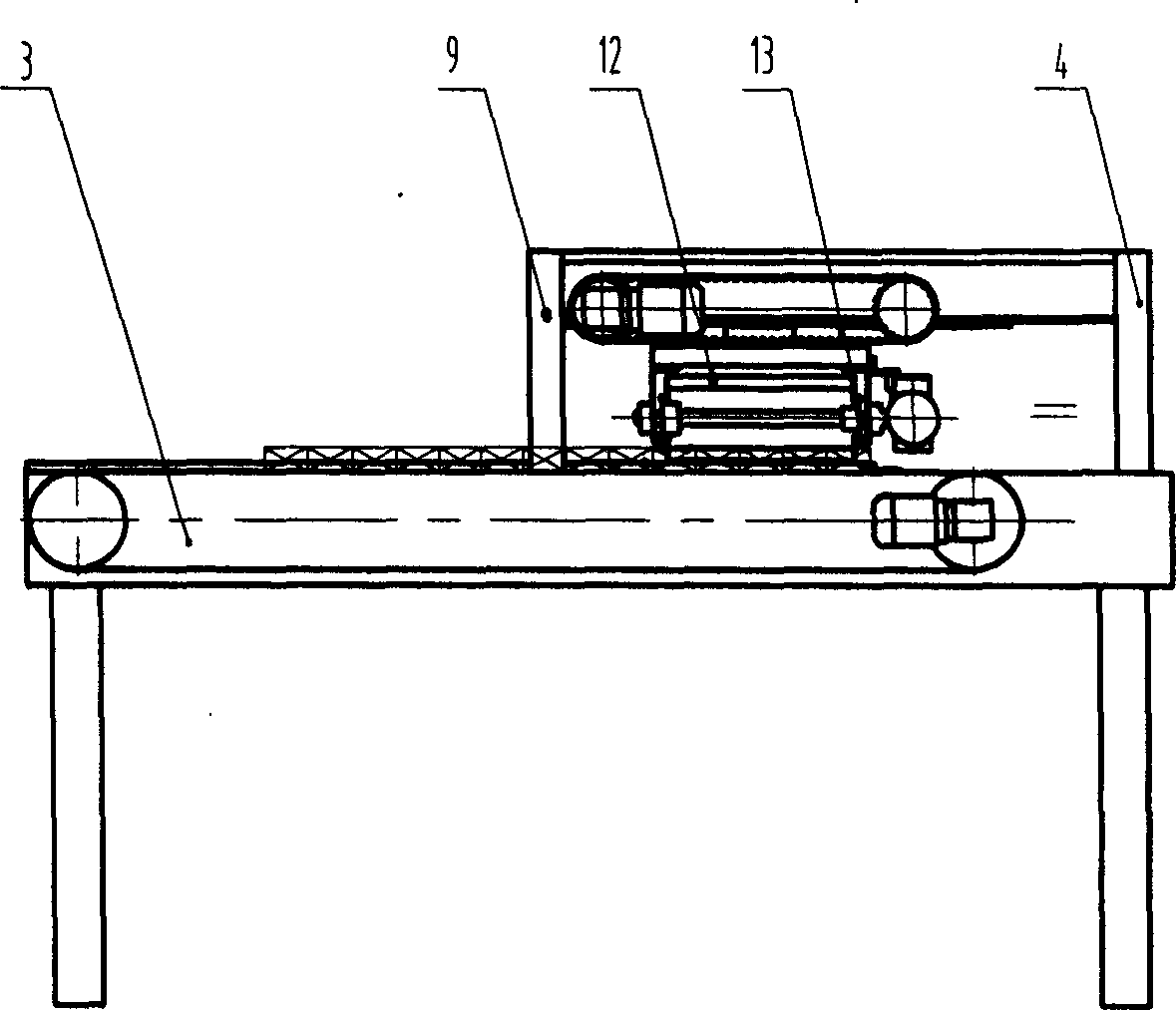

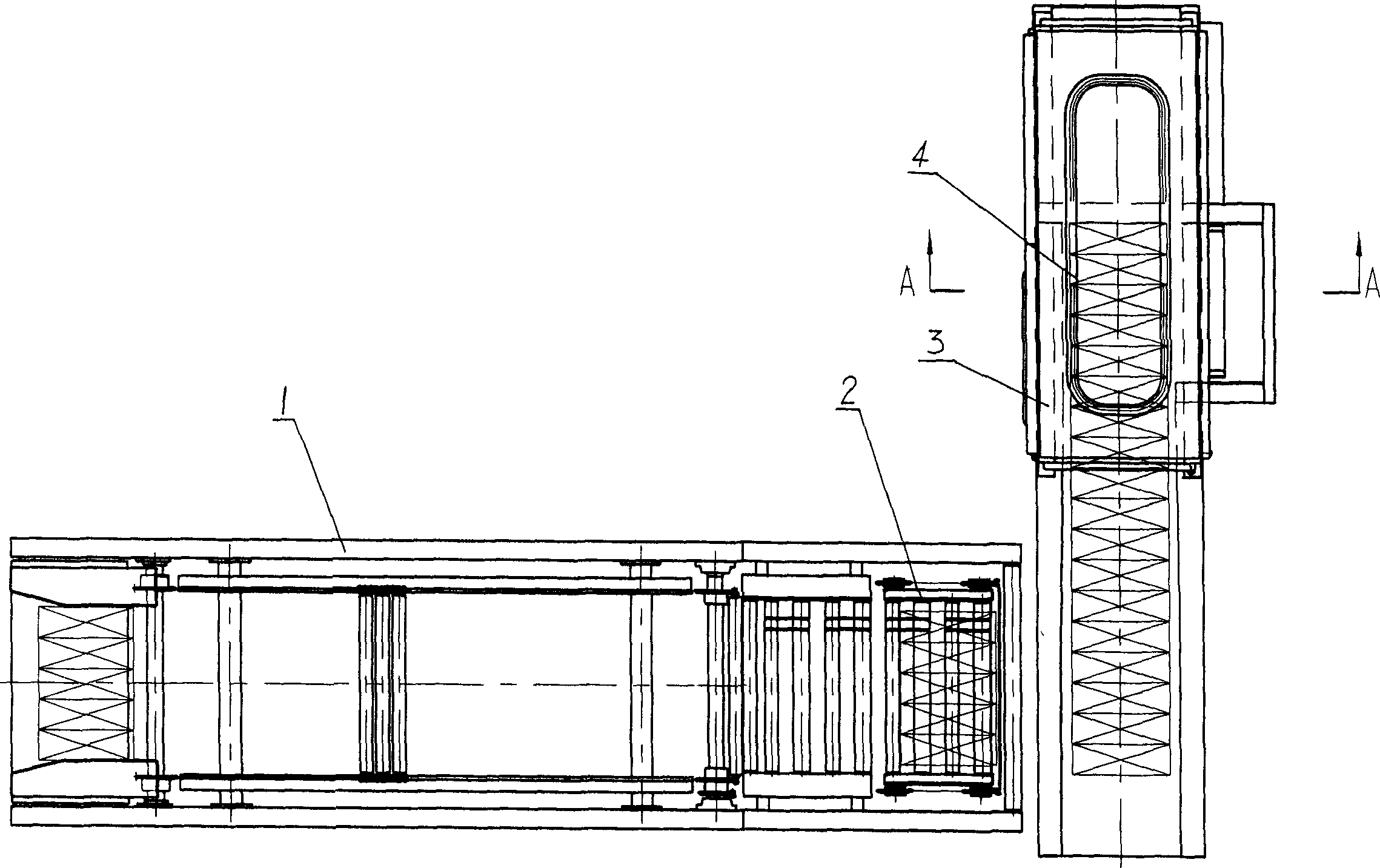

Side chain conveying device

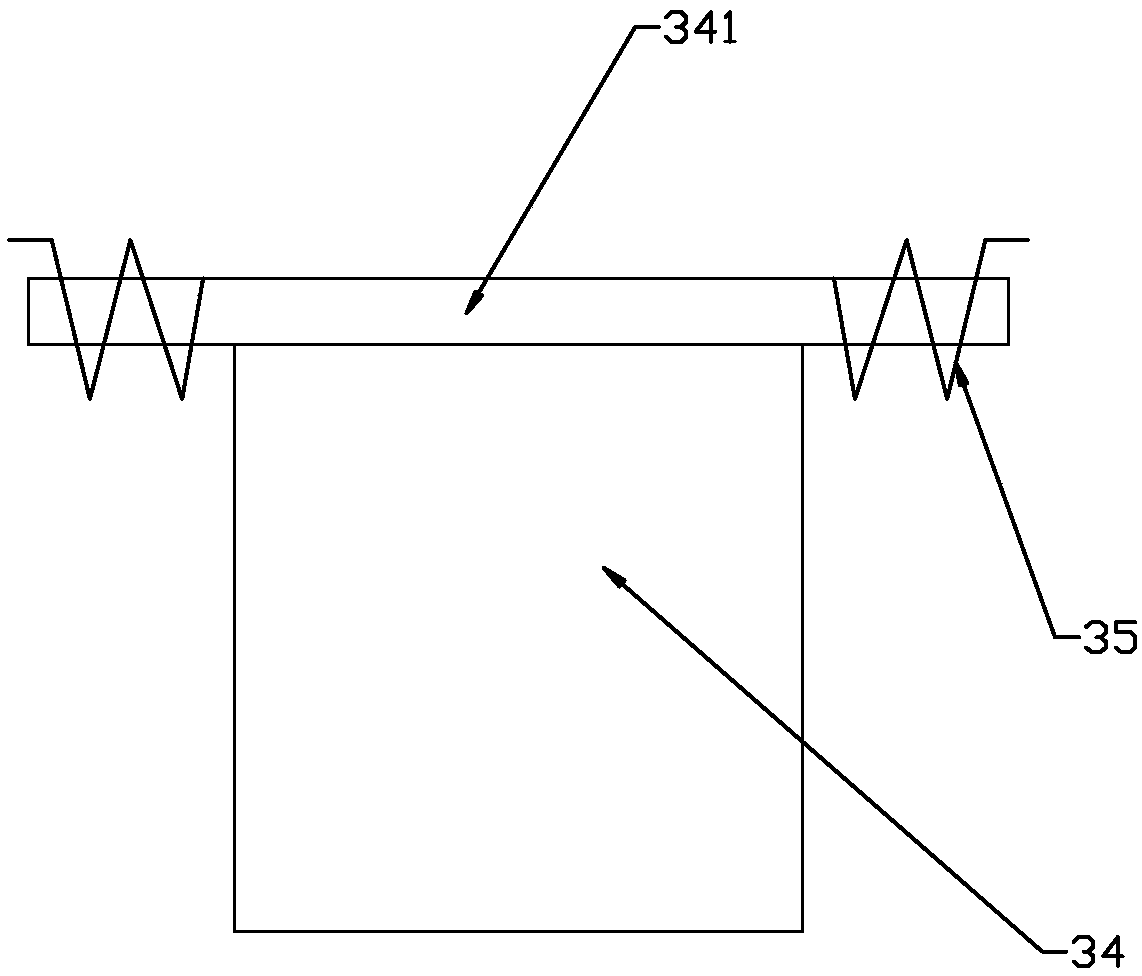

The invention discloses a side-chain transmission device, which comprises the following parts: frame (9), loop-shaped transmission chain (4) on the rack, chute (3) on the loop-shaped transmission chain intervally, shaping device (1) and pushing device (2) beside the loop-shaped transmission chain sequently. The invention can precede self-supplement for pile-shaped material effectively, which lessens the labor strength greatly.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

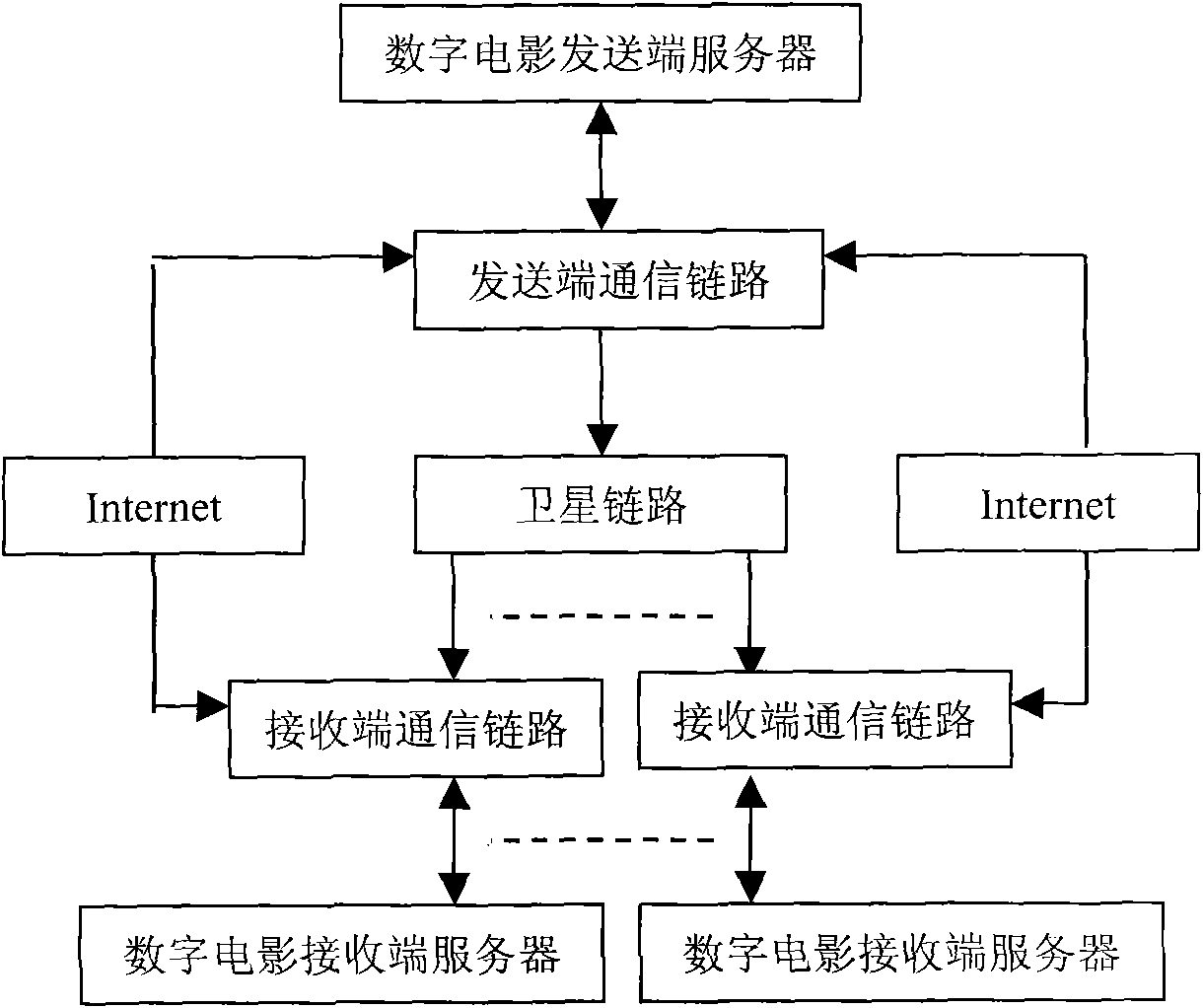

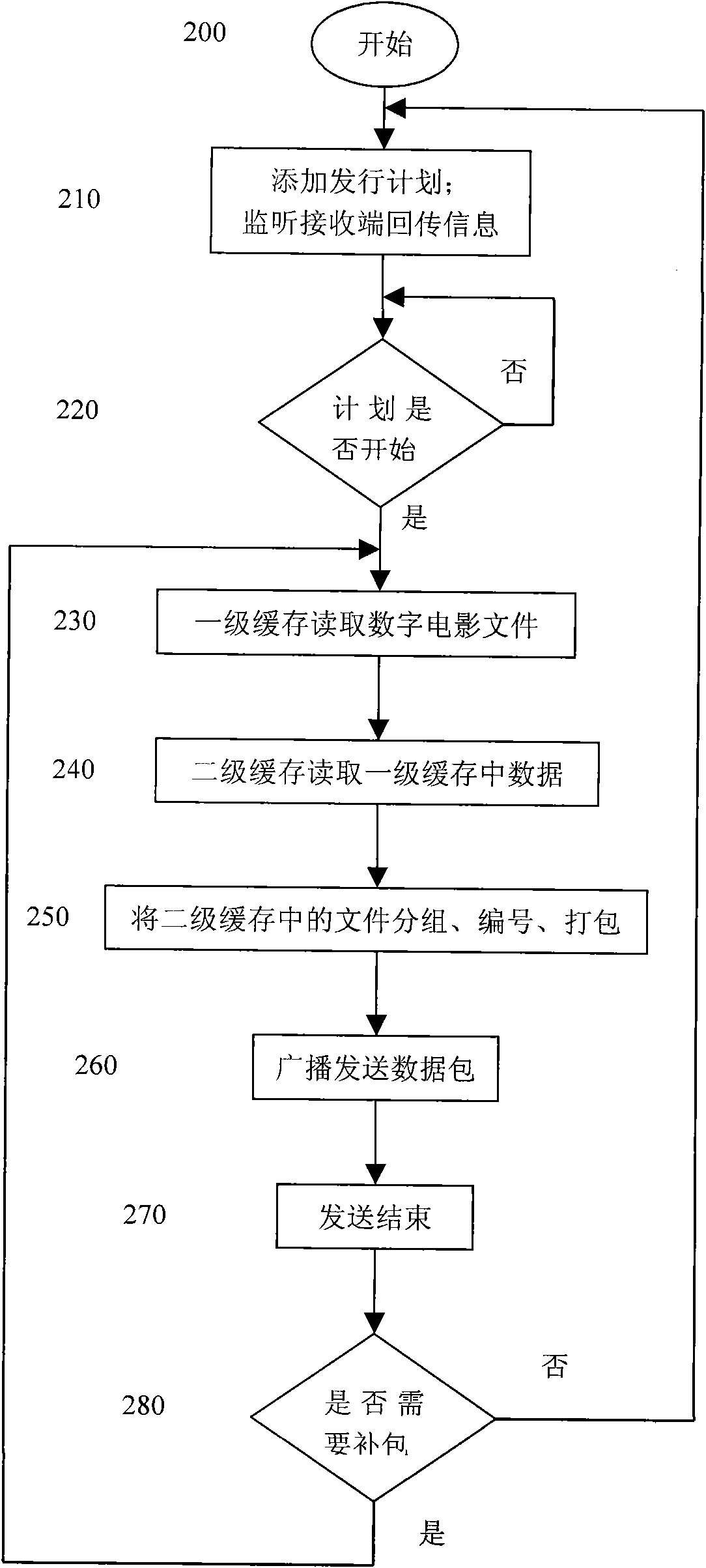

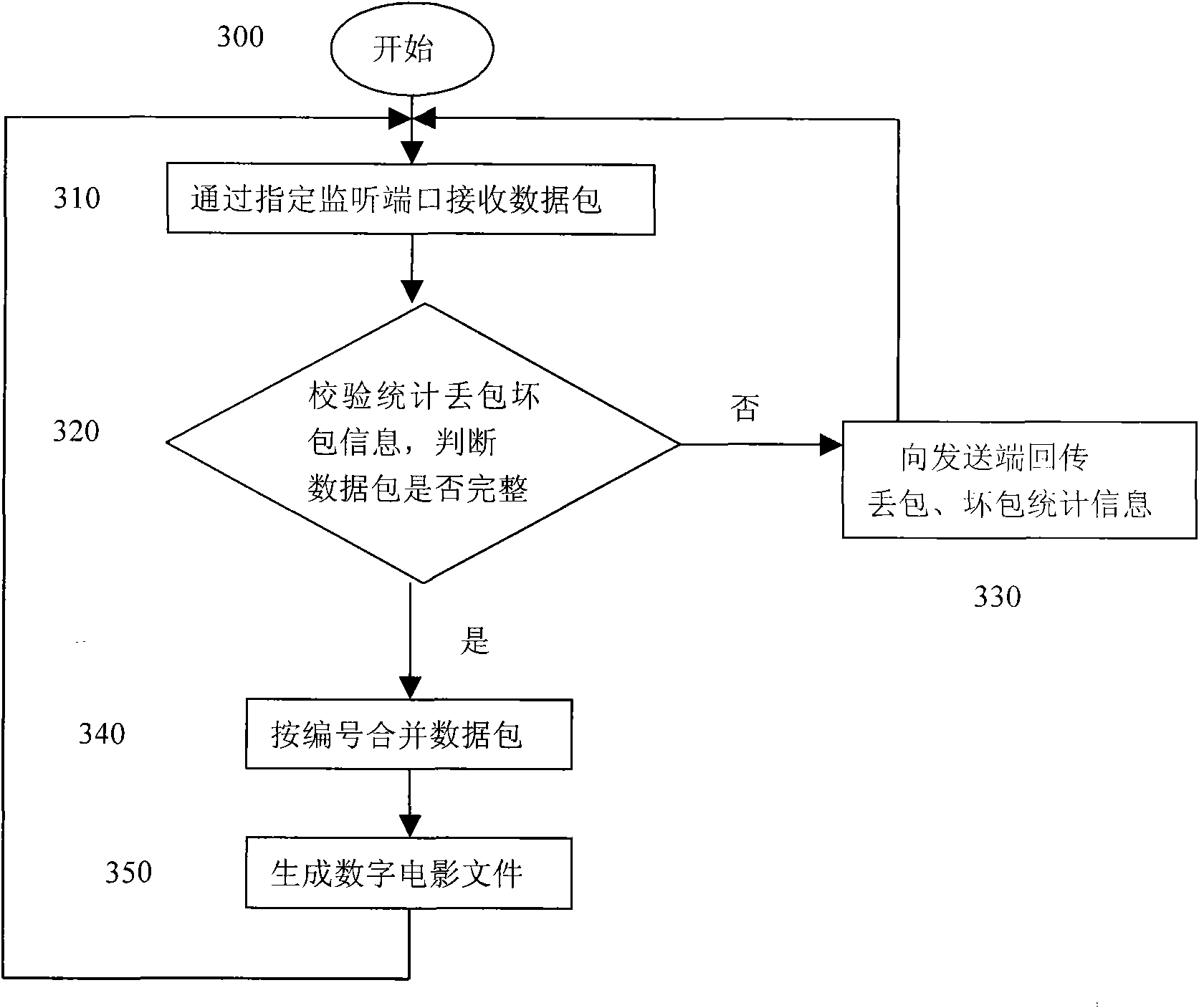

Method and device for network transmission of digital movie

InactiveCN101567794AImprove reading speedImprove efficiencySpecial service provision for substationPulse modulation television signal transmissionComplete dataNetwork packet

The invention relates to a method and a device for network transmission of a digital movie. A read digital movie file is grouped, numbered and packed by a sending terminal and is sent to a receiving terminal by a satellite link; after receiving data packets, the receiving terminal counts the number of wrong packets and transmits the information of the wrong packets back to the sending terminal; and the sending terminal complementally sends lost or damaged data packets to the receiving terminal according to the transmitted information of the wrong packets until the receiving terminal generates a complete digital movie file after receiving a complete data packet. The invention starts an L2 cache in a memory of a server of the sending terminal. An L1 cache with larger capacity reads the original digital movie file, and the L2 cache with smaller capacity reads data from the L1 cache and groups, numbers and packs the data read by the L2 cache. The invention can enhance the speed and the stability to read the file of the sending terminal and improves the use ratio of the network bandwidth and the transmission efficiency of the data.

Owner:CHINA BROADCASTING TELECOMM

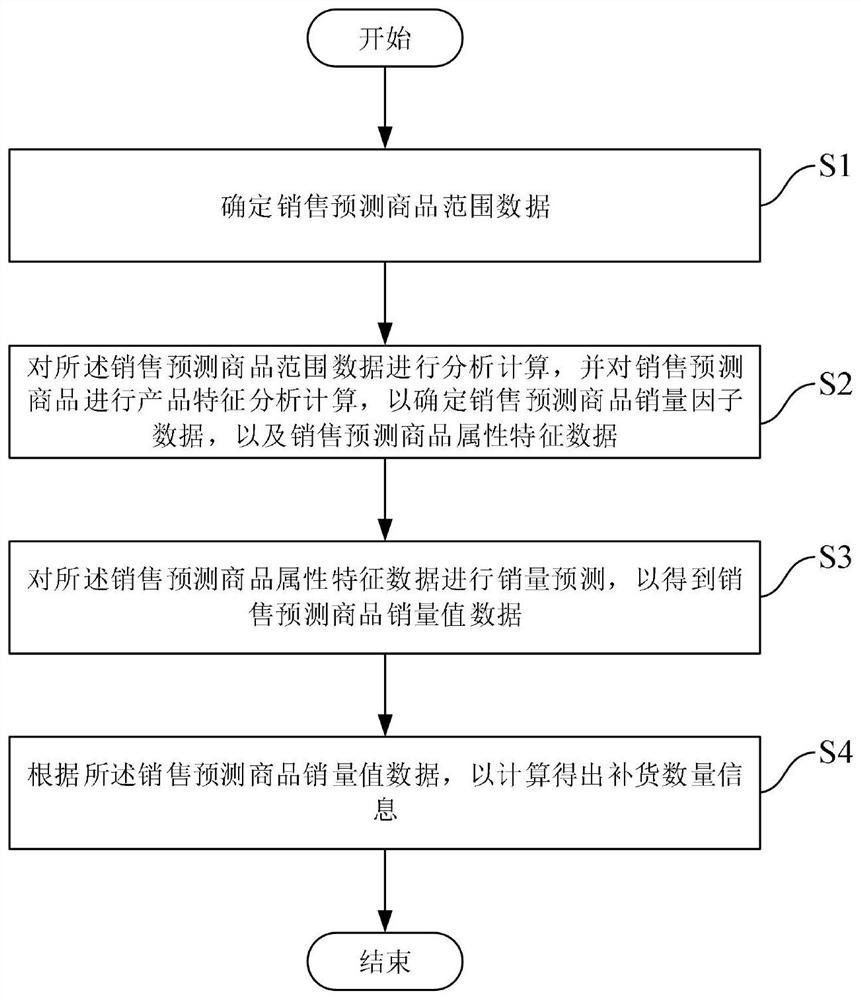

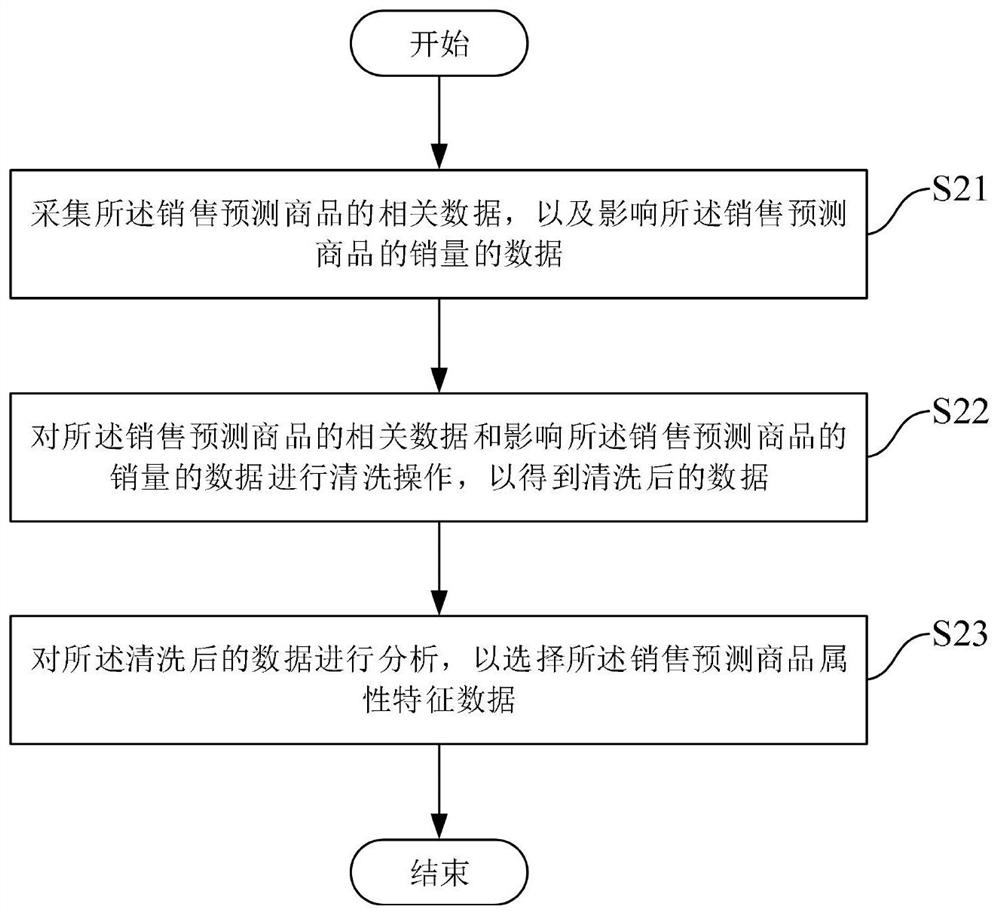

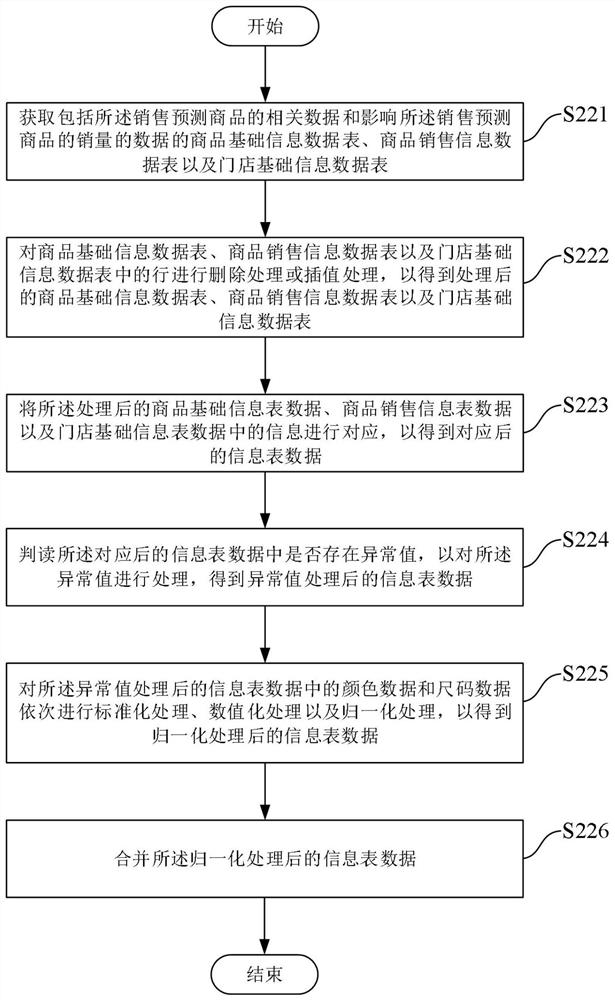

Intelligent replenishment method and system

PendingCN111882278AImprove purchasing experienceImprove replenishment efficiencyLogisticsData miningPurchasing

The invention discloses an intelligent replenishment method and system. The intelligent replenishment method comprises the steps: determining sales prediction commodity range data, performing analysisand calculation on the sales prediction commodity range data, and performing product feature analysis and calculation on sales prediction commodities to determine sales prediction commodity sales volume factor data and sales prediction commodity attribute feature data; performing sales prediction on the sales prediction commodity attribute feature data to obtain sales prediction commodity sales value data, and calculating replenishment quantity information according to the sales prediction commodity sales value data. According to the invention, the replenishment efficiency is improved, and the purchasing experience of customers is improved.

Owner:上海百胜软件股份有限公司

Automatic breakfast selling storage and delivery device and cold preservation transfer method

InactiveCN104392552AFall accuratelyAvoid falling and wanderingCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringPower apparatus

The invention belongs to the technical field of cooking machinery, and provides an automatic breakfast selling storage and delivery device and a cold preservation transfer method. The automatic breakfast selling storage and delivery device comprises a control device and a cold closet, the control device is positioned on the outer wall of the cold closet, and the cold closet comprises a shell, a door, a storage box, a linear actuator, a screw-rod linear module, a breakfast collector, a retaining plate, multiple counters and elastic piece groups. The screw-rod linear module comprises a transverse power unit, a transverse guide rail, two longitudinal power units and two longitudinal guide rails. The storage box comprises a box body, a latticed support, storage strips and rear end covers. Each elastic piece group is composed of a transverse flat elastic piece and an arc flat elastic piece connected into a whole; the counters are connected with the corresponding elastic piece groups; the retaining plate is clamped in gaps of the rear end covers; the breakfast collector is connected with the storage box and the retaining plate. The automatic breakfast selling storage and delivery device has the advantages of centralized breakfast storage, size reduction of a vending machine, storage quantity increase, replenishment efficiency improvement, capability of effectively keeping short-shelf-life food fresh, simple structure, low fault rate, convenience and quickness in maintenance and low cost.

Owner:SHANGHAI UNIV OF ENG SCI

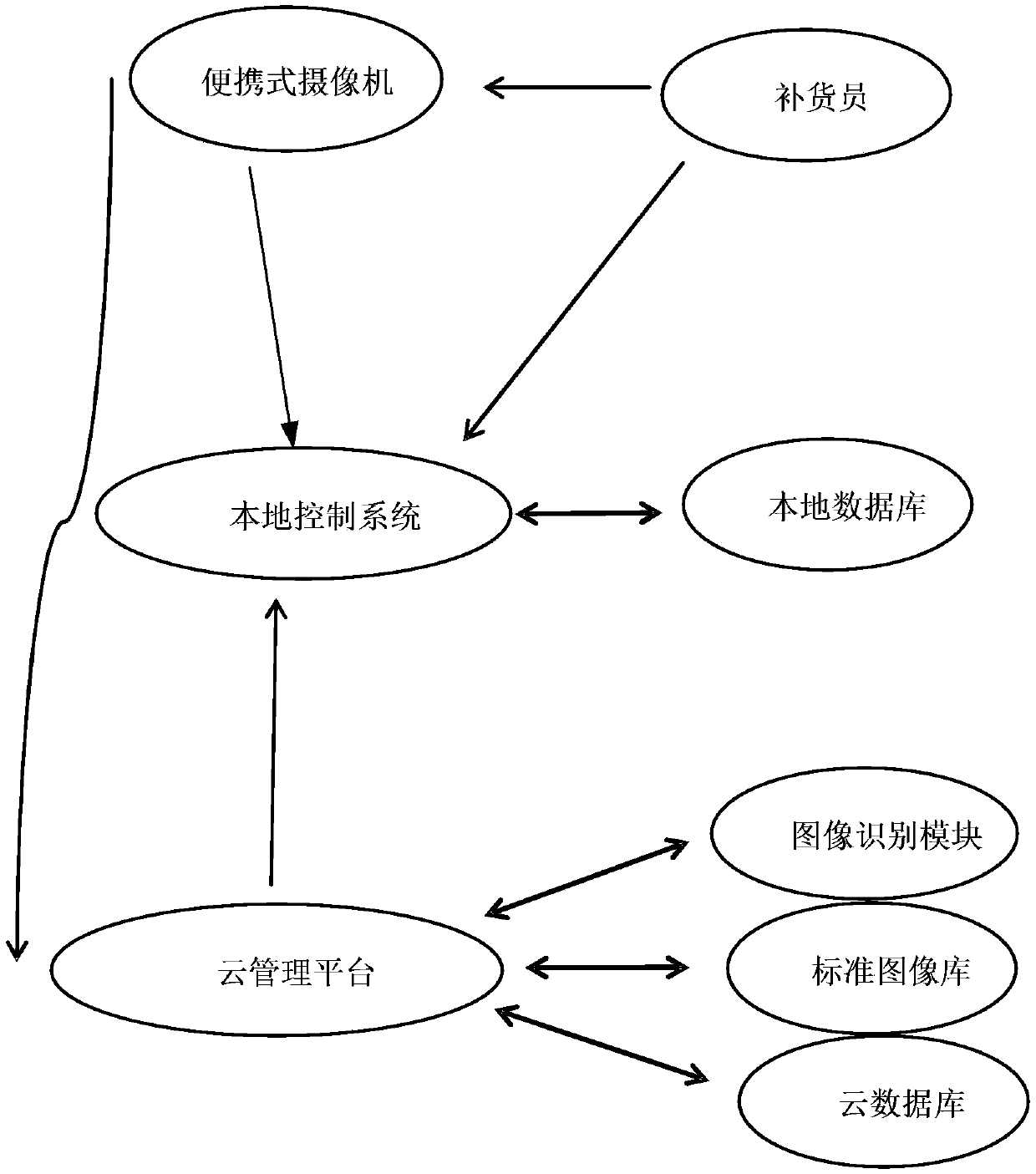

Method and system for updating intelligent inventory of vending machine based on video content identification

InactiveCN109544783AEasy to manageQuick managementCoin-freed apparatus detailsDatabase distribution/replicationComputer graphics (images)Computer terminal

The invention discloses a method and a system for updating an intelligent inventory of a vending machine based on video content identification. The method comprises the following steps of: step 1: obtaining a replenishment video in a replenishment process, and photographing a video of the replenishment process through a camera arranged in a cargo lane of the vending machine; step 2: identifying the inventory update information for products from the replenishment video, performing identification by a cloud server, or, performing identification by a replenishment terminal or a processor in a replenished vending machine, wherein the identification refers to identifying all the replenished product details in this replenishment through video analysis, and the identification for a certain product refers to extracting one image frame in the video to compare with a preset standard image base to confirm the names of a product in the current image; and step 3: storing inventory updating information into a storage space in the cloud server. The method and the system for updating an intelligent inventory of a vending machine based on video content identification are easy to be implemented andare high in automatic degree.

Owner:HUNAN KIMMA INTELLIGENT EQUIP MFR

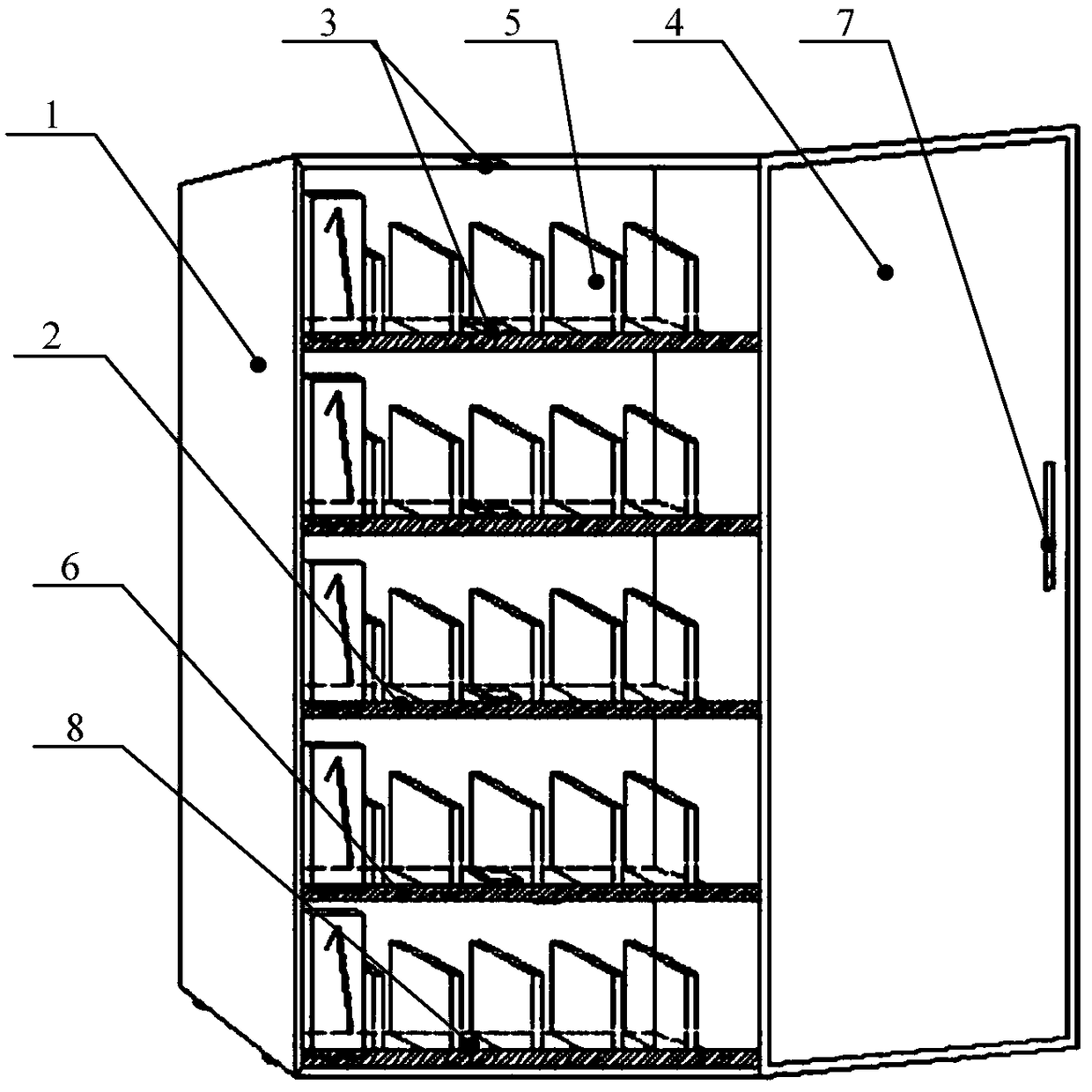

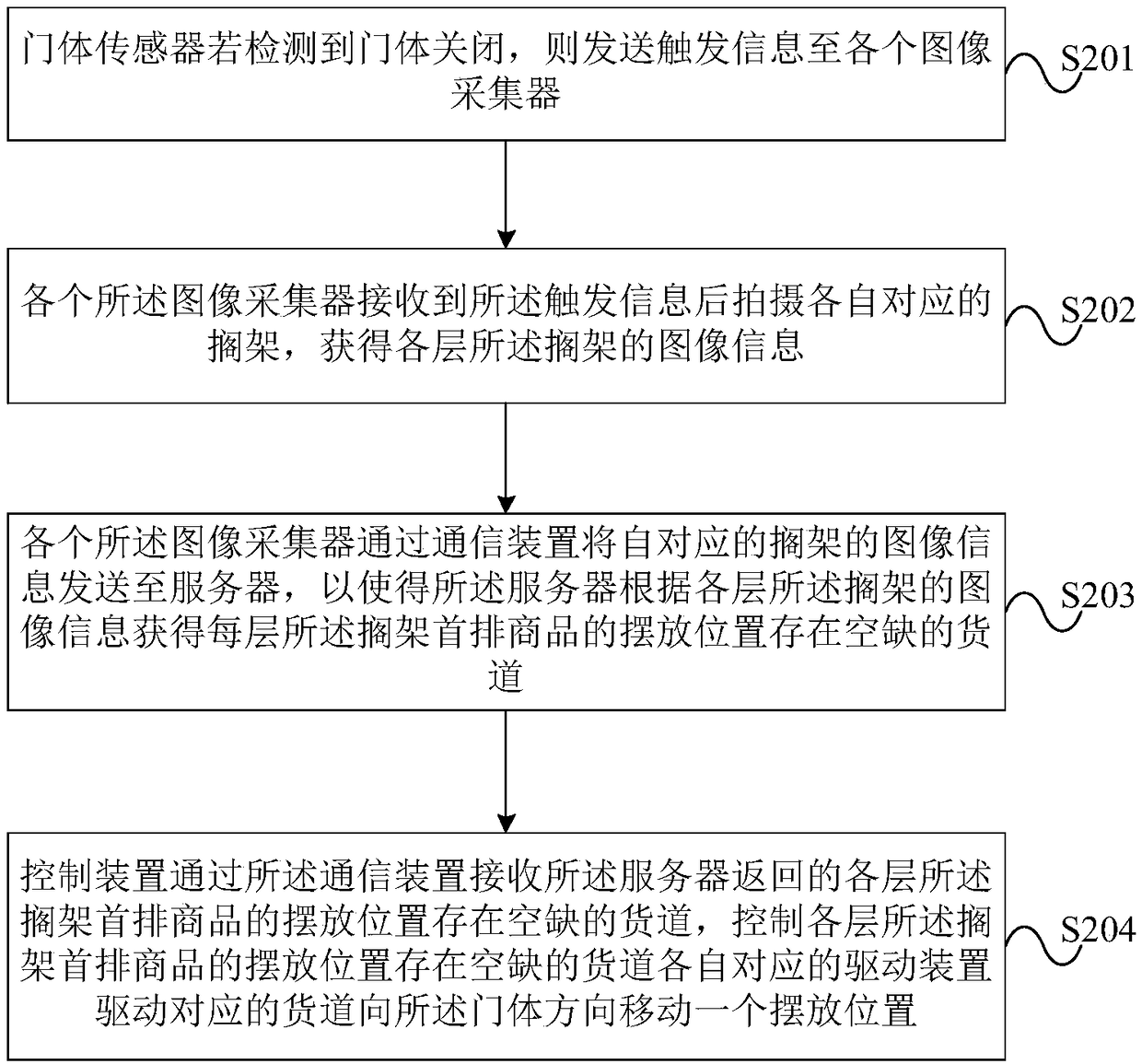

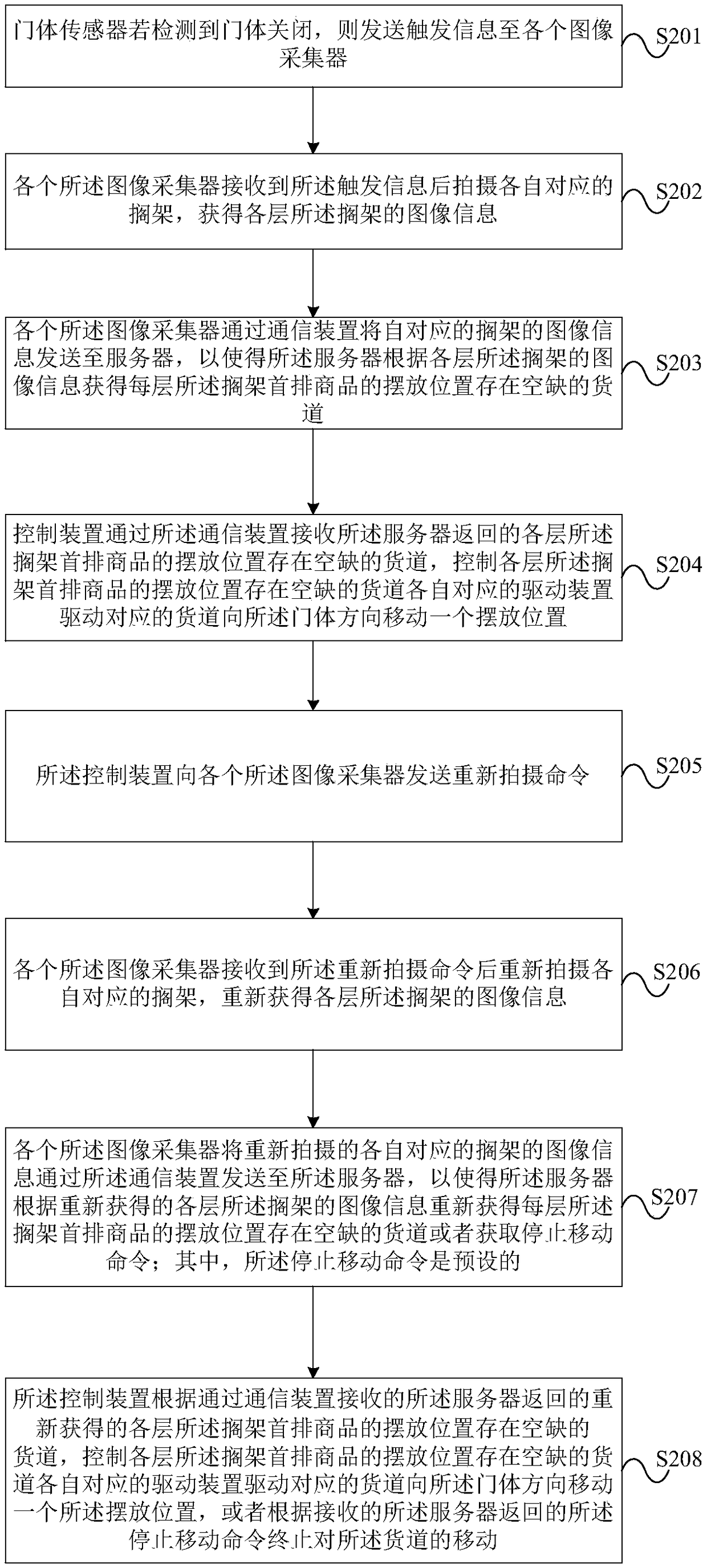

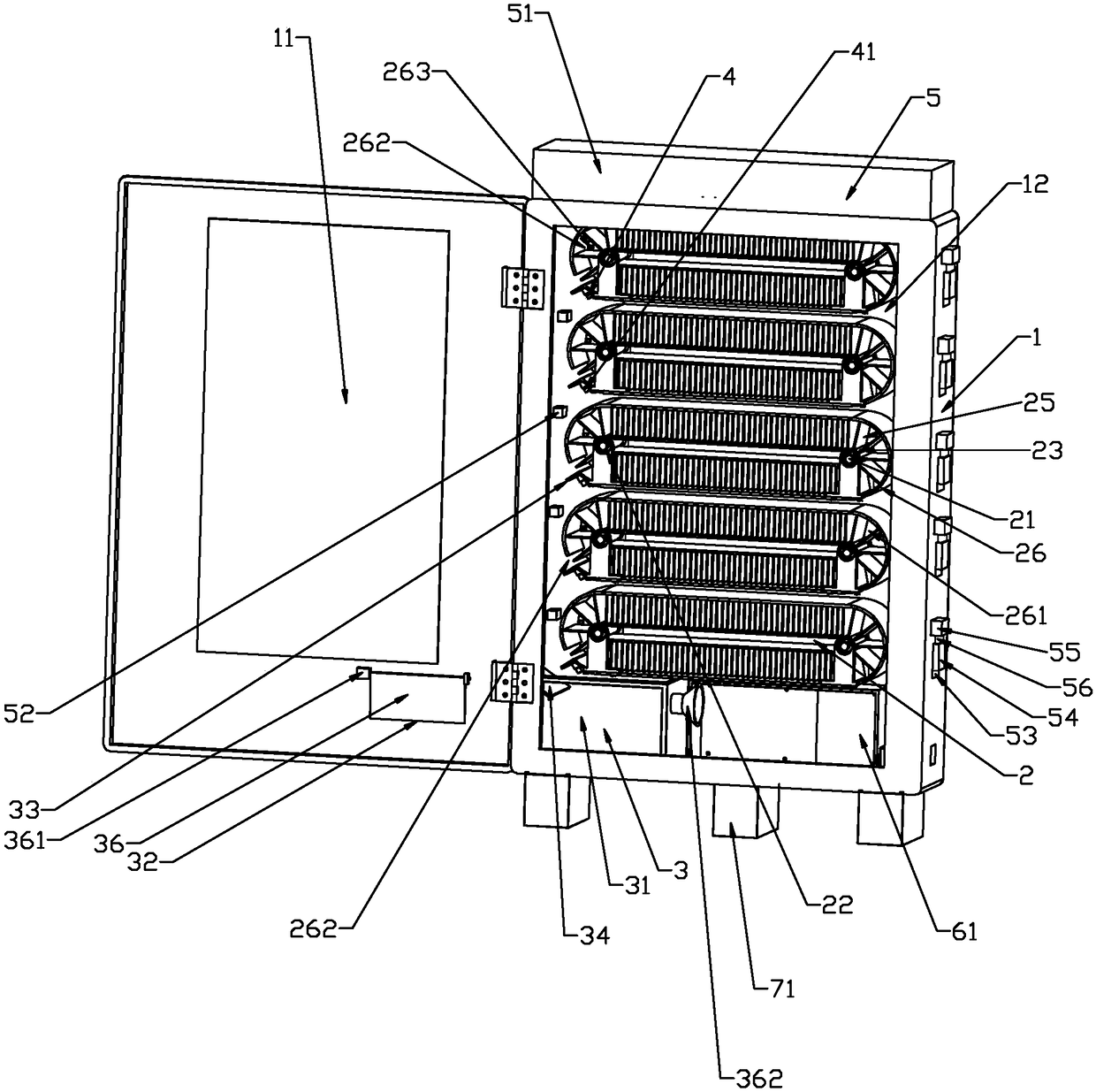

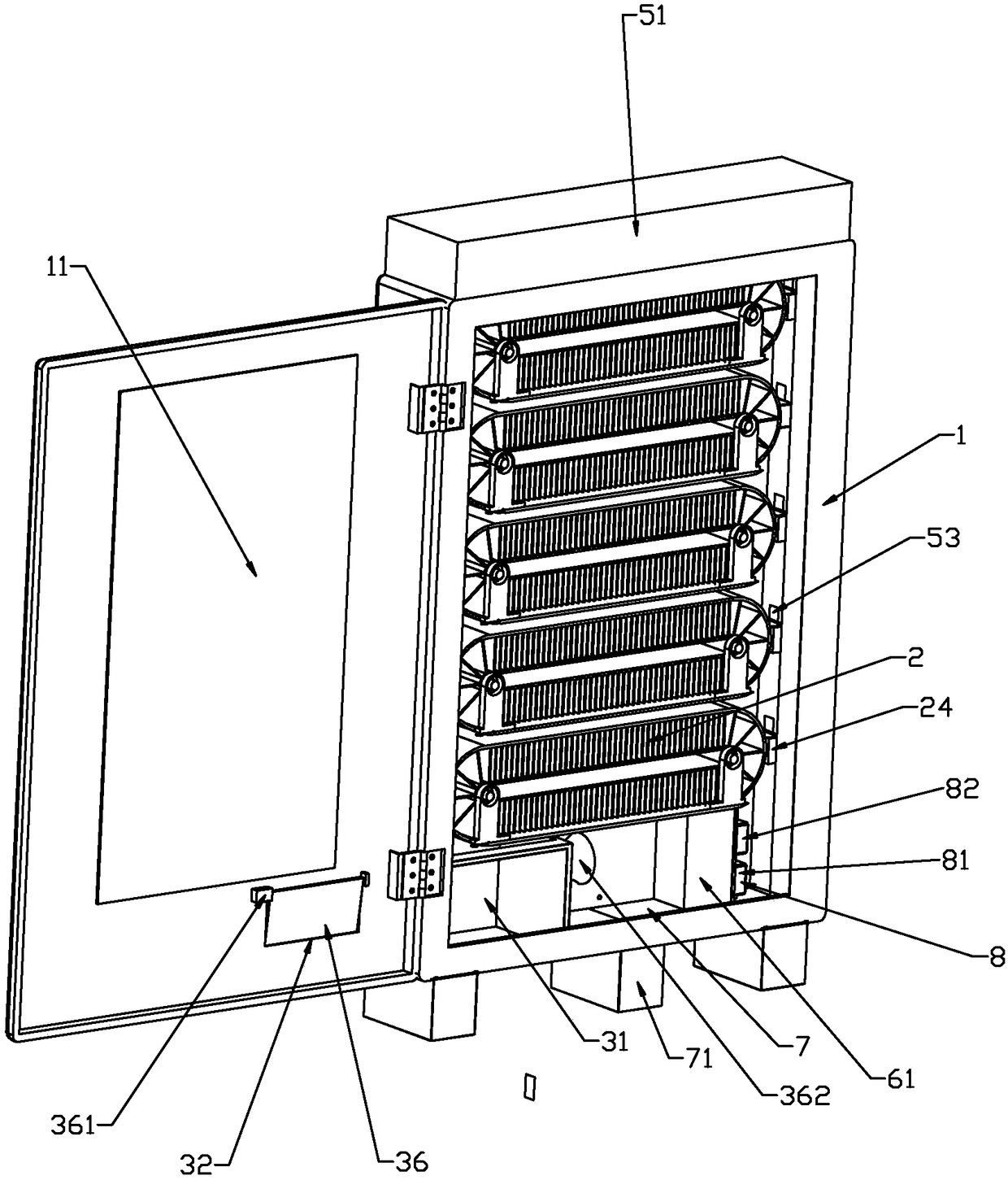

Vending machine and management method thereof

InactiveCN108986310AImprove replenishment efficiencyImplement auto-replenishmentCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringCommunication device

The invention provides a vending machine and a management method thereof. The vending machine comprises a cabinet, shelves, image acquirers, a control device, a door, a door sensor and a communicationdevice. At least one shelf is arranged in the cabinet, each shelf comprises a plurality of rows of movable goods passages, and each row of the goods passage is provided with a plurality of goods placement positions and a driving device for driving the corresponding goods passage to move goods towards the door. The door sensor is connected with the control device and used for detecting opening andclosing of the door. The control device is connected with the driving device, the communication device and the image acquirers, the image acquirers are arranged corresponding to the shelves and connected with the communication device, and the image acquirers are used for acquiring image information of the corresponding shelves and uploading the image information to a server through the communication device. The management method is applied to the vending machine. By the vending machine and the management method thereof, replenishing efficiency of goods in the first row of the shelves is improved.

Owner:HEFEI MIDEA INTELLIGENT TECH CO LTD

Intelligent temperature control antitheft self-service sauce selling machine

PendingCN108510650AEasy to storeAdd flavorCoin-freed apparatus detailsApparatus for dispensing discrete articlesTemperature controlData acquisition

The invention relates to an intelligent temperature control antitheft self-service sauce selling machine which comprises a cabinet, goods path devices, a discharge device, a statistic device and a temperature control device, wherein a containing chamber is arranged in the cabinet, the goods path devices are used for pushing sauce bags independently, the discharge device receives the sauce bags pushed by the goods path device so as to be taken out by purchasers, the statistic device is used for performing statistics on the sales quantity of different sauce bags located in different goods path devices, and the temperature control device is used for providing different preservation temperatures for different sauce bags located in different goods path devices. By adopting the above scheme, theinvention provides the intelligent temperature control antitheft self-service sauce selling machine which can automatically sell sauces, and perform control and data collection on the preservation temperature of various sauces reasonably so as to guide the sauce preparation quantity.

Owner:WENZHOU UNIVERSITY

Material box scheduling method and device, scheduling equipment, warehousing system and storage medium

ActiveCN113978993AImprove replenishment efficiencyImplement auto-replenishmentControl devices for conveyorsResourcesParallel computingEngineering

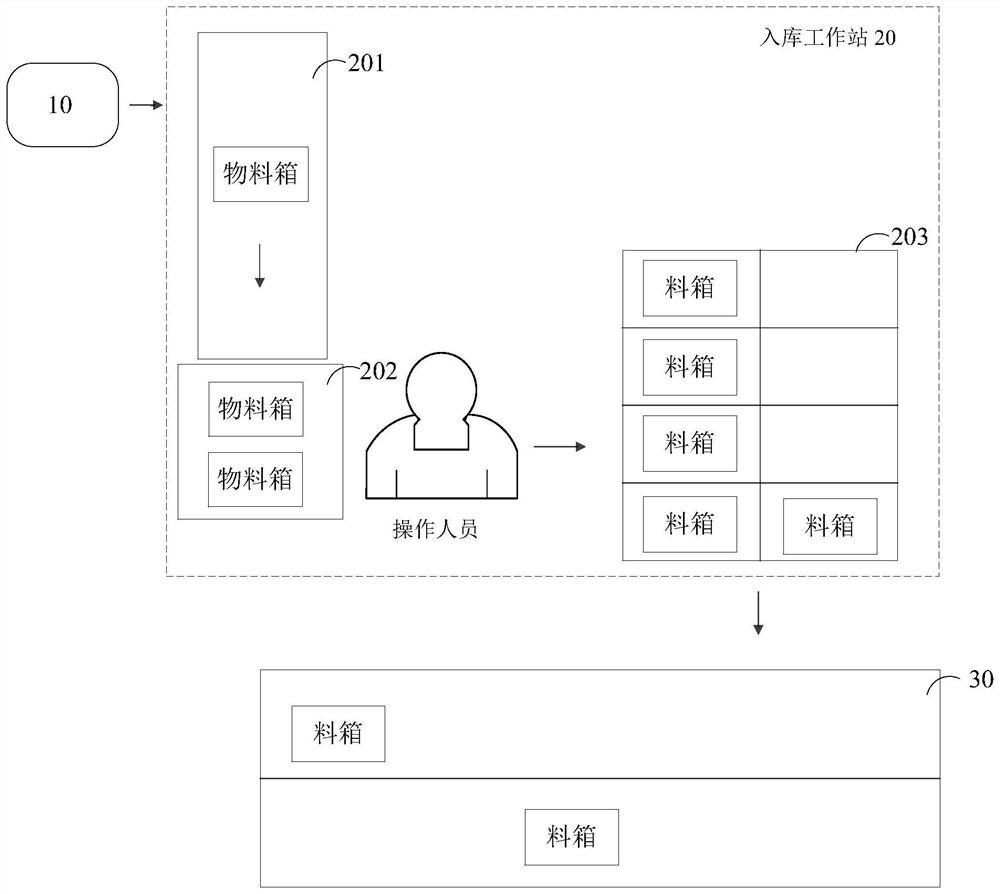

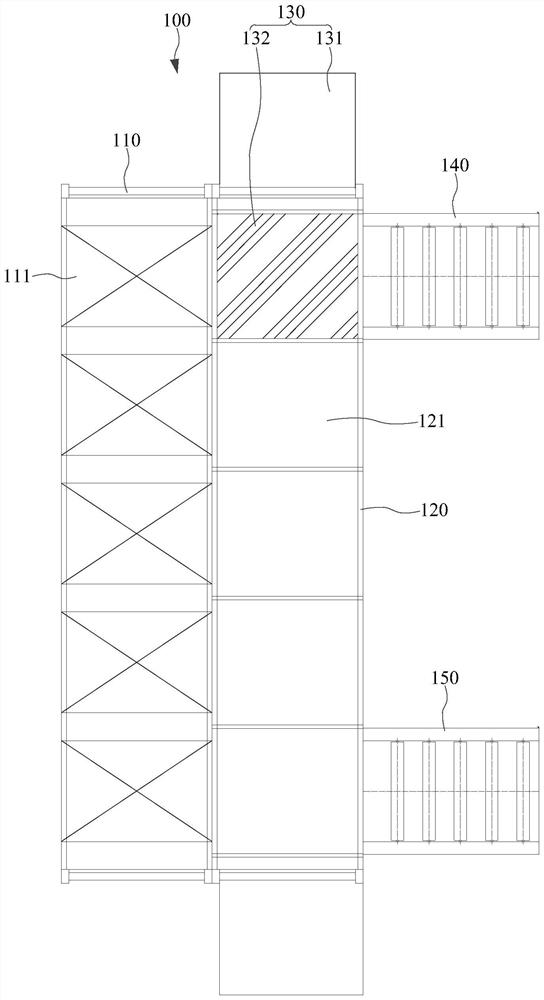

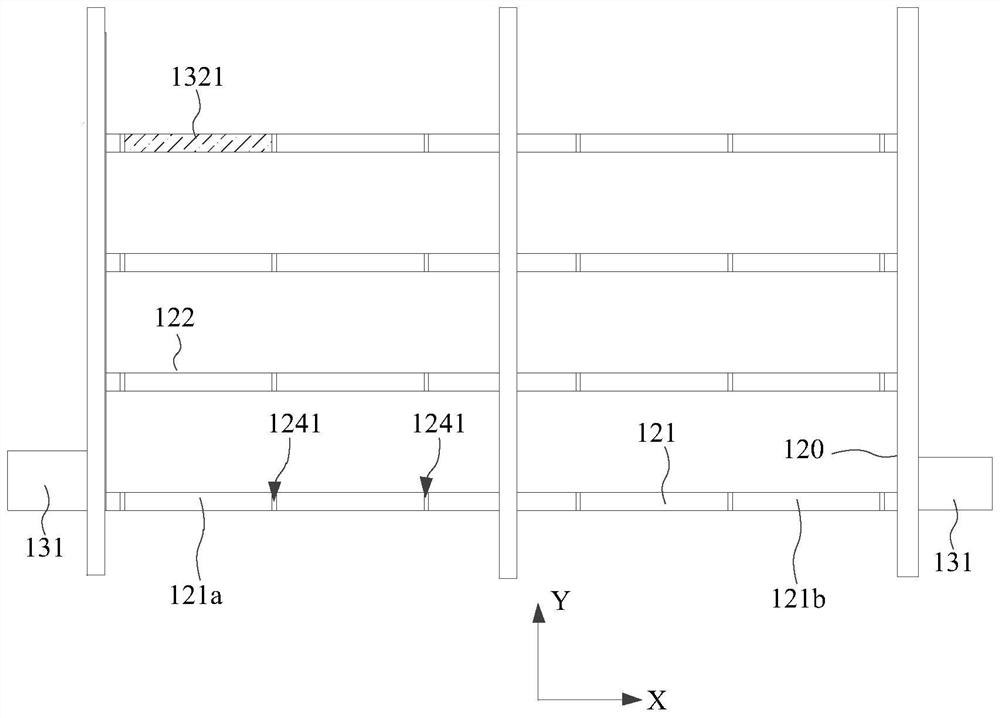

The embodiment of the invention provides a material box scheduling method and device, scheduling equipment, a warehousing system and a storage medium, and the material box scheduling method comprises the steps: obtaining the number of cache positions above a cache goods shelf of a warehousing work station when a to-be-warehoused material box exists on the cache goods shelf of the warehousing work station; according to the number of the empty cache positions and the storage positions corresponding to the to-be-stored material boxes, carrying instructions of one or more target robots are generated so as to control the one or more target robots to carry the to-be-stored material boxes to the corresponding storage positions from the cache positions where the to-be-stored material boxes are located, and carry at least one empty material box to the empty cache position or the cache position corresponding to the to-be-stored material box, wherein the storage position is an empty storage position located on a storage goods shelf of the warehouse, parallel scheduling of the to-be-stored material box and the empty material box is achieved, and the supplementing efficiency of the empty material box and the warehousing order processing efficiency are improved.

Owner:SHENZHEN KUBO SOFTWARE CO LTD +1

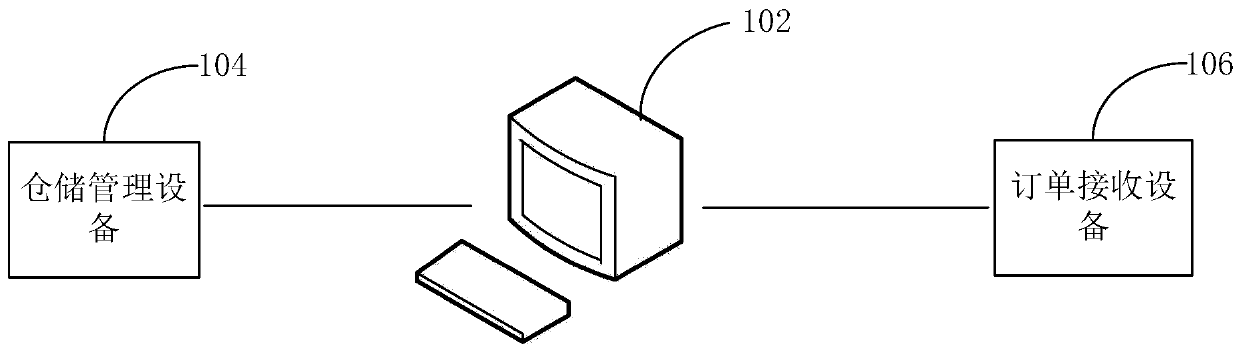

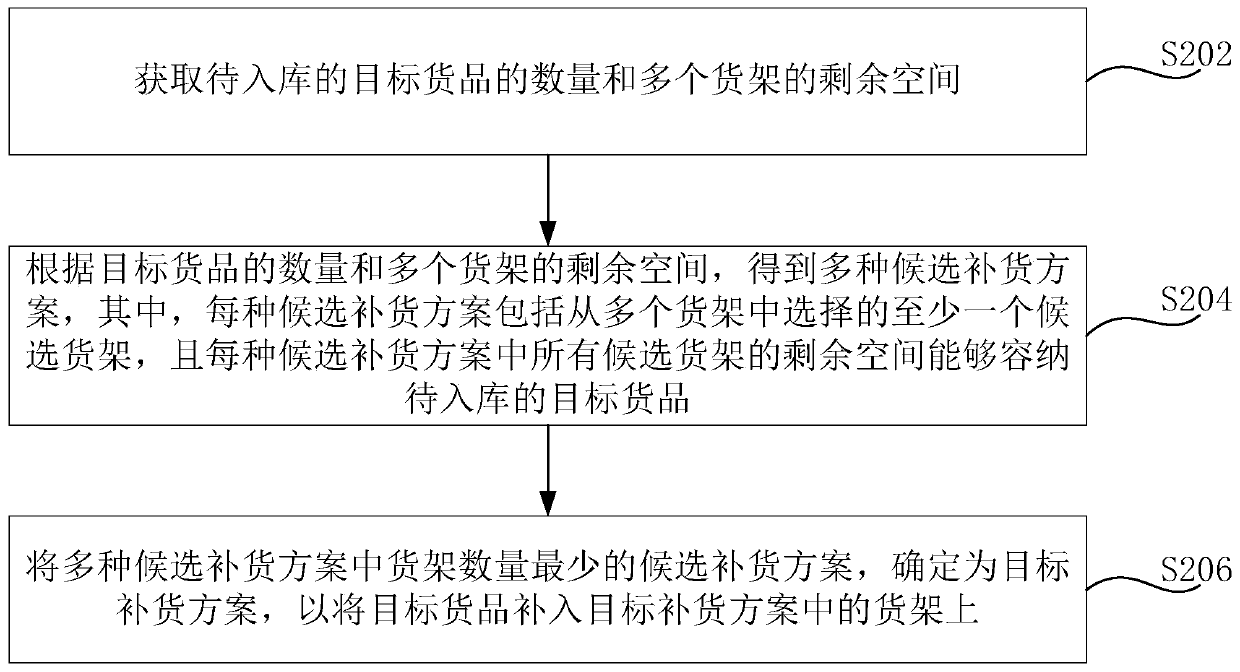

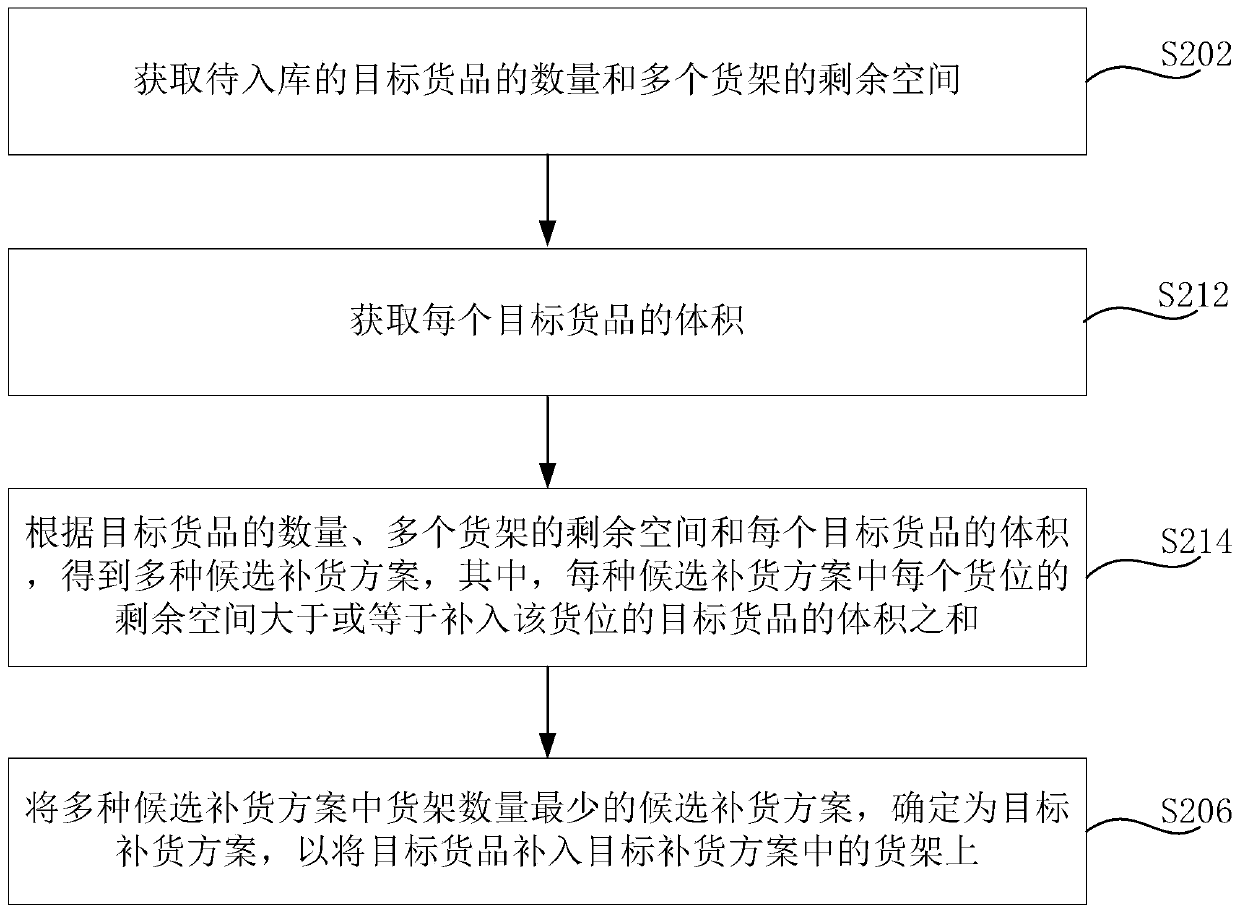

Goods warehousing processing method and device, warehousing system and computer equipment

The invention relates to a goods warehousing processing method and a device, a warehousing system, computer equipment and a computer readable storage medium. The method comprises the steps that the number of to-be-warehoused target goods and the remaining space of multiple shelves are acquired; multiple candidate replenishment schemes are obtained according to the number of the target goods and the remaining space of the multiple shelves, each candidate replenishment scheme comprises at least one candidate shelf selected from the multiple shelves, and the remaining space of all the candidate shelves in each candidate replenishment scheme can contain the target goods to be warehoused; and the candidate replenishment scheme with the least number of shelves in the plurality of candidate replenishment schemes is determined as a target replenishment scheme. According to the method, the number of the target goods to be warehoused and the remaining spaces of the multiple goods shelves are taken as consideration factors at the same time, and the number of the goods shelves required to be replenished with the goods is minimum, so that the finally formulated replenishment scheme is more suitable for an actual production scene, and the replenishment efficiency can be effectively improved by reducing the number of the goods shelves required for replenishment.

Owner:BEIJING KUANGSHI ROBOTICS TECH CO LTD

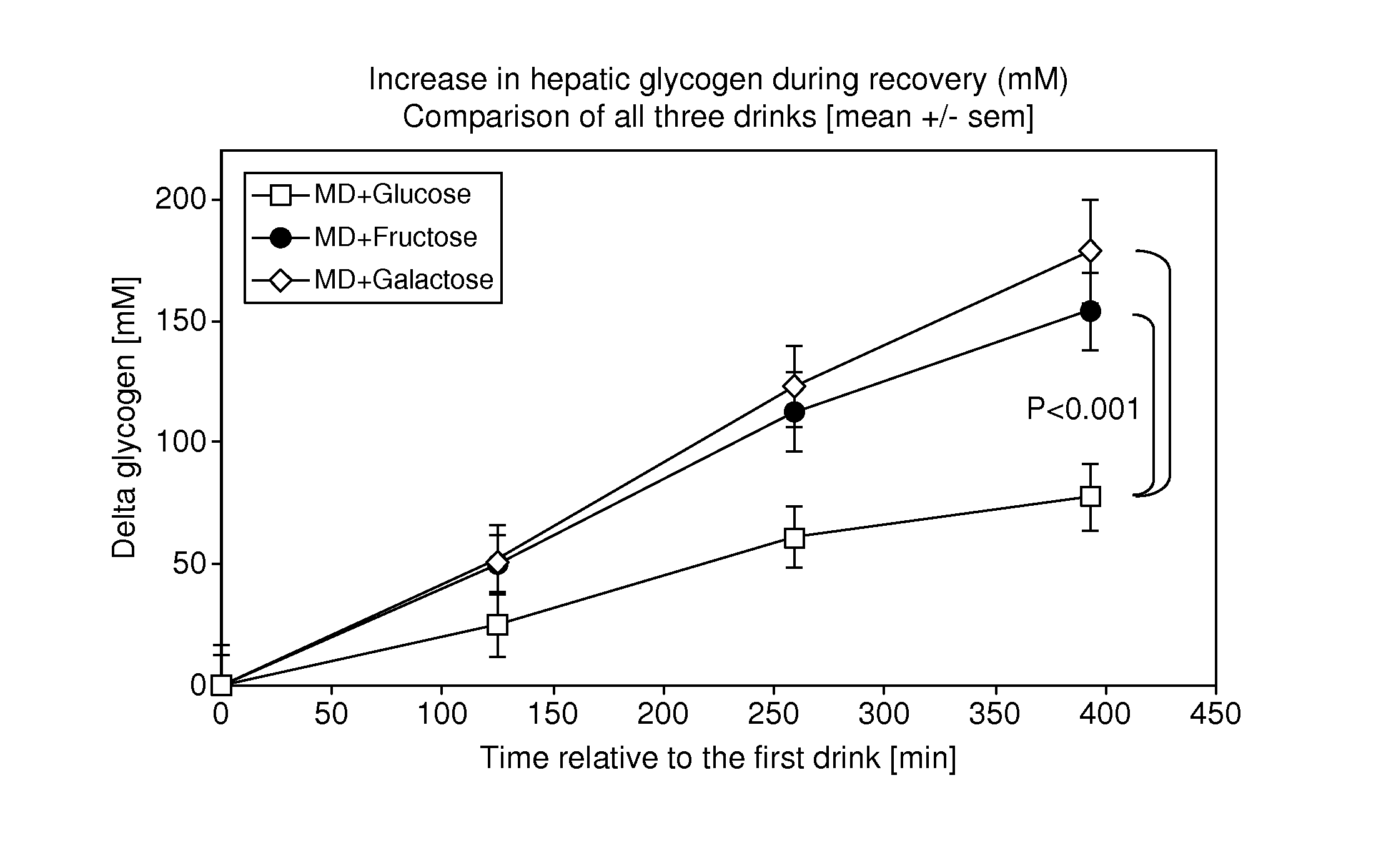

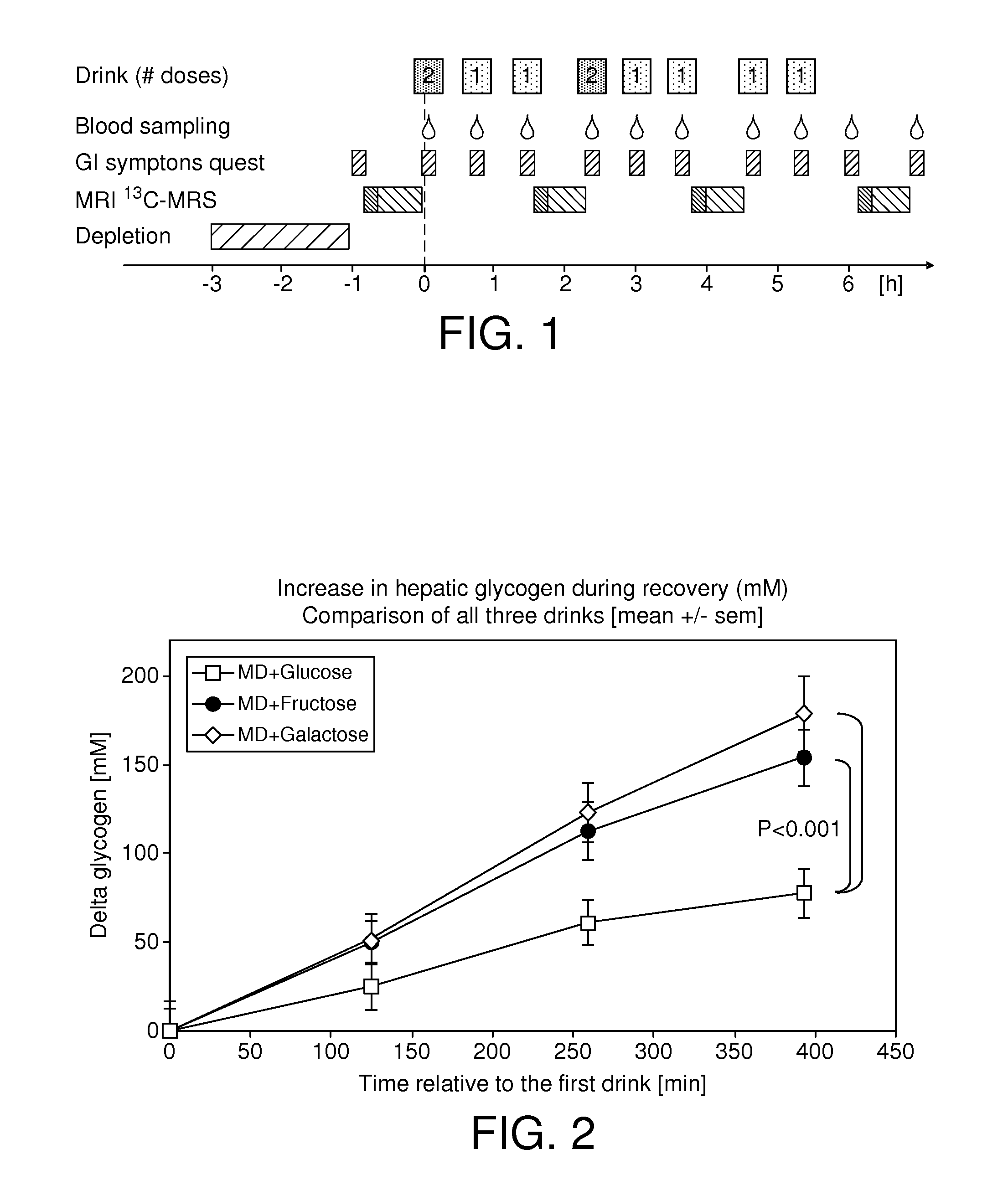

Liver glycogen synthesis

InactiveUS20110278878A1Effectively synthesizeFacilitate absorptionSugar food ingredientsMetabolism disorderSports nutritionBiology

This invention relates to a food product or beverage, in particular for the use in sports nutrition for replenishment of shortage in glycogen stored in the liver. In particular the invention relates to a use of a food product or beverage comprising a combination of carbohydrates for replenishment of shortage in glycogen stored in the liver.

Owner:PREMIER NUTRITION

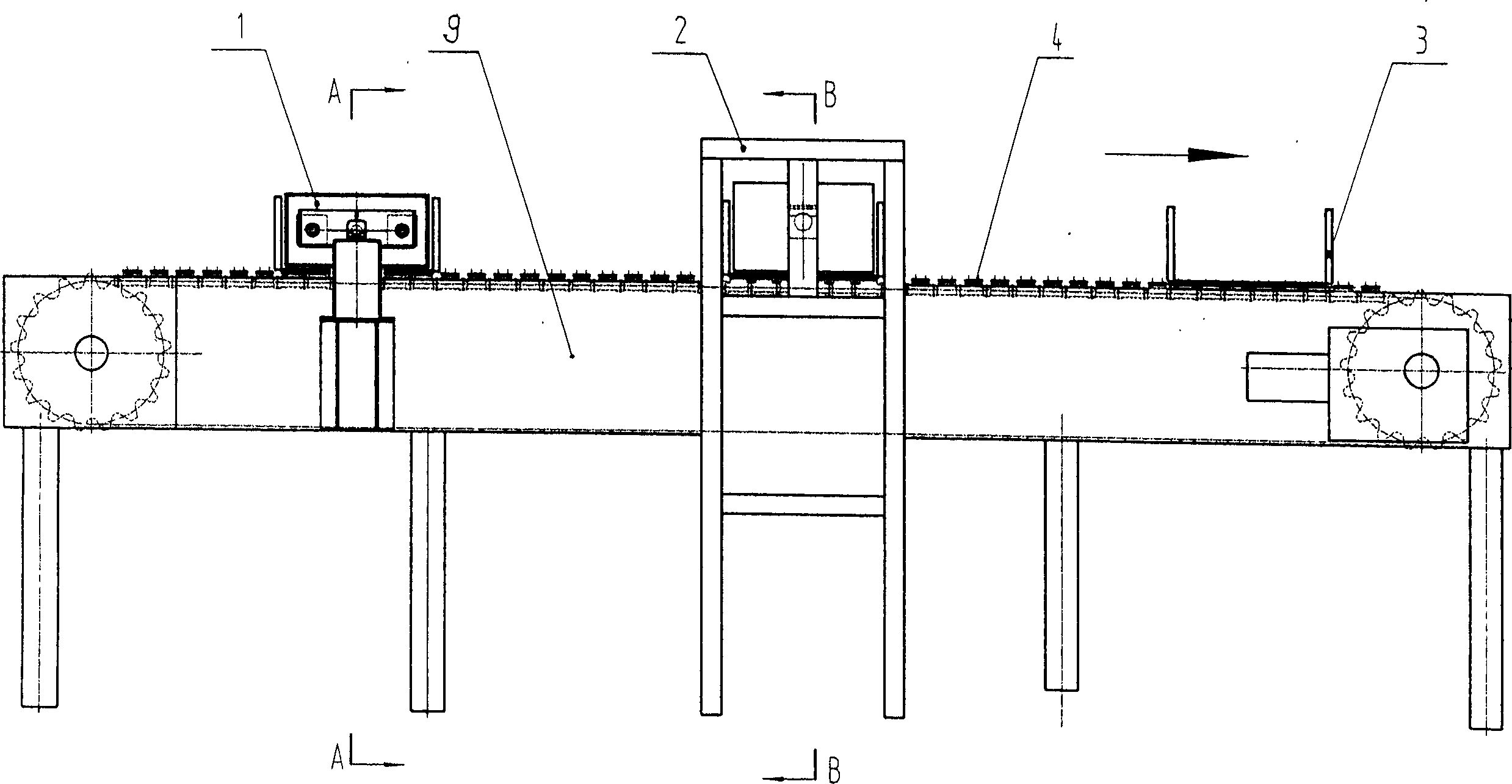

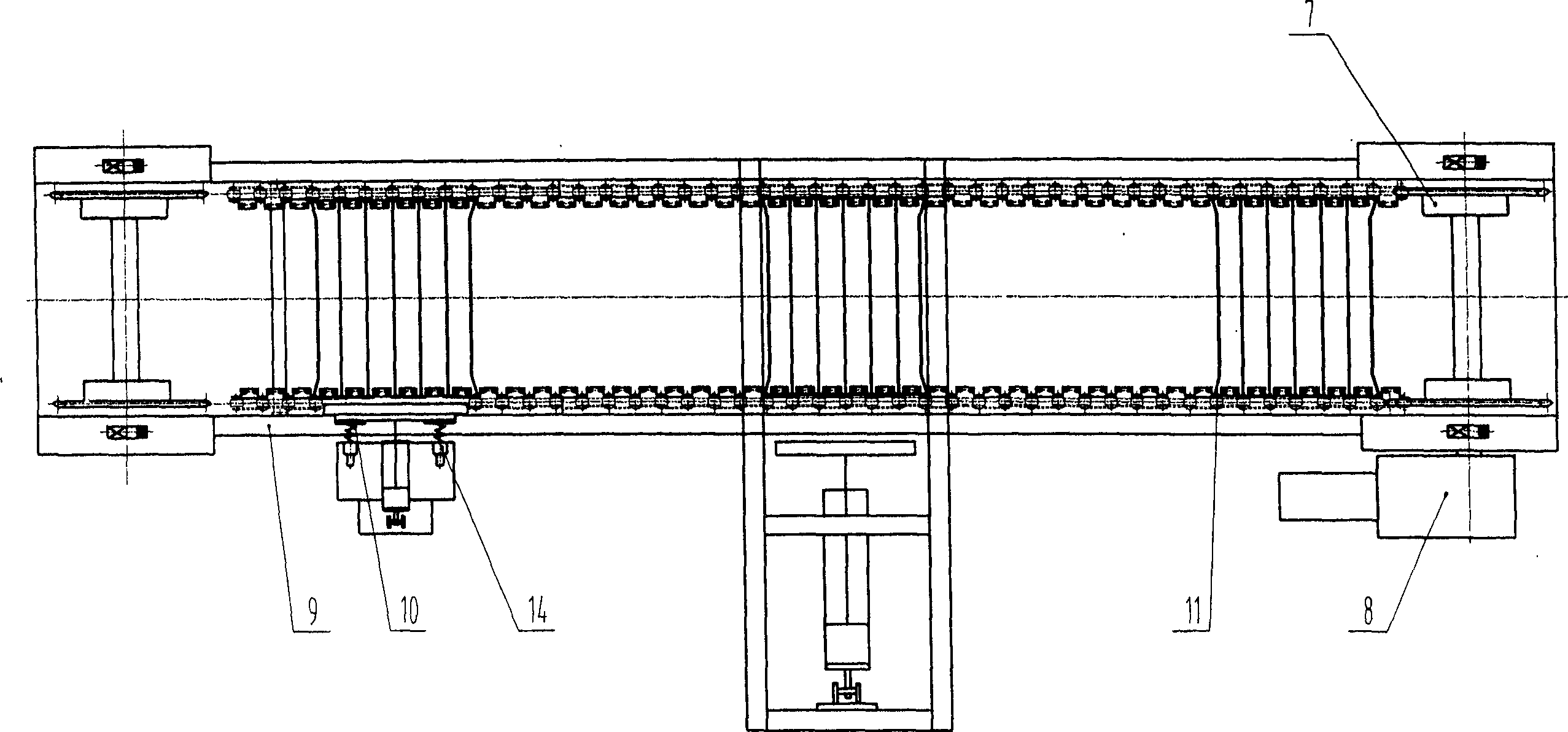

Automatic dispense system of randomly assembled sorting unit

ActiveCN1803320AImprove replenishment efficiencyEasy replenishmentDe-stacking articlesSortingDistribution systemEngineering

The invention discloses a self-distribution system to combine and pickup unit randomly, which consists of upstream distribution device and downstream interflow device along the material conveying line, wherein the distribution device contains pile-shaped material conveying structure (1) and distribution structure (2) in the output end of conveyer; the interflow device connects the output end of distribution structure, which contains distribution material conveying structure (3) and dialing structure (4) on the conveying structure. The invention can pick up and dispense random quantity of bar-shaped material, which replaces the worker to lessen the working strength greatly.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

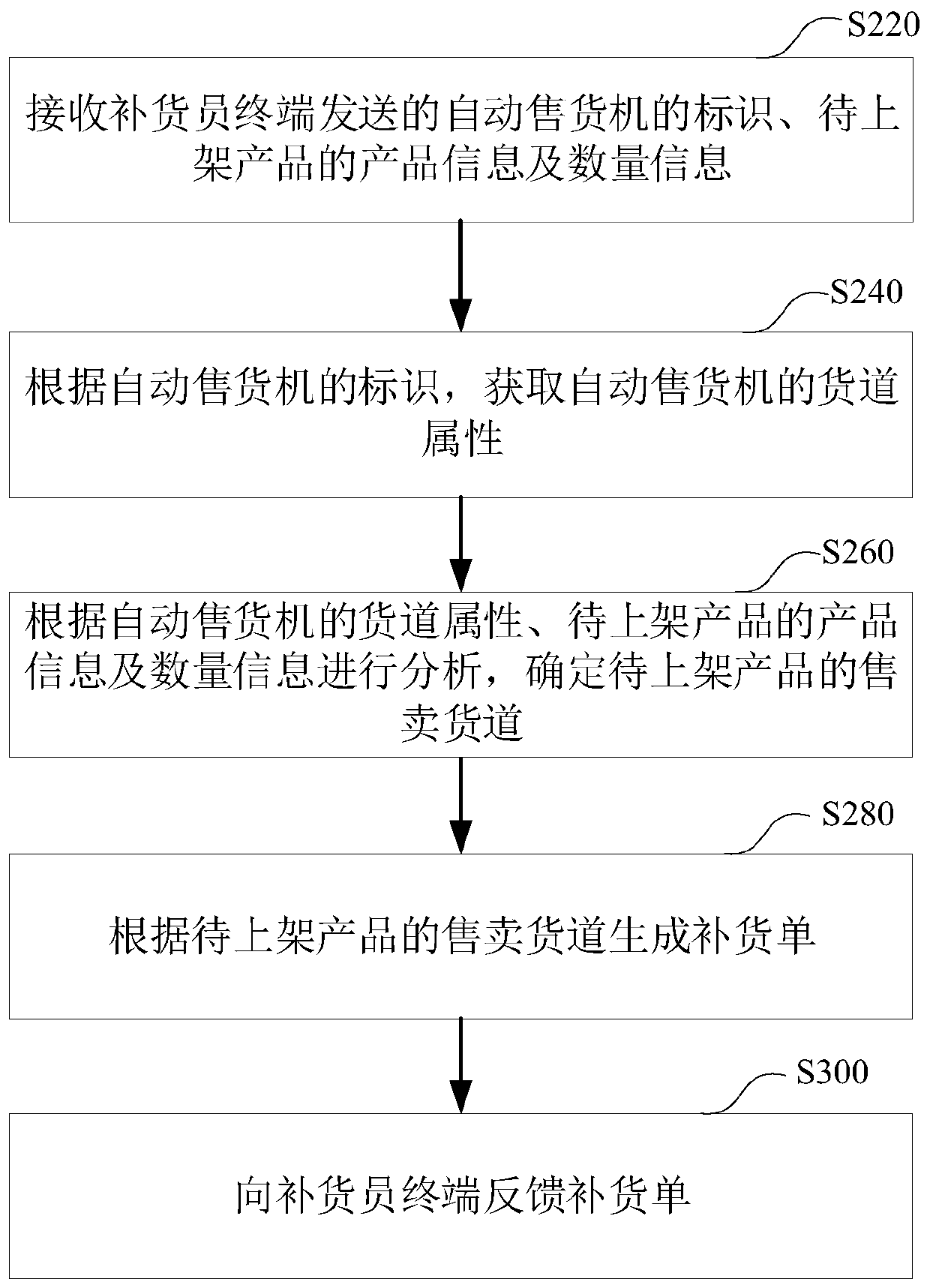

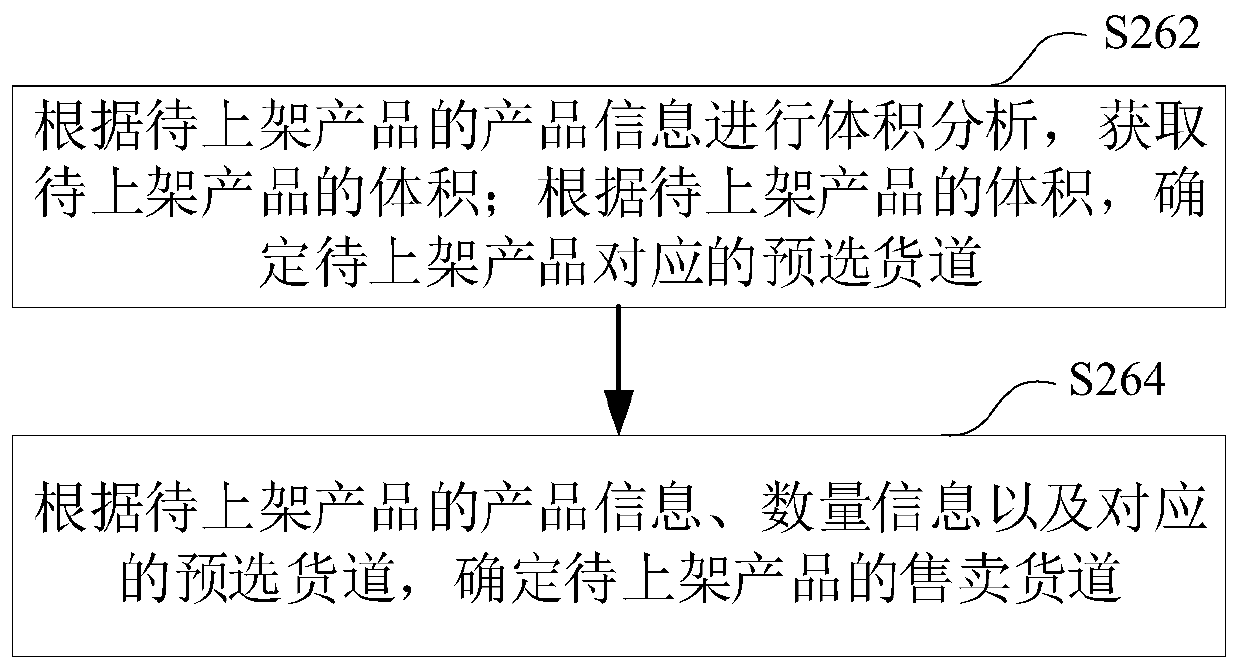

Vending machine replenishment method and device, computer equipment and storage medium

PendingCN111062665AImprove replenishment efficiencyCoin-freed apparatus detailsLogisticsMachineDatabase

The invention relates to a vending machine replenishment method and device, computer equipment and a storage medium. The method comprises the steps of receiving an identifier of a vending machine andproduct information and quantity information of to-be-shelved products sent by a replenisher terminal; according to the identifier of the vending machine, obtaining a goods channel attribute of the vending machine; performing analyzing according to the goods channel attribute of the vending machine and the product information and the quantity information of the to-be-shelved products, and determining a selling goods channel of the to-be-shelved products; generating a replenishment list according to the selling goods channel of the to-be-put-on-shelf product; and feeding back the replenishmentlist to the replenisher terminal. By adopting the method, the replenisher only needs to replenish according to the replenishment list generated by the server, and the replenishment efficiency is improved.

Owner:中鑫汇金(广州)科技有限公司

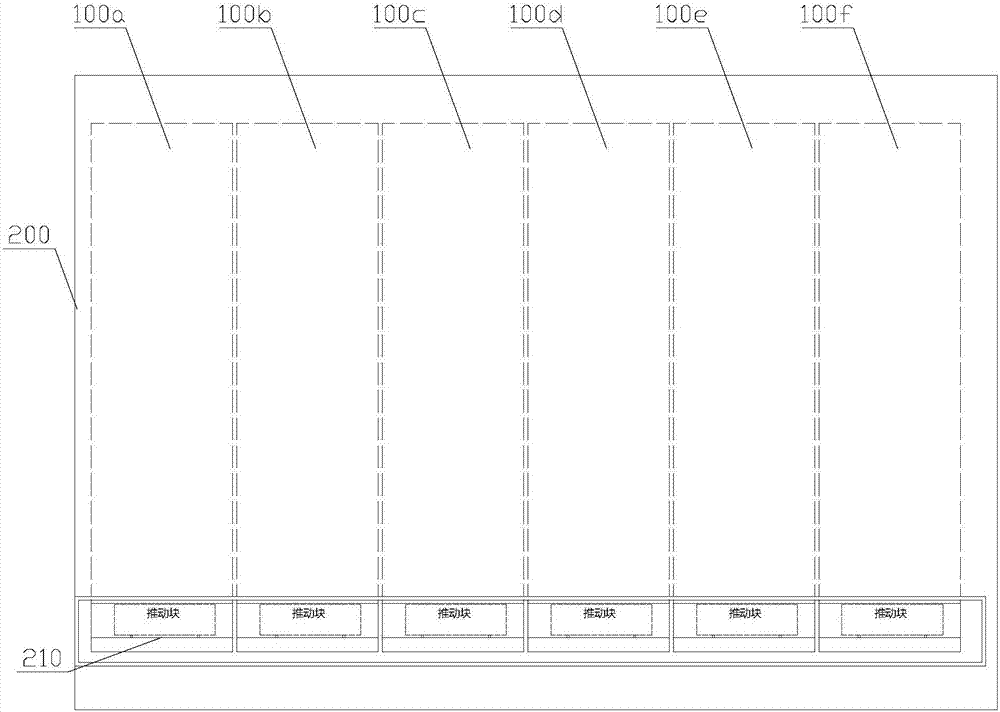

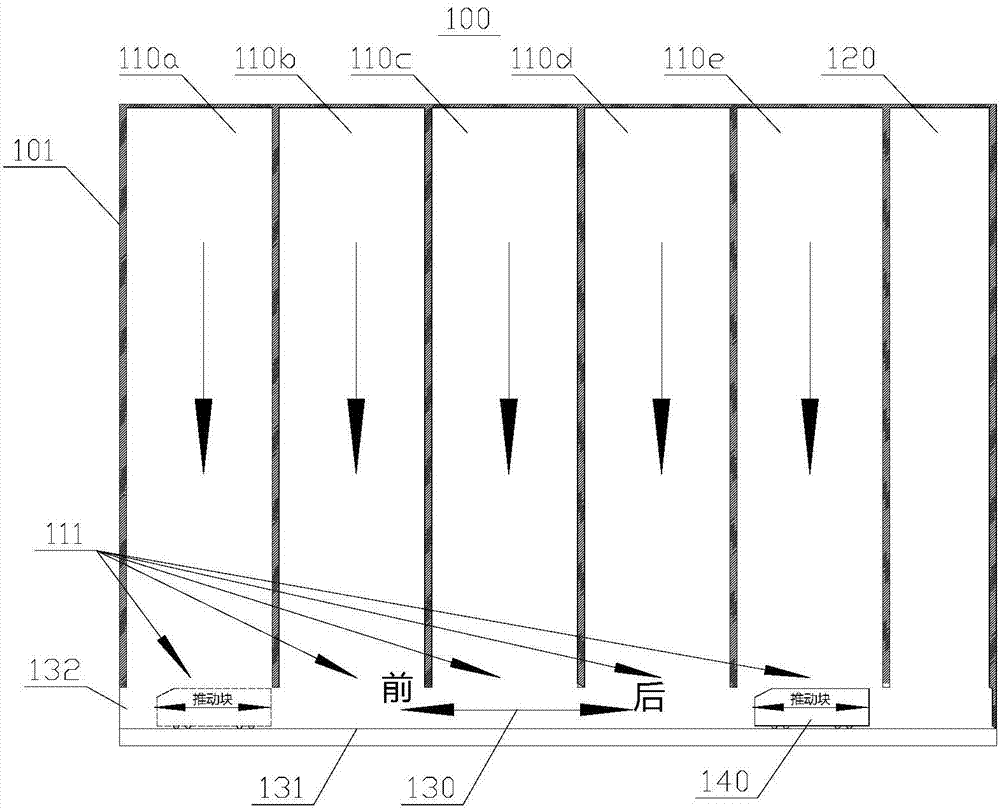

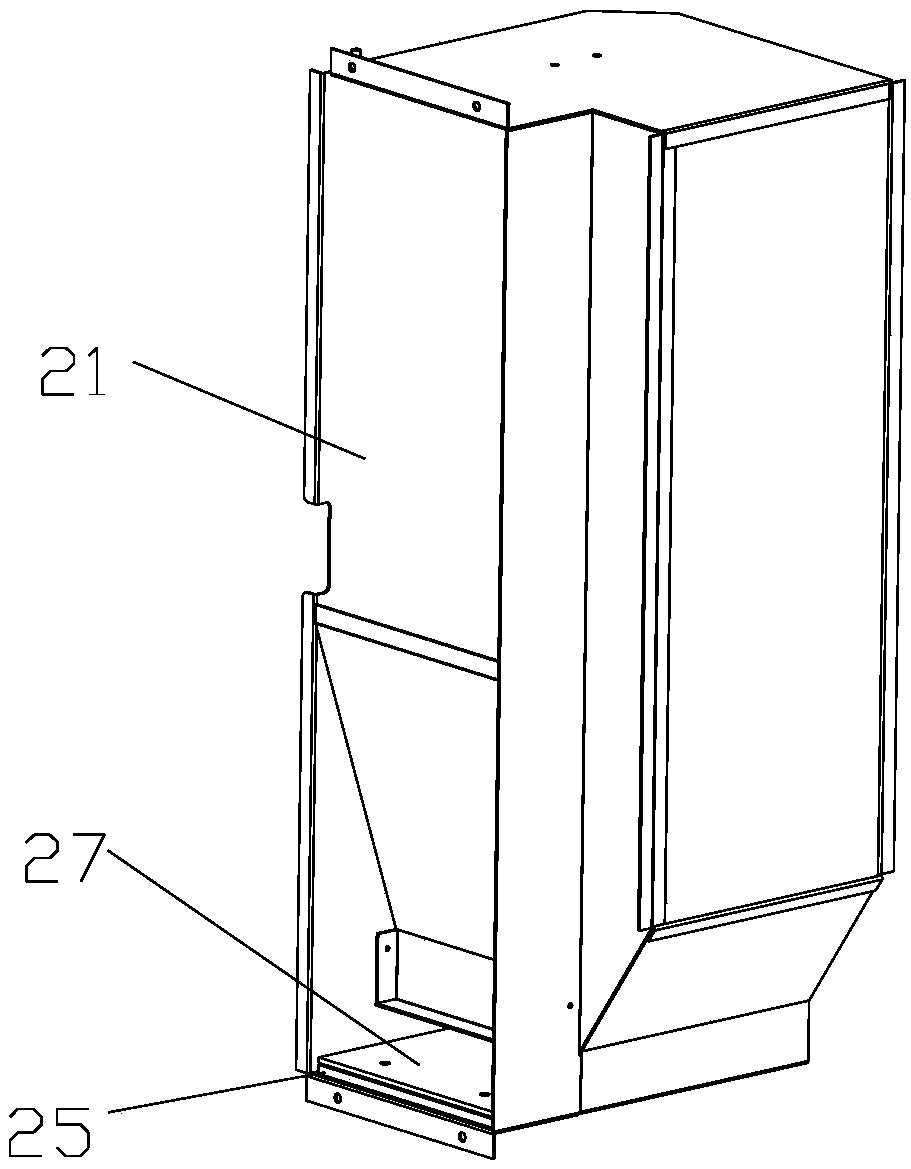

Vending machine and automatic goods discharging device

PendingCN107886630AImprove adaptabilityImprove replenishment efficiencyCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringMechanical engineering

The automatic vending machine and its automatic delivery device provided by the present invention include a housing, a push block and a controller; a delivery channel and a plurality of storage channels are formed in the housing; the delivery channel has a moving The track surface; the storage channel is used to store goods, and corresponds to one of the delivery channels; the controller controls the push block to reciprocate along the moving track surface; in the direction perpendicular to the moving track surface, the The distance between the storage outlet and the moving track surface is greater than the maximum size of the pushing block. The automatic delivery device can prevent the goods from being dropped or damaged from a high place, and improve the adaptability of the vending machine; it does not need to be filled at the vending machine site, which can improve the efficiency of replenishment; it does not need to set up a lot from bottom to top The driving device can make full use of the space in the casing and reduce the manufacturing cost of the automatic vending machine.

Owner:上海跃众文化传媒有限公司

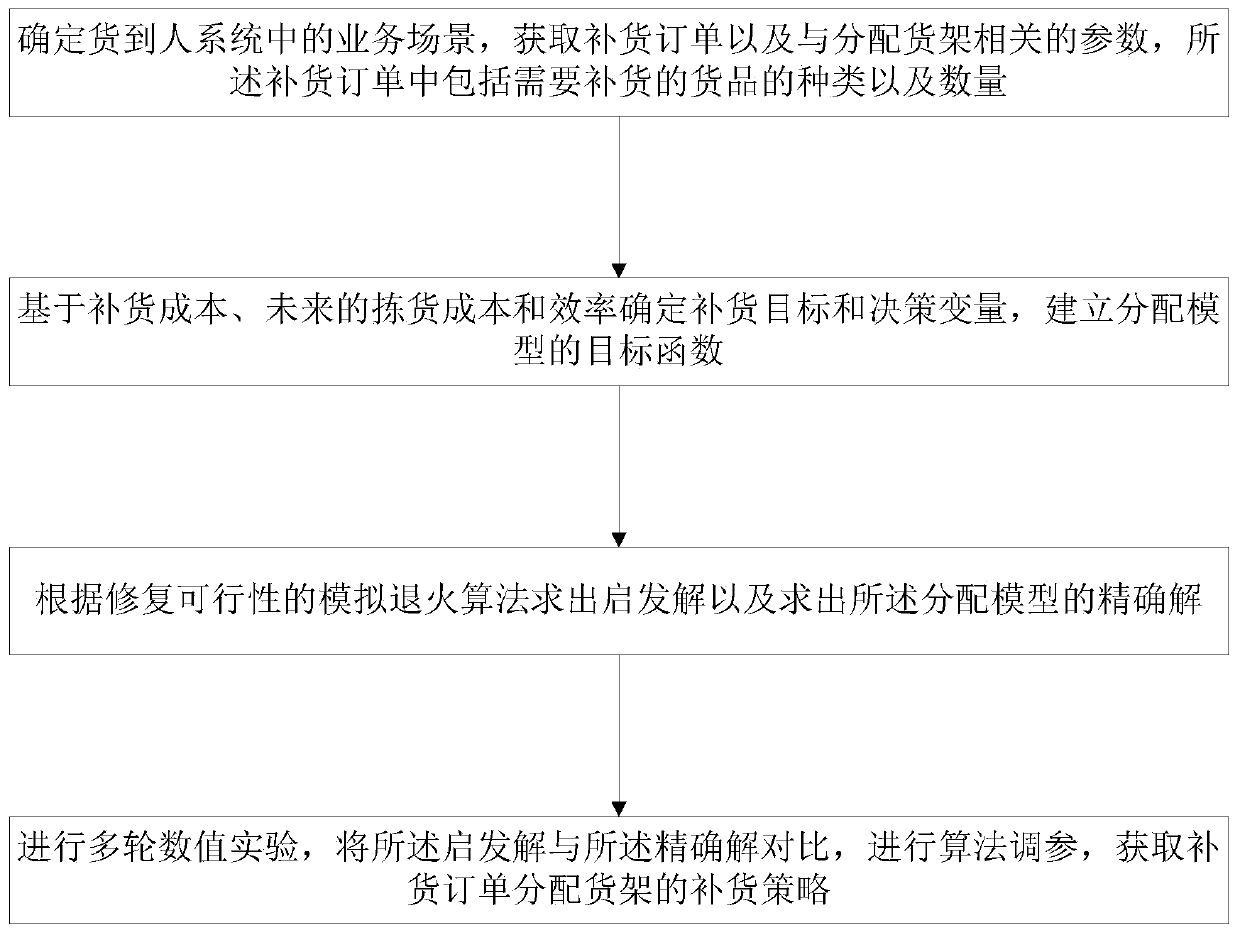

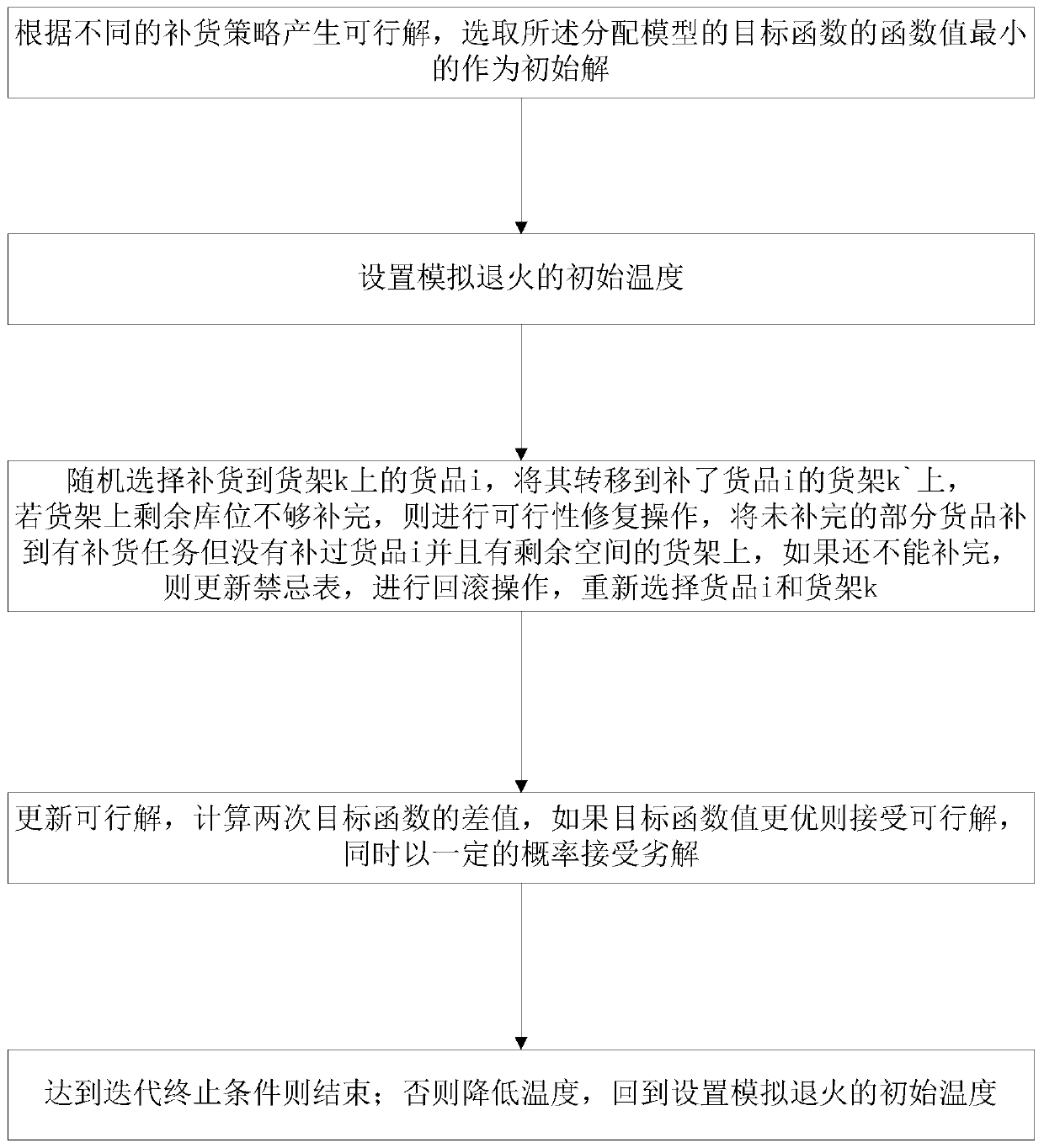

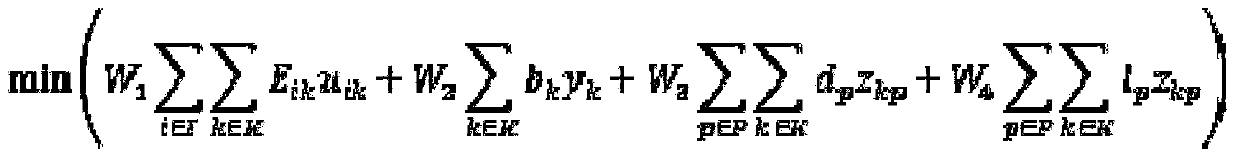

Method for allocating shelves according to replenishment orders and computer readable storage medium

PendingCN111582781AImprove replenishment and picking efficiencyReduce work costsForecastingLogisticsOperations researchIndustrial engineering

The invention provides a method for allocating shelves according to replenishment orders and a computer readable storage medium, and the method comprises the steps: determining a business scene in a cargo-to-man system, obtaining the replenishment orders and parameters related to the allocation shelves, and the replenishment orders comprising the types and number of cargos needing replenishment; determining a replenishment target and a decision variable based on the replenishment cost and the future order picking cost and efficiency, and establishing a target function of a distribution model;solving a heuristic solution and solving an accurate solution of the allocation model according to a simulated annealing algorithm of repair feasibility; and performing multiple rounds of numerical experiments, comparing the heuristic solution with the accurate solution, and performing algorithm parameter adjustment to obtain a replenishment strategy of a replenishment order allocation shelf. By comprehensively considering the replenishment efficiency and the efficiency of the future picking process, the objective function of the model is established and solved, accurate mathematical guidanceis provided for replenishment decision making, and the working cost is reduced while the replenishment efficiency and the picking efficiency are improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

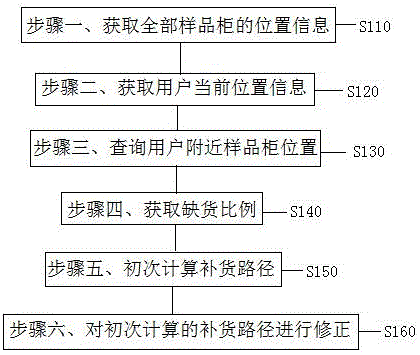

Method for quickly searching surrounding sample cabinet and carrying out replenishment

InactiveCN106560851APrecise positioningGood replenishment pathLocation information based serviceLogisticsStockoutComputer science

The invention discloses a method for quickly searching a surrounding sample cabinet and carrying out replenishment, and the method comprises the following steps: 1, enabling a background server to obtain the position information of all sample cabinets; 2, enabling the background server to obtain the current position information of a maintainer; 3, carrying out the query of the position of a sample cabinet nearby a user; 4, enabling each sample cabinet to transmit a stockout proportion of the sample cabinet to the background server, wherein the a stockout proportion is the ratio of the number of samples obtained by the user to the number of samples when the cabinet is full of samples; 5, calculating a replenishment path for the first time; 6, correcting the calculated replenishment path. The method carries out the correction of the initial replenishment path through calculating the initial replenishment path, obtains the optimal replenishment path, and improves the replenishment efficiency.

Owner:SHENZHEN YIHAOGUI TECH CO LTD

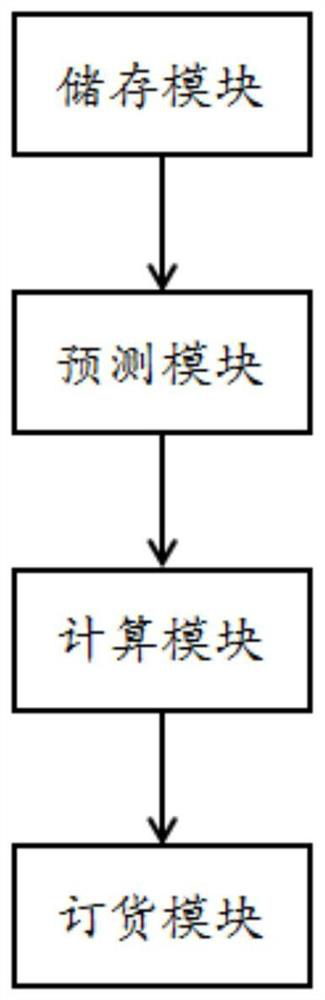

Automatic replenishment system for medical consumables

PendingCN113035340AImprove replenishment efficiencyLow costHealthcare resources and facilitiesLogisticsElectronic contractsPrediction probability

The invention relates to the technical field of medical consumable replenishment, in particular to an automatic replenishment system for medical consumables which comprises: a storage module used for generating a sample set composed of operation names and doctor names; a prediction module which is used for calculating the sample number of the medical consumables contained in each sample set and the total sample number of all the medical consumables contained in each sample set, and calculating consumable demand prediction probabilities corresponding to the operation names, the doctor names, the consumable types and the consumable specifications according to the number of the samples and the total number of the samples; a calculation module which is used for calculating the replenishment quantity of the consumables; and an ordering module which is used for generating an order set according to the online electronic contract and the consumable replenishment quantity, analyzing the dealer inventory according to the order set, and judging whether the dealer inventory meets the requirement or not, generating a delivery notification according to the shipable order, and sending the delivery notification to a dealer. The technical problem that in the prior art, the efficiency of automatic replenishment of medical consumables is low is solved.

Owner:贵州和瑞医疗科技有限公司

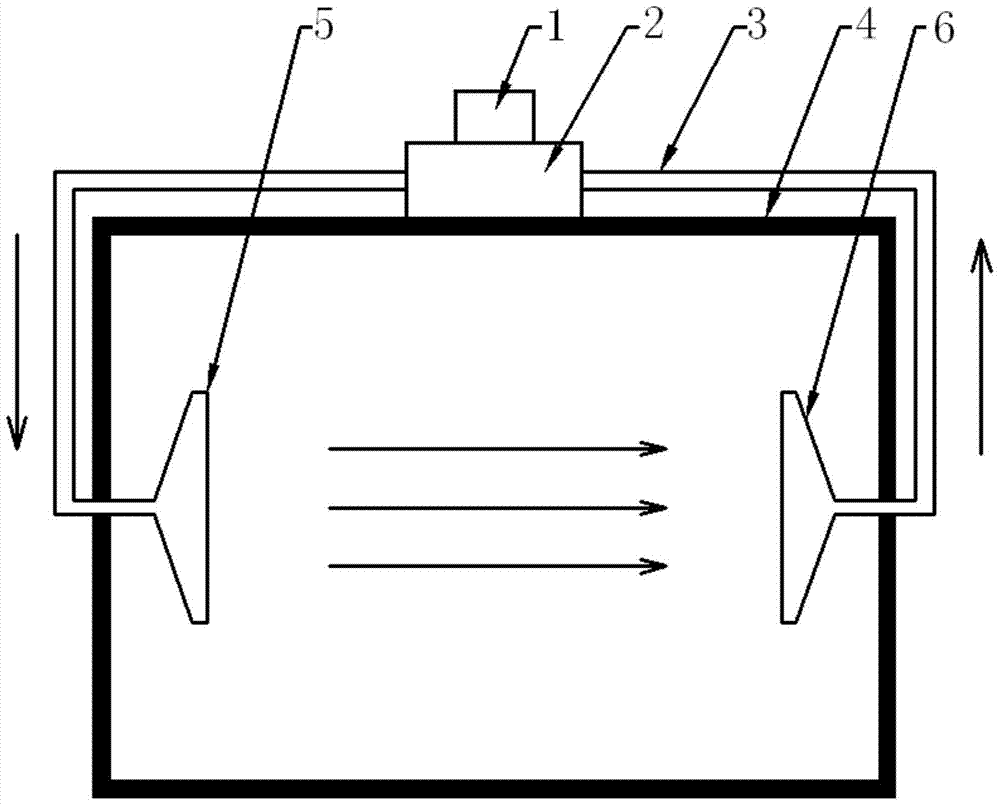

A high-speed light-curing 3D printing device and printing method

ActiveCN105014974BTroubleshoot sticking to glassImprove replenishment efficiencyManufacturing platforms/substrates3D object support structuresLiquid statePhysical chemistry

The invention discloses a high-speed light-curing 3D printing device and method, wherein the device includes a liquid pool filled with liquid photosensitive resin, a printing platform and an irradiation light source, and the bottom of the liquid pool is provided with a corresponding to the printing platform and the irradiation light source. A transparent plate, the side of the transparent plate facing the printing platform is covered with a transparent anti-adhesive coating; it also includes: a liquid outlet and a liquid inlet arranged on the side wall of the liquid pool; a pipeline connecting the liquid outlet and the liquid inlet; A drive unit is arranged on the pipeline for driving the liquid photosensitive resin to circulate between the liquid outlet, the liquid inlet and the pipeline. The invention avoids the problem that the cured photosensitive resin sticks to the glass plate caused by too fast laser irradiation by coating the transparent anti-adhesive coating on the curing window. There are pipes on both sides of the printing area to promote the flow of liquid photosensitive resin, which improves the fluidity of the photosensitive resin near the printing area, accelerates the replenishment of photosensitive resin, and realizes the rapid printing of SLA.

Owner:苏州永沁泉智能设备有限公司

Replenishment method, mobile terminal and replenishment system for automatic vending machine

InactiveCN109345695AIncrease shipping costsImprove replenishment efficiencyCoin-freed apparatus detailsApparatus for dispensing discrete articlesUltimate tensile strengthProcess design

The invention discloses a replenishment method, a mobile terminal, and a replenishment system for an automatic vending machine. The replenishment method for the automatic vending machine comprises thefollowing steps: step 1: associating the mobile terminal used for replenishment with a to-be-replenished automatic vending machine, wherein the associating method comprises: (1) associating based onan identification code; (2) associating based on a location; (3) associating based on a door opening state signal; step 2: the replenishment mobile terminal or an operator replenishes the associated automatic vending machine based on the replenishment data acquired by the replenishment mobile terminal, wherein the replenishment data is obtained from a server or directly obtained from the automaticvending machine associated in step 1. The replenishment method for the automatic vending machine has a reasonable process design, and can efficiently and rapidly replenish, which can significantly reduce the work intensity of a staff.

Owner:HUNAN KIMMA INTELLIGENT EQUIP MFR

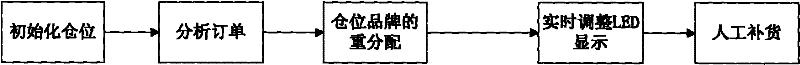

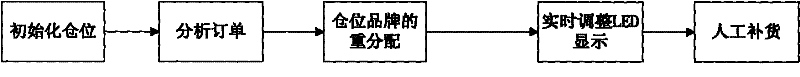

Freight space automatic display method used for sorting system

The invention discloses a freight space automatic display method used for a sorting system. The method comprises the following steps: carrying out freight space initialization according to an order brand composition, and displaying initial data through a freight space LED display screen; in a sorting process, carrying out freight brand redistribution according to real-time sorting condition of an order and rest orders; sending a freight brand distribution result in a database to an LED synchronic control card, and controlling corresponding freight space LED display screens to display. According to the freight space automatic display method used for a sorting system in the invention, in running state, sorting equipment changes and refreshes LED display screen information in real time according to the order composition and sorting state. Brand management of the equipment is more flexible and reasonable, and sorting speed and replenishment efficiency are raised.

Owner:姜新荣

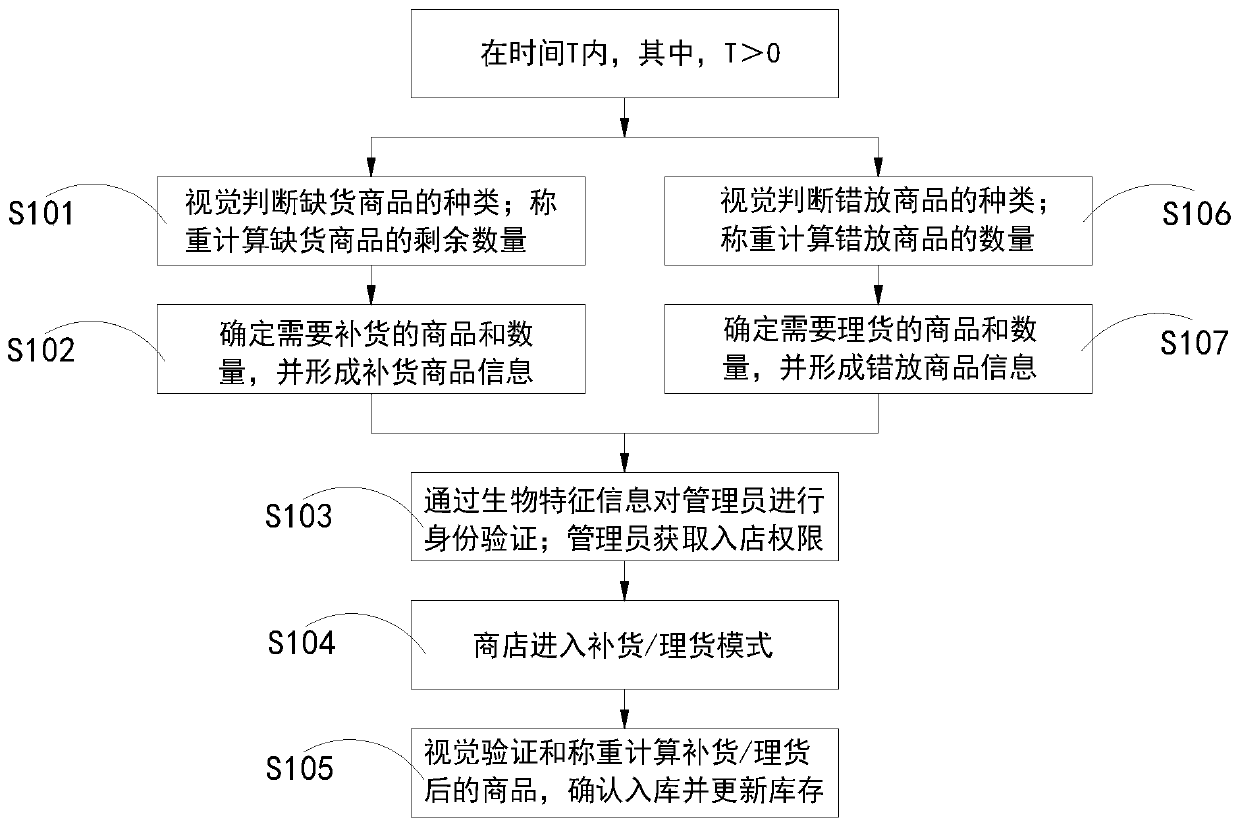

Replenishment method for unmanned store

PendingCN111539670ASolve the problem of manual replenishmentReduce labor costsCharacter and pattern recognitionBuying/selling/leasing transactionsStockoutIndustrial engineering

The invention provides a replenishment method for an unmanned store, and relates to the technical field of unmanned stores. The method comprises the following steps: visually judging the types of out-of-stock commodities in time T; weighing and calculating the residual quantity of the stockout commodities; wherein T is greater than 0; and determining commodities and the number of the commodities needing replenishment, and forming replenishment commodity information. According to the invention, visual judgment and weight change recognition are combined; according to the method, the commodity recognition speed can be improved, and the commodity recognition error can be greatly reduced, so that an administrator can obtain more accurate replenishment information, the replenishment work of theadministrator is more targeted, the replenishment efficiency of the administrator is improved to a greater extent, and a foundation is laid for intelligently solving the defects of an inventory end ofan unmanned store.

Owner:无锡创思感知科技有限公司

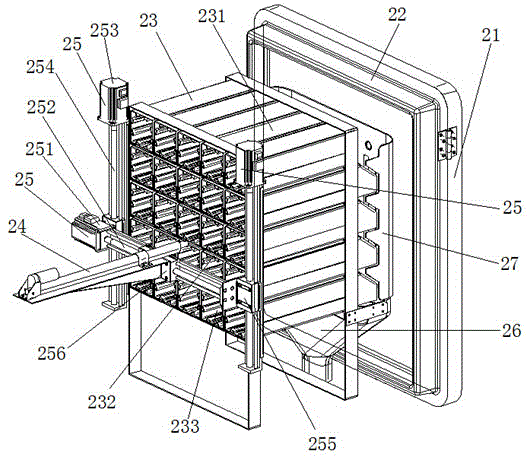

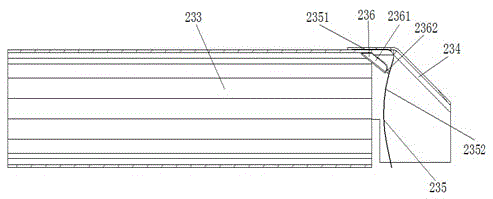

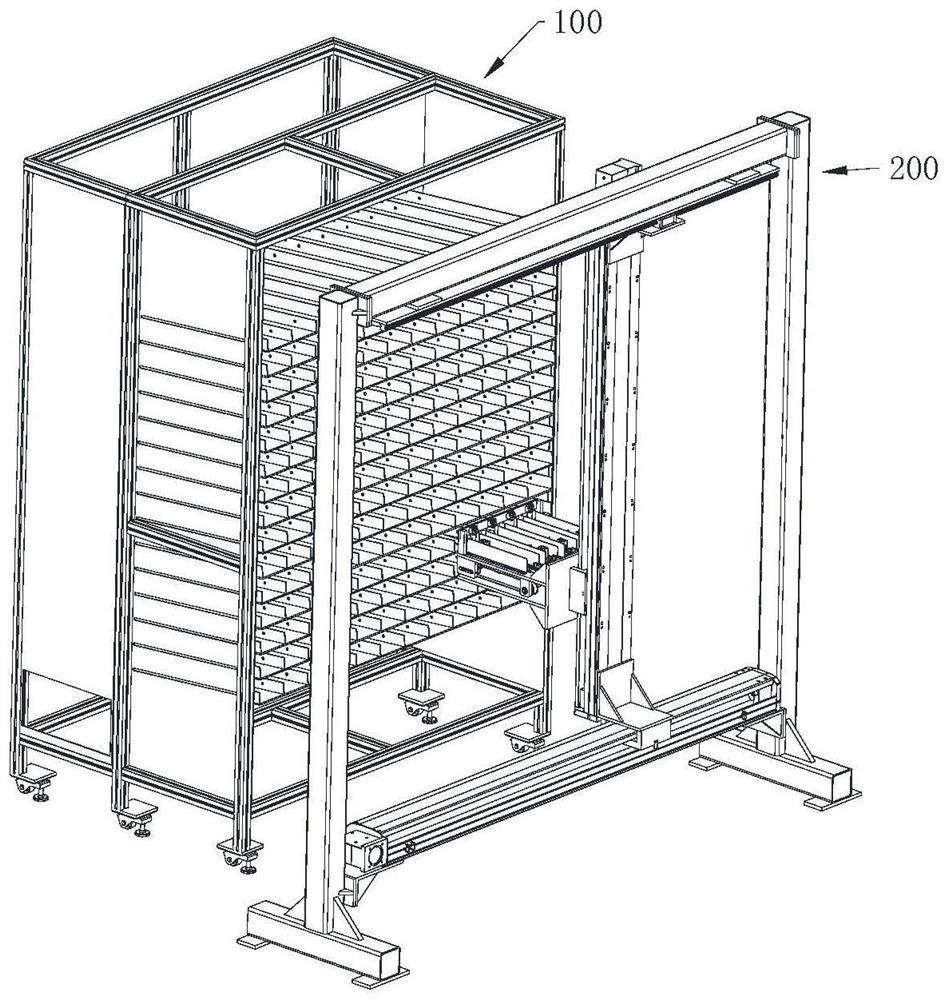

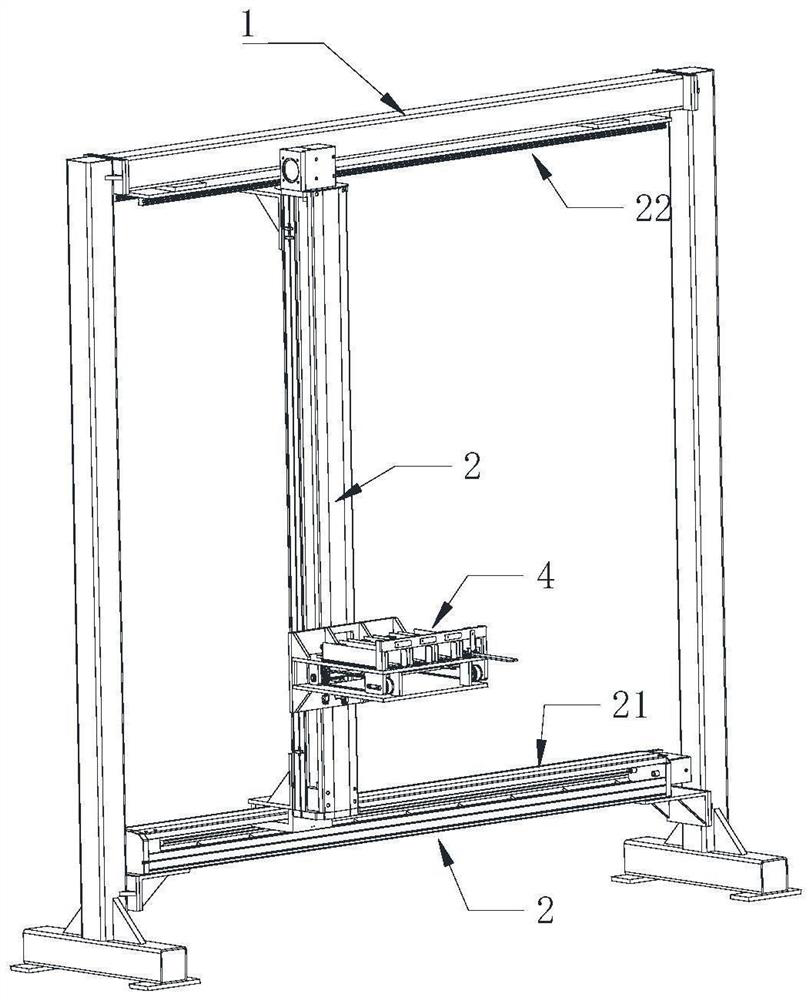

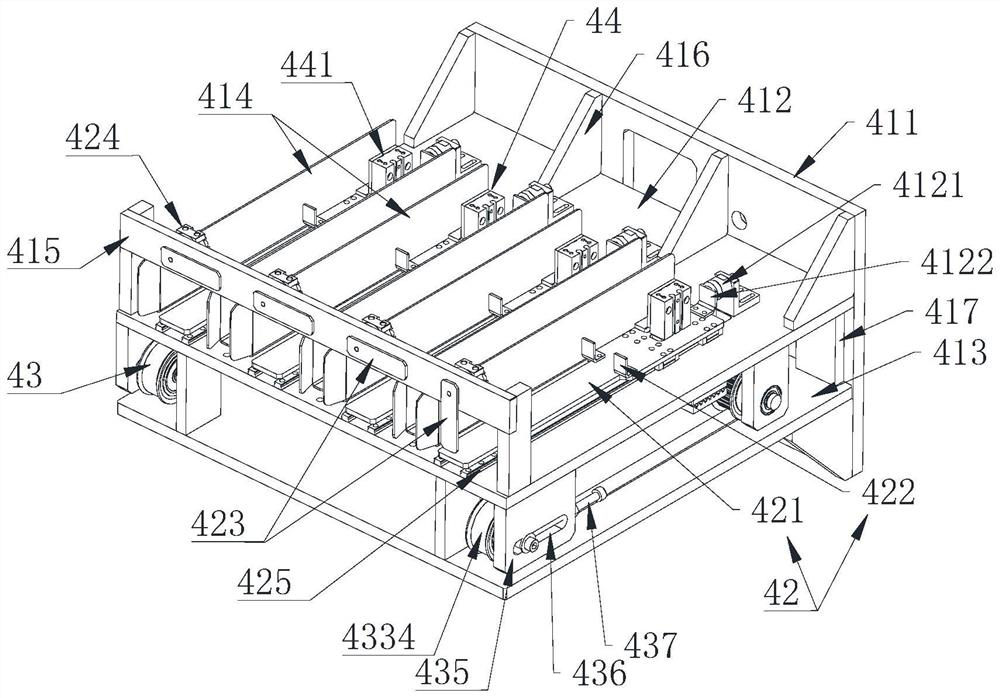

Automatic feeding device, storage equipment and feeding method

ActiveCN114030802AImprove the efficiency of replenishmentReduce waiting timeClimate change adaptationStorage devicesProcess engineeringIndustrial engineering

The invention provides an automatic feeding device, storage equipment and a feeding method, relates to the technical field of storage equipment, and solves the technical problems of low feeding efficiency, low efficiency and long waiting time of a feeding structure. The automatic feeding device comprises a rack, a first moving module, a second moving module and a pushing mechanism, the second moving module is installed on the rack through the first moving module, and the pushing mechanism is installed on the second moving module; the material pushing mechanism is provided with at least two channels and can push multiple or multiple kinds of materials into material supplementing position; and material storage equipment comprises a stock bin and an automatic feeding device arranged beside the stock bin. By arranging the material pushing mechanism with multiple channels, various products can be fed into a supplementing bin after being taken at a time, multiple or different types of materials can be supplemented, the product supplementing efficiency is improved, the waiting time for supplementing the bin is shortened, and a conveying device of the storage bin is omitted.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

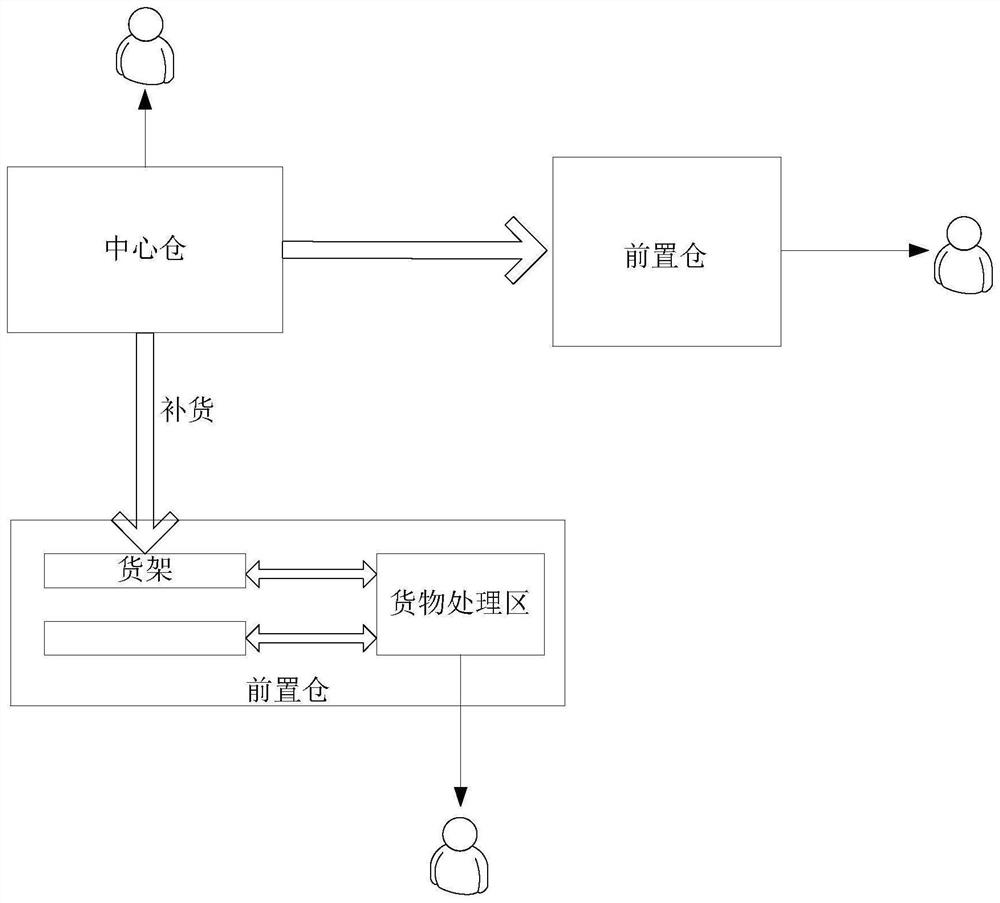

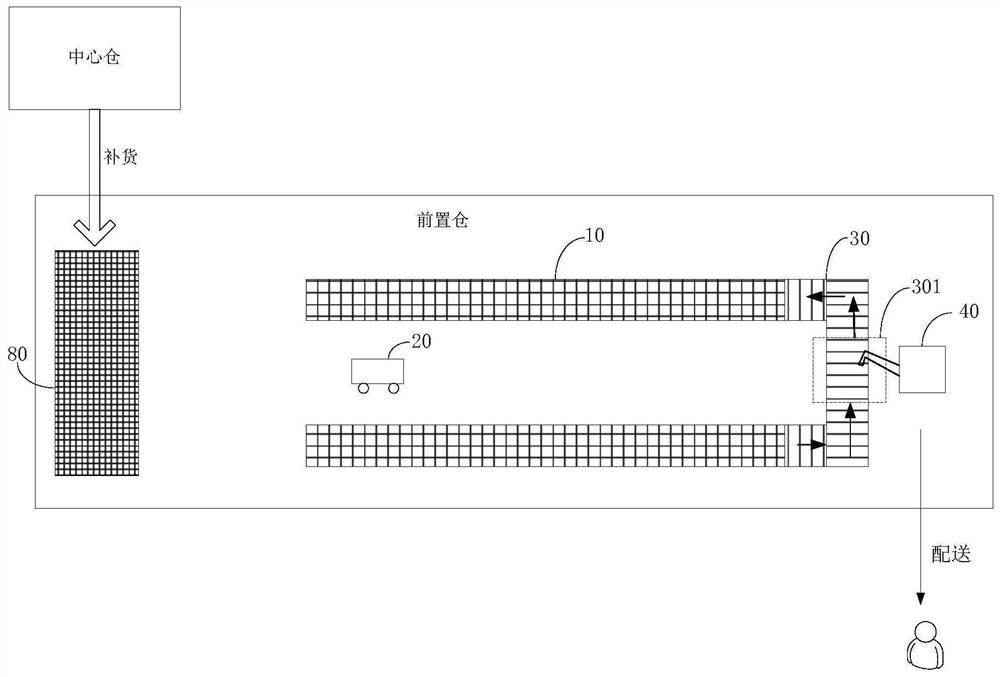

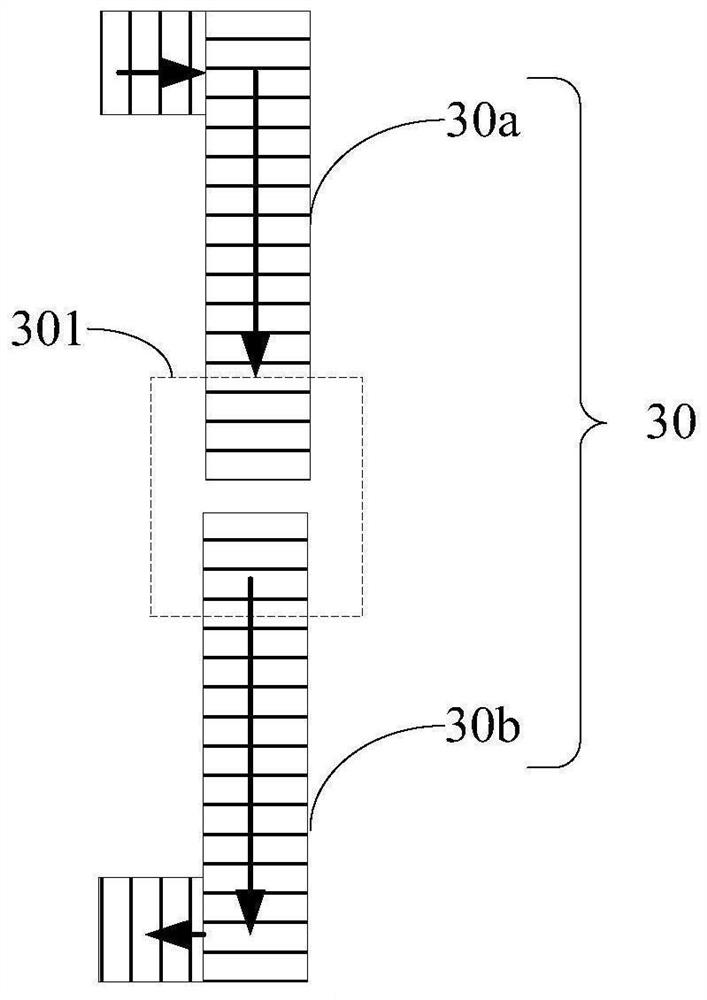

Front warehouse goods processing method, control terminal, robot and system

PendingCN112340337AEnsure sufficientReplenishment time shortenedStorage devicesOrder processingIndustrial engineering

The invention provides a front warehouse goods processing method, a control terminal, a robot and a system. The method comprises the steps that the goods remaining amount of a first goods shelf is obtained, and the first goods shelf is a goods shelf for a first robot in a front warehouse to store and take goods for order task processing; when the goods remaining amount meets the replenishment condition, a first replenishment instruction is output, the first replenishment instruction is used for instructing the first robot to carry the goods on a second goods shelf to the first goods shelf forreplenishment, and the second goods shelf is a goods shelf which is arranged in the front bin and used for replenishment of the first goods shelf; the goods on the second goods shelf include goods carried from a center bin; and when the goods on the second goods shelf are reduced, a second goods replenishment instruction is output, and the second goods replenishment instruction is used for instructing a second robot to carry the reduced goods to the second goods shelf from the center bin. According to the method, the replenishment time of the front warehouse is short, the replenishment efficiency is high, and the order processing efficiency of the front warehouse can be improved.

Owner:HAI ROBOTICS CO LTD

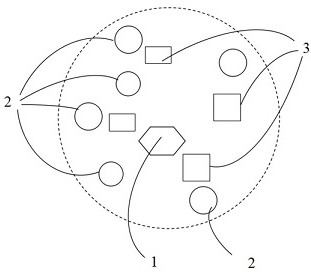

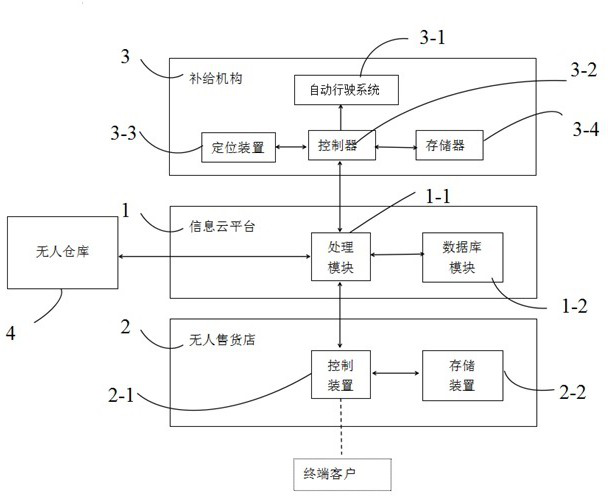

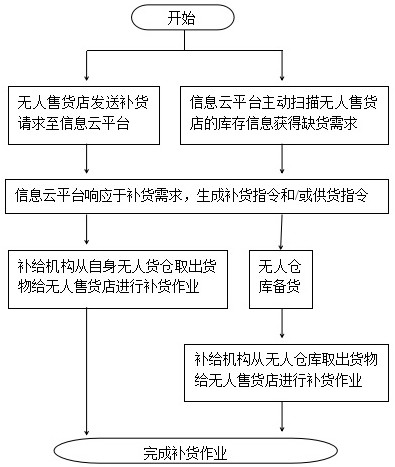

Full-link automatic replenishment method and vending system

InactiveCN111724530ARealize unmannedDigitizationCoin-freed apparatus detailsLogisticsMachineComputer science

The invention provides a full-link automatic replenishment method and a vending system. A full link comprises an information cloud platform, an unmanned warehouse, at least one replenishment mechanismwith the unmanned warehouse and at least one unmanned vending store with the unmanned warehouse, and the replenishment mechanism is also provided with an automatic driving system for unmanned driving. The replenishment method comprises the steps that the information cloud platform generates a replenishment instruction in response to a replenishment demand of the unmanned vending store, and sendsthe replenishment instruction to a replenishment mechanism; and the replenishment mechanism responds to the replenishment instruction to perform replenishment operation on the unmanned vending store,specifically, the replenishment mechanism takes out goods from the unmanned warehouse to the unmanned vending store for replenishment or takes out the goods from the unmanned warehouse to replenish the unmanned vending store. According to the full-link automatic vending system, replenishment efficiency is improved, time cost is reduced, manual participation is not needed in a whole process, and full-link automation that a machine replaces people is truly achieved.

Owner:JIANGSU HUAZHANG LOGISTICS TECH CO LTD

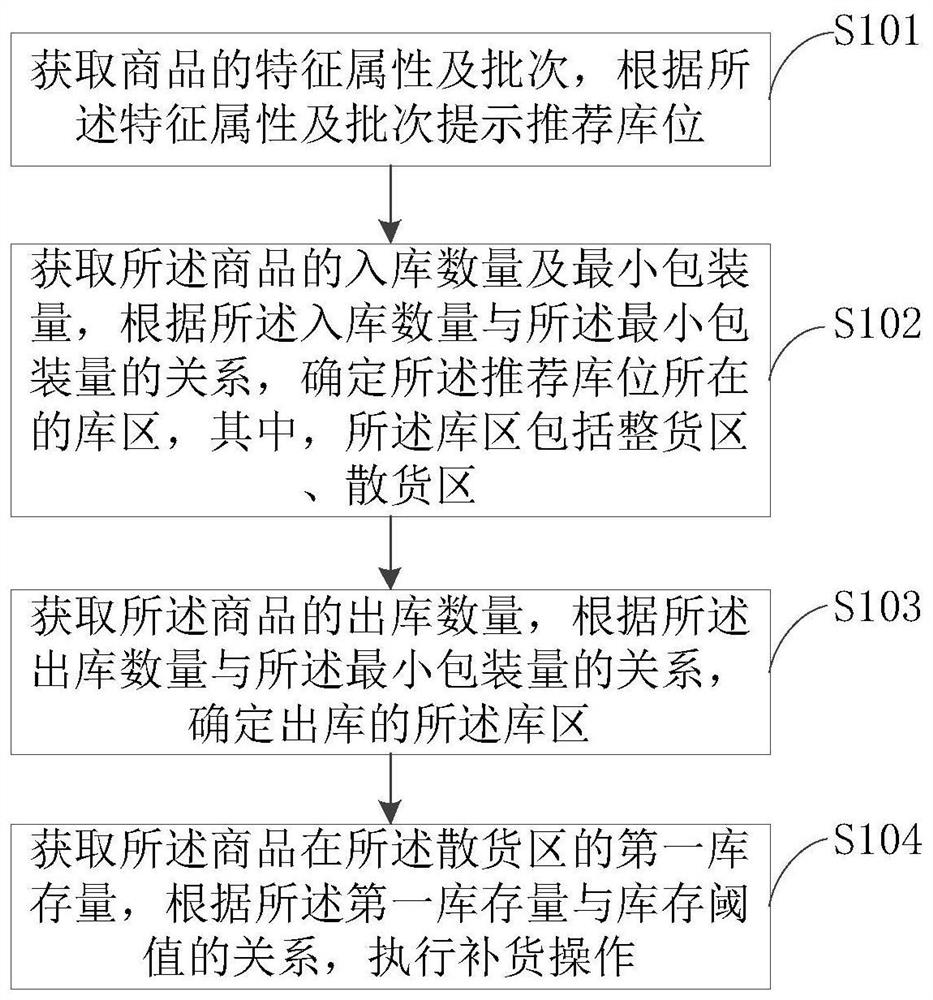

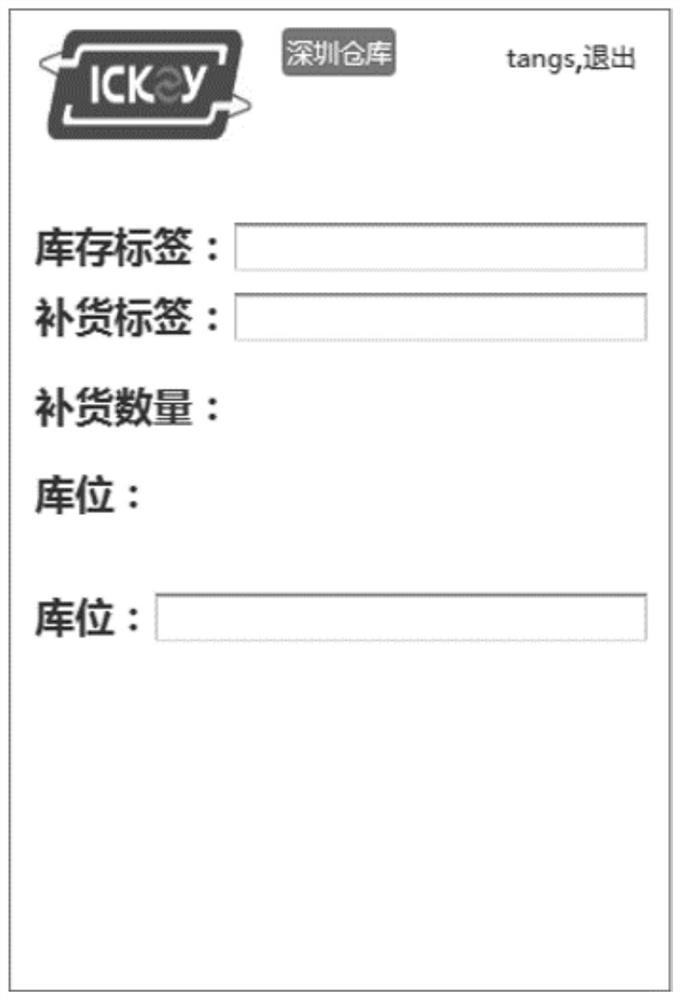

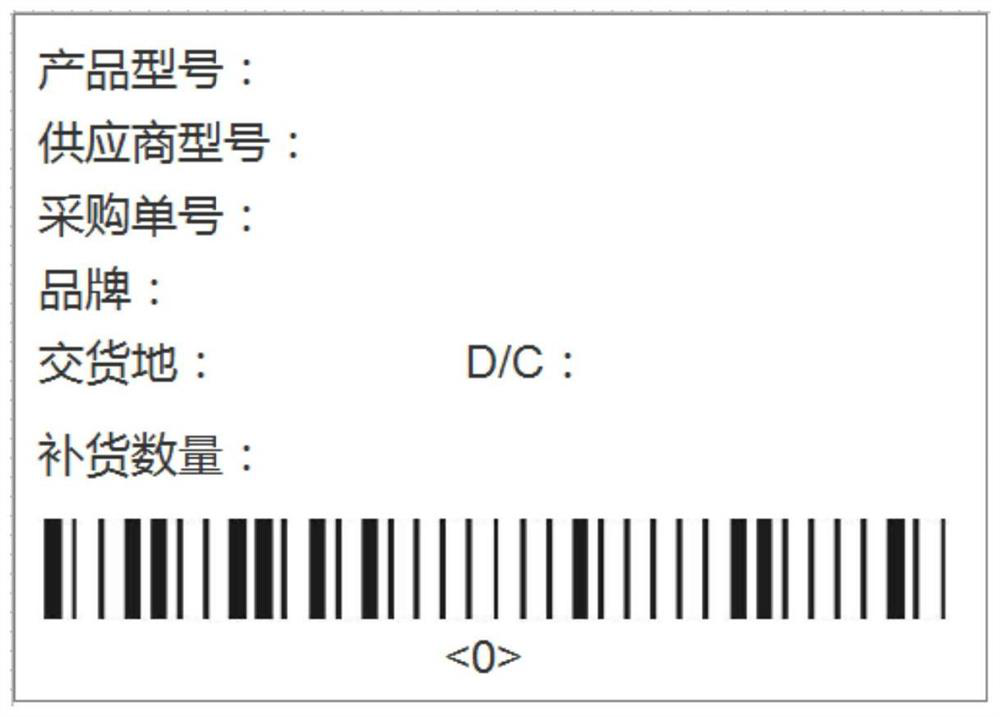

Warehouse-in and warehouse-out management and replenishment method and device and storage medium

PendingCN112633803AImprove management efficiencyImprove replenishment efficiencyLogisticsBulk cargoOperations research

The invention discloses a warehouse-in and warehouse-out management and replenishment method and device and a storage medium, and the method comprises the following steps: obtaining the feature attributes and batches of commodities, and prompting a recommended storage location according to the feature attributes and batches; obtaining the warehousing number and the minimum packaging amount of the commodities, determining the warehouse area where the recommended warehouse location is located according to the relation between the warehousing number and the minimum packaging amount, and the warehouse area comprising a whole commodity area and a bulk commodity area; obtaining the warehouse-out quantity of the commodities, and determining a warehouse-out warehouse area according to the relationship between the warehouse-out quantity and the minimum packaging quantity; and obtaining a first inventory of the commodity in the bulk cargo area, and executing a replenishment operation according to a relationship between the first inventory and an inventory threshold. The warehouse-in and warehouse-out management and replenishment method can prompt the recommended warehouse location and determine the warehouse-in and warehouse-out warehouse area according to the characteristic attribute of the commodity and the relationship between the batch, the warehouse-in and warehouse-out quantity and the minimum packaging quantity, and can execute the replenishment operation according to the relationship between the first inventory and the inventory threshold, thereby improving the warehouse-in and warehouse-out management and replenishment efficiency.

Owner:云汉芯城(上海)互联网科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com