A high-speed light-curing 3D printing device and printing method

A 3D printing and light curing technology, applied in the field of 3D printing, can solve problems such as limiting the speed of 3D printing, and achieve the effect of improving fluidity, increasing printing speed and continuous lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the drawings and implementation process.

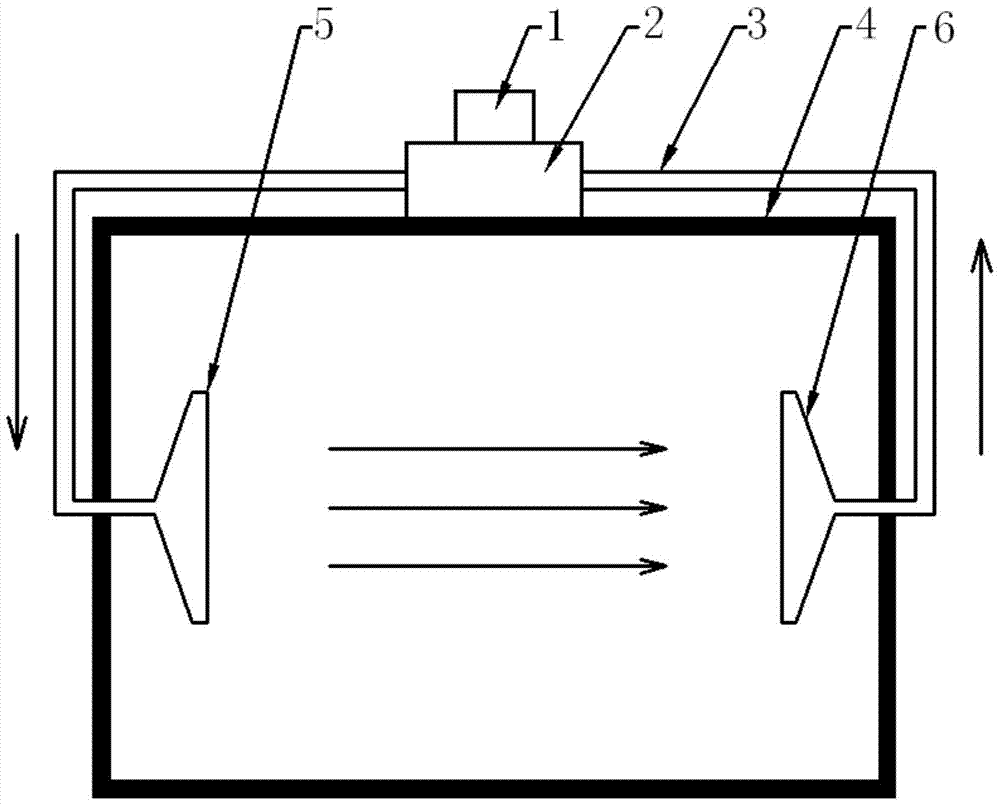

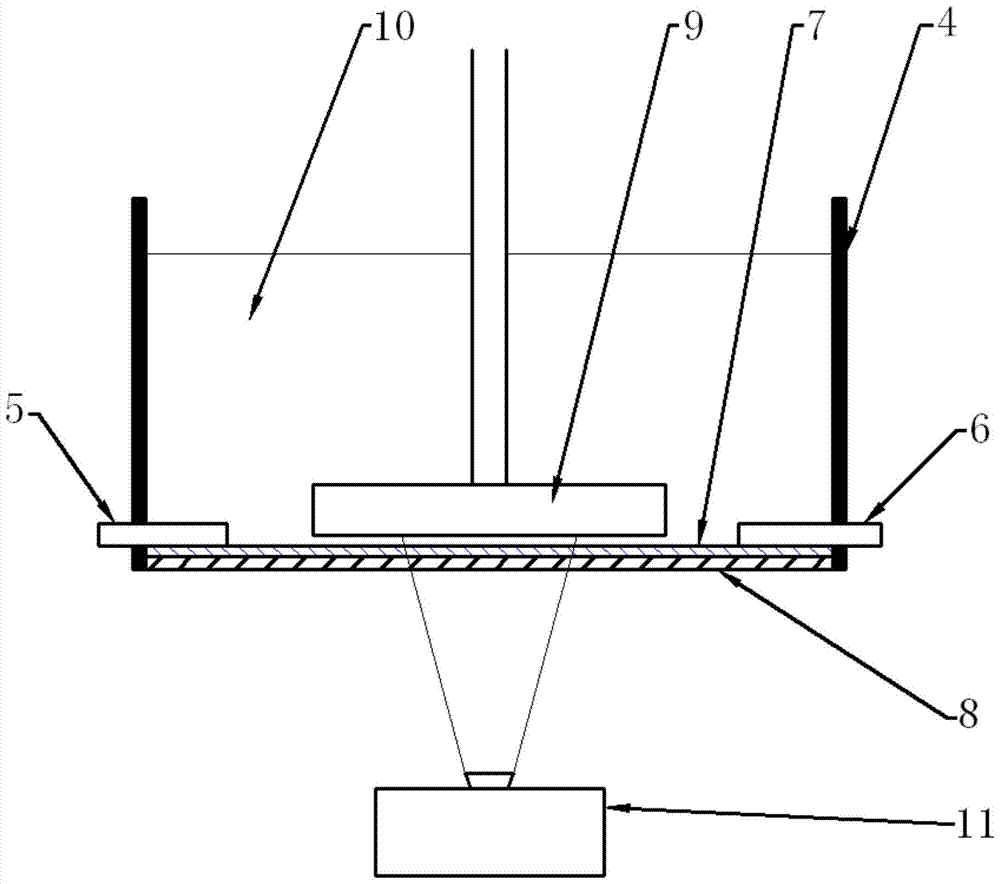

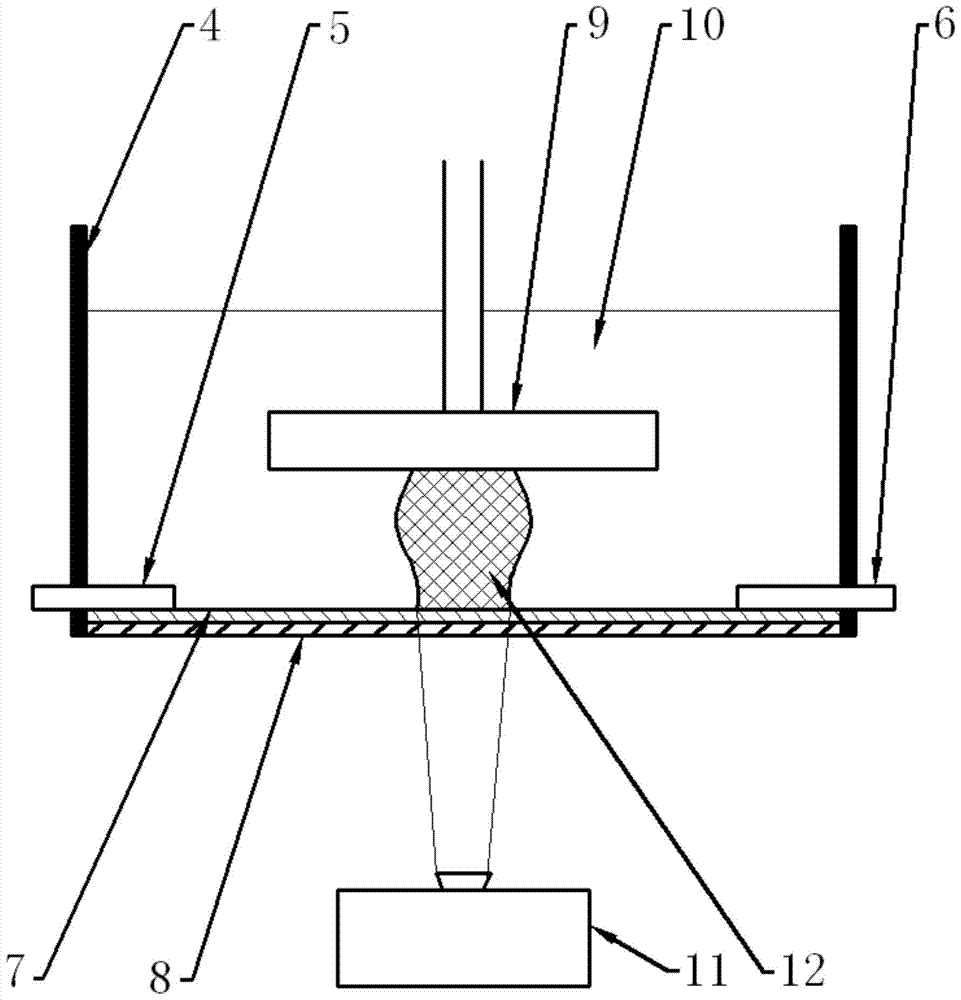

[0037] Such as figure 1 , figure 2As shown, the structure of the high-speed light-curing 3D printing device of the present invention is as follows: a liquid photosensitive resin 10 is housed in the liquid pool 4, and a light-transmitting glass plate 8 is arranged at the bottom of the liquid pool 4, and the upper side of the glass plate 8 is coated with Anti-adhesive coating 7, pipeline liquid outlet 5 and pipeline liquid inlet 6 are respectively installed at a certain distance from both sides of printing platform 9, pipeline liquid outlet 5 and pipeline liquid inlet 6 pass through the side wall of liquid pool 4 and are on the outside Connected by pipe 3. The pipeline 3 is connected with a pump 2 that drives the liquid to pump the liquid photosensitive resin 10 in the pipeline from one side of the pump inlet to the other side of the pump outlet. The mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com