Automatic dispense system of randomly assembled sorting unit

A technology of automatic distribution and distribution device, which is applied in the direction of sorting, unstacking of objects, conveyor objects, etc., which can solve the problems of high labor intensity of workers, small amount of one-time storage, and heavy replenishment workload, etc., to improve Replenishment and distribution efficiency, ease of layout and installation, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

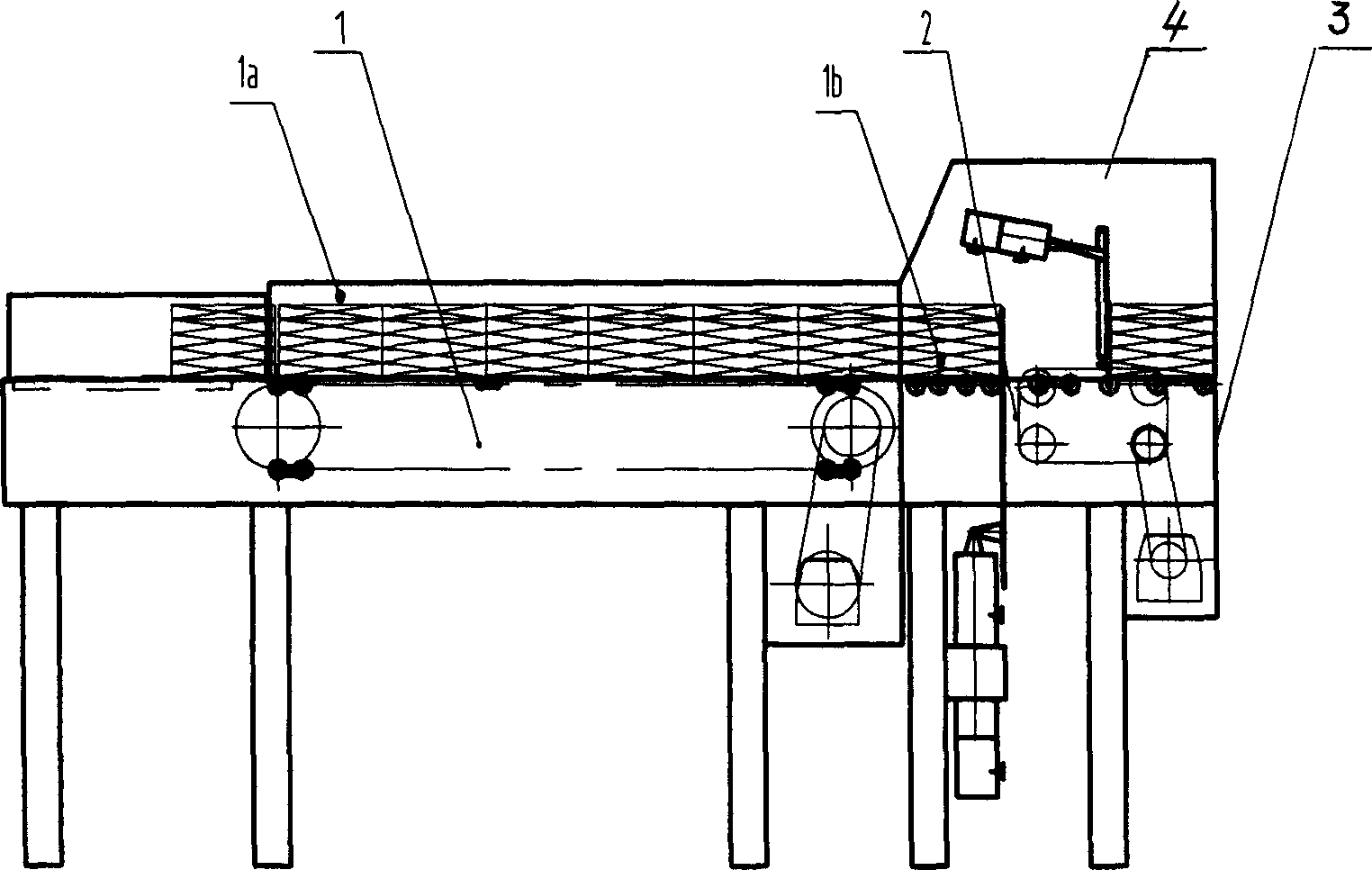

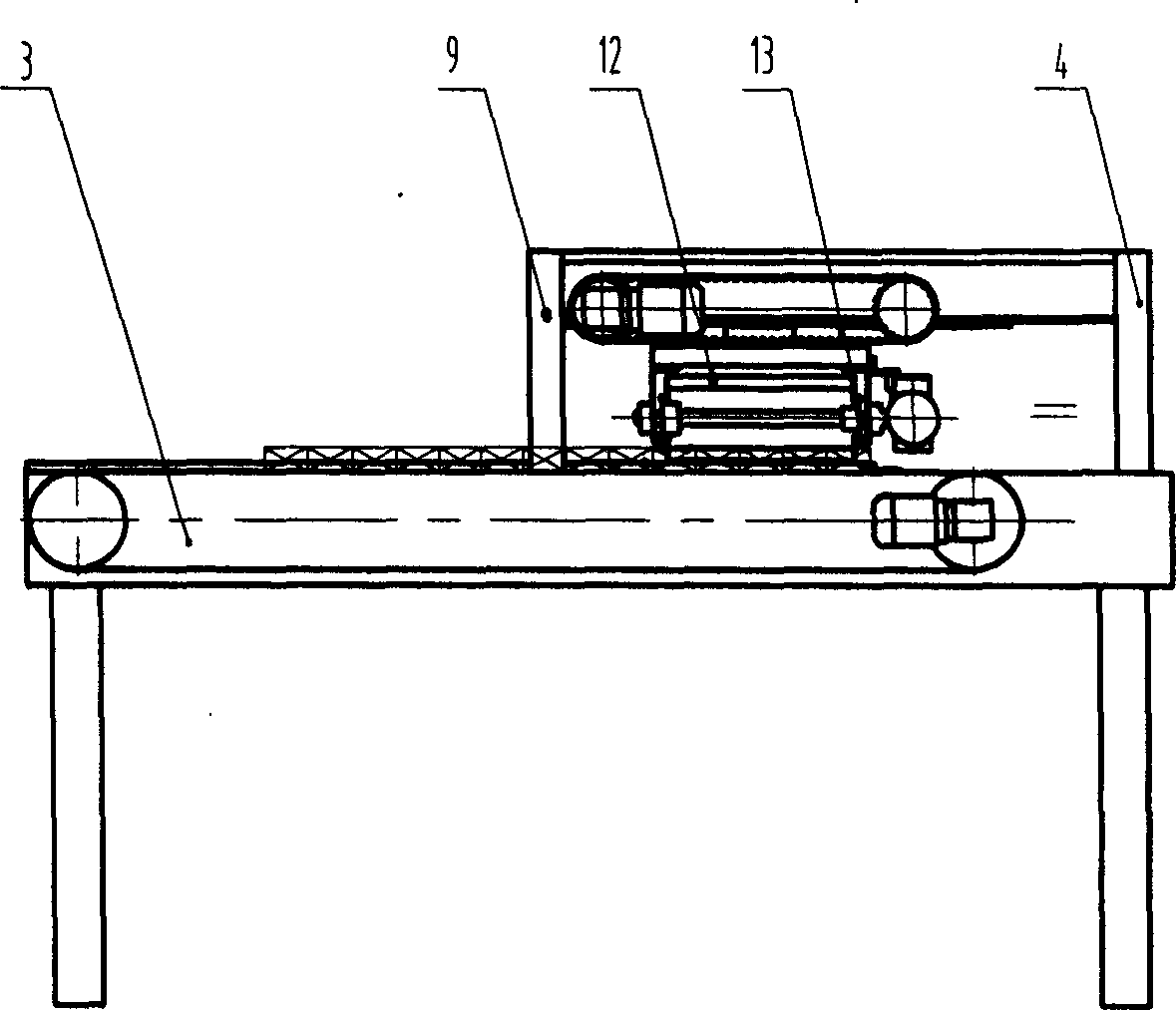

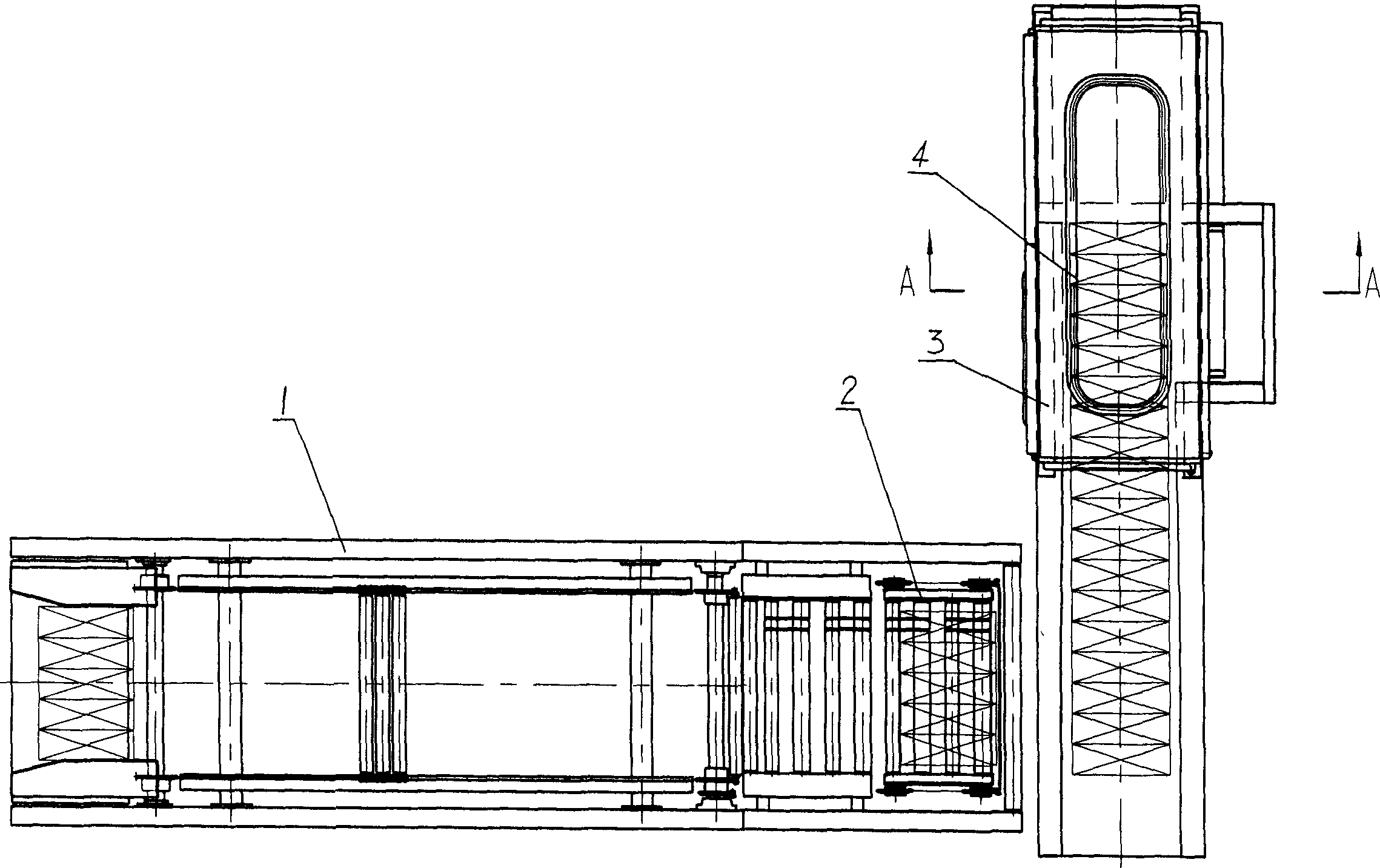

[0015] As shown in the figure, the present invention includes an upstream distributing device and a downstream merging device arranged along the material conveying line. The end is provided with a material retaining mechanism 5, which is composed of a material retaining door 14 and a pneumatic or electric door opening mechanism. The pile-shaped material conveying mechanism 1 includes a material horizontal conveying section 1a and a subsequent material buffer section 1b, and the material buffer section 1b can be set as Figure 5 The shown fixed horizontal conveying roller table has a material blocking mechanism 5 at its outlet end, and the material blocking mechanism 5 is a guard plate driven by a cylinder or a motor, and a pressing mechanism 8 is arranged above it. Connect the feed port of the distribution mechanism 2 to the outlet of the pile-shaped material conveying mechanism 1, and set the material shifting mechanism 6 at the bottom of the distribution mechanism 2, and use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com