Replenishment method for unmanned store

A replenishment method and store technology, applied in weighing, logistics, instruments, etc., can solve the problems of multiple labor costs, time costs, and consumption, so as to avoid labor costs and time costs, improve replenishment efficiency, and replenishment work more targeted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

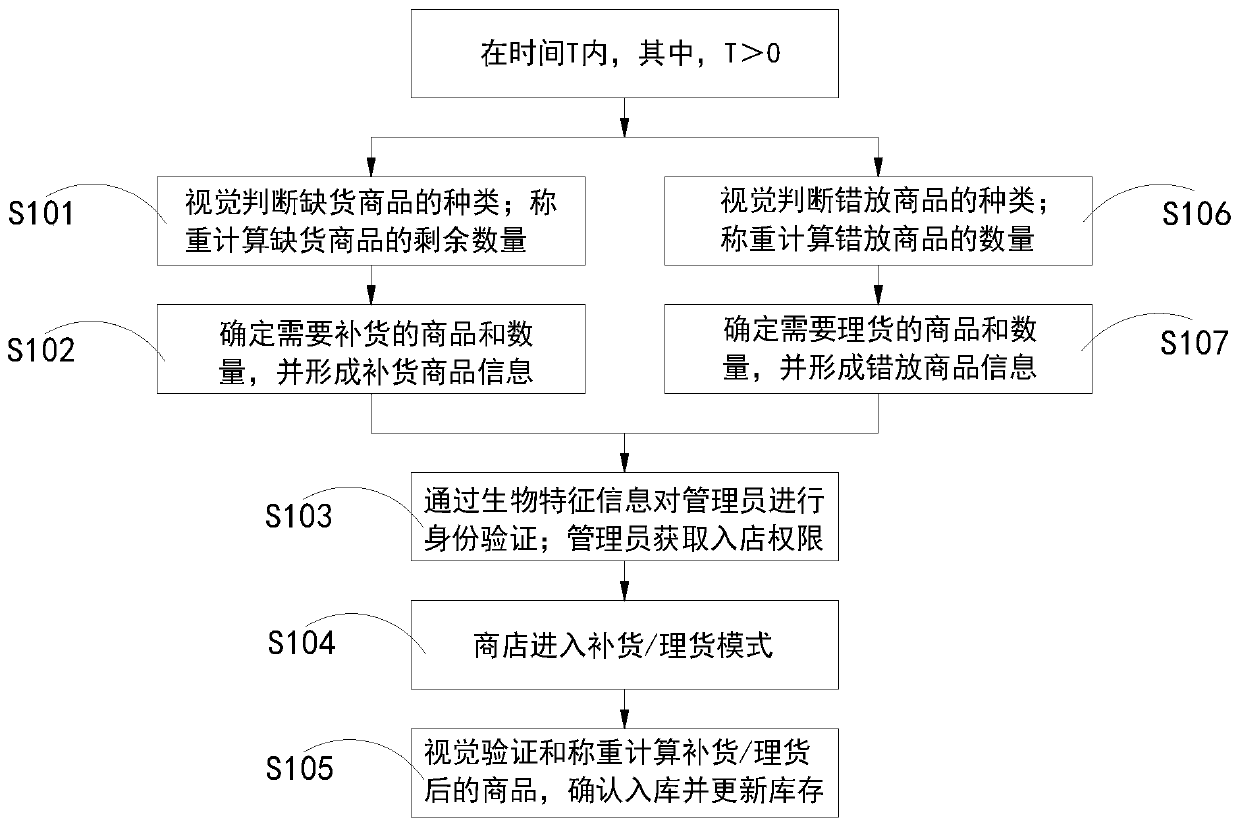

[0024] In order to solve the replenishment work of the unmanned store in the prior art, the administrator still needs to manually check the commodity inventory and then manually replenish the stock, so that the disadvantages of the commodity inventory are not solved in an intelligent way, and more labor costs are required and time cost, embodiment 1 provides a replenishment method for unmanned stores, such as figure 1 shown, including:

[0025] Step S101: within the time T, visually judge the type of the out-of-stock commodity; weigh and calculate the remaining quantity of the out-of-stock commodity; wherein, T>0;

[0026] Step S102: Determine the commodities and quantities that need to be replenished, and form replenishment commodity information.

[0027] Among them, the visual judgment is mainly based on the comparison of the current product image on the shelf with the pre-recorded inventory image by the camera. The camera can be installed on the top of each cargo lane on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com