Robot automatic sorting method and system based on simultaneous picking and sorting

An automatic sorting system and automatic sorting technology, applied in the field of warehousing and logistics, can solve the problems of low hit rate of picking goods, inability to find goods manually, and rising labor costs, so as to achieve high sorting hit rate and avoid mixed traffic of people and vehicles. , The effect of high traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

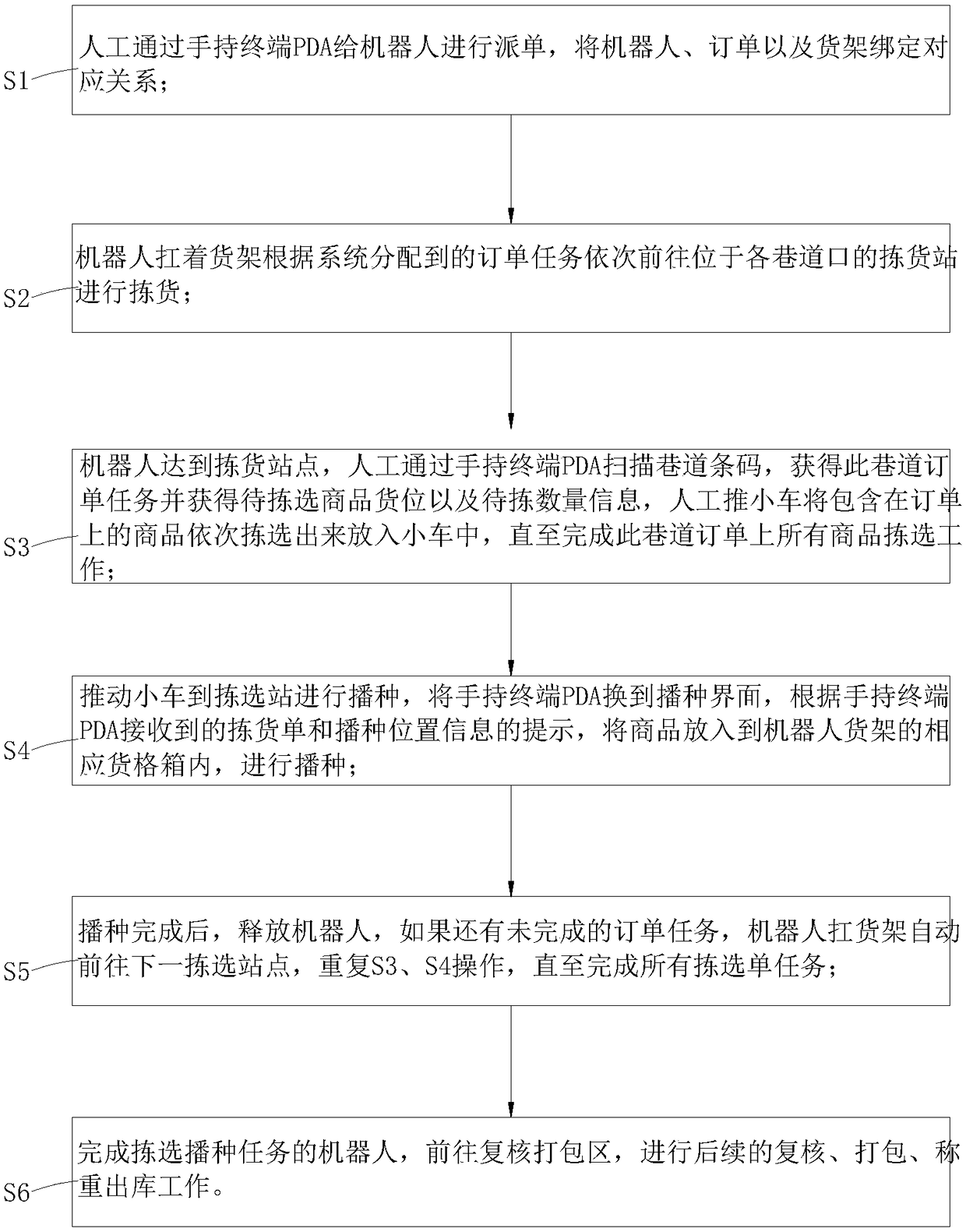

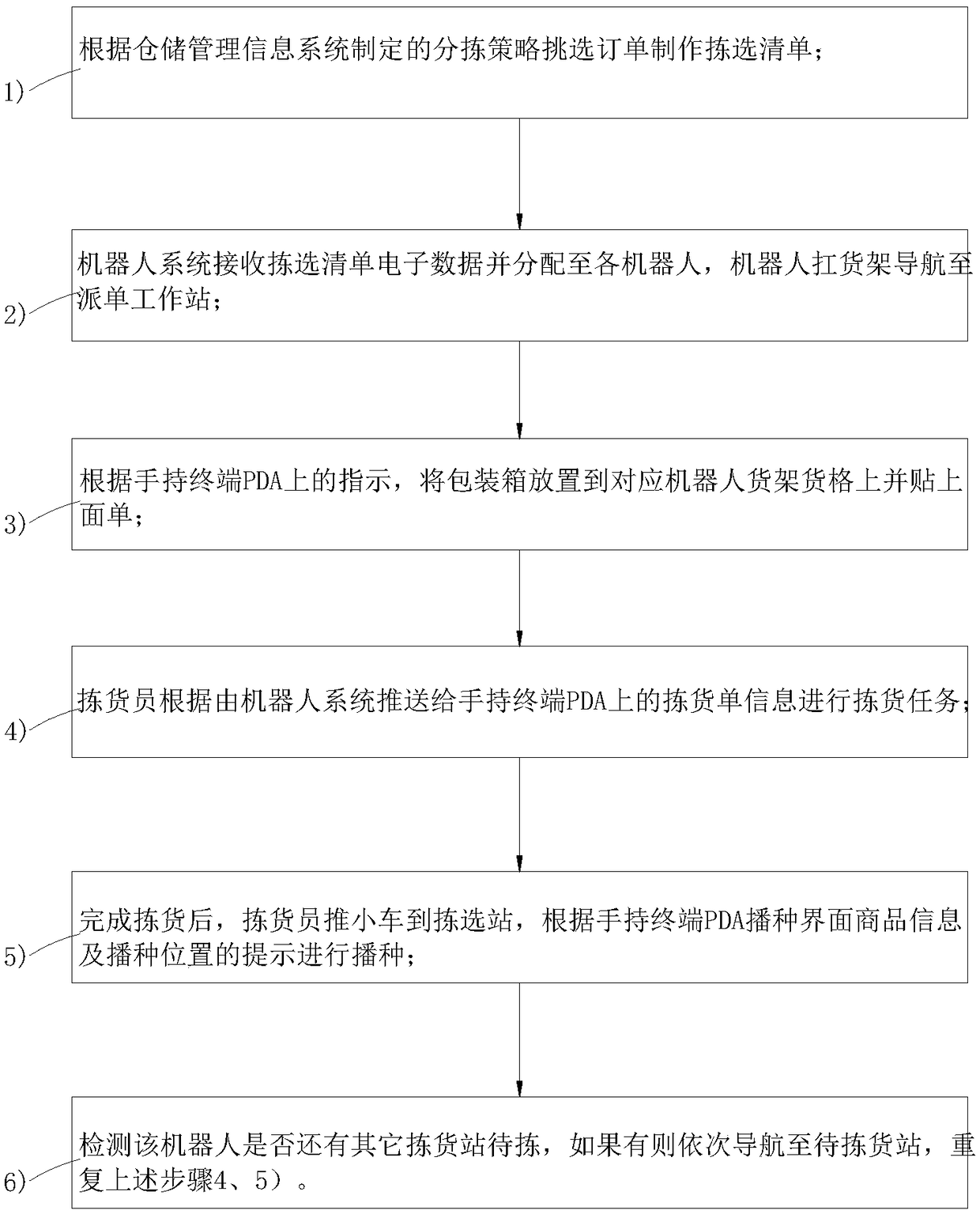

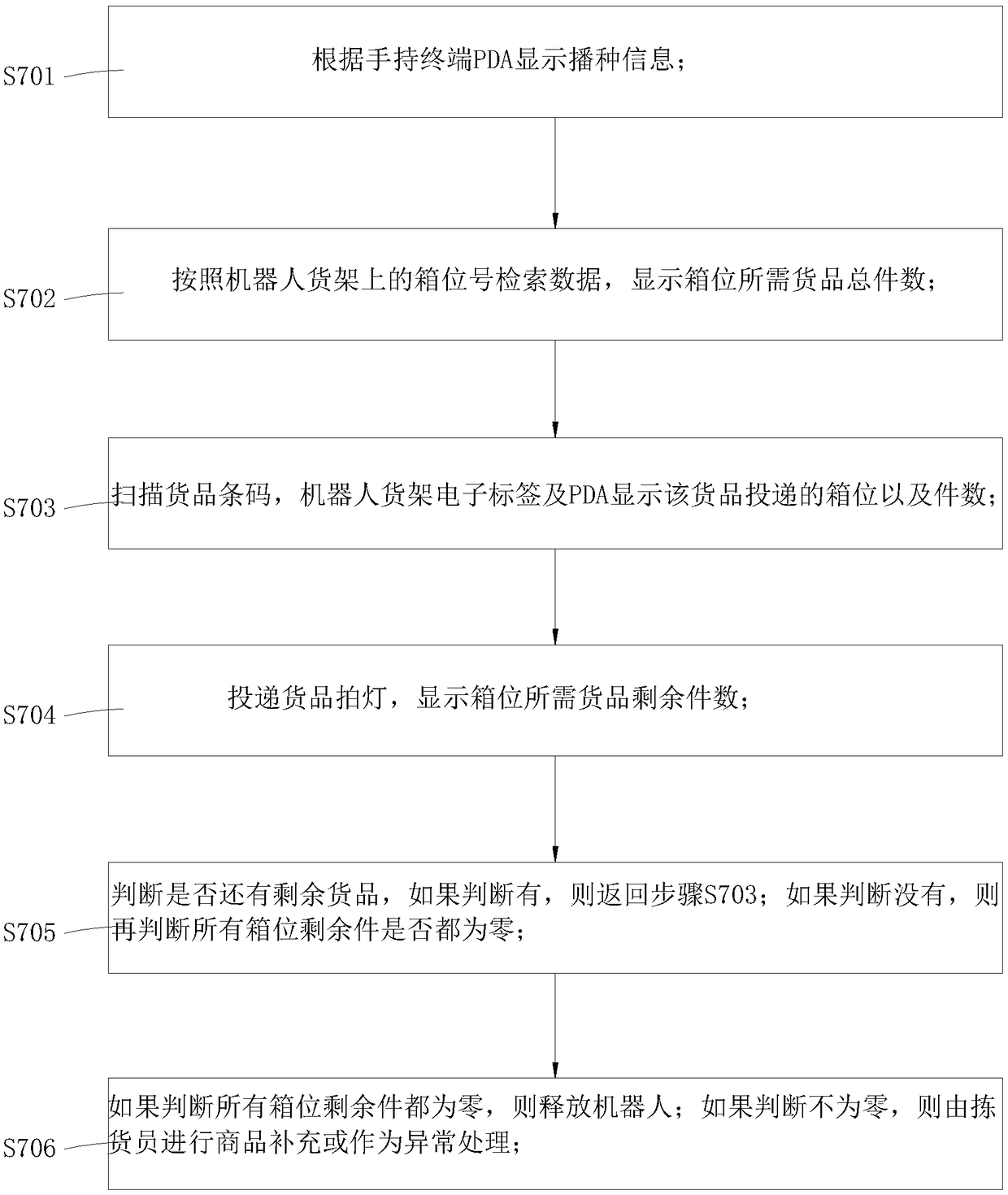

[0058] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0059] The present invention is aimed at the problems of low single shelf sorting hit rate, low sorting efficiency and low robot energy efficiency in the shelf-to-person storage robot system in the existing logistics storage robot sorting technology, and the vehicle-to-person storage robot system has problems The second sorting process is added to the planting post, which increases the problem of labor costs, and then proposes a robot automatic sorting method and system based on sorting and sorting. The automatic sorting method and system have manual participation in sorting Picking, the picking and sowing tasks are completed at the same time at the picking station. Since the picking and sowing are completed at the same picking station, the process is reduced while reducing the personnel at the planting station and reducing labor costs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com