Branching device and branching method for processing high-precision multiple thread part

A technology of multi-thread thread and thread-splitting device, which is applied in the field of thread-splitting devices for multi-thread threads and processing high-precision multi-thread thread parts. Problems such as air travel and clearance can be avoided to achieve the effect of avoiding equipment air travel, ensuring processing quality, and convenient and accurate line separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

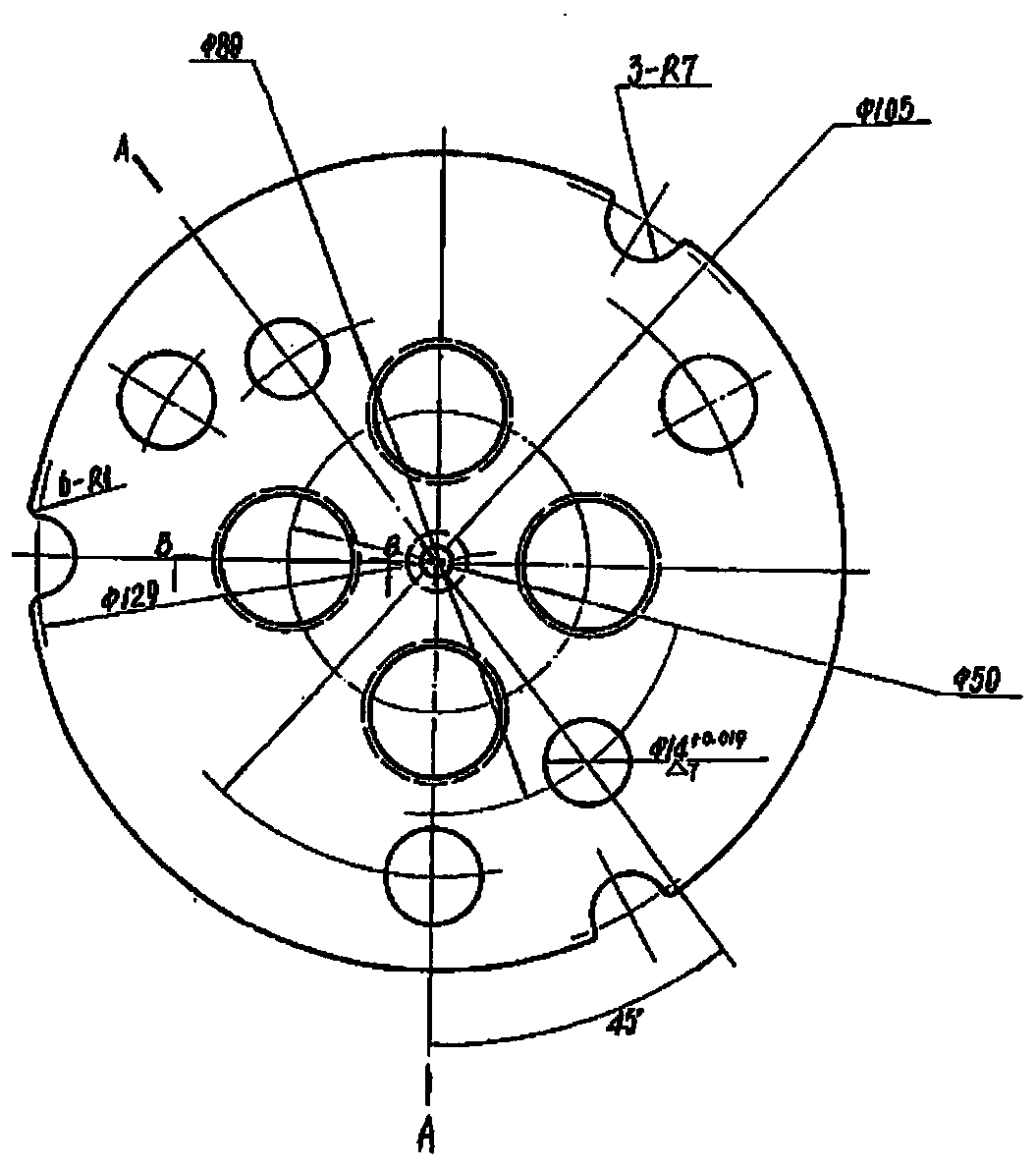

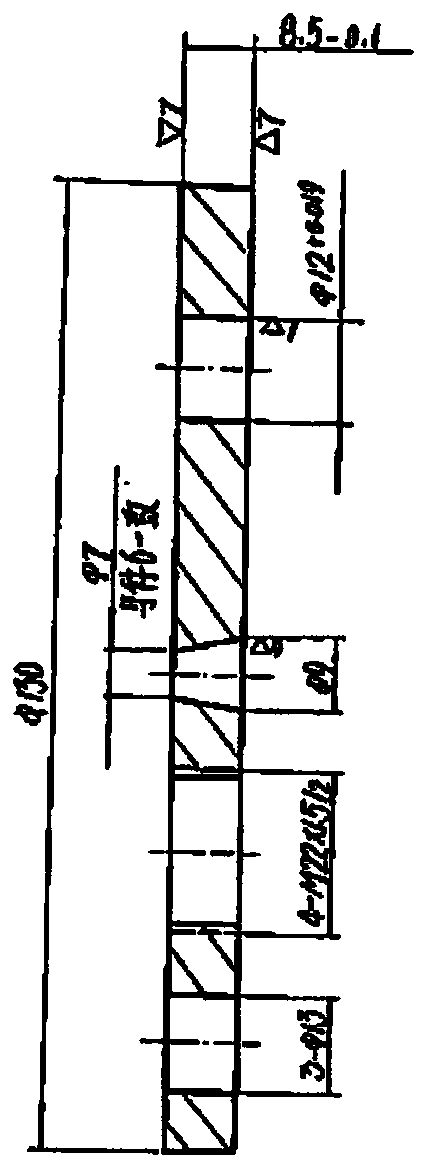

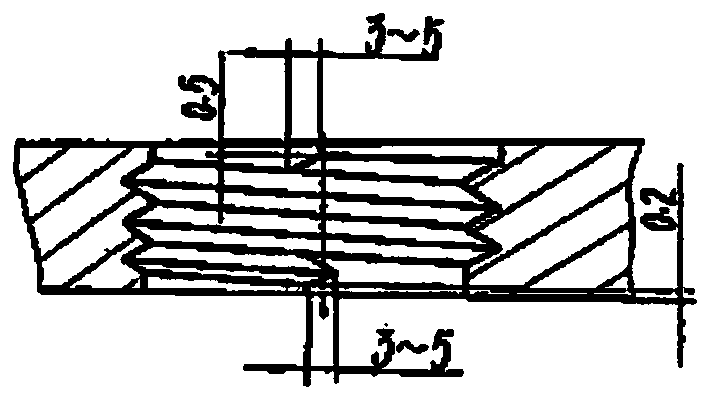

[0034] see Figure 4 as well as Figure 5 , the present invention provides a line dividing device for processing high-precision multi-thread thread parts, the line dividing device for processing high-precision multi-line thread parts includes a base 1 and a positioning plate 2; the base 1 and the positioning plate 2 are parallel and The connection is fixed by bolts; the base 1 is provided with a positioning pin 4; the positioning plate 2 is provided with a pin hole matching the shape of the positioning pin 4; the pin hole is two or more, and the two or more pin holes are equal The cloth is placed on the positioning plate 2; the positioning plate 2 is provided with a limit screw 5 for fixing the workpiece 9 to be processed.

[0035] The positioning plate 2 is in clearance fit with the base 1; the positioning plate 2 can rotate around the axial direction of the bolt after the positioning pin 4 is pulled out from the pin hole. The positioning plate 2 is provided with a step thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com