Shifting roll and shifting method

A technology for shifting clutches and gears, applied in the direction of components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problems of increased burden and time-consuming synchronization, improve operational reliability and achieve cost efficiency , the effect of high operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

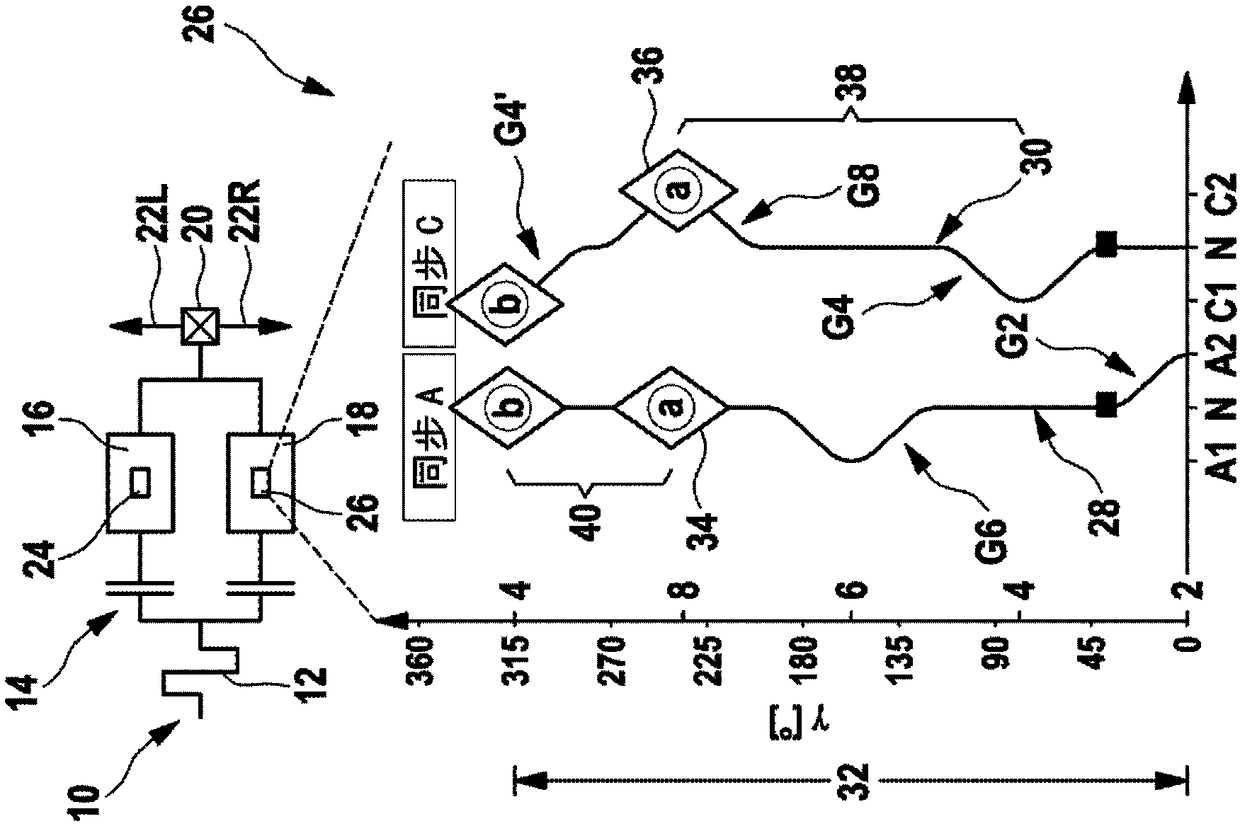

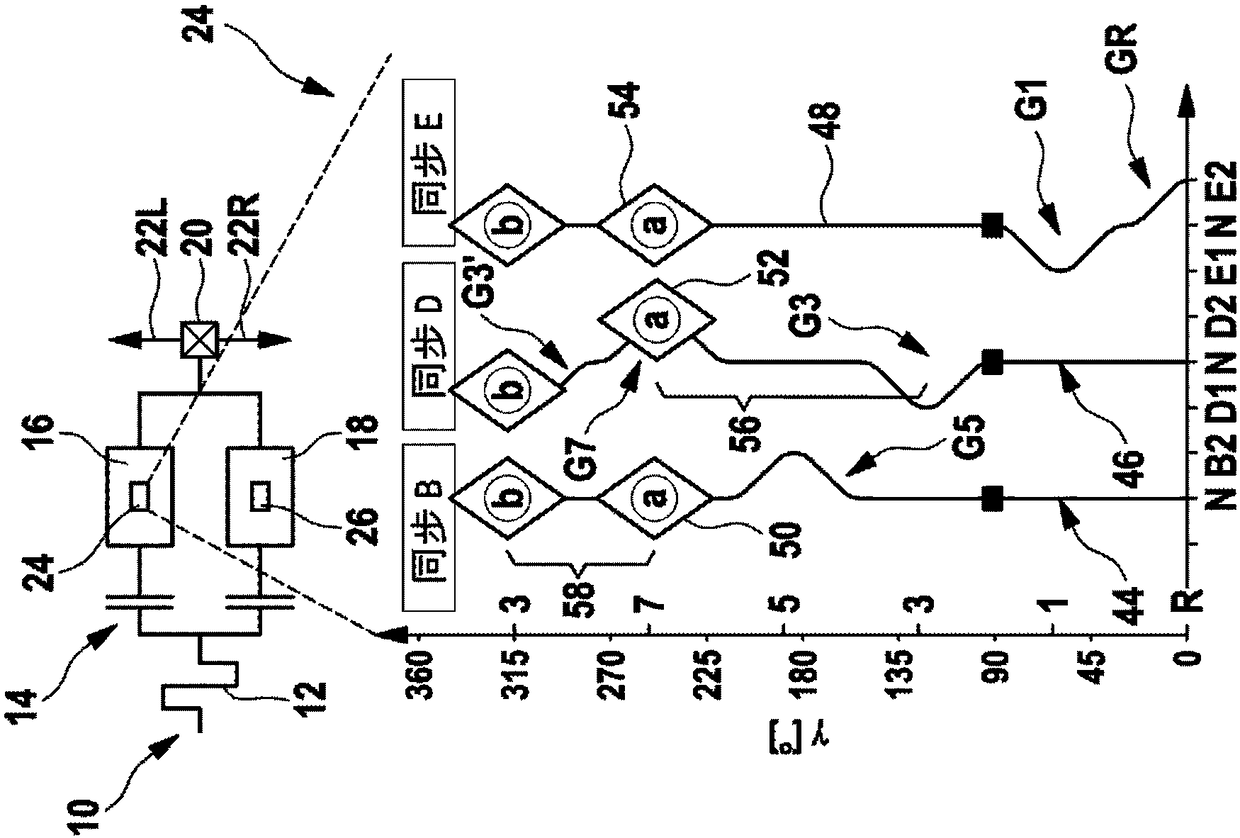

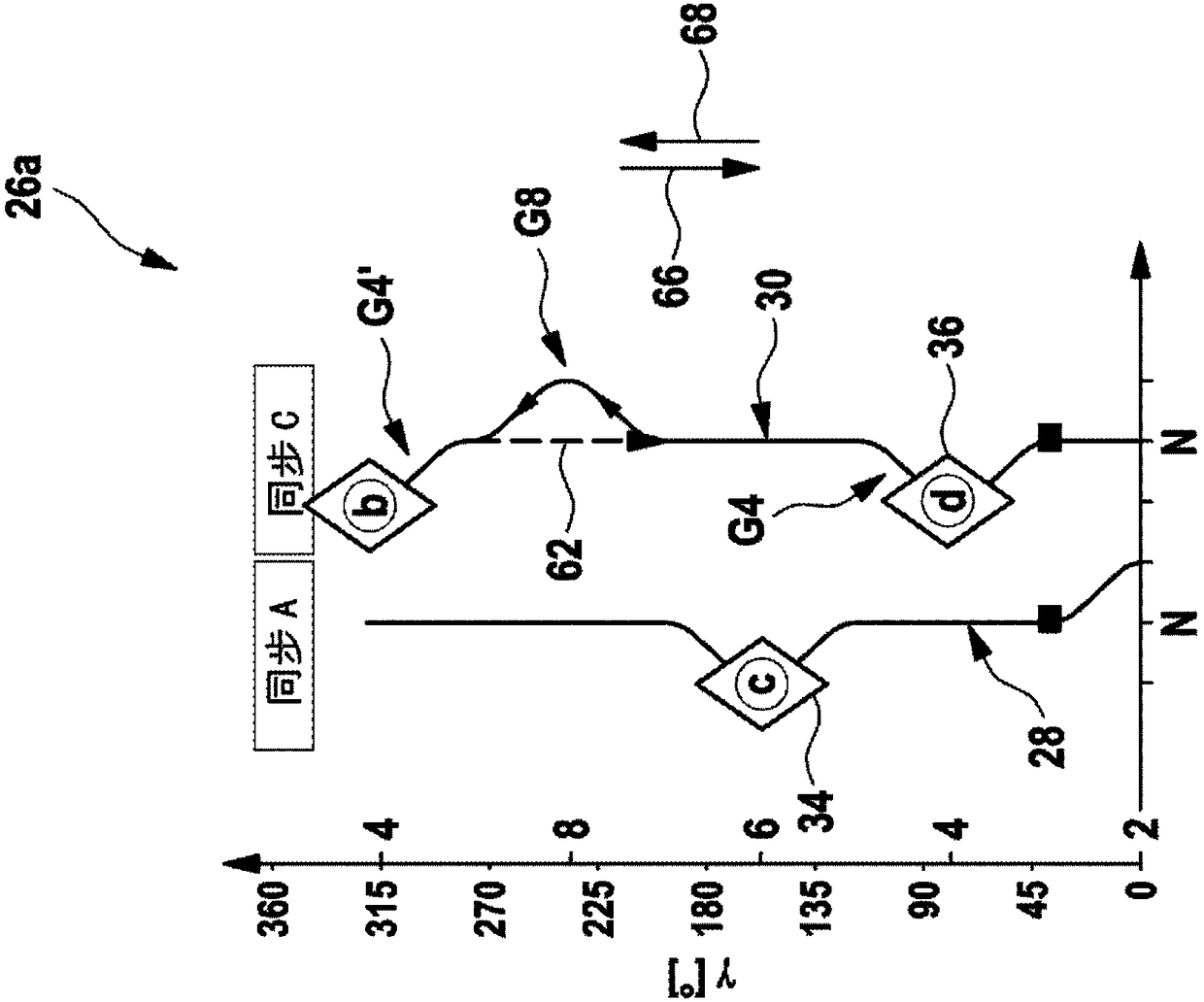

[0080] figure 1 A drive line 10 for a motor vehicle, in particular a passenger car, is shown schematically.

[0081] The drive line 10 has a drive motor 12 which can be formed, for example, as an internal combustion engine motor or as a hybrid drive. Furthermore, the drive line 10 contains a clutch configuration, which is here formed as a double clutch configuration 14 . The drive line 10 also has a countershaft transmission in the form of a spur gear, which has a plurality of forward gears and usually at least one reverse gear. Here, the transmission is divided into a first subtransmission 16 and a second subtransmission 18 , wherein the first subtransmission 16 corresponds to the odd forward gears and reverse gear, and wherein the second subtransmission 18 corresponds to the even forward gears.

[0082] The subtransmissions 16 , 18 are each connected to the drive motor 12 via a clutch of the dual clutch arrangement 14 . The outputs of the subtransmissions 16 , 18 are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com