Motor end cover sealing device capable of preventing dust and sand from entering interior of motor

A technology of motor end cover and sealing device, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., and can solve the problems of motor burnout, raceway jamming, and no dustproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

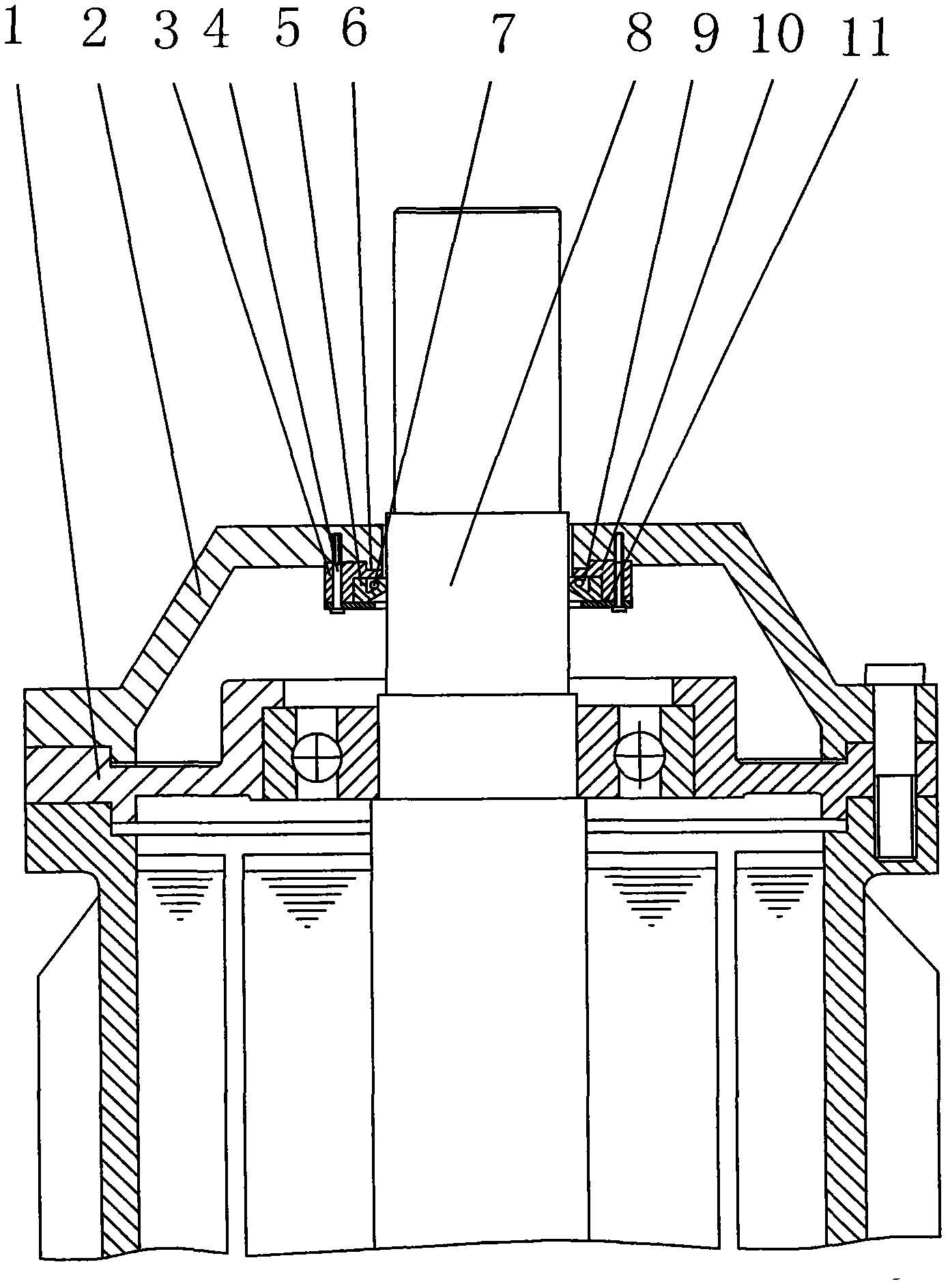

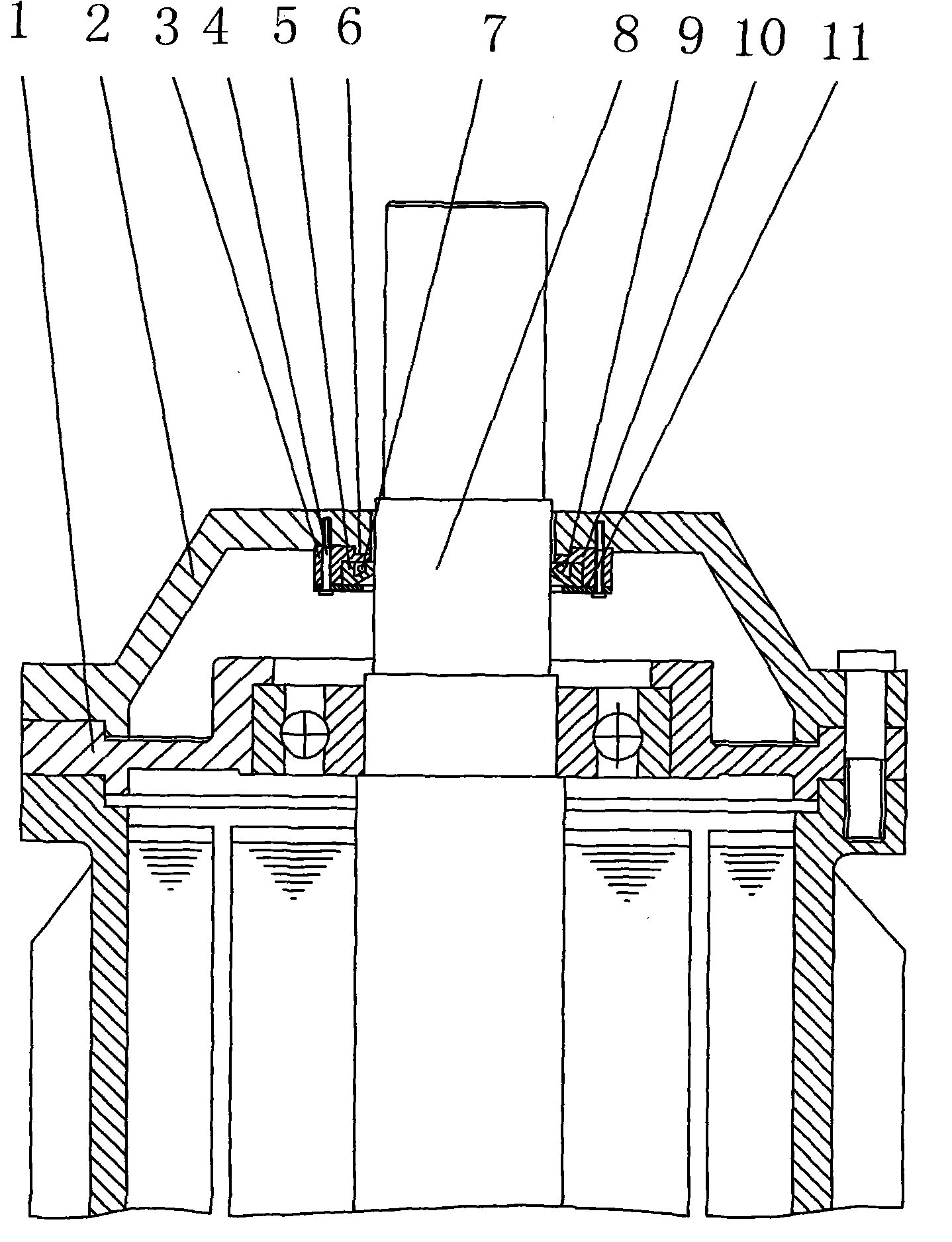

[0011] Such as figure 1 The embodiments described are as follows: a motor end cover sealing device that can prevent lime sand from entering the motor. A plane and a positioning circular step 6 are processed inside the motor end cover 2 at the motor shaft 8 of the motor 1. The rubber oil seal seat 3 is installed on the positioning circular step 6 . The rubber oil seal seat 3 composed of the seat body 10 and the cover plate 11 is fixed on the motor end cover 2 by screws 4 . Install a rubber oil seal 5 in the rubber oil seal seat 3. The lip of the rubber oil seal 5 faces the motor end cover 2 . The inner ring of the rubber oil seal 5 is tightly attached to the motor shaft 8 . A tension spring ring 7 is housed in the groove lip 9 of the rubber oil seal 5 .

[0012] The roughness of the motor shaft 8 in contact with the rubber oil seal 5 should be ≥ Ra1.6, the surface hardness should be ≥ HRC40 or chrome-plated on the surface of the motor shaft 8 in contact with the rubber oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com