Quick change device shared by multiple stations

A multi-station, wire sleeve technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of easy confusion and unfavorable on-site management, and achieve the effect of accurate positioning and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

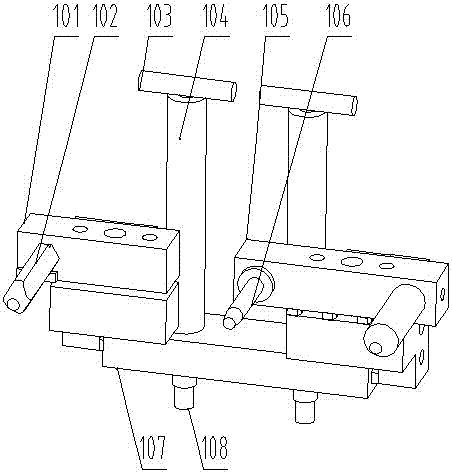

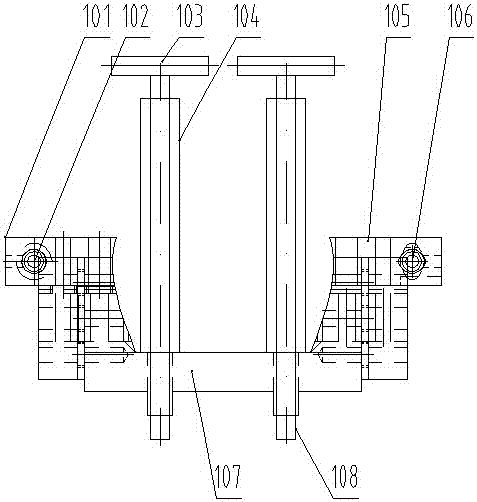

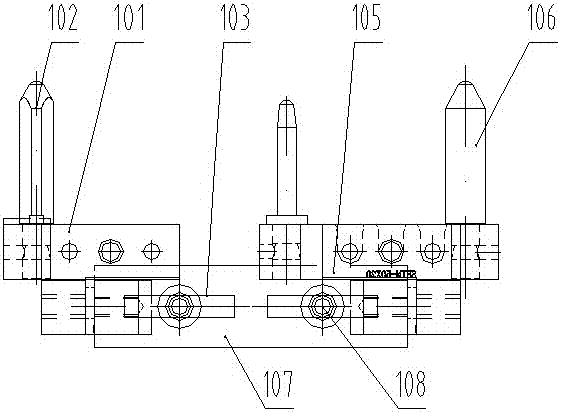

[0016] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a quick-change device shared by multiple stations, comprising a quick-change device 1 and a connecting seat 2; 108; it is characterized in that: the outside of described screw mandrel 108 is provided with external thread, the inboard of described wire sleeve 104 is provided with internal thread, and the external thread of described screw mandrel 108 matches with the internal thread of described wire sleeve 104, The bottom of the wire sleeve 104 is provided with a step, the bottom of the wire sleeve 104 passes through the round hole on the seat plate 107, and the wire sleeve 104 is socket connected with the round hole on the seat plate 107, and the screw rod The upper end of 108 is connected with handle 103, and the upper part of left and right ends of described seat board 107 is respectively fixed with left transfer block 101 and right transfer block 105, and the front part of described left transfer bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com