Non-checkerboard-pattern calibration plate for calibrating white light scanner

A technology for calibrating plates and scanners, applied in the field of visual measurement, can solve the problems of high layout density, prone to errors, and interfere with the imaging quality of photos, and achieve the effects of improving imaging quality, reducing errors, and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

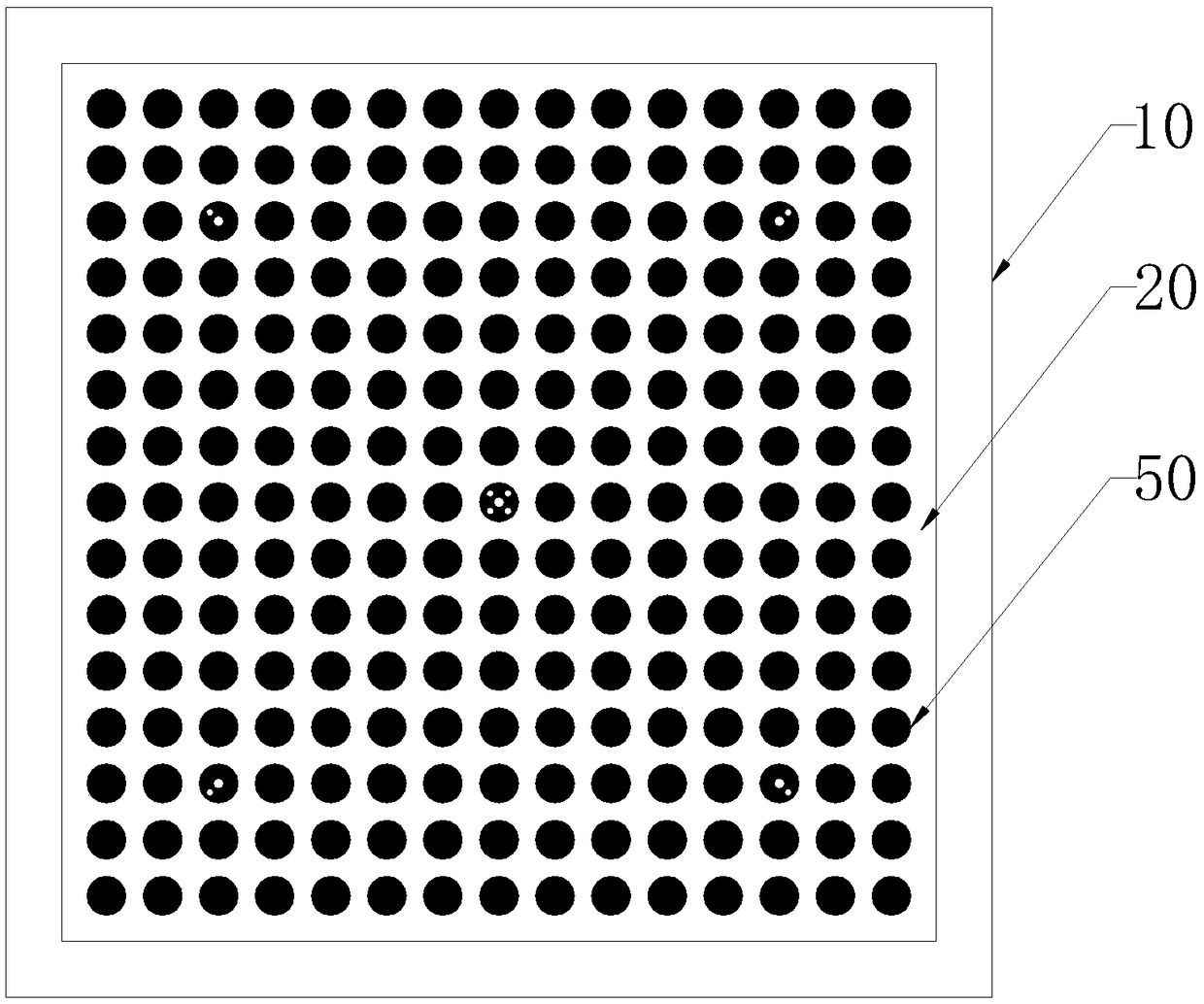

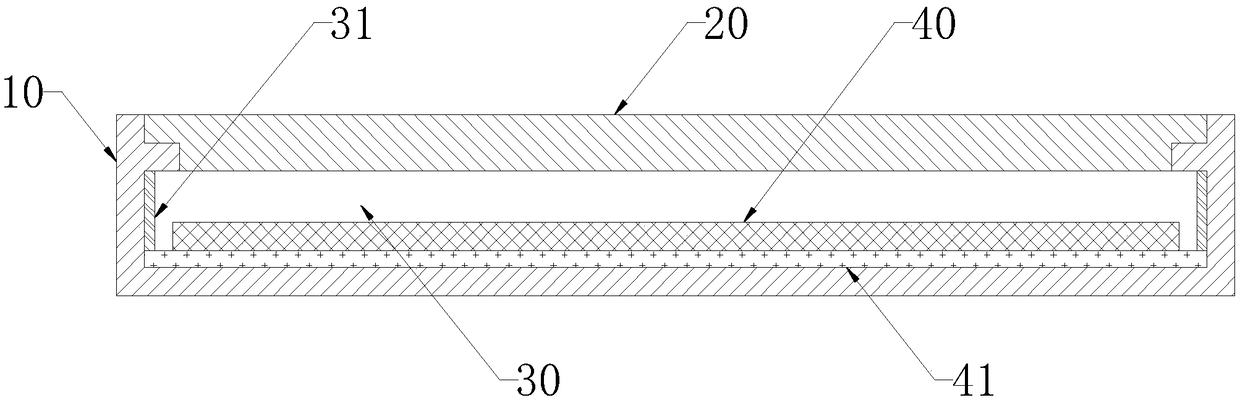

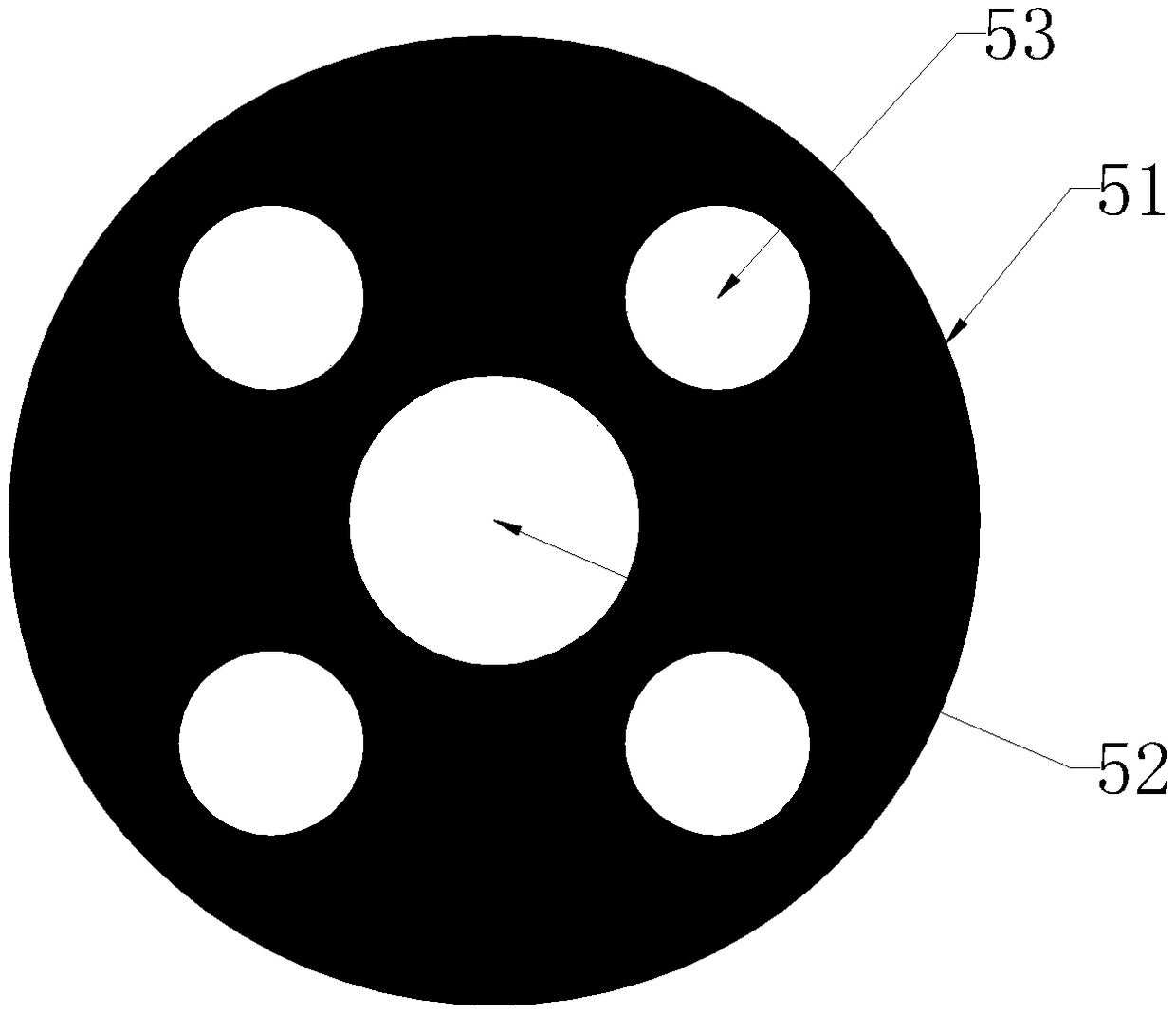

[0023] A non-checkerboard format calibration plate for white light scanner calibration, comprising a light-shielding back plate 10 and a light-transmitting calibration plate 20, the center of the back plate is provided with a cavity 30 with an opening, and the cavity 30 A luminous plate 40 is fixed inside, and the calibration plate 20 is fixed at the opening of the cavity 30. On the surface of the calibration plate 20, there are rectangular arrays of marking circles 50 of the same size. Among the marking circles 50 of the rectangular array are A positioning circle 51 is provided, a central circle 52 is provided at the center of the positioning circle 51 , and at least one auxiliary circle 53 is provided beside the central circle 52 .

[0024] Wherein, the size of each sign circle 50 is the same, and the distance of adjacent sign circles 50 is the same, the positioning circle 51 that is set in the sign circle 50 has inner central circle 52 and auxiliary circle 53 distinguishing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com