Automobile braking arm tool

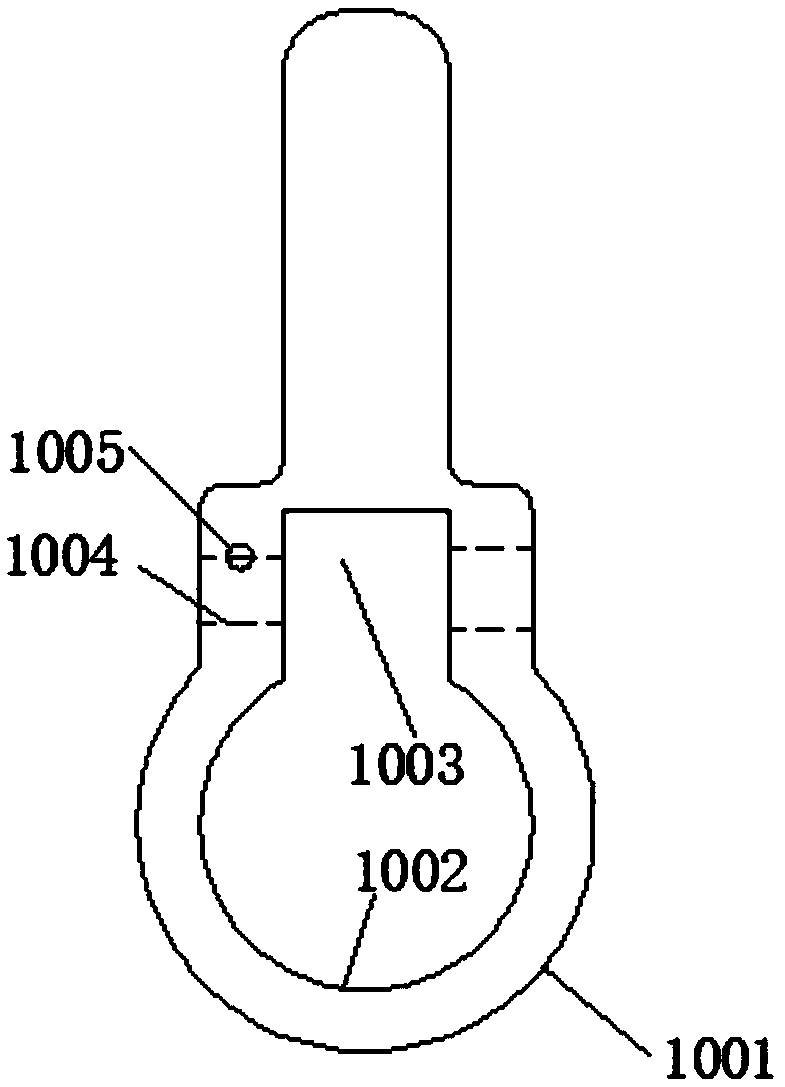

A technology of automobile braking and tooling, which is applied in the direction of manufacturing tools, metal processing equipment, and drilling molds for workpieces, etc., and can solve the problem of large dimensional errors, the incompatibility between the pin hole 1005 and the second hole 1004, and the brake arm 1001 Scrap and other issues, to achieve the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

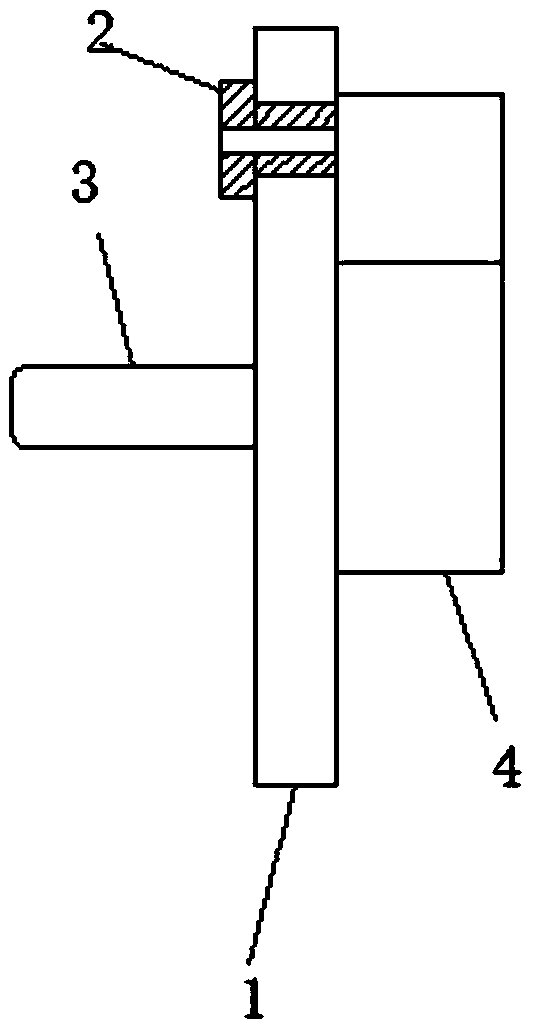

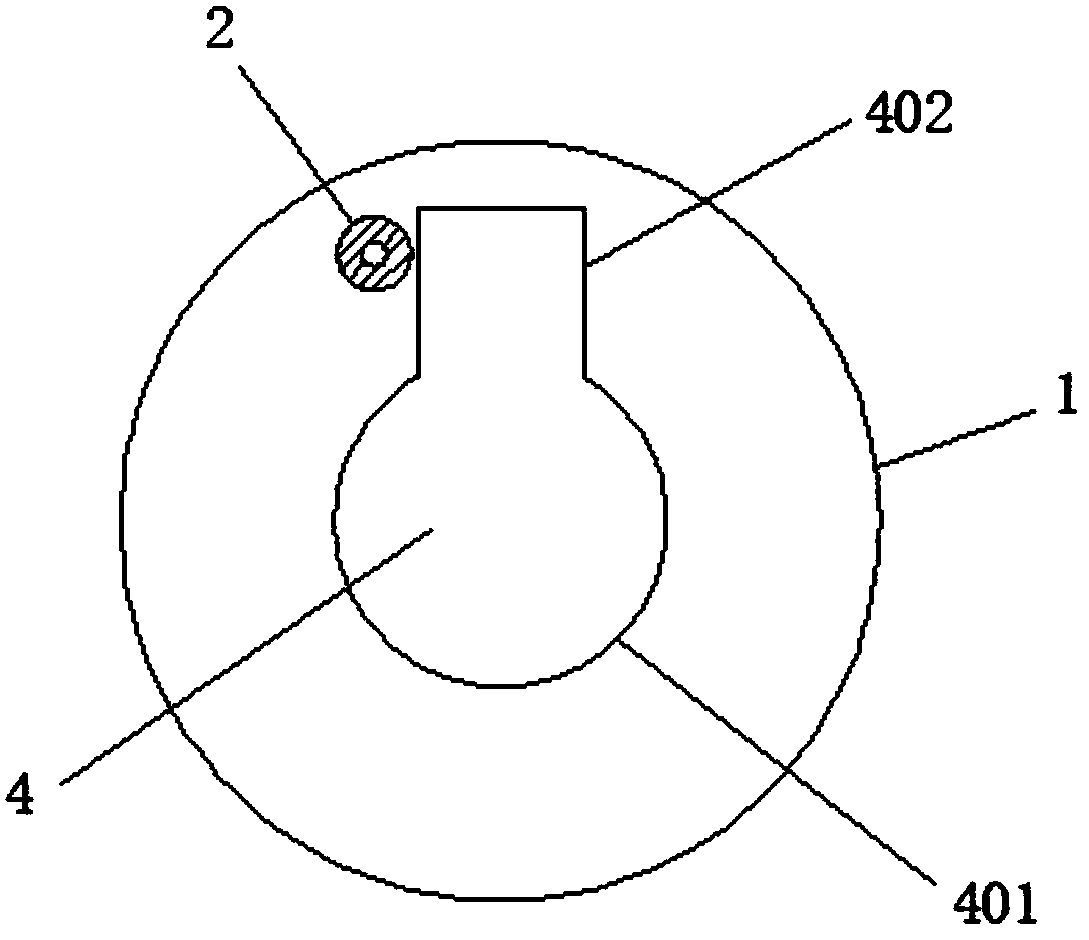

[0011] Such as Figure 1 ~ Figure 2 As shown, the automobile brake arm tooling includes a template 1, a drill sleeve 2, a handle 3, and a positioning block 4. The template 1 has a handle 3 on the left, a positioning block 4 on the right, and a positioning circle under the positioning block 4. 401, a positioning block 402 is set on the positioning circle 401, and a drill sleeve 2 is arranged on the left side of the positioning block 402. The positioning block of the present invention is positioned with the hole 1 and the square groove of the brake arm, and the drill sleeve is used as a reference to process the pin Hole, so that the position of the pin hole and the hole 1 and the square groove meet the technical requirements, and the stability is high.

[0012] Those skilled in the art also understand t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com