Meat automatic forming machine

An automatic forming machine, the technology of meat, applied in the direction of cleaning method using gas flow, metal processing, cleaning method and utensils, etc., can solve the problems of low work efficiency, poor shape consistency of meat pieces, cumbersome operation, etc., and achieve pressing and cutting High efficiency and good molding consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

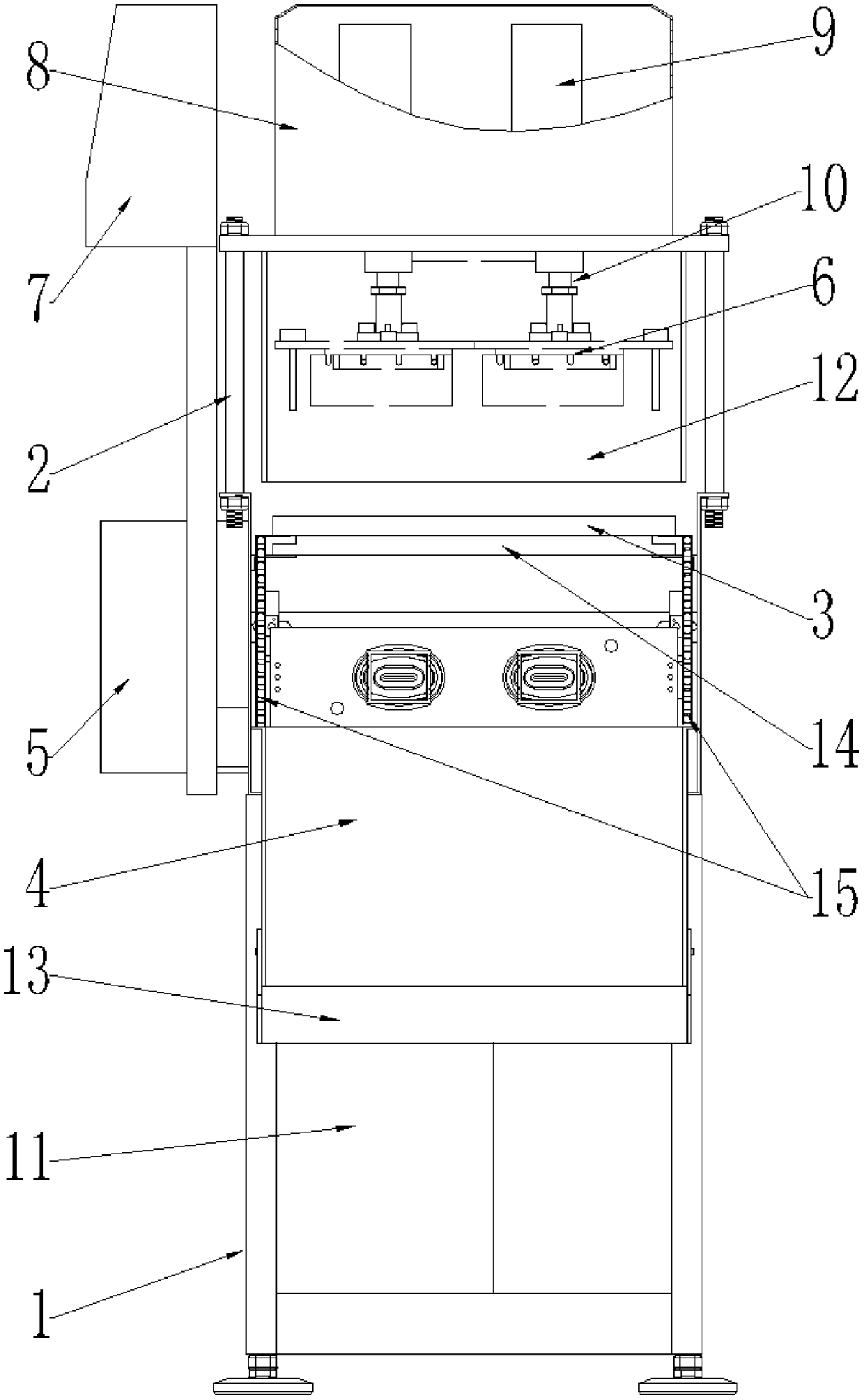

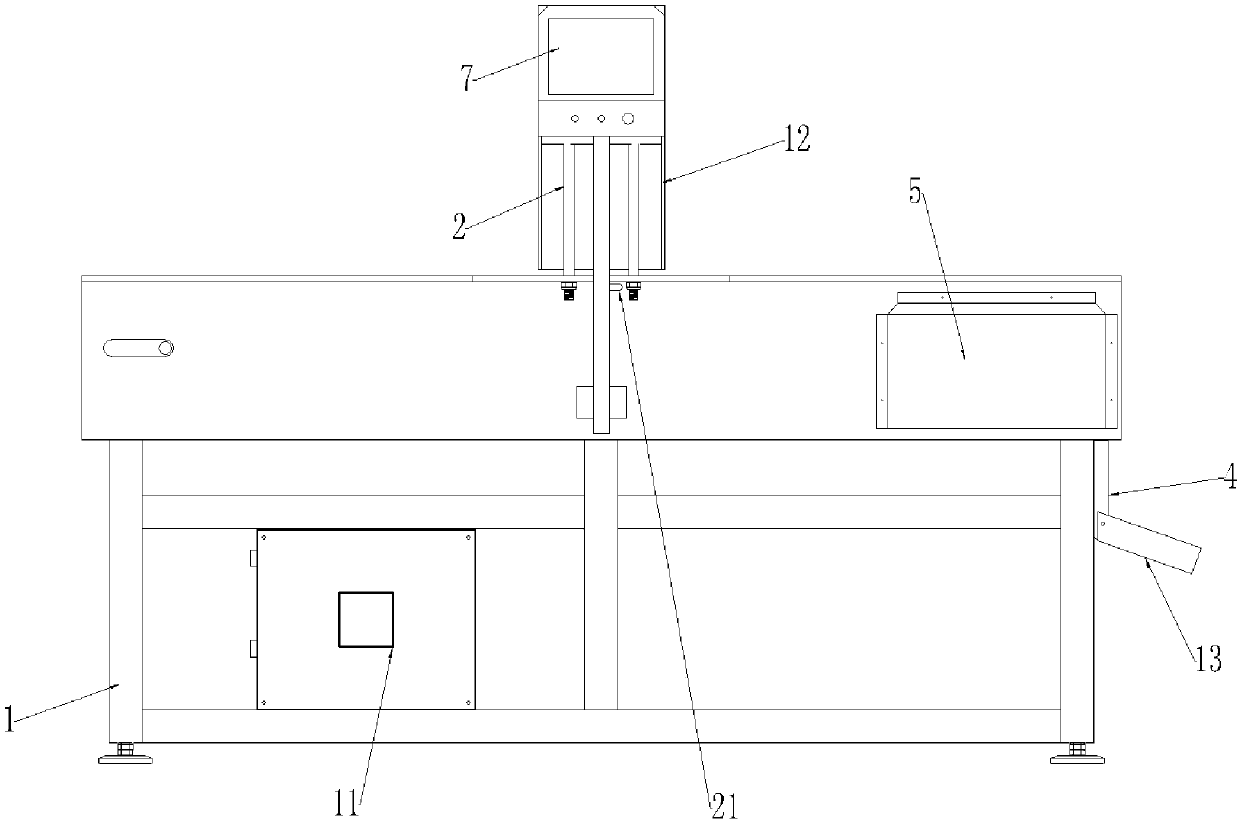

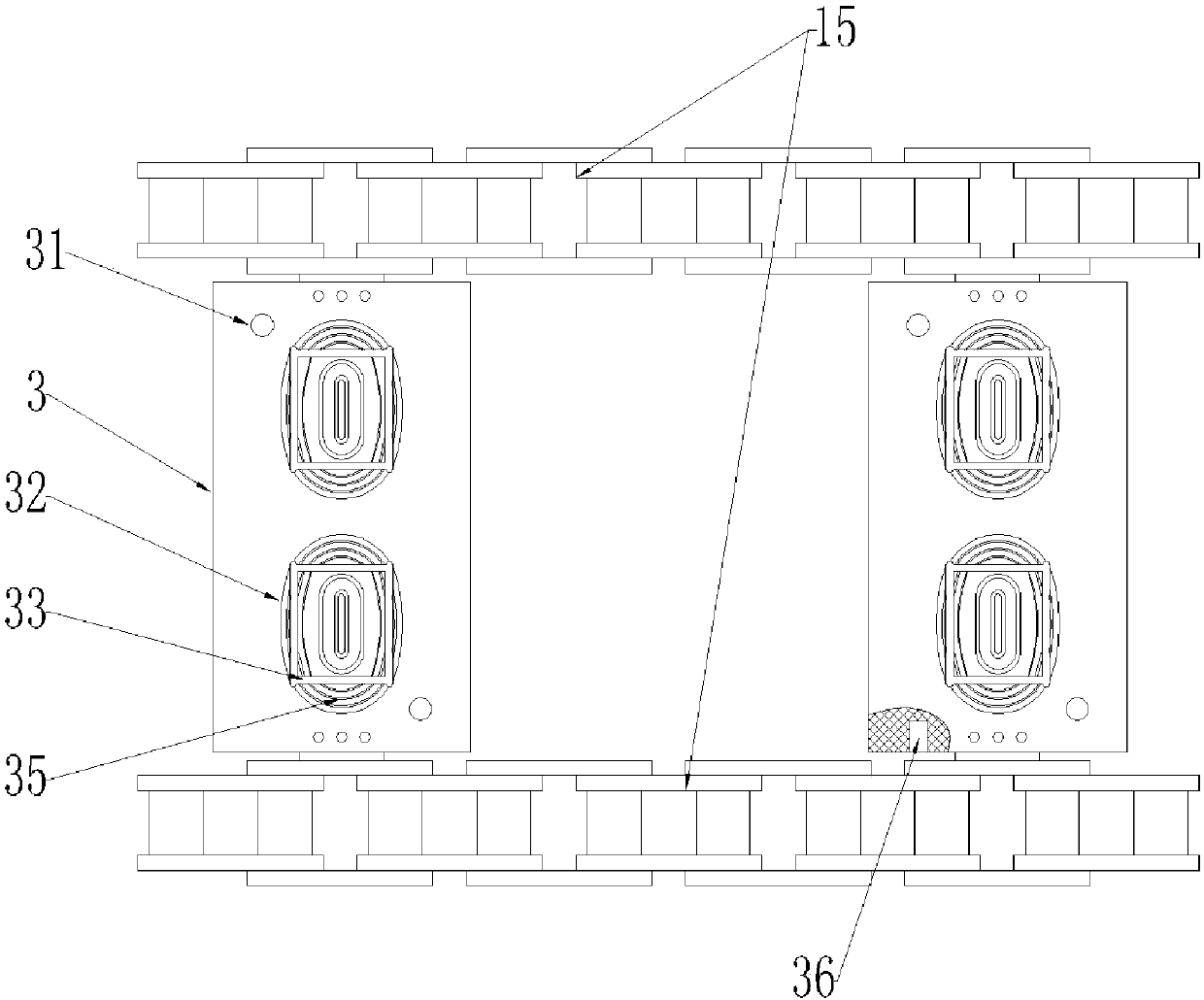

[0024] Such as figure 1 and figure 2 As shown, the meat automatic forming machine includes a frame 1, and the conveyor chain device is provided on the frame 1; The chain 15 is provided with a drive sprocket shaft and a driven sprocket shaft rotating on the frame 1, and the conveyor chain 15 is connected to the drive sprocket shaft and the driven sprocket shaft. The drive sprocket shaft is connected with a conveyor chain driving device, and the conveyor chain driving device includes a reduction box and a servo motor located in the drive box 5, and the reduction box is a worm gear reducer. Several templates 3 are provided between the two conveyor chains 15, such as image 3 As shown, the two ends of the template 3 are respectively fixed on the two conveying chains 15; wherein, a connecting plate is arranged on the chain plate of the conveying chain 15, and the template 3 is fixed on the connecting plate by screws or bolts or pins, etc. The template 3 moves synchronously with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com