Patents

Literature

518 results about "Chain device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copyright management method and system

ActiveCN107145768ARealize immutableOffice automationProgram/content distribution protectionOperating systemChain device

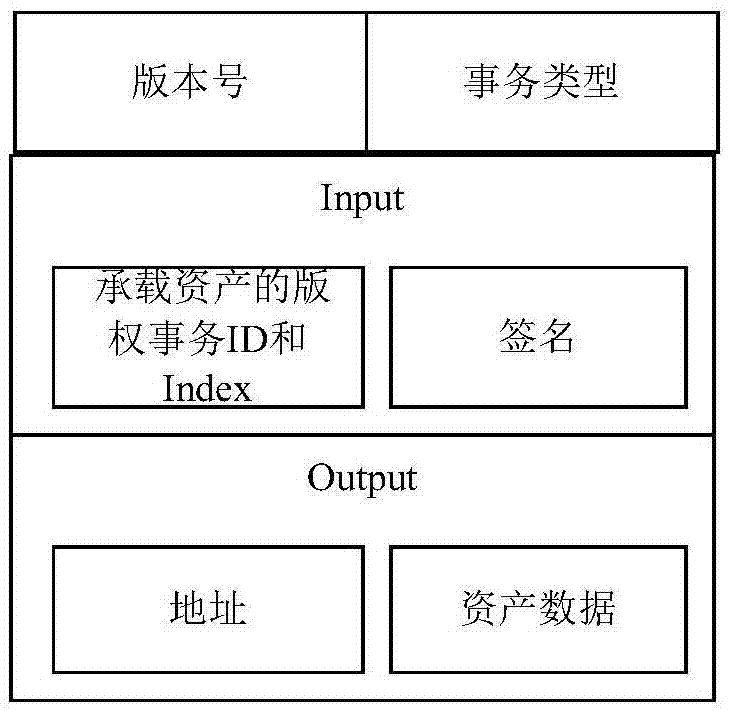

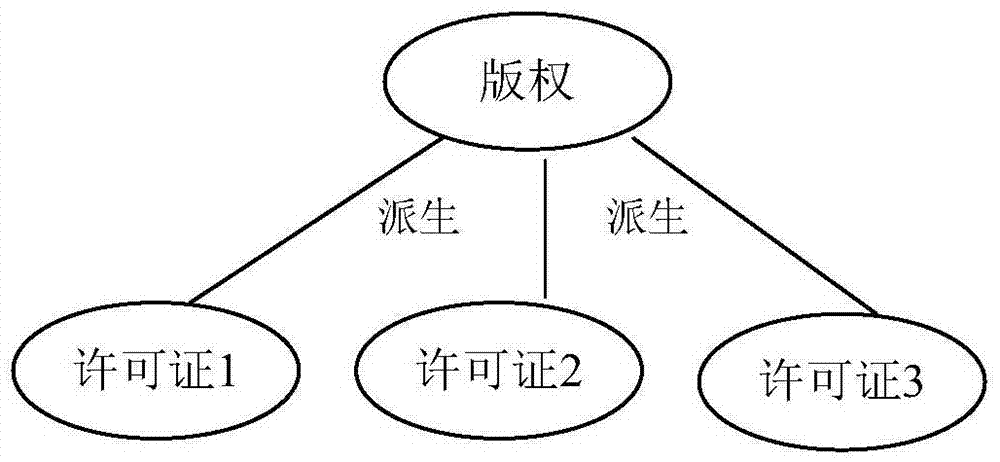

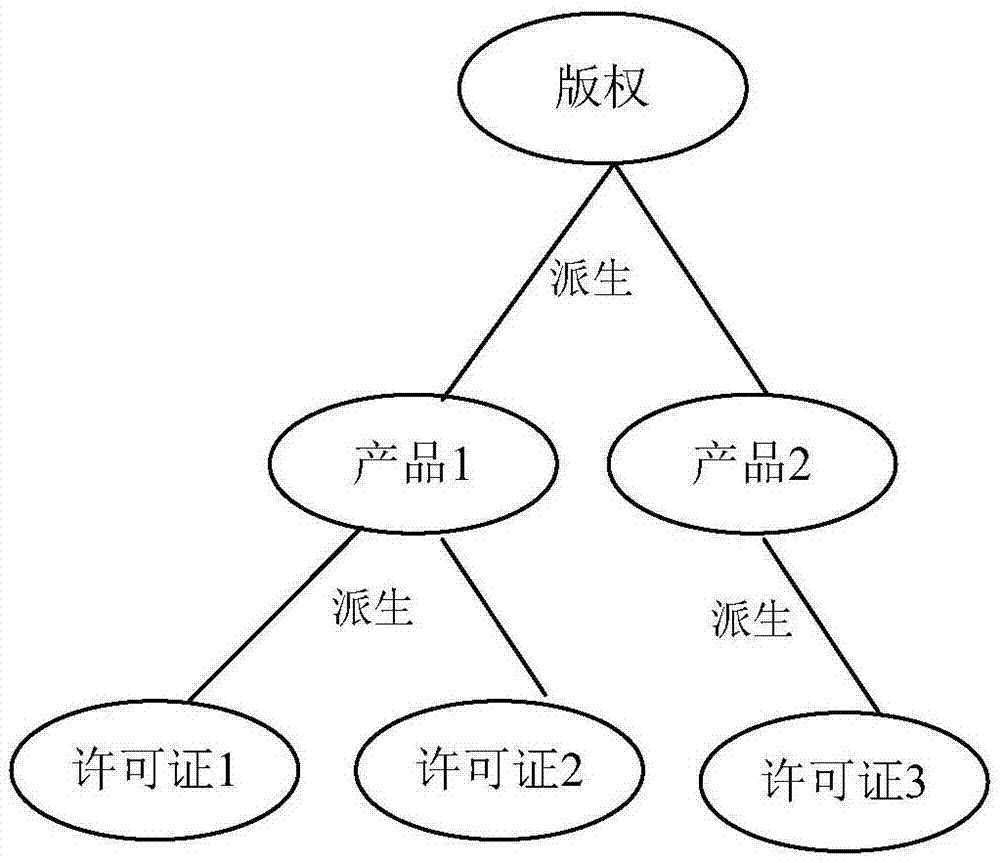

The embodiment of the invention provides a copyright management method. The method comprises steps of receiving a copyright processing request, constructing a copyright management business according to the copyright processing request, and storing the copyright management business to a block chain for processing. All block chain devices store the block chain; and the copyright management business can be processed in a credible and safe way.

Owner:HUAWEI TECH CO LTD

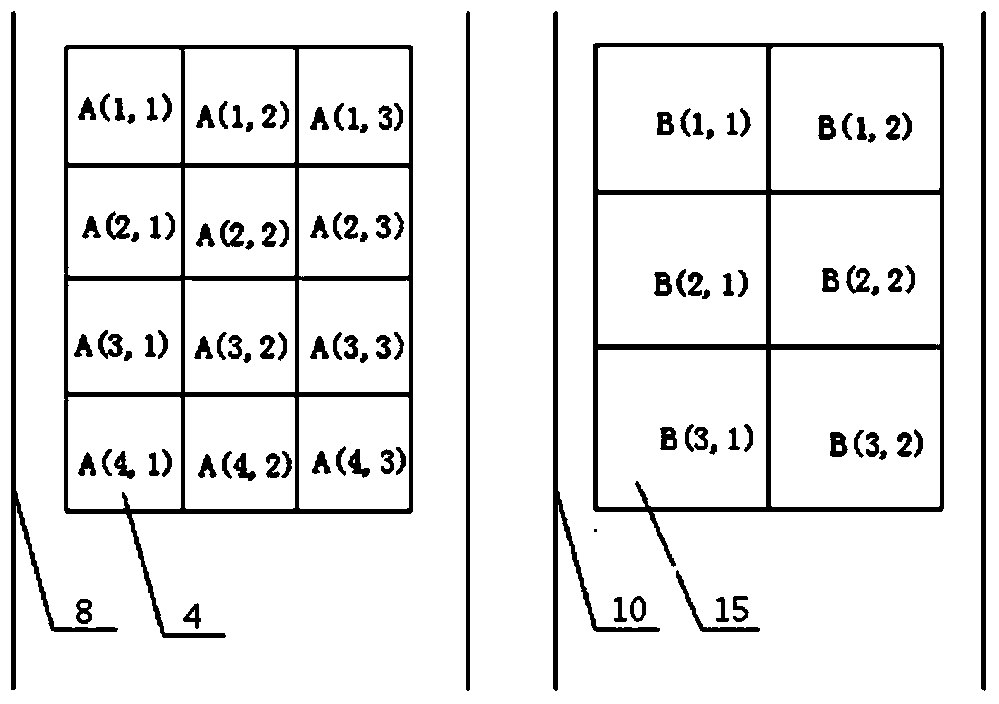

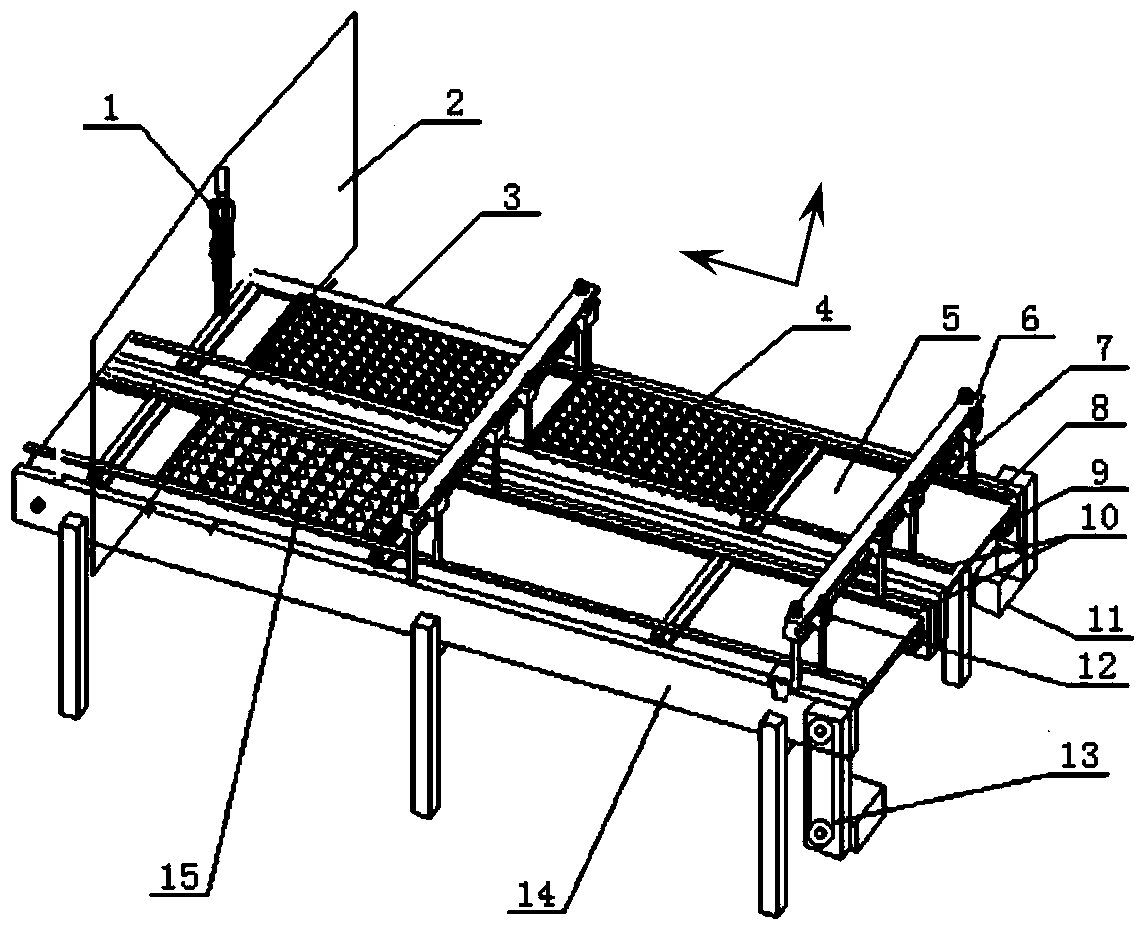

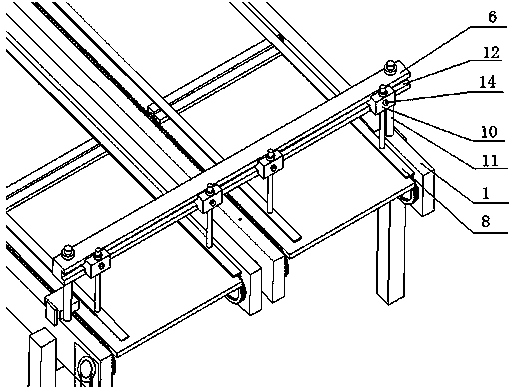

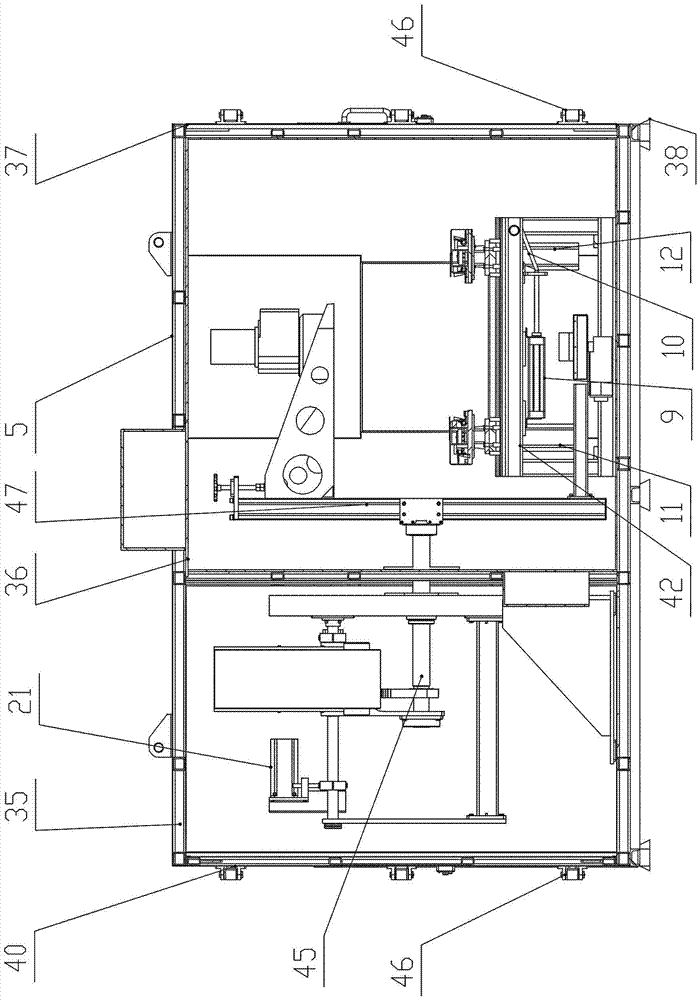

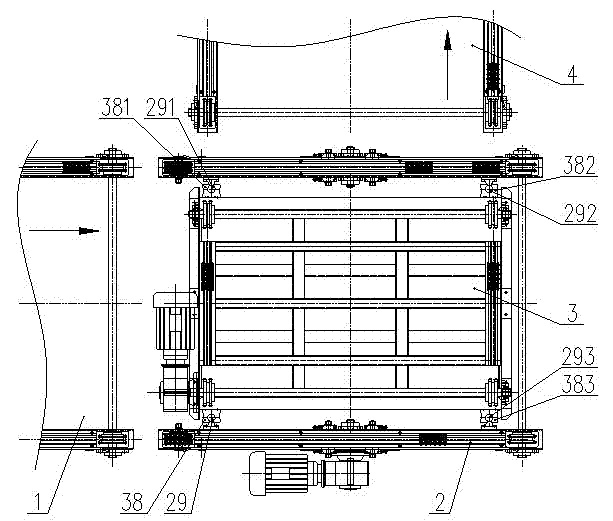

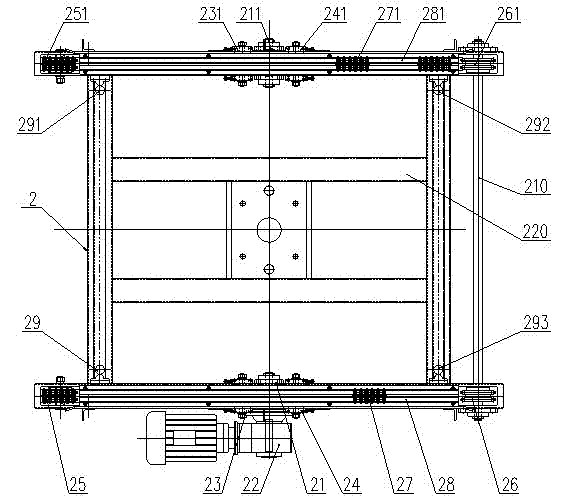

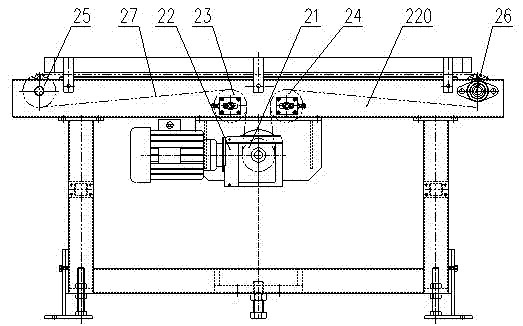

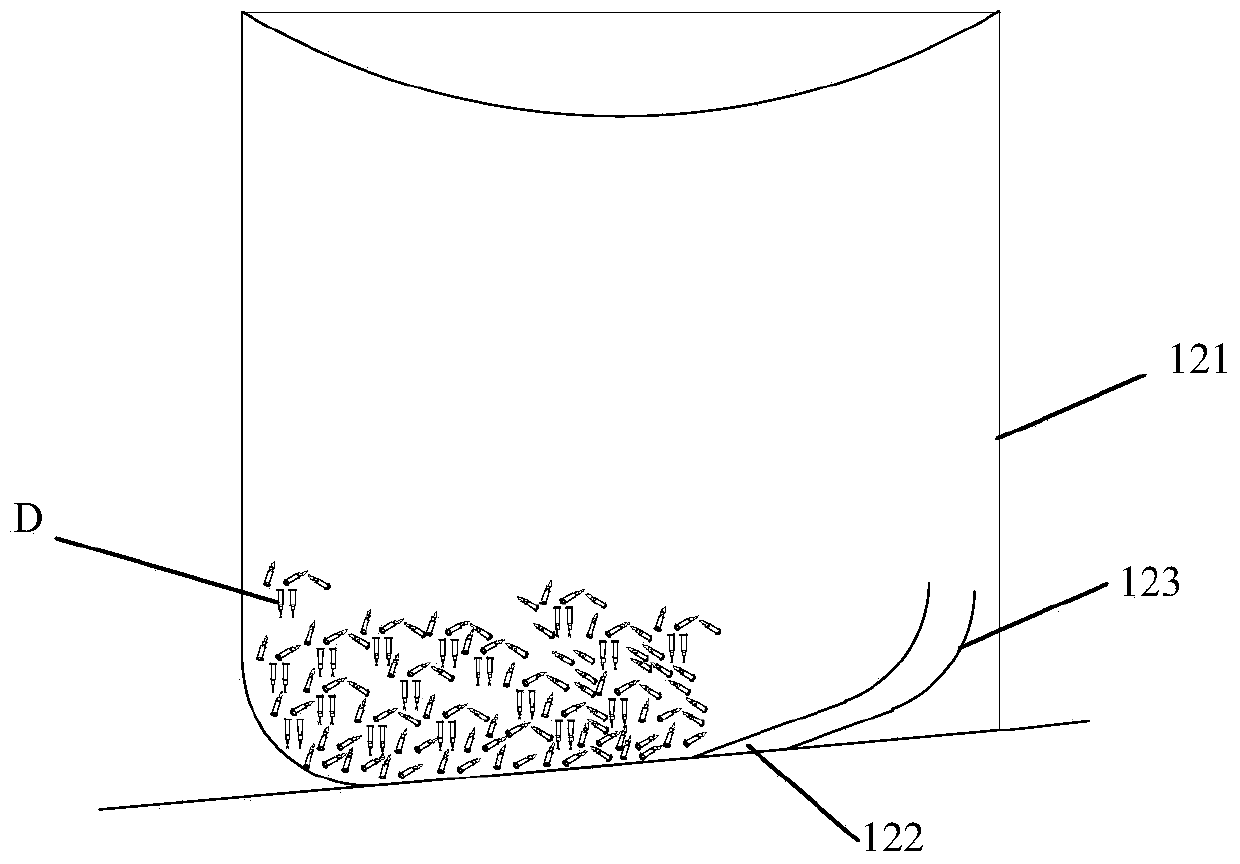

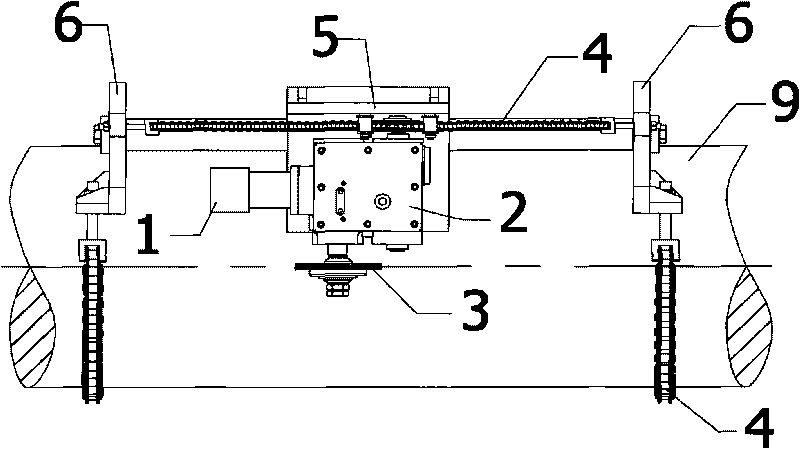

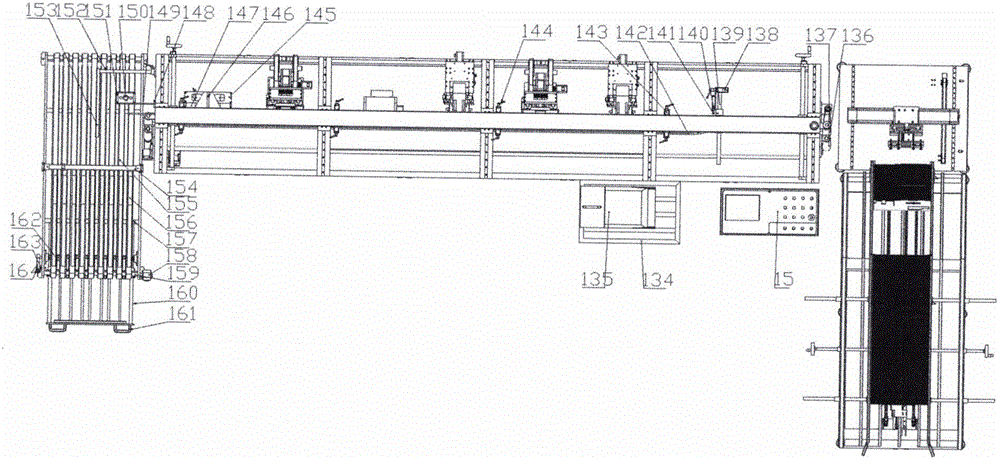

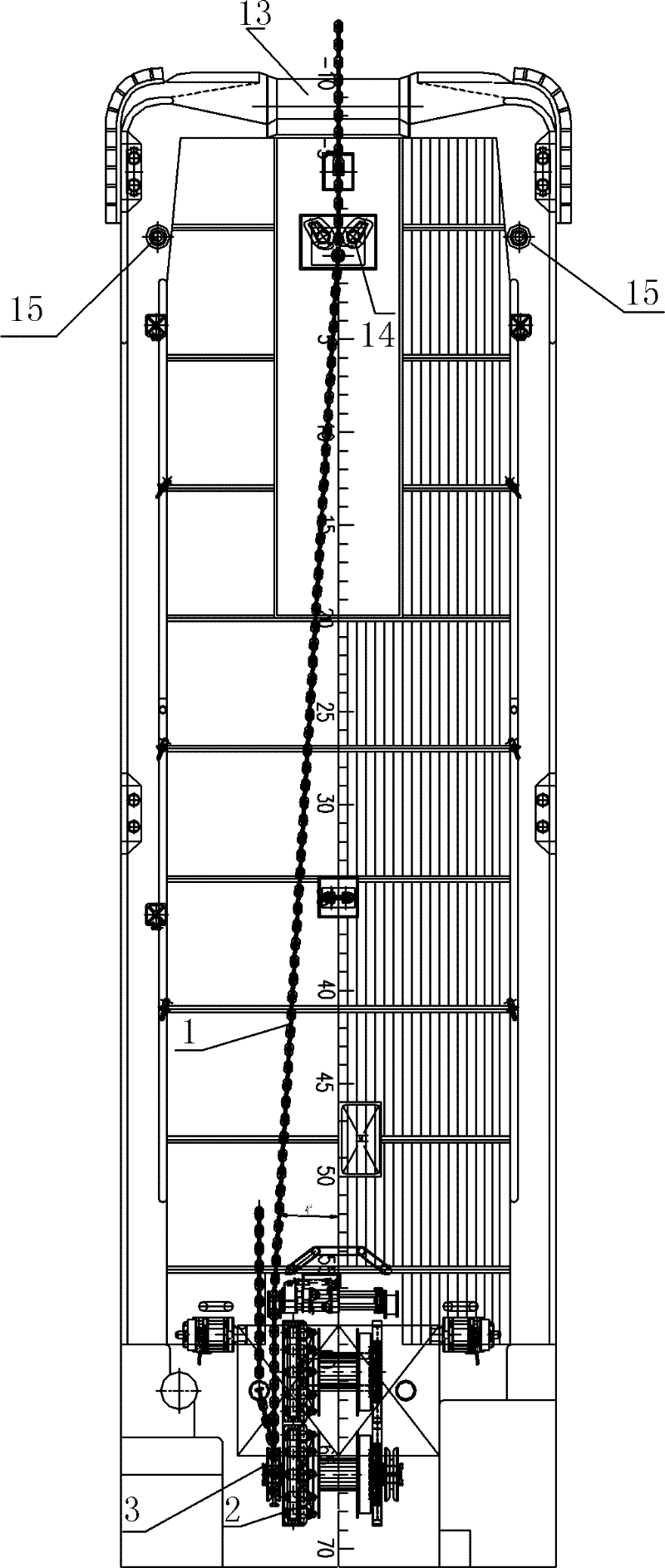

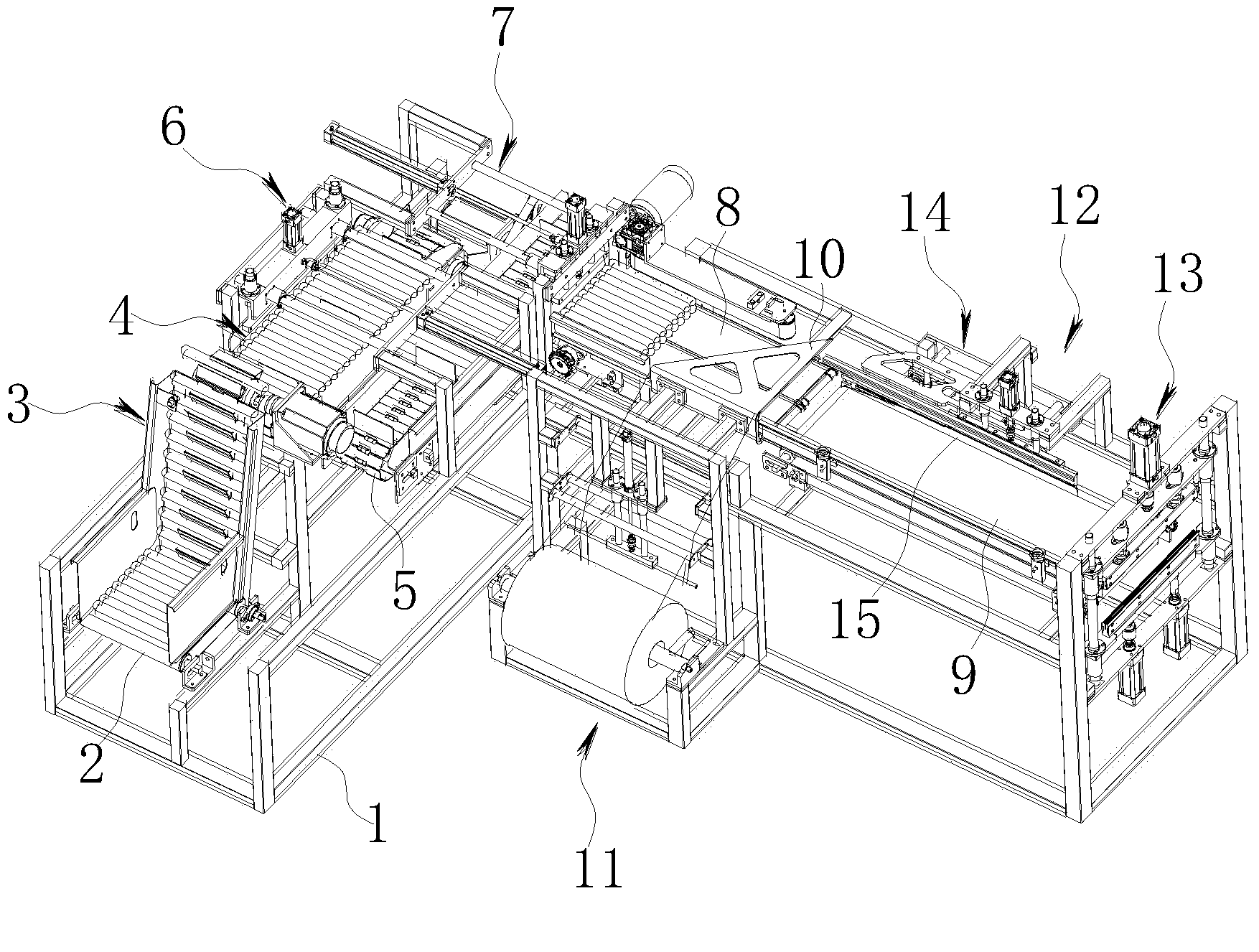

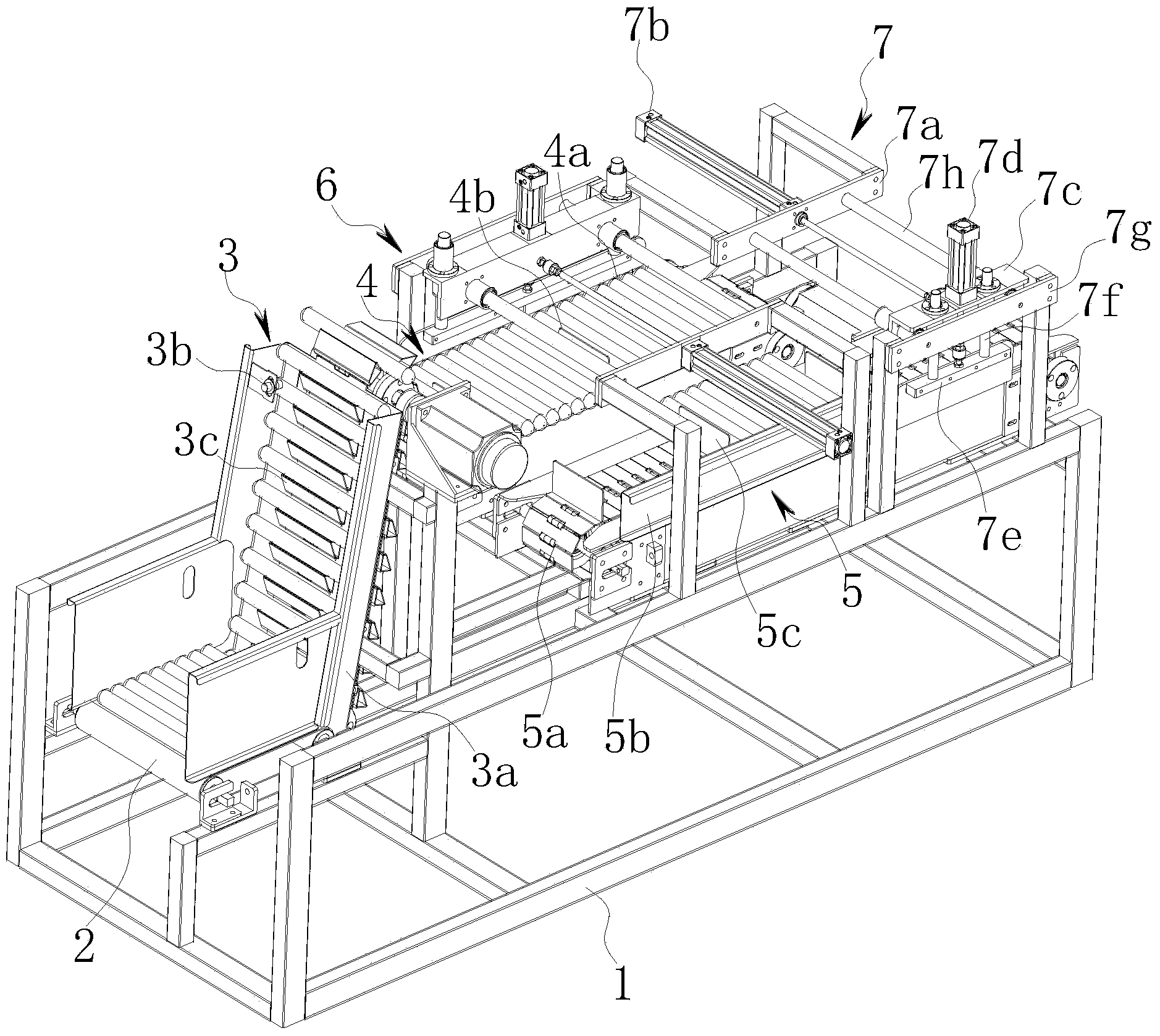

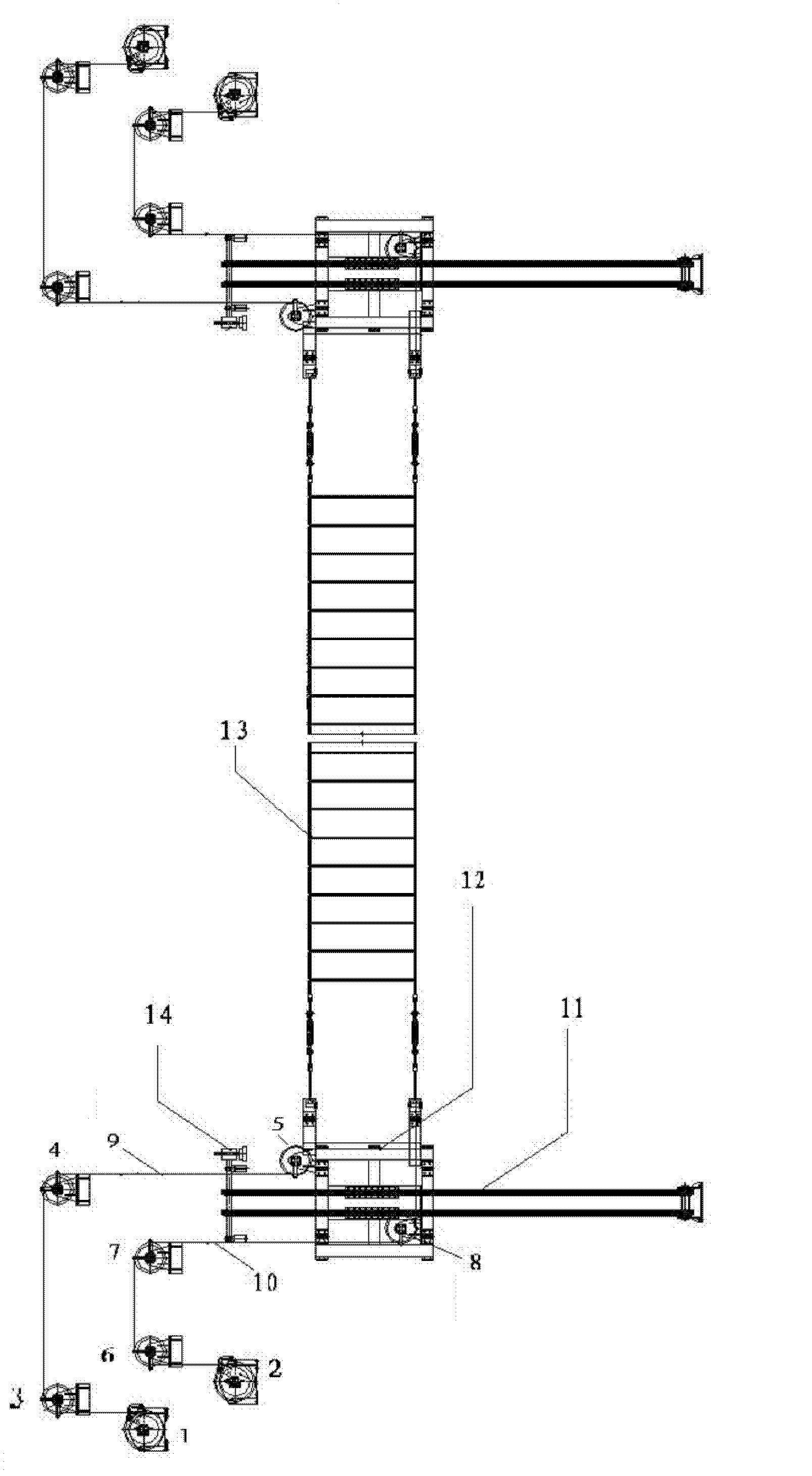

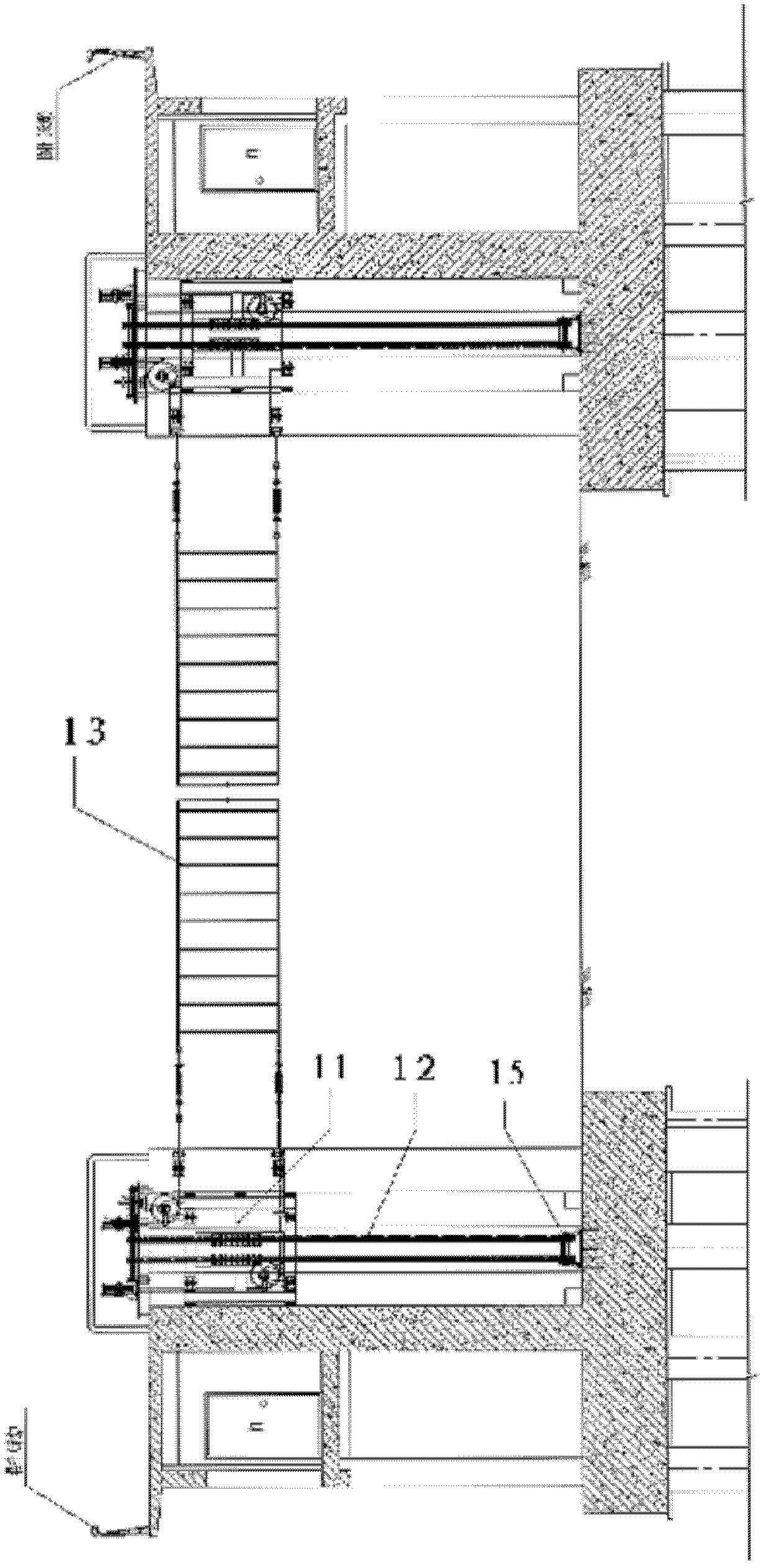

Conveying and positioning device and method used for automatic potted tray seedling transplanter

InactiveCN103787051AAvoid damageAdaptableControl devices for conveyorsTransplantingMotor driveChain device

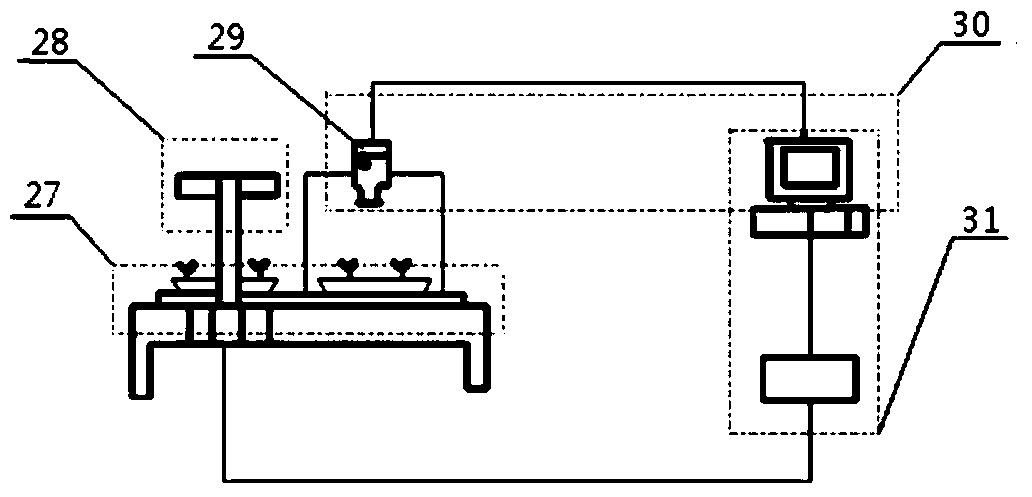

The invention provides a conveying and positioning device and method used for an automatic potted seedling transplanter. A conveying platform is fixedly mounted on a conveying rack, a seedling tray conveying guide device is mounted on the conveying platform, seedling supplying and planting trays are placed among conveying guide rails on the conveying platform, horizontal conveying chain devices are mounted on two sides of the conveying rack, a plurality of potted tray pushing plates are mounted on each horizontal conveying chain, and a transmission chain device is mounted on the outer side of the conveying platform. When a servo motor drives a transmission chain to rotate by one cycle, the potted tray pushing plates on the horizontal conveying chains move for a certain distance along with the transmission chain to realize positioning and conveying of the seedling supplying and planting trays. Adjusting devices used for adjusting transverse positions of the potted trays are mounted on two sides of the conveying rack, and the adjusting devices execute seedling tray transverse position adjusting instructions given by a transplanting control center to realize transverse accurate positioning of the seedling supplying and planting trays. The conveying and positioning device is high in accuracy and good in stability and reliability, damage to potted tray seedling pots can be reduced, and transplanting efficiency of potted tray seedlings can be improved.

Owner:JIANGSU UNIV

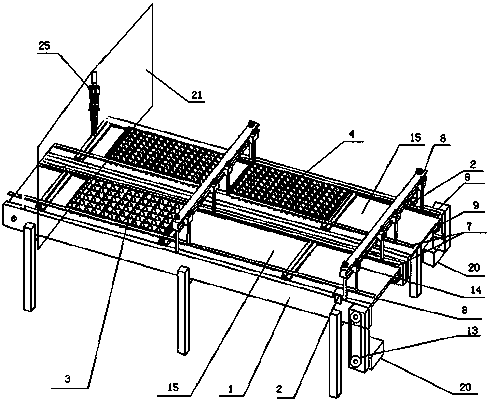

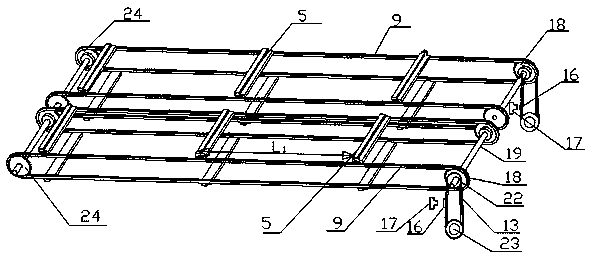

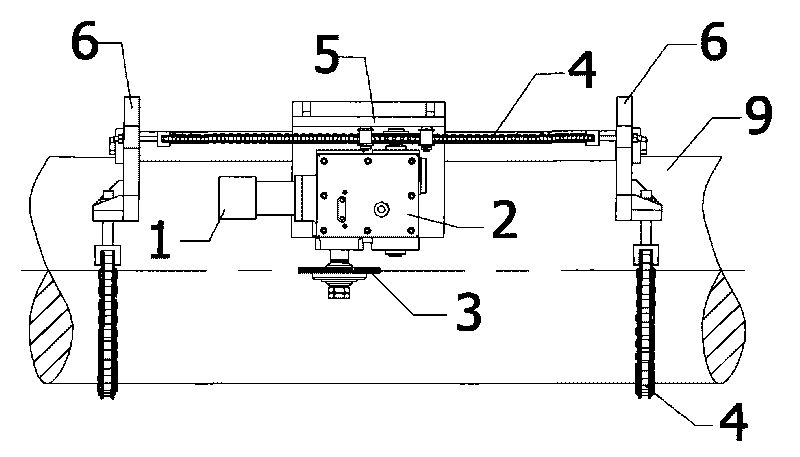

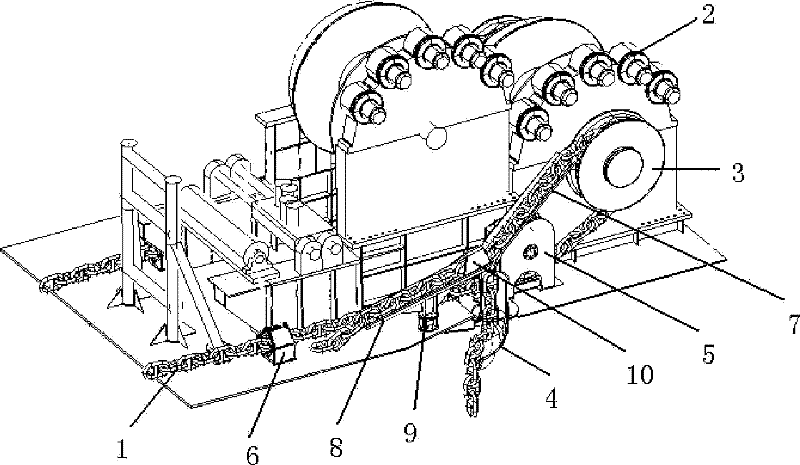

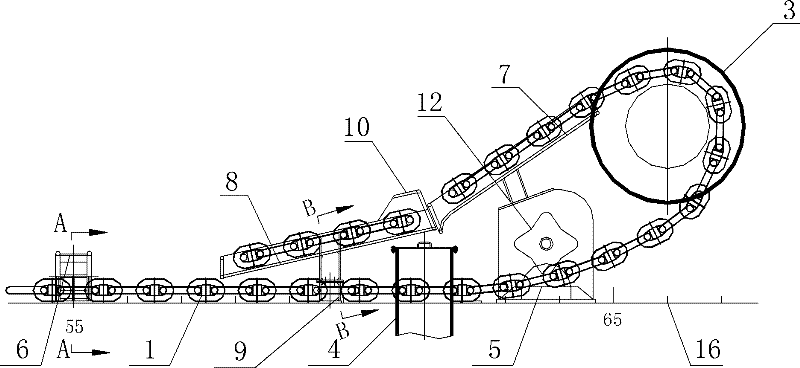

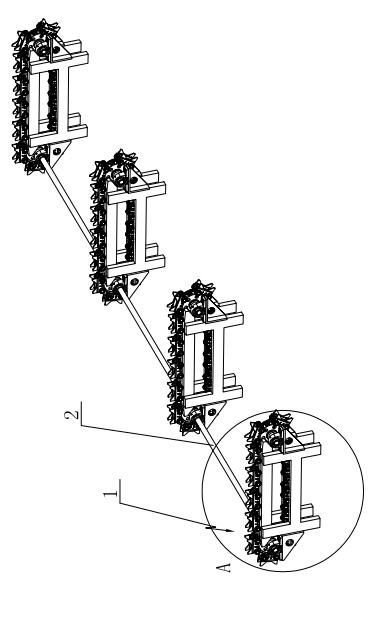

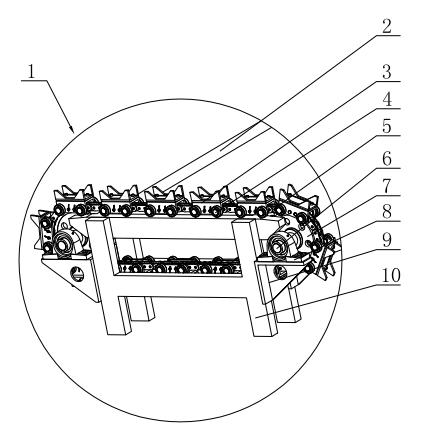

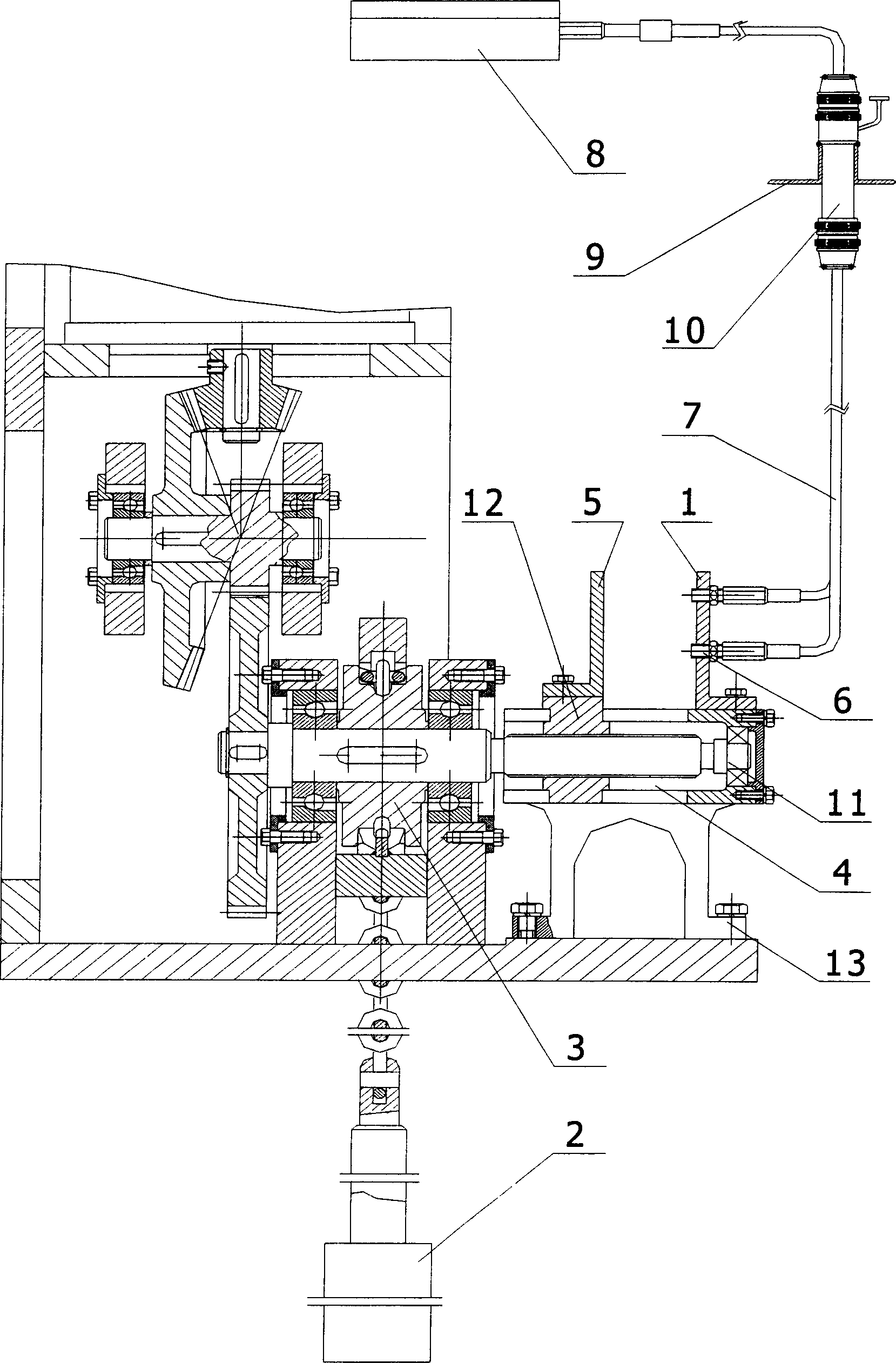

Hole tray conveying locating device for pot seedling transplanter

The invention provides a hole tray conveying locating device for a pot seedling transplanter. The pot seedling transplanter is provided with two hole tray conveying locating devices identical in structure, the two hole tray conveying locating devices are parallel to each other, conveying platforms are fixedly installed on a conveying table frame, a hole tray conveying guiding device is installed above the conveying platforms, hole trays are placed on the conveying platforms and between two conveying guide rails, horizontal conveying chain devices are installed on two sides of the conveying table frame, a plurality of hole tray push plates are installed on horizontal conveying chains at intervals of L1, a transmission chain device is installed on the outer side of the conveying table frame, and a Hall sensor is installed on one side of a transmission chain. When a servo motor drives the transmission chain to rotate for a round, the hole tray push plates on the horizontal conveying chains move a distance of L1, simultaneously the Hall sensor on one side of the transmission chain obtains induction signal once, and accordingly hole tray locating conveying is achieved. The hole tray conveying locating device is high in conveying locating precision, stable and reliable and is mainly applied to pot seedling transplantation.

Owner:JIANGSU UNIV

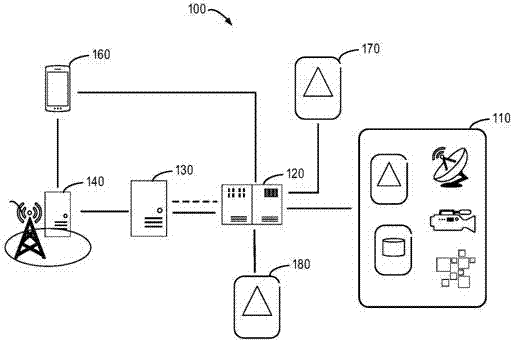

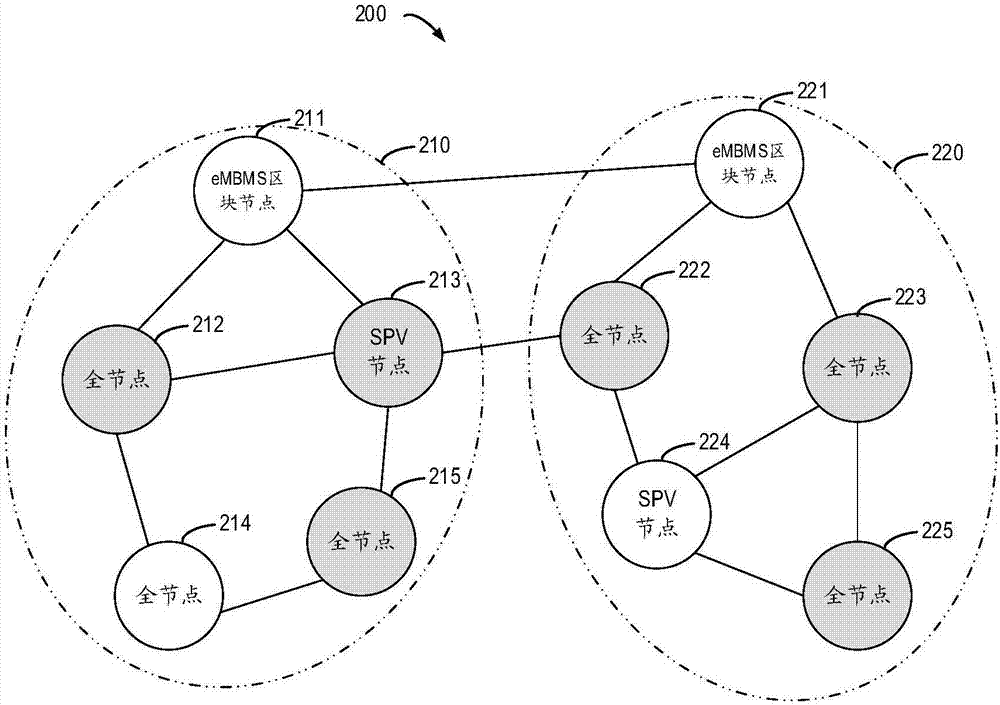

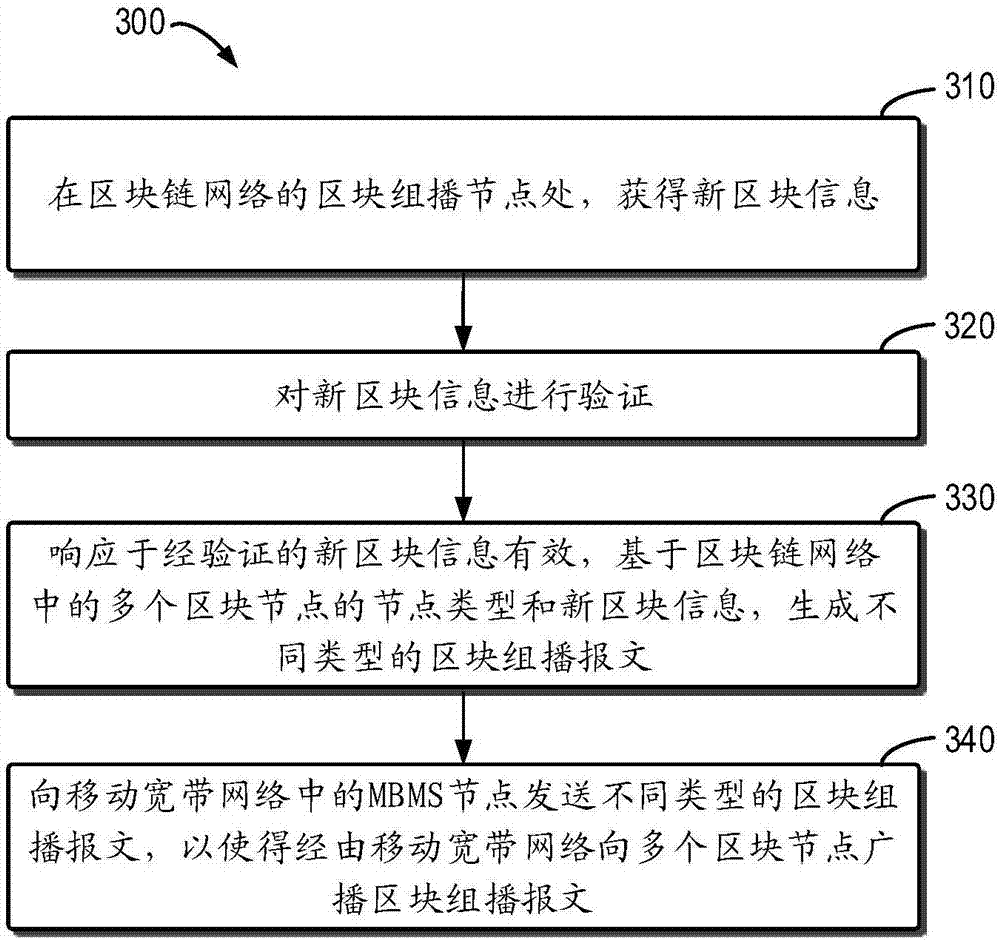

Block chain unicast/multicast network, block chain device and communication method thereof in mobile broadband network

ActiveCN107277781ASolve resource problemsSolve the shortcomings that easily cause network stormsSynchronisation arrangementNetwork traffic/resource managementMulticast networkBroadband

Embodiments of the disclosure relate to a block chain unicast / multicast network, a block chain device and a communication method thereof in a mobile broadband network. A method executed at a block multicast node of a block chain network includes obtaining and validating new block information. The method further includes steps of generating different types of block multicast messages in response to the validated new block information and on the basis of the type of the block node in a multicast area and the new block information, and sending the different types of block multicast messages to a multimedia broadcast and multicast service (MBMS) node in the mobile broadband network such that the messages are broadcasted to a plurality of block nodes via the mobile broadband network. The embodiments of the disclosure synchronize the latest block chain to all the nodes through the MBMS multicasting, which effectively solves the problem that a traditional P2P network occupies too many network resources and easily causes a network storm. In addition, the block chain nodes rapidly synchronize a block chain through MBMS multicasting, which has the advantages of good real-time performance and easy implementation.

Owner:上海道块信息技术有限公司

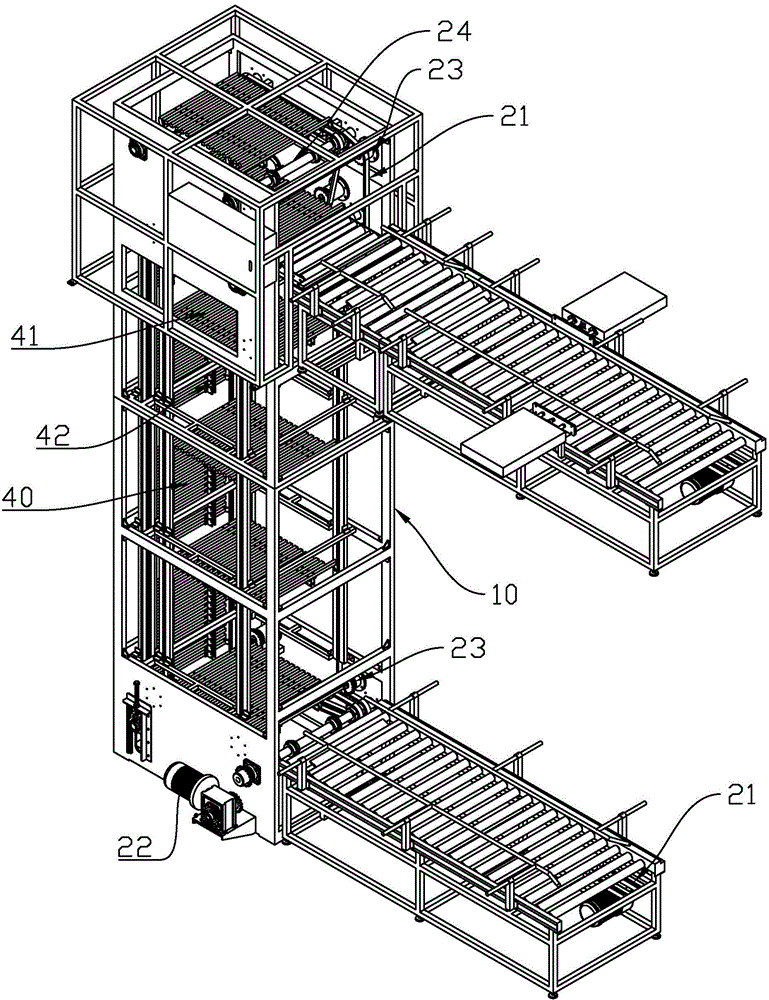

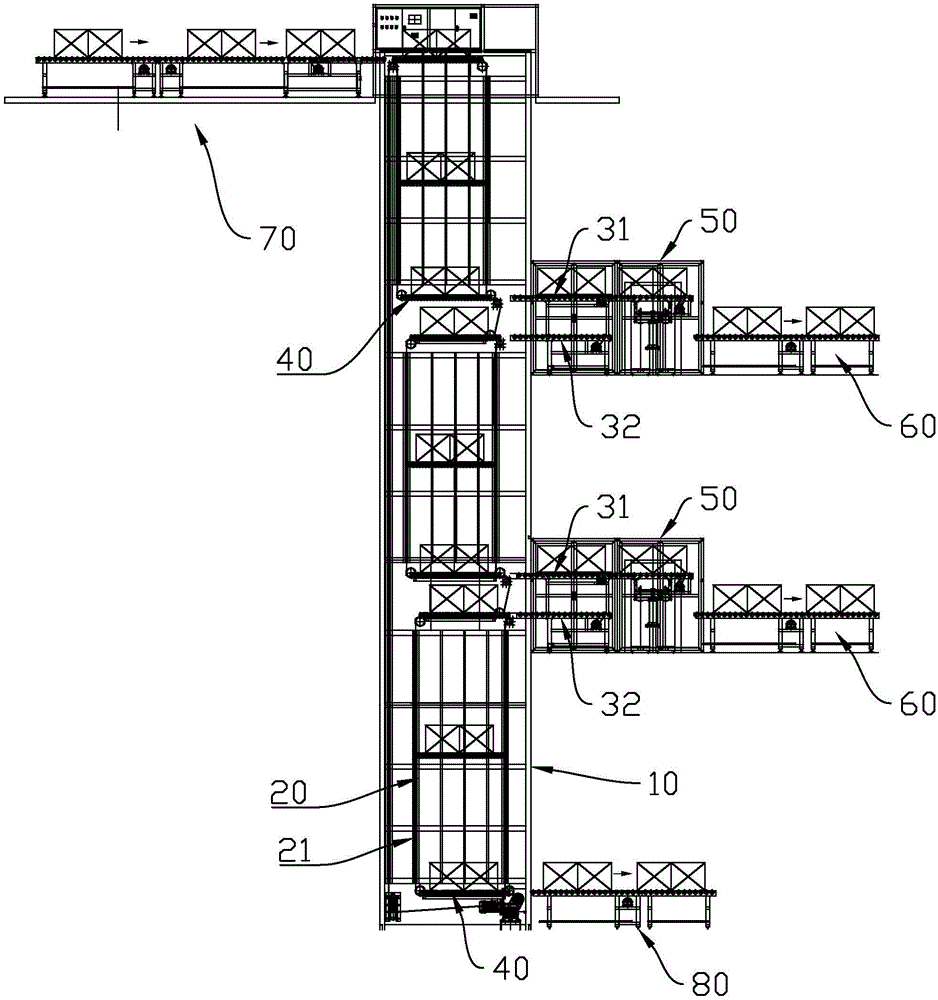

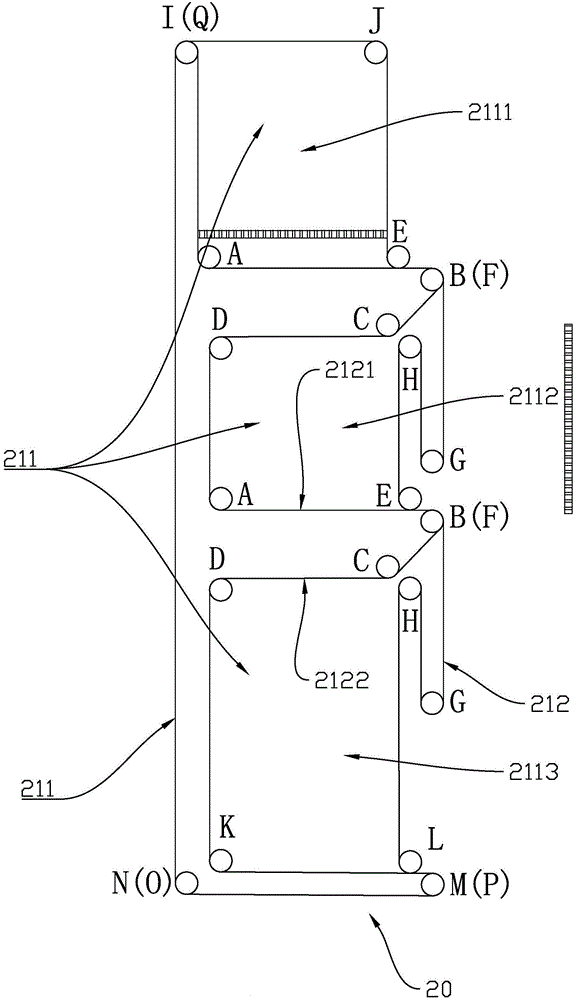

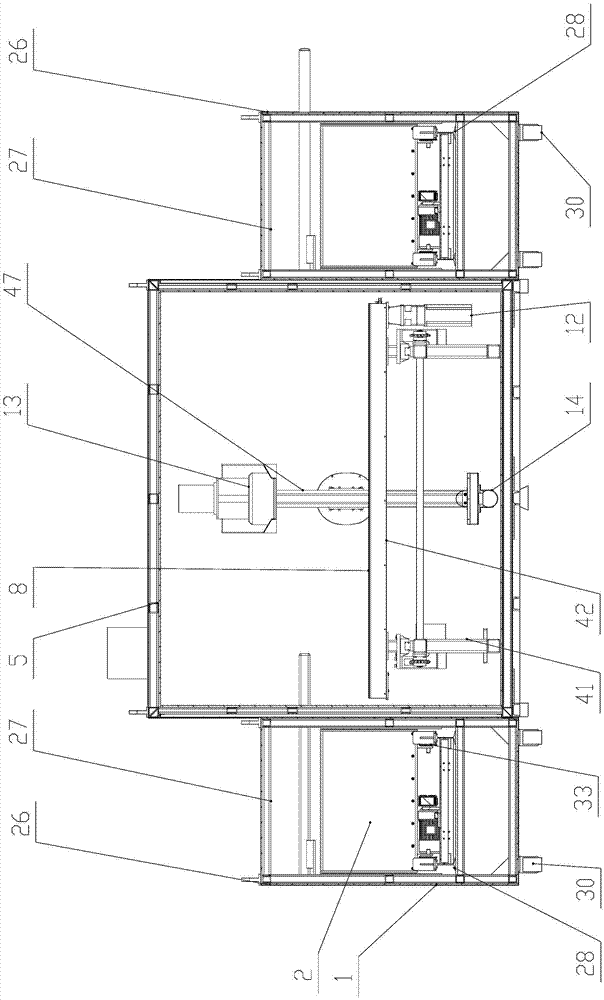

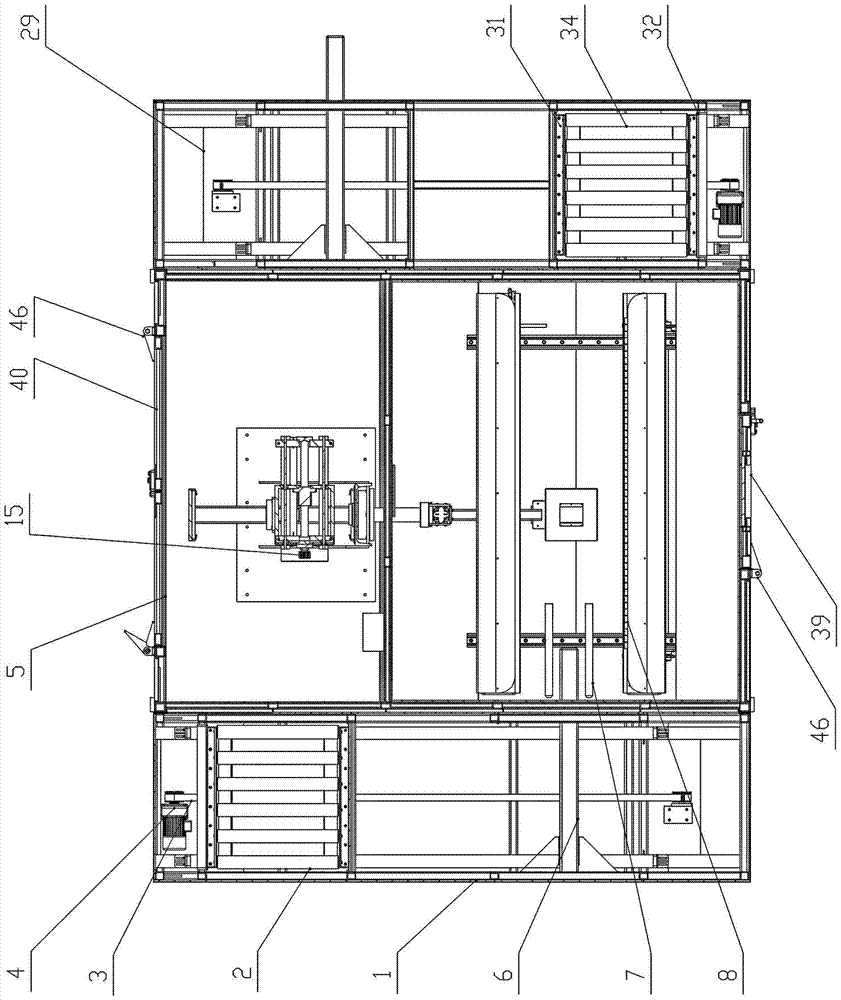

Multilayer interconnection shutter lifting device

ActiveCN104058241ARealize multi-layer interoperable transportationImprove delivery efficiencyConveyor partsMechanical conveyorsButt jointEngineering

The invention relates to a multi-layer interconnection shutter lifting device, which is characterized by comprising a rack, a circulating chain conveyor, a connecting platform and pallets. The circulating chain conveyor comprises symmetrically arranged circulating conveying chains, and each chain is provided with a plurality of vertical conveying sections for vertically conveying articles and a plurality of horizontal conveying sections for horizontally conveying articles, wherein the horizontal conveying section comprises first and second horizontal conveying sections which are arranged up and down in parallel at intervals and have opposite conveying directions, and the connecting platform is respectively butt-jointed with the first and second horizontal conveying sections of each layer; the pallets are sectionally and densely distributed on the chains, and vertically and horizontally convey the articles along the rotation direction of the chains in a circulating way, so that the articles at the vertical conveying section are horizontally conveyed to the first connecting platform through the first horizontal conveying section, the articles on the second connecting platform are vertically conveyed to a first horizontal conveying section at the adjacent layer through the second horizontal conveying section, and the articles can be conveyed between layers in an interconnection way through the vertical conveying and the horizontal conveying of the chains, and thus the articles can be conveyed upwards or downwards to any layer.

Owner:深圳市瑞杰机电工程有限公司

Combined hub X-ray real-time imaging automatic detection device

ActiveCN103048340AExtended service lifeImprove protectionMaterial analysis using wave/particle radiationProcess engineeringChain link

Owner:DONGDAN AOLONG RADIATIVE INSTR GRP

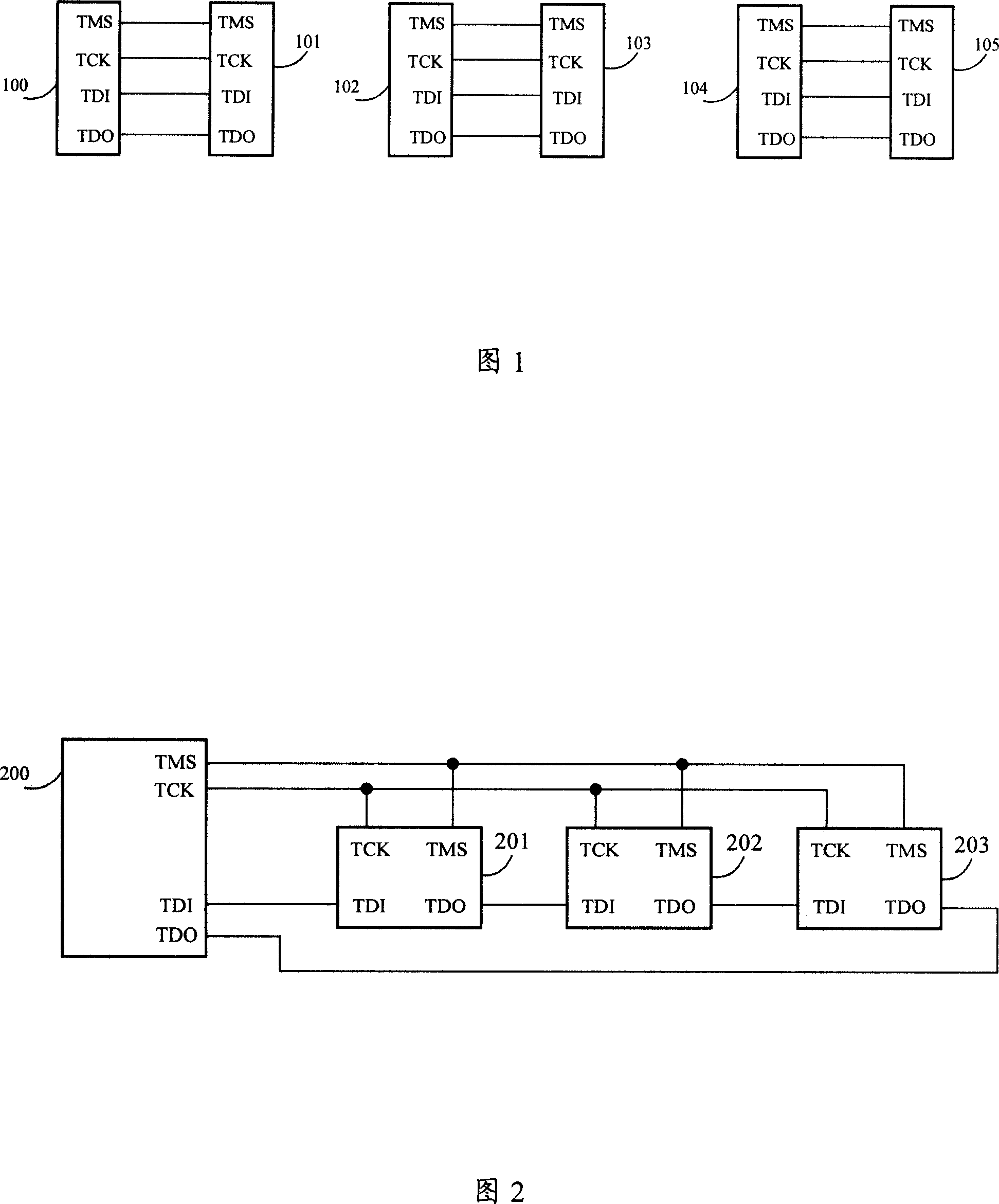

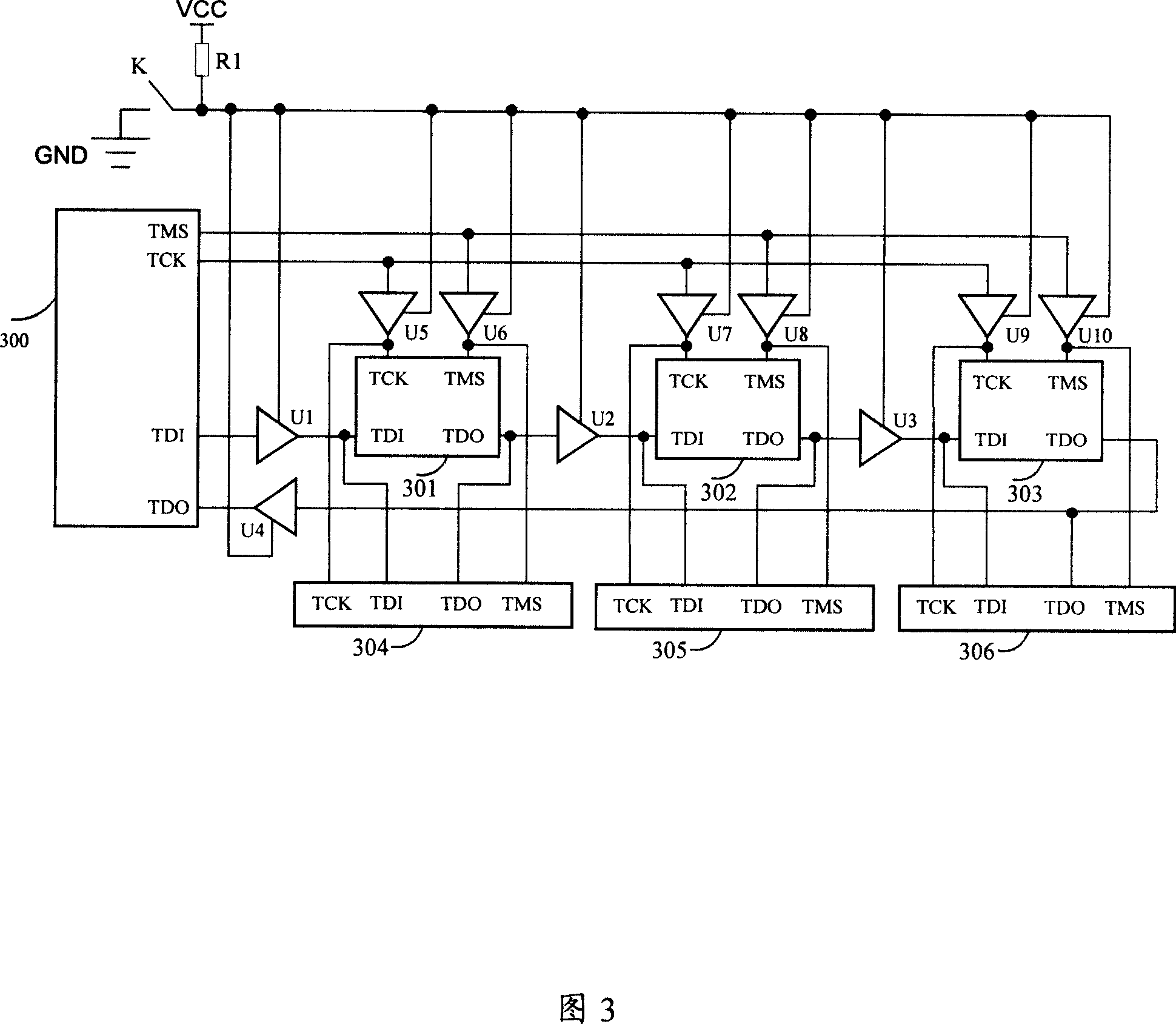

Multifunctional combined testing moving group chain device

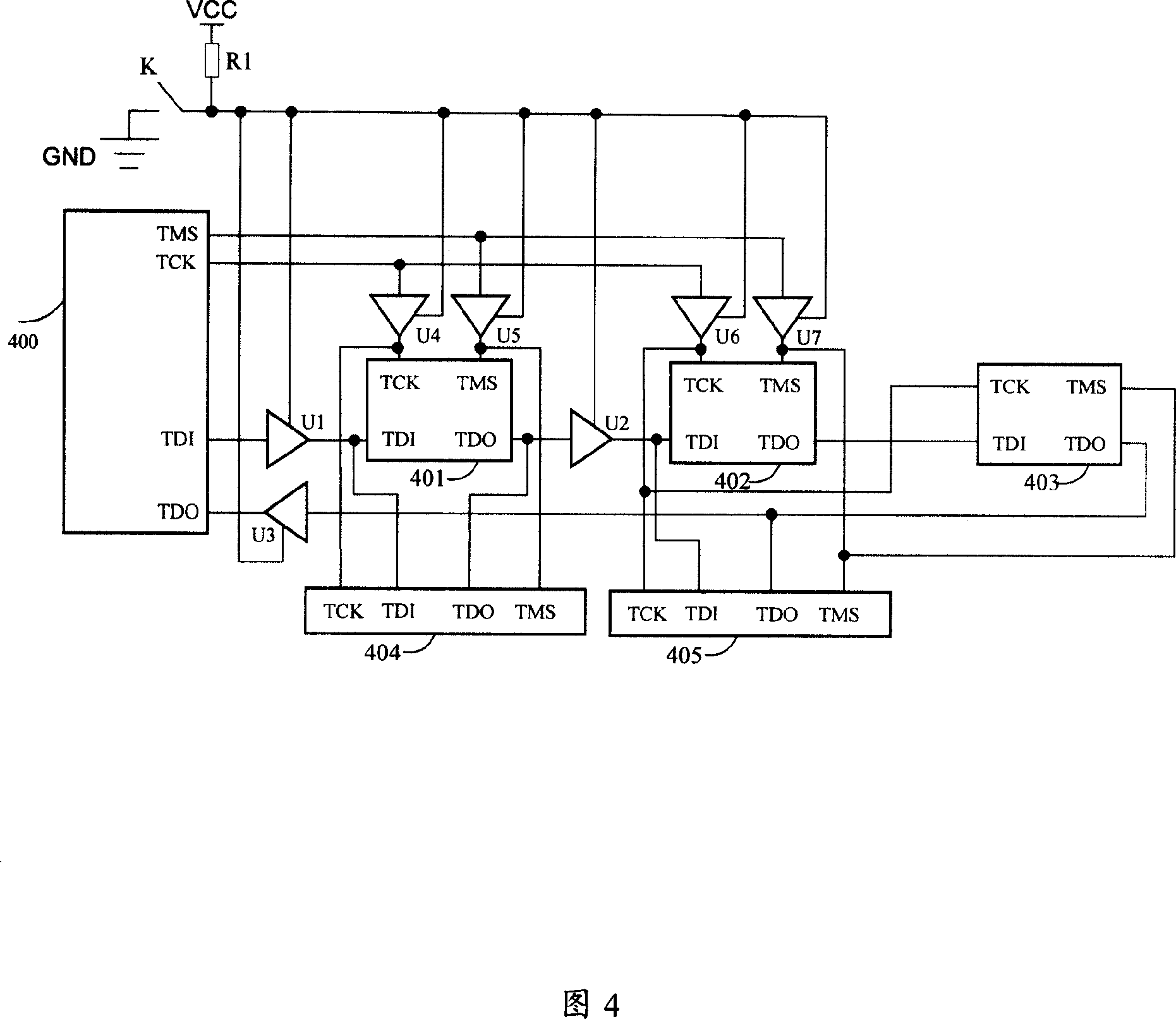

The present invention discloses a multi-function JTAG chain device comprising a boundary scan connector that is used for boundary scanning and at least two JTAG components which are connected to form a JTAG chain and are connected with the boundary scan connector. The device also comprises a controllable switch, a switch control device and a debugging connector that serves for the downloading and debugging of each JTAG component. A controllable switch is arranged in series respectively between the test data input TDI pin of the boundary scan connector and TDI pin of the JTAG component that is connected with the boundary scan connector; between test data output TDO pins in series of the JTAG chain and TDI pin; between TDO pins of the boundary scan connector and TDO pins of the JTAG component; and in each parallel-connection branch lines formed by the test mode selection input TMS / test clock input TCK pins and TMS / TCK pins of each JTAG component. All controllable switches are all under the control of the switch control device; TDI, TDO, TMS and TCK pins of each JTAG component are connected respectively with TDI, TDO, TMS and TCK pins of the debugging connector.

Owner:DATANG MOBILE COMM EQUIP CO LTD +1

Transfer mechanism at 90-degree corner of conveyor track

The invention discloses a transfer mechanism at a 90-degree corner of a conveyor track. The transfer mechanism is used for conveying sterilization trays in a sterilization production line. The transfer mechanism comprises a transverse drive chain device and a longitudinal drive chain device, wherein the transverse drive chain device comprises a transverse rack on which a transverse drive chain mechanism matched with a transverse conveyor track is arranged; the longitudinal lifting drive chain device can be lifted up and down and comprises a longitudinal rack on which a longitudinal drive chain mechanism matched with a longitudinal conveyor track is arranged; and the lower end of the longitudinal rack is connected with a piston rod of a lifting cylinder. With the transfer mechanism at the 90-degree corner of the conveyor track, the arrangement of the sterilization trays on the conveyer rack is not changed, and the purposes of small occupied area and low investment cost are achieved.

Owner:JIANGSU SHENNONG AUTOCLAVE

Cross-data-block data access method, apparatus and system, and computer readable medium

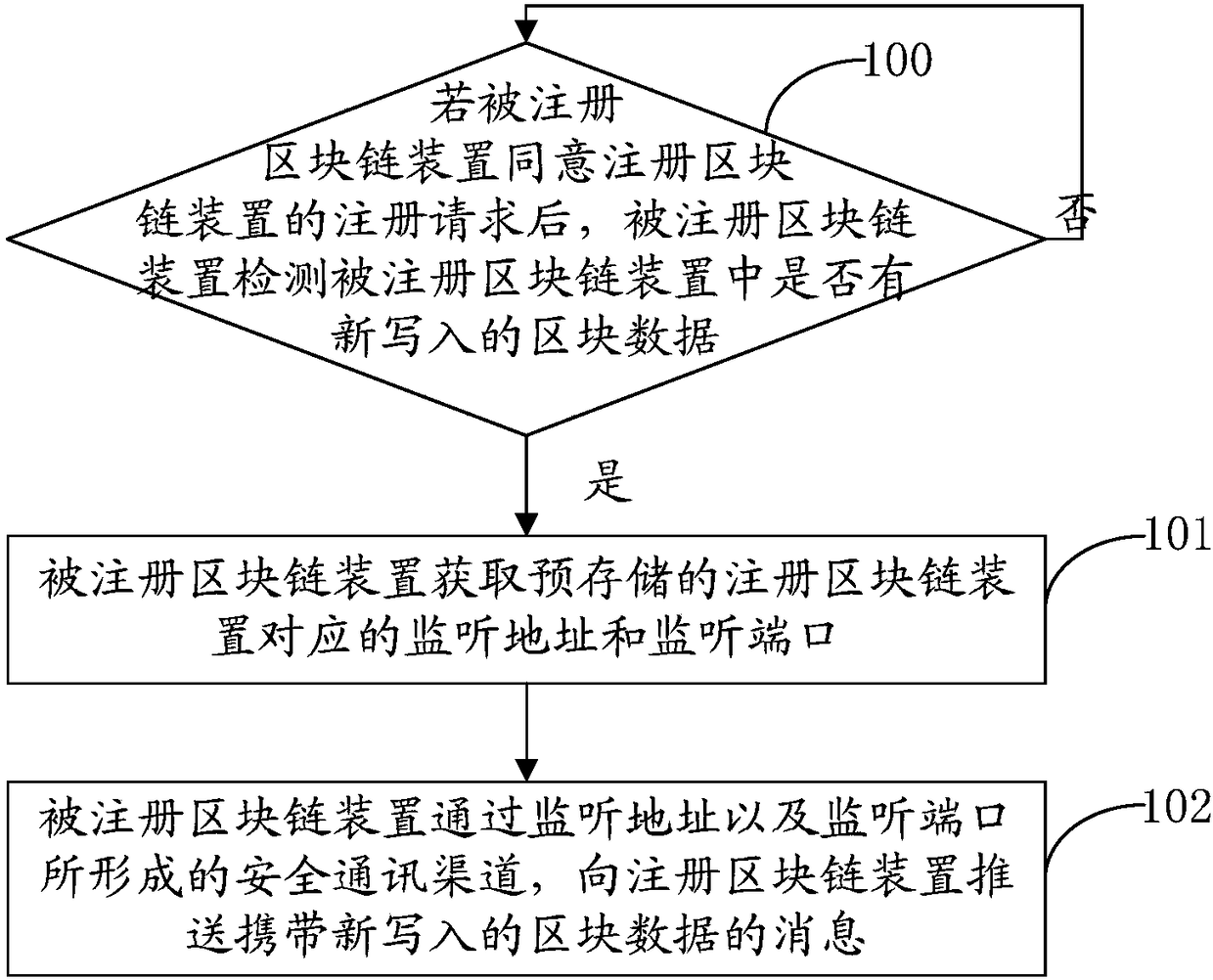

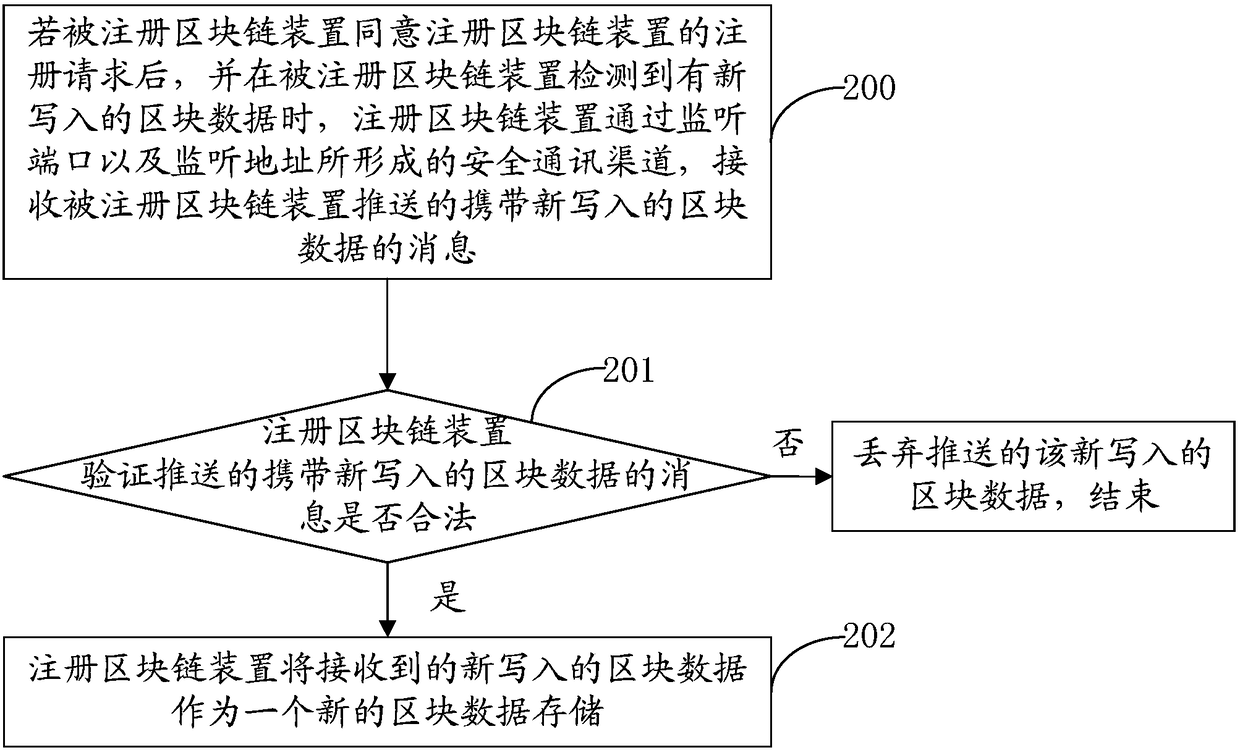

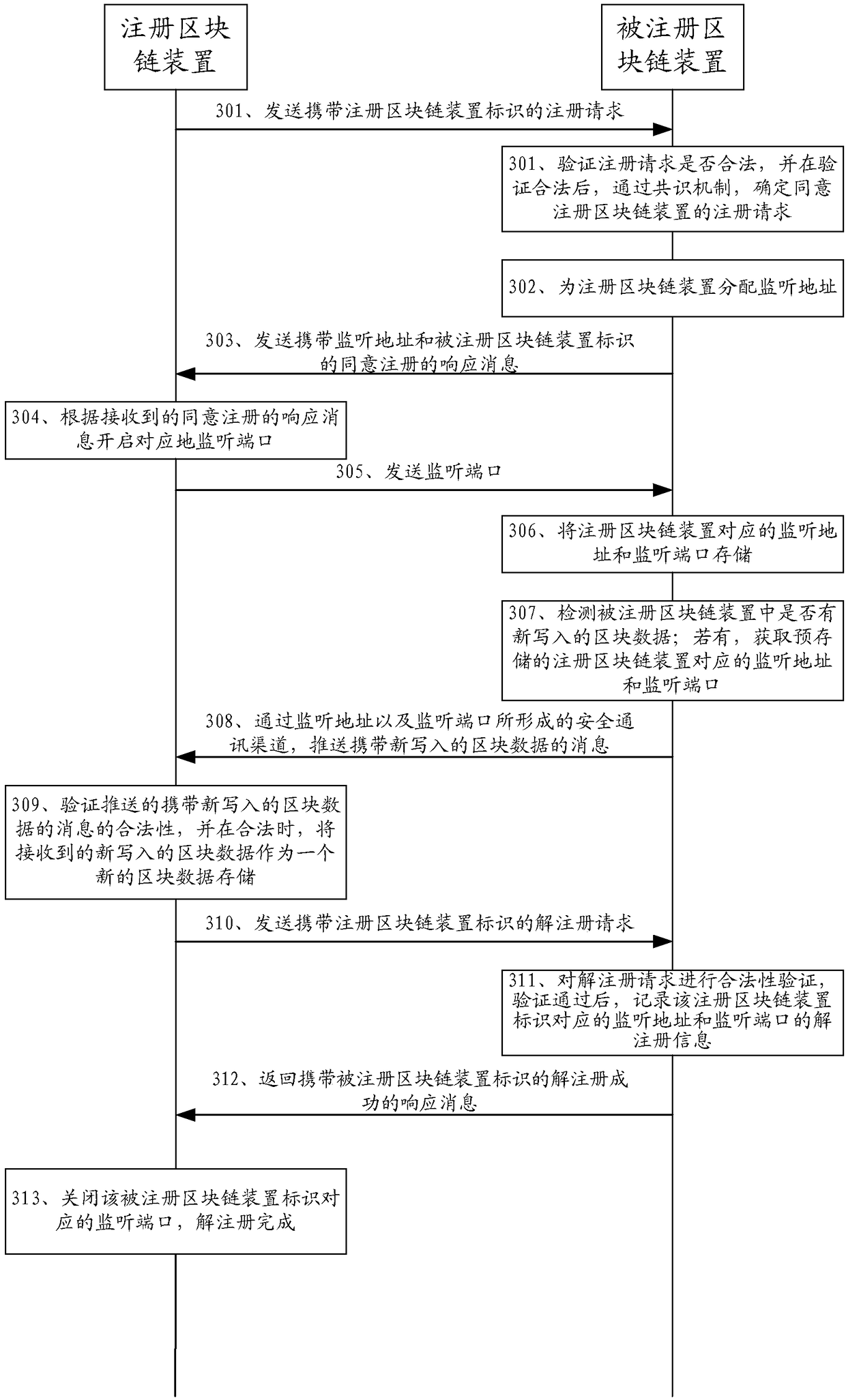

ActiveCN108366105AImplement data accessRealize monitoringDatabase management systemsDatabase distribution/replicationAccess methodData access

The invention provides a cross-data-block data access method, apparatus and system, and a computer readable medium. The method comprises the following steps: if a registered block chain device agreesto a registration request of a registration block chain device, the registered block chain device detects whether there are newly written block data in the registered block chain device; if yes, the registered block chain device obtains a monitoring address and a monitoring port corresponding to a pre-stored registered block chain device; and the registered block chain device pushes a message carrying the newly written block data to the registration block chain device through a secure communication channel formed by the monitoring address and the monitoring port. By adoption of the technical scheme of the invention, the monitoring of the registered block chain device by the registration block chain device and the notification of the registered block chain device on the registration block chain device are achieved through a registration mechanism, and finally cross-data-block data access is achieved. In the cross-data-block data access of the invention, no manual participation is needed, and the access efficiency is high.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

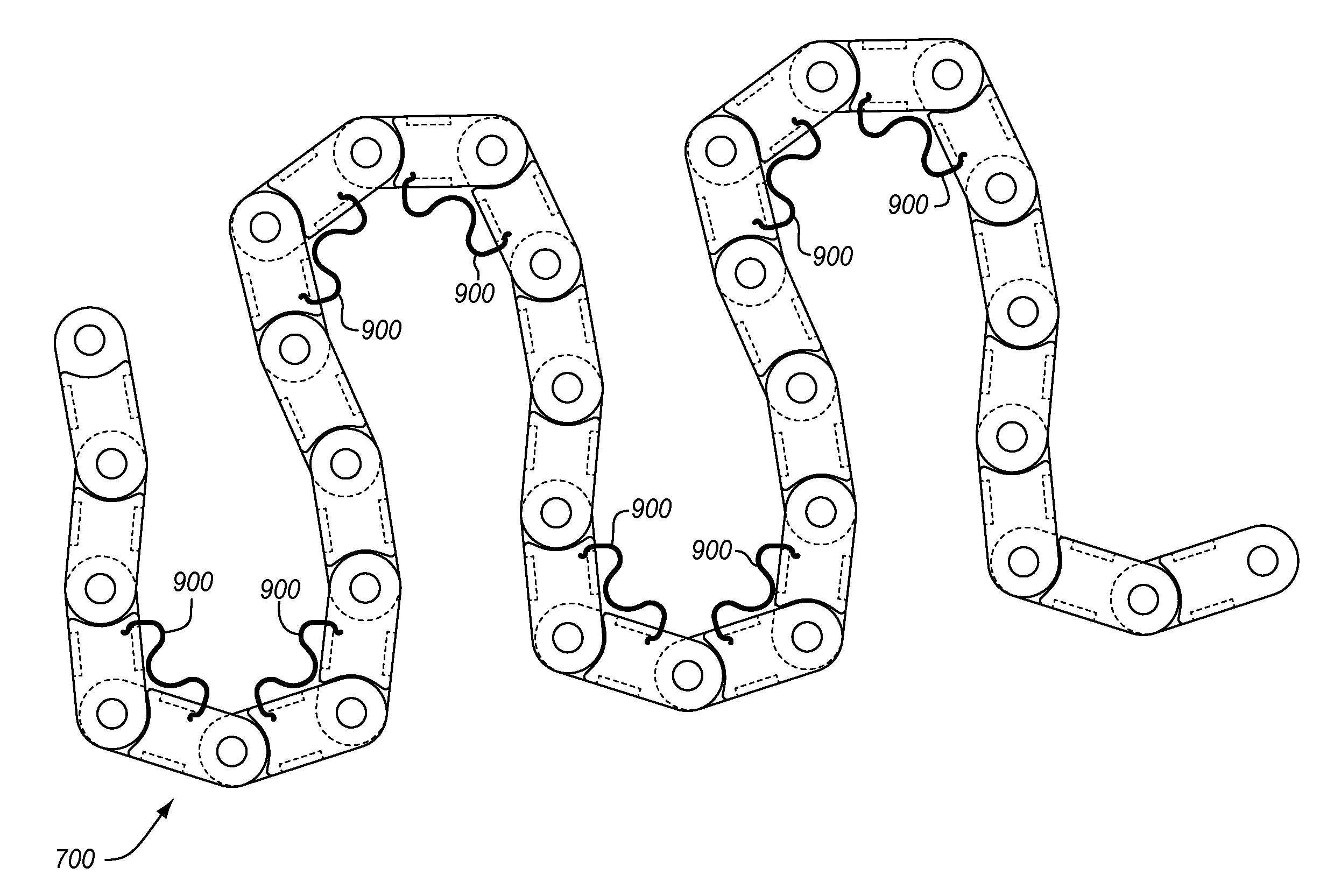

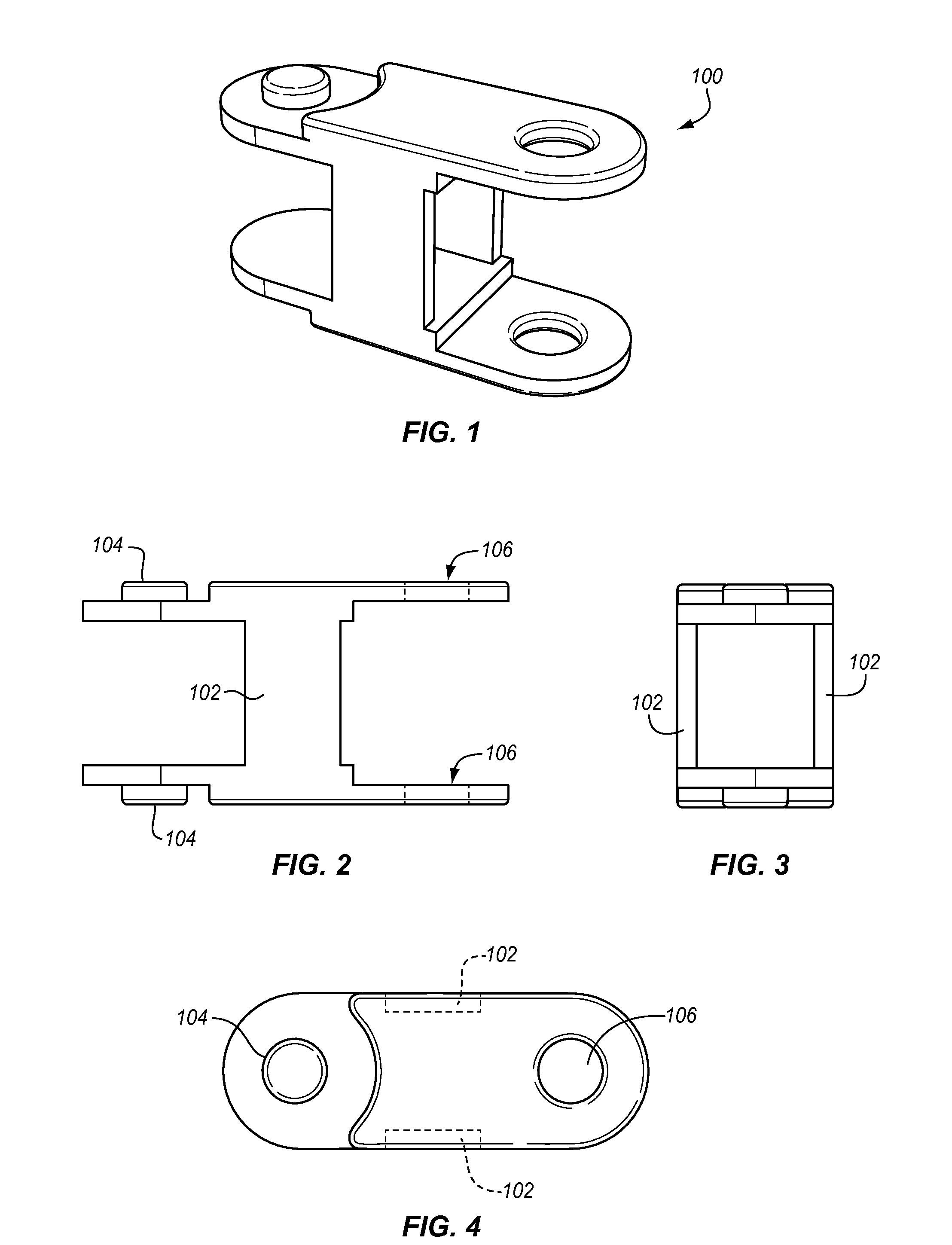

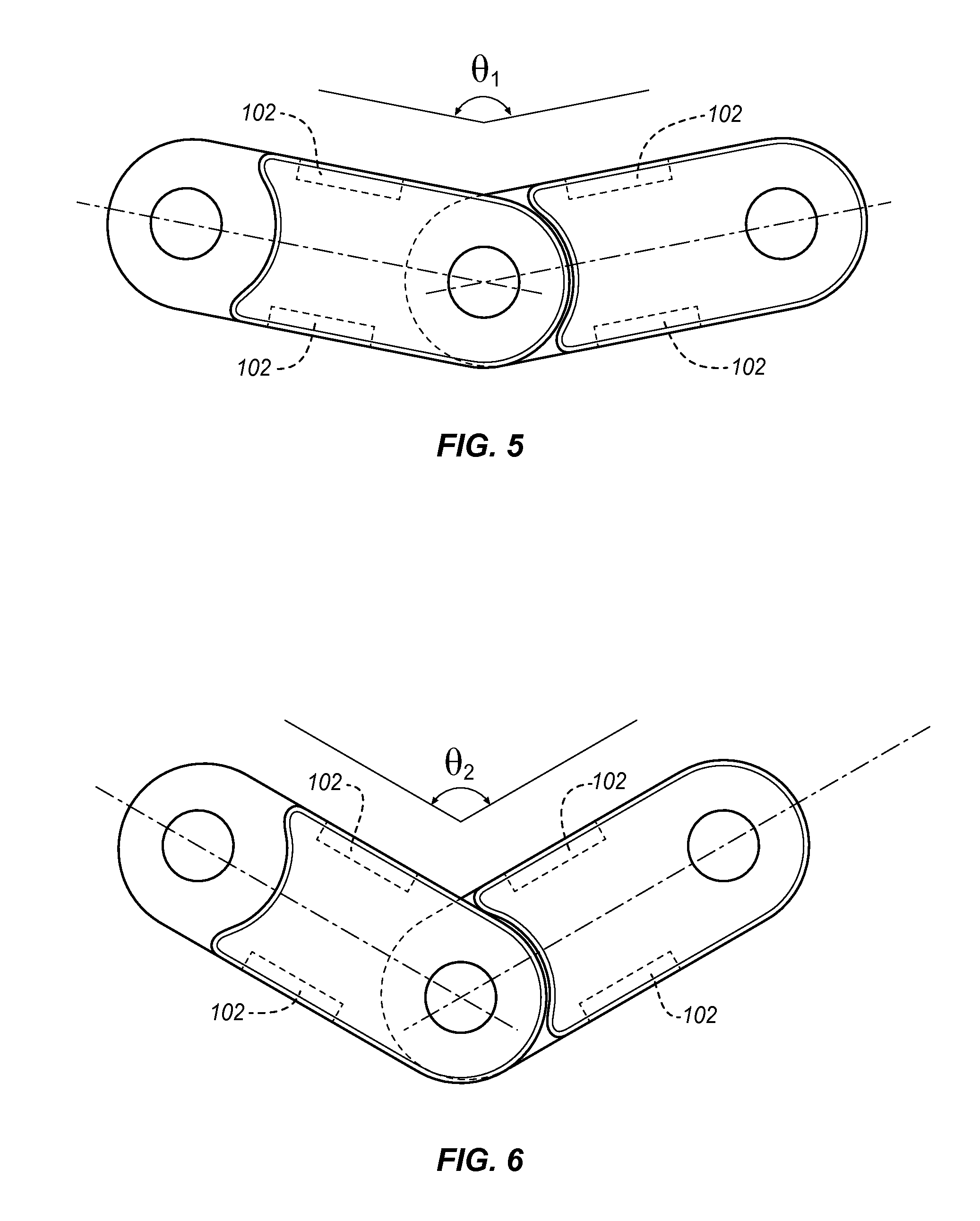

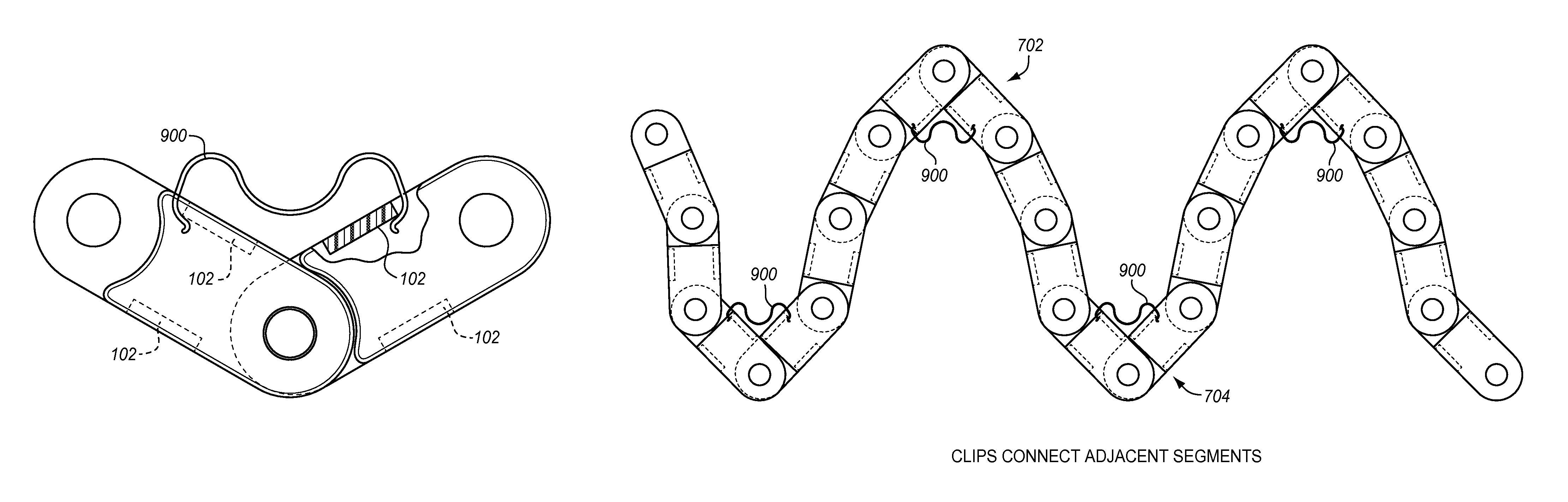

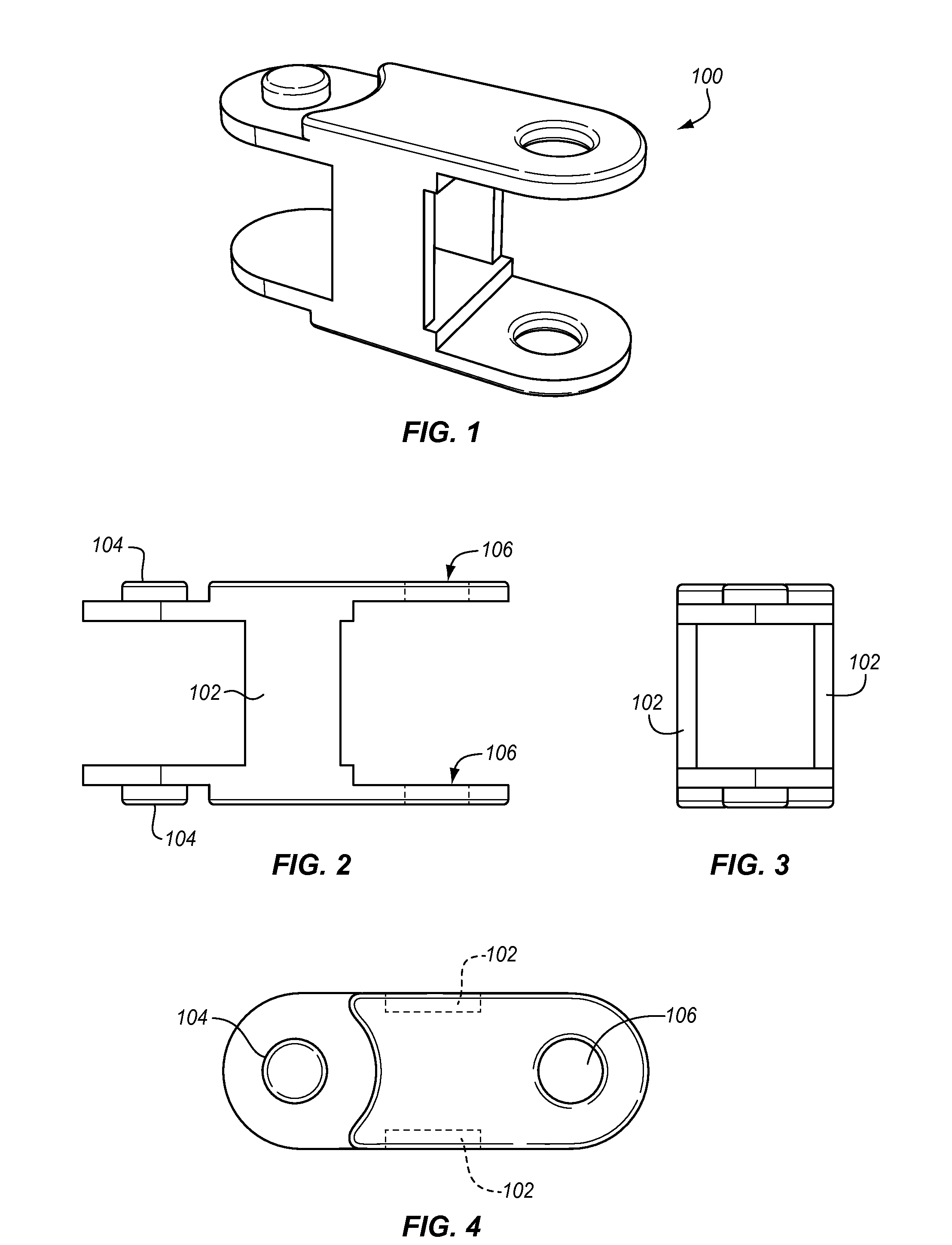

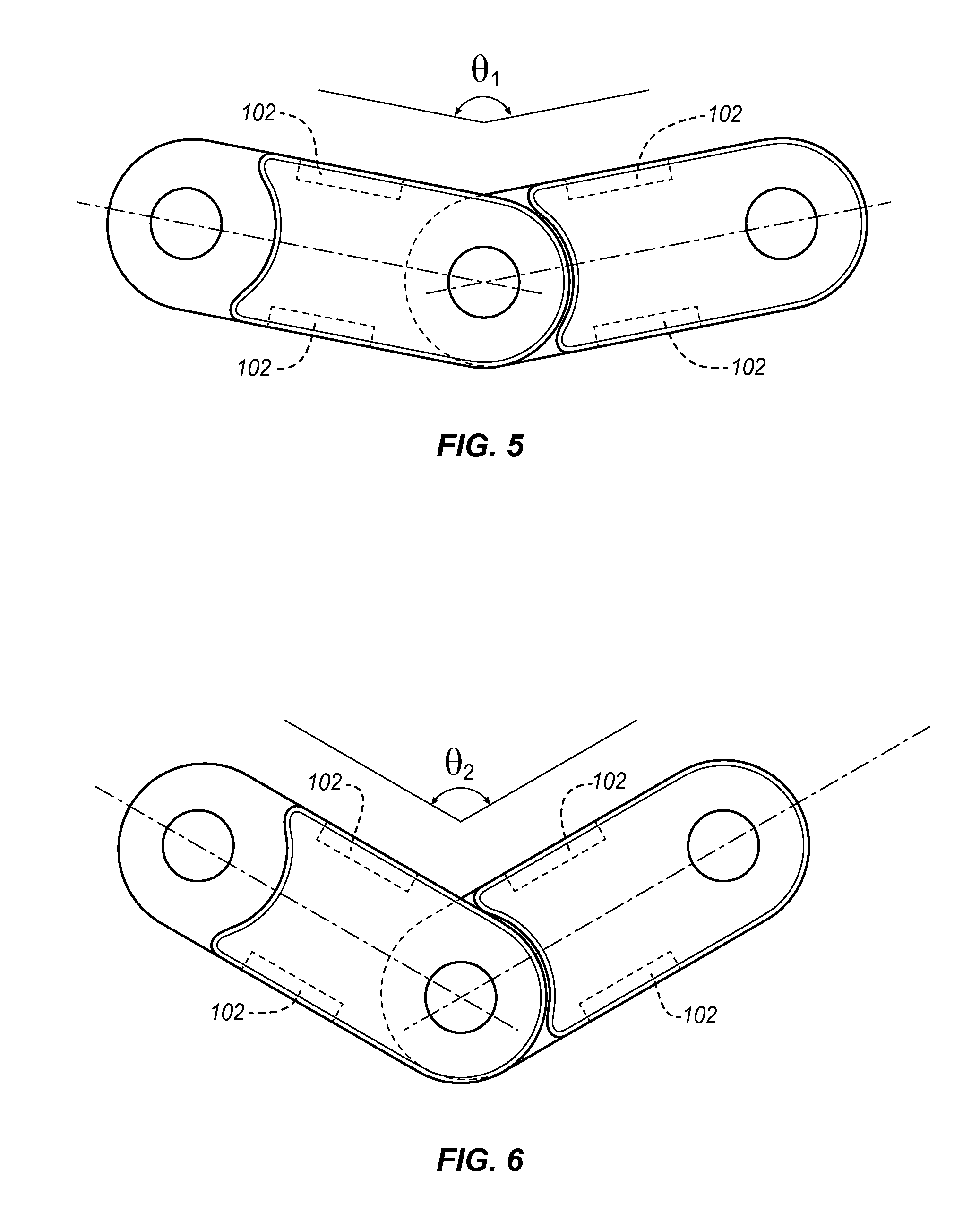

Systems and methods for tool-less retractable storage of lengths of cable chain

InactiveUS20120311990A1Easy to assembleEasily shape memoryPipe supportsHauling chainsSpring forceEngineering

Devices and systems for tool-less assembly of cable chains that are capable of being retractably stored. The device comprises a first contact element, a second contact element, and a lengthwise member. The first contact element is adapted for movable contact with a receiving member of a first cable chain segment. The second contact element is adapted for movable contact with a receiving member of a second cable chain segment. The lengthwise member is fixedly attached to the contact elements. When an angle between the first and the second cable chain segments is a first value, the lengthwise member experiences elastic deformation, generating a spring force at each contact element sufficient to pull the receiving member of the first cable chain segment rotatably towards the receiving member of the second cable chain segment, thereby reducing the angle between the first and the second cable chain segments to a second value.

Owner:AVAGO TECH INT SALES PTE LTD

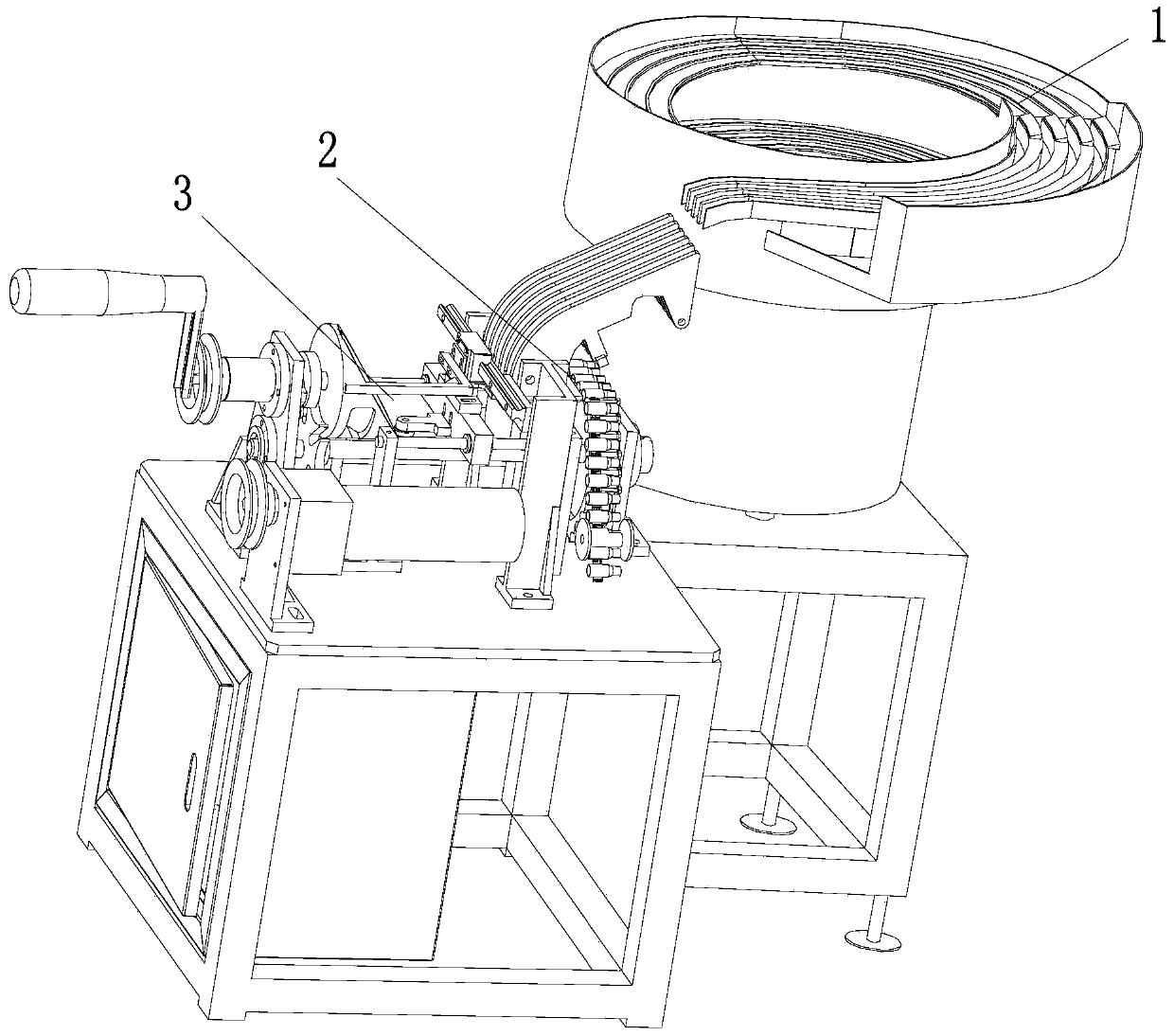

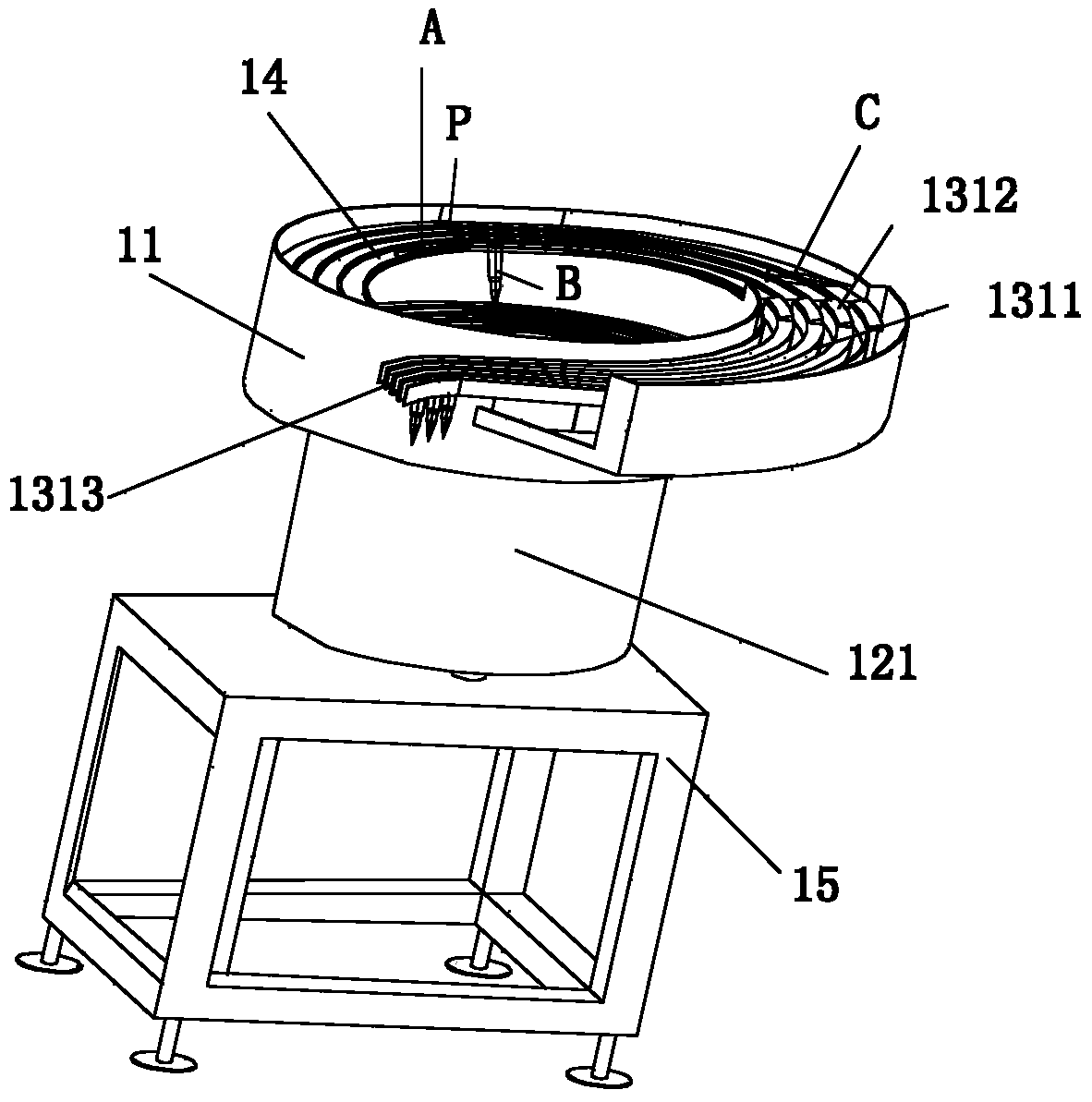

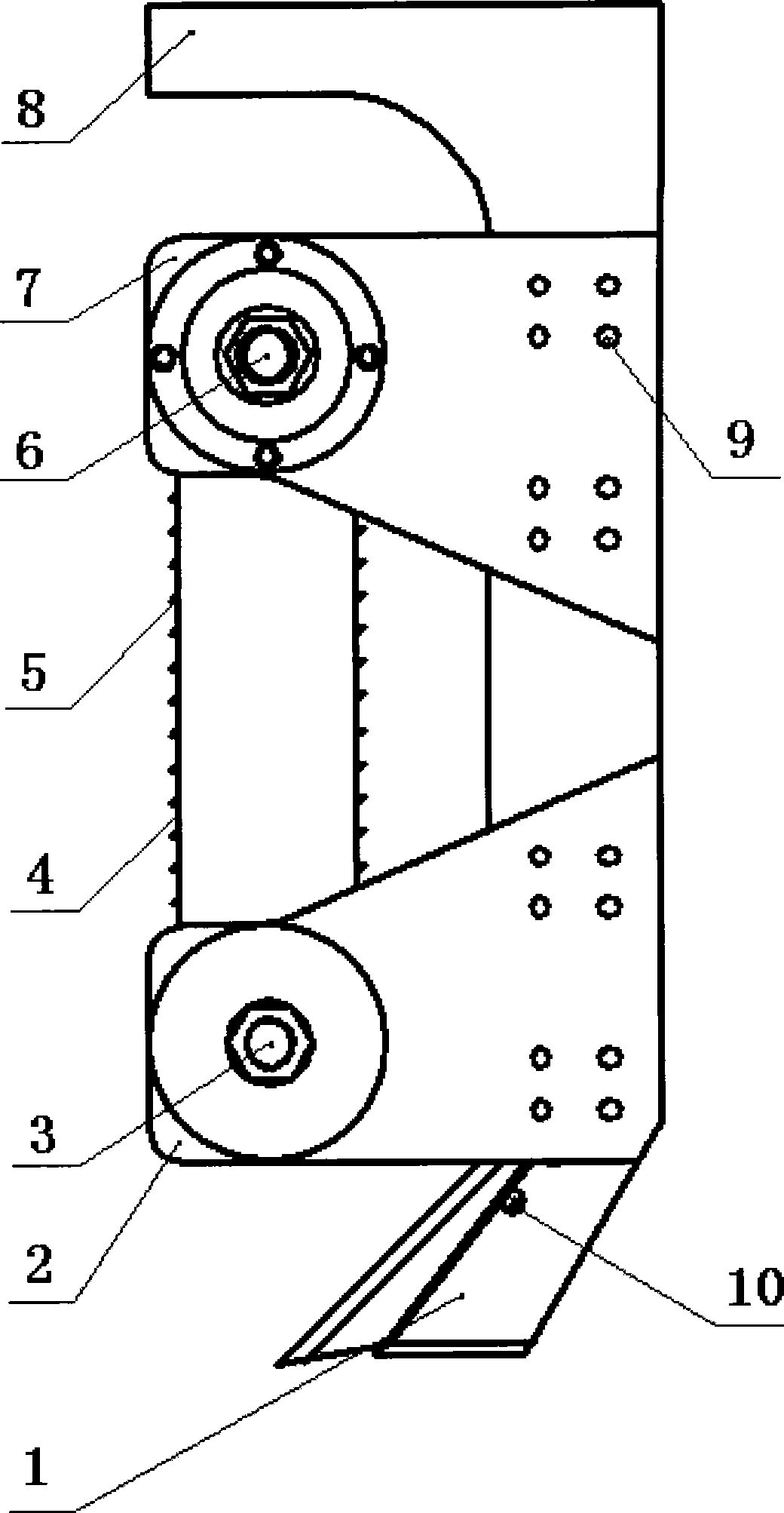

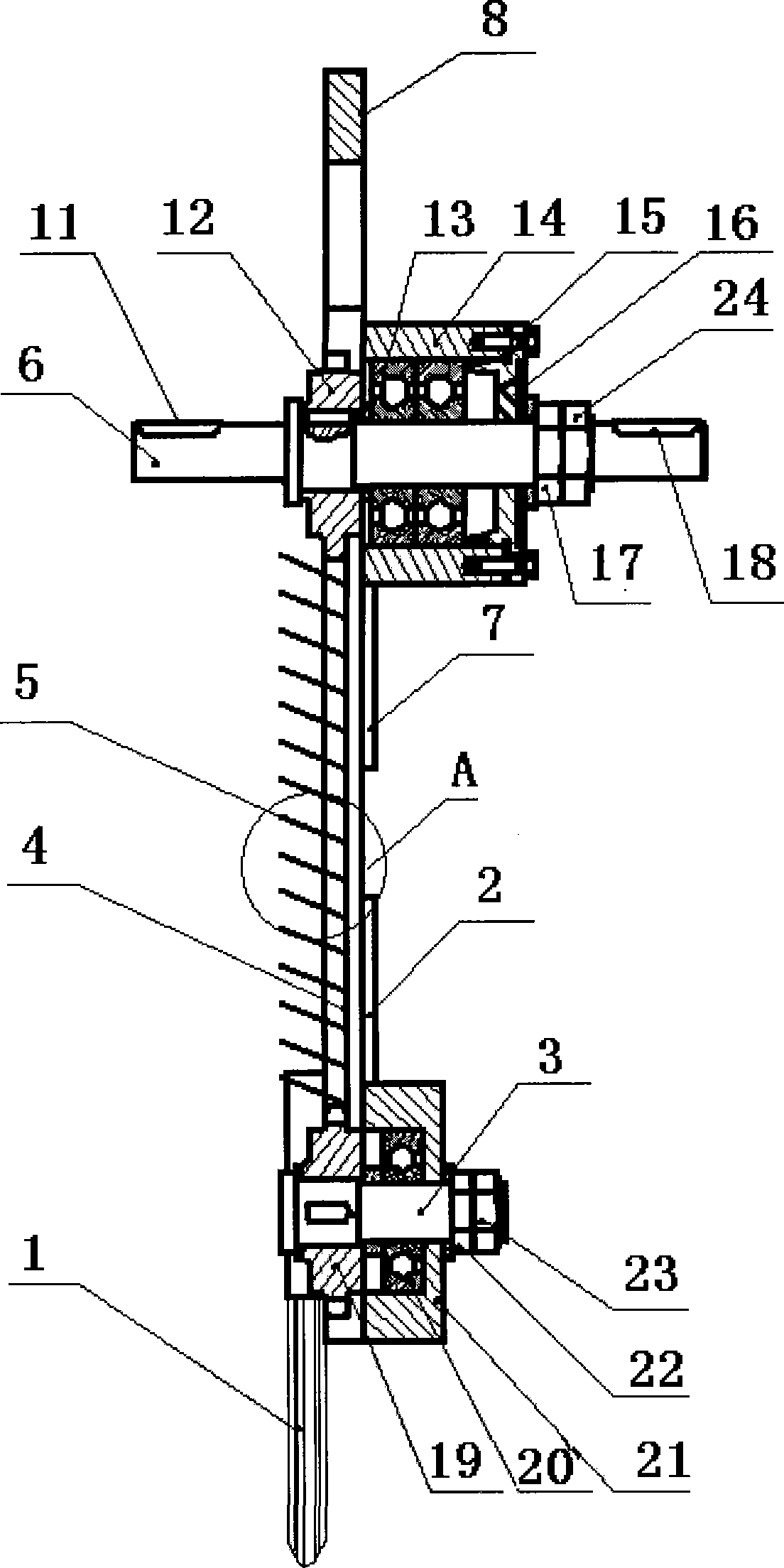

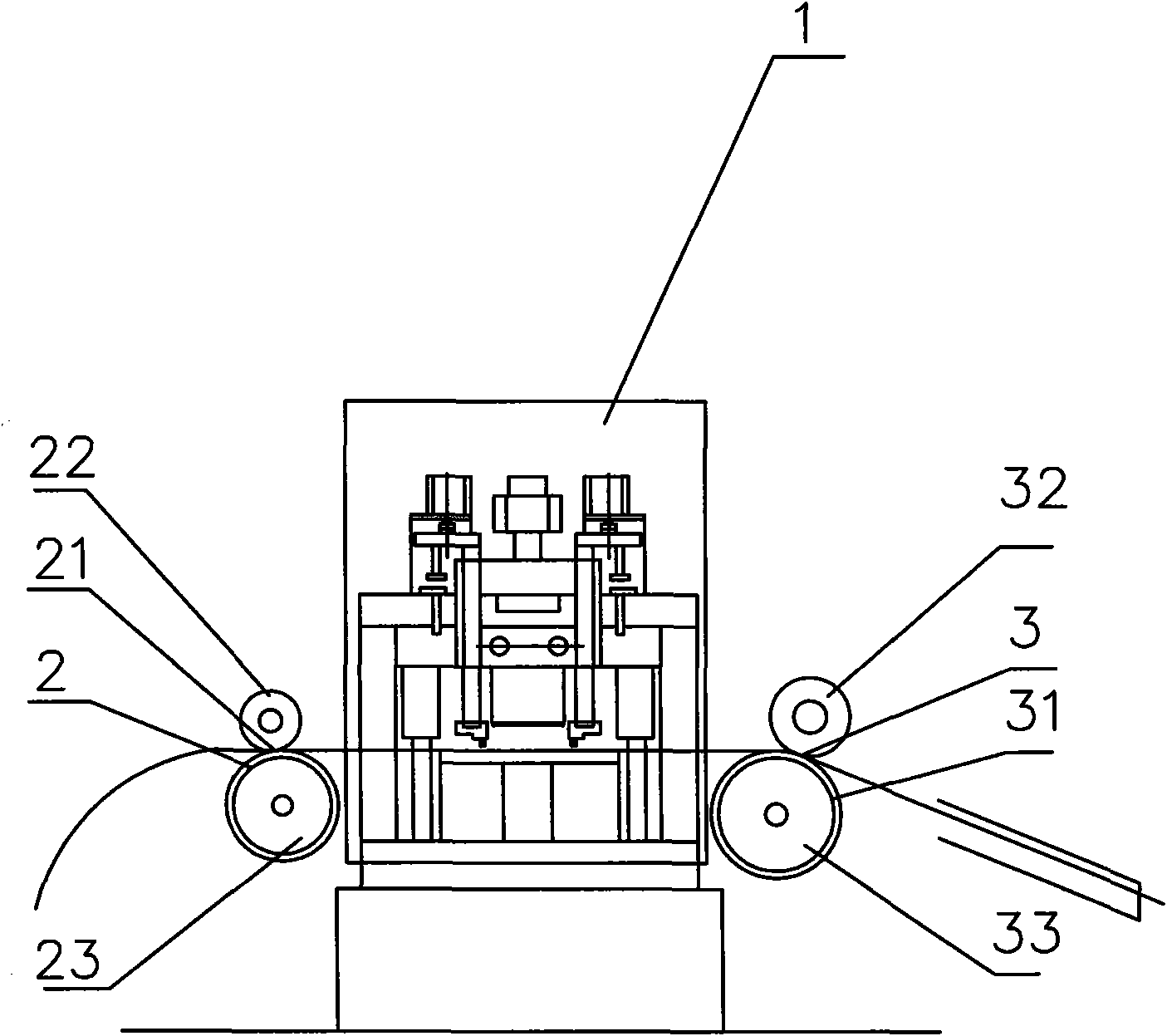

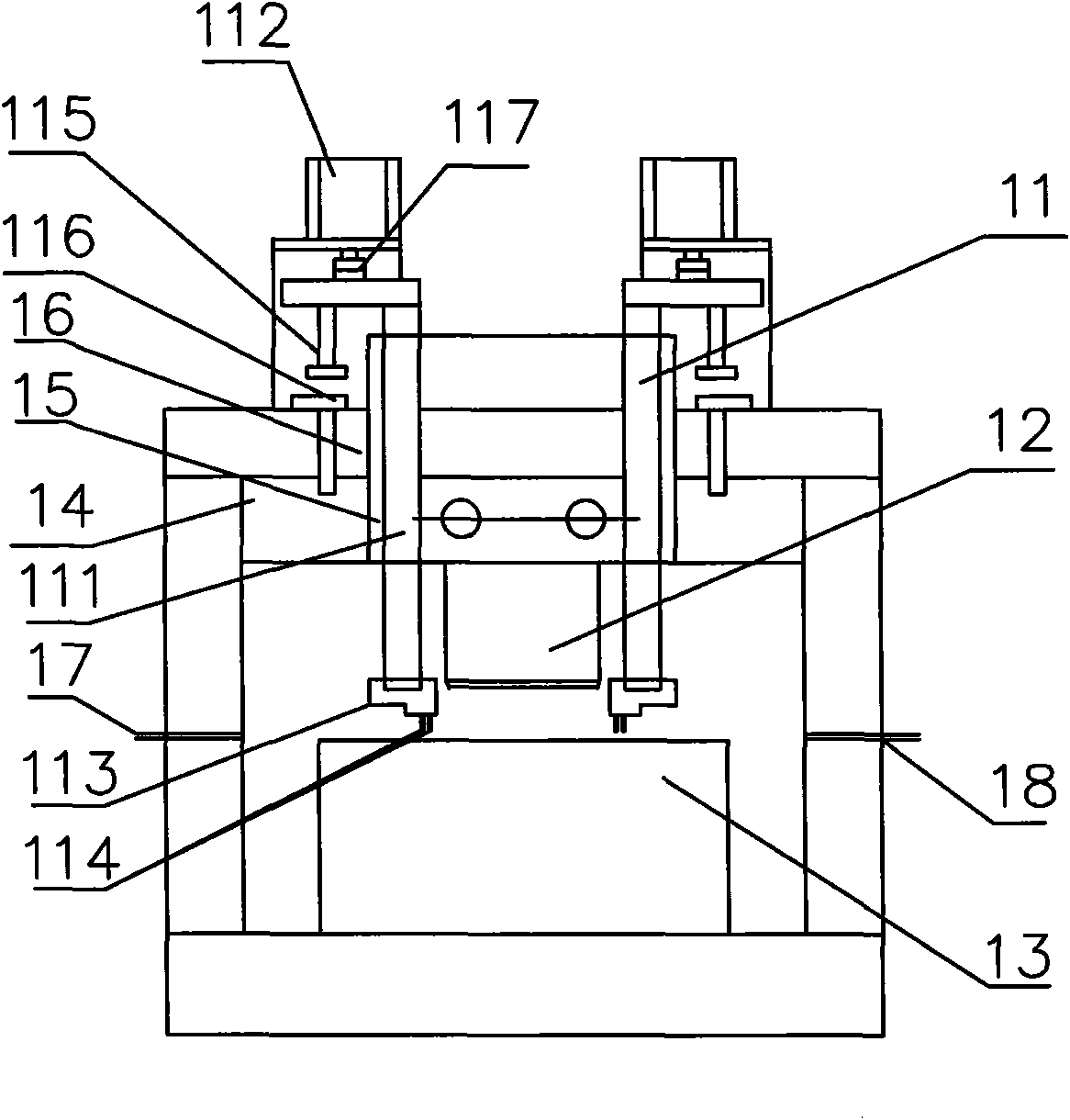

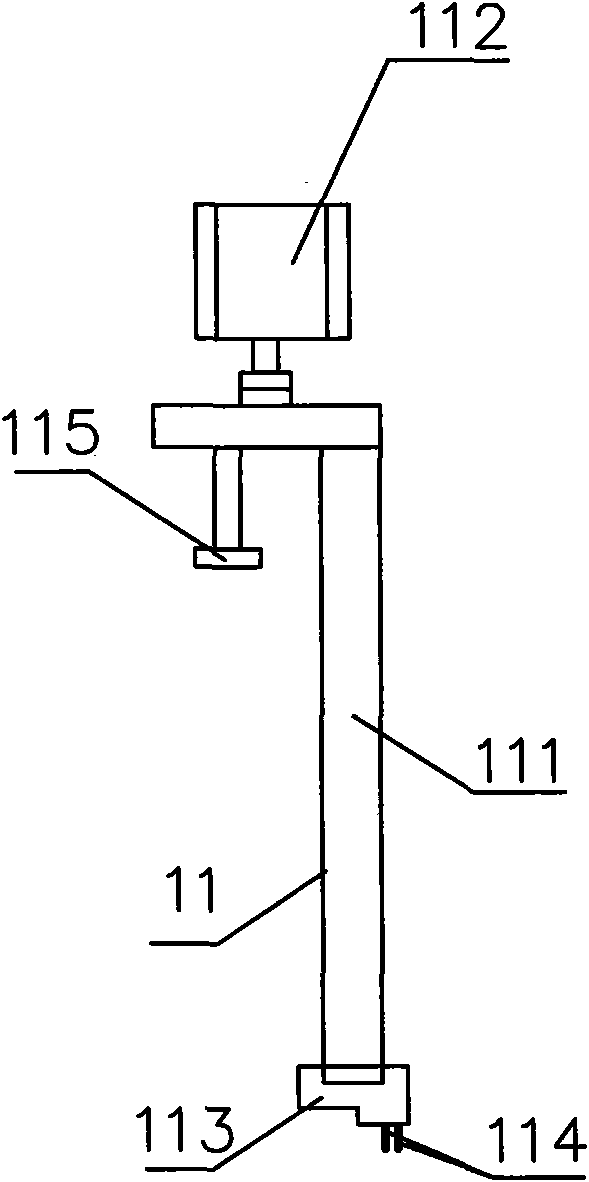

Device and method for automatically assembling bullet chain

ActiveCN103615937AClosely arrangedAvoid technical problems such as empty loadingAmmunitionEngineeringChain device

The invention provides a device and method for automatically assembling a bullet chain, and relates to bullet chain assembling devices. The device is provided with a bullet sequencing device, a feeding device of a bullet chain assembly mechanism, and an automatic bullet chaining device; the bullet sequencing device is provided with a stainless steel bucket, a scattered bullet container, bullet slide rails, a bullet slide groove and a machine frame; the feeding device is provided with guide plates, partition plates, a guide plate base, a bullet pressing guide groove, a baffle, a bullet chain moving wheel, an auxiliary shaft base, a main shaft, a bullet chain guide wheel and a machine frame; the automatic bullet chaining device is provided with a transmission motor, a motor base, a machine frame, a main rotating shaft, bearing blocks, a main shaft base, a bevel wheel, a six-position grooved wheel, a sliding rod, a partition plate, a sliding block, a track, a pushing plate, a pushing plate base, linear bearings, shafts, a bearing, a vertical base, a hand-operated rotating handle and belt wheels. Scattered bullets are transmitted to the feeding device after being sequenced; a discharging port of the feeding device is connected with the automatic bullet chaining device, and the bullet, which is closest to the automatic bullet chaining device, is pressed in the bullet chain; a bullet chain which is not provided with the bullets is used for replacing the bullet chain which is provided with the bullets, and the bullet chain provided with the bullets is conveyed out.

Owner:厦门晟妍机械科技有限公司

Initiative reciprocating type zero-tillage anti-blocking unit body

InactiveCN101379904AAdjustable tightnessAdjustable spacingPlantingFurrow making/coveringCouplingAgricultural engineering

The invention discloses an active reciprocating no-tillage anti-blocking unit, and belongs to the technical field of agricultural machinery. The structure of the unit consists of a furrowing device and an anti-blocking device. A furrow opener is fixed at the lower end of a shovel shaft of the furrow opener to form the furrowing device with concave structure. The anti-blocking device consists of an upper retaining plate and a lower retaining plate which are fixed on the shovel shaft of the furrow opener face to face, as well as a long shaft, a short shaft, an upper chain wheel, a lower chain wheel, a plectrum chain and the like. The anti-blocking plectrum chain is provided above the furrow opener, and long shafts of all anti-blocking unit bodies are connected by couplings. The active reciprocating no-tillage anti-blocking unit has the advantages: the plectrum chain is provided above the furrow opener, which is favorable for cleaning the deposit during furrowing by the furrow opener, reducing the seeding resistance and is good for the trafficability characteristic of a machine; power-drive blockage prevention is adopted, which enhances the blockage prevention effect obviously by regulating the rotary speed of the plectrum chain device; and the unit bodies are connected by the couplings, can realize the adjustability of the seeding row spacing and are applicable to operations at various areas. The active reciprocating no-tillage anti-blocking unit is applicable to the no-tillage seeding machine for wheat and corn.

Owner:CHINA AGRI UNIV

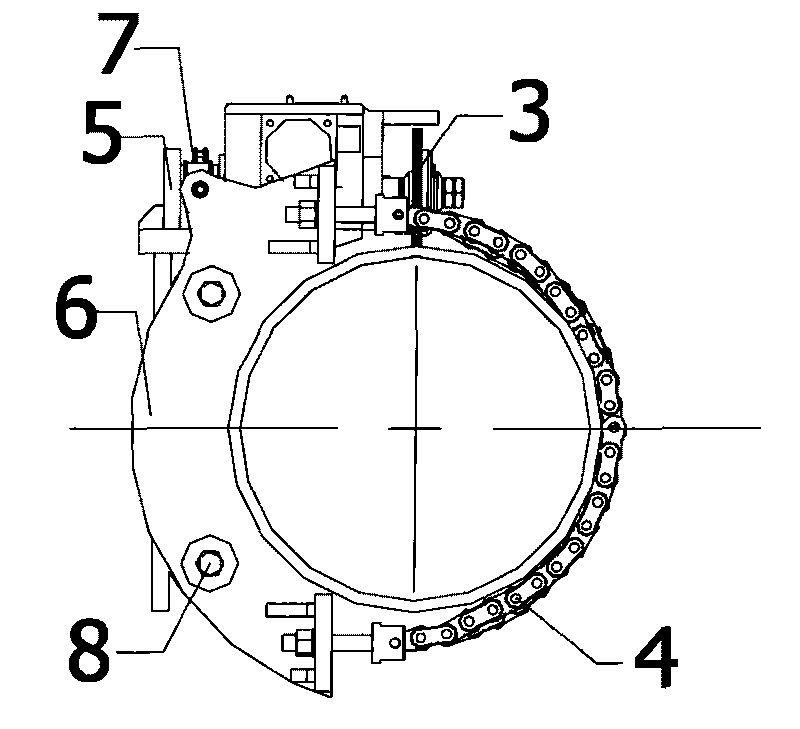

Steel pipe vertical seam cutting machine device

InactiveCN101758284AReduce cleanupEliminate potential safety hazardsTube shearing machinesHydraulic motorMilling cutter

The invention provides a steel pipe vertical seam cutting machine, which consists of a milling cutter 3, a press chain device 5, a speed change gear box 2, a hydraulic motor 1, a guide rail 8, a climbing wheel 7, a chain 4 and an annular plate fixing device 6. The device adopts the mechanical cutting method, eliminates the potential safety hazard for stripping off an outer pipe by oxy arc cutting, omits the cleaning work of an inner pipe, simplifies the construction process, further improves the construction speed of the offshore pipeline leak source restoration, and lowers the construction cost.

Owner:NEPTUNE OFFSHORE ENG DEV

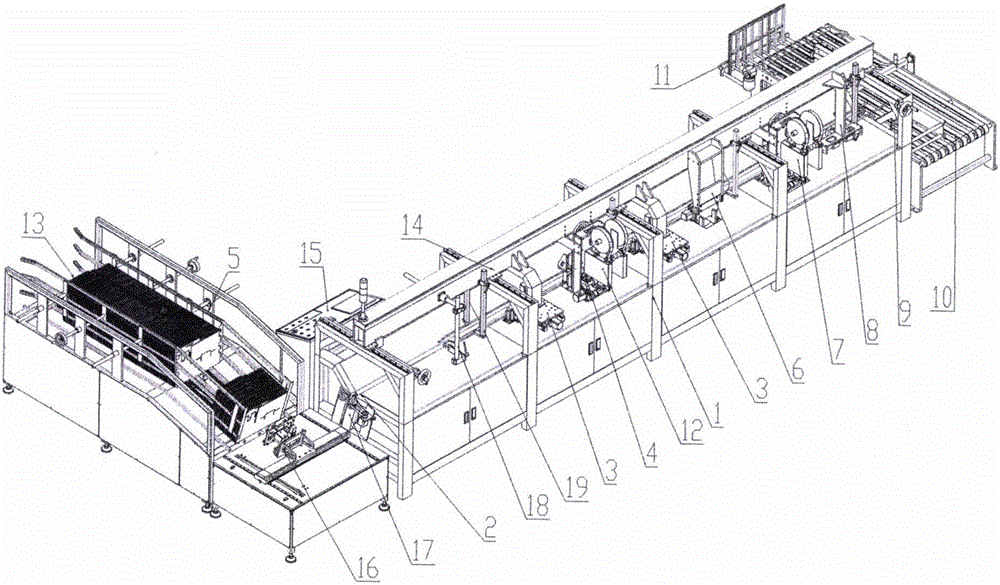

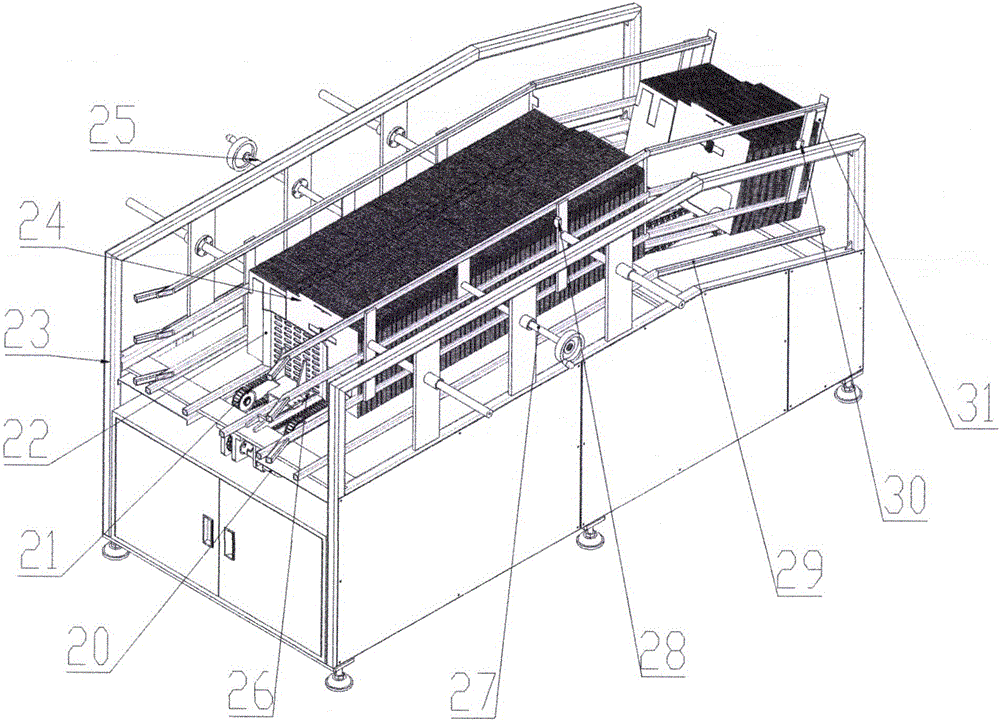

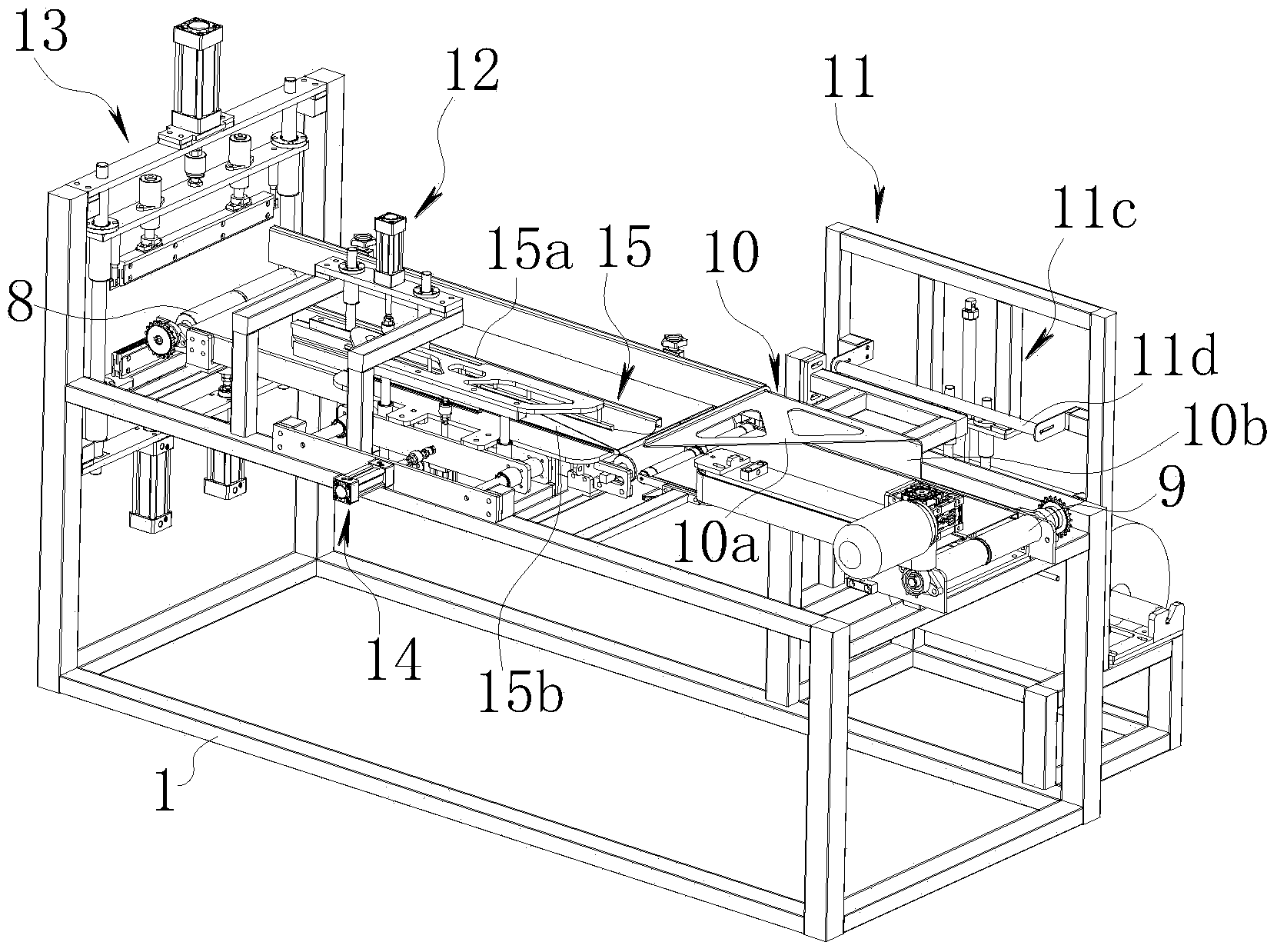

Machine equipment for online mounting of lifting ribbon

ActiveCN106393792AIncrease productivityReduce management costsBox making operationsPaper-makingUltrasonic weldingControl system

The invention discloses machine equipment for online mounting of a lifting ribbon. The machine equipment comprises a main body conveying rack, a carton conveying chain device, an adhesive coating device, a reinforcing band mounting device, a stock bin device, a lifting ribbon mounting device, an ultrasonic welding device, an automatic detecting device, an automatic rejecting device, a collecting plate conveying device, a collecting plate stacking device, an automatic unwinding device, an upper plate width adjusting component, a main body station translation cross beam, a transfer control system, a separate plate conveying device, a carton inputting compression roller component, a flip guiding device and a pressing plate guide rod component. The invention also discloses a process flow of the equipment. According to the machine equipment and the process flow thereof disclosed by the invention, mechanical automatic mounting is realized, the production efficiency is high, and the uncontrollability of offline sampling inspection for the quality of a product is overcome; by adoption of an automatic detection technology and an automatic rejection technology, the qualification rate of the quality of the product is 90 to 99 percent, the mounting of lifting handles of gift boxes with various sizes can be finished, labor force for mounting the lifting handles of packing boxes in the milk beverage industry is greatly reduced, and the production cost is reduced.

Owner:江苏力奥智能装备有限公司

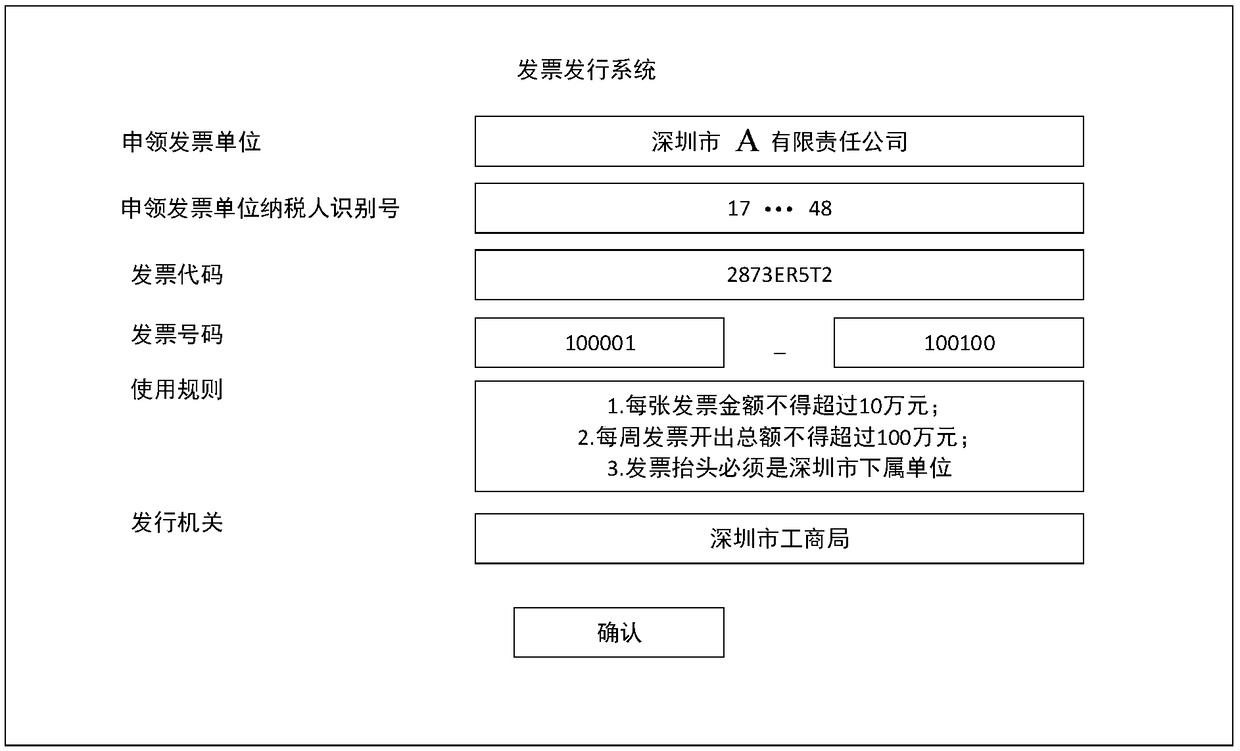

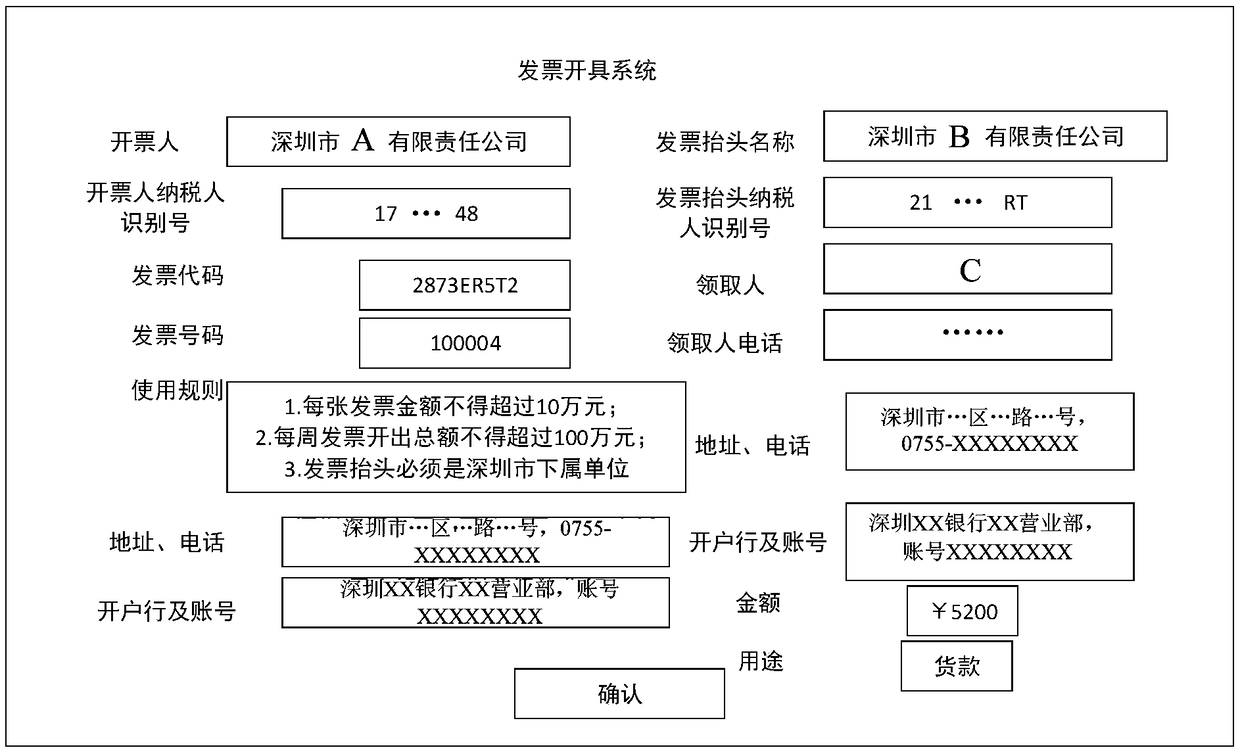

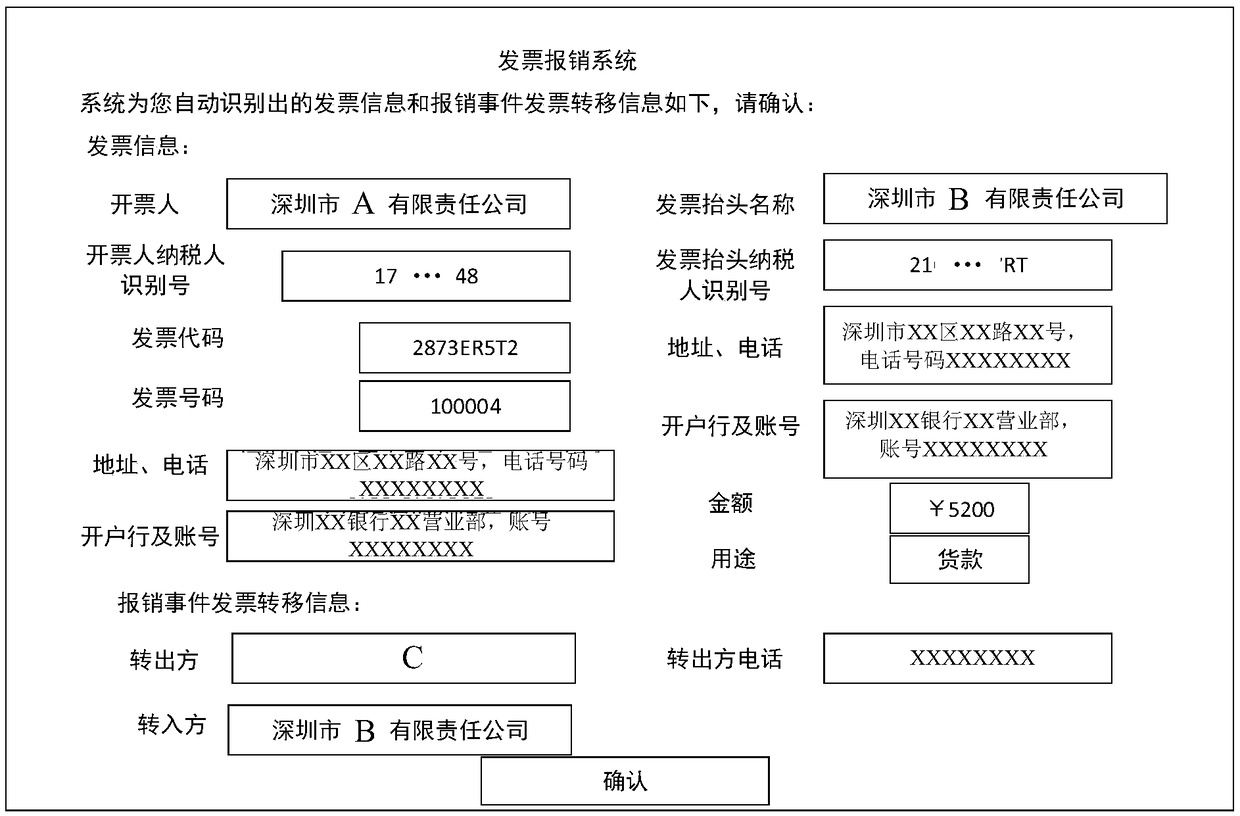

Invoice block chain recording method, apparatus, block chain gateway server and medium

ActiveCN109241772AImprove leakageReduce leakageDigital data protectionBilling/invoicingComputer networkInvoice

The present disclosure provides an invoice block chain recording method, apparatus, block chain gateway server and medium. The method includes, in response to receiving an invoice issuance event uplink request, allocating a block chain device in each block chain node to carry a sub-block chain corresponding to the invoice identifier based on the invoice identifier included in the invoice issuanceevent uplink request; Recording the issuance invoice event information in the issuance invoice event uplink request on the sub-block chain; In response to receiving any invoice event uplink request with the invoice identification, recording invoice event information in the invoice event uplink request on the sub-block chain. The embodiment of that present disclosure is capable of reducing invoiceinformation disclosure in the case when invoice information is recorded into a block chain.

Owner:深圳市智税链科技有限公司

Guide chain device

InactiveCN102381440APerfect systematic processHigh degree of automationWaterborne vesselsHeavy weightChain device

The invention discloses a guide chain device, which relates to the field of guide chains of multipurpose work ships. A limiting seat, a limiting box and a guide chain groove are applied in a combined manner, and accordingly requirements of lifting and throwing of an anchor chain under working conditions of a long dragging distance and heavy weight can be met. The guide chain device is simple in structure, convenient in installation and suitable for guiding the anchor chain on a multipurpose work ship for a long distance, and anchor lifting and throwing operation can be effectively carried out when the guide chain device is cooperated with a power machine.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

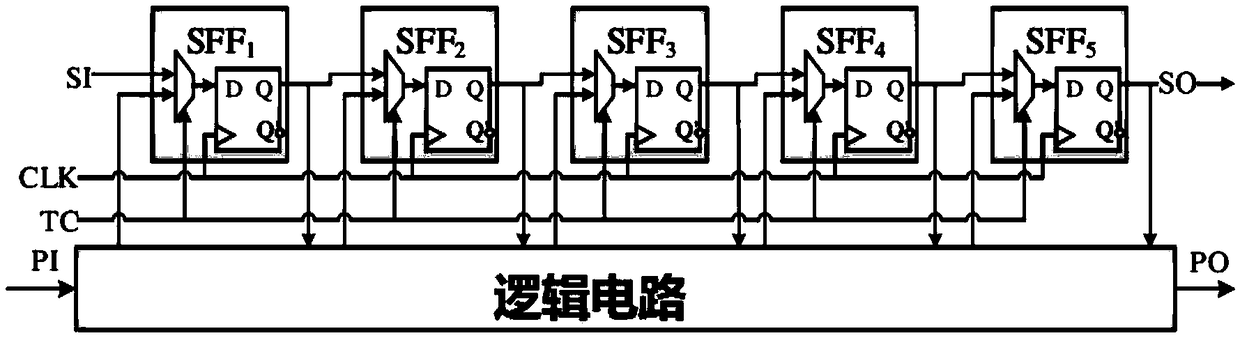

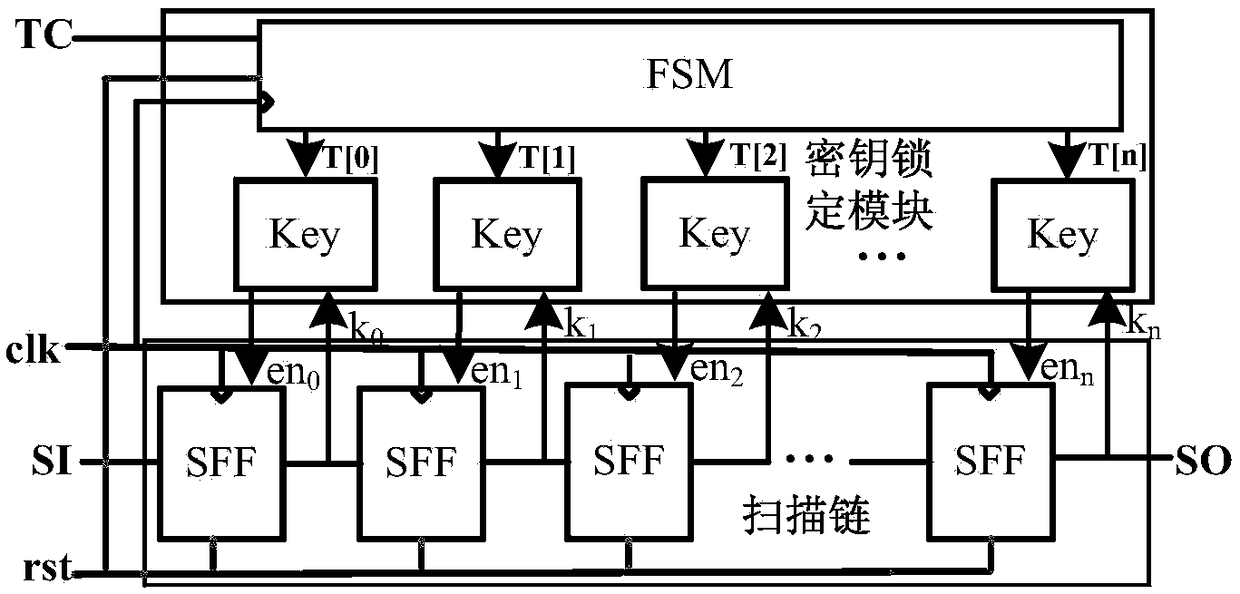

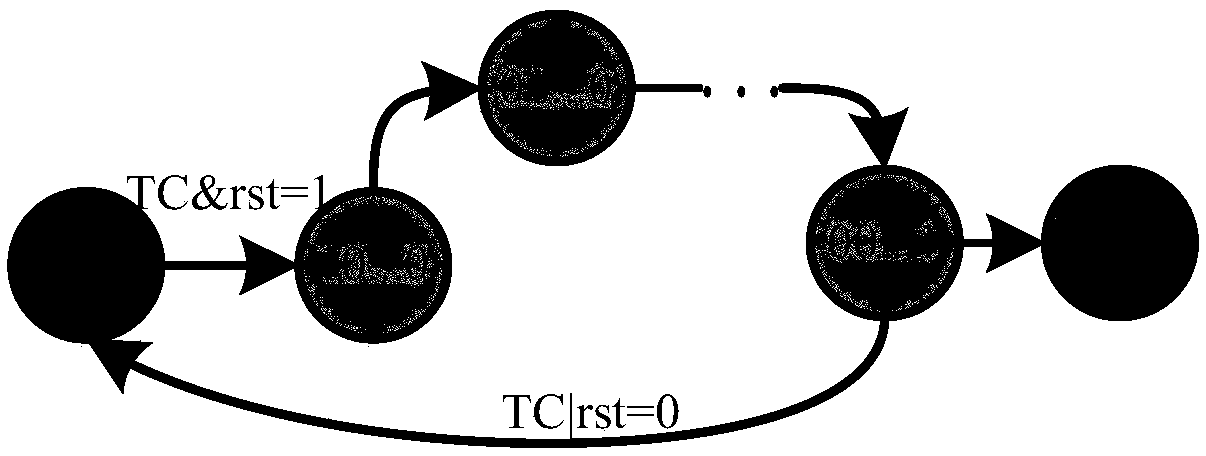

Successive verification type safe scanning chain device and method based on logic encryption

InactiveCN108896903ADefense against scan chain attacksGuaranteed testabilityElectronic circuit testingDigital data authenticationComputer moduleControllability

The invention belongs to the technical field of safety testability of integrated circuits. On the basis of ensuring the observability and controllability of a chip, an identity identification and verification structure is added, inner secret key information is successively verified, the safety grade of a scanning chain is improved and the risk of the leakage of inner information of the chip is greatly reduced. According to the invention, the device comprises a secret key locking module Key, a sequence enabling module FSM and the scanning chain. When the secrete key locking module Key monitorsthat the key enters the test mode, whether the secret keys input by an input end S1 are correct is successively verified. When correct secret key information is input, the scanning chain is used for scanning input and scanning output. The sequence enabling module FSM successively carries out secret key verification on a secret key locking module of each grade after the circuit enters the test module. The device and the method are mainly applied to designing and detection occasions of the integrated circuits.

Owner:TIANJIN UNIV

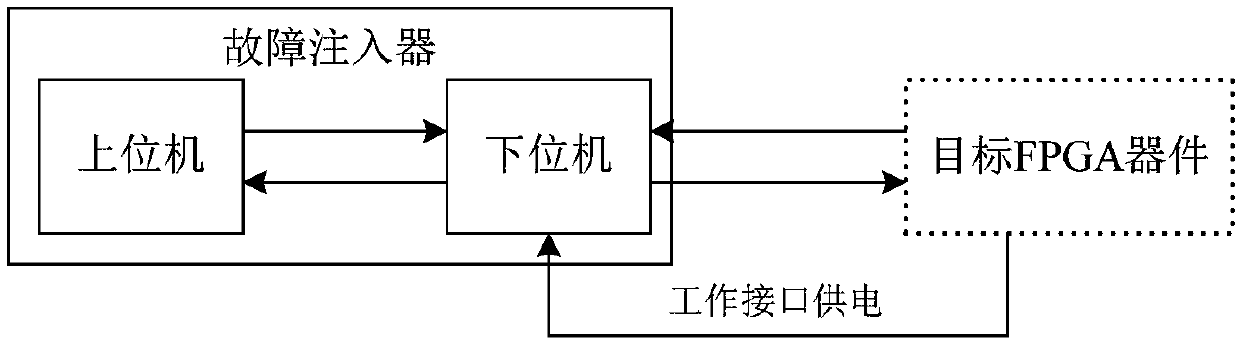

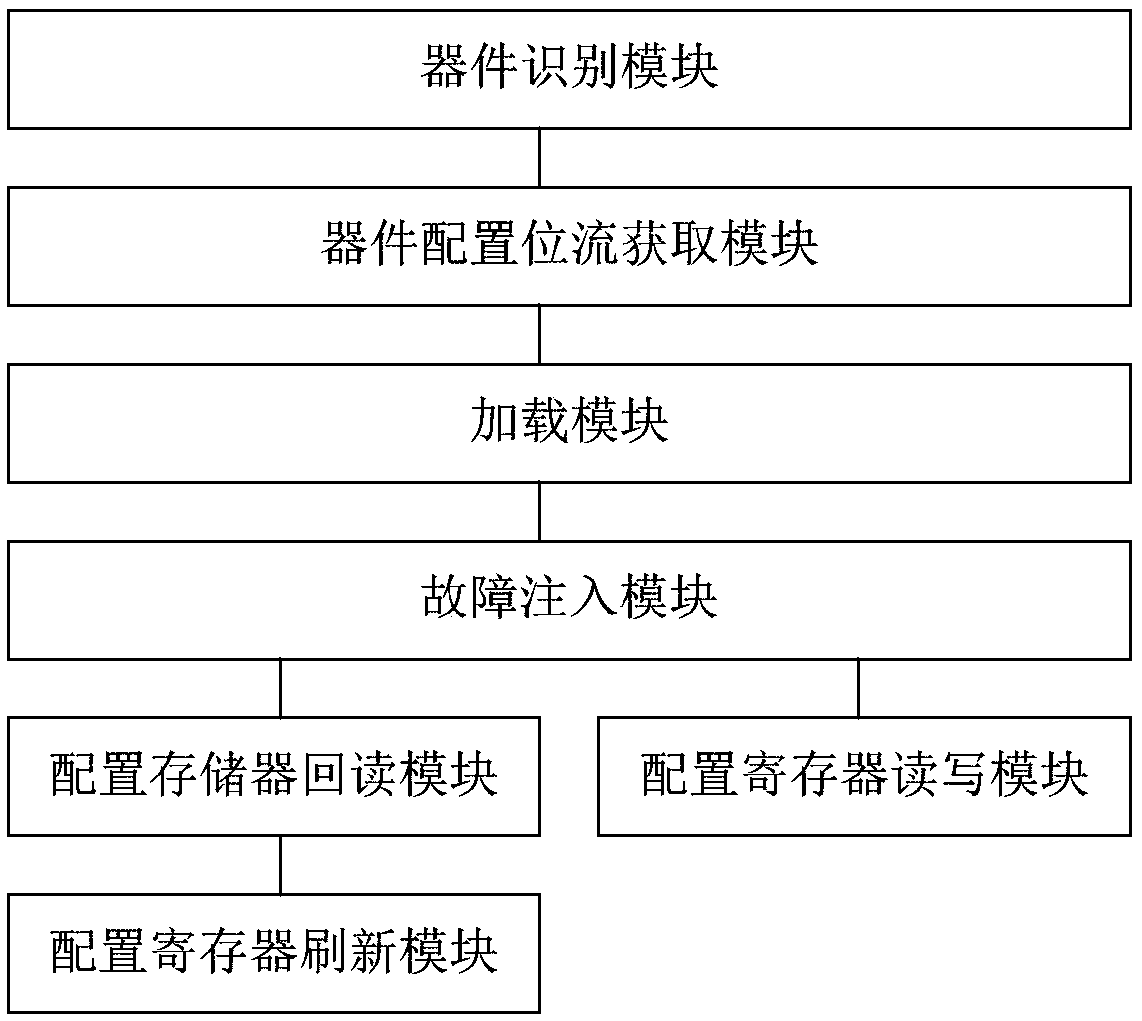

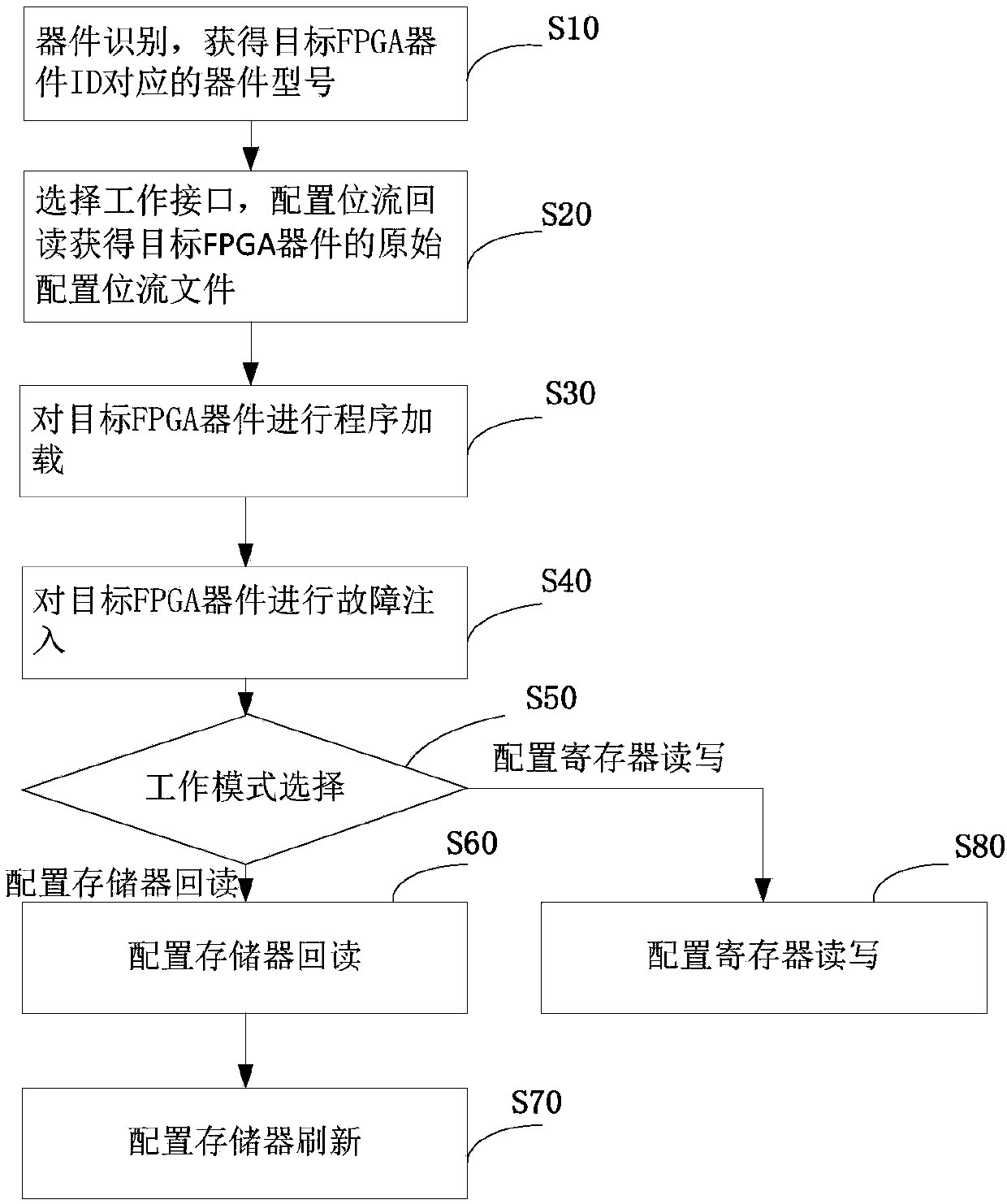

SRAM type FPGA turnover fault injection device and fault injection method

ActiveCN107678896AFault injection implementationFault injection satisfiesReliability/availability analysisFaulty hardware testing methodsDevice typeSoftware fault

The invention provides an SRAM type FPGA turnover fault injection device and fault injection method. An upper computer indicates a lower computer to perform chain device identification, thereby obtaining a device type corresponding to an ID of a target FPGA device; the upper computer selects a working interface and indicates the lower computer to perform configuration bit stream backward reading through the working interface; an original configuration bit stream file of the target FPGA device is obtained; the upper computer indicates the lower computer to finish power-on program loading of thetarget FPGA device by utilizing the original configuration bit stream file of the target FPGA device; the upper computer generates a turnover fault injection bit stream file according to a fault injection type; and the lower computer is indicated to finish fault injection for the target FPGA device through the selected working interface by utilizing the fault injection bit stream file. The shortcomings that an existing hardware fault injection device is complex and high in cost, a test result after injection is low in credibility because an existing fault model for software fault injection isinsufficiently real, and the like can be overcome.

Owner:湖南斯北图科技有限公司

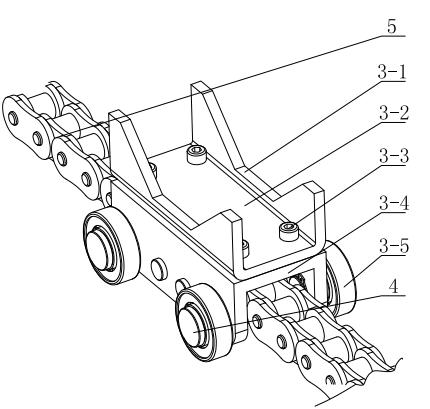

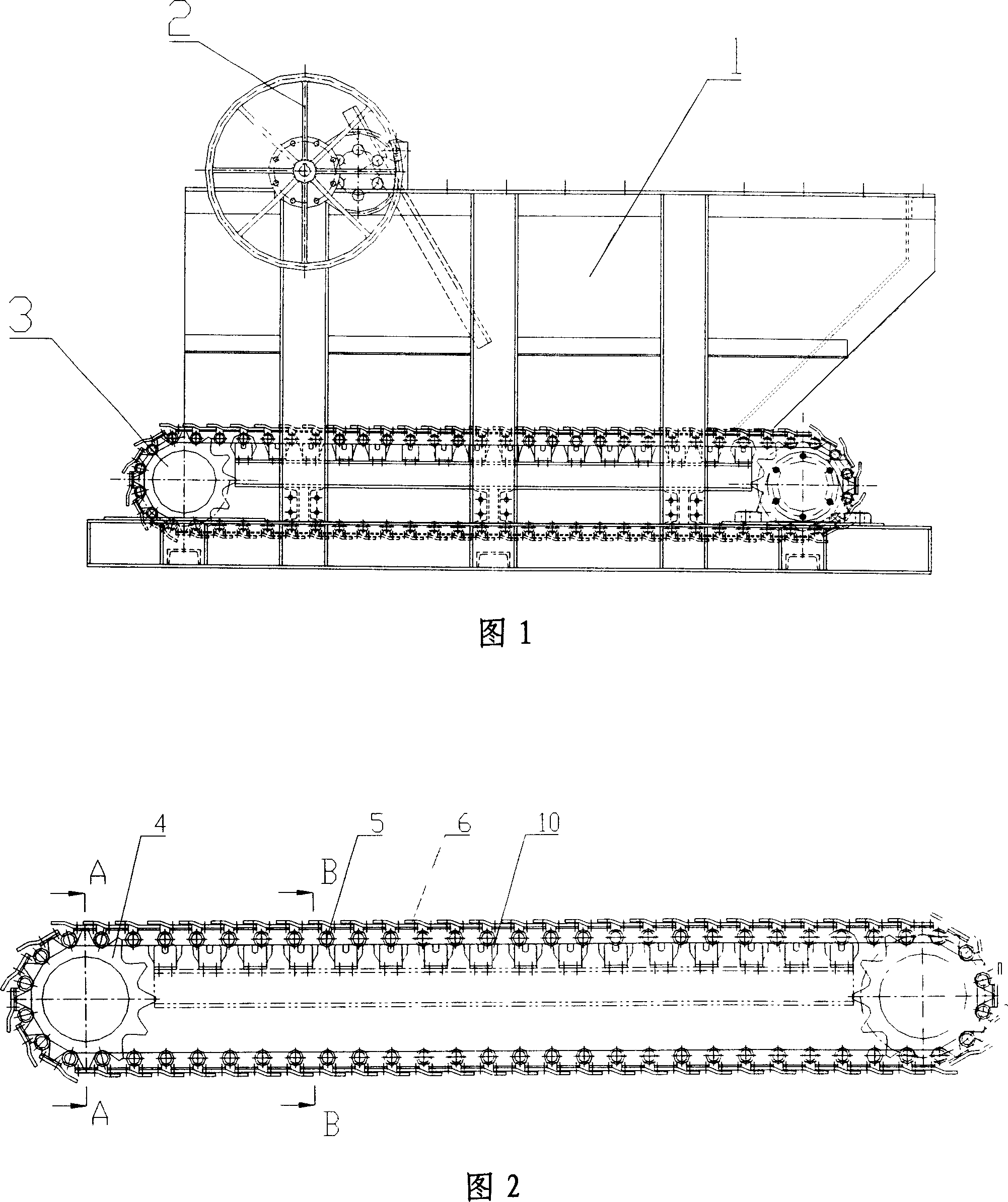

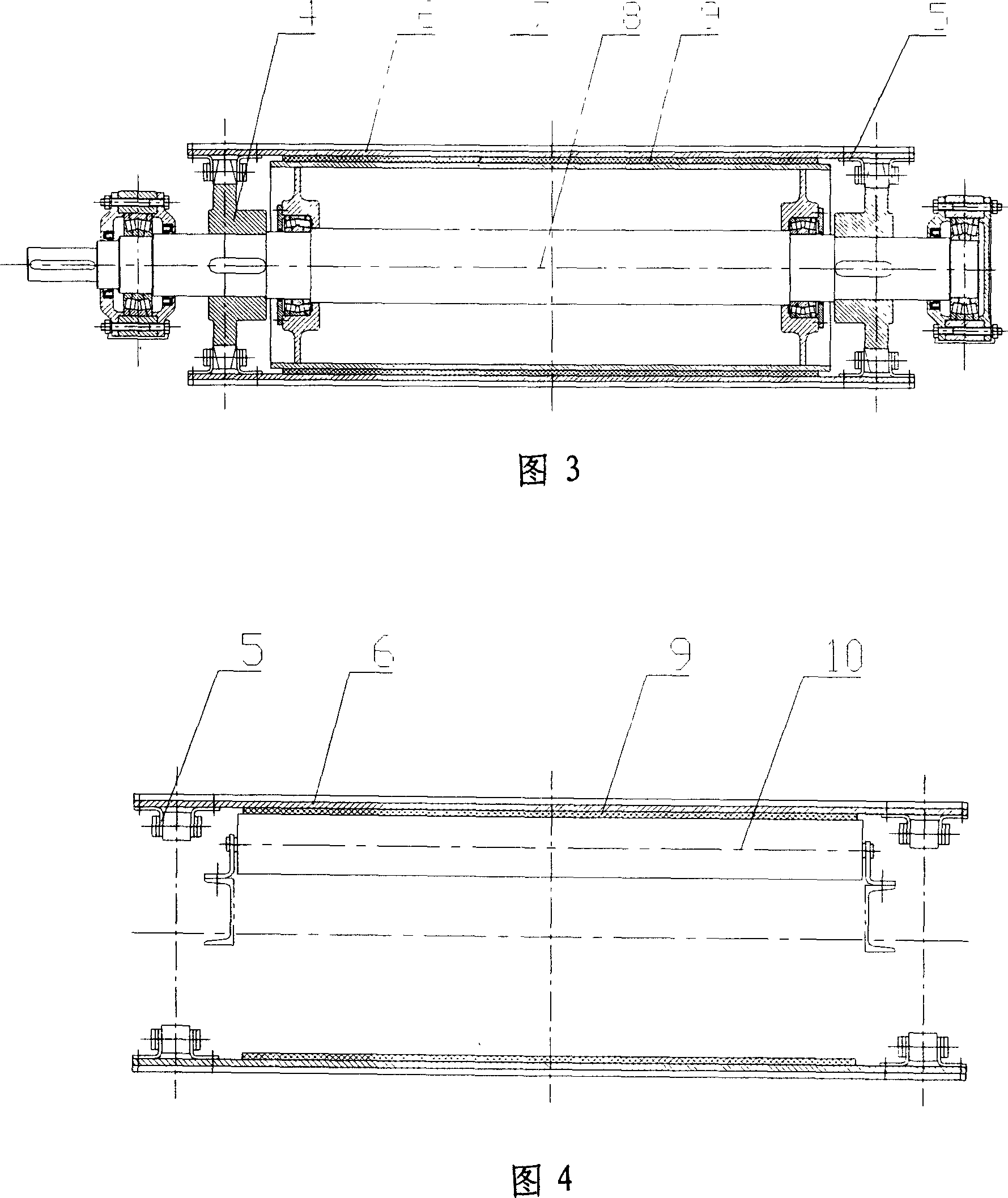

Conveying chain device

InactiveCN102583011ASmooth transition transmissionSmooth and safe transition transmissionConveyorsDrive shaftAgricultural engineering

The invention relates to a conveying chain device, which is characterized in that a plurality of groups of chain transmission mechanisms are connected at intervals by a transmission shaft; and each chain transmission mechanism comprises a rack, chain wheels, a chain and a plurality of trolleys, wherein triangular support frames are respectively arranged on the two sides of the rack; the chain wheels are arranged on the triangular support frames by a pin shaft; the chain is meshed between the two chain wheels; the plurality of trolleys are arranged on the chain at intervals uniformly by a pin shaft; each trolley has the following structure: an upper bottom plate, a lower bottom plate and travelling wheels; the upper bottom plate has a concave structure; trapezoid-shaped slots are arranged on the two side surface of the upper bottom plate; a groove is arranged at the bottom of the lower bottom plate; the upper bottom plate and the lower bottom plate are connected oppositely and fastened by a plurality of screws; and the chain passes through the groove at the bottom of the lower bottom plate; and the travelling wheels are installed on the left side and the right side of the lower bottom plate by a pin shaft. The conveying chain device is simple in structure, convenient to manufacture and install and low in cost.

Owner:WUXI KENKE HEAVY IND EQUIP

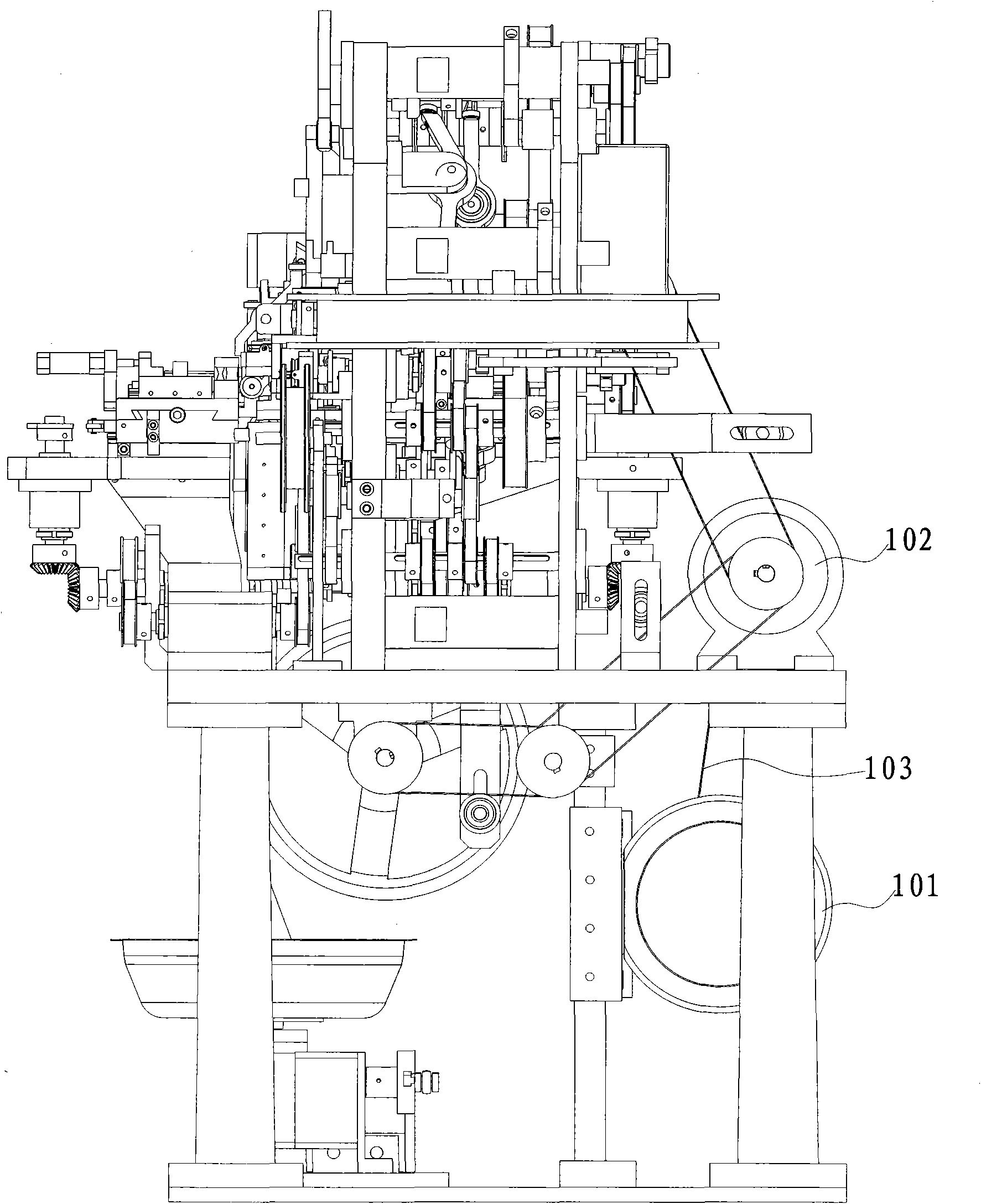

Automatic explosive cartridge medium-package packaging machine

The invention discloses an automatic explosive cartridge medium-package packaging machine, and belongs to the technical field of emulsion explosive packaging equipment. According to the technical scheme, the automatic explosive cartridge medium-package packaging machine comprises a rack, wherein a feeding belt device, a stacking chain plate device and a first horizontal conveying device which are sequentially connected to one another are arranged on the rack; a second horizontal conveying device and a first pushing mechanism are arranged on a side of the first horizontal conveying device; a second pushing mechanism is arranged on the rack and on a side of the second horizontal conveying device; a third horizontal conveying device and a fourth horizontal conveying device are sequentially arranged on the rack and on the side of the second horizontal conveying device; a film forming sleeve is sleeved on the periphery of the third horizontal conveying device; a film supplying device is arranged on the rack and on a side of the film forming sleeve; a longitudinal film sealing device is arranged on a side of the fourth horizontal conveying device; and a transverse sealing and film cutting device is arranged at a discharging end of the fourth horizontal conveying device. The automatic explosive cartridge medium-package packaging machine is compact in structure, high in work efficiency and easy to maintain, and is used for automatically packaging explosive cartridges.

Owner:广东振声智能装备有限公司 +2

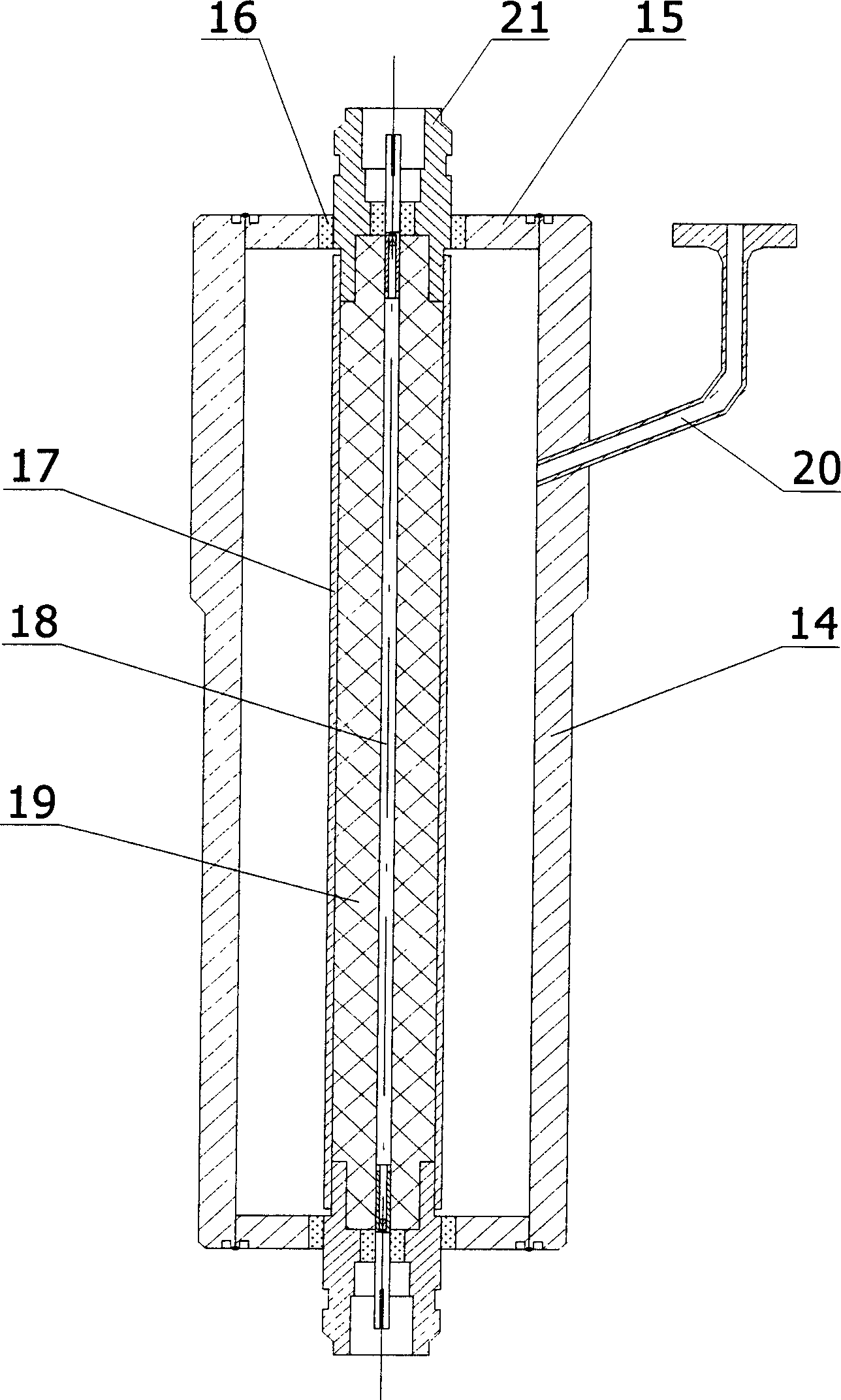

Control rod rod position measuring system based on electric vortex sensor

ActiveCN1538464AImprove temperature stabilityStrong radiation resistanceNuclear energy generationNuclear monitoringElectricityAudio power amplifier

The system includes control rod assembly, chain wheel-link belt, current vortex sensor, precision lead screw-nut assembly and body to be measured. The said precision lead screw-nut assembly includes precision lead screw, nut and support. Precision lead screw is connected to chain wheel, and the body to be measured is fixed on the nut. The current vortex sensor includes probe of sensor, signal transmission cable and preamplifier. Sealed penetration piece welded to pressure borderline of a loop is setup in middle of the signal transmission cable. Probe of sensor fixed on the said support is corresponding to the body to be measured. The advantages are high measurement accuracy, fast speed, stable operation and easy of maintenance.

Owner:TSINGHUA UNIV

Systems and methods for tool-less retractable storage of lengths of cable chain

InactiveUS8549831B2Easy to assembleEasily alter shape memoryPipe supportsHauling chainsSpring forceContact element

Devices and systems for tool-less assembly of cable chains that are capable of being retractably stored. The device comprises a first contact element, a second contact element, and a lengthwise member. The first contact element is adapted for movable contact with a receiving member of a first cable chain segment. The second contact element is adapted for movable contact with a receiving member of a second cable chain segment. The lengthwise member is fixedly attached to the contact elements. When an angle between the first and the second cable chain segments is a first value, the lengthwise member experiences elastic deformation, generating a spring force at each contact element sufficient to pull the receiving member of the first cable chain segment rotatably towards the receiving member of the second cable chain segment, thereby reducing the angle between the first and the second cable chain segments to a second value.

Owner:AVAGO TECH INT SALES PTE LTD

Gapping machine with positioning devices

InactiveCN102100427AImprove accuracyIncrease success rateSlide fastenersEngineeringBilateral symmetry

The invention relates to a zipper processing mechanical device and discloses a gapping machine with positioning devices, which comprises a gapping die, an input guide chain device for conveying a zipper chain to the gapping die and an output guide chain device for outputting the zipper chain from the gapping die, wherein the gapping die comprises a gapping top knife device, a gapping bottom knife device, a fixed seat, a framework of the gapping die, a guide groove and two positioning devices in bilateral symmetry, the gapping die further comprises the zipper chain import end and the zipper chain export end, each positioning device is a cylinder double-needle positioning device, a moving rod which can enable the guide groove to move through a guide rail, a cylinder fixedly connected on the moving rod, a needle die movably connected with the moving rod and two positioning needles fixedly connected on the needle die are mounted on each cylinder double-needle positioning device, and the cylinders are fixed on the framework of the gapping die through the fixed seat. The structure is conductive to accuracy and success rate of positioning, and can ensure the directions of high and low teeth at the upper stop end and the lower stop end of the zipper chain, and enable the gapping machine to be applicable to the zipper chains with different tooth distances.

Owner:SHENZHEN LANCER M&E TECH

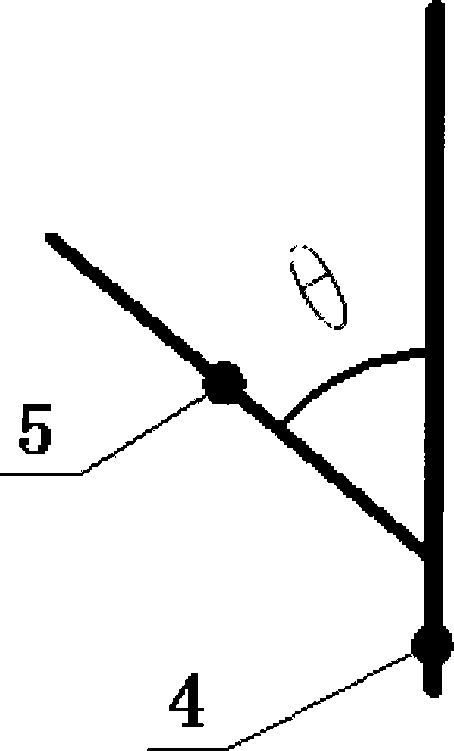

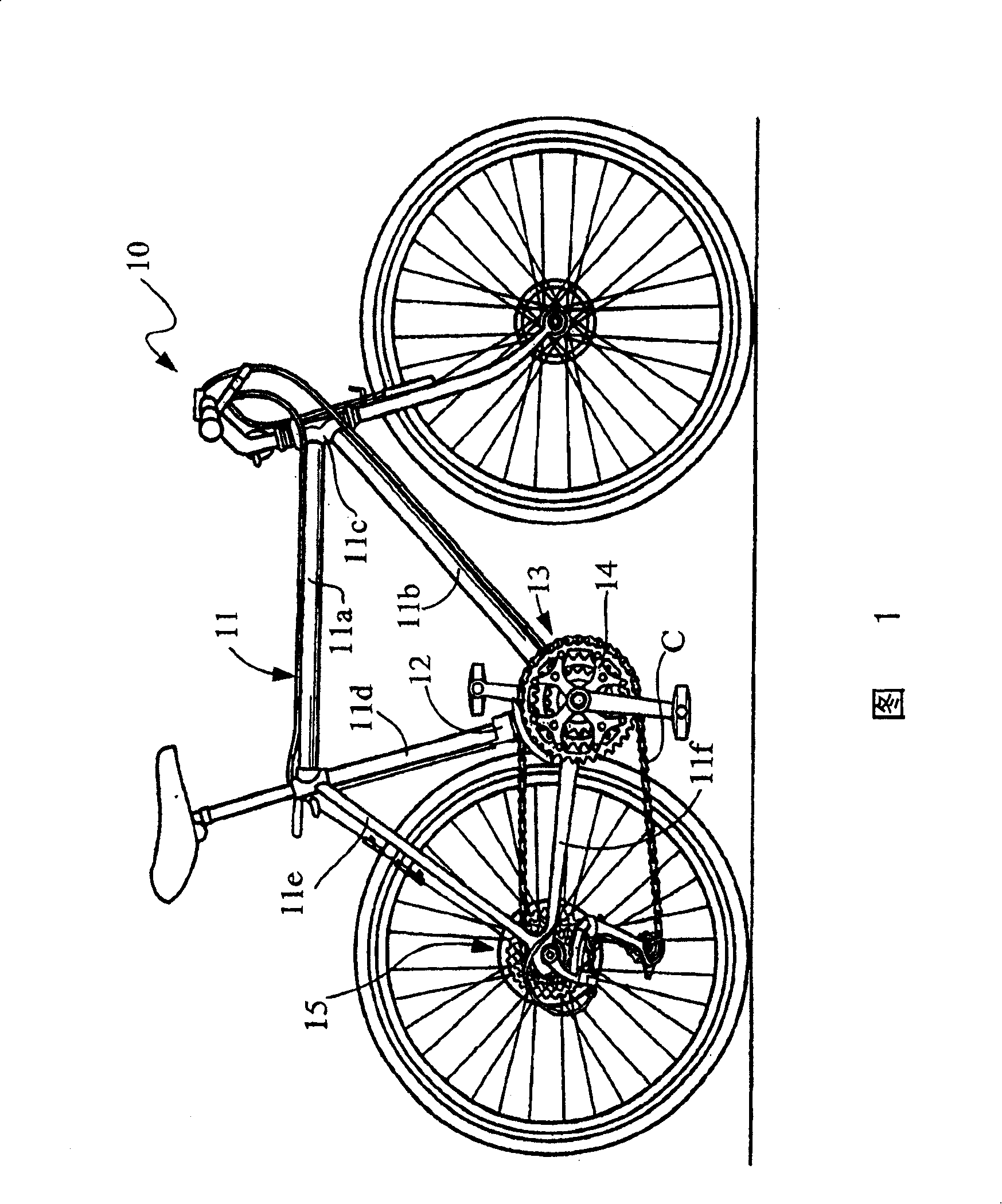

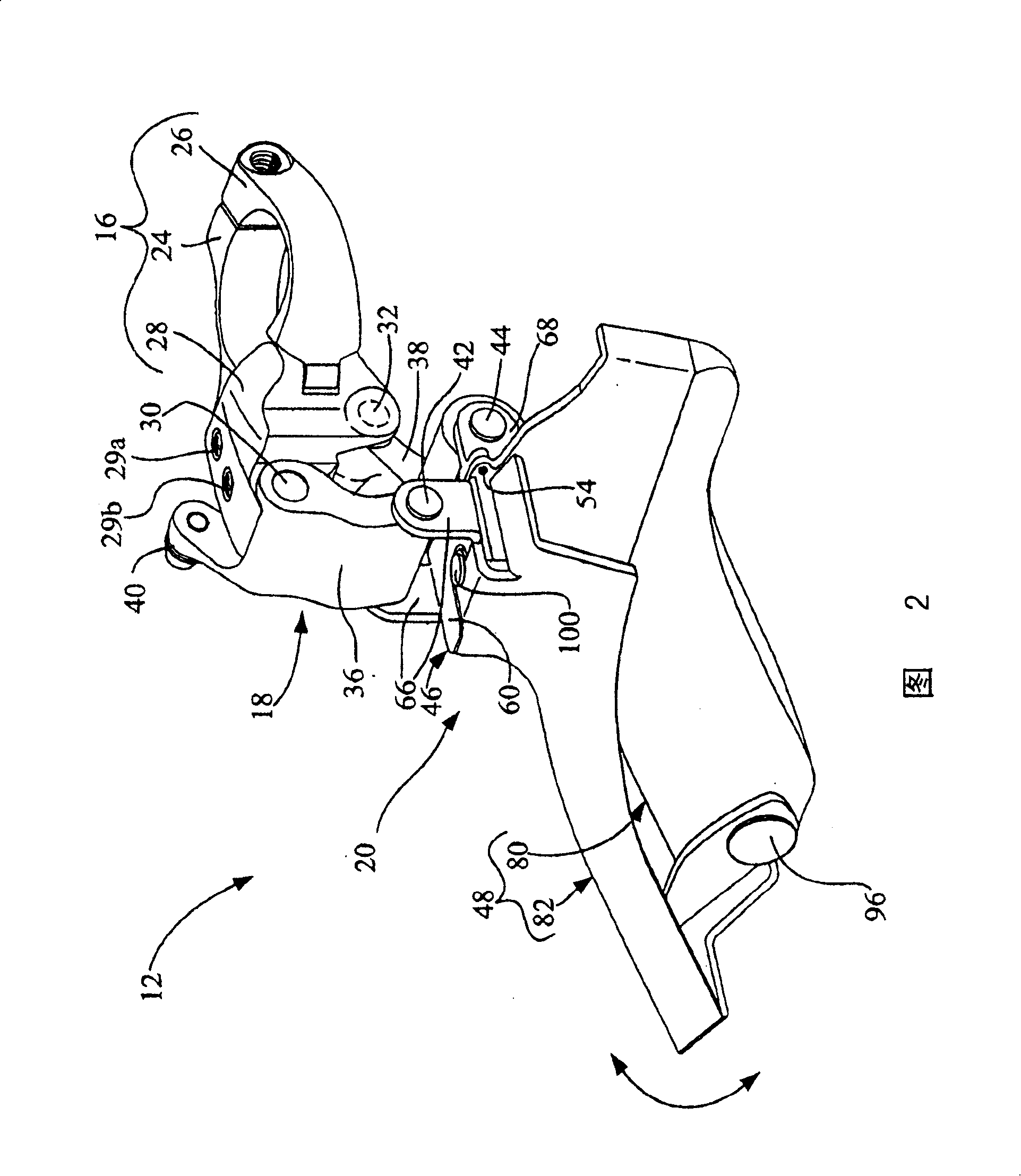

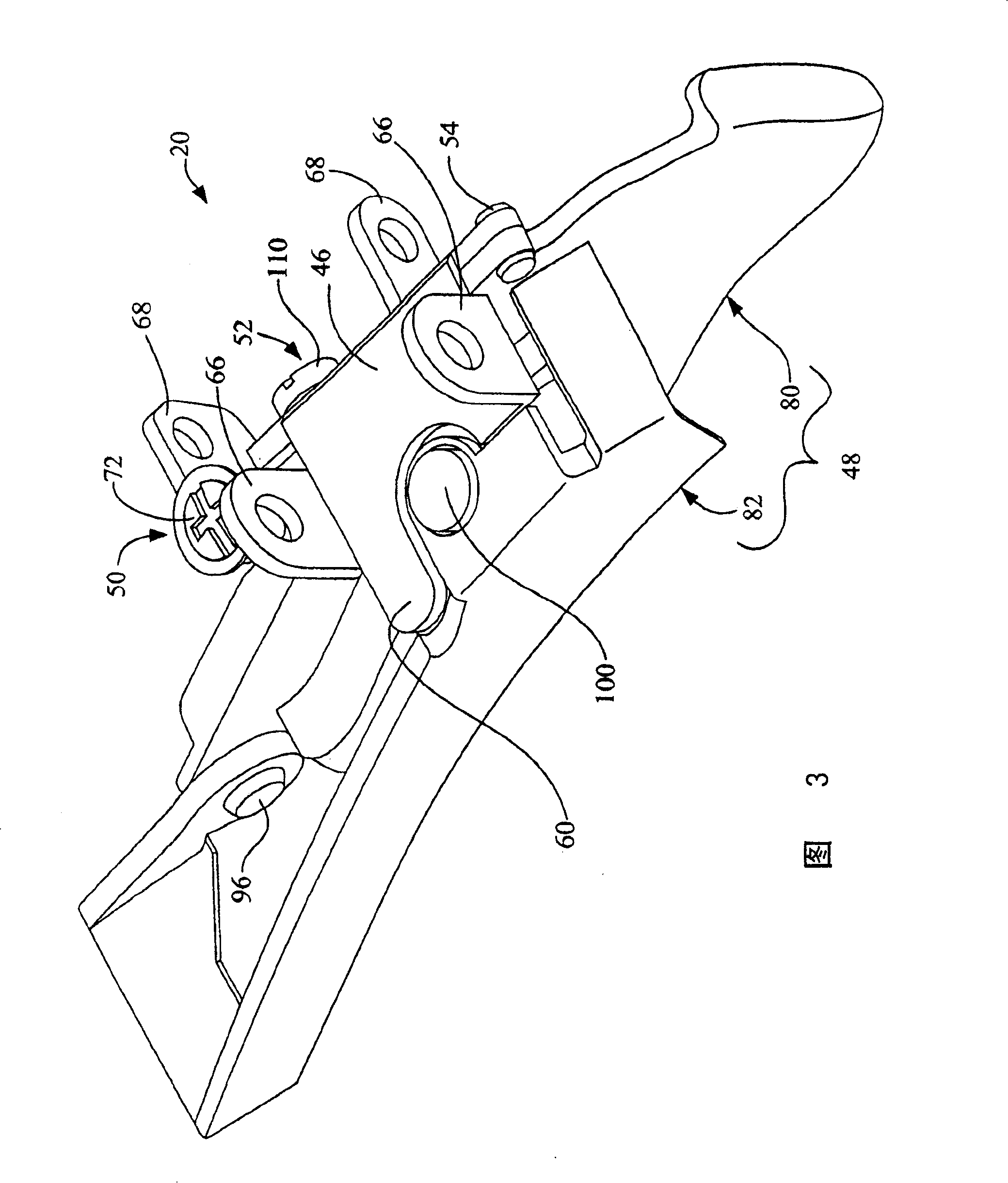

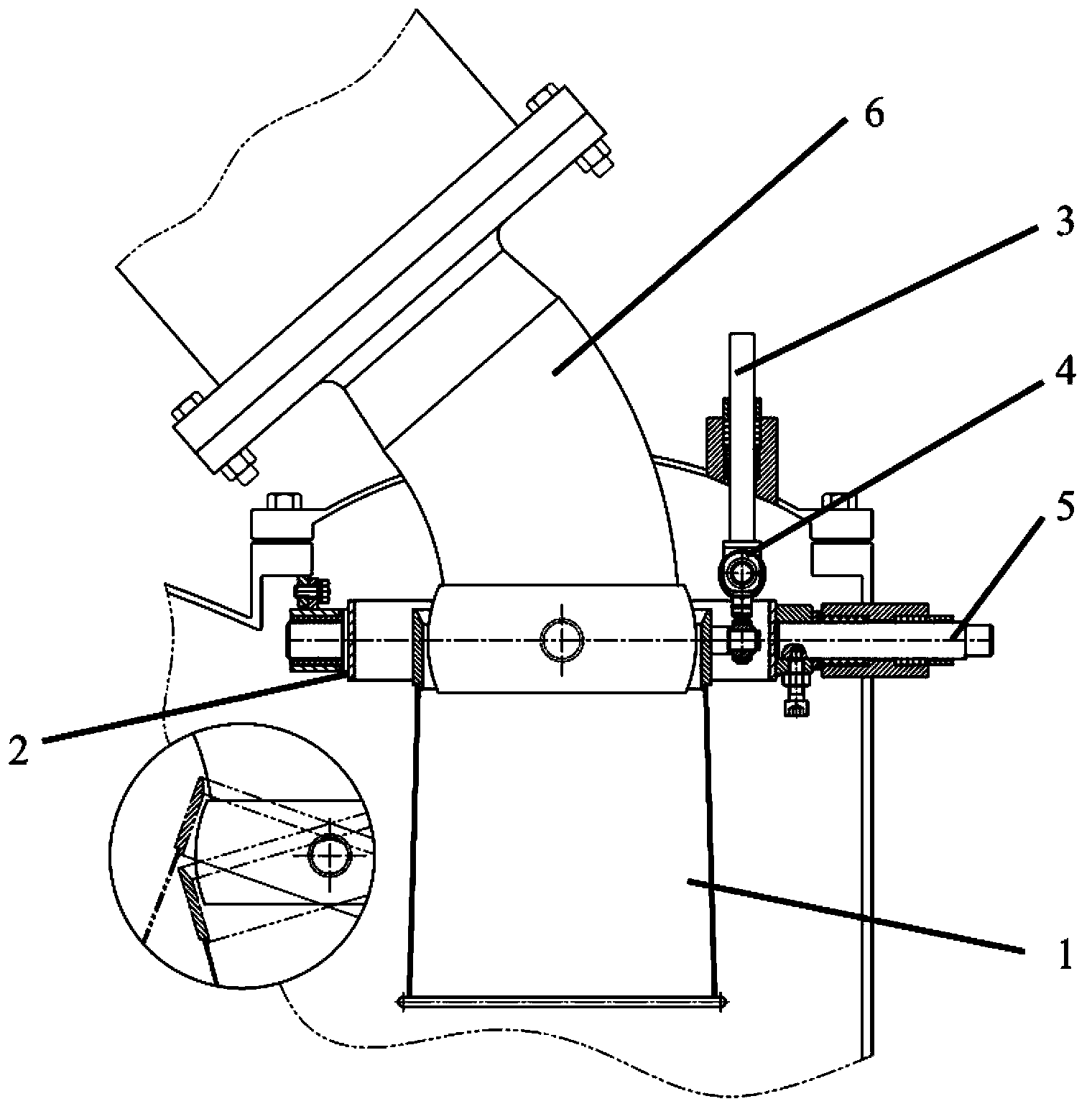

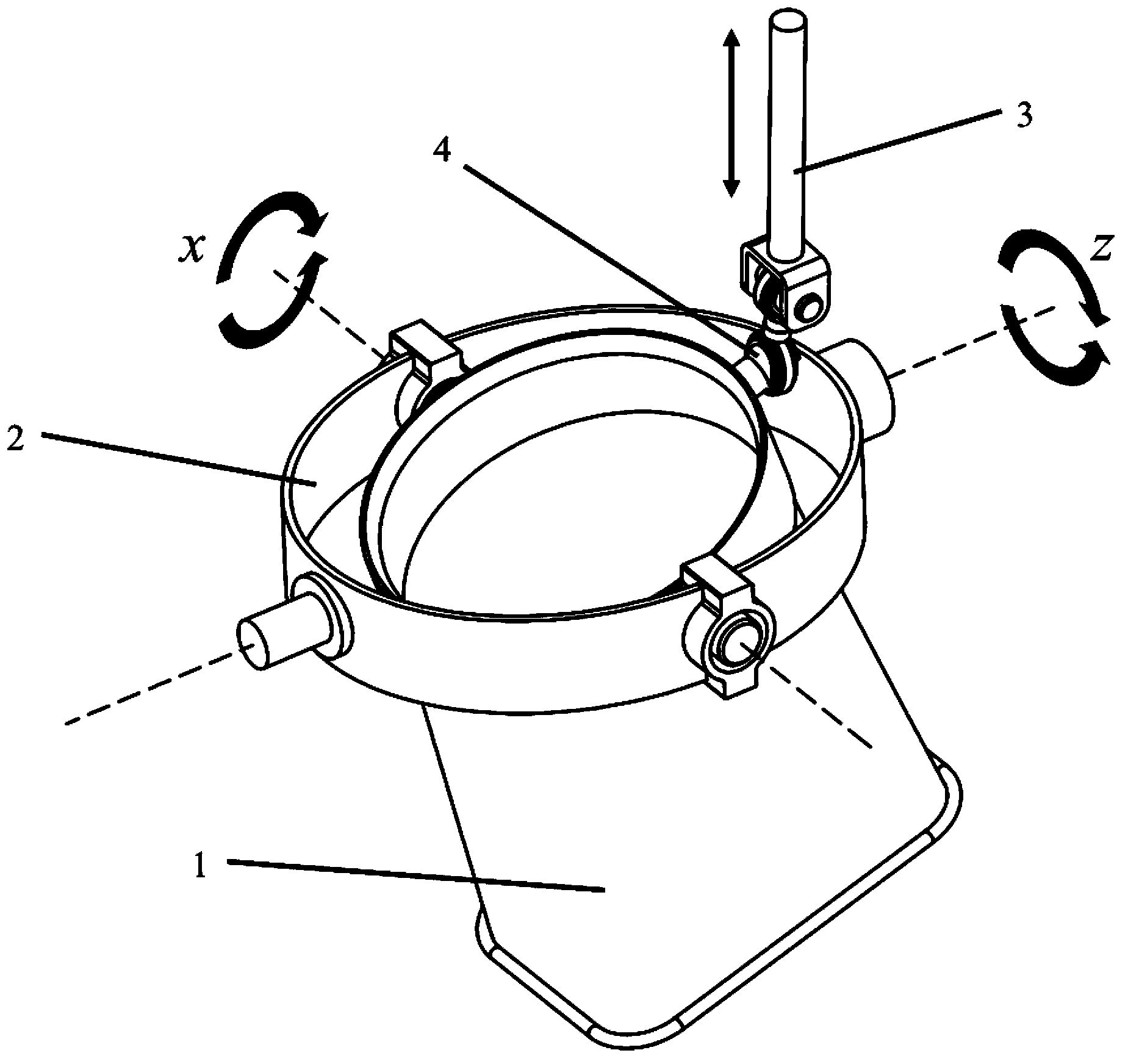

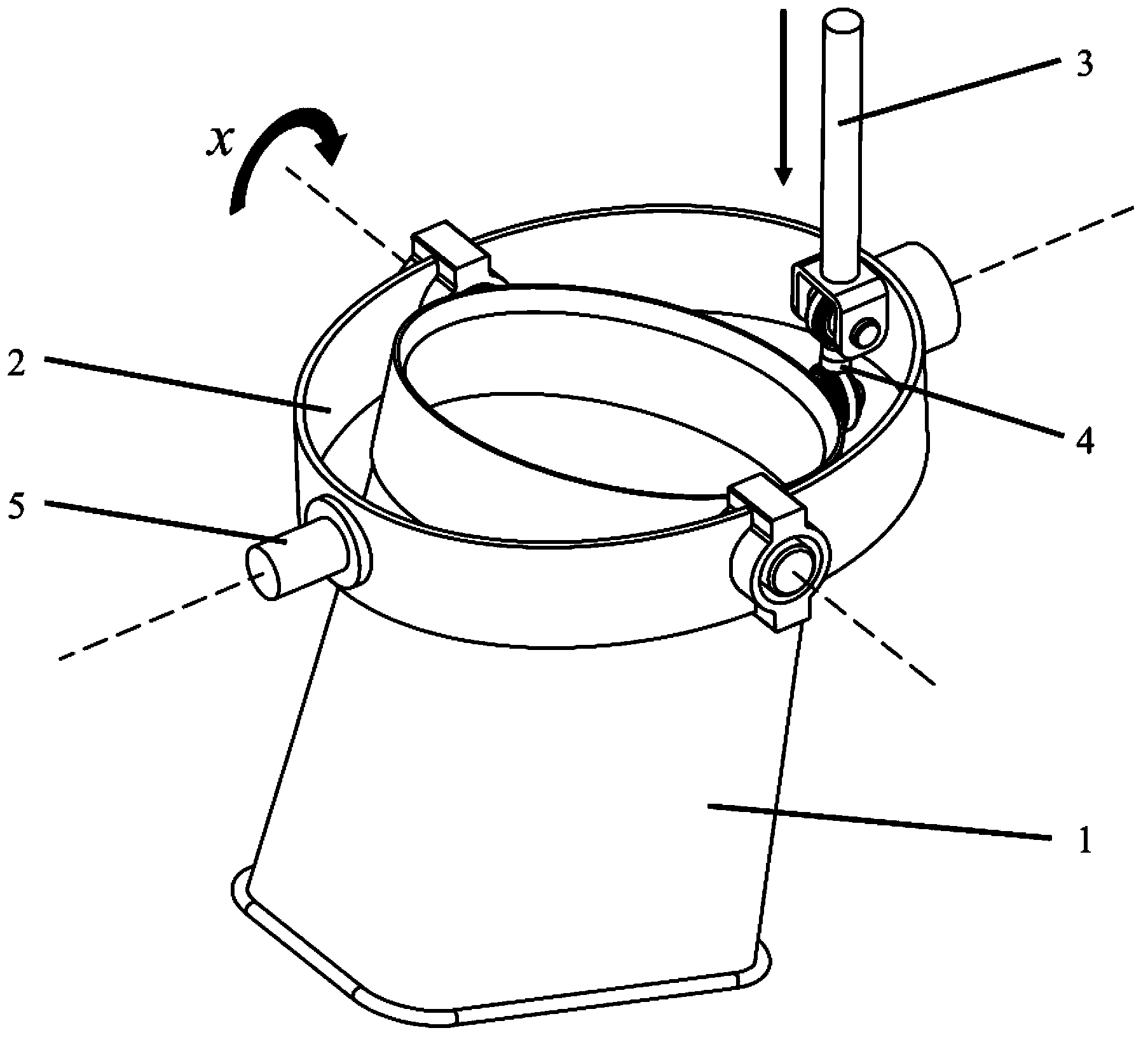

Bicycle front derailleur with angle regulating mechanism

A front chain-poke device of a bicycle comprises a base component, a movable component and a leading-chain device with an angle-adjusting plate component; wherein, the base component is designed to be connected with one part of the bicycle; the movable component is provided with a first bearing side and a second bearing side, and the first bearing side is connected to the base component while the second bearing side is isolated from the first bearing side; the movable component is designed to facilitate the second bearing side to move between a retracting position and an extending position relatively to the base component; the angle-adjusting plate component is connected to the second bearing side so as to make movement together with the second bearing side; the leading-chain device comprises a chain cover which operates and connects the angle-adjusting plate component so as to selectively adjust the angle orientation of the chain cover relatively to the angle-adjusting plate component.

Owner:SHIMANO SINGAPORE PRIVATE LTD

Overwater ship-stopping device

The invention relates to the field of water conservancy and shipping engineering and specifically relates to an overwater ship-stopping device. The overwater ship-stopping device is characterized by comprising a constant tension system and a lifting system, wherein the constant tension system comprises a hydraulic winch, fixed pulleys and a device box; the lifting system comprises a speed reducer, a chain wheel, a chain and a device box; started from a roller on the hydraulic winch, a steel wire rope is upward vertically connected with the fixed pulley (a), is horizontally connected with the fixed pulley (b) toward the right side, is downward vertically connected with the fixed pulley (c), and then is horizontally connected with one end of the upper part of a stopping net toward the right side; the device box is arranged between the fixed pulley (c) and the fixed pulley (f); two vertical chain devices are arranged inside the fixed pulley (c) and the fixed pulley (f); a normally closed brake is connected with the top of the chain; and river ways on left and right two sides are symmetrically arranged. Compared with the prior art, the overwater ship-stopping device has the advantages that a ship can be efficiently prevented from being damaged under the condition of ensuring effective stopping, the vertical lifting of the stopping net is realized by the lifting system, the sea traffic is quickly stopped or recovered, and the operation is flexible.

Owner:SHANGHAI YOUWEI ENG DESIGN

Mining plate-belt feeder

The invention relates to an ore belt feeder, particularly a continuous feeder being sprocket driven, which comprises the drive sprocket on the drive shaft and the adhesive band end roller, chain mat fixed on the chain through screws, adhesive band arranged inside the chain mat, chain at both sides of the adhesive band, several carrying roller under the adhesive band with rolling bearing at both sides with the carrying roller supporting the chain mat through adhesive band, driving the continuous running of chains and chain mat through drive sprocket, realizing the goal of feeding material. The adhesive band head roller shares the same drive shaft with the drive sprocket, with the chain mat and adhesive band running at the same speed through chain driving. It is simple in structure, small in rolling friction, reduced in power consumption and running noise, with the chain mat being rigid with high impact feature.

Owner:WENSHANG ZHONGMEI MACHINE

Fabric swaying device of fabric dyeing machine

ActiveCN104109958ASolve the leakage problemClosely connectedTextile storage in superimposed formLiquid/gas/vapor treatment of propelled fabricsElectronic control systemEngineering

The invention discloses a fabric swaying device of a fabric dyeing machine. The fabric swaying device comprises fabric guide tubes of the dyeing machine, fabric swaying hoppers, a motor, cylinders and support rings. Shaft sleeves and rotary shafts are arranged on the support rings, the support rings are connected with the fabric swaying hoppers by shafts, and the fabric swaying hoppers are connected with pistons by ball chain devices. The rotary shafts are connected with rockers and are further connected with the motor by four-bar linkage structures, and the four-bar linkage structures comprise connecting bars and cranks. The pistons are connected with plungers of the cylinders. Pneumatic control and the motor can be operated by the aid of an electronic control system. The outer wall of the tail of each fabric guide tube is in the shape of a spherical surface, the circular top of each fabric swaying hopper covers the tail of the corresponding fabric guide tube, and various positions of the top of each fabric swaying hopper can closely cling to the corresponding fabric guide tube during swaying. The fabric swaying device can be provided with the multiple four-bar linkage structures, and each four-bar linkage structure is connected with the corresponding fabric swaying hopper. The fabric swaying device has the advantage that the fabric swaying device can be widely applied to the industry of printing and dyeing machinery.

Owner:FONGS NAT ENG (SHENZHEN) CO LTD

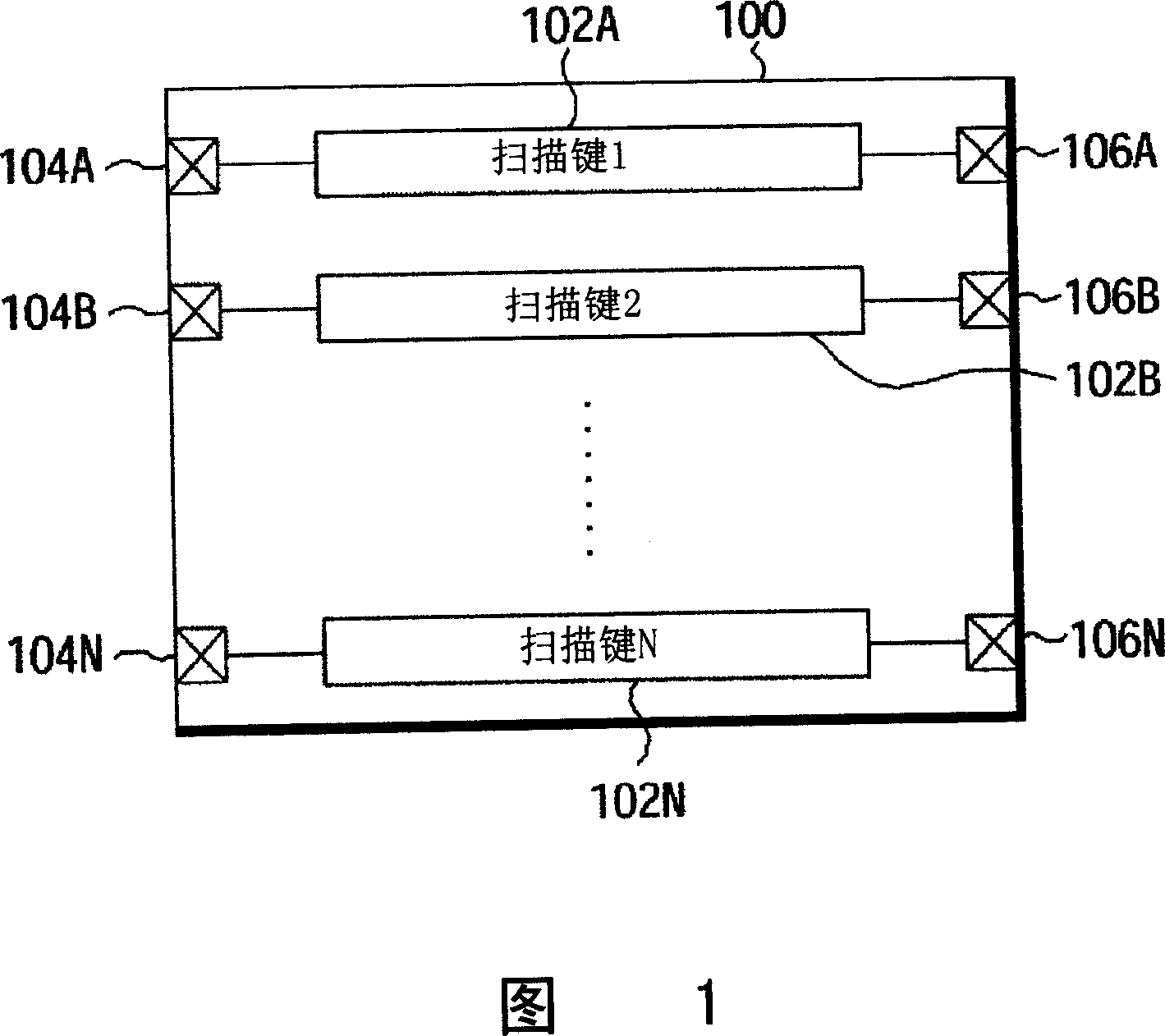

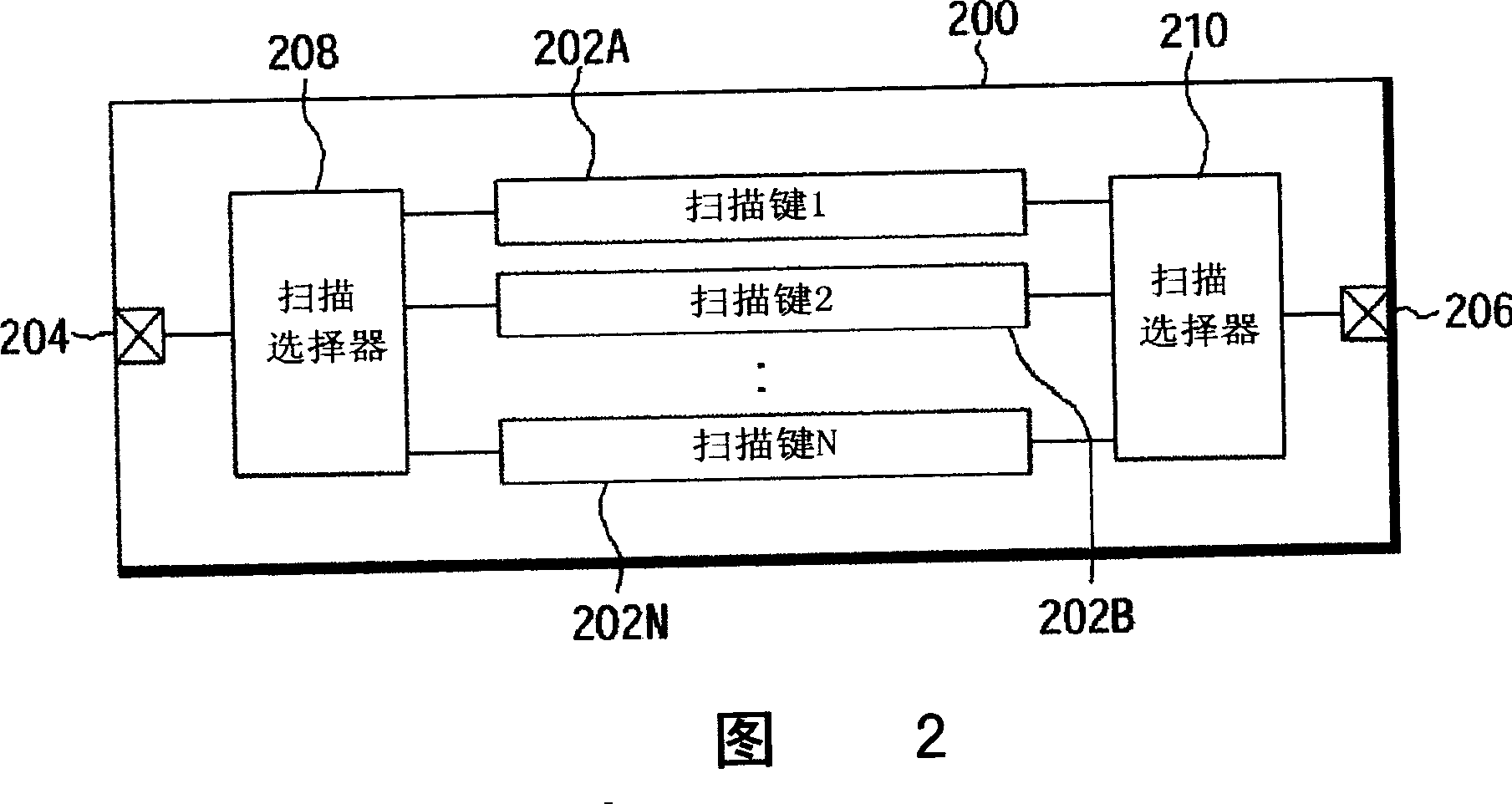

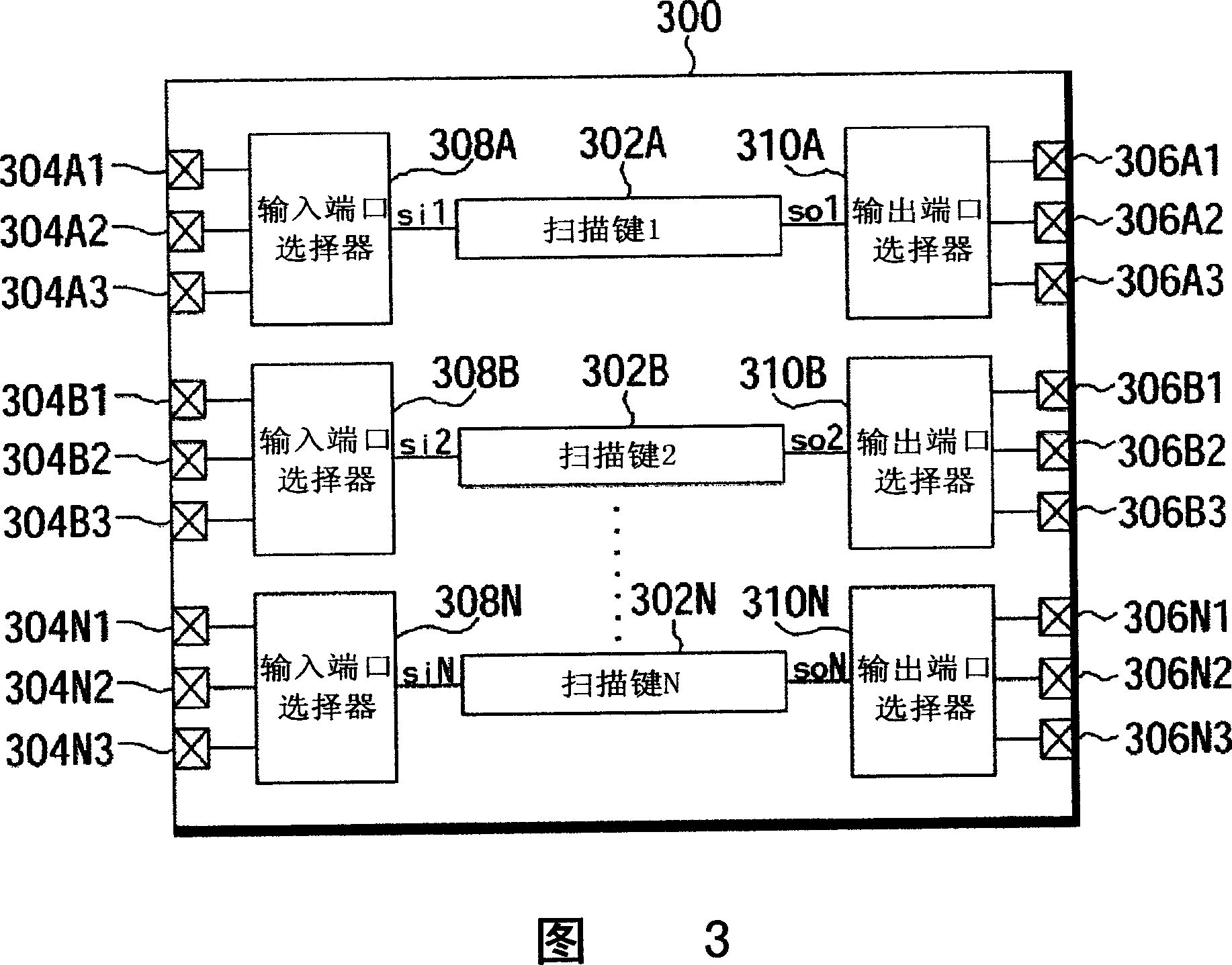

Device with programmable scan chain for use in multi-chip assembly and programming method therefor

The planning scanning chain device comprises a scanning chain with scanning input and output, several No. 1 input or output, input selector, selecting one of the input or output, coupling with the scanning input, several No. 2 input and output end, an output selector, selecting one of the No. 2 output or input with coupled scanning output. The planning scanning chain device comprises a scanning chain with scanning input and output, several No. 1 input or output, input selector, selecting one of the input or output, coupling with the scanning input, several No. 2 input and output end, an output selector, selecting one of the No. 2 output or input with coupled scanning output.

Owner:PROLIFIC TECH INC

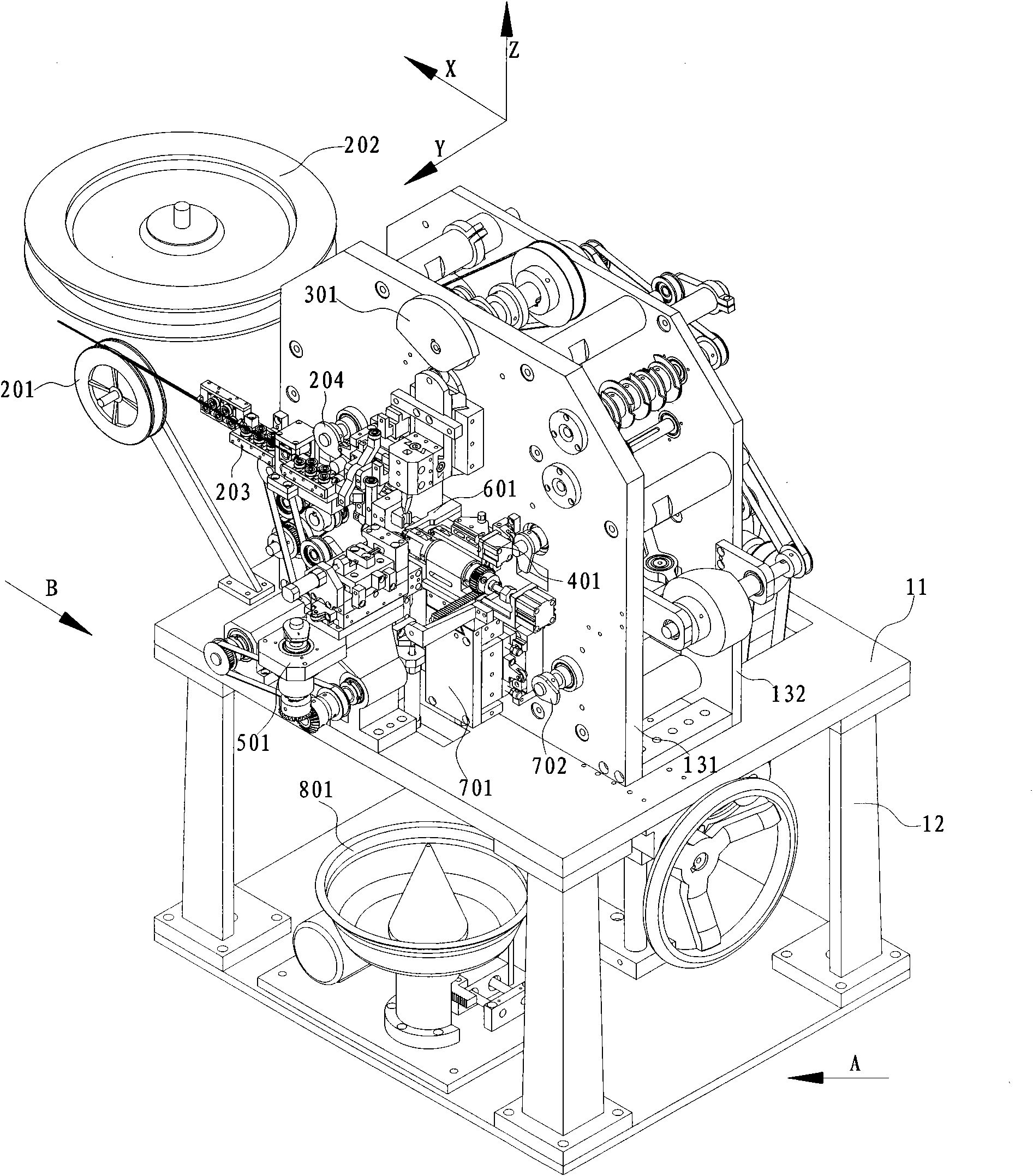

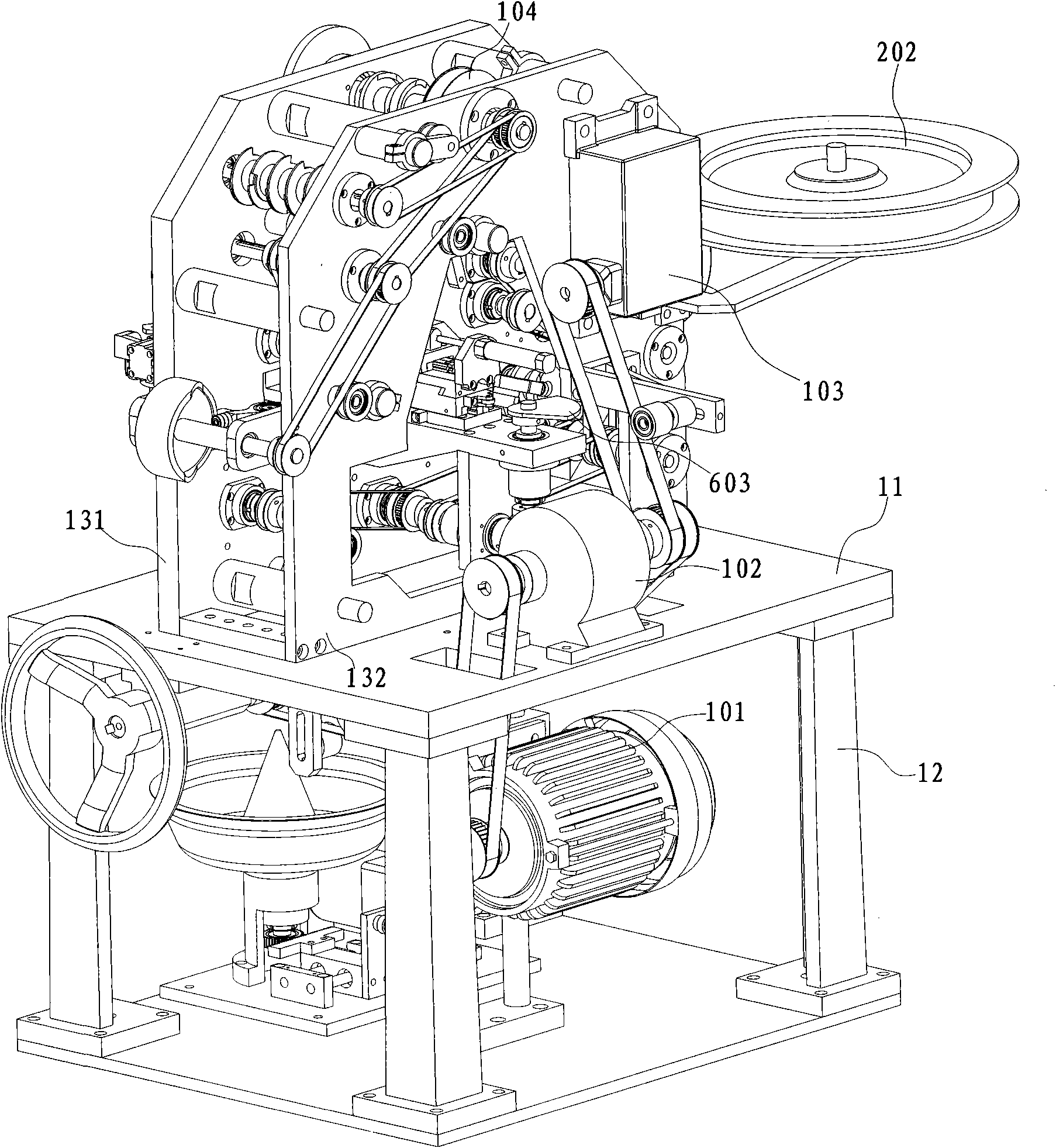

Full-automatic bitch chain machine for shoe-shaped silver ingot chain

The invention relates to a full-automatic bitch chain machine for a shoe-shaped silver ingot chain, at least comprising a frame. The full-automatic bitch chain machine for the shoe-shaped silver ingot chain also comprises a driving device, a pretreatment device, a feeding device, a blanking device, a fineline drawing device, a fineline section molding device, a fineline exterior molding device and a bitch chain device. The full-automatic bitch chain machine for the shoe-shaped silver ingot chain can carry out continuous process starting from raw materials until the manufacturing of the finished shoe-shaped silver ingot chain is finally achieved. The invention has high automaticity, omits manual operation and effectively saves the manual cost of manufacturing the shoe-shaped silver ingot chain. The shoe-shaped silver ingot chain manufactured by the invention has extremely elegant appearance.

Owner:深圳市龙兴机械科技有限公司

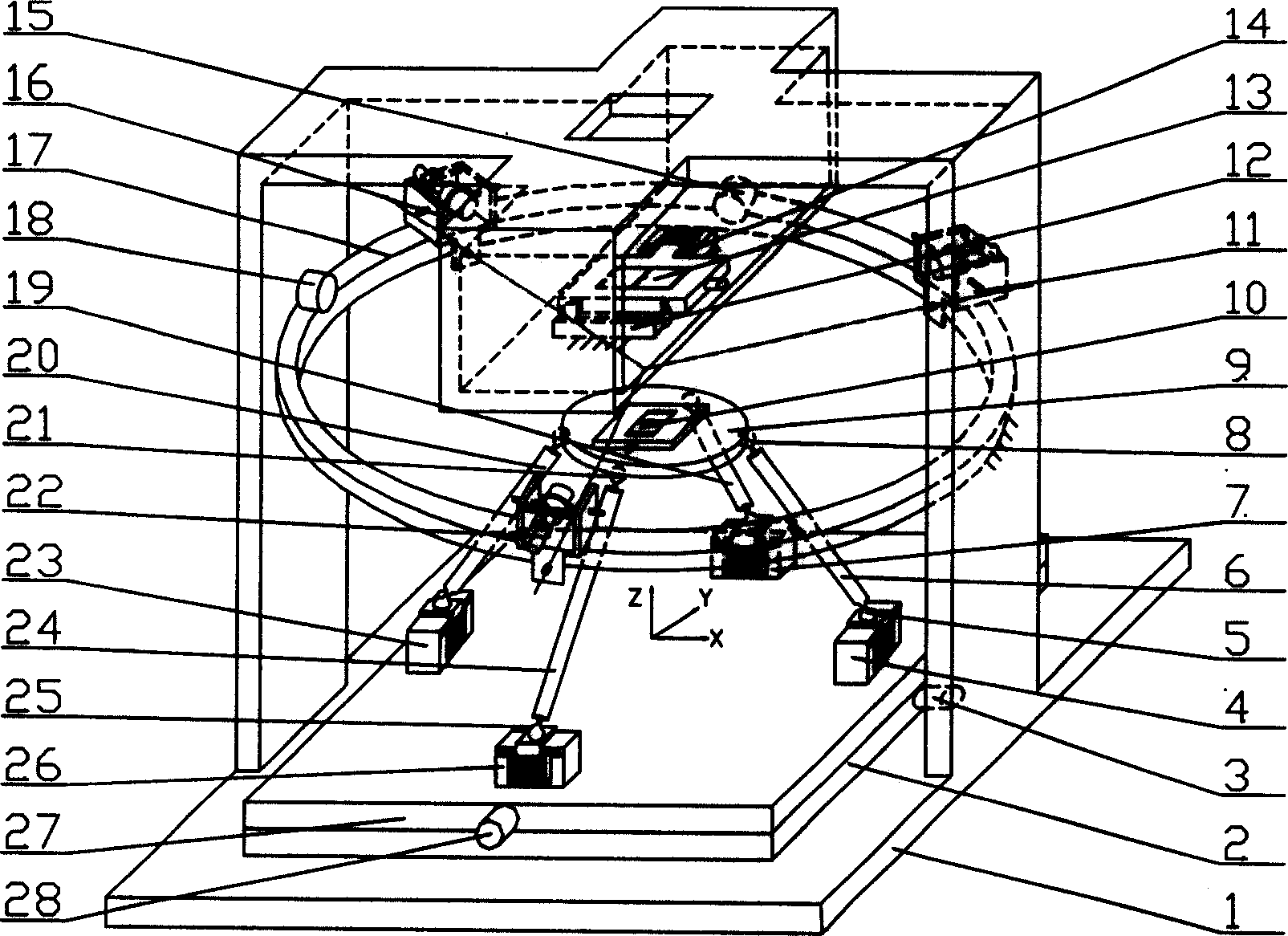

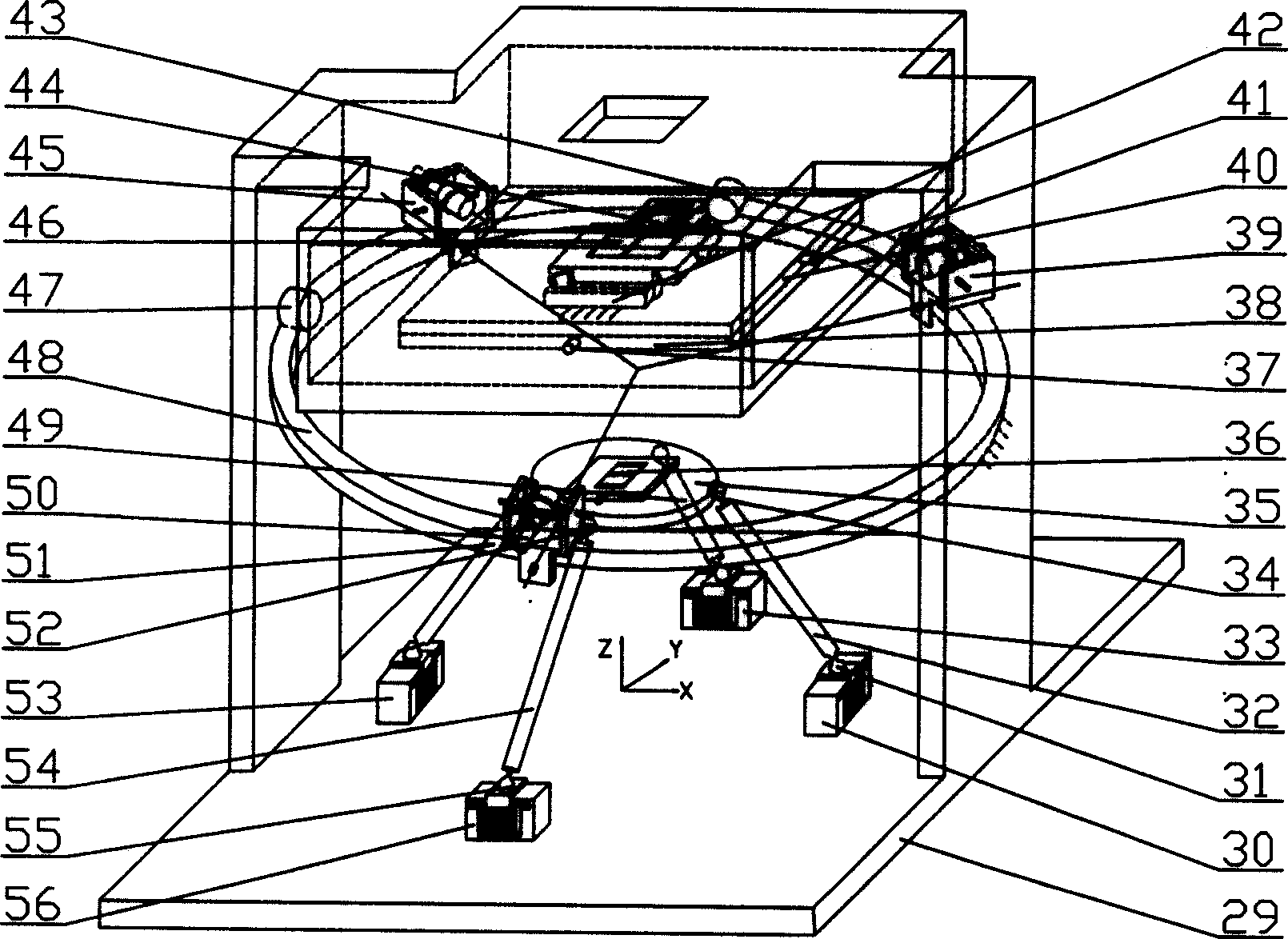

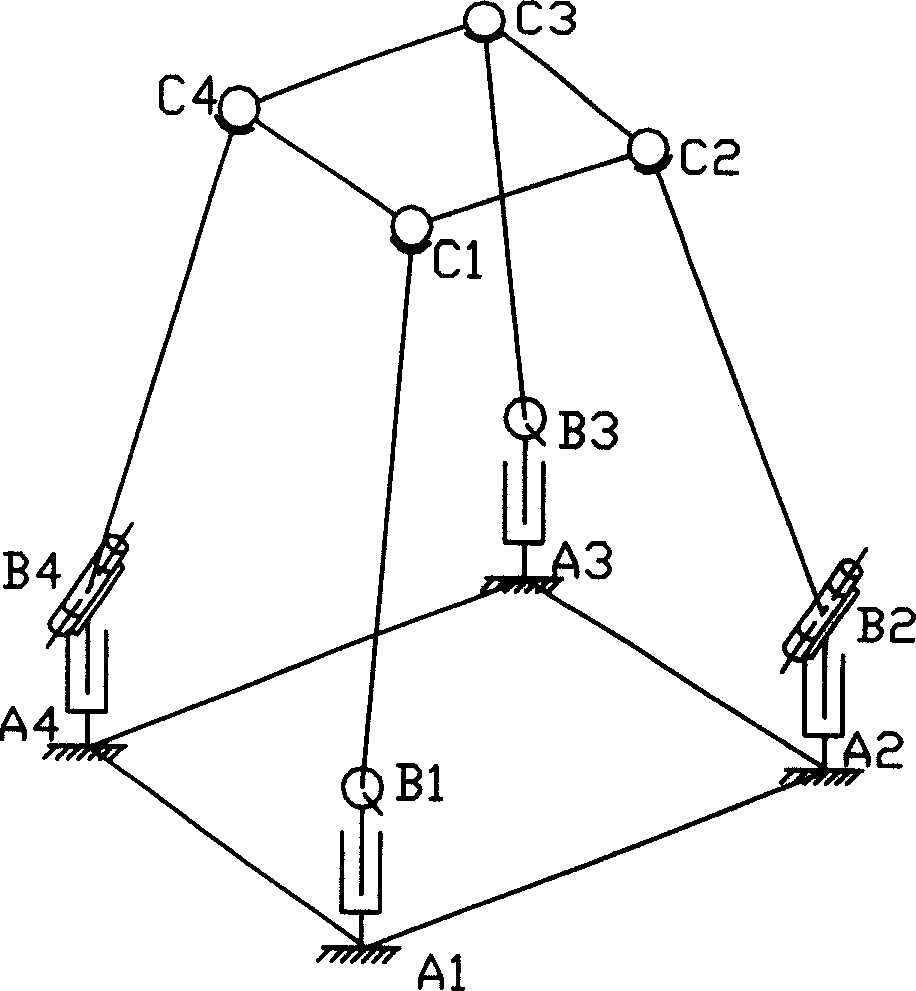

Precisively butting apparatus for photoelectric device package

InactiveCN1614758ASemi-permeable membranesSemiconductor/solid-state device manufacturingEngineeringChain device

The invention consists of a base, a two-way translational platform, four locating beds, an actuated platform, a length control bar, a top optical fiber champing device and a bottom optical fiber champing device. The one end of length control bar is connected with the actuated platform through ball pivot and the other end of length control bar is connected with two locating beds through revolving joint. The length control bar is connected with another two locating beds through hooke articulation or ball pivot to form parallel space closed chain device.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com