Overwater ship-stopping device

A facility and equipment box technology, applied in the fields of water conservancy and shipping engineering, can solve the problems of insufficient operation reliability and lack of controllability, and achieve the effect of quickly blocking or restoring navigation, preventing damage to ships, and flexible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings. The equipment is very clear to those skilled in the art.

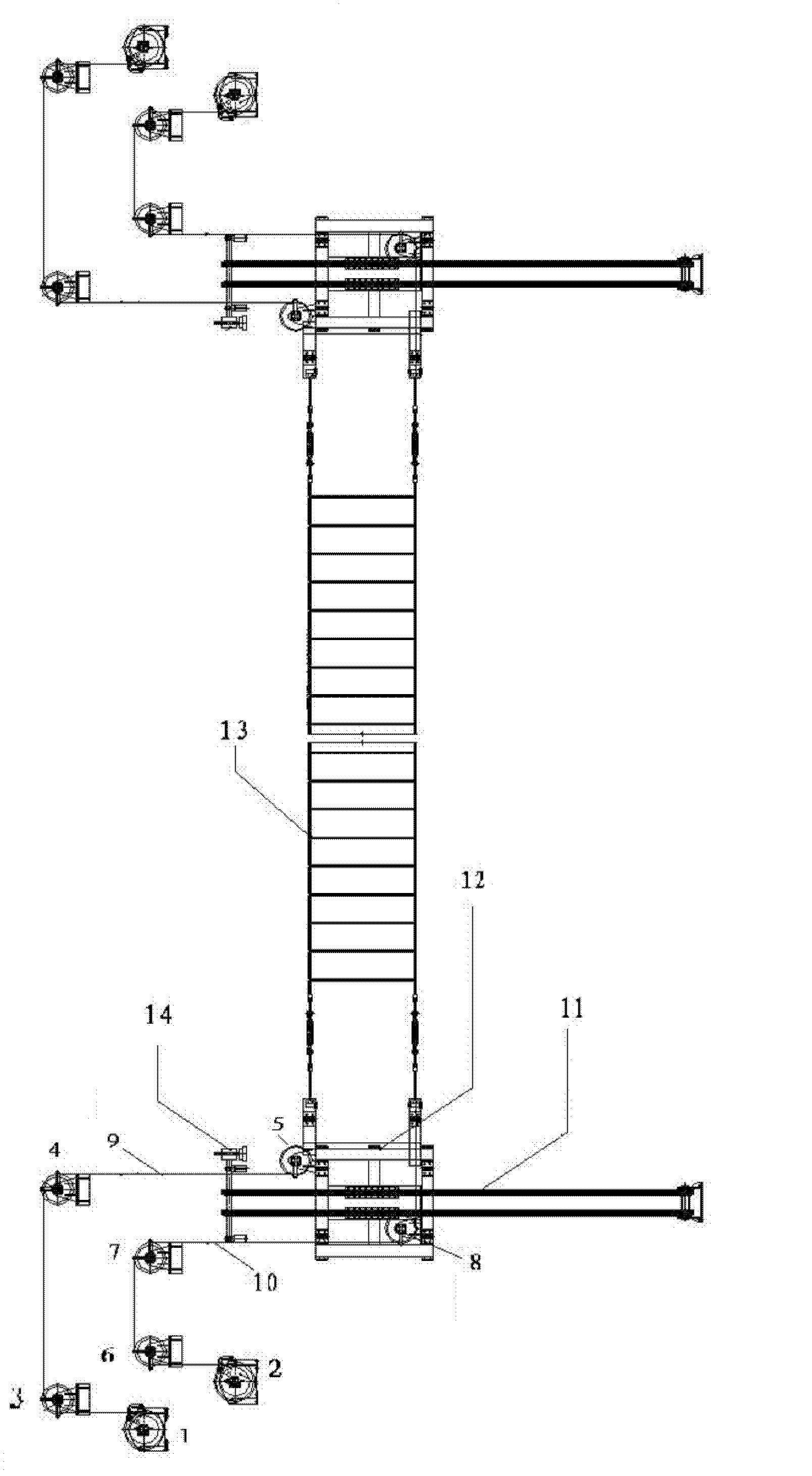

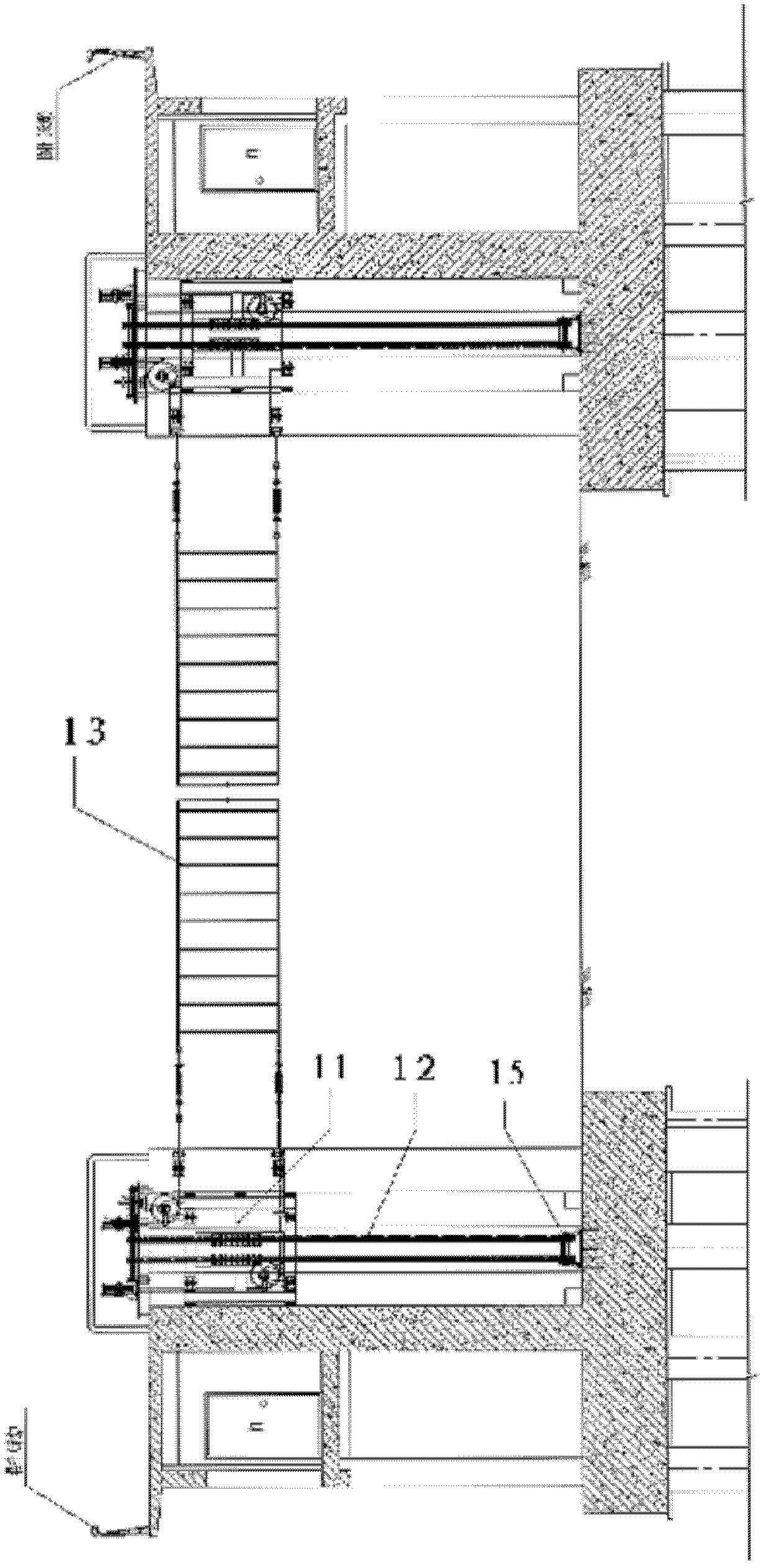

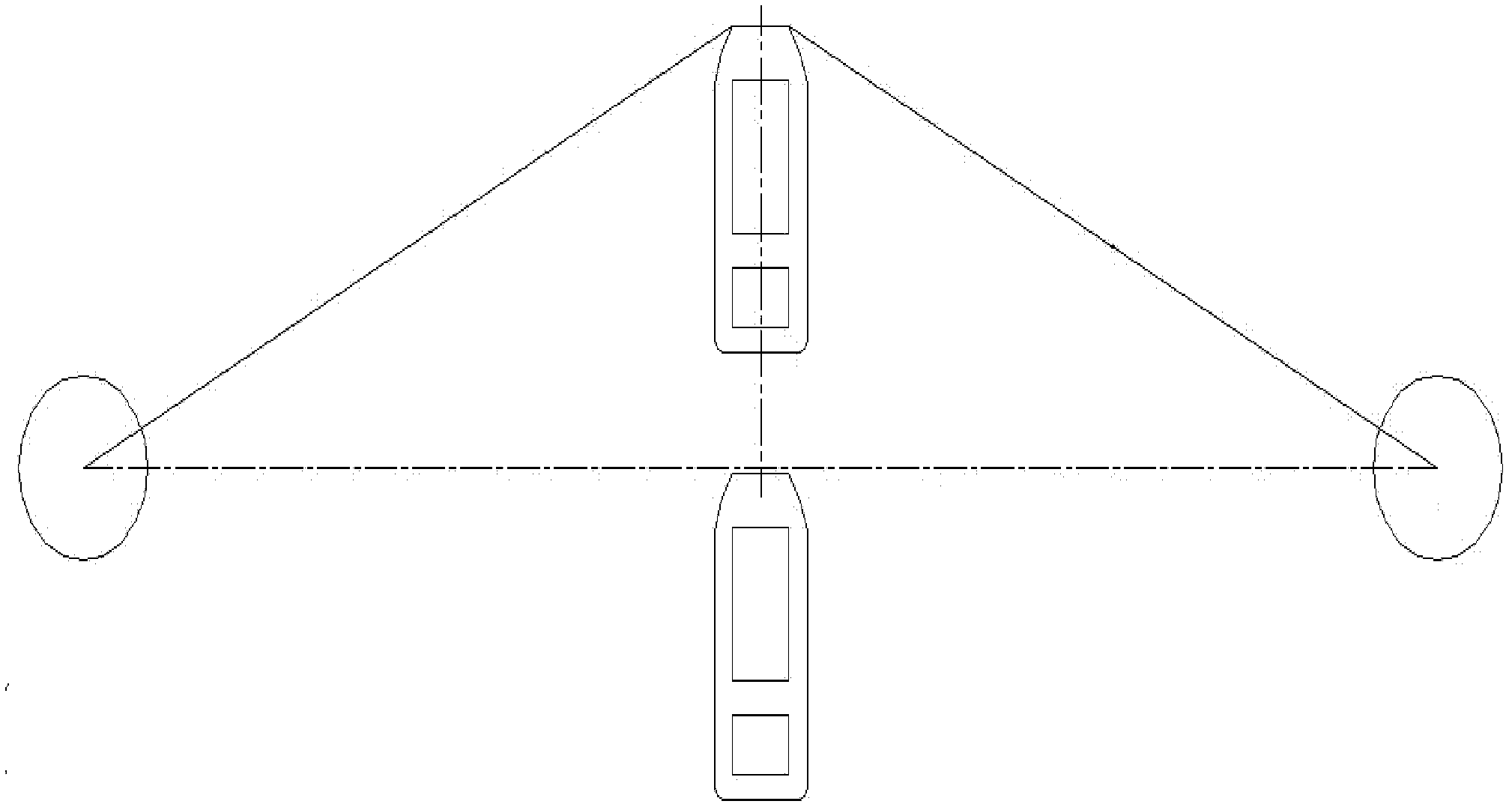

[0016] See figure 1 , The principle of the system of the present invention is: the first hydraulic winch and the second hydraulic winch are respectively provided on both banks of the river, and the steel wire rope (a) 9 on the first hydraulic winch (a) 1 is on the hydraulic winch (a) 1 Connect the fixed pulley (a) 3 vertically upward, connect the fixed pulley (b) 4 horizontally to the right, and connect the fixed pulley (c) 5 vertically downward, and then connect the upper end of the blocking net to the right horizontally. Second, the steel wire rope (b) 10 on the hydraulic winch (b) 2 starts from the drum on the hydraulic winch (b) 2 and connects the fixed pulley (d) 6 vertically upwards, and connects the fixed pulley (e) 7 horizontally to the right. The fixed pulley (f) 8 is vertically connected downward, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com