Full-automatic bitch chain machine for shoe-shaped silver ingot chain

A fully automatic, chain buckle technology, applied in the direction of metal chains, etc., can solve the problems of ingot chain appearance is not beautiful enough, manual operation production efficiency is low, etc., to save labor costs, save manual operation, and the effect of high exquisite appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below, in conjunction with the accompanying drawings and specific implementation methods, the fully automatic ingot chain buckle chain machine of the present invention will be further described, so as to understand the technical idea claimed by the present invention more clearly.

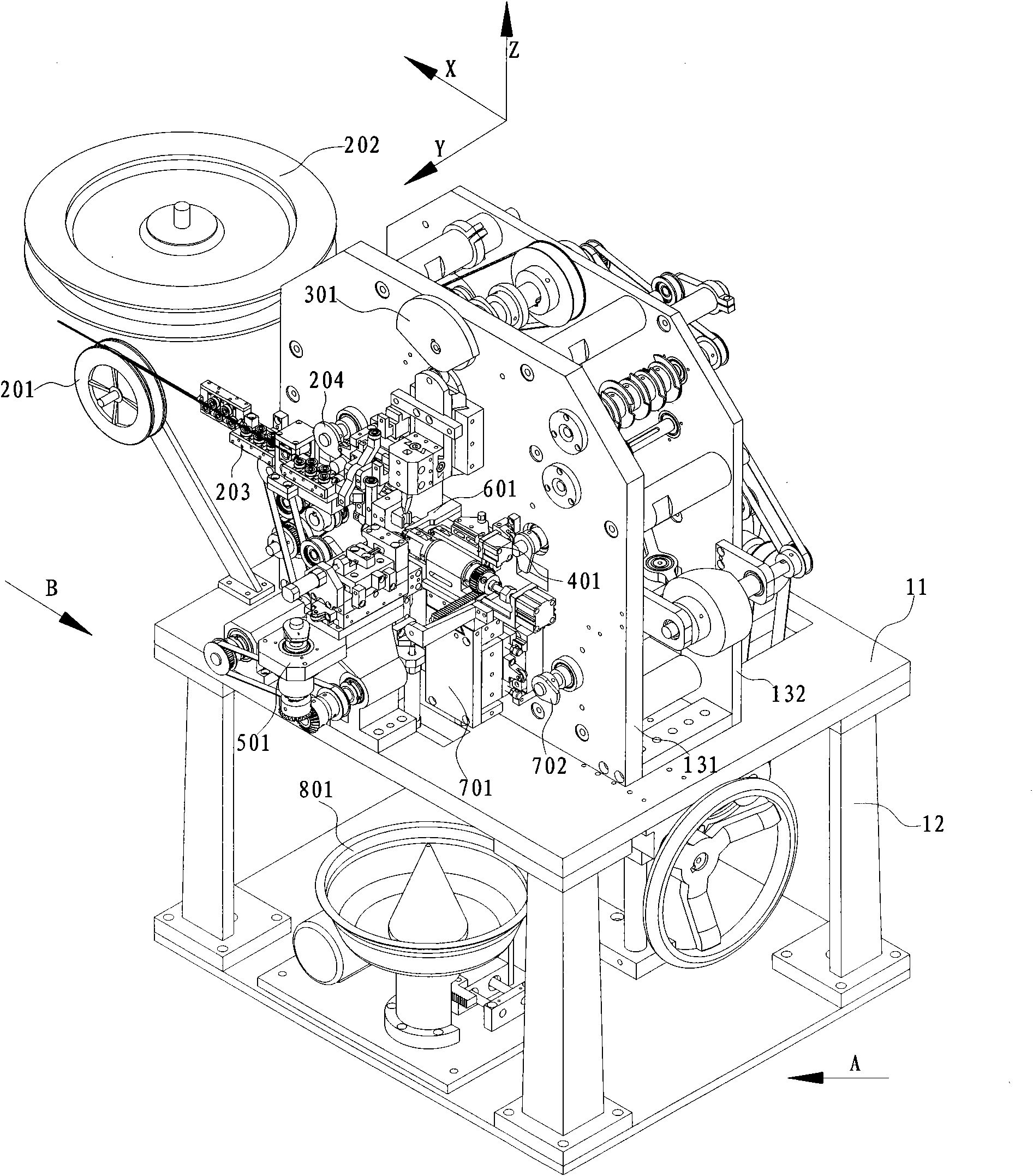

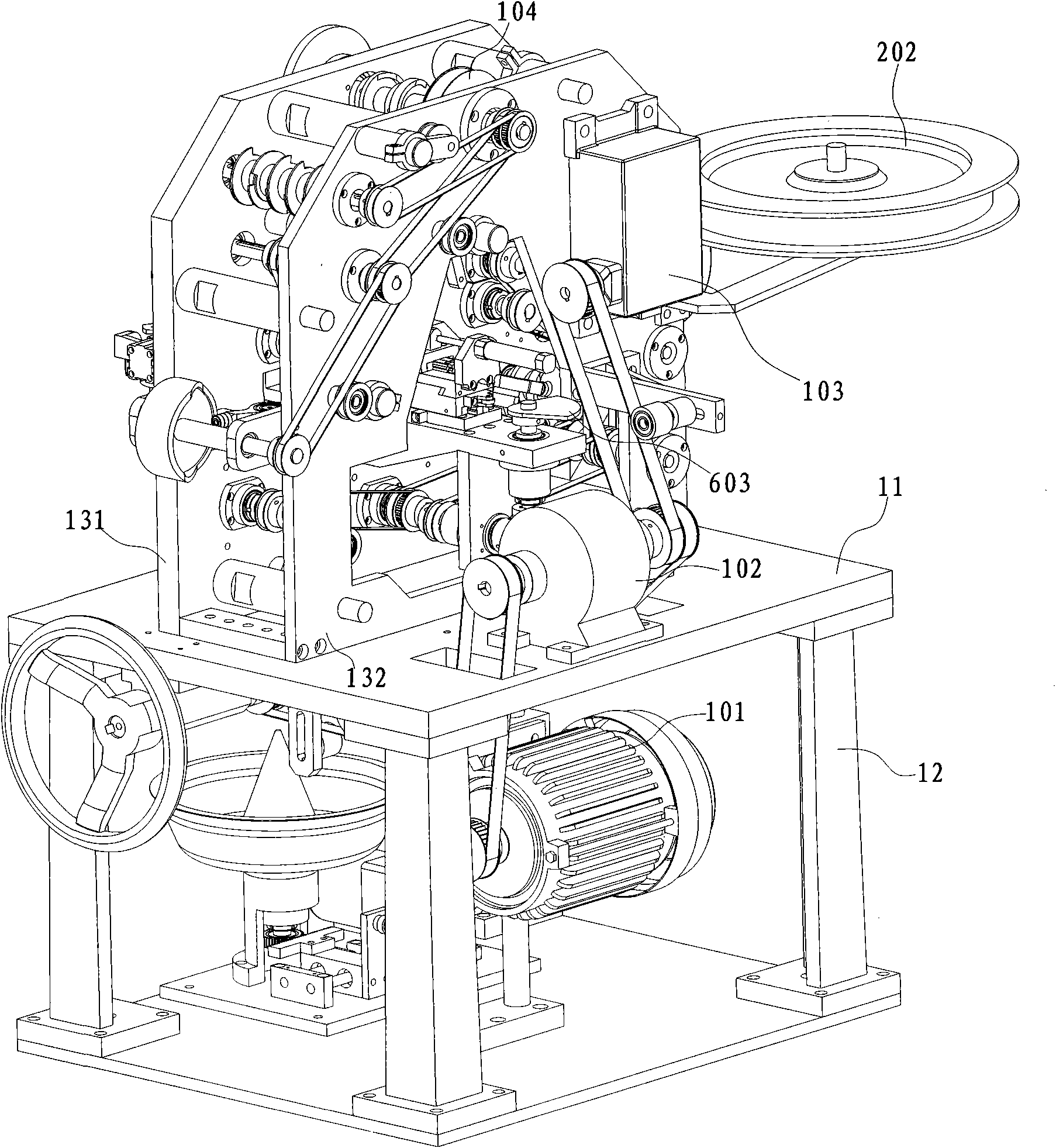

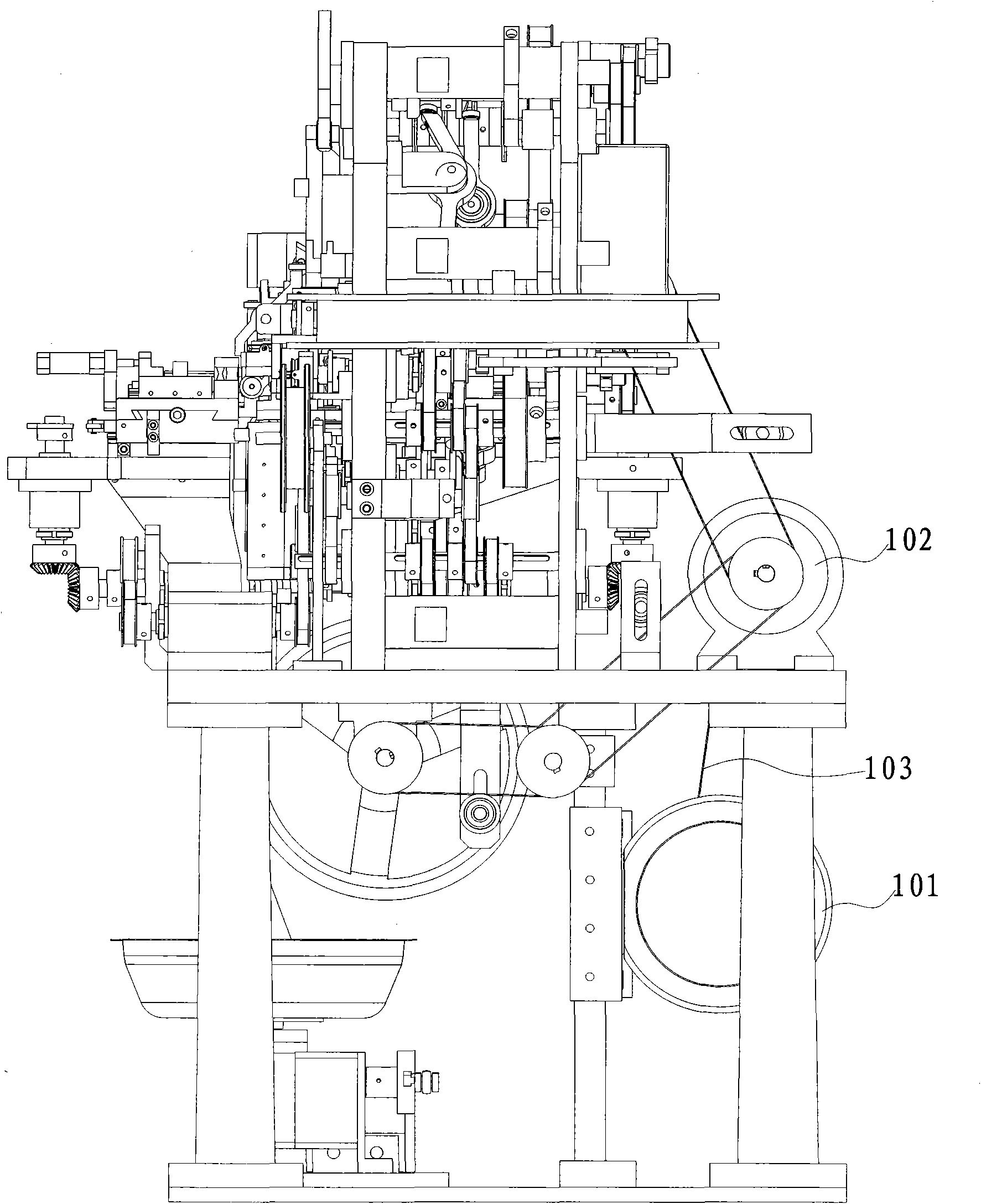

[0041] like figure 1 , 2 Shown in , 3, be a kind of full-automatic ingot chain buckle chain machine of the present invention, be provided with support frame at its body bottom, support frame comprises the support leg 12 that is positioned at its bottom, and the support plate 11 on the support leg 12, in A space is formed below the support plate 11, and a finished product receiving tray 801 is installed in the space.

[0042] In the space formed below the above-mentioned support plate 11, a motor 101 is installed, and a clutch 102 is fixedly installed on the top of the support plate 11. The rotor of the motor 101 is connected to the input end of the clutch 102 through a belt, and a speed chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com