Machine equipment for online mounting of lifting ribbon

A kind of machine equipment, lifting belt technology, applied in the direction of container, packaging, transportation and packaging, can solve the problems of low efficiency, high labor cost, hidden danger of life safety, etc., to reduce labor cost and personnel management cost, Solve the effect of high labor cost and rapid production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

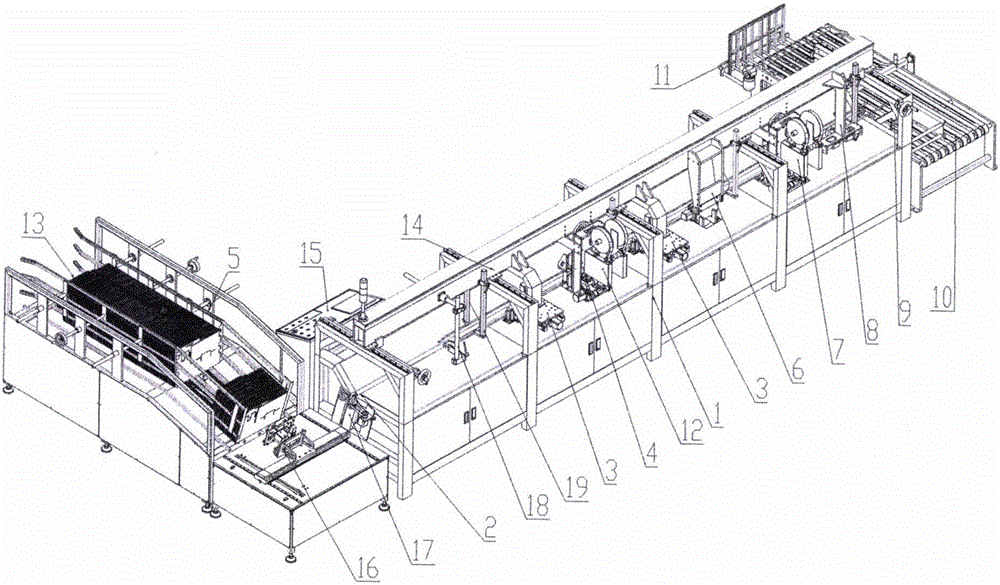

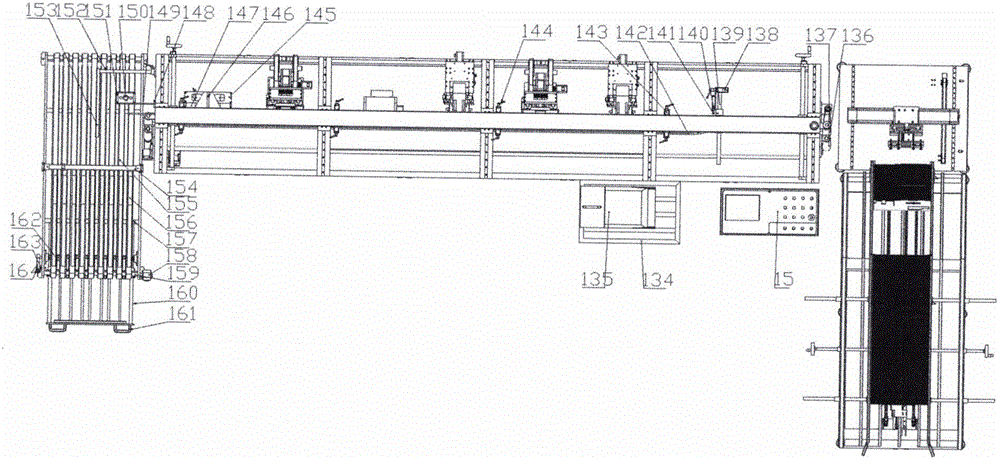

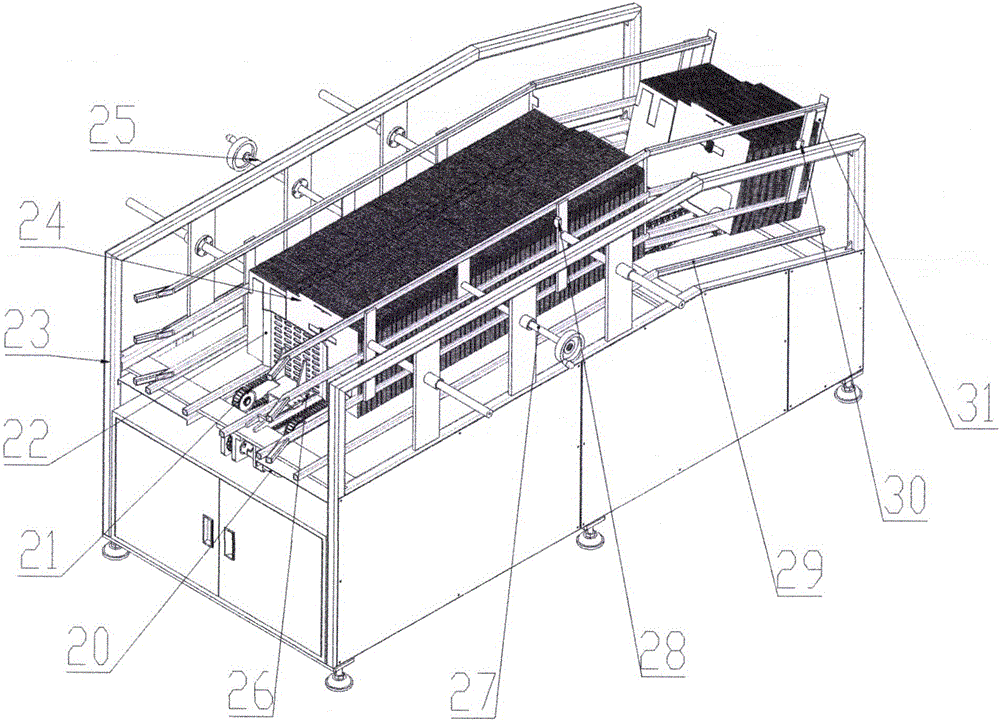

[0038] see Figure 1-16 , a machine device for online installation of lifting belts, including a main body conveyor frame 1, a carton conveyor chain device 2, an adhesive coating device 3, a reinforcing belt installation device 4, a hopper device 5, and a lifting belt installation device 6 , Ultrasonic welding device 7, automatic detection device 8, automatic rejecting device 9, receiving board conveying device 10, receiving board palletizing device 11, automatic unwinding device 12, upper board width adjustment assembly 13, main station translation beam 14, operation Control system 15, board separating conveying device 16, carton input pressure roller assembly 17, cover guide device 18 and platen guide rod assembly 19, the main body conveying frame 1 includes a gantry support 47, a gantry translation guide rail 48, and a conveying inclined plate 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com