Fabric swaying device of fabric dyeing machine

A cloth dyeing machine and dyeing machine technology, applied in the direction of processing textile material carrier, liquid/gas/steam jet propulsion fabric, folded textile material preservation, etc., can solve the problem of unfavorable cloth guiding, increase of production cost, and inability to centrally blow and disperse cloth And other problems, to achieve the effect of good expansion efficiency and prevent cloth entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] By following embodiment, and in conjunction with accompanying drawing, the present invention is further elaborated:

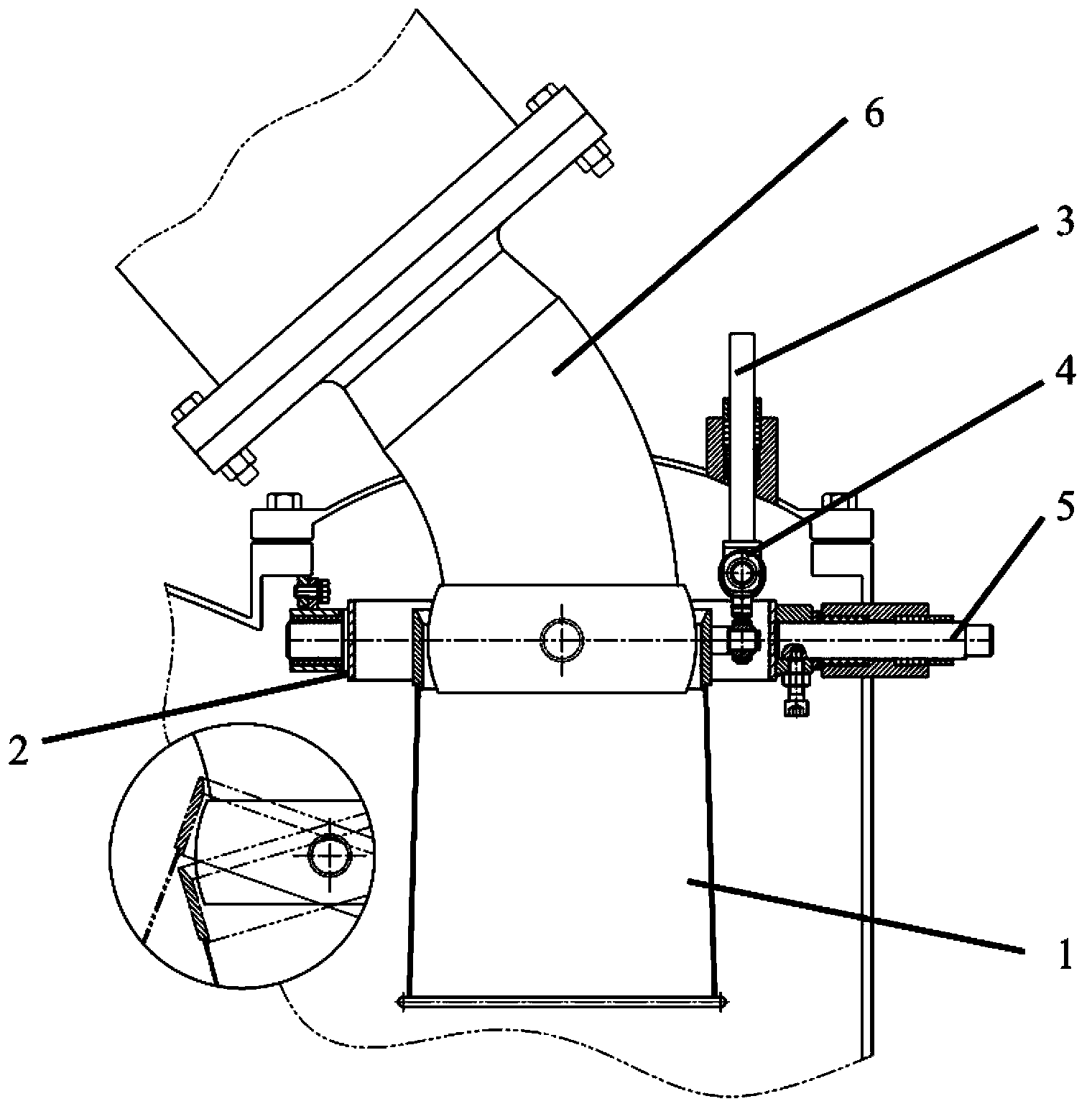

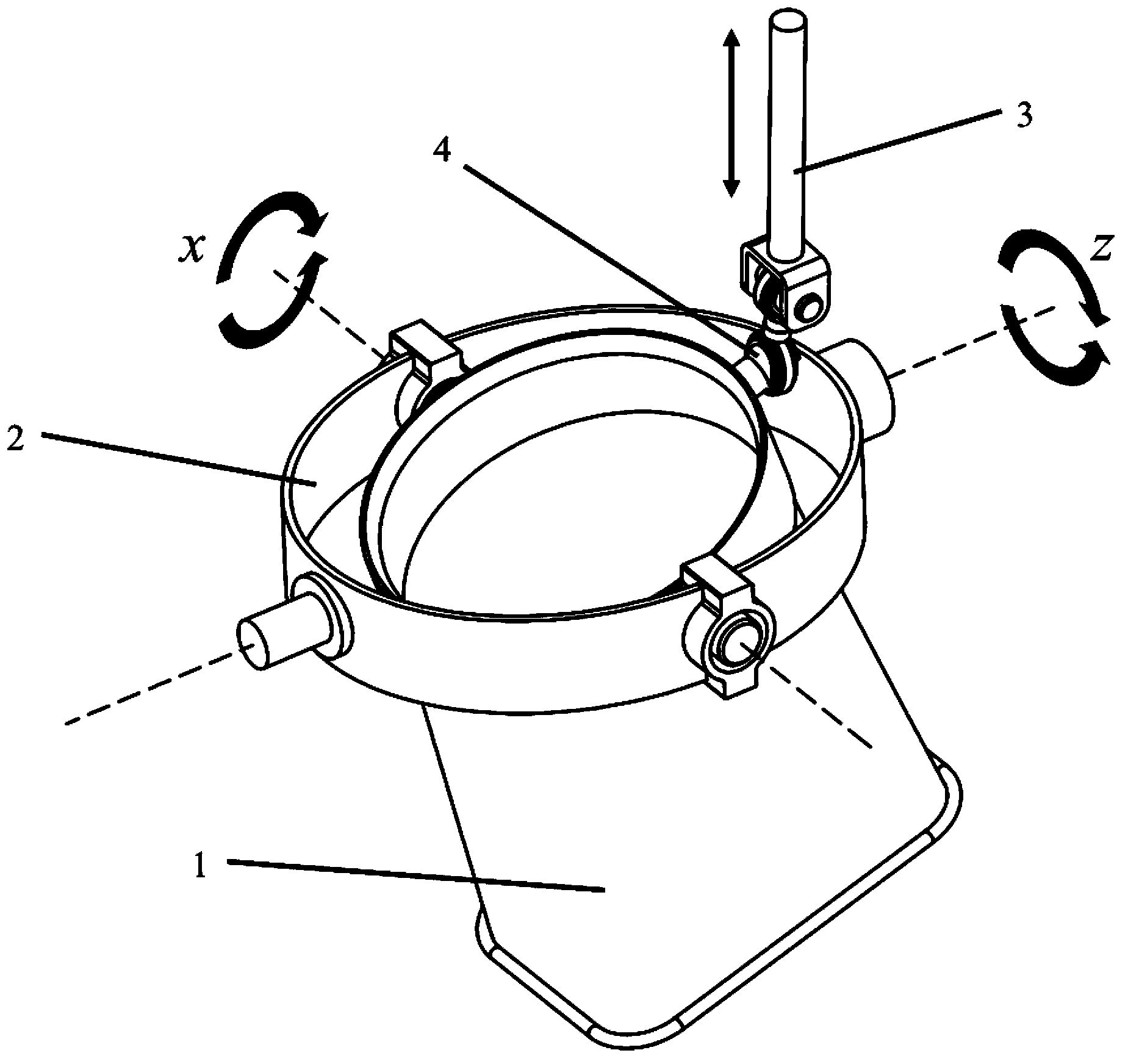

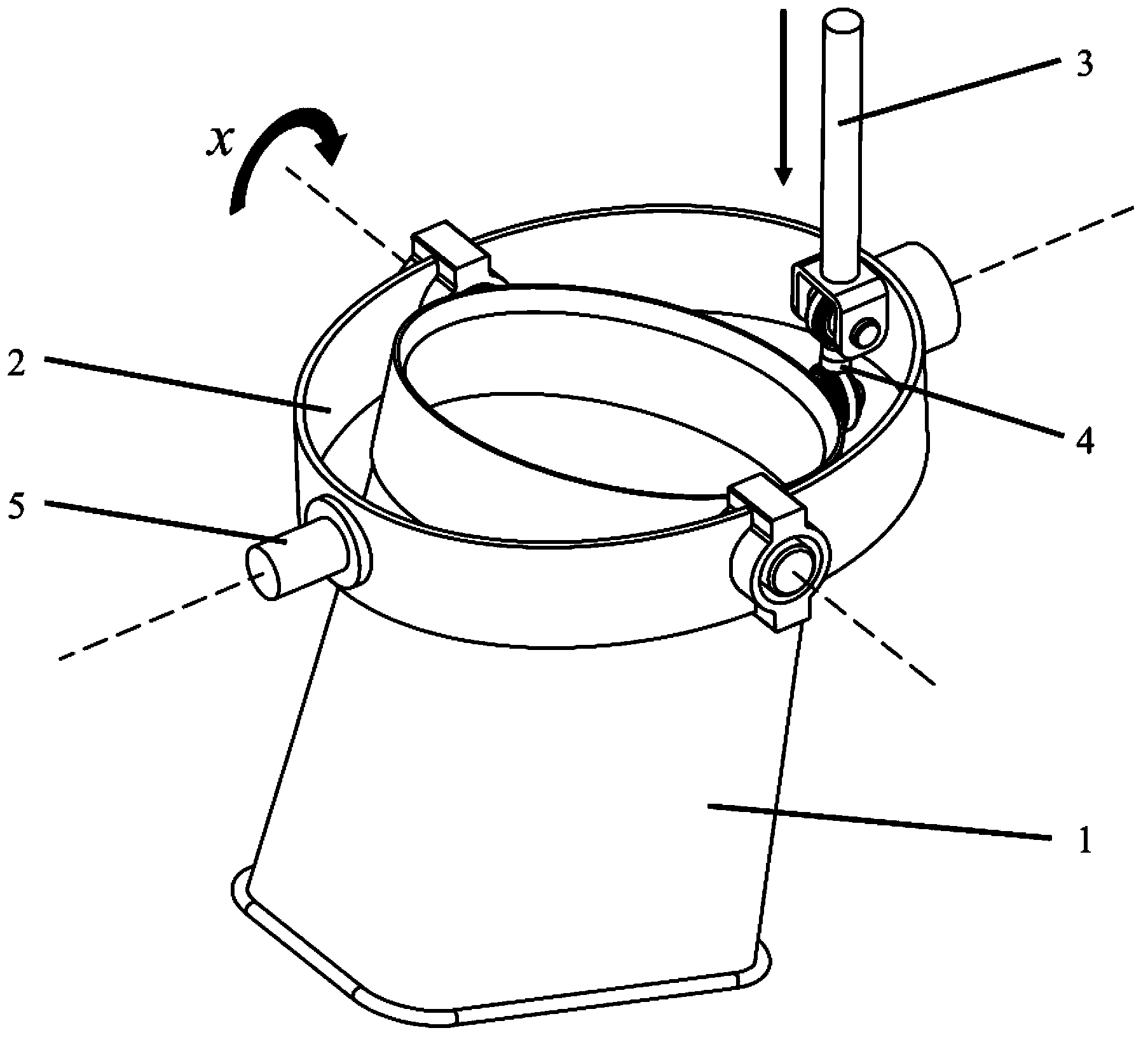

[0050] exist figure 1 , shows the cross-sectional view of the tail of the nozzle of the cloth dyeing machine according to the embodiment of the present invention. The periphery of the tail of the cloth guide pipe 6 is arc-shaped, so that the top of the left and right bucket 1 can be wrapped and rotated around its periphery, such as figure 1As shown in the circle in the lower left corner, two arbitrary positions (solid line and single dotted line) of the control bucket 1 are respectively shown when it rotates on one of the axes. The left and right bucket 1 is connected with the support ring 2 and the ball joint 4 . The supporting ring 2 is connected with the bracket in the dyeing machine, and can form an axial swing relative to the dyeing machine. The support ring is connected to the rotating shaft 5 on the above-mentioned one swinging shaft, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com