Agent for leak prevention and leak stoppage while drilling and preparation process thereof

A technology of preparation process and plugging agent, which is applied in the field of oil drilling plugging, which can solve the problems of increased leakage rate, leakage loss, and deterioration, and achieve the effects of reducing well control risks, reducing oil and gas invasion into the wellbore, and reducing leakage volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The anti-leakage plugging agent while drilling of the present invention has the following formula by mass percentage: silicon oxide: 30%, aluminum oxide 15%, calcium oxide 15%, bentonite 15%, expansion powder 5%, sodium alginate 10%, organic fiber 10%, wherein the diameter of the organic fiber is ≤50μm, the length is between 0.5-1mm, and the temperature resistance is above 175°C. The preparation technology of anti-leakage plugging agent while drilling, it comprises the steps:

[0027] (1) First mix silica, alumina, calcium oxide, bentonite, expansion powder, and sodium alginate according to mass percentage, that is, silica: 30%, alumina 15%, calcium oxide 15%, bentonite 15%, expansion powder 5%, sodium alginate 10%;

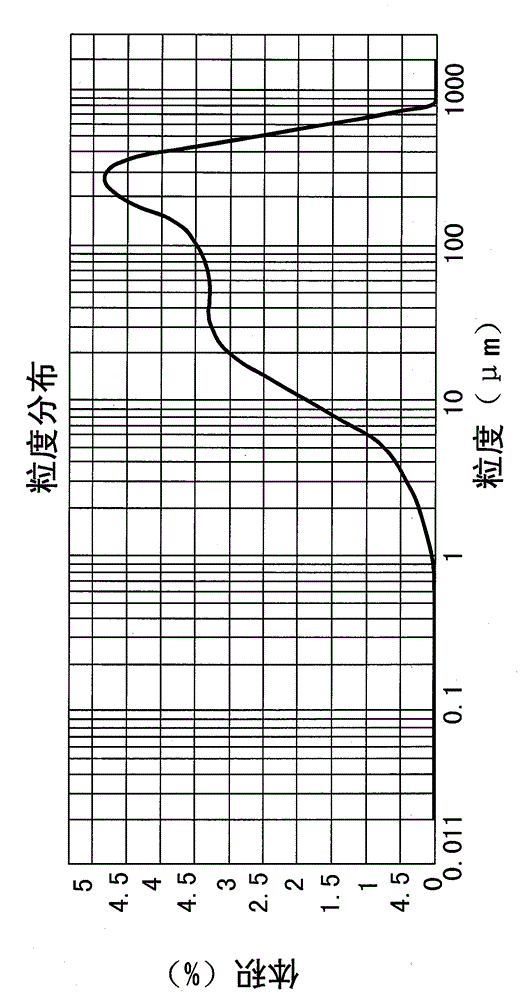

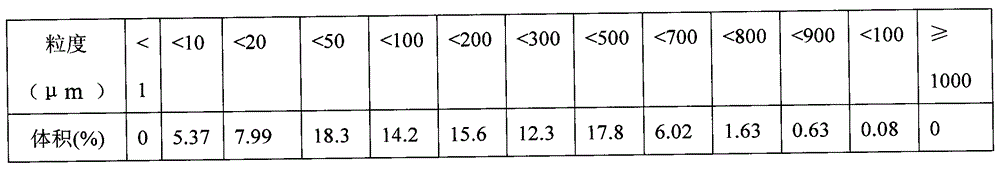

[0028] (2) Afterwards, the mixture prepared in step (1) is ground with a planetary ball mill until the particle size reaches 1-1000 μm, and the particles with a particle size between 1 and 158.5 μm (about 100 meshes) account for about 55% of the total sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com