Plugging agent while drilling, preparation method of plugging agent while drilling and application of plugging agent while drilling in water-based drilling fluid

A technology of water-based drilling fluid and plugging while drilling, which is applied in the field of drilling fluid and can solve problems such as formation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

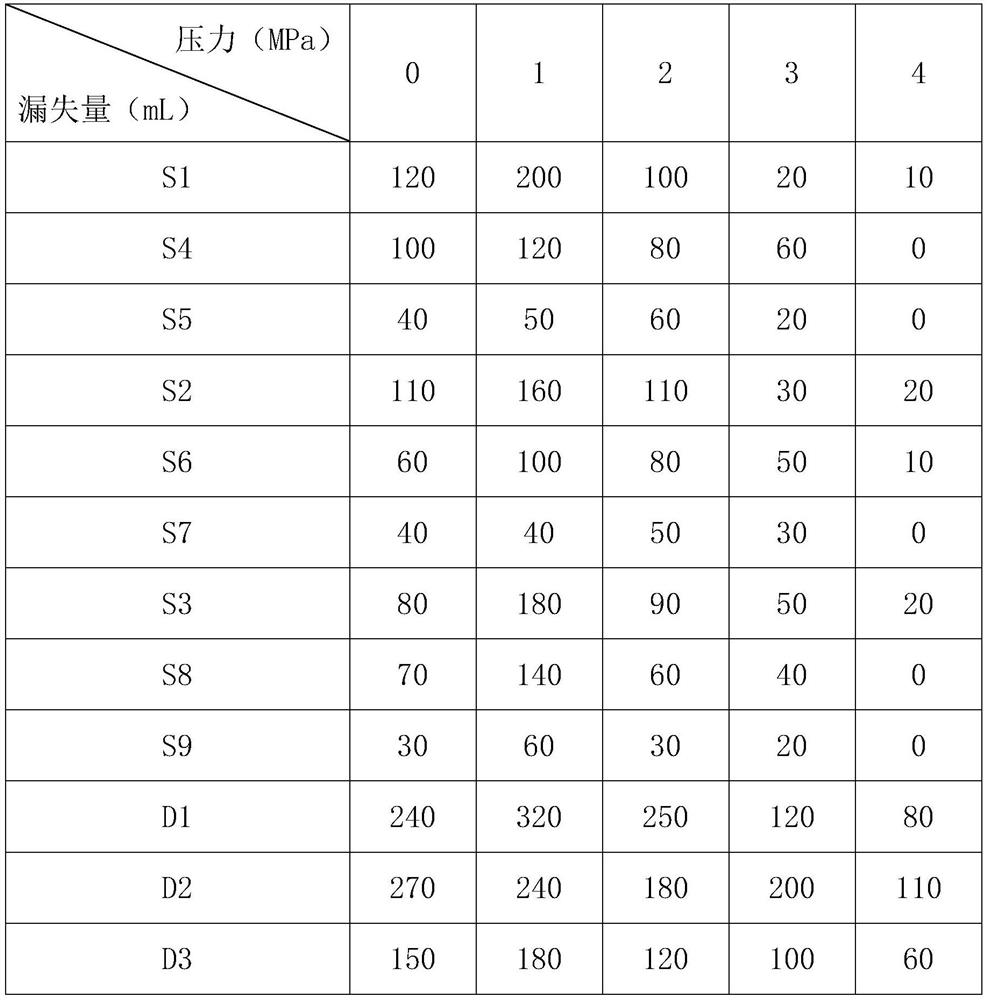

Examples

preparation example 1

[0038] This preparation example is used to illustrate the preparation method of water-based drilling fluid.

[0039] (1) 6 parts by weight of bentonite and 0.3 parts by weight of sodium carbonate were added to 100 parts by weight of water and stirred for 6 hours, and left to stand for 24 hours;

[0040] (2) Under high-speed stirring conditions, 0.6 parts by weight of coating agent PAC-141, 4 parts by weight of fluid loss additive, 4 parts by weight of inhibitor, 2 parts by weight of viscosity reducer, 3 parts by weight of high-efficiency Lubricants and 20 parts by weight of the weighting agent are added to the prehydrated base slurry.

Embodiment 1

[0042] This example is used to illustrate the preparation of lost circulation agent while drilling and its use in water-based drilling fluid.

[0043] (1) Mixing: first mix 35kg elastic graphite, 30kg calcium carbonate, 20kg coke particles and 15kg vermiculite evenly;

[0044] (2) Grinding: Grinding the mixture prepared in step (1) in a HGM80 mill until the particle size is 1 μm to 800 μm;

[0045] (3) Stirring: 60kg and 20kg of asbestos fibers and 20kg of mica flakes in the mixture prepared in step (2) are stirred evenly in a mixer to obtain the finished product.

[0046] In step (2), the particle size of the grinding is proportioned in the following manner: particles with a particle size between 1 and 500 μm account for 58 to 62% of the total volume, and particles with a particle size between 1 and 600 μm account for 58% of the total volume. 80-84%, and particles with a particle size between 1-700 μm account for 91-95% of the total volume.

[0047] In step (3), the length ...

Embodiment 2

[0051] This example is used to illustrate the preparation of lost circulation agent while drilling and its use in water-based drilling fluid.

[0052] (1) Mixing: first mix 34kg elastic graphite, 31kg calcium carbonate, 19kg coke particles and 16kg vermiculite evenly;

[0053] (2) Grinding: Grinding the mixture prepared in step (1) in a HGM80 mill until the particle size is 1-800 μm;

[0054] (3) Stirring: 60kg and 20kg of asbestos fibers and 20kg of mica flakes in the mixture prepared in step (2) are stirred evenly in a mixer to obtain the finished product.

[0055] In step (2), the particle size of the grinding is proportioned in the following manner: particles with a particle size between 1 and 500 μm account for 58 to 62% of the total volume, and particles with a particle size between 1 and 600 μm account for 58% of the total volume. 80-84%, and particles with a particle size between 1-700 μm account for 91-95% of the total volume.

[0056] In step (3), the length of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com