Patents

Literature

64results about How to "Reduce well control risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

One-trip string two-layer layering perforation-layering testing combining tubular column and operation method thereof

ActiveCN106150445AImprove admission qualityIncrease the proportion of stratified oil testingFluid removalWell/borehole valve arrangementsHierarchical testInternal pressure

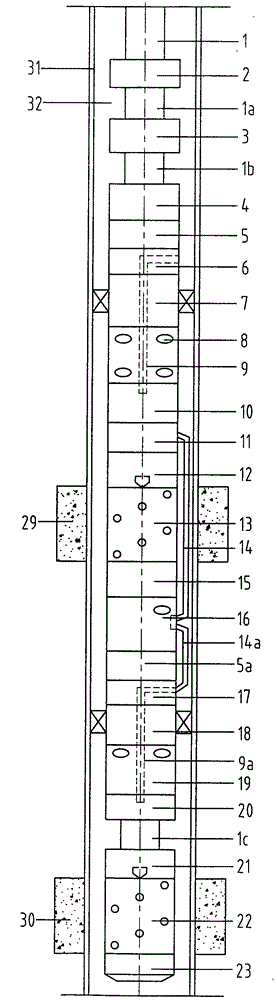

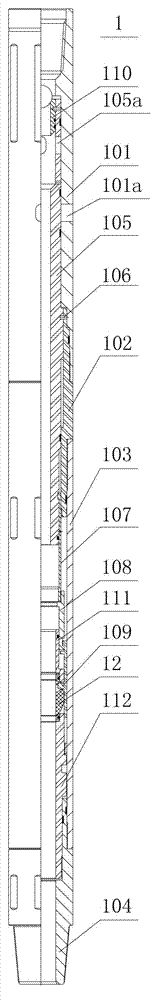

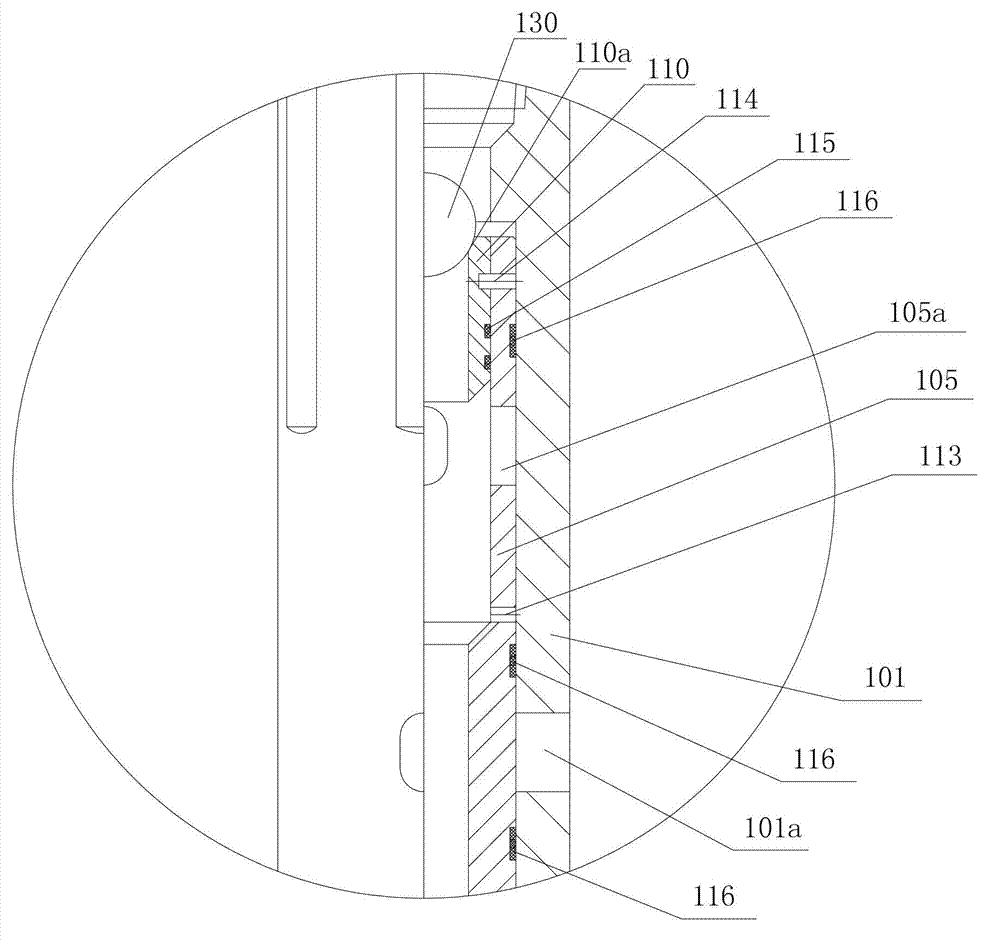

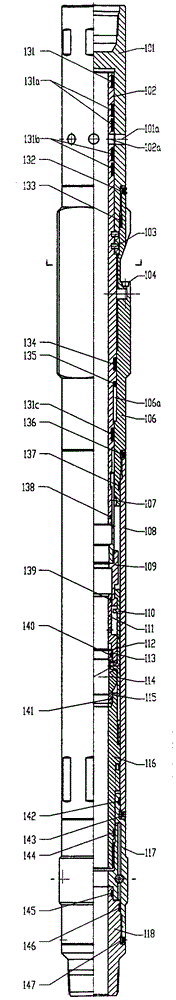

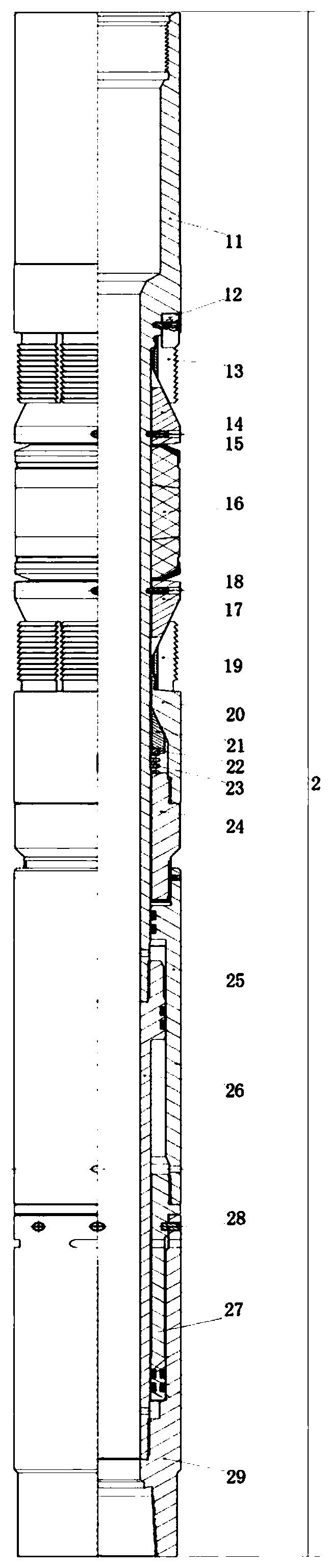

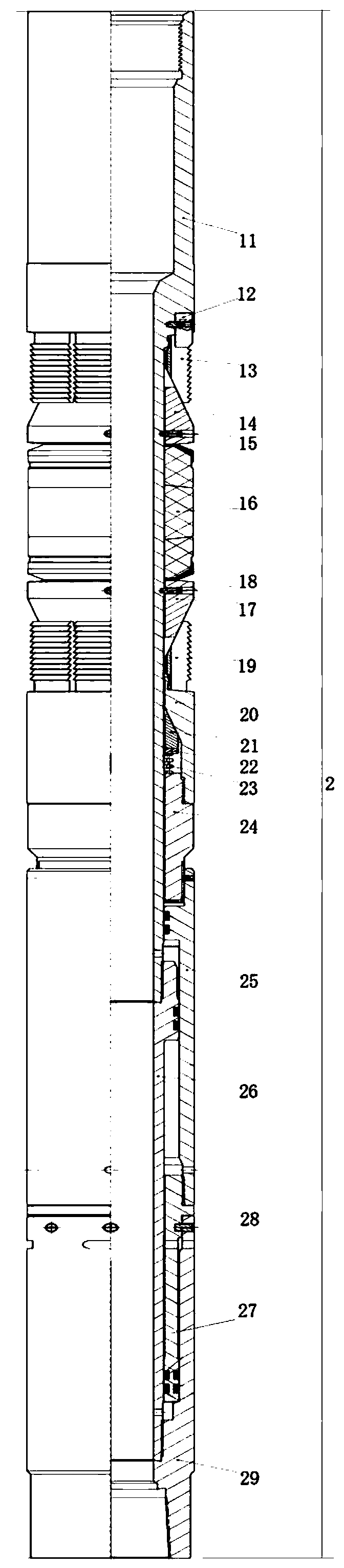

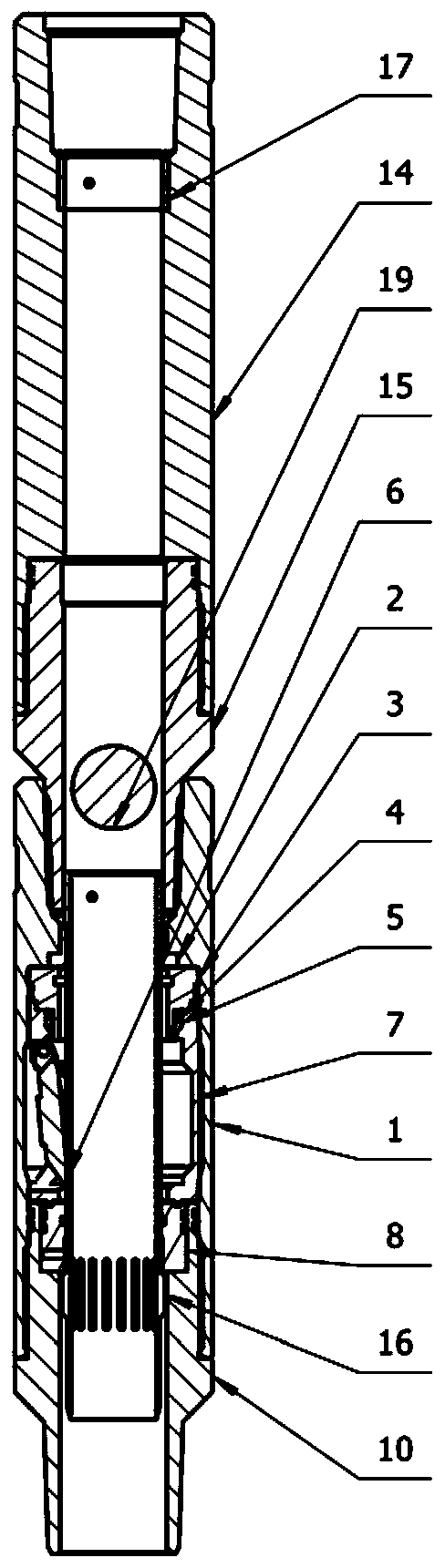

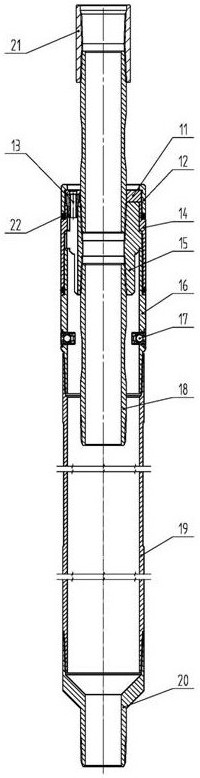

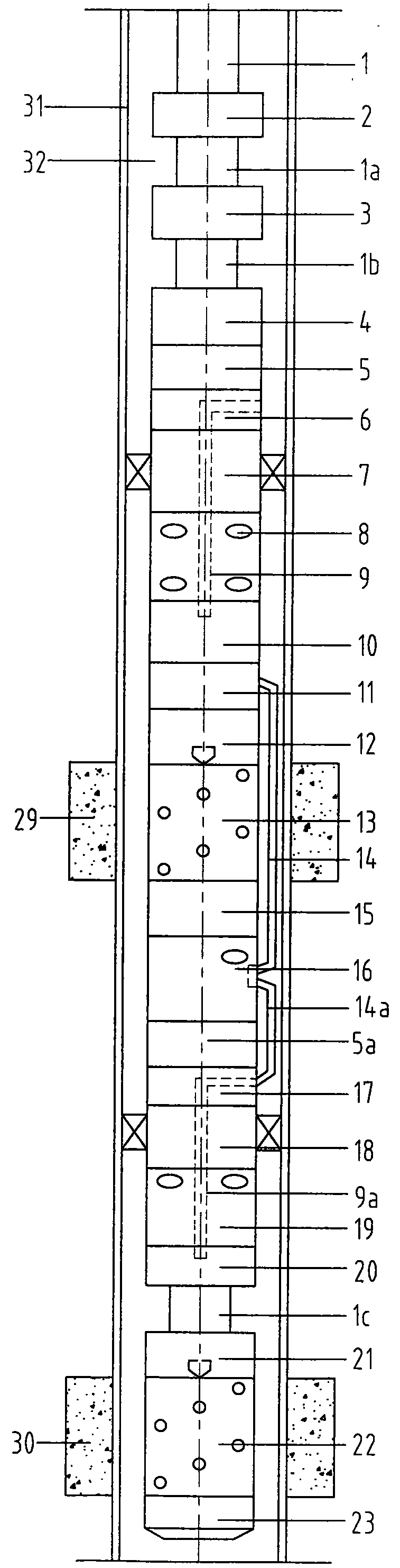

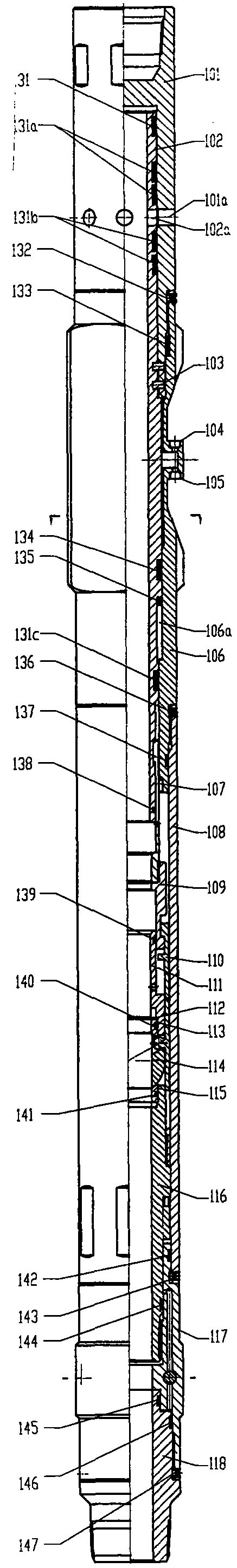

The invention relates to a one-trip string two-layer layering perforation-layering testing combining tubular column and an operation method. The tubular column comprises a first oil tube, a depth correction short joint, a second oil tube, a circulating valve, a third oil tube, a testing valve assembly, a second pressure gauge supporting cylinder, a second pressure transfer joint, a straddle packer, a second sieve tube, a spacer tube, a pressure guiding joint, a second ignition head, a second perforating gun, a pressure release device, sealing layer well shut-in sampling valve, a damping pressure gauge supporting cylinder, a first pressure transfer joint, an anchor packer, a first sieve tube, a shock absorber, a fourth oil tube, a first ignition head, a first perforating gun, a pressure relieving device, a second inner pressure transfer tube, a first pressure transfer tube and a first outer pressure transfer tube. The sealing layer well shut-in sampling valve is located between the second perforating gun and the anchor packer. The damping pressure gauge supporting cylinder is located below the sealing layer well shut-in sampling valve. by adopting the tubular column, two-layer layering perforation and layering testing combination can be completed, final well shut-in of the first layer does not need to occupy the operation machine time independently, down-hole sampling is convenient, and the tubular column has the advantages of being short in period, low in cost and the like.

Owner:DAQING DANFENG PETROLEUM TECH DEV CO LTD

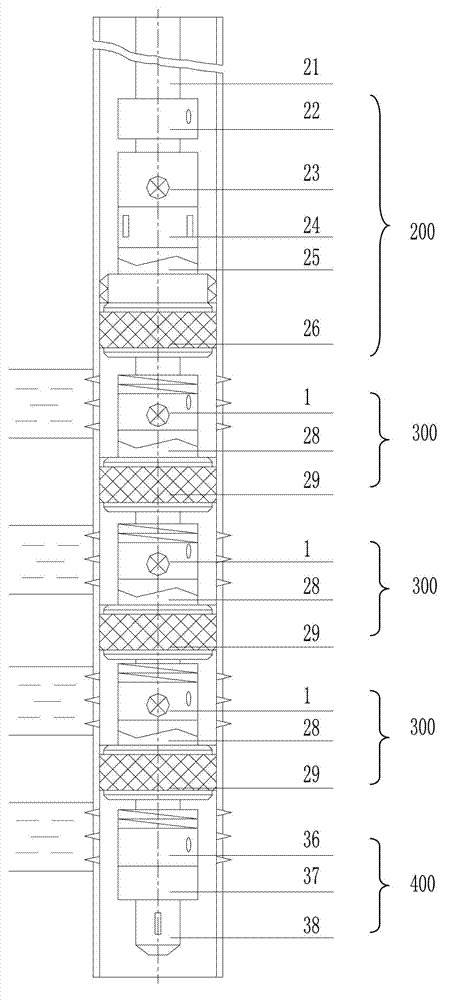

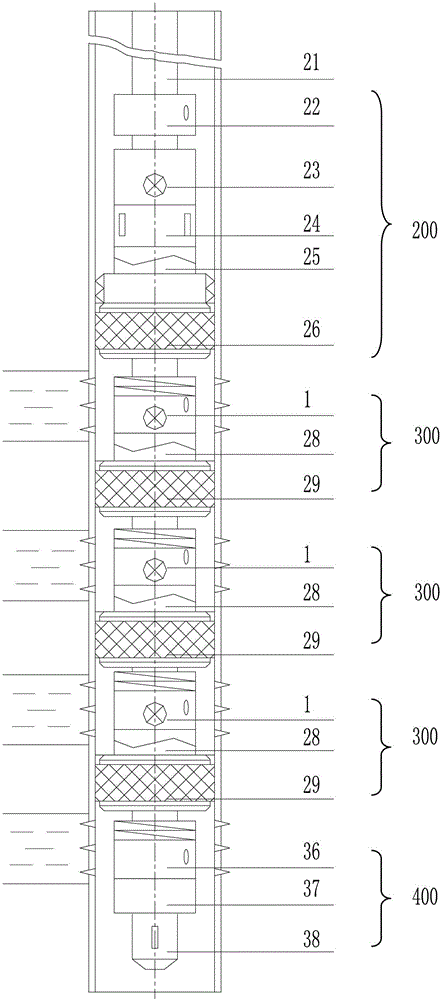

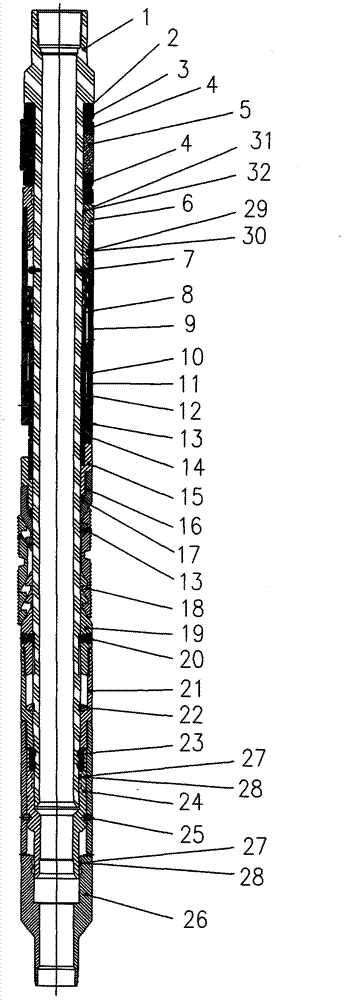

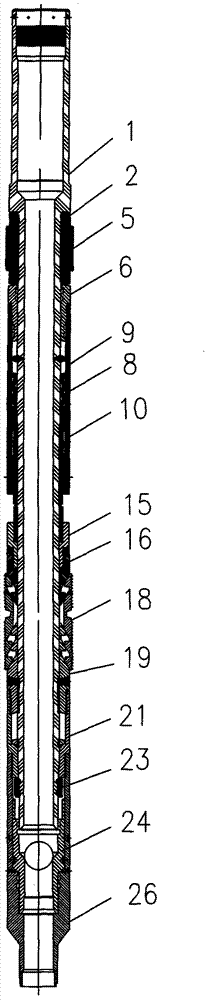

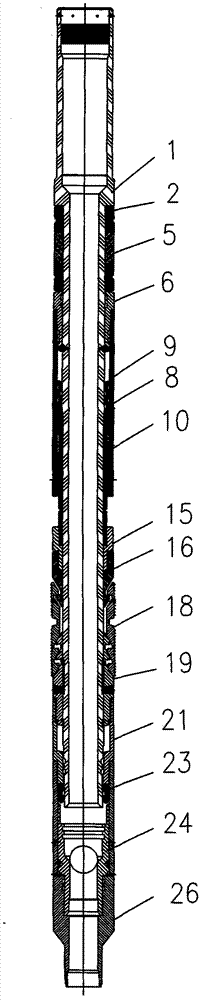

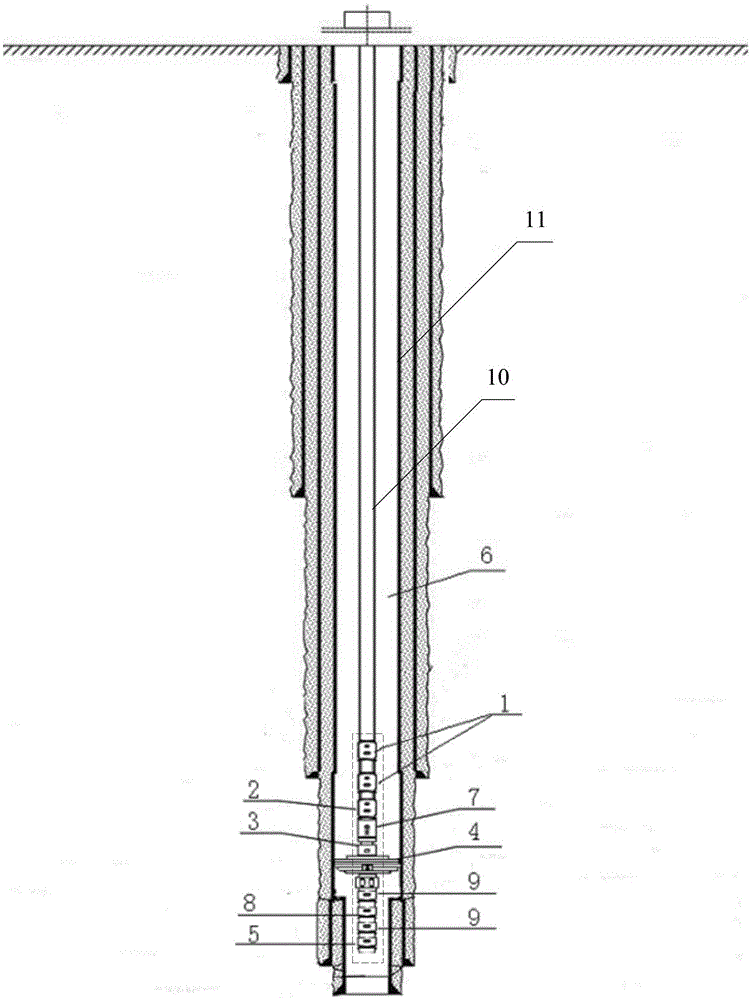

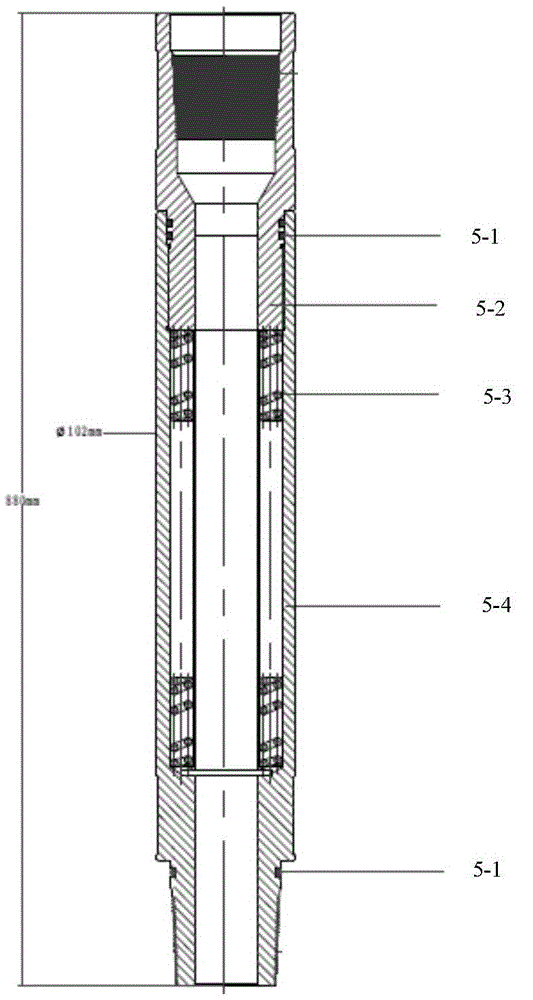

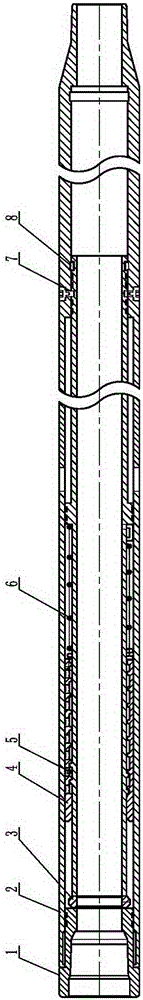

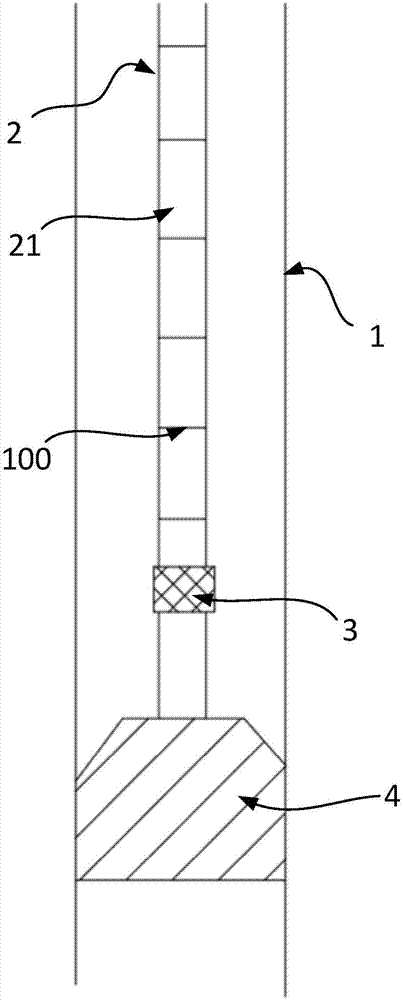

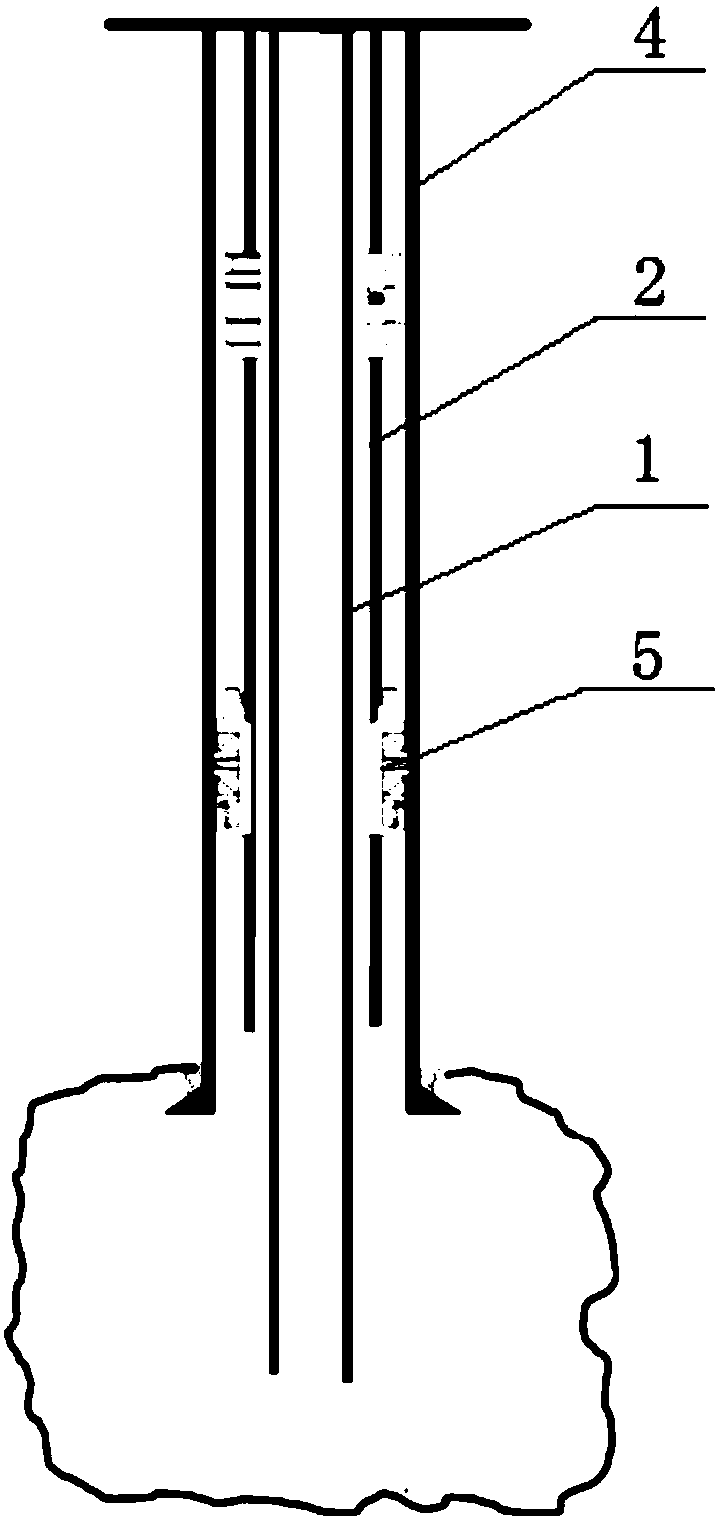

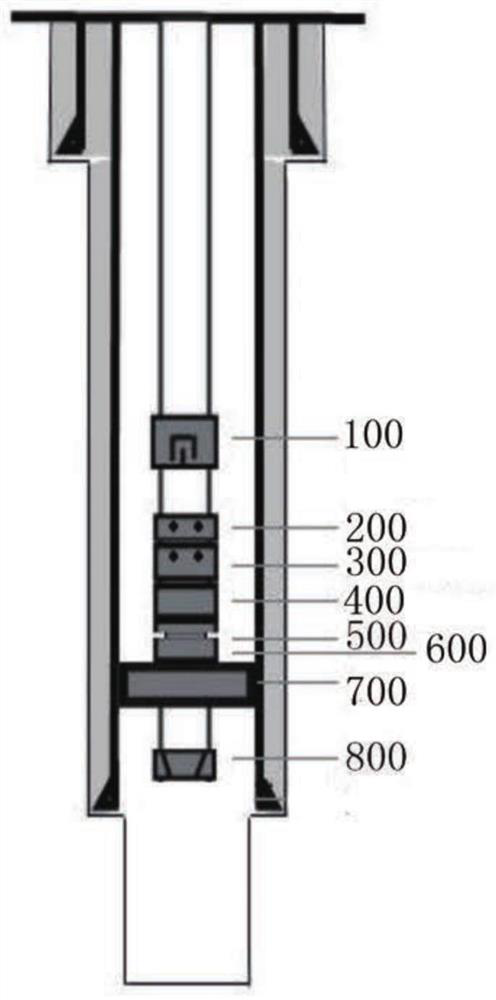

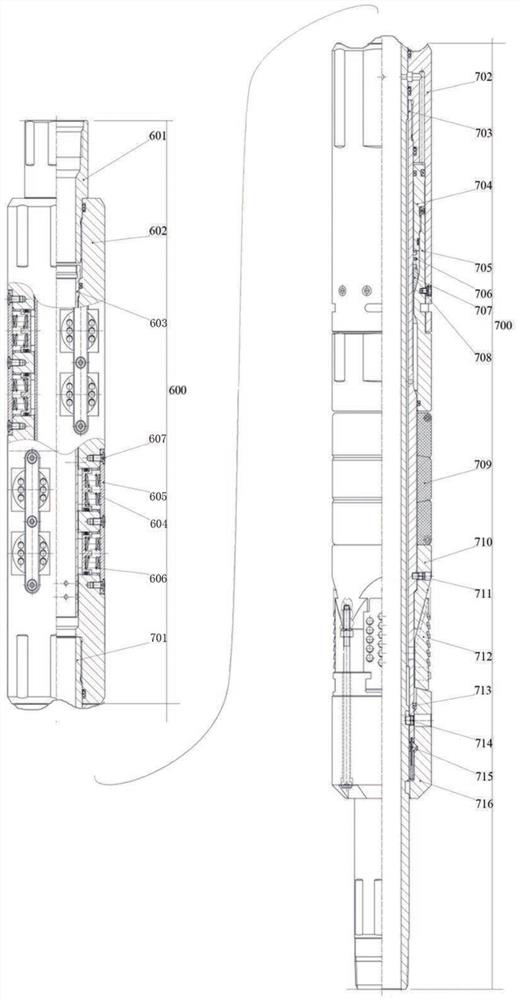

Multi-layer multi-section continuous oil testing system without lifting tubular column and operation method thereof

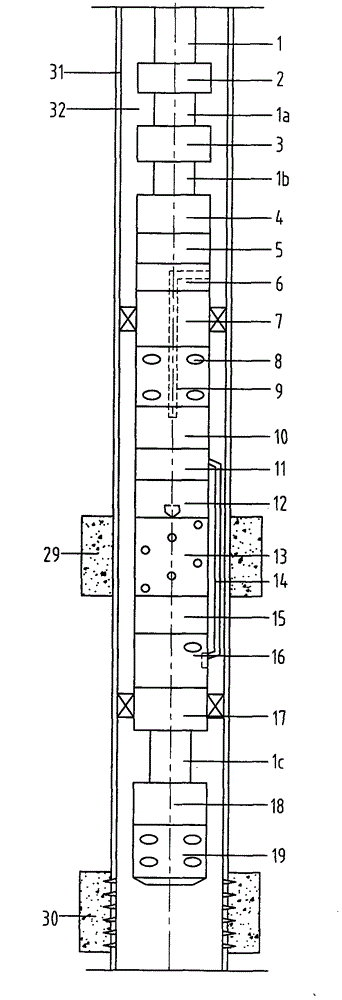

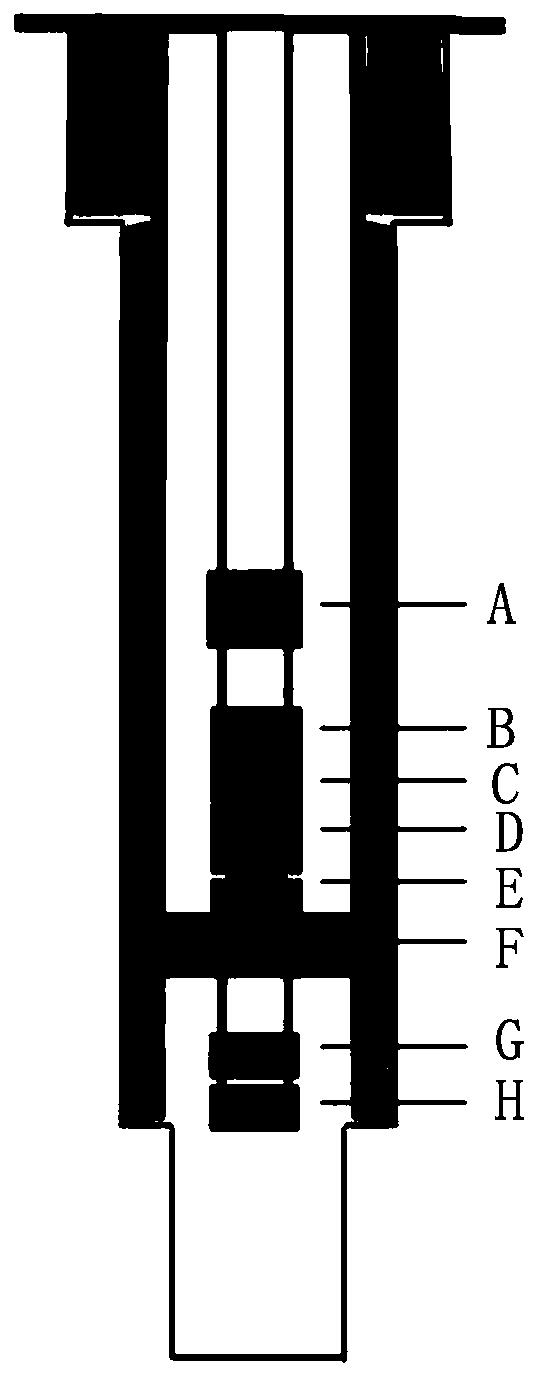

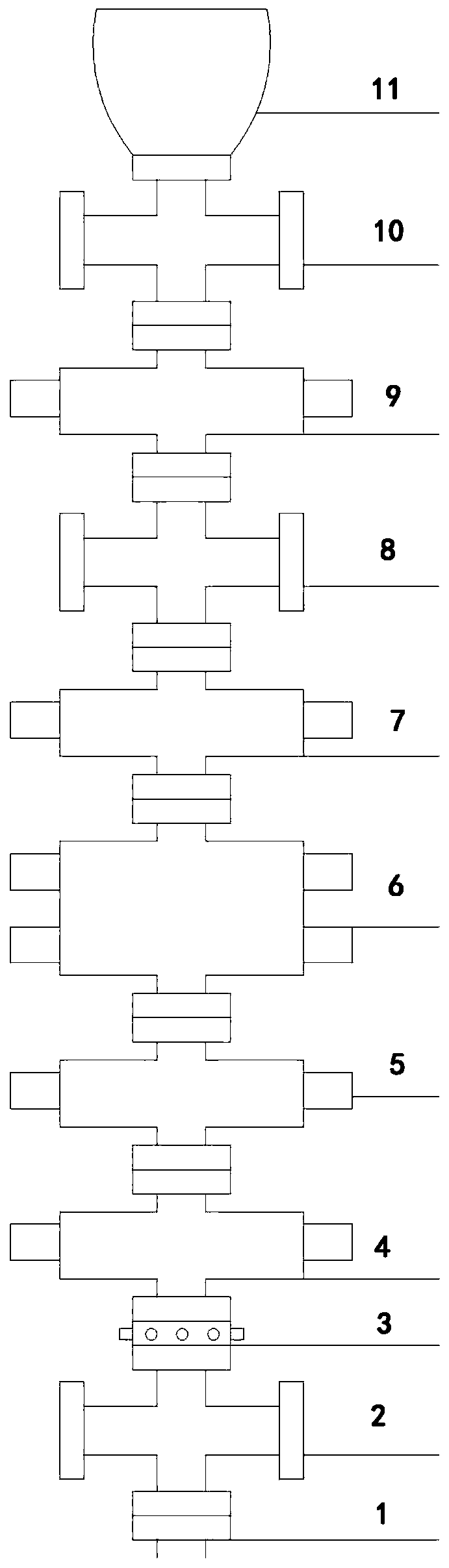

ActiveCN103114843ACompact and reasonable structureShort cycleSurveyFluid removalHierarchical testEngineering

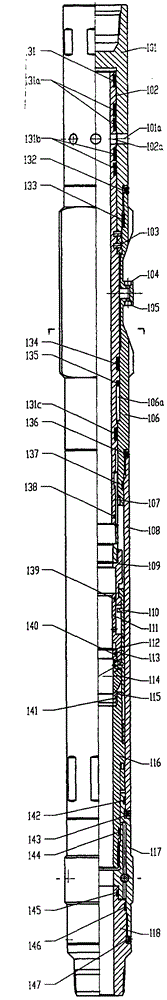

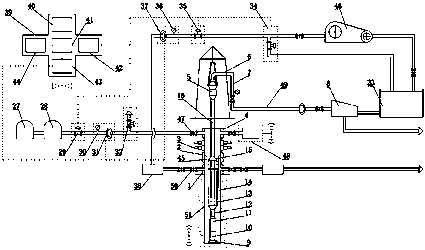

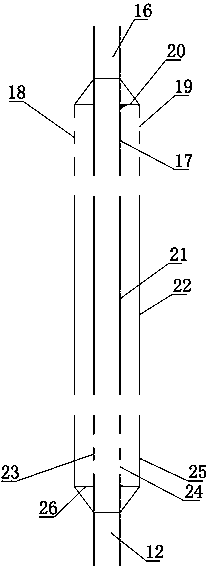

The invention relates to a multi-layer multi-section continuous oil testing system without lifting a tubular column. The system is connected on the downhole testing tubular column in series and comprises an upper sub-system, a plurality of layered testing systems and a lower sub-system which are sequentially connected in series along the axial direction of the tubular column, wherein the upper sub-system comprises a manifold circulating valve, a main testing valve, a full-bore pressure gage support barrel, a safe connector and a top hydraulic packer which are sequentially connected in series along the axial direction of the tubular column. The plurality of layered testing systems are sequentially connected on the tubular column in series along the axial direction of the tubular column, each layered testing system corresponds to one oil layer, and each layered testing system comprises a hydraulic switching valve, a safe connector and a layered hydraulic packer. The lower sub-system comprises a hydraulic sliding sleeve, a pressure transmitting connector and a monitoring pressure gage which are sequentially connected in series along the axial direction of the tubular column. By means of the system, multi-layer and multi-section continuous testing, capacity increasing revamp, liquid discharging and a series of downhole operation processes can be completed without lifting the tubular column, and the system has the advantages of being simple in construction operation, convenient to assemble, short in construction period and the like.

Owner:PETROCHINA CO LTD

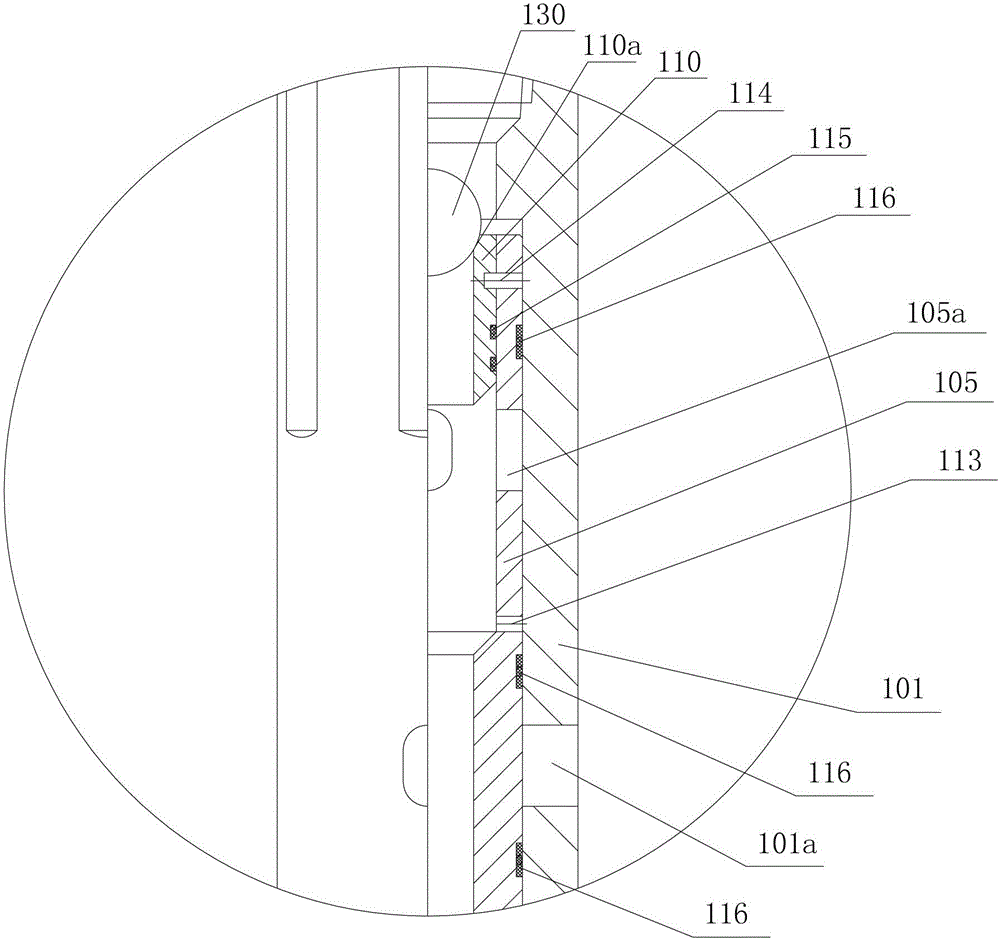

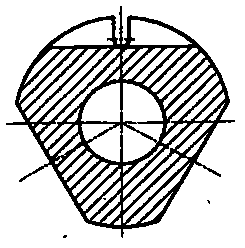

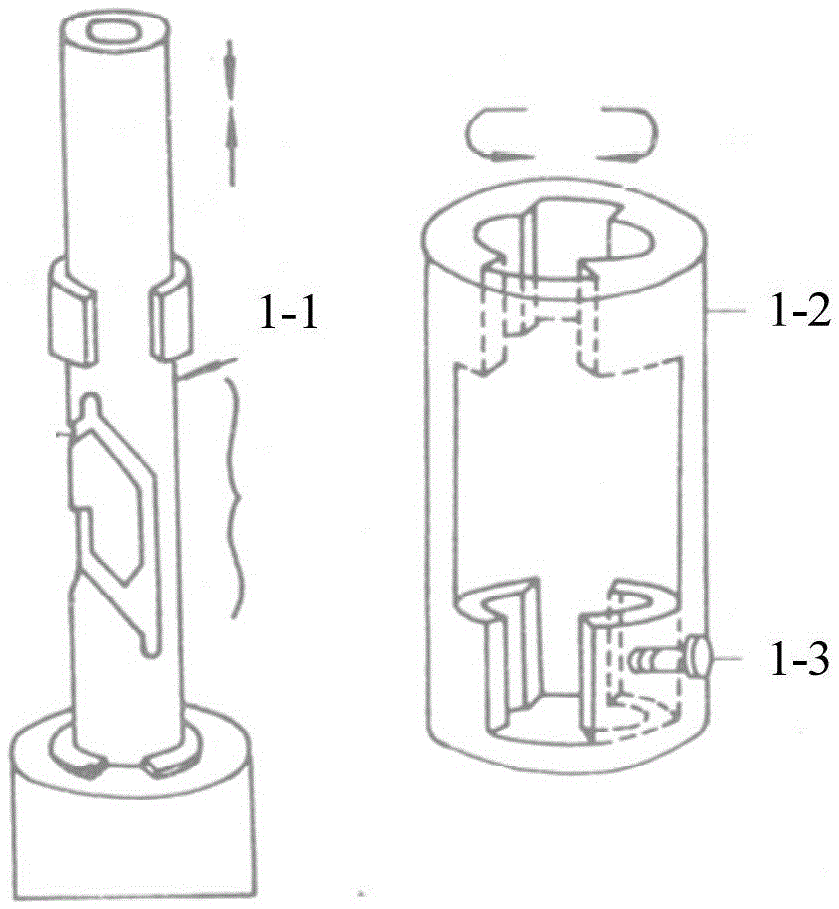

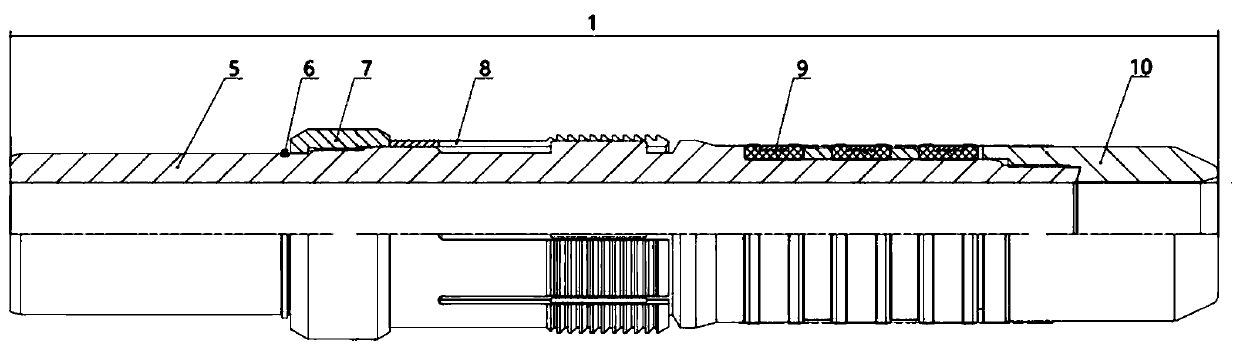

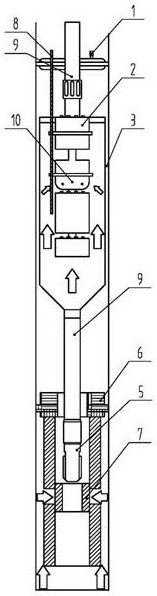

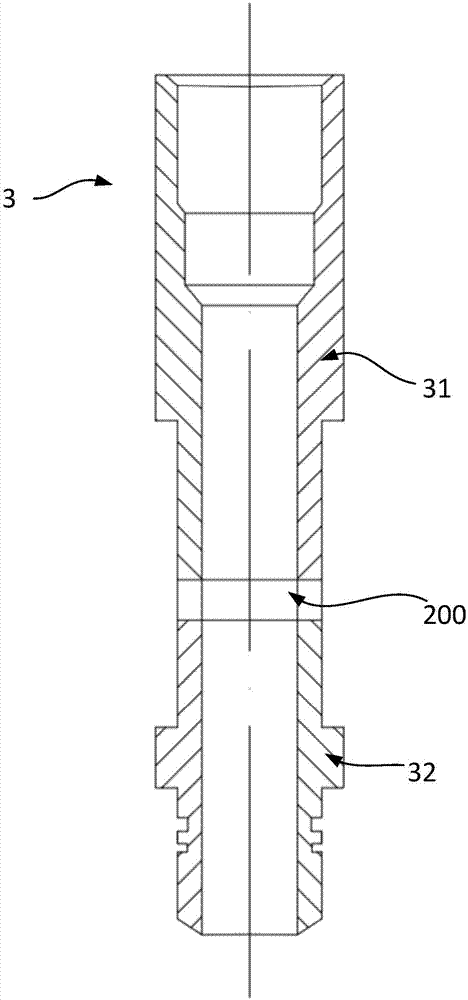

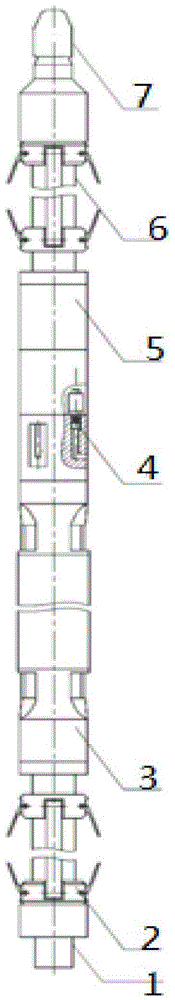

Hydraulic switching valve

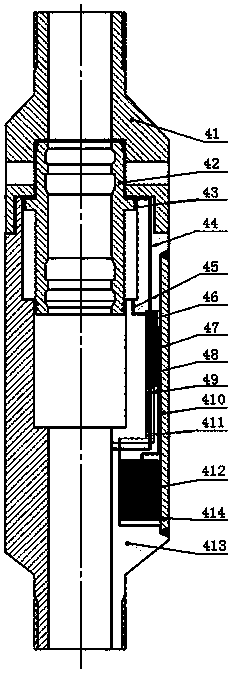

ActiveCN103147720ACompact and reasonable structureShort cycleWell/borehole valve arrangementsSealing/packingUpper jointEngineering

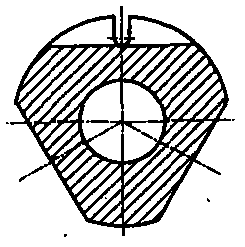

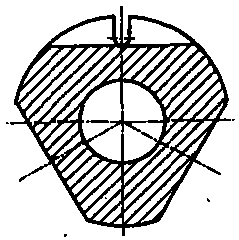

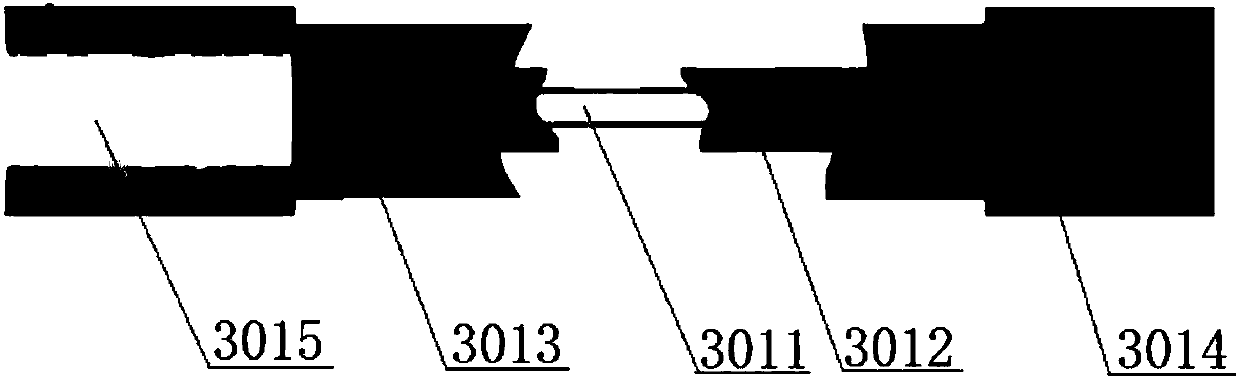

The invention relates to a hydraulic switching valve connected to an underground testing tubular column. The hydraulic switching valve is a hollow tube body and is provided with an outer layer, an intermediate layer and an inner layer, wherein an upper joint, an intermediate joint, a ball valve outer barrel and a lower joint are arranged on the outer layer in the axial direction; the intermediate layer is provided with a slideable hollow mandrel fixed on the intermediate joint through a mandrel shear pin; a connecting claw, a connecting pup joint, an upper seat ring and a lower seat ring are further arranged at the lower end of the mandrel; two parallel grooves are formed in the side wall of the upper seat ring, two strip-shaped motion arms are respectively embedded into the two parallel grooves, and the top ends of the motion arms are buckled with the bottom end of the connecting pup joint; a ball seat sleeve body of which the top end can be clamped and sealed by a shot ball is arranged at the upper part of the mandrel, in the inner layer; a ball valve assembly is arranged in the upper seat ring, as well as the lower seat ring, in the inner layer, and is provided with an upper ball seat, a lower ball seat and a ball valve combined into the two ball seats, a seat spring is arranged between the ball valve and the upper ball seat, and the ball valve is matched with a bulged operation end of each motion arm; an upper joint is provided with an outer circulation hole; and the mandrel is provided with an inner circulation hole and a pressure release hole positioned between the inner circulation hole and the outer circulation hole.

Owner:PETROCHINA CO LTD

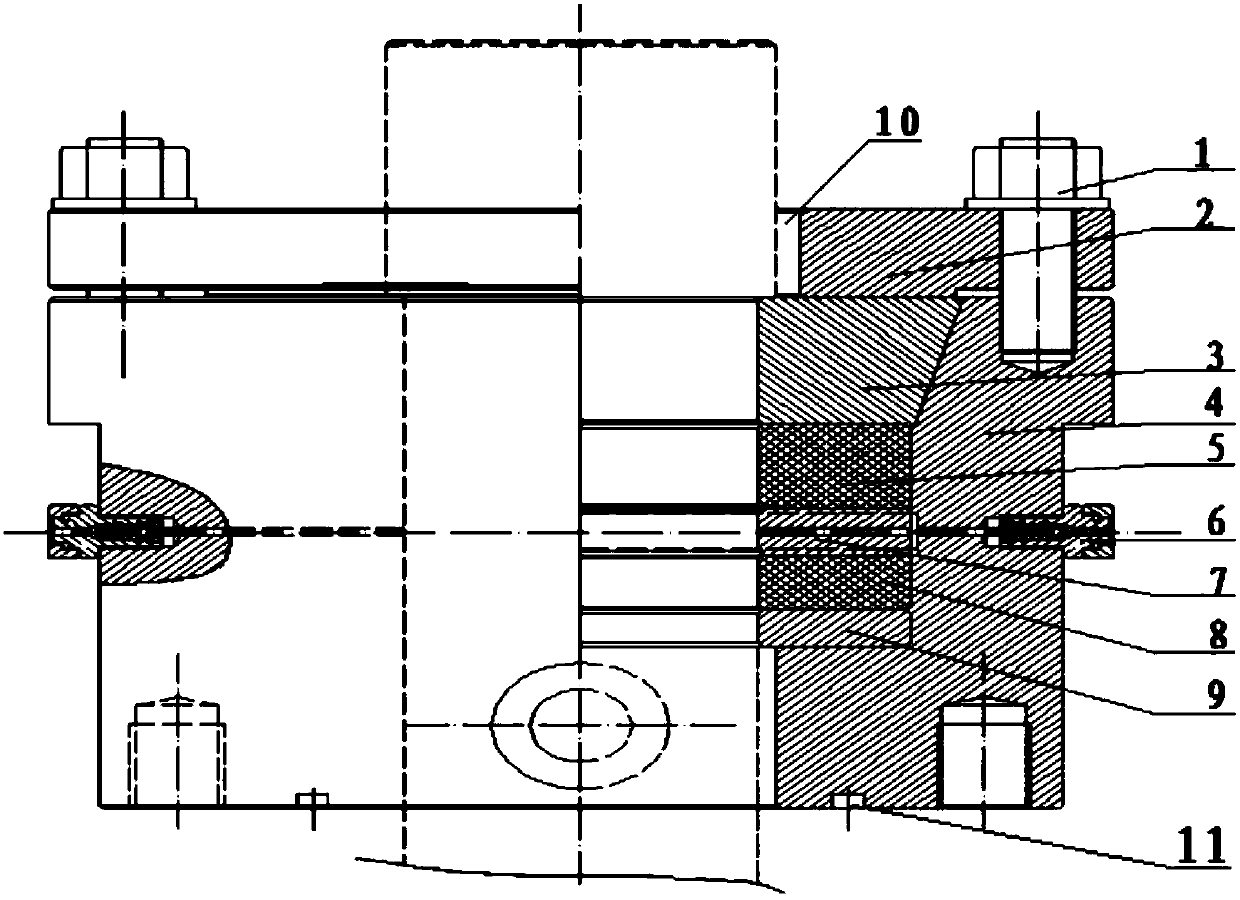

Hydraulic setting/unsetting high-pressure packer

The invention relates to the technical field of downhole tools for petroleum and gas gas-lift wells, particularly a hydraulic setting / unsetting high-pressure packer which comprises a mandrel and, a rubber barrel seal assembly, a piston assembly, a slip assembly, an unsetting assembly and a lower joint, wherein the rubber barrel seal assembly, the piston assembly, the slip assembly, the unsetting assembly and the lower joint are sequentially sheathed on the outer wall of the mandrel from top to bottom in the axial direction of the mandrel; a piston of the piston assembly is connected with the upper end of a slip upper seat through an adaptation joint; the lower end of the slip assembly is connected with the upper end of the lower joint through a connecting outer barrel of the unsetting assembly; the upper end of the piston outer barrel is connected with a clamping ring; the piston outer barrel, an inner lock ratchet outer barrel and the upper end of a setting pin barrel are sequentially connected from top to bottom; the lower end surface of the setting pin barrel contacts the upper end surface of the adaptation joint; the unsetting seat slip sleeve is arranged between the mandrel and the lower joint; and an inner lock ratchet is arranged between the piston and the inner lock ratchet outer barrel. The packer has the advantages of reasonable structure, high pressure bearing level and low aftertreatment cost.

Owner:XINJIANG SINOGASOLINEEUM ENG

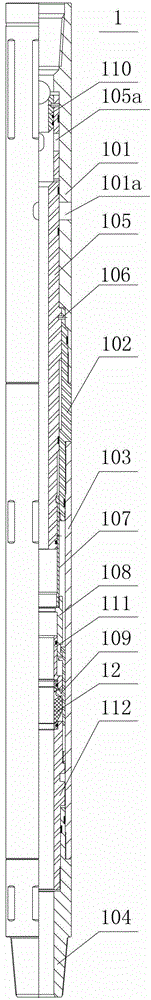

Straddle perforating and testing combining string capable of firstly testing lower layer and operation method thereof

ActiveCN106150446AImprove admission qualityOptimize work timeSurveyFluid removalInternal pressureEngineering

Provided is a straddle perforating and testing combining string capable of firstly testing a lower layer and an operation method thereof. The combining string comprises a first oil tube, a depth correction short section, a second oil tube, a circulating valve, a third oil tube, a testing valve assembly, a second pressure meter supporting tube, a pressure transfer connector, a straddle packer, a screening tube connector, a spacer tube, a pressure guide connector, an ignition head, a perforating gun, a pressure release device, a sealing layer shut-in valve, a slip packer, a fourth oil tube, a damping pressure meter supporting tube, a first screening tube, an inner pressure transfer tube and an outer pressure transfer tube; the sealing layer shut-in valve is located between the perforating gun and the slip packer, the damping pressure meter supporting tube is located below the sealing layer shut-in valve, and the two ends of the outer pressure transfer tube are connected to the pressure guide connector and an outer pressure transfer tube inlet of the sealing layer shut-in valve. By means of the string, a perforated layer below the lower packer can be tested firstly, and then straddle perforating and testing combining construction is conducted on an un-perforated layer between the two packers, so that final shut-in of the first layer do not need to occupy the time of an operation machine separately; the advantages of being short in period, low in cost and the like are achieved.

Owner:华信唐山石油装备有限公司

Intelligent well cementation slide sleeve separate-layer fracturing transformation process pipe column without stage limitation

ActiveCN103696748ASimplify construction proceduresShorten the construction periodFluid removalWell/borehole valve arrangementsWell cementingUltimate tensile strength

The invention discloses an intelligent well cementation slide sleeve separate-layer fracturing transformation process pipe column without stage limitation. The pipe column is designed for realizing the separate layer transformation of a straight well of an oil-gas well without stage limitation and meeting the process requirements of multi-stage fracturing transformation of oil-gas fields, the pipe column is arranged in a cement ring, the upper end of the pipe column is connected with a well opening, the pipe column consists of multi-stage intelligent well cementation slide sleeves, a floating hoop and a floating shoe, the multi-stage intelligent well cementation slide sleeves are connected through a sleeve, and the floating hoop and the floating shoe are arranged at the tail end of the pipe column. A piston is arranged in the intelligent well cementation slide sleeve cavity, an upper tube body is provided with a radial fracturing end opening, and a hydraulic pipeline for communicating a two-position four-way electromagnetic valve, a battery, a wireless sensing receiving device, an antenna, a water tank, an upper cavity of the tube body and a lower cavity of the tube body is buried in a groove formed in the tube wall of the lower tube body. The pipe column has the advantages that the separate-layer fracturing transformation without stage limitation can be realized, the construction period can be greatly shortened, the cost is saved, the international products can be replaced, the drilling work intensity can be reduced, electronic balls can be directly thrown for opening the first layer well cementation slide sleeve, the perforation is not needed, after the fracturing completion, all slide sleeves can be opened through ball throwing, the full through diameter can be realized, and the drilling and grinding well control risk can be reduced.

Owner:PETROCHINA CO LTD

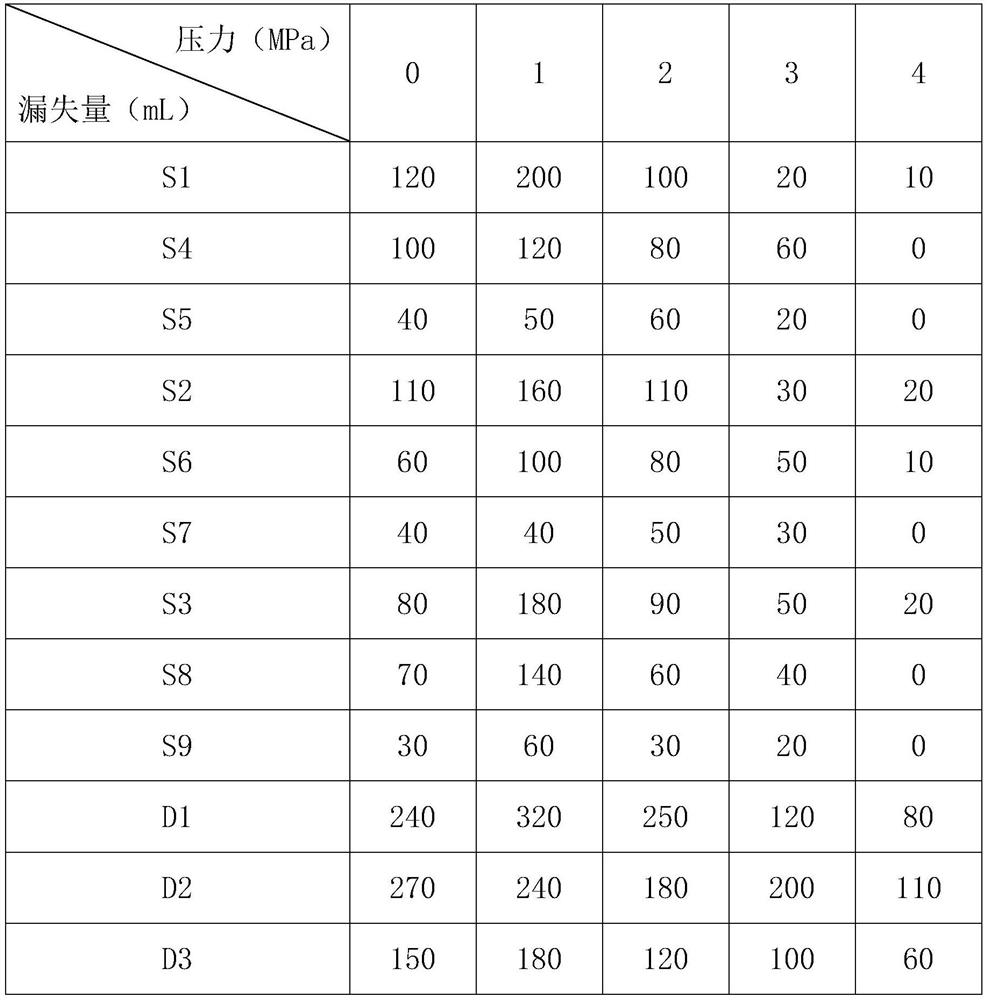

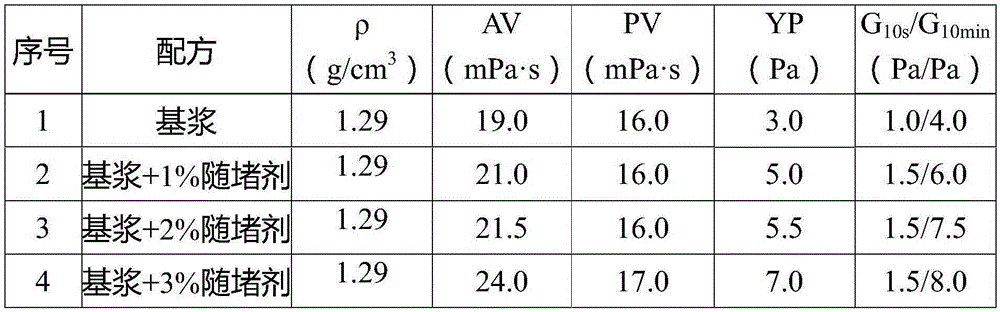

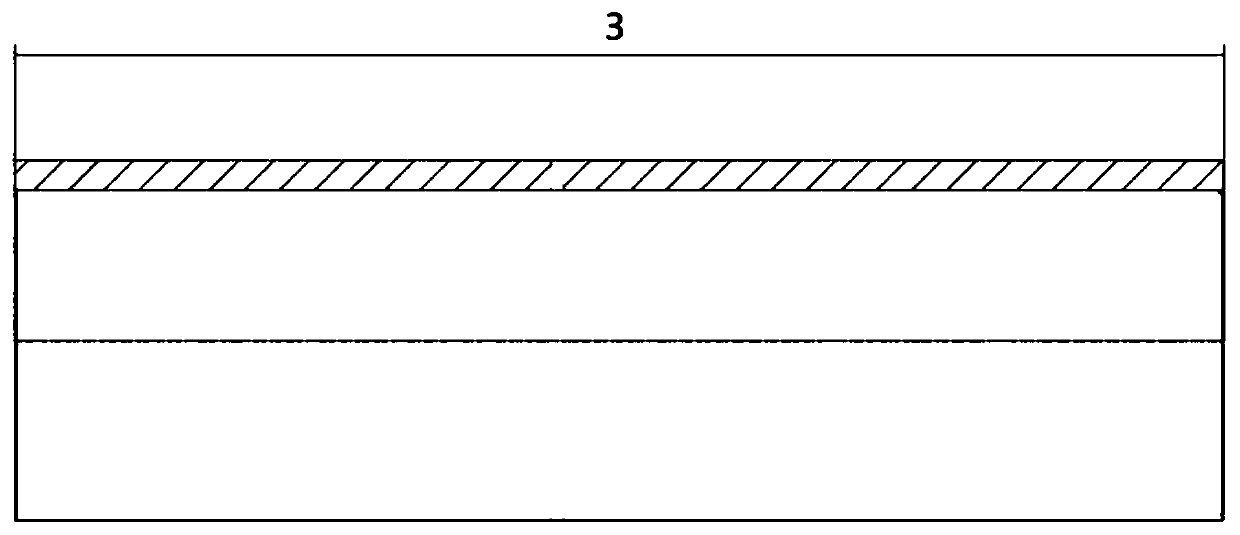

Plugging agent while drilling, preparation method of plugging agent while drilling and application of plugging agent while drilling in water-based drilling fluid

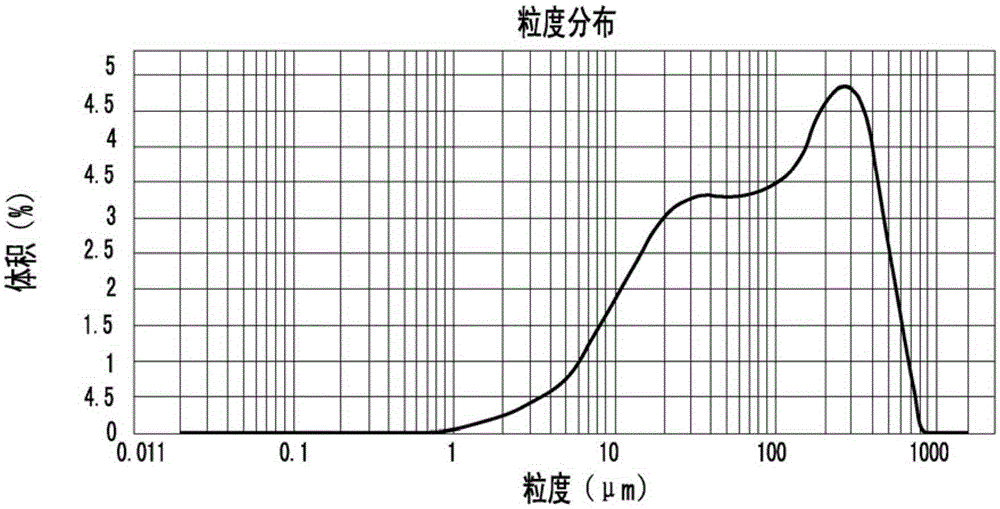

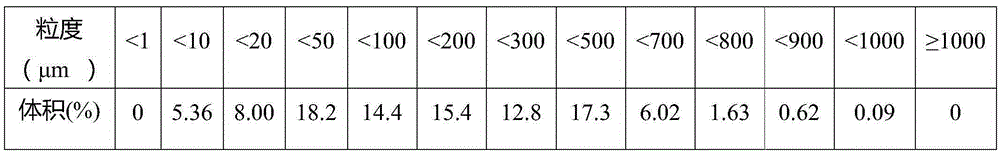

InactiveCN112778983APrevent mutual substitutionGood dispersionDrilling compositionGeotechnical engineeringDrilling fluid

The invention discloses a plugging agent while drilling, a preparation method of the plugging agent while drilling and an application of the plugging agent while drilling in water-based drilling fluid, the plugging agent is composed of a particle mixture, asbestos fibers and mica sheets, and the mass ratio of the particle mixture to the asbestos fibers to the mica sheets is 60: 20: 20. the particle mixture is prepared from 34 to 36 parts of elastic graphite, 29 to 31 parts of calcium carbonate, 19 to 21 parts of coke particles and 14 to 16 parts of vermiculite. The plugging agent while drilling can be applied to formation leakage of pores and micro-cracks in a drilling well, and can quickly form a mud cake to plug the micro-cracks in the formation, so that the purposes of leakage prevention while drilling and plugging are achieved. The drilling fluid additive can be well dispersed into the drilling fluid, and has small influence on the viscosity and shearing force of the drilling fluid. The plugging agent while drilling disclosed by the invention can be applied to plugging leakage of a micro-crack stratum, has better filling, bridge plugging or plugging effects, prevents mutual replacement between oil gas and well slurry, reduces the leakage amount and reduces the well control risk.

Owner:SOUTHWEST PETROLEUM UNIV

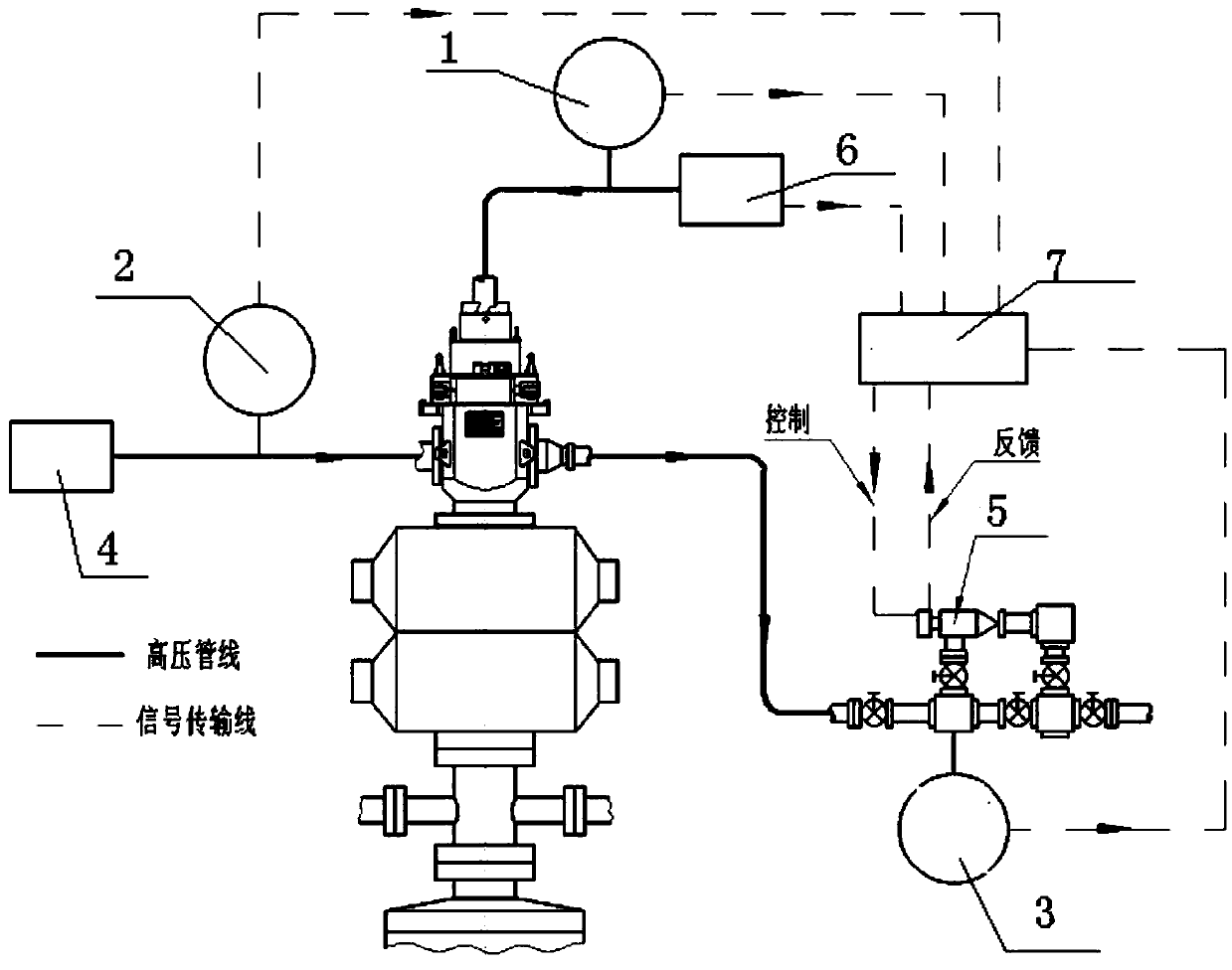

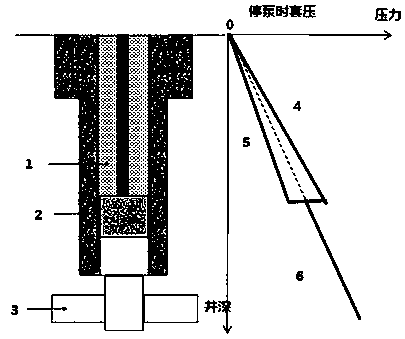

Automatic control system and method for wellhead pressure return

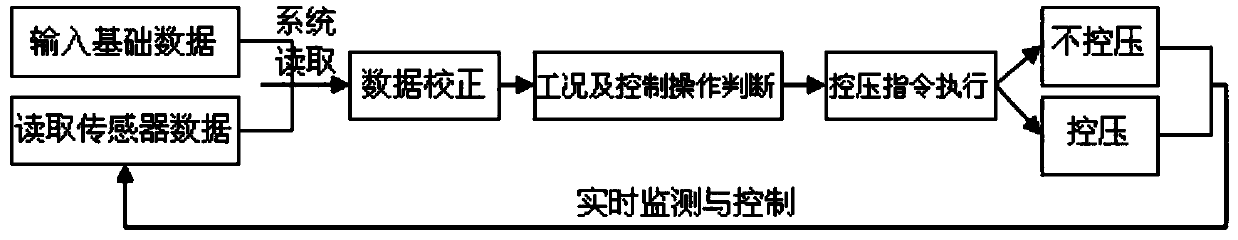

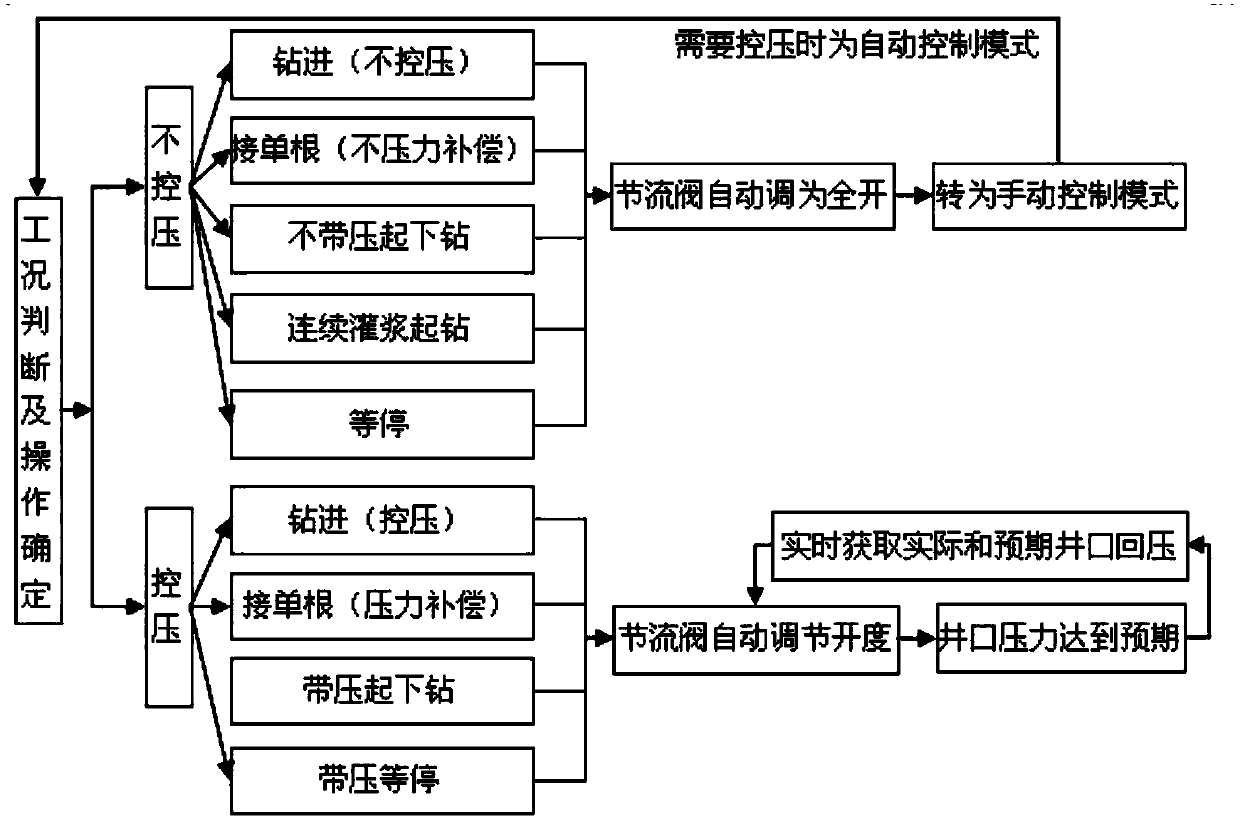

PendingCN109538144ARealization of back pressure automatic controlMeet the needs of managed pressure drillingFlushingTotal factory controlAutomatic controlAutomatic train control

The invention belongs to the technical field of pressure control drilling engineering, and specifically relates to an automatic control system and method for wellhead pressure return. The system includes a first pressure sensor, a second pressure sensor, a third pressure sensor, a compensation pump, a throttle valve, a well depth sensor and an analysis controller. The problems that existing fine pressure control equipment has multiple matching equipment, complex pressure control systems and high input costs, is not in accordance with a low-cost development strategy of a Changqing oilfield andhas difficulties in later popularization are solved. The system achieves automatic control of the wellhead pressure return, meets the requirement of wellhead pressure control drilling in the whole process, improves the safety operation ability, reduces the risk of wellhead control in water injection area of the Changqing oilfield, and helps to develop a low-cost pressure automatic control system and an optimization matching process adapted to the wellhead pressure control drilling in the water injection area.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Following-drilling plugging agent and preparation technology thereof

The invention provides a following-drilling plugging agent. The following-drilling plugging agent comprises limestone powder, aluminum oxide, quicklime powder, sodium bentonite, an expanding agent, methyl glucosides and mineral fibers; the diameter of the the mineral fibers is smaller than or equal to 60 microns, the length ranges from 0.5 mm to 1 mm, and the mineral fibers can bear the temperature over 170 DEG C. A preparation technology of the following-drilling plugging agent comprises the steps of mixing, grinding and stirring. The following-drilling plugging agent is applied to stratum leakage of pores with the diameters of the pore throat smaller than or equal to 1 mm and microcracks with the widths of cracks smaller than or equal to 1 mm in well drilling, a mud cake can be rapidly formed, the microcracks with different widths can be plugged, and therefore the purposes of following-drilling leakage prevention and leakage stoppage are achieved; good compatibility is achieved, the following-drilling plugging agent can be suitable for drilling fluid with different densities for different systems, effective plugging for leakage of the microcracks can be achieved, the preparation technology is simple, and operation is convenient.

Owner:CHINA PETROCHEMICAL CORP +2

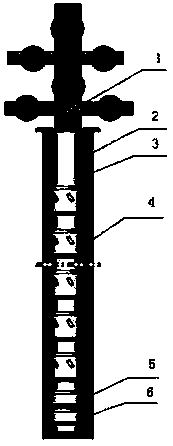

Oil testing device and oil testing pipe column

InactiveCN106812521ASafe and efficient oil testSafe and controllable operationDrilling rodsWell/borehole valve arrangementsControllabilityHigh pressure gas

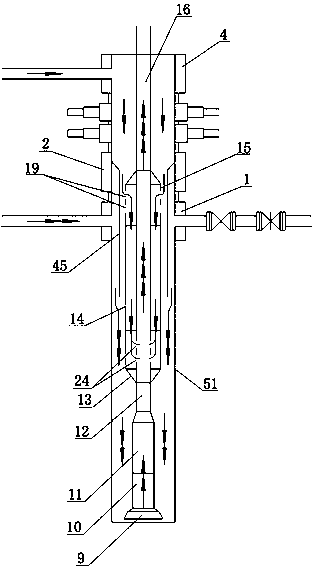

The invention provides an oil testing device and an oil testing pipe column. The oil testing device comprises an integrated pipe column which is provided with an electronic manometer holding barrel, a packer, an E valve, a second circulating valve and at least one first circulating valve from bottom to top. The electronic manometer holding barrel is used for suspension of a temperature manometer for recording well bottom temperature and pressure; the packer is in a settable structure and used for packing an oil jacket annulus between an oil pipe and a casing pipe; after setting of the packer, drilling fluid is replaced with well completion fluid trough the E valve by circulation, and then the E valve is turned off to realize isolation of the oil pipe and the casing pipe; the oil jacket annulus above the packer and a stratum below the packer are communicated by the second circulating valve through radial communication to realize unsetting of the packer; the first circulating valve realizes well bottom static temperature and static pressure measurement through radial communication and axial closure. The oil testing device has advantages that by integration of multiple functions, safety and controllability of each step in an oil test period are guaranteed, well control risks are low, and safety and high efficiency in oil testing of ultra-deep high-temperature high-pressure gas wells are realized.

Owner:PETROCHINA CO LTD

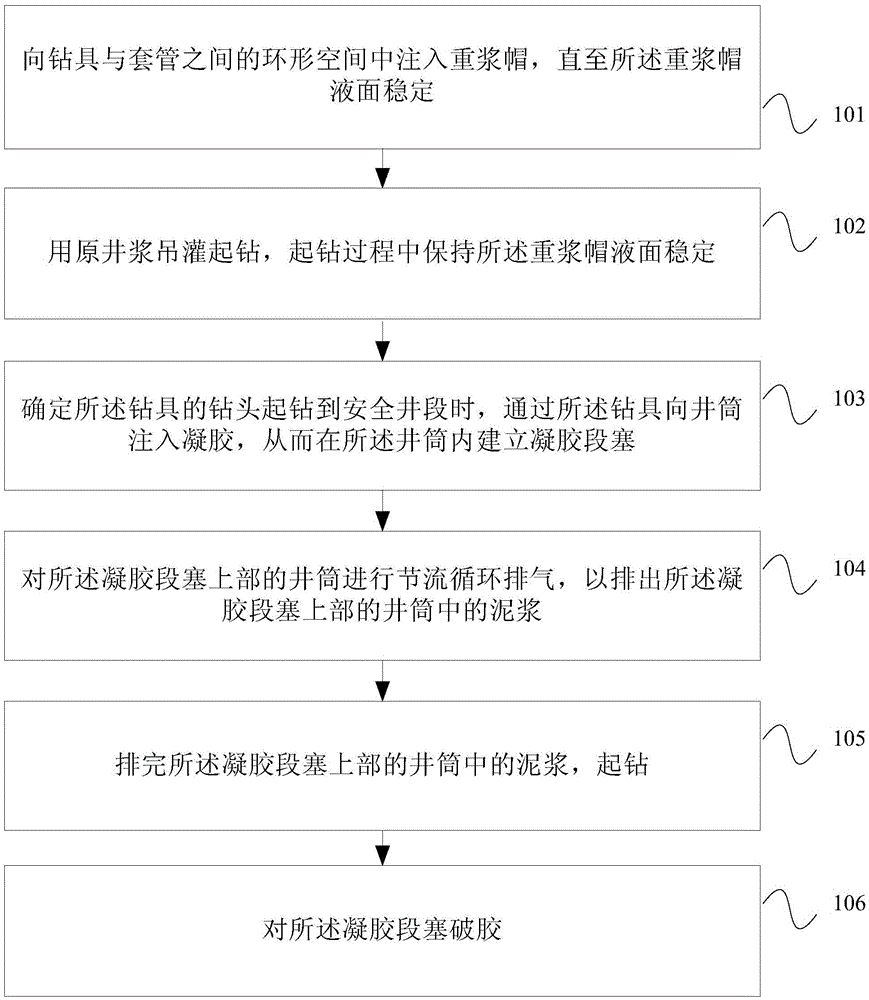

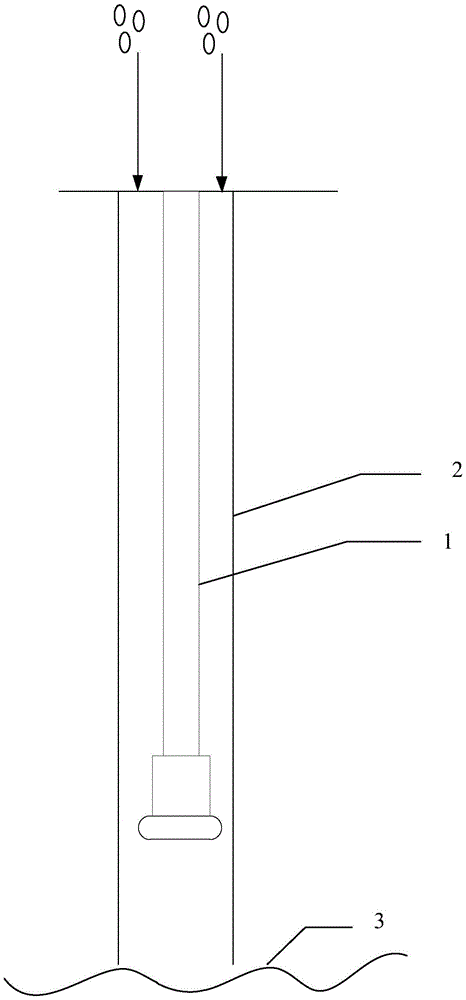

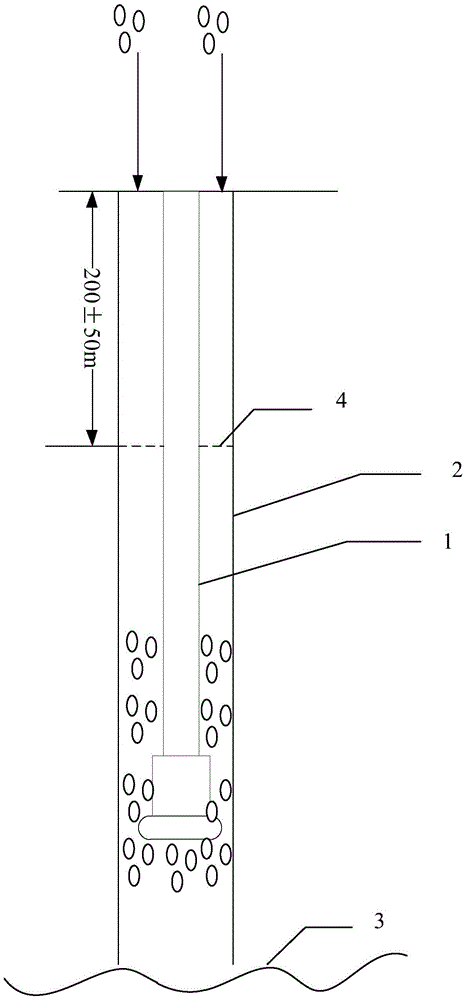

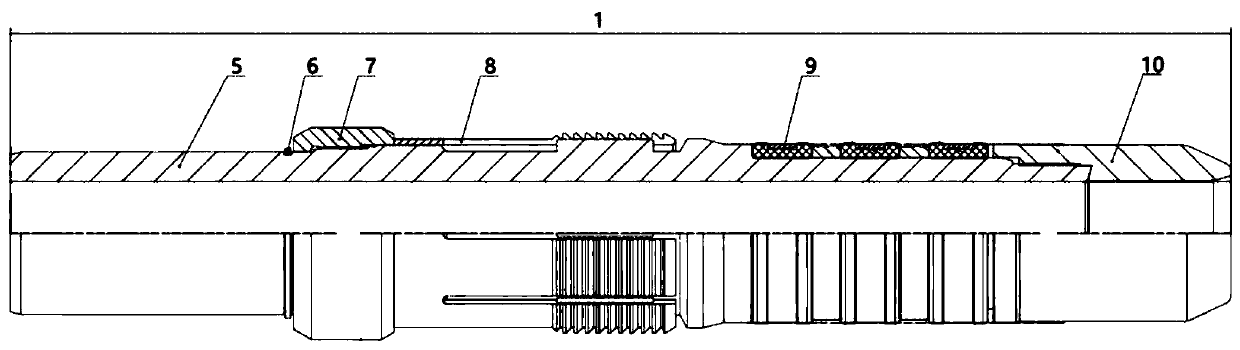

Gel isolation well control method

The invention provides a gel isolation well control method. The method includes the steps that heavy sizing caps are injected into annular space between a drilling tool and a sleeve pipe from a well mouth, filling and pulling out are carried out, when a drill bit reaches a safe well section, the drilling tool injects gel into a mineshaft to form a gel section plug, throttling circulation exhausting is conducted on the part, above the gel section plug, of the mineshaft so as to discharge slurry polluted by gas out of the part, above the gel section plug, of the mineshaft, the complexity of downhole conditions is reduced, therefore, the probability of well kick, well blowout and well leakage accidents occurring in the high-temperature and high-pressure gas field well drilling process is reduced, and the purpose of reducing the well control risk is achieved.

Owner:PETROCHINA CO LTD

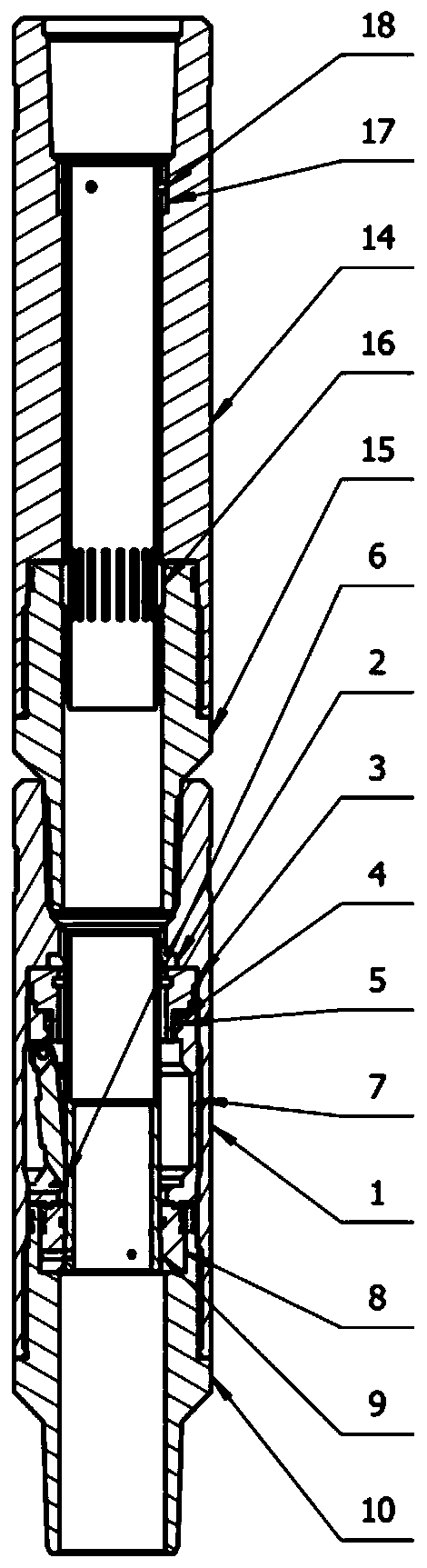

Bidirectional slip type hydraulic permanent packer

The invention provides a bidirectional slip type hydraulic permanent packer. The packer comprises an upper mandrel, a lower mandrel, an upper hydraulic outer cylinder, a lower hydraulic outer cylinder, a first shearing fixing piece, a second shearing fixing piece, a third shearing fixing piece, an upper slip, an upper cone, a rubber cylinder, a lower cone, a lower slip, a locking ring sleeve, an inner locking ring, a retaining piece, an elastic piece and an annular piston, wherein the upper slip, the upper cone, the rubber cylinder, the lower cone, the lower slip, the locking ring sleeve, theinner locking ring, the retaining piece and the elastic piece are sequentially arranged on the upper mandrel in a sleeving mode from top to bottom, and the annular piston is arranged on the lower mandrel in a sleeving mode; the lower end of the upper mandrel is connected with the upper end of the lower mandrel, and the lower end of the lower mandrel is connected with the lower hydraulic outer cylinder; the upper end of the upper slip is fixedly connected with the upper mandrel, the lower end of the upper slip is arranged on the conical surface of the upper cone in a sleeving mode, and the lower section of the upper cone is connected with the upper mandrel through the first shearing fixing piece; the rubber cylinder is arranged between the upper cone and the lower cone; the upper section ofthe lower cone is connected with the upper mandrel through the second shearing fixing piece; and the upper end of the lower slip is arranged on the conical surface of the lower cone in a sleeving mode. The packer has the advantages of bidirectional sealing, releasing, secondary tie-back and the like.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

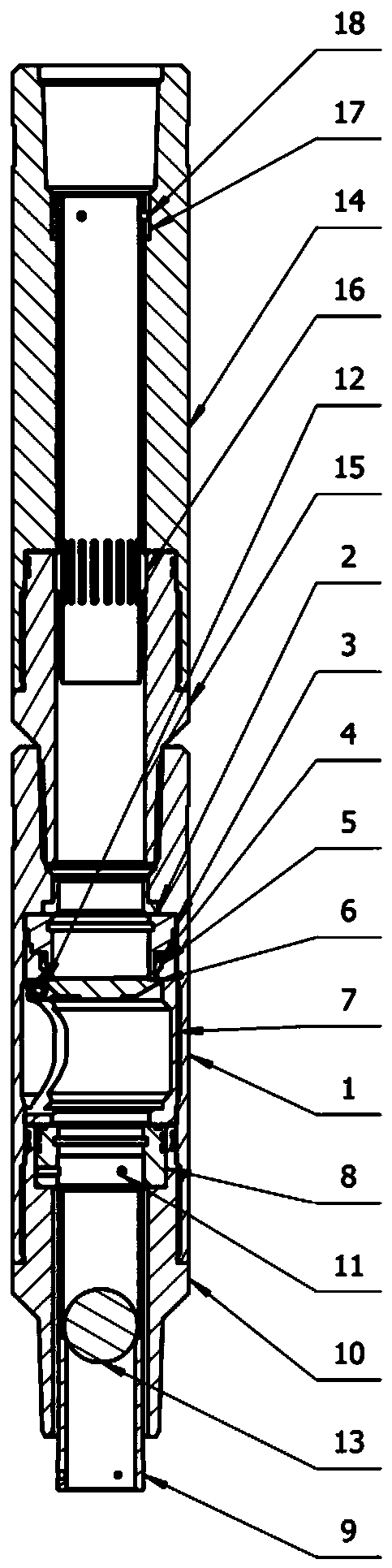

Integrated downhole operation tool based on bidirectional slip hydraulic permanent packer

The invention provides an integrated downhole operation tool based on a bidirectional slip hydraulic permanent packer. The operation tool comprises a test valve, a pressure gauge supporting cylinder,a liquid replacing valve, a plugging valve and the bidirectional slip hydraulic permanent packer, wherein the packer comprises an upper mandrel, a lower mandrel, an upper hydraulic outer cylinder, a lower hydraulic outer cylinder, a first shearing fixing piece, a second shearing fixing piece, a third shearing fixing piece, an upper slip, an upper cone, a rubber cylinder, a lower cone, a lower slip, a lock ring assembly, a double-male short section and an annular piston, wherein the upper slip, the upper cone, the rubber cylinder, the lower cone, the lower slip, the lock ring assembly and the double-male short section are sequentially arranged on the upper mandrel in a sleeving mode from top to bottom, and the annular piston is arranged on the lower mandrel in a sleeving mode. The upper endof the test valve can be connected with the upstream of the integrated downhole operation tool, the lower end of the test valve is connected with the upper end of a pressure gauge, the lower end of the pressure gauge is connected with the upper end of the liquid replacing valve, the lower end of the liquid replacing valve is connected with the upper end of the plugging valve, and the lower end ofthe plugging valve is connected with the bidirectional slip hydraulic permanent packer. The integrated downhole operation tool has the functions of oil testing and well completion production.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

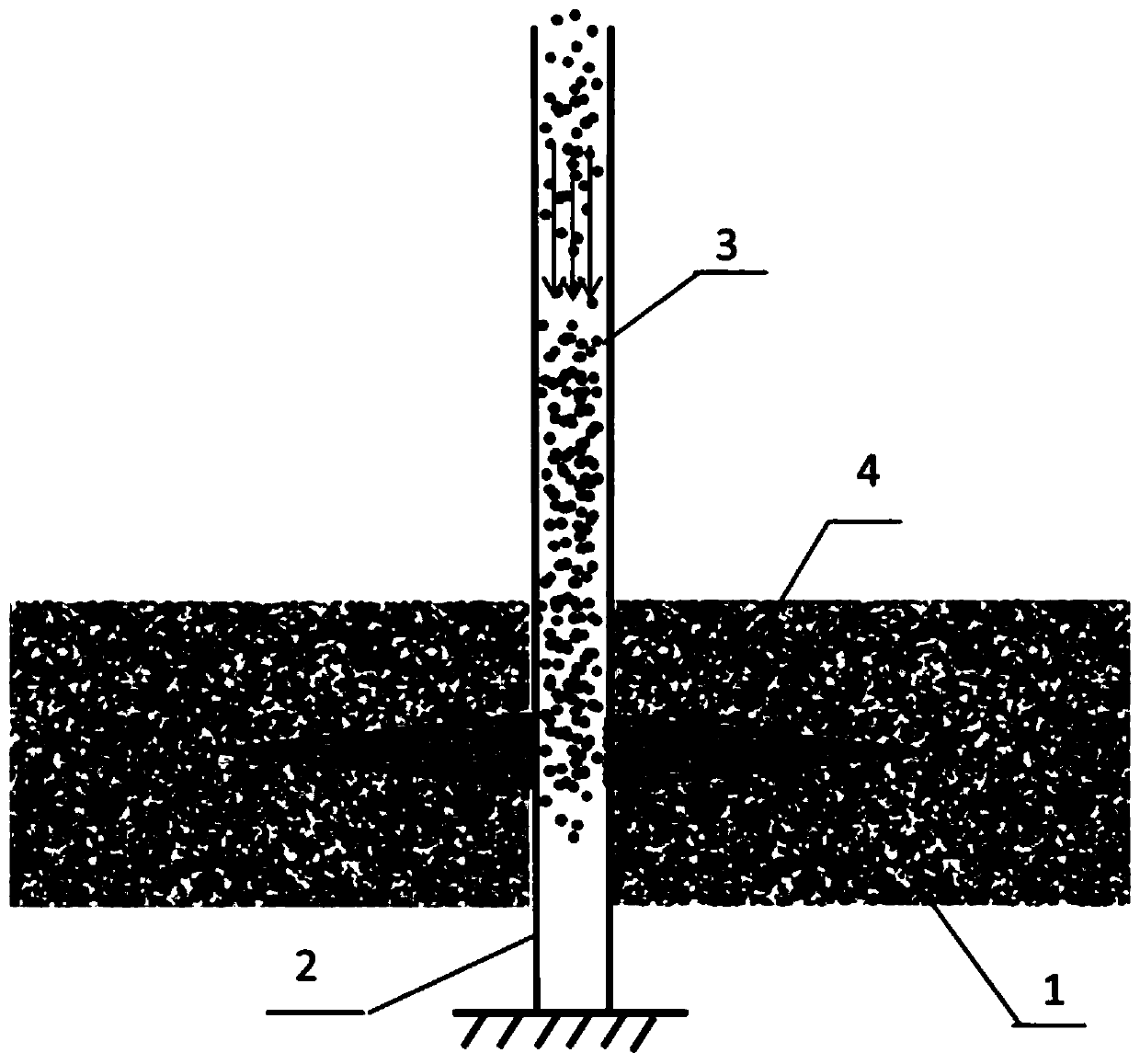

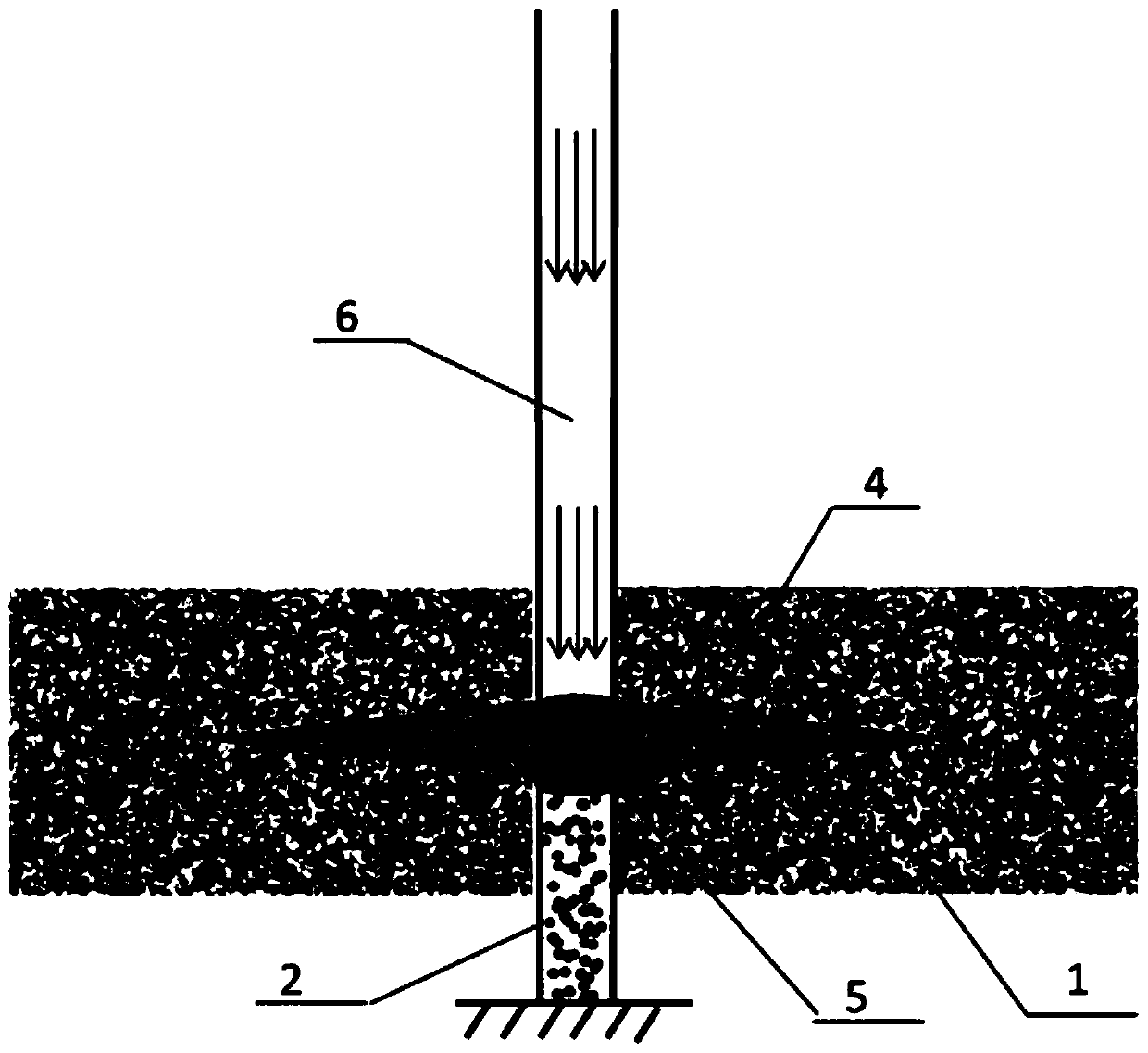

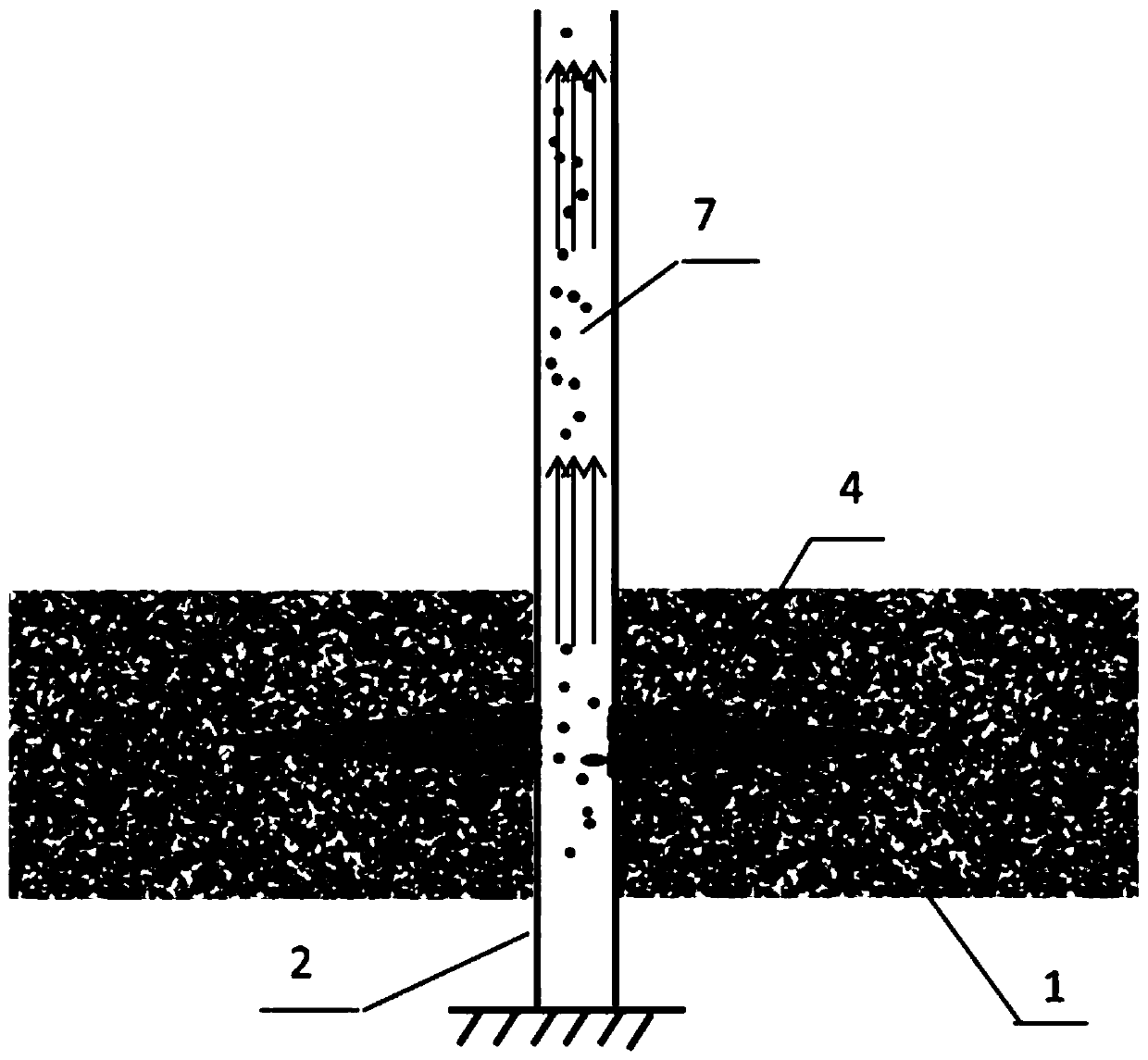

Gas-lift reverse circulation well drilling system and automatic control method

ActiveCN110608005ASimple on-site operationEasy process changeConstructionsGeothermal energy generationAutomatic controlDouble wall

The invention discloses a gas-lift reverse circulation well drilling system and an automatic control method. The system comprises a wellhead device, an in-well drilling tool, a flow line, a gas injecting pipeline, a drilling liquid injecting pipeline and an automatic control system, wherein the in-well drilling tool comprises a drill bit, a downhole electromagnetic PWD, a drill collar, a lower single-wall drill rod, a gas-water mixer, a double-wall drill rod, an air injection valve and an upper single-wall drill rod; each of the gas injecting pipeline and drilling fluid injecting pipeline is provided with an automatic throttle valve, a pressure gauge, a flowmeter and an automatic pressure relief valve; the automatic control system comprises a signal receiver, a computer, a display, a PLC (programmable logic controller) and a parameter input module; and during the gas lift reverse circulation drilling process, the automatic control system monitors the bottom pressure in real time, adjusts the gas injection quantity parameter and the drilling fluid injection parameter and realizes the automatic and accurate control of the bottom pressure. The system has the beneficial effects that the well control risk is reduced by matching with conventional well control equipment at a well mouth; and the bottom hole pressure is accurately controlled to prevent the occurrence of lost circulationand overflow.

Owner:SOUTHWEST PETROLEUM UNIV

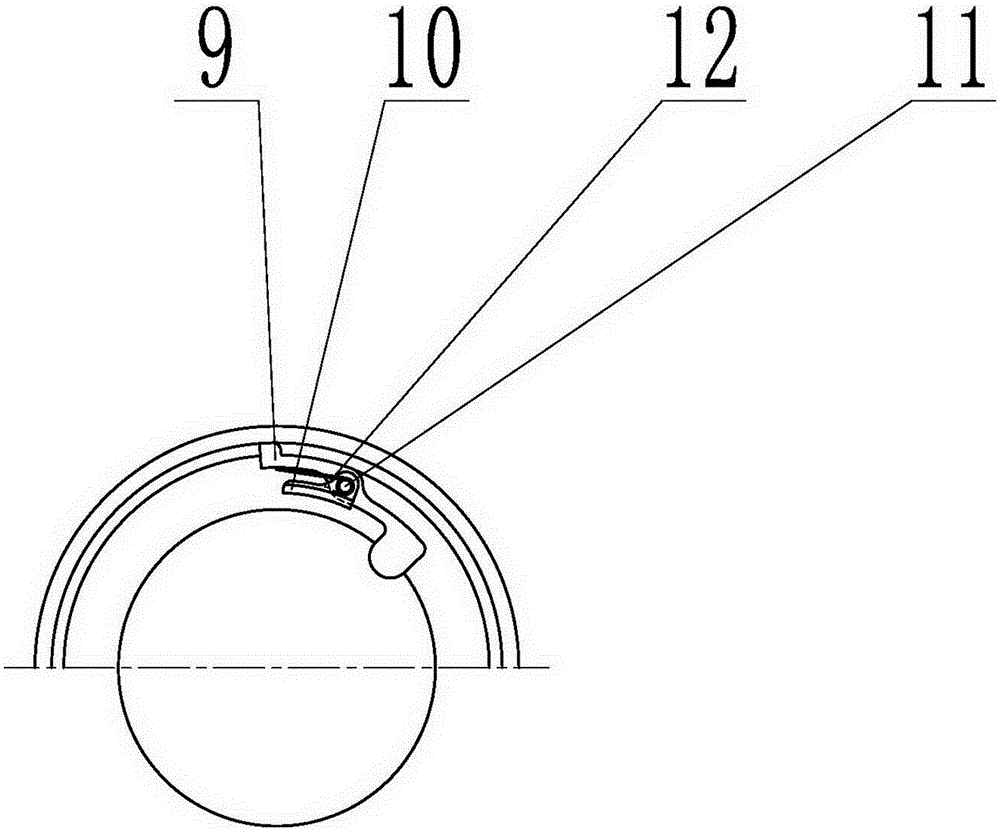

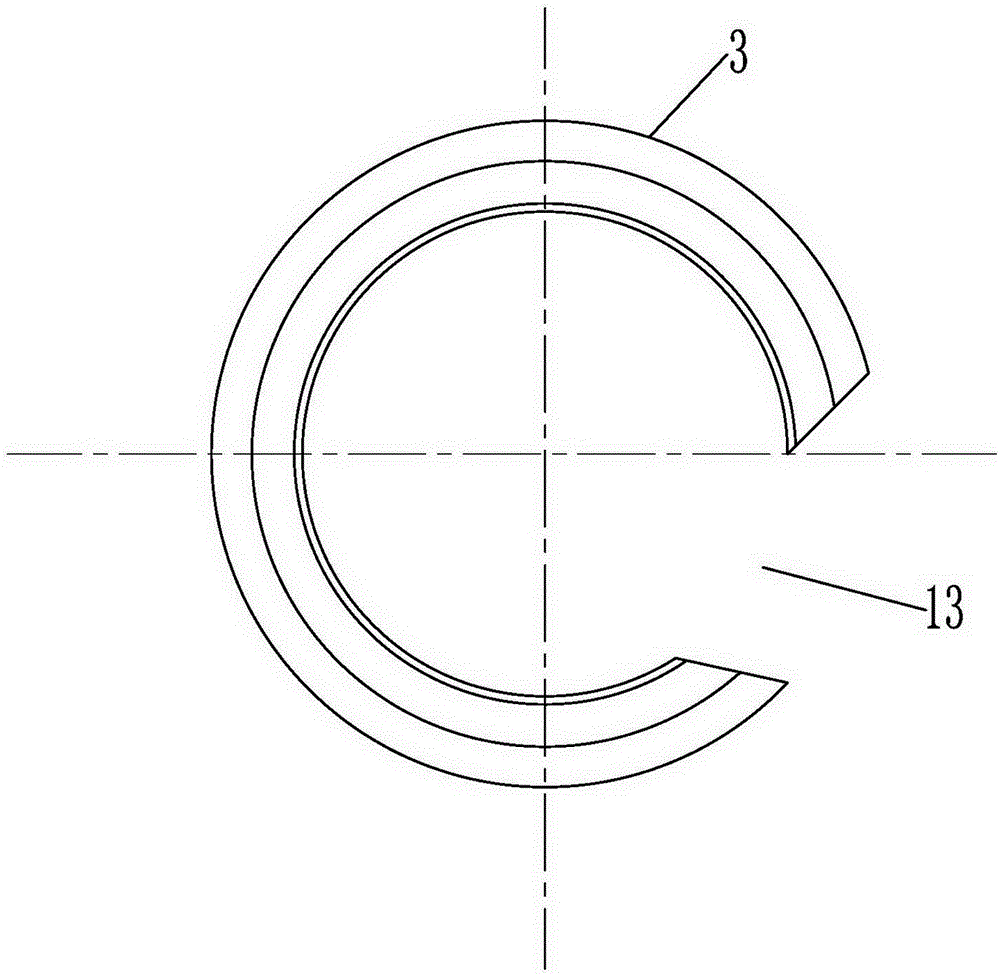

Guide rail type intelligent sliding sleeve sieve tube tool

ActiveCN105134161AImprove opening rateSimple designFluid removalWell/borehole valve arrangementsAcid fracturingTube tool

The invention belongs to the field of full-bore segmented acid fracturing in mining well-completion practice of oil and gas wells, and in particular relates to a guide rail type sliding sleeve sieve tube tool which comprises a lifted joint and a shell, wherein the shell is provided with a retractable C ring ball seat, a counting sleeve, a locating sleeve, a spring, a shear pin and a spacing ring. In an operation process, balls with the same size are always thrown to trigger an ejection device and seal the ball seat. The pressure grade for opening a sieve pore shear pin can not be changed with the change of the segmented grade of acid fracturing, and the pressure of each segment of the shear pin subjected to acid fracturing is same, so that the open rate of a sliding sleeve is increased, the acid fracturing efficiency is increased, and the well control risk and operation cost are further reduced. The tool is simple in design structure, has few components, is convenient to install, relatively saves trouble and labor, and is worthy of being popularized and used in oil and gas fields in China.

Owner:XINJIANG GANGTUO ENERGY TECH

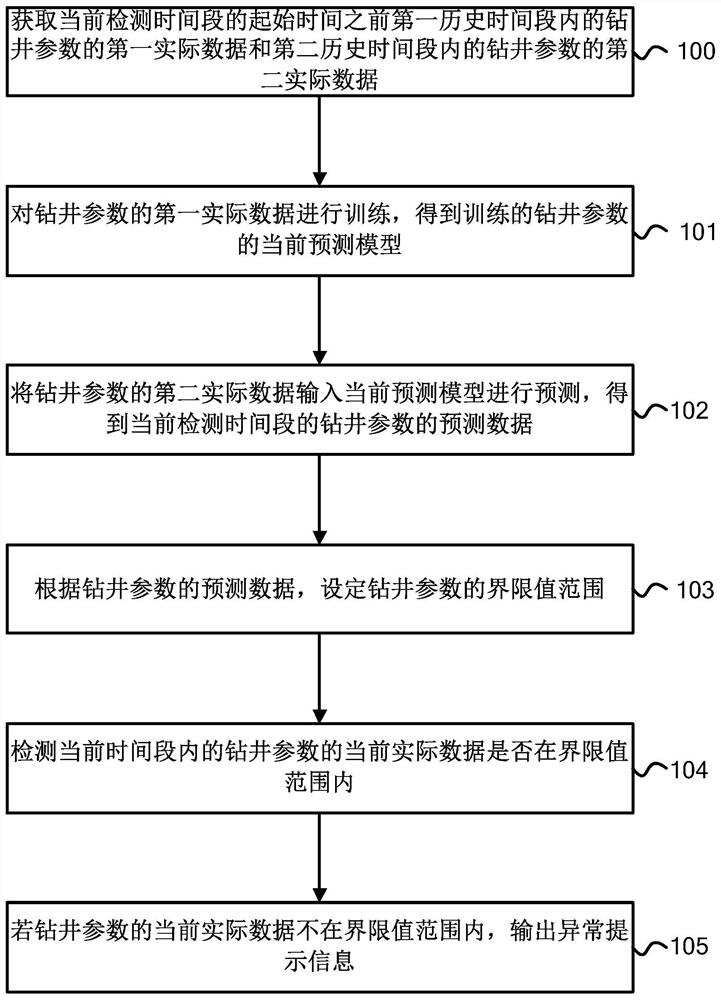

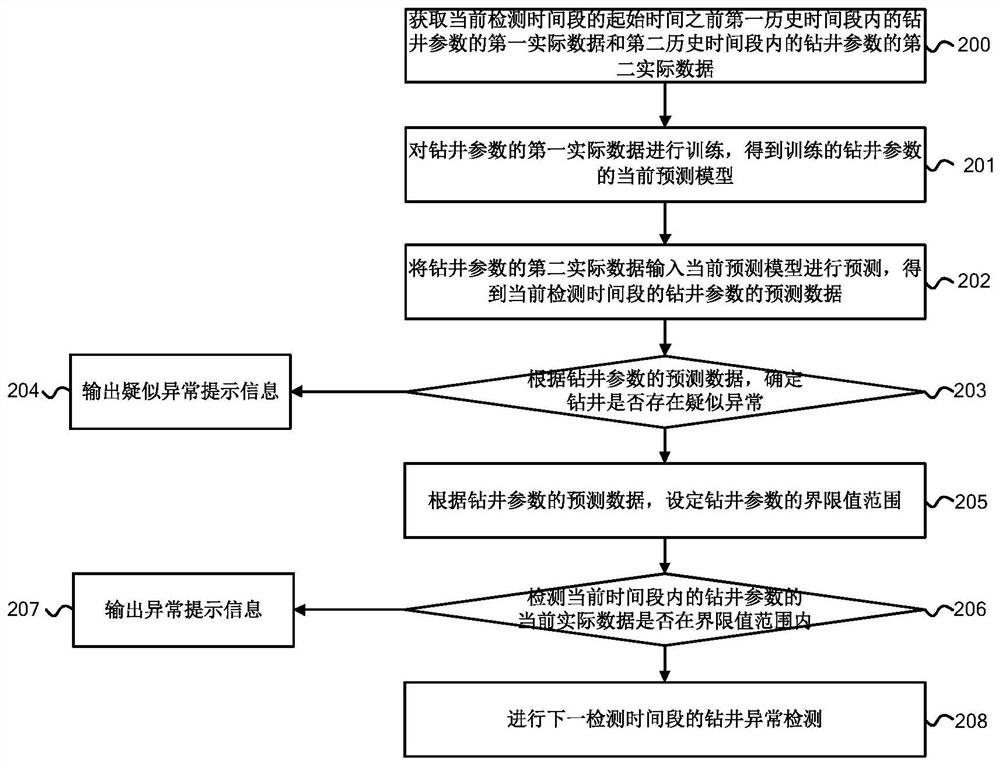

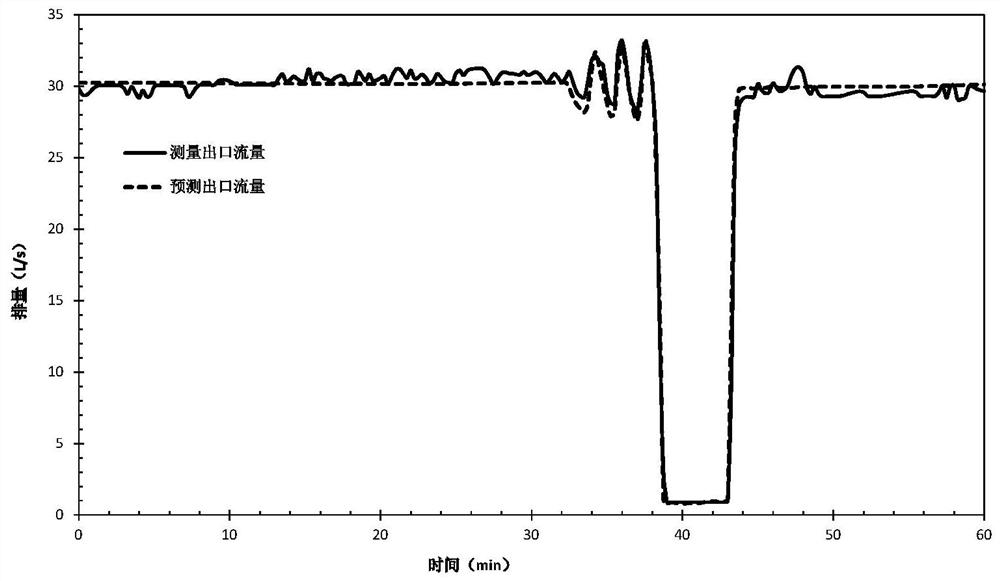

Drilling anomaly detection method, device and equipment, drilling well and storage medium

PendingCN113775327AReduce false negative rateReduce the phenomenon of "false alarms"SurveyAnomaly detectionWell drilling

The invention discloses a drilling anomaly detection method, device and equipment, a drilling well and a storage medium. The method comprises the steps that first actual data of drilling parameters in a first historical time period before the starting time of a current detection time period and second actual data of the drilling parameters in a second historical time period are acquired; the first actual data of the drilling parameters is trained to obtain a current prediction model of the trained drilling parameters; the second actual data of the drilling parameters is input into the current prediction model for prediction, and after prediction data of the drilling parameters in the current detection time period is obtained, a threshold value range of the drilling parameters is set; whether the current actual data of the drilling parameters in the current time period is within the threshold value range or not is detected; and if the current actual data of the drilling parameters is not within the threshold value range, anomaly prompt information is output, so that the false alarm rate and the missing alarm rate of drilling anomalies are reduced, the reliability of anomaly detection is improved, and then the well control risk is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Down-hole sliding-sleeve-type blowout-preventing switching valve

PendingCN110029963APlay the role of blowout preventionAddress riskConstructionsWell/borehole valve arrangementsEngineeringValve seat

The invention provides a down-hole sliding-sleeve-type blowout-preventing switching valve, which comprises a blowout-preventing switching valve body and a blowout-preventing sliding sleeve body. The blowout-preventing sliding sleeve body is arranged above the blowout-preventing switching valve body to be fixed, and the blowout-preventing switching valve body is internally provided with an anti-abrasion alloy sleeve, a blowout-preventing switching valve seat, a sealing device, a blowout-preventing switching tongue plate, a tongue plate supporting skeleton, a blowout-preventing switching valve sliding sleeve fixing ring, a blowout-preventing switching valve sliding sleeve, a blowout-preventing switching valve lower joint, a dowel and a torsional spring; the sleeve-shaped blowout-preventing switching valve seat is arranged below the anti-abrasion alloy sleeve; a ring-shaped elastic seal is used for sealing and mounting the blowout-preventing switching valve seat onto the blowout-preventing switching valve body, and the dowel and the torsional spring sleeving the dowel are arranged on the blowout-preventing switching valve seat; a dowel hole formed in the blowout-preventing switching tongue plate can rotate around the dowel, the blowout-preventing switching valve sliding sleeve fixing ring is arranged below the blowout-preventing switching valve seat, and the blowout-preventing switching valve sliding sleeve is arranged in the blowout-preventing switching valve sliding sleeve fixing ring in a lined mode; and the blowout-preventing switching valve lower joint is fixed to the lower part of the blowout-preventing switching valve sliding sleeve fixing ring.

Owner:JIANGSU XINCAIYANG ELECTROMECHANICAL TECH

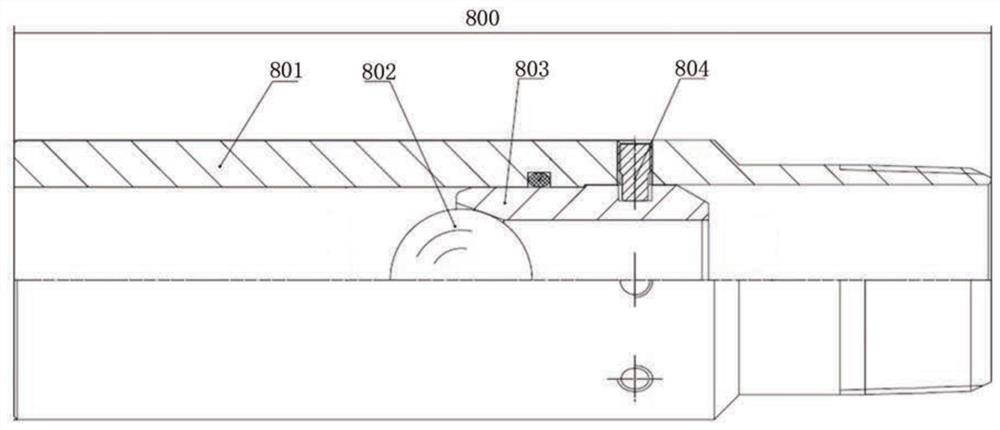

Pressurized operation device and pressurized operation method for completion of gas-driven injection well

ActiveCN110630204ASave gas injection resourcesReduce well control riskFluid removalSealing/packingInjection wellTechnical support

The invention discloses a pressurized operation device and a pressurized operation method for the completion of a gas-driven injection well, and belongs to the field of pressurized operation. The pressurized operation method of a pressurized operation device for the completion of a gas-driven injection well comprises the following steps: 1) setting a tubing wellhead with a bridge plug; 2) installing the pressurized operation device; 3) lifting a pipe string under pressure; 4) lowering a completion process pipe string under pressure; 5) extruding and injecting annulus protection fluid; 6) setting a packer and sitting a tubing hanger. The pressurized operation method of a pressurized operation device for the completion of a gas-driven injection well solves the shortcomings of high wellhead pressure, difficult pressure relief, long venting time, and high safety and environmental protection pressure of the injection well under the gas-driven condition in an oil field, and can realize the lifting and lowering of the completion pipe string under a wellhead pressurized condition, thereby providing a key technical support for the supporting operation of the shaft of the gas-driven injection well in the oil field.

Owner:PETROCHINA CO LTD

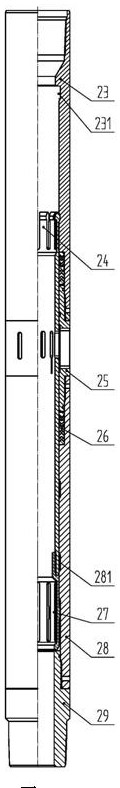

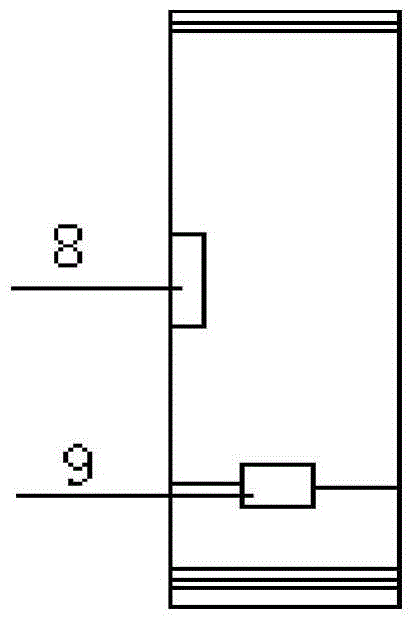

Well completion pipe string and production pipe string of electric pump producing well and construction method thereof

InactiveCN113494273AImprove well control safetyReduce the number of tripsFluid removalWell/borehole valve arrangementsControl engineeringProcess engineering

The invention relates to a well completion pipe string and a production pipe string of an electric pump producing well and a construction method thereof. The well completion pipe string comprises a left-in-well packer and a well completion oil pipe, wherein the lower portion of the left-in-well packer is further connected with a pipe insertion sliding sleeve, the pipe insertion sliding sleeve is provided with a closing sleeve, a positioning sleeve, an upper connecting sleeve and a lower connecting sleeve, a liquid flow hole or groove is formed in a pipe body of the closing sleeve, and a positioning rib is arranged on the pipe body of the positioning sleeve. The production pipe string comprises an electric pump conversion hanger and an electric pump unit, wherein an electric pump unit outer sheath is further mounted outside the electric pump conversion hanger and the electric pump unit, the lower end of the electric pump unit outer sheath is further connected with a sliding sleeve opening and closing tool through a production oil pipe, a switch head of the sliding sleeve opening and closing tool can be inserted into the closing sleeve of the insertion pipe sliding sleeve, and the closing sleeve and the upper connecting sleeve can communicate or be closed. By lowering and lifting the production pipe string, the sliding sleeve opening and closing tool located at the lower end can open and close the upper connecting sleeve in the pipe inserting sliding sleeve, and the lowering times of the pipe column are greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sucker rod and oil well using same

The invention discloses a sucker rod and an oil well using the same. The sucker rod can be arranged in an oil pipe; the lower end of the sucker rod is used for being connected with an oil well pump; the sucker rod comprises a plurality of sucker rod sections connected in series through a first thread; a connecting piece is arranged in the predetermined position of the sucker rod; the connecting piece comprises a first part and a second part which are connected in the length direction of the sucker rod; the first part and / or the second part are / is connected with the sucker rod sections through the first thread; the first part is connected with the second part through a second thread; and one of the first thread and the second thread is a positive thread, and the other is a reverse thread. According to the sucker rod and the oil well using the same, waste of the sucker rod can be reduced when the sucker rod is pulled out and clamped, and the clamping freeing work time is shortened.

Owner:PETROCHINA CO LTD

Wellhead suspension device

PendingCN110805407AMeet suspension sealing requirementsImprove sealingSealing/packingCouplingWell control

The invention provides a wellhead suspension device, and belongs to the field of oil well equipment. The wellhead suspension device comprises a fastener, a gland, a cone, a housing, a first sealing piece, a grease injection nozzle, a first backing ring, a second sealing piece, a second backing ring and a casing coupling, wherein a concave step is arranged on the inner wall of the housing in the circumferential direction; the second backing ring, the second sealing piece, the first backing ring, the first sealing piece and the cone are sequentially inlaid in the concave step on the inner wall of the housing; the grease injection nozzle is arranged on the outer wall of the housing and communicates with the first backing ring; the fastener is detachably connected with the gland and the housing; the casing coupling is connected with a casing; and the inner walls of the cone, the first sealing piece, the first backing ring, the second sealing piece and the second backing ring abut against the outer wall of the casing. According to the wellhead suspension device, the wellhead casing suspension sealing requirement is met, meanwhile, the pressure bearing capacity of a wellhead is the sameas that of an original wellhead device, and the well control risk is reduced.

Owner:PETROCHINA CO LTD

Two-layer delamination perforation-delamination test combined pipe string in one trip and its operation method

ActiveCN106150445BImprove admission qualityIncrease the proportion of stratified oil testingFluid removalWell/borehole valve arrangementsInternal pressureHierarchical test

The invention relates to a one-trip string two-layer layering perforation-layering testing combining tubular column and an operation method. The tubular column comprises a first oil tube, a depth correction short joint, a second oil tube, a circulating valve, a third oil tube, a testing valve assembly, a second pressure gauge supporting cylinder, a second pressure transfer joint, a straddle packer, a second sieve tube, a spacer tube, a pressure guiding joint, a second ignition head, a second perforating gun, a pressure release device, sealing layer well shut-in sampling valve, a damping pressure gauge supporting cylinder, a first pressure transfer joint, an anchor packer, a first sieve tube, a shock absorber, a fourth oil tube, a first ignition head, a first perforating gun, a pressure relieving device, a second inner pressure transfer tube, a first pressure transfer tube and a first outer pressure transfer tube. The sealing layer well shut-in sampling valve is located between the second perforating gun and the anchor packer. The damping pressure gauge supporting cylinder is located below the sealing layer well shut-in sampling valve. by adopting the tubular column, two-layer layering perforation and layering testing combination can be completed, final well shut-in of the first layer does not need to occupy the operation machine time independently, down-hole sampling is convenient, and the tubular column has the advantages of being short in period, low in cost and the like.

Owner:DAQING DANFENG PETROLEUM TECH DEV CO LTD

Method for pulling out halogen discharging pipe

The invention discloses a method for pulling out a halogen discharging pipe, which belongs to the technical field of a salt cavern underground gas reservoir. The method comprises the following steps:loading a cutting apparatus into a halogen discharging pipe, cutting the halogen discharging pipe by using the cutting apparatus, so that the lower end surface of the halogen discharging pipe is located in a first casing pipe; loading a first oil passing pipe expansion-type packer into the halogen discharging pipe until the first oil passing pipe expansion-type packer extends out of the halogen discharging pipe and seals the first casing pipe; and uplifting the halogen discharging pipe until the halogen discharging pipe is pulled out of the first casing pipe. According to the method for pulling out the halogen discharging pipe provided by the invention, when the halogen discharging pipe is uplifted, only the halogen discharging pipe in an oil pipe needs to be uplifted without driving the first oil passing pipe expansion-type packer to move upwards, and the high-pressure natural gas in an inner cavity of the salt cavern can be prevented from entering the upper part of the oil pipe, so that the abrasion for the first oil passing pipe expansion-type packer can be avoided, and the well control risk can be reduced.

Owner:PETROCHINA CO LTD

Drilling fluid leakage determining instrument

The invention provides a drilling fluid leakage determining instrument. The drilling fluid leakage determining instrument comprises a measuring instrument mainly composed of an upper positioning joint, a lower centralizer, a flow guide pipe component, a pressure and temperature measuring component, an electronic measurement and control component, an upper centralizer and a male gun head which are connected with one another, wherein a rotor flow meter is arranged in the flow guide pipe component; the pressure and temperature measuring component comprises a pressure and temperature sensor; the electronic measurement and control component comprises a system controller, a data memory and a power supply. The drilling fluid leakage determining instrument further comprises an outer barrel short joint and cable transmission equipment, wherein the outer barrel short joint forms a butt joint relation with the upper positioning joint of the measuring instrument, and the cable transmission equipment forms butt joint with the male gun head of the measuring instrument. The drilling fluid leakage determining instrument provided by the utility model adopts three ways of pressure, flow rate and temperature to perform measurement and comprehensive analysis on drilling fluid leakage positions so as to accurately obtain leakage horizons. The instrument is mounted at a position close to a drill bit in the form of the short joint and can perform leakage position measurement after leakage occurs and transmit data in a down-into-cable butt joint way, thereby avoiding well control risk caused by the fact that a drilling tool is out of a downhole.

Owner:SINOPEC SHENGLI PETROLEUM ENG CO LTD DRILLING TECH RES INST

Preparation method and construction method of prefabricated fracturing displacement isolator

The invention discloses a preparation method and construction method of a prefabricated fracturing displacement isolator. A polymer and plant starch are mixed evenly, and an expansion agent and a curing agent are added into the mixture of the polymer and the plant starch, stirred and mixed evenly to obtain a raw material mixture; then the raw material mixture is injected into a mold of a rubber plug, and the displacement isolator is obtained. Raw materials for preparation of the rubber plug are wide in source and easily obtained, the preparation method is simple and feasible, the operation method is simple, the cost is reduced while the efficiency is improved, and the viscous fingering and over-displacement problems caused by an existing gas field fracturing displacement fluid stage are solved on the basis that the operation difficulty of field construction is not increased.

Owner:PETROCHINA CO LTD

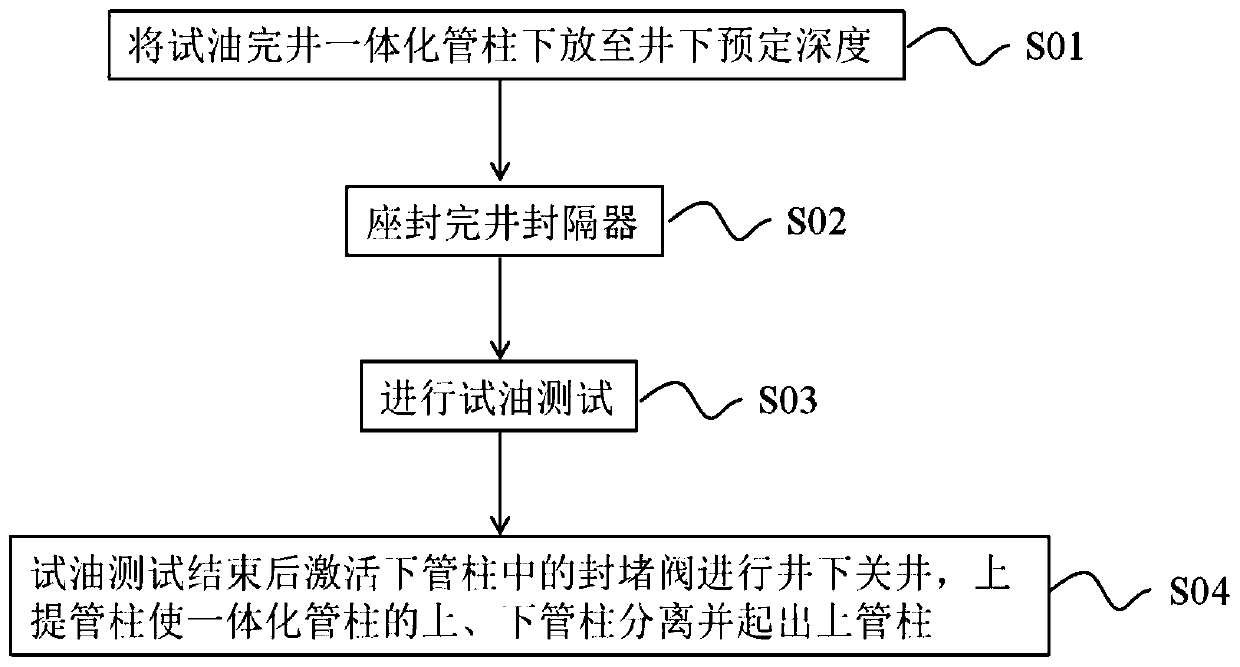

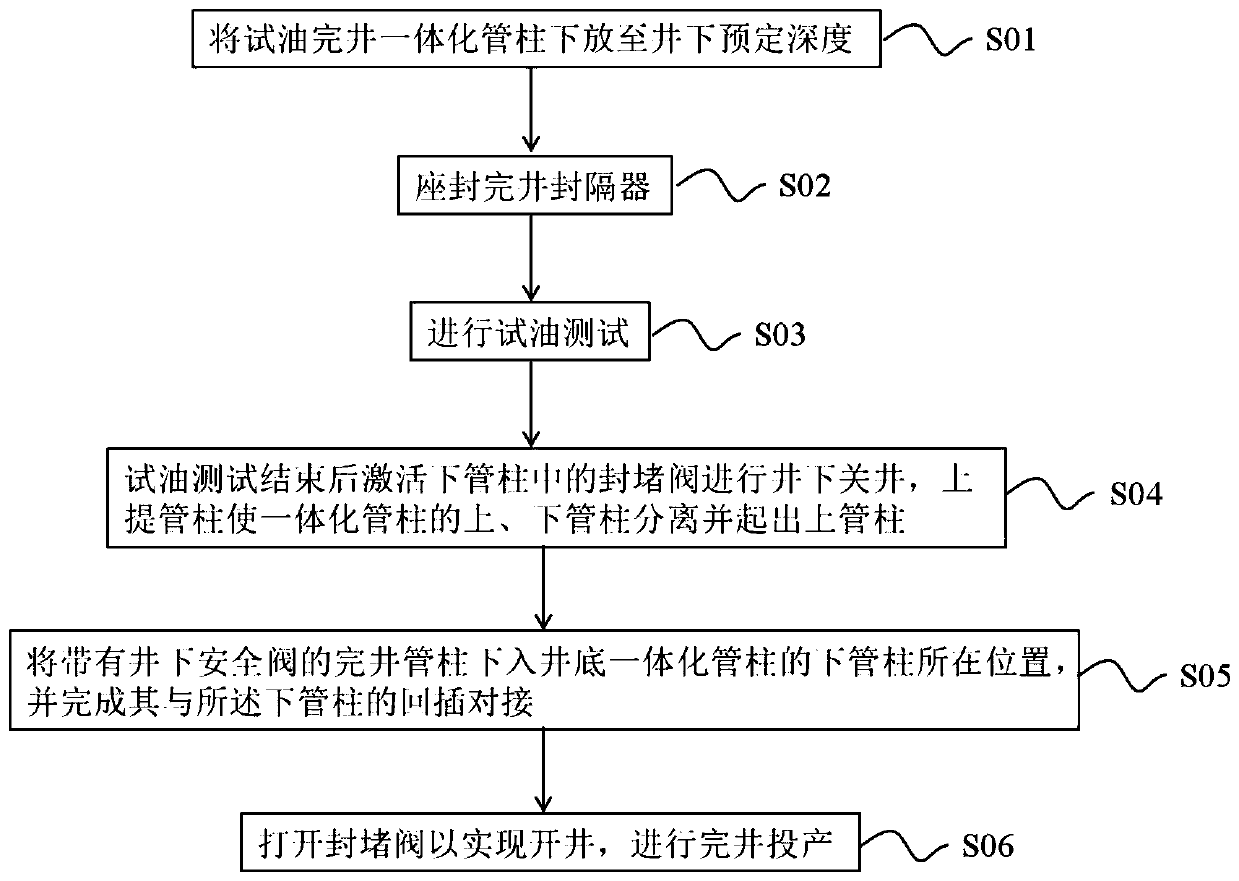

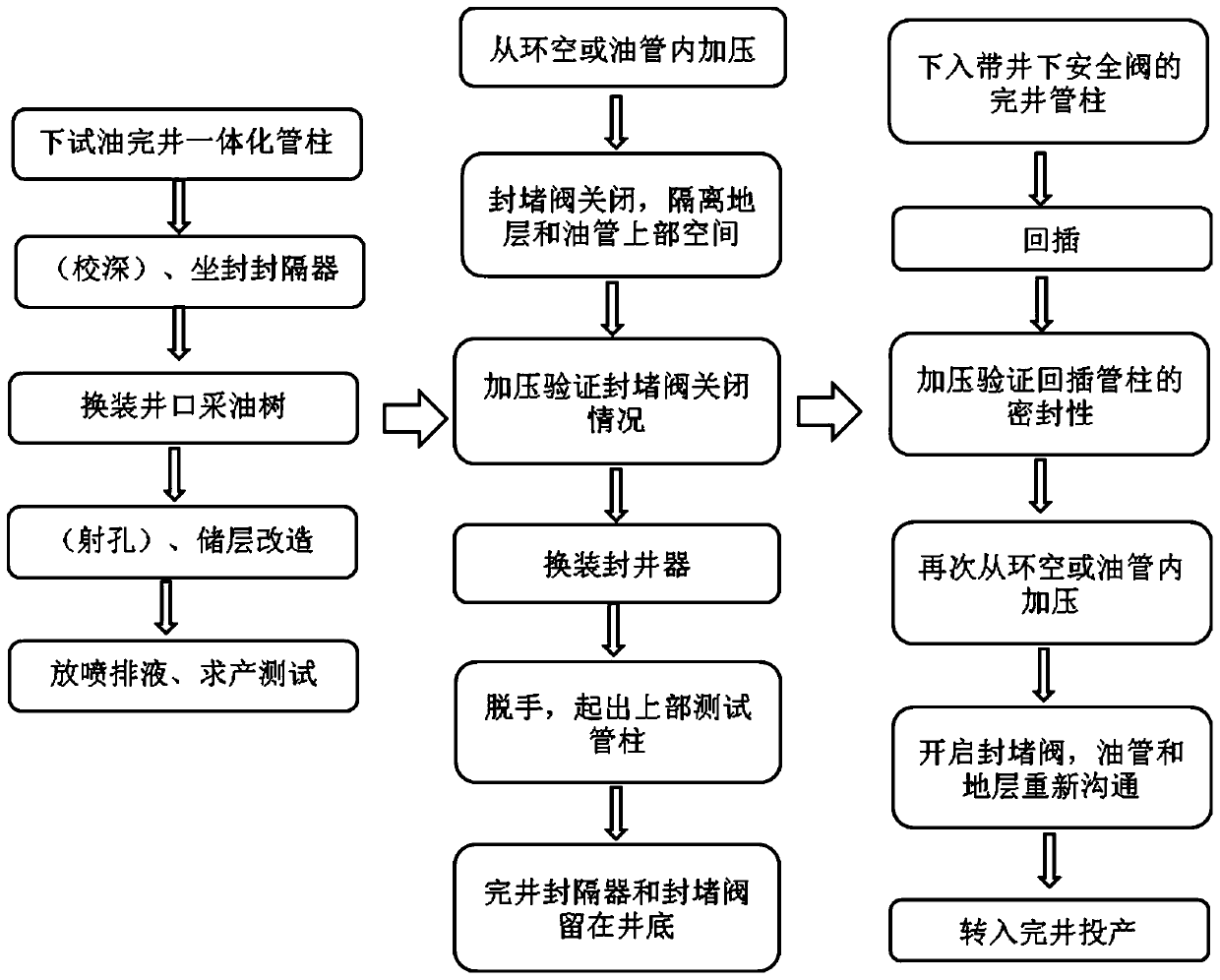

Integrated method for oil testing and well completion

PendingCN110500084AReduce operating proceduresHigh efficiency of oil testing and layer transferSurveyDrilling rodsWell controlDownhole safety valve

The invention provides an integrated method for oil testing and well completion. The integrated method includes the steps that when an oil testing test is performed, an integrated pipe column composedof an upper pipe column and a lower pipe column which are detachably connected is lowered to a downhole predetermined depth, a packer in the integrated pipe column is subjected to setting, the oil testing test is performed, after the oil testing test is completed, a plugging valve is activated to perform shut-in downhole, and the upper pipe column and the lower pipe column are separated and the upper pipe column is lifted out; and when well completion and production are performed, a completion pipe column with a downhole safety valve is lowered into the bottom of a well and connected with thelower pipe column in a back inserting and abutting mode, the plugging valve is opened by pressure from an annulus or an oil pipe to realize well completion, and well completion and production are performed. The integrated method has the beneficial effects that the method has the advantages of saving operation procedures, being high in efficiency of well testing transfer, reducing engineering complexity, protecting oil and gas layers, reducing well control risks, reducing costs and the like.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

Drilling leakage zone position recognition system

PendingCN107542451AAccurately find out the leakage layerLittle impact on drilling constructionSurveyConstructionsWell drillingRadio frequency

The invention provides a drilling leakage zone position recognition system, which can be used for judging the accurate leakage occurring position. An externally embedded measuring pup joint is used; by measuring three parameters of the pressure, the flow rate and the temperature of an annular space, the drilling fluid leakage occurring position is measured and comprehensively analyzed, so that theleakage zone position is accurately obtained; and through a radio frequency technology, stored data is fast read. The instrument is arranged in a position near a drilling bit in a pup joint form; theleakage parameters are recorded and stored; then, a radio frequency tag is used for reading the data; and the read data are processed and analyzed on the ground. The technology has small influence onthe drilling construction; and the well control risk is favorably reduced.

Owner:中石化石油工程技术服务有限公司 +2

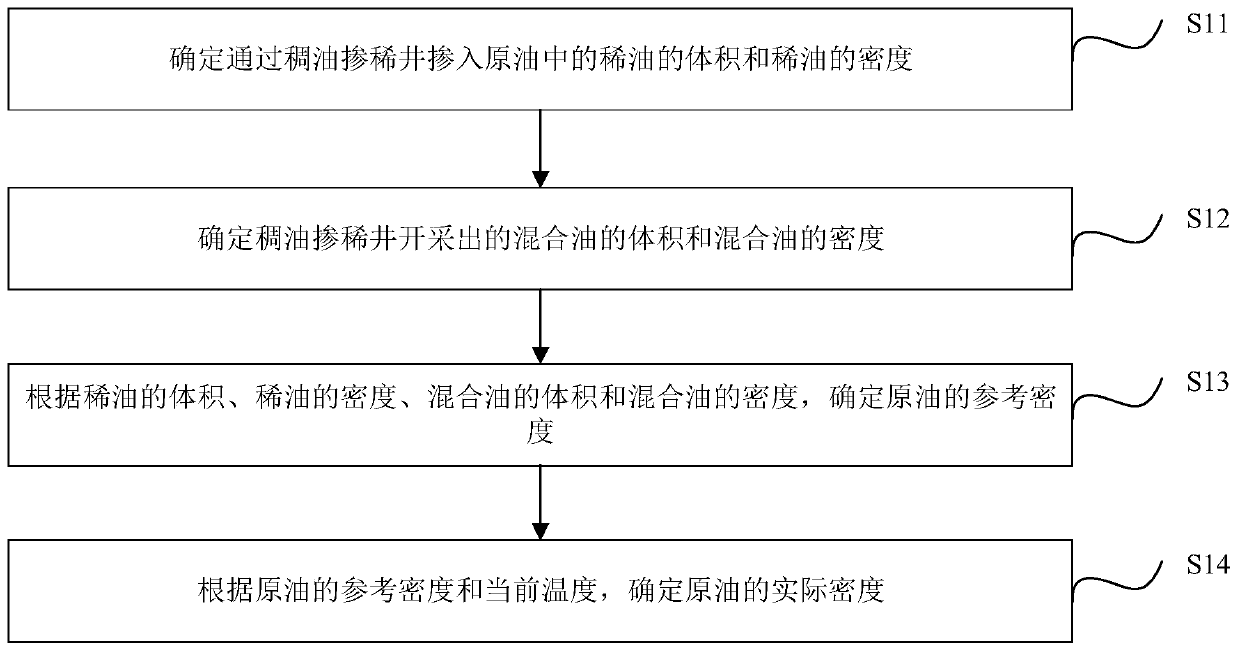

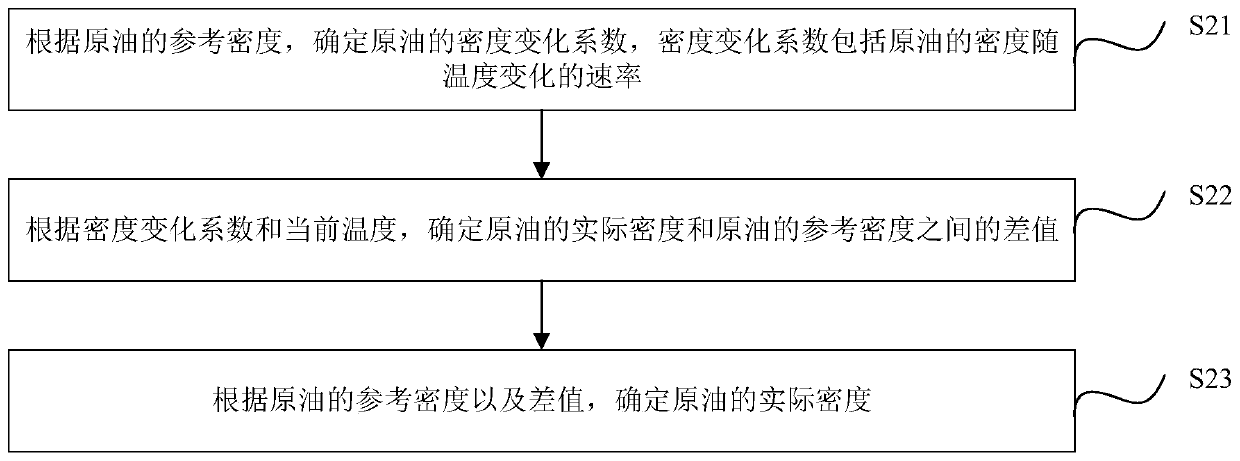

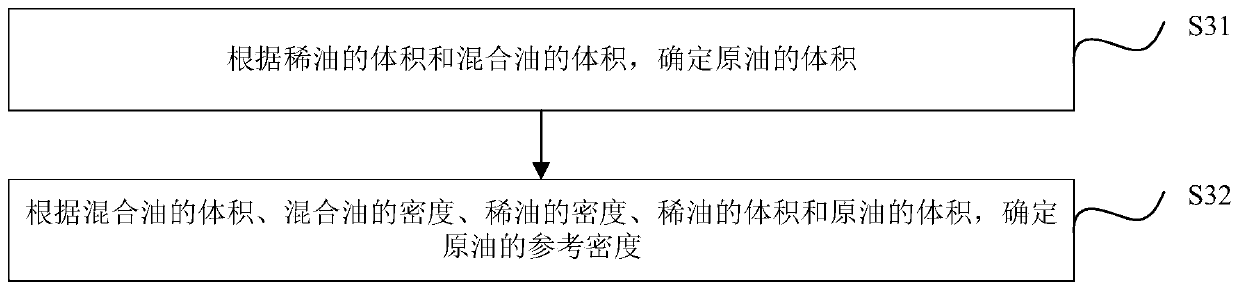

Stratum crude oil density determining method and device

PendingCN111380776AAvoid the Risk of Stress ImbalancesReduce well control riskSpecific gravity measurementCrude oilPhysical chemistry

The invention provides a stratum crude oil density determining method and device. The stratum crude oil density determining method comprises the steps of determining the volume and density of thin oilmixed into crude oil through a thick oil mixing well; determining the volume and the density of the mixed oil exploited from the thickened oil blending well; determining the reference density of thecrude oil according to the volume of the thin oil, the density of the thin oil, the volume of the mixed oil and the density of the mixed oil; and determining the actual density of the crude oil according to the reference density and the current temperature of the crude oil. According to the stratum crude oil determining method and device, the well control risk is reduced.

Owner:PETROCHINA CO LTD

An integrated downhole operation tool based on a two-way slip retrievable hydraulic packer

ActiveCN110778288BReduce operating proceduresHigh efficiency of oil testing and layer transferSealing/packingBlocked valvesStructural engineering

The invention provides an integrated downhole operation tool based on a two-way slip retrievable hydraulic packer. The working tools include: a test valve, a pressure gauge holder, a fluid replacement valve, a plugging valve and a two-way slip retrievable hydraulic packer. Wherein, the packer includes: a central mandrel, a first shearing fixture, a second shearing fixture, a third shearing fixture, and a liquid cylinder sleeved on the outer wall of the central mandrel in sequence from top to bottom The outer cylinder, the locking mandrel and the limit assembly are sequentially sleeved on the outer wall of the locking mandrel, the annular piston, the locking ring assembly, the rubber tube, the cone and the slips. The upper end of the test valve is connected to the upstream of the integrated downhole operation tool, the lower end of the test valve is connected to the upper end of the pressure gauge, the lower end of the pressure gauge is connected to the upper end of the replacement valve, the lower end of the replacement valve is connected to the upper end of the blocking valve, and the lower end of the blocking valve is connected to the two-way Slips recoverable hydraulic packer connection. The invention has the functions of oil testing and well completion and putting into production at the same time, and can be recycled and used.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

Gel solid slug segmented trip method

InactiveCN109630063ANo serious lossPrecise pressure well control safetySealing/packingWell drillingNormal mode

The invention discloses a gel solid slug segmented trip method, and relates to the field of drilling operation of sulfur-containing oil and gas wells. The method comprises the following steps that step1, under-pressure trip-out is performed to a designed well depth, a designed amount of gel is pumped, and trip-out is performed to the upper portion of a gel slug; step2, circulation is performed forn hours, and gel solidification is triggered through formation temperature; step3, after gel is solidified, it is verified whether or not the downhole pressure is completely blocked, and if yes, tripis performed through a well-opened normal mode; step4, during trip-in, well-opened trip-in is performed to the rear of the top of the gel solid slug, the gel solid slug is drilled, then aftercompaction is performed, under-pressure drip-in is performed to the shaft bottom, and drilling is restored. The method can achieve the well control safety during fine pressure-controlled trip, ensures that adrilling fluid cannot be lost in the whole drilling process, and effectively protects the oil and gas reservoirs.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com