Method for pulling out halogen discharging pipe

A tubing and casing technology, applied in the field of starting and discharging brine pipes, can solve the problems of increasing well control risk and single well control method, and achieve the effects of reducing well control risk, low operating cost and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

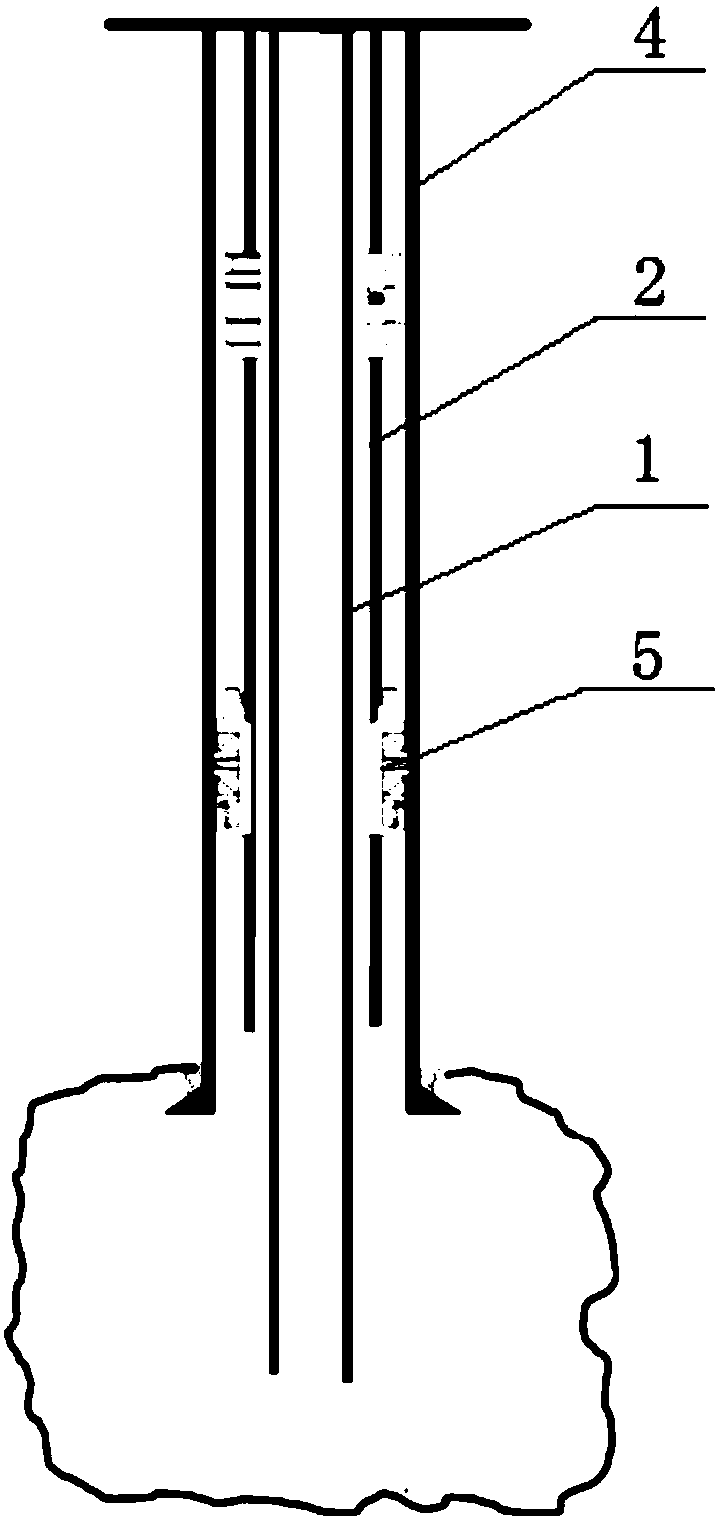

[0053] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0054] An embodiment of the present invention provides a method for starting and discharging a brine pipe, the method comprising:

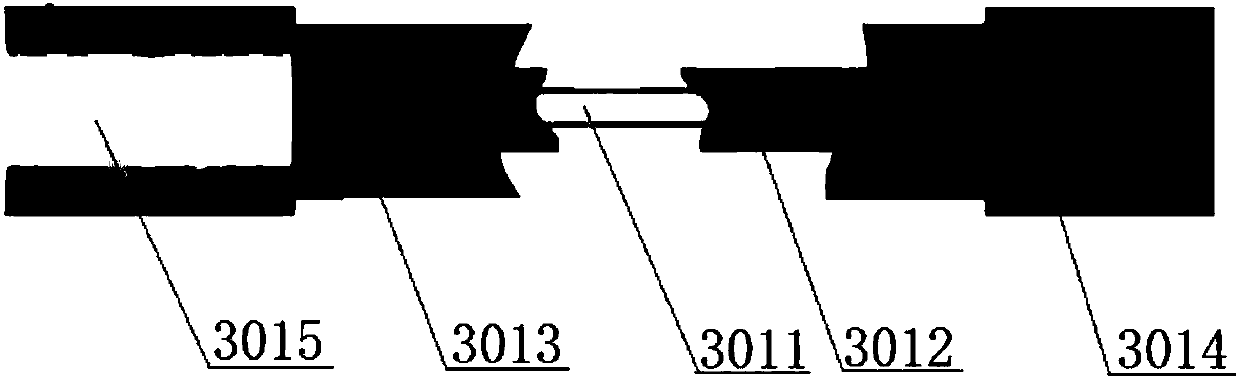

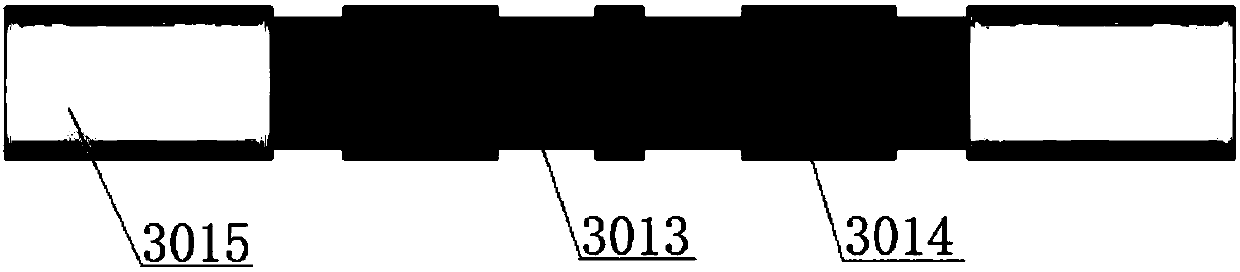

[0055] Step 101 : Insert a cutting device into the brine discharge pipe 1 , and use the cutting device to cut the brine discharge pipe 1 so that the lower end surface of the brine discharge pipe 1 is located in the first casing 2 .

[0056] Step 102: Run the first oil-passing expandable packer 301 into the brine discharge pipe 1 until the first oil-passing expandable packer 301 passes through the halogen discharge pipe 1 and seal it in the first casing 2 Blocking.

[0057] Step 103: Lift the brine discharge pipe 1 until it comes out from the first casing 2 .

[0058] It should be noted that the first tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com