Gas-lift reverse circulation well drilling system and automatic control method

A technology of gas lift reverse circulation and automatic control system, which is applied in earthwork drilling, wellbore flushing, wellbore/well parts, etc., which can solve the problems of difficult drilling, achieve simple on-site operation, convenient process conversion, and prevent lost circulation and the overflow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

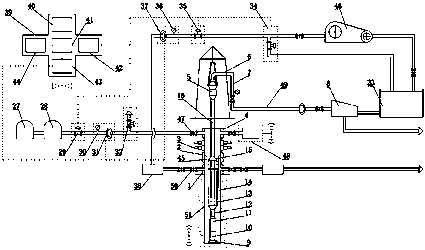

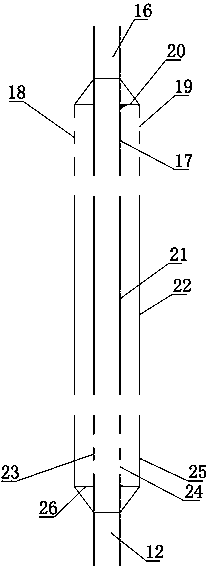

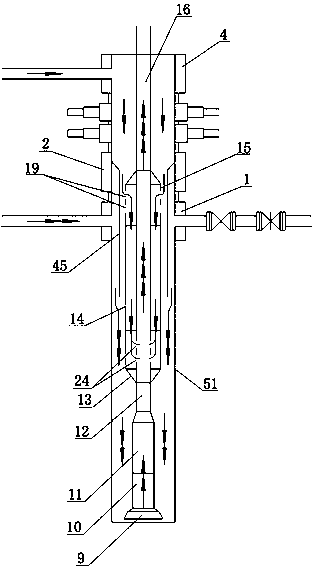

[0044] like Figure 1~5 As shown, a gas lift reverse circulation drilling system includes a wellhead device, a return pipeline, an in-hole drilling tool, a gas injection pipeline, a drilling fluid injection pipeline and an automatic control system 39;

[0045] The wellhead device includes a drilling spool 1 arranged on the top of the wellhead, and the top of the drilling spool 1 is provided with a rising nipple 2, a ram blowout preventer 3 and a rotating blowout preventer 4 in sequence, and the rotating blowout preventer 4 An annular liquid level monitoring echo instrument 48 is installed on the bypass valve on the right side, and an air-water isolation pipe 45 is arranged in the rising joint 2, and the upper end of the air-water isolation pipe 45 is flanged outwards and fixed on the On the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com