Patents

Literature

48results about How to "Automatic pressure control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

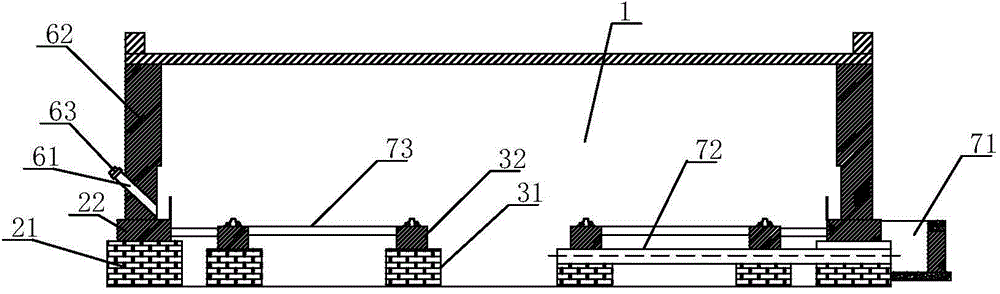

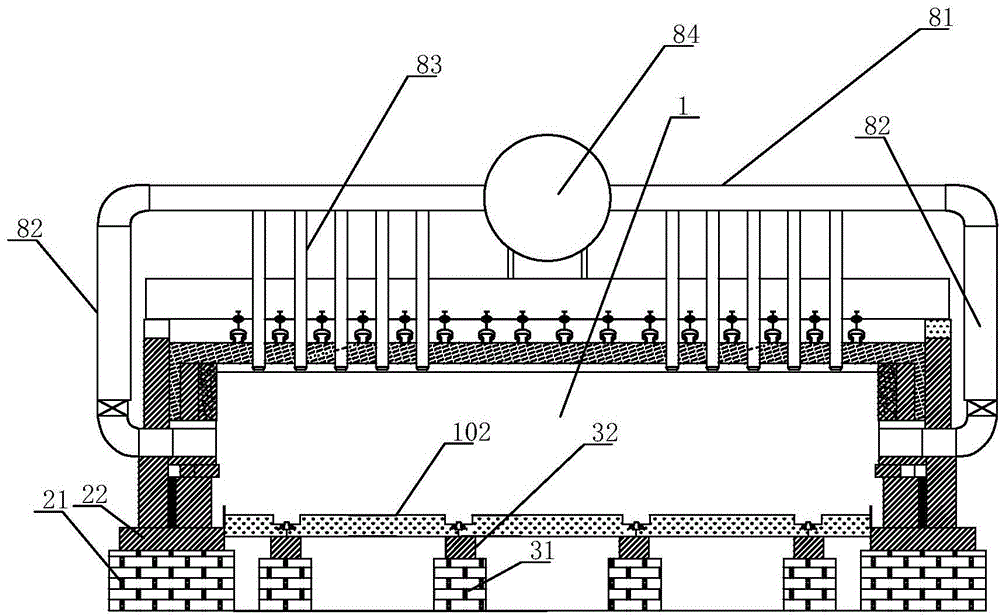

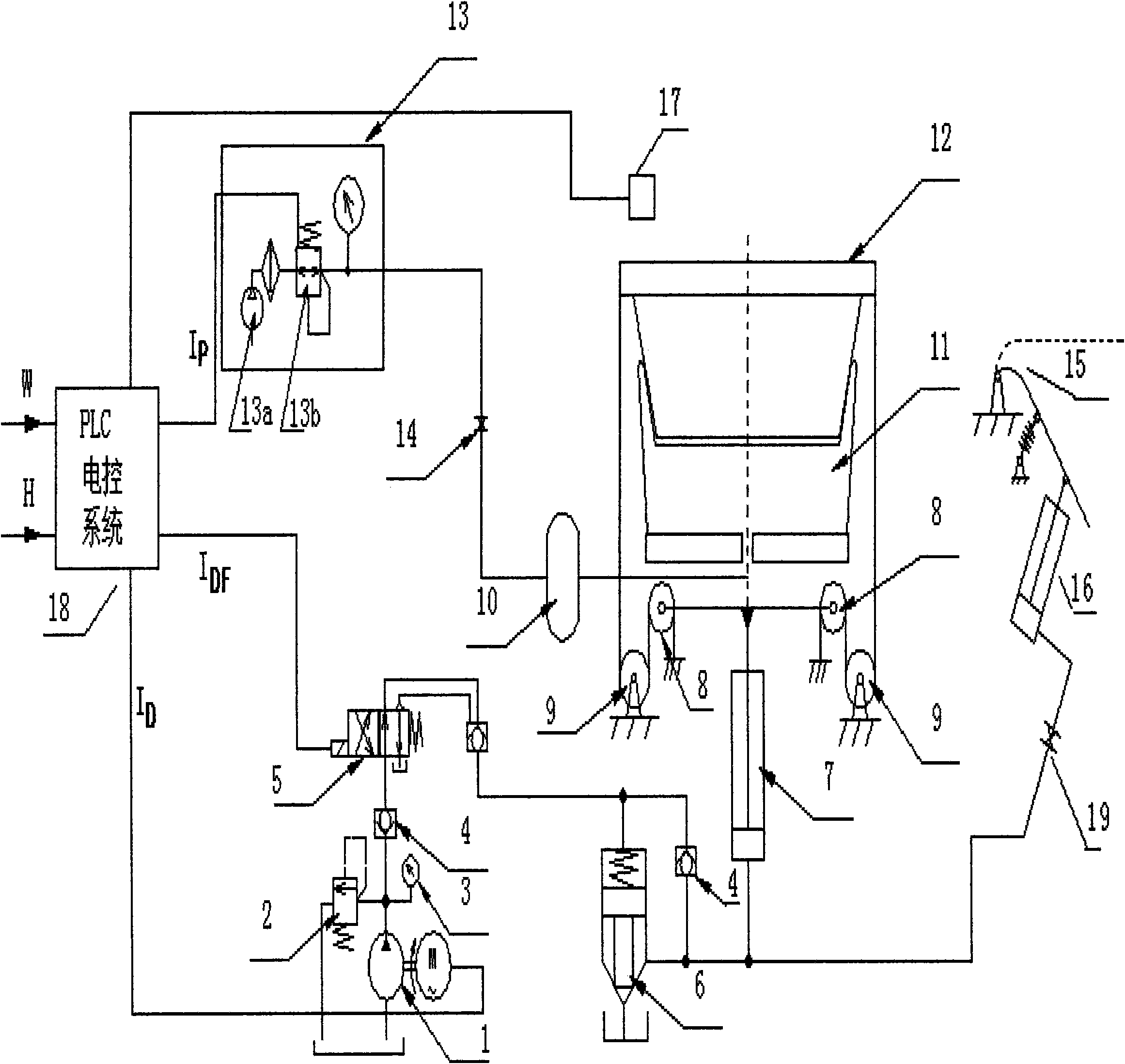

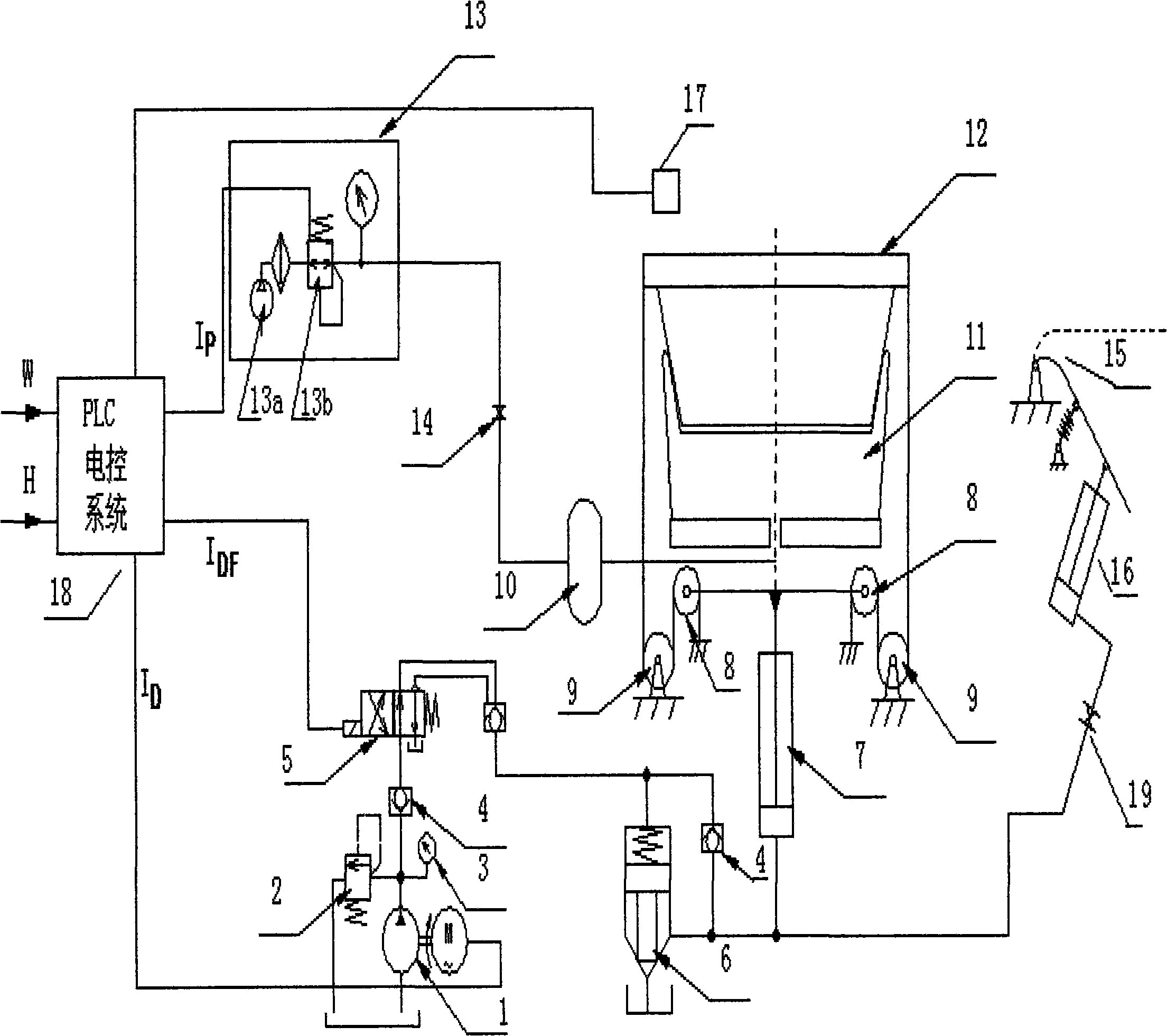

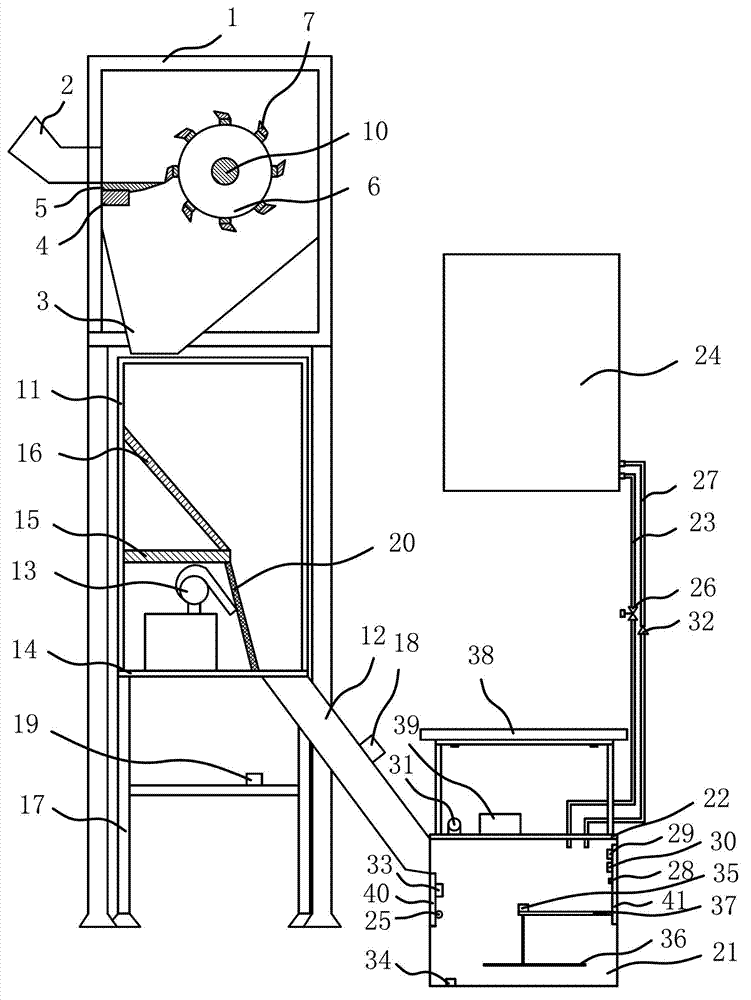

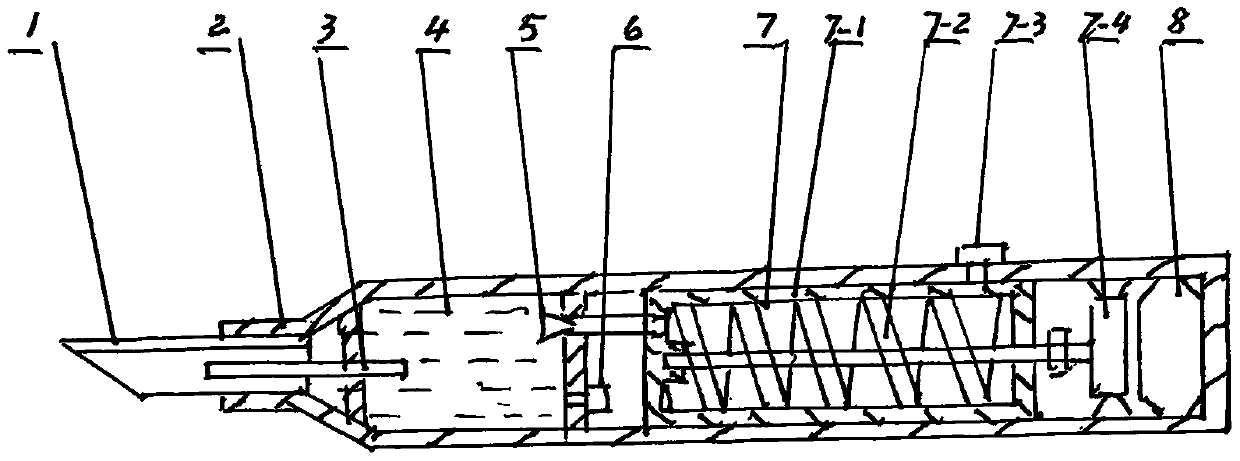

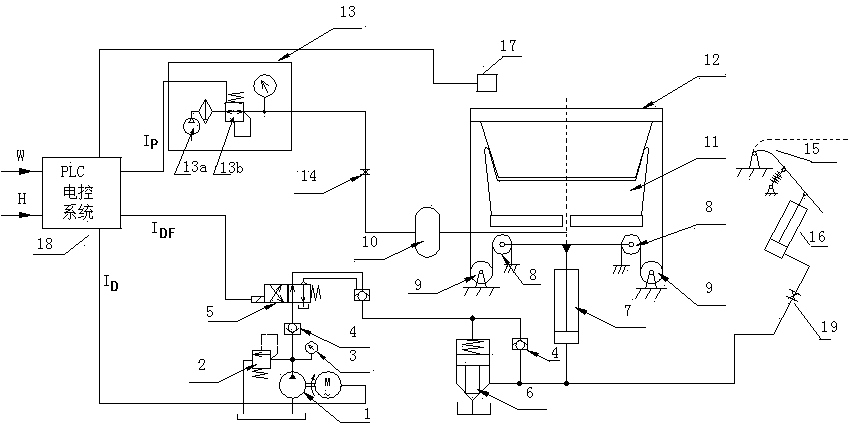

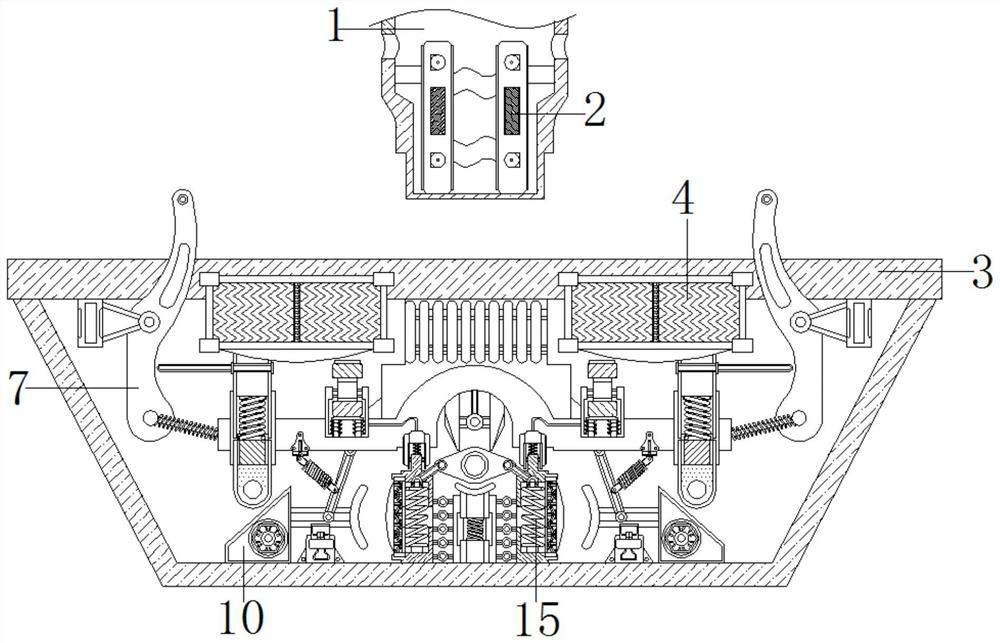

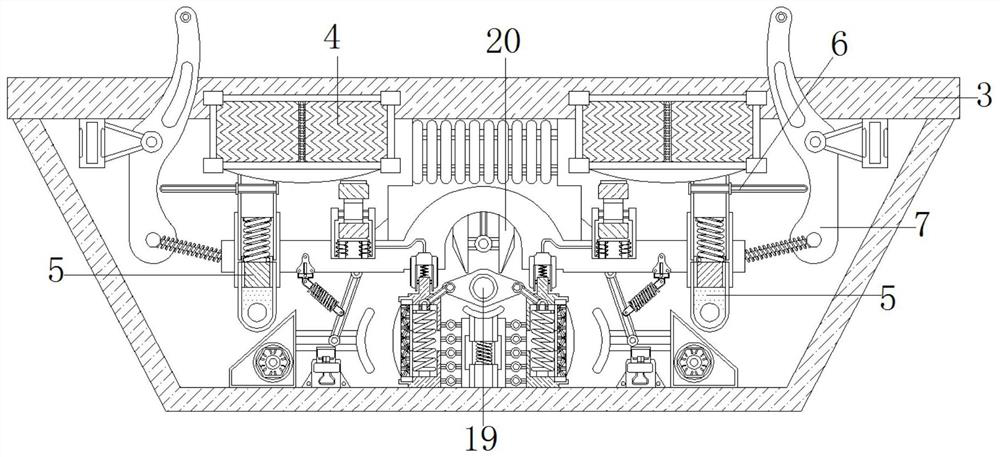

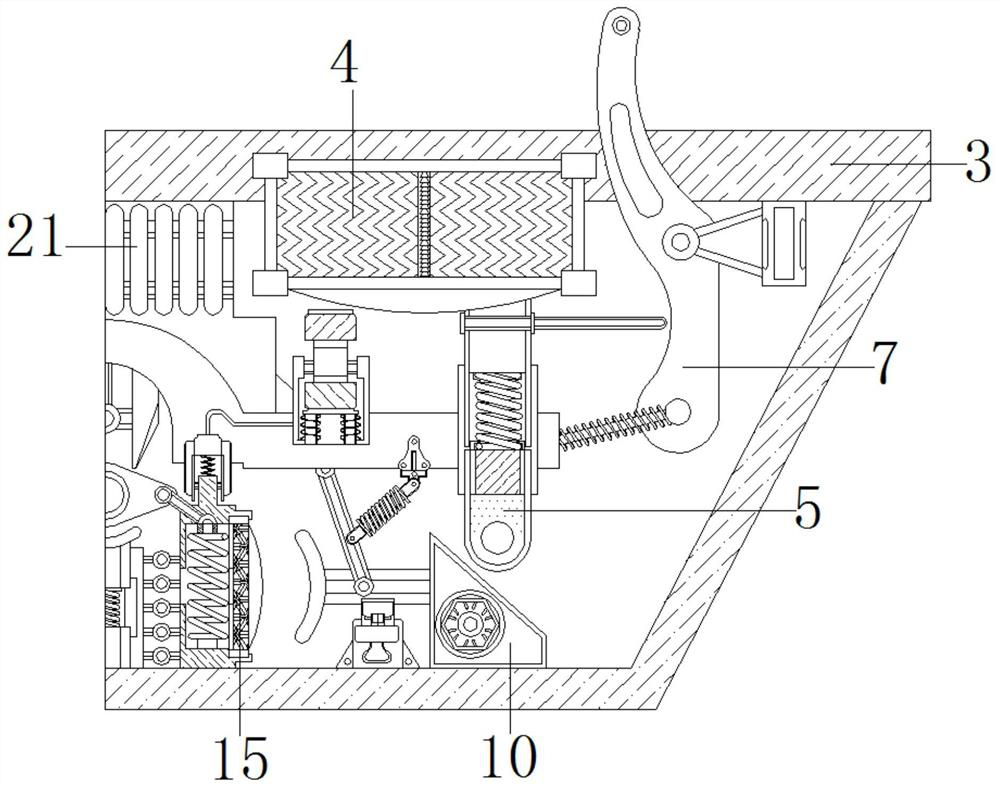

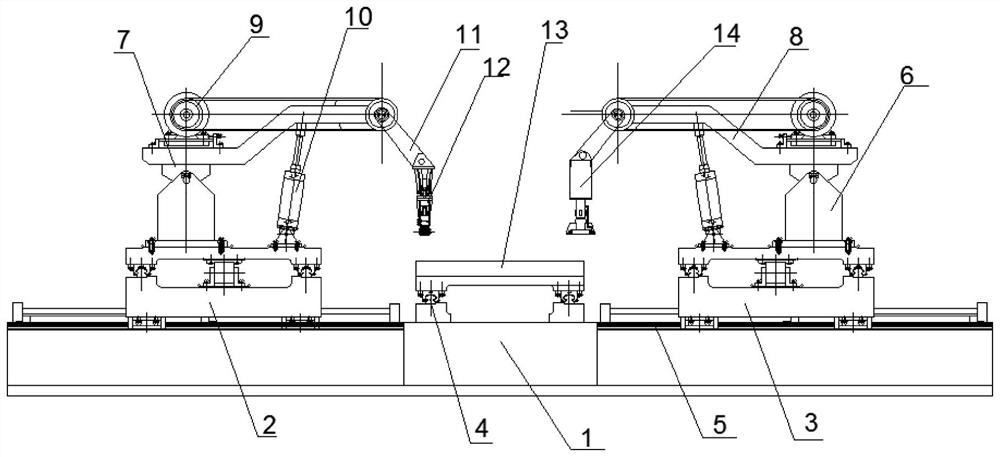

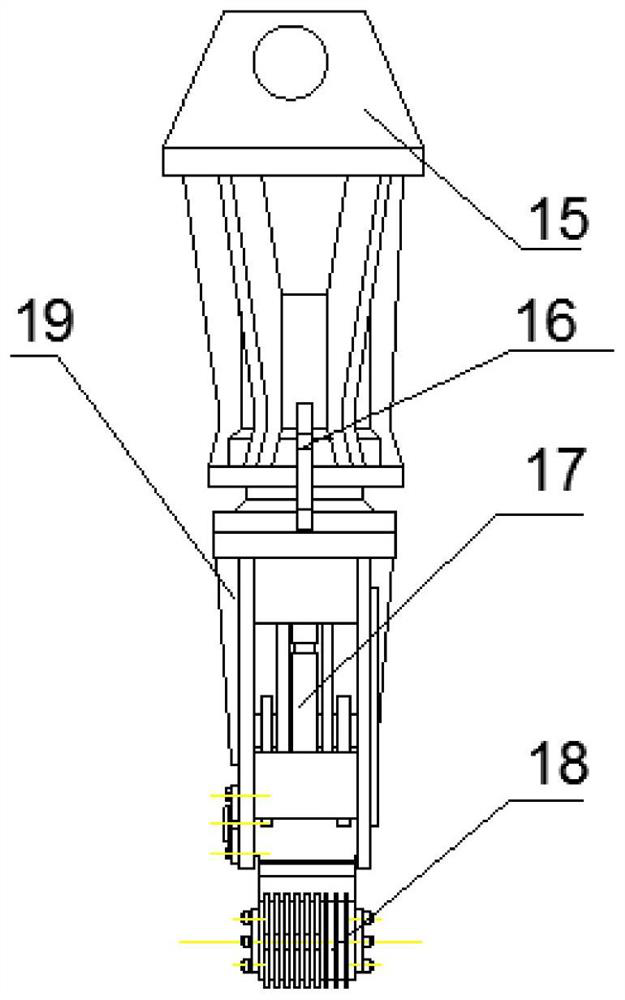

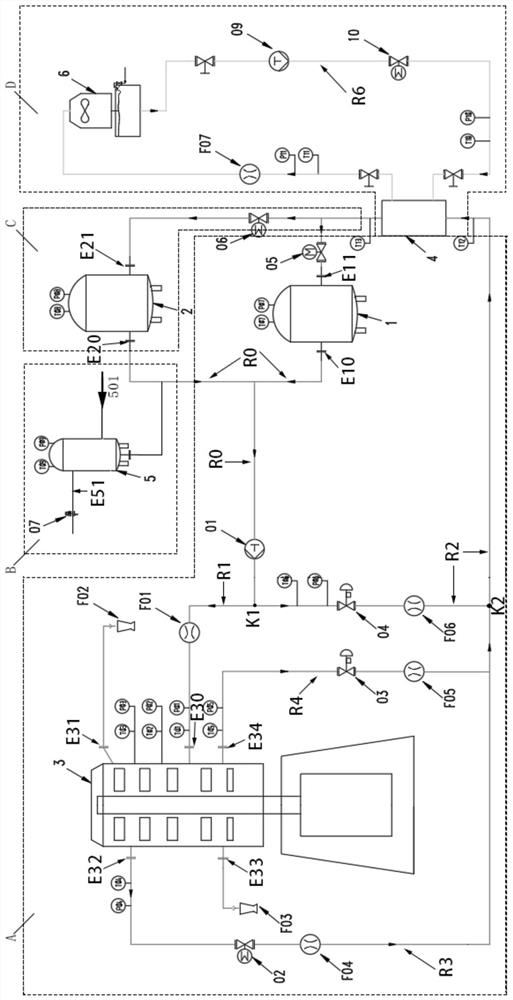

Biomass power plant fuel system

ActiveCN101532673AAutomatic pressure controlImprove performancePressesLump/pulverulent fuel feeder/distributionHigh densityProcess engineering

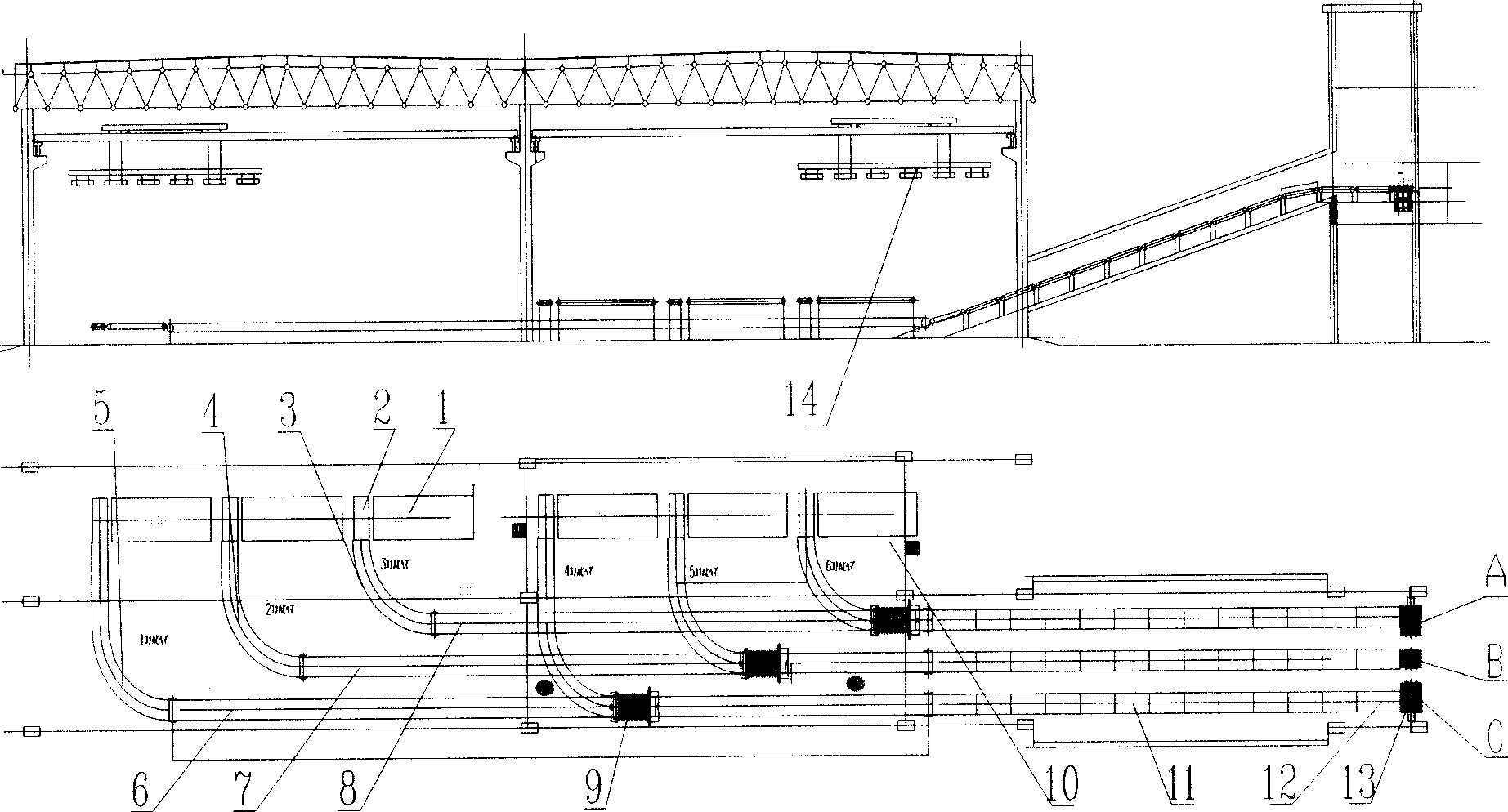

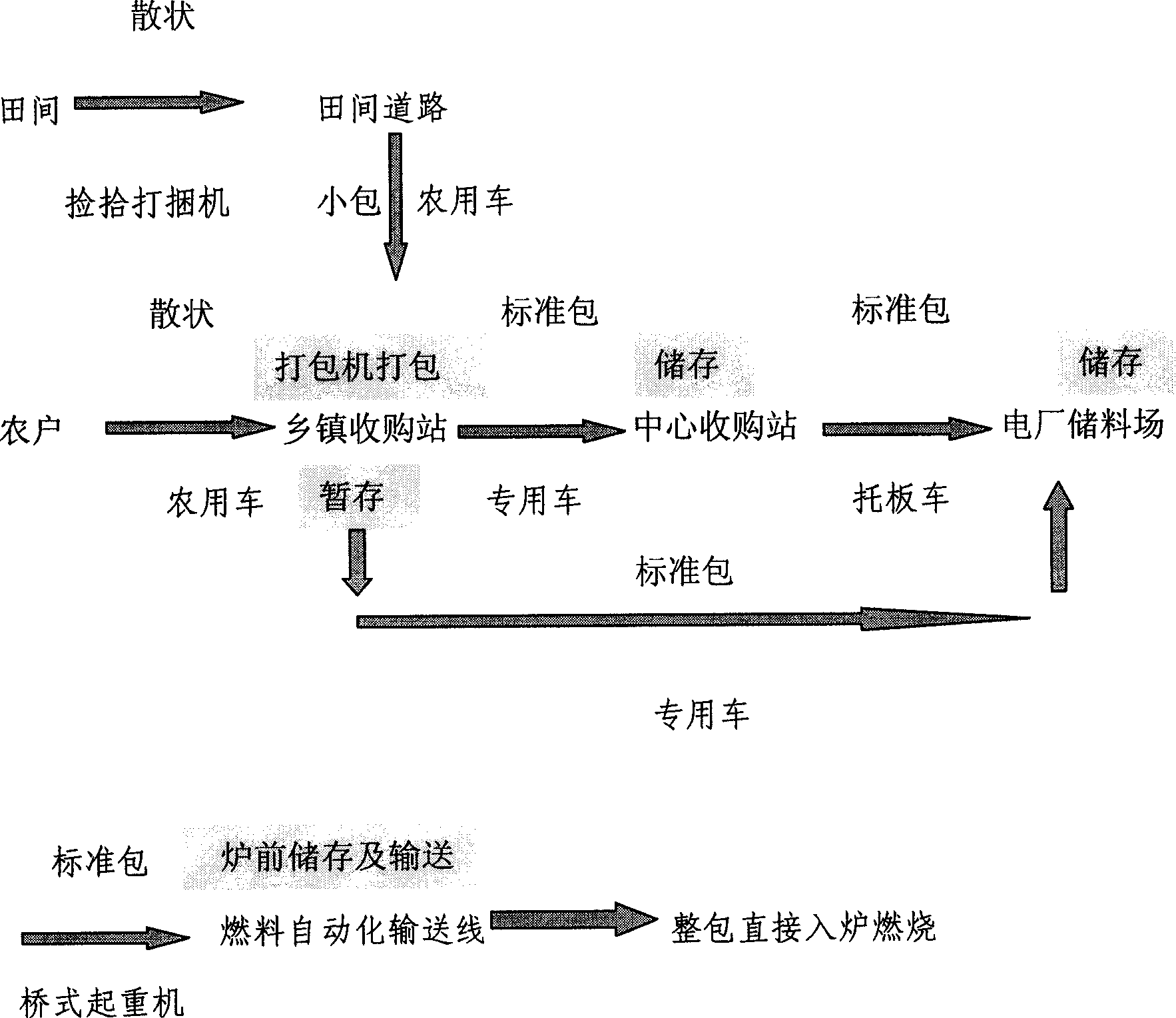

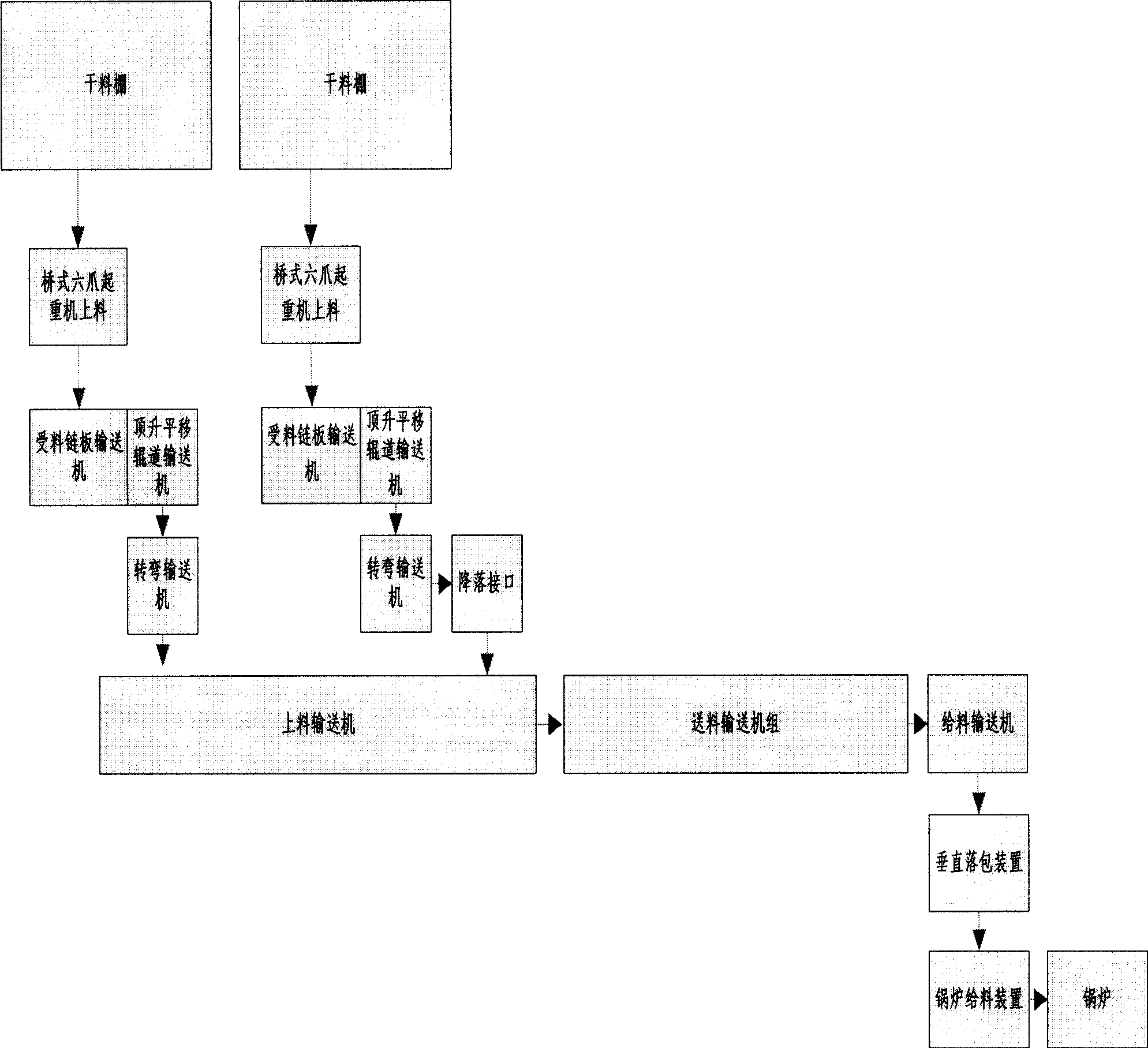

At present, when a biomass power plant burns yellow straws, the mode that the yellow straws are packed and then crushed, or crushed and then packed and baled off is adopted, and as crushing equipment can not adapt to the loose and soft characters of the yellow straws, the crushing effect is poor; and the problems that the crushed straws needs to be conveyed by a spiral packing auger before entering a stove and the packing auger is intertwined by the straws can not be solved. The existing operating power plant which burns the yellow straws now burns rice hulls and peanut shells and the like instead of the yellow straws due to the incapability of solving the problems. In order to achieve the entire pack burning of the biomass fuel and direct burning on a fire grate, a whole set of biomass power plant fuel supply system which adapts to the mode is developed and designed, the system mainly comprises systems and equipment such as a process route which adapts to the mode and a high-density straw packer, a crane and a bucket grab thereof, an automatic conveyor line for entire pack feeding, and the like. The system is successfully applied in Jiangsu Donghai Longyuan Biomass Power Plant.

Owner:GUODIAN LONGYUAN POWER TECH ENG

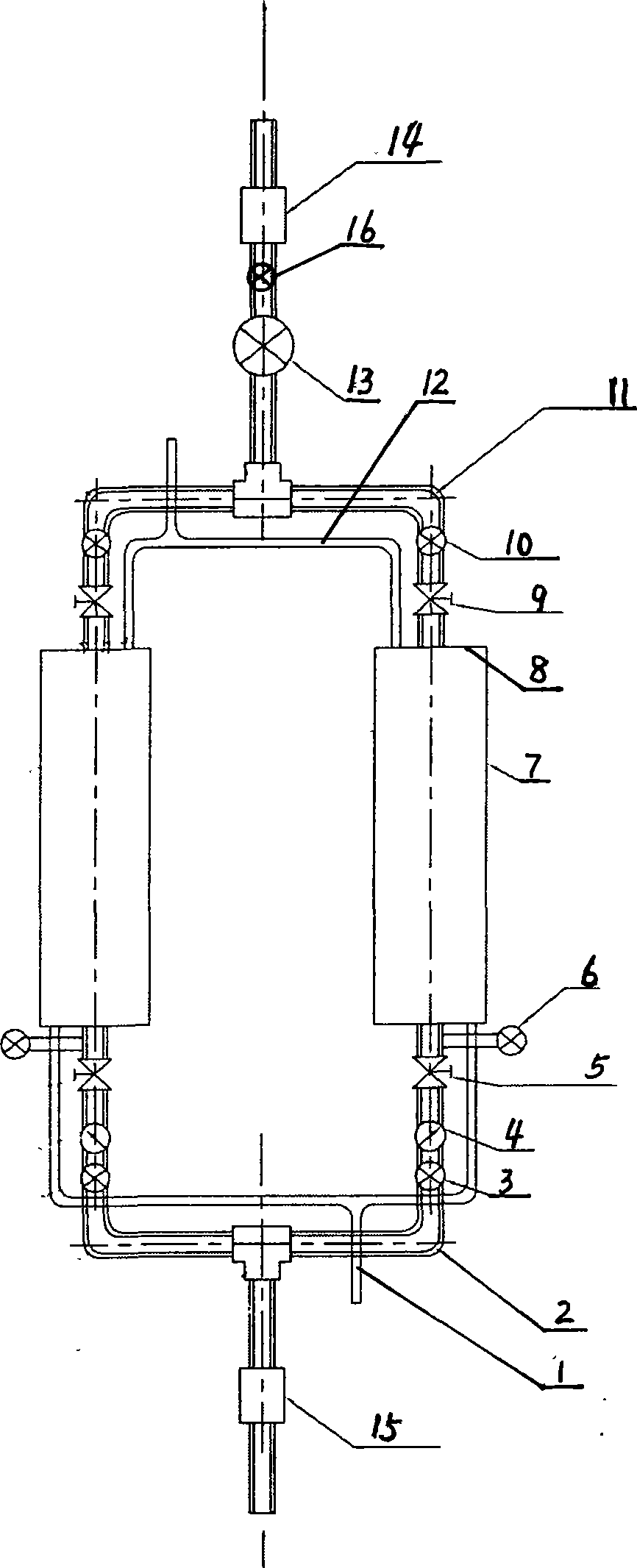

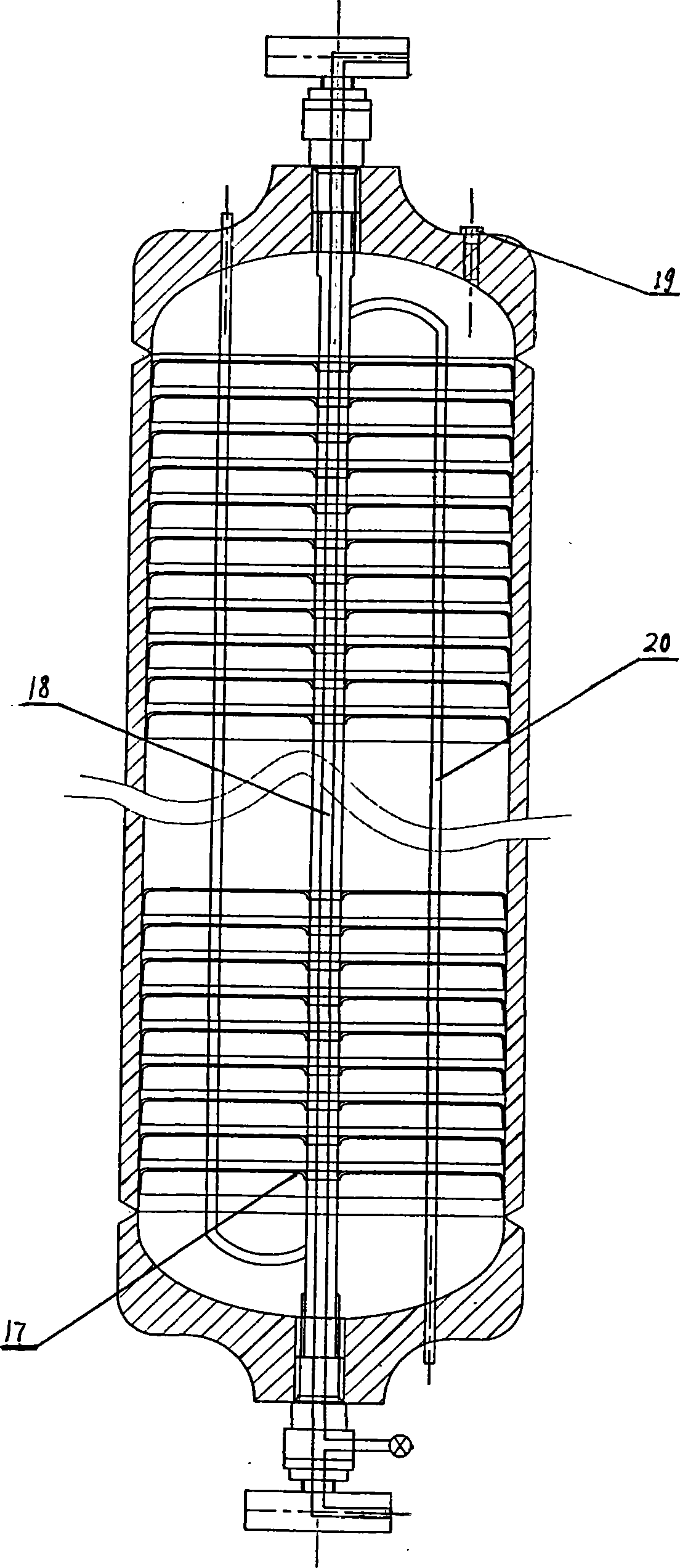

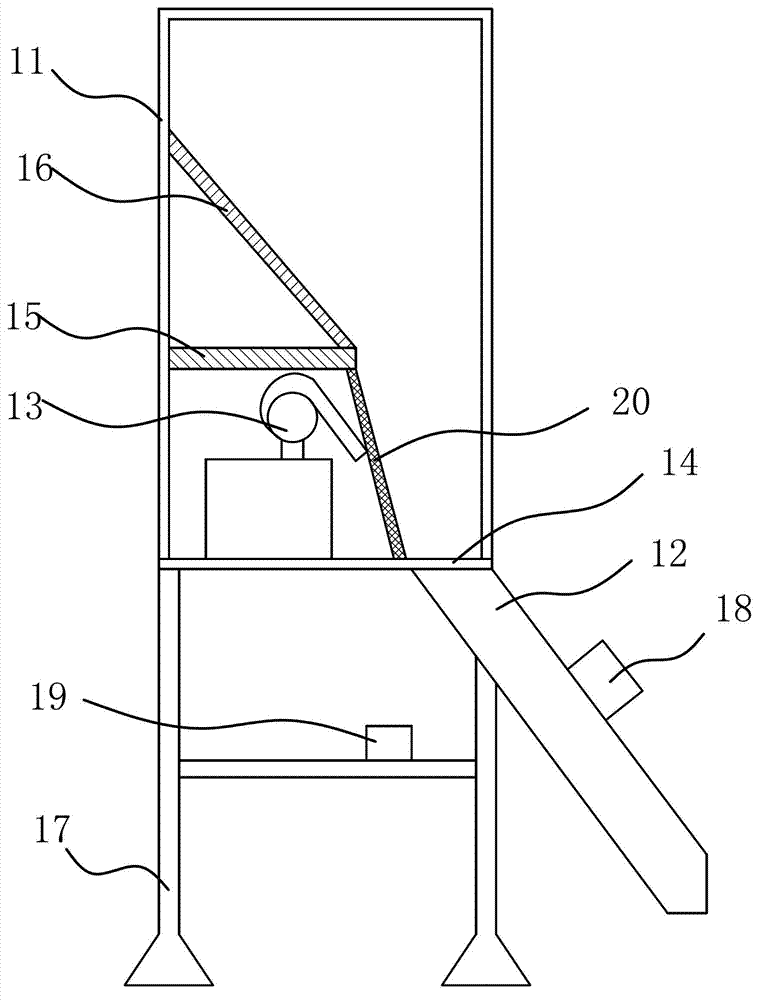

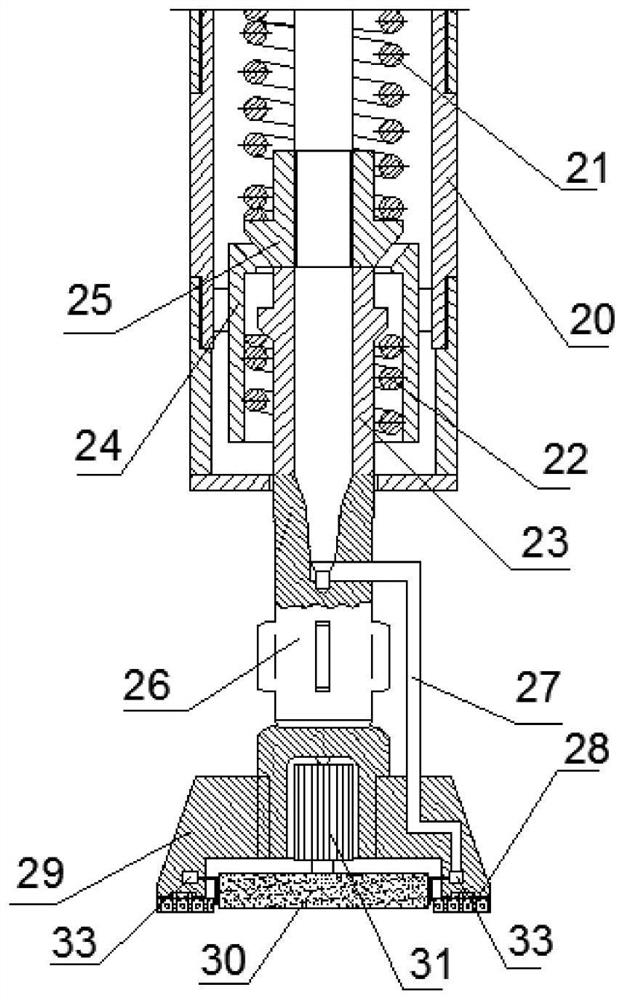

Solid hydrogen-storing conveying apparatus

InactiveCN101251228AImprove dynamic performanceImprove the activation effectFixed capacity gas holdersHydrogen technologiesEngineeringThermal water

The invention provides a solid hydrogen storage conveying device. The device is at least provided with a solid hydrogen storage tank, an end enclosure of one end of the solid hydrogen storage tank is respectively connected with an air inlet pipeline and a cold water pipeline, an end enclosure of the other end is respectively connected with an air outlet pipeline and a hot water pipeline, the air inlet pipeline is connected with a safety valve and a pressure transmitter, the air outlet pipeline is connected with an electromagnetic valve, an air outlet collection pipe is also connected with a master control electromagnetic valve and a master control pressure reducing valve.

Owner:石锋

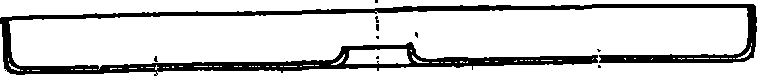

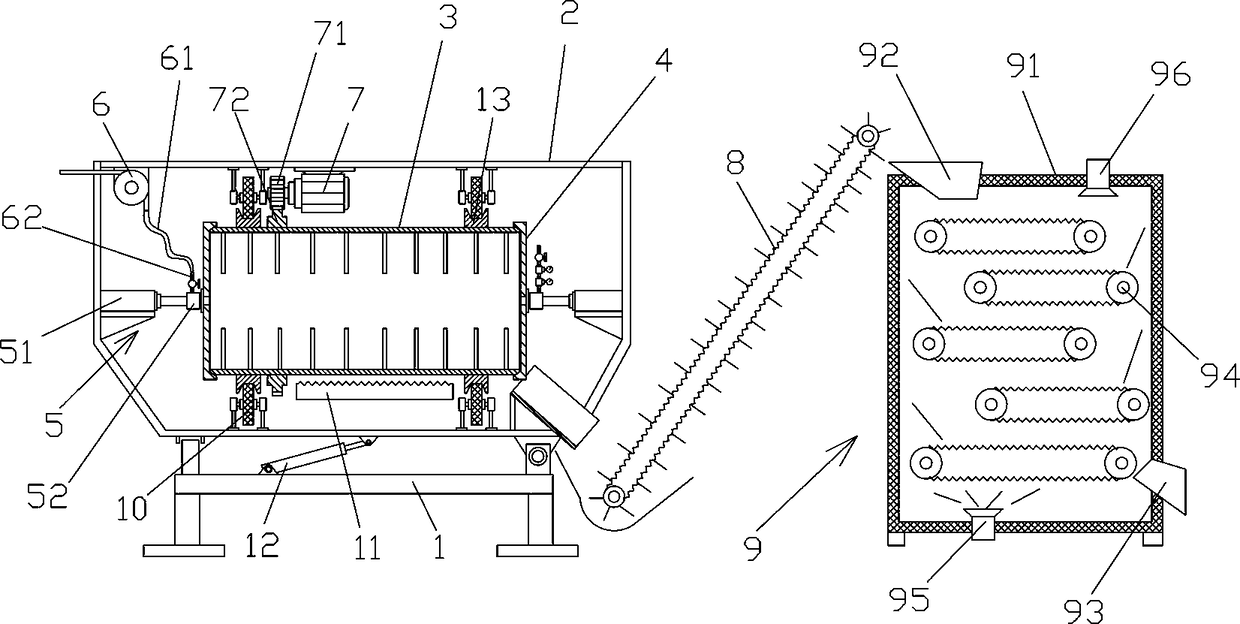

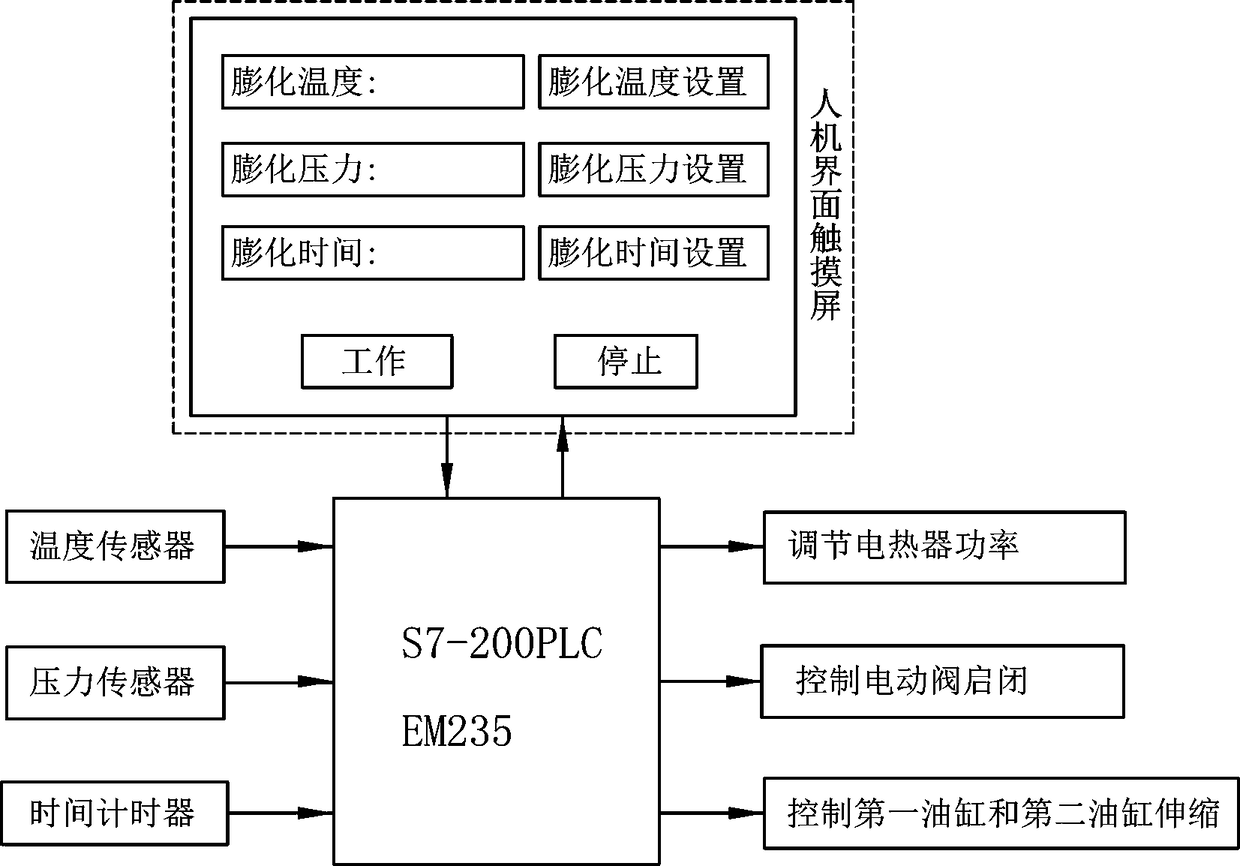

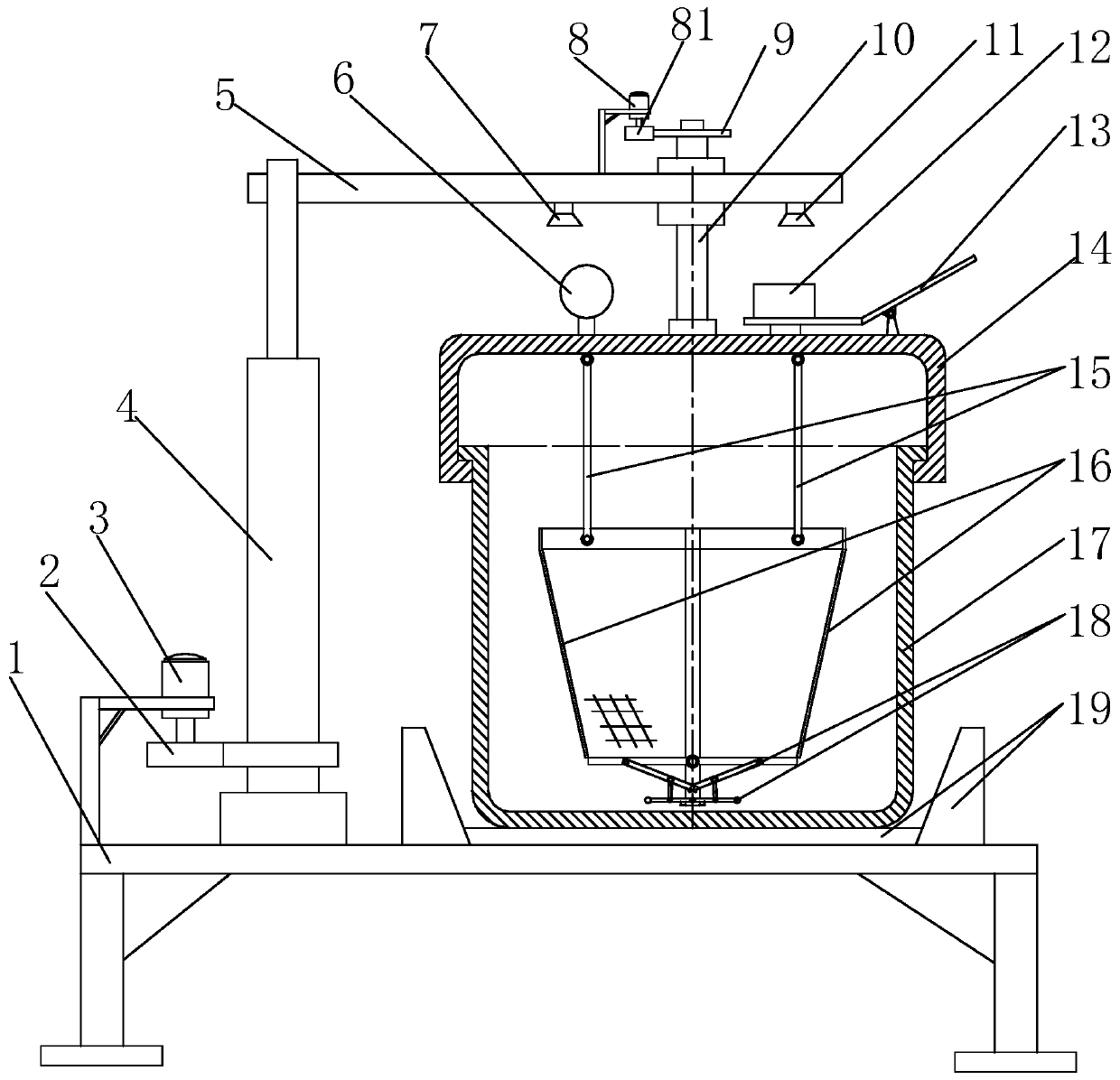

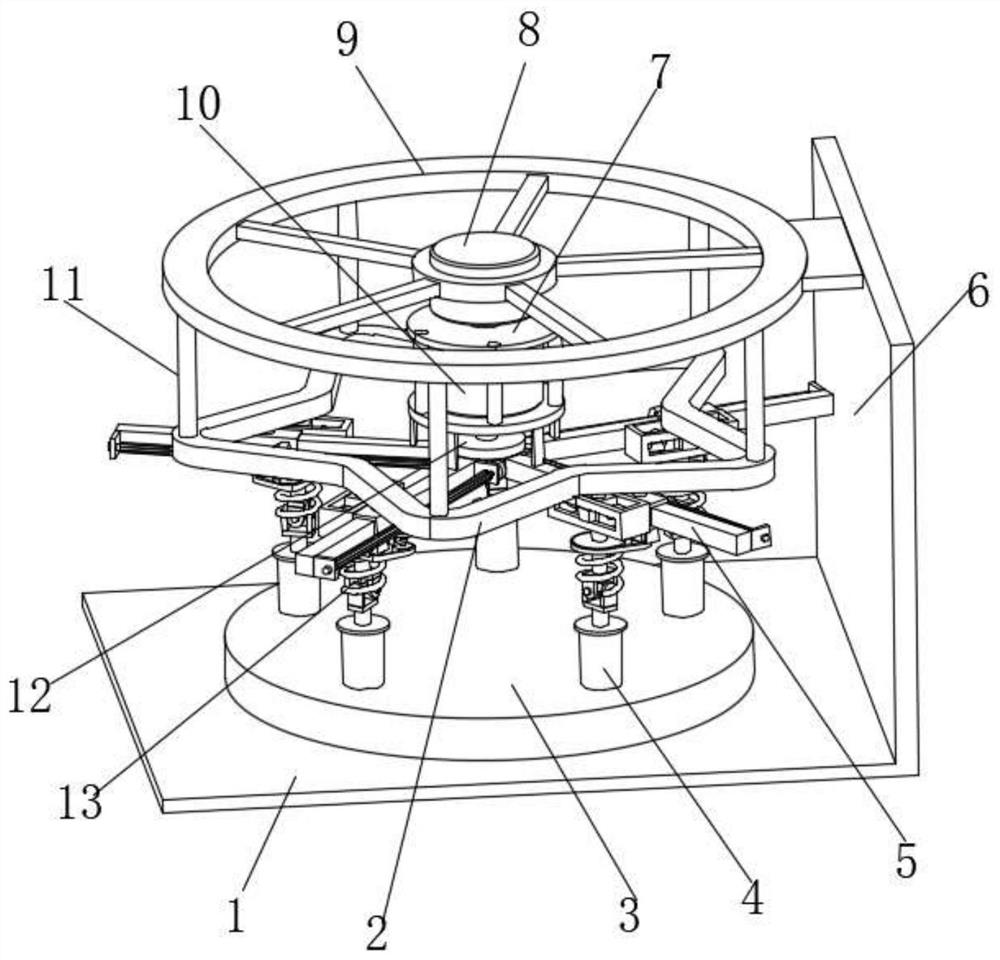

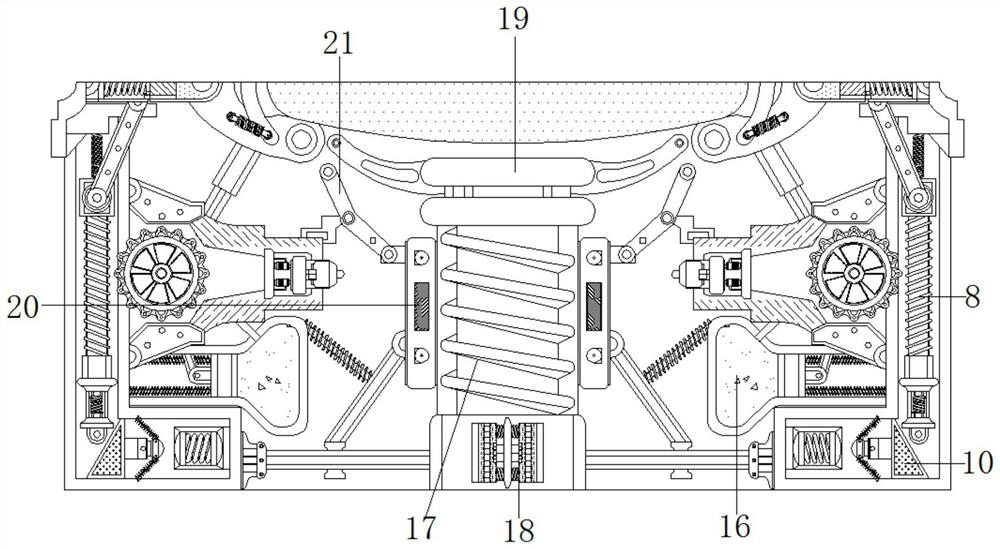

Watermelon seed processing device and method

PendingCN109259275AControl puffing timeControl pressureFood shapingLoading/unloadingEngineeringDrive motor

The invention discloses a watermelon seed processing device and method. The watermelon seed processing device comprises a puffing device, a drying device and a conveying device, the puffing device comprises a support, a rack and a charging barrel, one end of the rack is hinged to the support while the other of the same is connected with the support through a first oil cylinder, a driving motor, anelectric heater and multiple groups of supporting wheels are mounted in the rack, the charging barrel is arranged in the rack, multiple circles of rails are fixedly mounted outside the charging barrel, each rail is assembled on the corresponding supporting wheel, the driving motor drives the charging barrel to rotate on the supporting wheels through a gear and a gear ring, an end cap is mounted on each of two sides of the charging barrel, the electric heater is arranged below the charging barrel, an air incoming pipe and an air exhausting pipe are communicated on the two end caps respectively, and a valve is mounted on each of the air incoming pipe and the air exhausting pipe. The watermelon seed processing device can puff watermelon seeds to enable the surfaces of the watermelon seeds togenerate cracks and damage surface shells of the watermelon seeds, in this way, the watermelon seeds are easy to be shelled.

Owner:WUHAN XUDONG FOOD +1

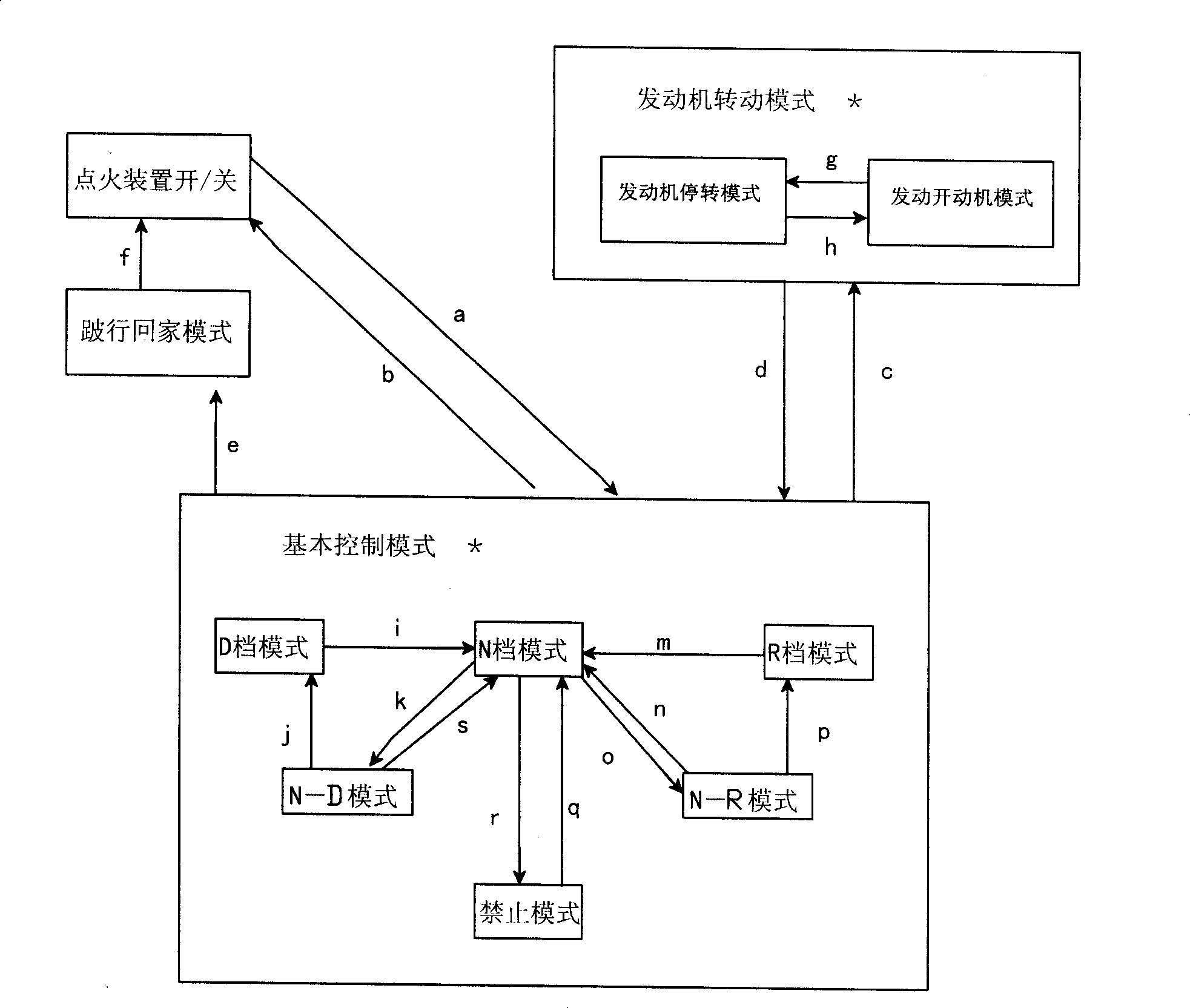

Basic control method for vehicle mounted with CVT

ActiveCN101363535AExtend your lifeReduce unnecessary impactGearing controlDriver/operatorMotor drive

The invention discloses a method for controlling an automobile equipped with a CVT and the method fully considers the influence of the anthropogenic factors of drivers and the automobile driving environment. The technical scheme is as follows: the method for controlling an automobile equipped with a CVT comprises a basic controlling method for an automobile and a controlling method used when an automobile is in a moving state; the working mode of the basic controlling method comprises a stopping and starting mode, a CVT basic controlling mode, a motor driving mode and a limping back home mode; the working mode of a controlling method used when an automobile is in a moving state comprises a travel reduction mode, a constant speed mode and an acceleration driving mode. The invention controls the CVT according to the anthropogenic factors of drivers, the automobile driving environment and the corresponding controlling strategy, which allows the CTV to realize intelligent controlling, prolongs the service life of part, reduces unnecessary compact, saves fuels, and enhances traveling comfort.

Owner:WUHU WANLIYANG TRANSMISSION CO LTD

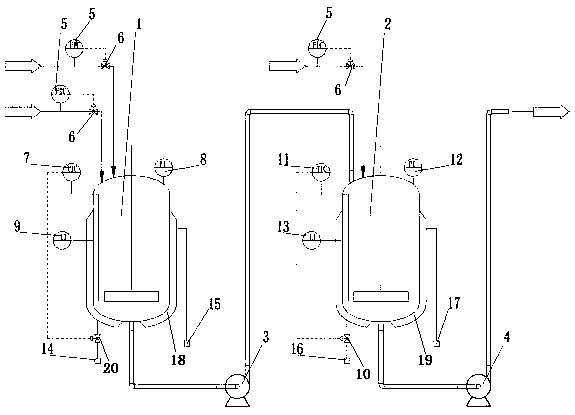

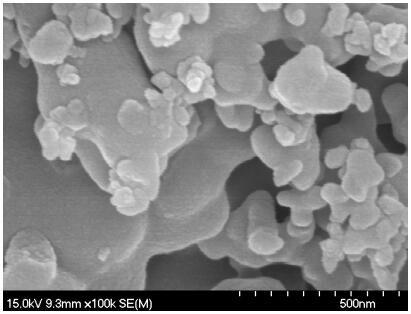

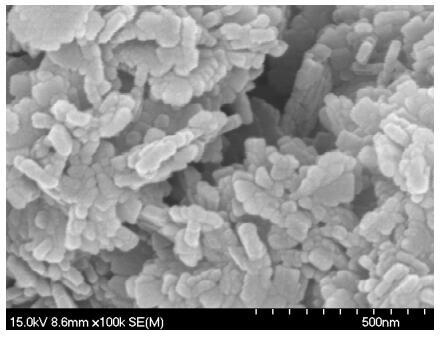

Iron phosphate synthesizing process and device

The invention discloses an iron phosphate synthesizing process and device. The iron phosphate synthesizing process includes: adding an iron solution containing ferrous ions into an oxidation kettle, stirring at the same time, adding an oxidizing agent into the oxidation kettle, controlling the temperature of the solution in the oxidation kettle to be not larger than 70 DEG C, and acquiring an oxidized iron solution after the fact that the solution in the oxidation kettle does not contain the ferrous ions is detected; conveying the oxidized iron solution in the oxidization kettle into a precipitation kettle through an oxidation kettle discharge pump, stirring at the same time, slowly adding a pH regulator into the precipitation kettle to control the pH of the solution in the precipitation kettle to be 1.0-2.5, rising the temperature to 90-95 DEG C after the pH regulation to perform iron phosphate crystal form conversion reaction for 1-4 hours, and then pumping out the iron phosphate suspension in the precipitation kettle after the reaction. The iron phosphate synthesizing process has the advantages that various types of oxidizing agents and pH regulators can be selected, wide raw material selection range is achieved, process equipment is high in automation level, and automatic temperature control, automatic feeding control and automatic pressure alarm can be achieved.

Owner:博创宏远新材料有限公司

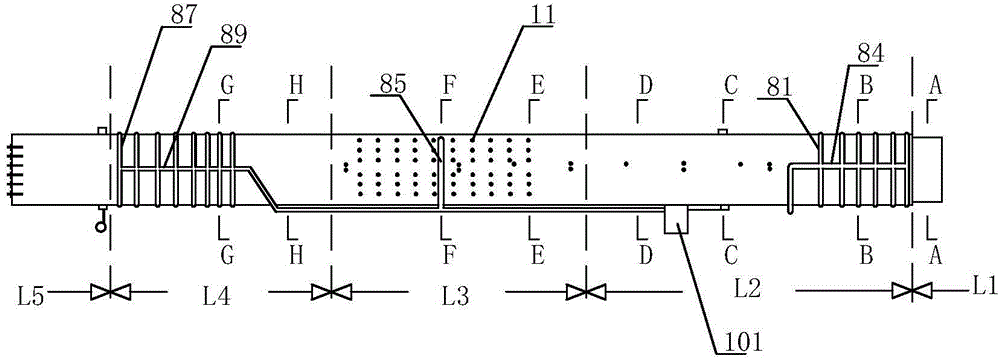

Tunnel kiln with automatic temperature control system

The invention discloses a tunnel kiln with an automatic temperature control system. The tunnel kiln with the automatic temperature control system comprises a kiln body extending horizontally and a kiln car driving in the kiln body. A working channel comprises an entrance section, a preheating section, a sintering section, a holding section and a cooling section in sequence in the extending direction. The sintering section is provided with a first hot air supply device for controlling the temperature in the working channel. The holding section is provided with a second hot air supply device for controlling the temperature in the working channel. The preheating section and the sintering section are provided with a barometric sensor used for sensing the barometric pressure in the working channel and a temperature sensor used for sensing the temperature in the working channel. The temperature sensor and the barometric sensor are connected with a control system, and the control system is connected with a hot air machine. According to the tunnel kiln with the automatic temperature control system, the temperature sensor and the barometric sensor are connected with the control system, and the first hot air supply device and the second hot air supply device are arranged, so that the temperature control and pressure control in the kiln can be achieved, the labor cost is saved, and the scientific management degree is improved.

Owner:长兴震铭耐火材料有限公司

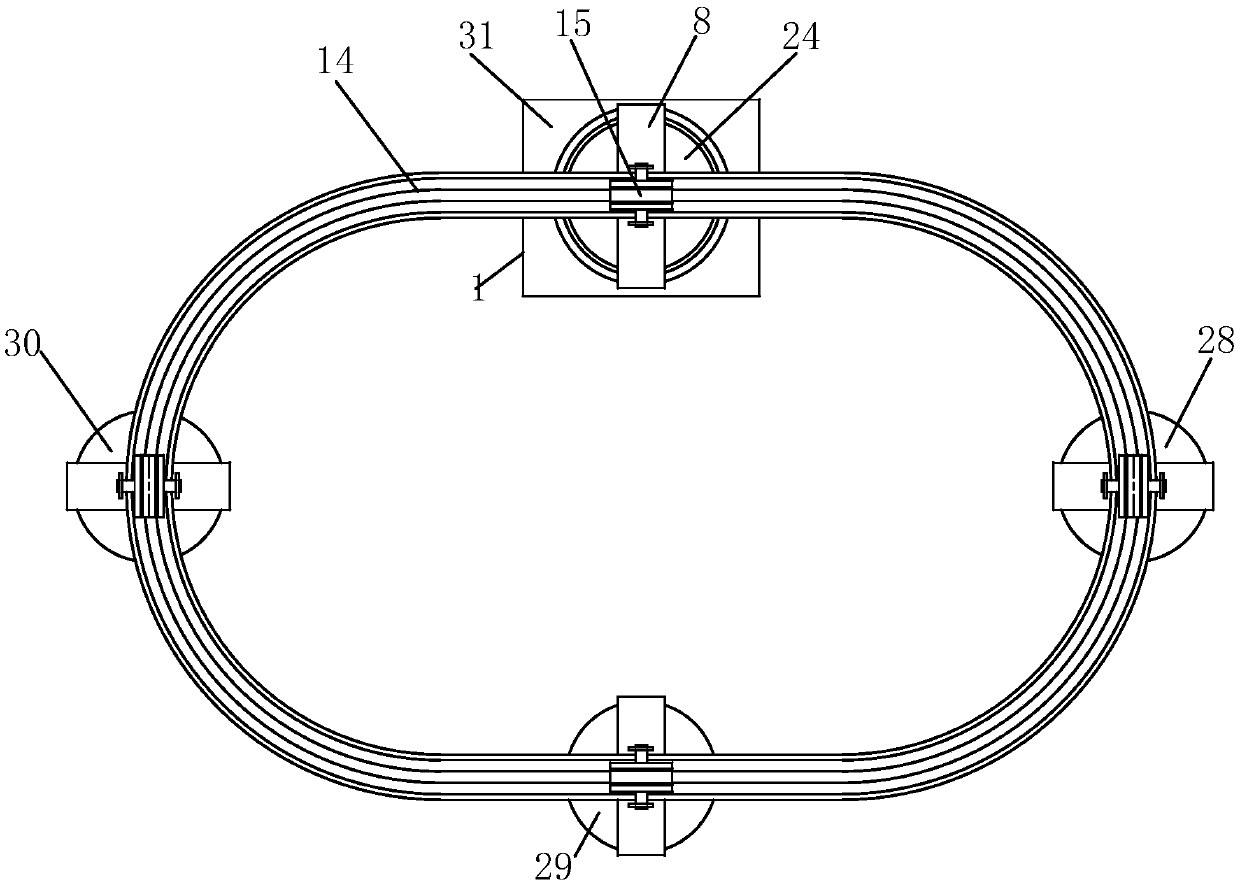

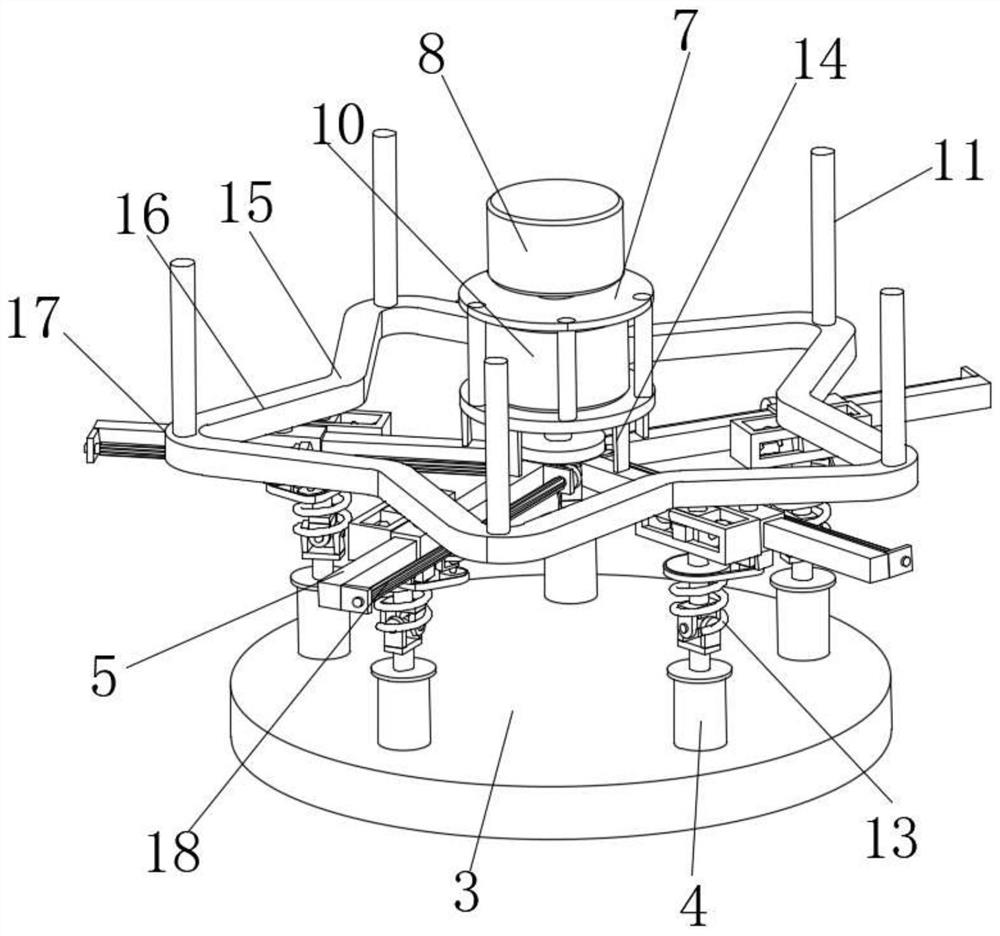

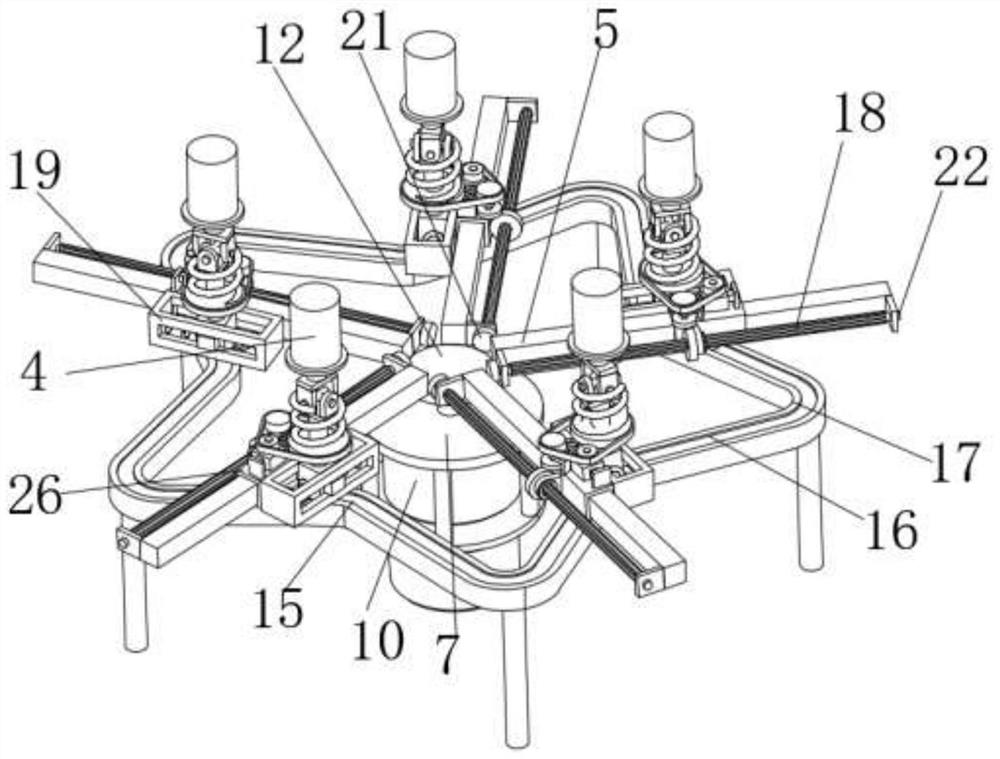

Continuous high-pressure cooking device used for seed nut food

PendingCN109566964AGood cooking effectImprove cooking efficiencyFood scienceFood processingSnack foodEngineering

The invention discloses a continuous high-pressure cooking device used for seed nut food. A top cover is rotatably connected with the top of a pot in a clamped mode, top cover lifting air cylinders are connected with the outer portion of the pot, a top cover fixing frame with a rotating shaft is connected with the top cover lifting air cylinders, a driven gear A is installed at the top end of therotating shaft, a rotating power mechanism is installed on the top cover fixing frame, a driving gear A is installed on a power output shaft of the rotating power mechanism, and the bottom end of therotating shaft is fixed to the top of the top cover; a walking motor is fixedly installed on the top of a walking fixing frame, a driving gear B is installed on a power output shaft of the walking motor, a driven gear B is fixed to the end portion of one end of a walking axle, a walking wheel is fixed to the end portion of the other end of the walking axle, the walking wheel is installed on a guiding rail in a walking matched suspended mode, and a netted material bucket is arranged in an inner cavity of the pot. By means of the continuous high-pressure cooking device used for the seed nut food, multi-station continuous cooking treatment can be conducted on the seed nut snack food, and the problems that kernels can hardly be tasty, shells are hard to crack, energy consumption is high, baking time is long, the efficiency is low, and the like are solved.

Owner:WUHAN XUDONG FOOD +1

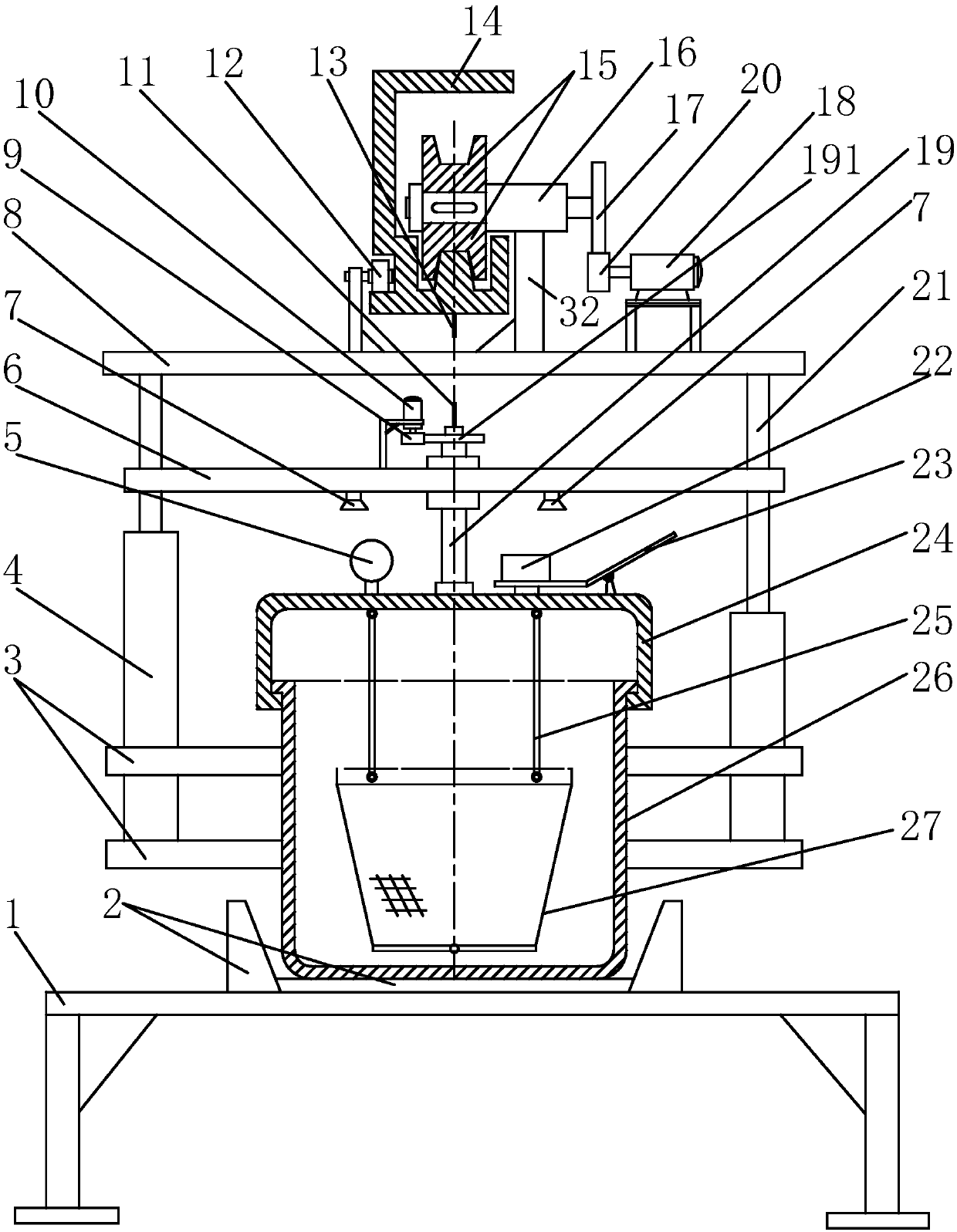

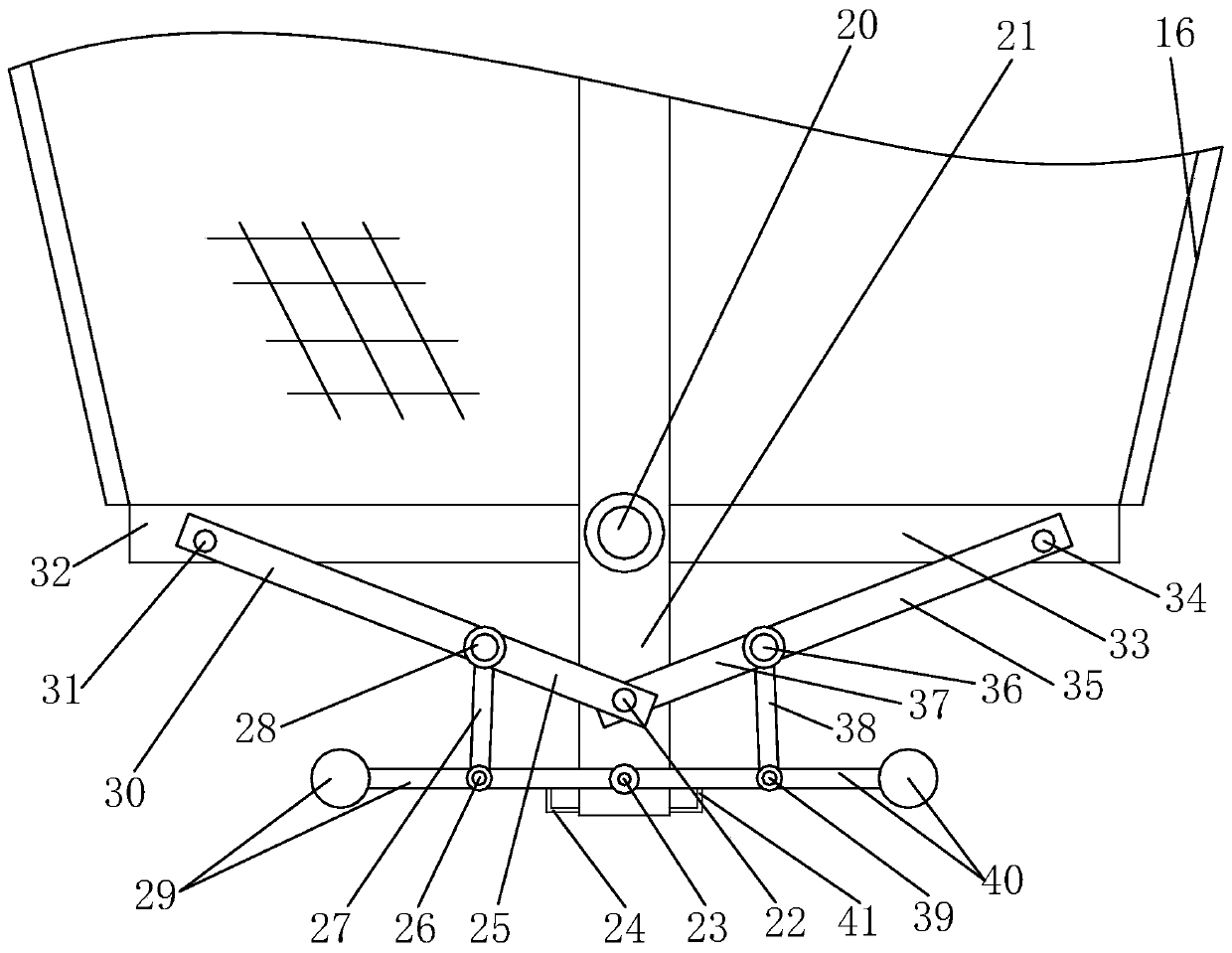

Gap-type high-pressure boiling device for seed nut food

The invention discloses a gap-type high-pressure boiling device for seed nut food. The gap-type high-pressure boiling device for seed nut food comprise a rack, a rotary power mechanism A, a top lift cylinder, a lifting arm, a rotary power mechanism B, a top cover rotating shaft, a top cover, a boiling pot body and a mesh material barrel, the top of the rack is mounted with the rotating power mechanism A through a bracket, a driving gear A is mounted on the rotating power mechanism A, and a driven gear A is mounted on the top lift cylinder; the lifting arm is fixed on the top of a lifting rod of the top lift cylinder, the rotary power mechanism B is mounted on the lifting arm, the driving gear A is mounted on the rotary power mechanism B, the top cover rotating shaft is rotatably mounted onthe lifting arm, and a driven gear B is mounted on the top end of the top cover rotating shaft, the boiling pot body is arranged on an electric heating seat, and the mesh material barrel is arrangedinside the boiling pot body. The device carries out high-pressure boiling treatment on the seed nut snack food, and solves the problems that the seed kernel is difficult to taste, the shell is difficult to remove, the energy consumption is high, the baking time is long, and the efficiency is low.

Owner:WUHAN XUDONG FOOD +1

Self-controlling jump assisting platform

InactiveCN101920088AAutomatic pressure controlAchieving assist heightJumping apparatusAutomatic controlAir spring

The invention relates to a self-controlling jump assisting platform, comprising a table plate and a backward somersault pedal; the bottom part of the table plate is provided with an air spring; the bottom part of the backward somersault is provided with a pedal oil cylinder; the jump-assisting platform is internally provided with an electronic control device; a control output end of the electronic control device is connected with a hydraulic device and a pneumatic device through a signal line; the data input of the electronic control device includes a photoelectric switch installed on the table plate. The electric system automatically controls the pressure of the air spring according to the athlete weight W and required jump assisting height H; because the air spring is controlled along with the magnitude of the charging pressure because of the magnitude of the spring rigidity of the air spring, the magnitude of the jump assisting power is changed in the same jump assisting route, thereby realizing the required jump assisting height H.

Owner:QINGDAO XUNLI TECH

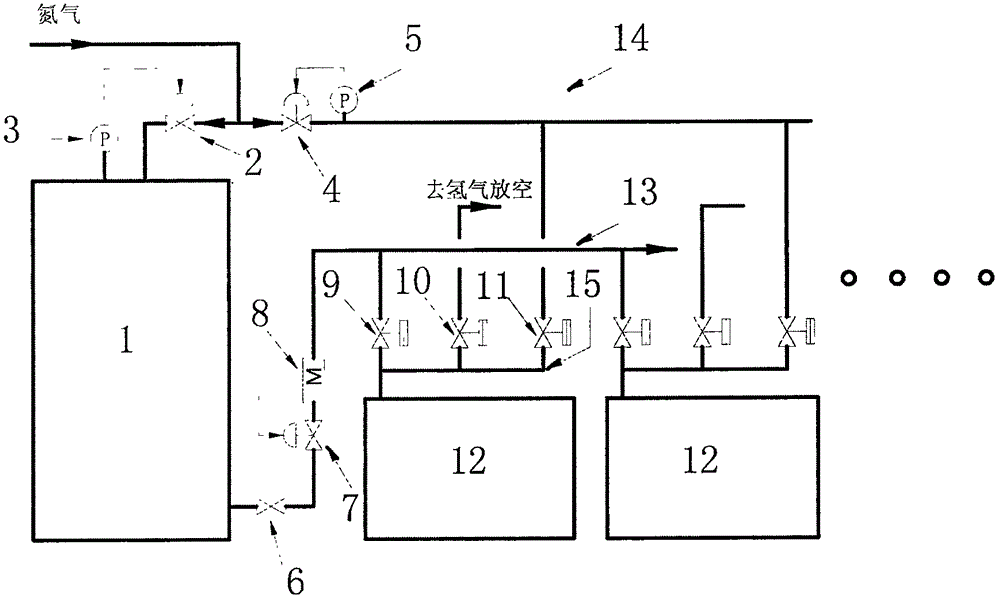

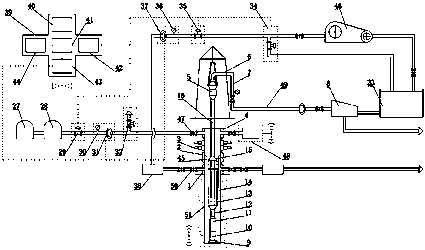

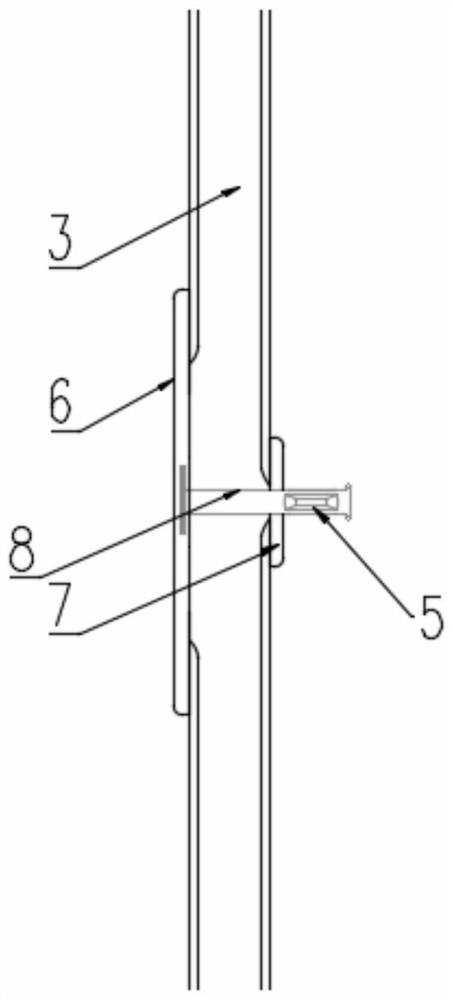

Automatic hydrogen fluoride feeding device for electrolytic bath and using method of automatic hydrogen fluoride feeding device

PendingCN106757145AAutomatic pressure controlStable pressureElectrolysis componentsAutomatic controlPressure balance

The invention discloses an automatic hydrogen fluoride feeding device for an electrolytic bath and a using method of the automatic hydrogen fluoride feeding device. The device comprises a hydrogen fluoride storage tank, an adjusting valve, a flow meter, a hydrogen fluoride passing header pipe, a nitrogen header pipe, a passing pipe and an electric circuit. A storage tank pressure adjusting valve, a corresponding storage tank pressure sensor, a nitrogen pressure adjusting valve, a corresponding nitrogen pressure sensor and the nitrogen header pipe are sequentially in pipe connection with the top of the hydrogen fluoride storage tank. A pipeline between the storage tank pressure adjusting valve and the nitrogen pressure adjusting valve communicates with a nitrogen source. One end of a nitrogen replacement valve is connected with the nitrogen header pipe, and the other end of the nitrogen replacement valve is connected with the passing pipe. A hydrogen fluoride outlet in the bottom of the hydrogen fluoride storage tank is sequentially in pipeline connection with the hydrogen fluoride flow adjusting valve, the hydrogen fluoride flow meter and the hydrogen fluoride passing header pipe. One end of a hydrogen fluoride passing valve is connected with the passing header pipe, and the other end of the hydrogen fluoride passing valve is connected with the passing pipe. One end of a pressure balance valve is connected with the passing pipe, the other end of the pressure balance valve communicates with a nitrogen emptying system, and the electric circuit comprises an electrolytic bath current sampling device and an automatic control system. The electrolytic bath can operate stably through the automatic hydrogen fluoride feeding device.

Owner:昊华气体有限公司

Gear machining deburring machine

InactiveCN112809478AEasy to cleanSimple structureEdge grinding machinesGrinding carriagesGear wheelElectric machinery

The invention relates to the technical field of gear machining, in particular to a gear machining deburring machine. The gear machining deburring machine comprises a top frame, a first motor is fixed to the top frame, an output shaft of the first motor is connected with a mounting frame, a second motor is fixed to the mounting frame, the end of an output shaft of the second motor is connected with a driving gear, the mounting frame is fixedly connected with a plurality of sliding rods through fixing plates, the sliding rods are annularly arrayed around the driving gear, supporting plates are perpendicularly fixed to two ends of each sliding rod, a rotating shaft is rotationally connected between each two supporting plates, one end of each rotating shaft is coaxially connected with a transmission gear, the transmission gears are meshed with the driving gear, the middle of each rotating shaft is provided with a spline shaft coaxially arranged with the rotating shaft, each sliding rod is sleeved with a sliding sleeve in sliding fit with the sliding rod, a mounting plate is fixed to each sliding sleeve, and a rotating ring is rotationally mounted on each mounting plate. With the gear machining deburring machine, the working efficiency of gear deburring machining can be improved.

Owner:蚌埠美域装饰工程有限公司

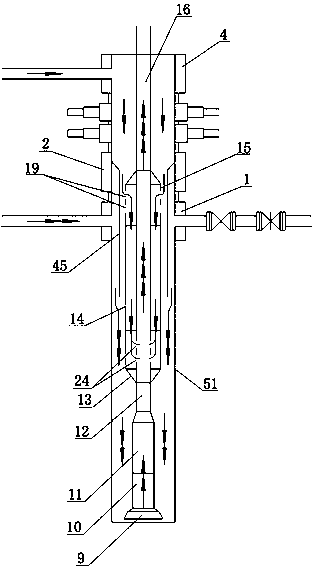

Gas-lift reverse circulation well drilling system and automatic control method

ActiveCN110608005ASimple on-site operationEasy process changeConstructionsGeothermal energy generationAutomatic controlDouble wall

The invention discloses a gas-lift reverse circulation well drilling system and an automatic control method. The system comprises a wellhead device, an in-well drilling tool, a flow line, a gas injecting pipeline, a drilling liquid injecting pipeline and an automatic control system, wherein the in-well drilling tool comprises a drill bit, a downhole electromagnetic PWD, a drill collar, a lower single-wall drill rod, a gas-water mixer, a double-wall drill rod, an air injection valve and an upper single-wall drill rod; each of the gas injecting pipeline and drilling fluid injecting pipeline is provided with an automatic throttle valve, a pressure gauge, a flowmeter and an automatic pressure relief valve; the automatic control system comprises a signal receiver, a computer, a display, a PLC (programmable logic controller) and a parameter input module; and during the gas lift reverse circulation drilling process, the automatic control system monitors the bottom pressure in real time, adjusts the gas injection quantity parameter and the drilling fluid injection parameter and realizes the automatic and accurate control of the bottom pressure. The system has the beneficial effects that the well control risk is reduced by matching with conventional well control equipment at a well mouth; and the bottom hole pressure is accurately controlled to prevent the occurrence of lost circulationand overflow.

Owner:SOUTHWEST PETROLEUM UNIV

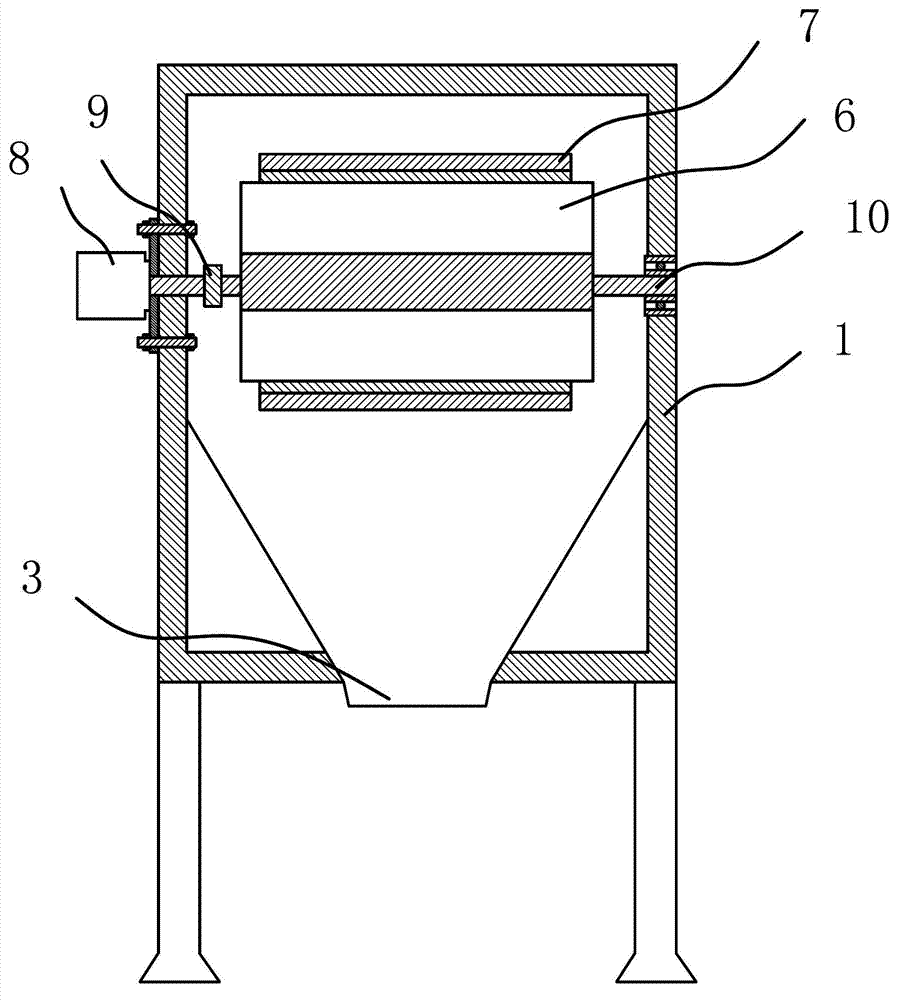

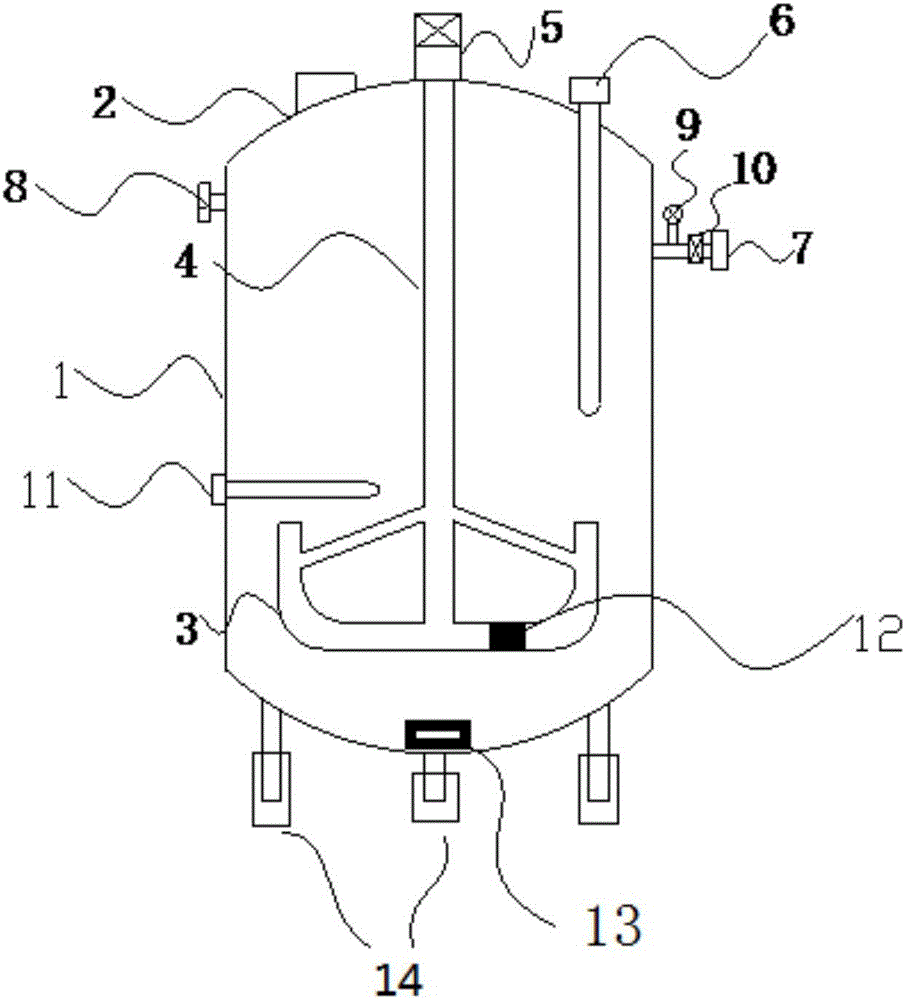

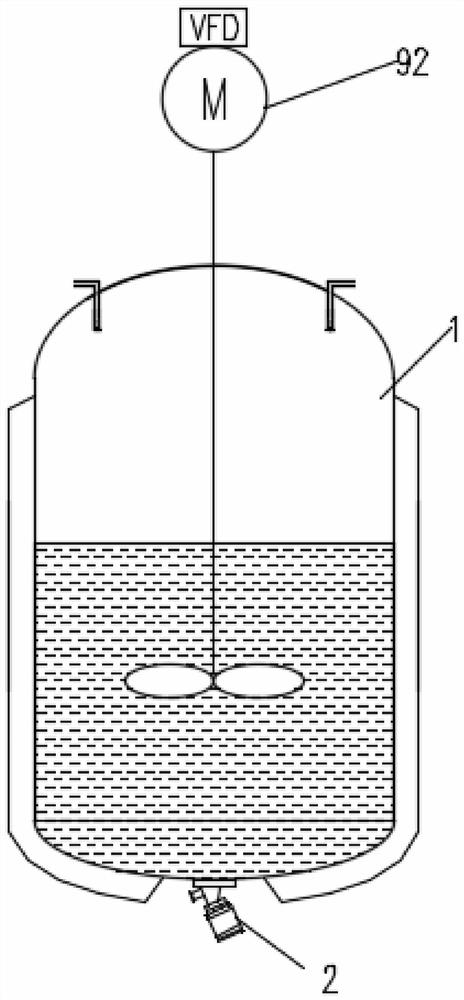

System for generating sewage gas by straw

ActiveCN103194387ASimple structureEasy to maintainBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringSewage

The invention provides a system for generating sewage gas by a straw, belongs to the technical field of sewage gas, and solves the technical problems that the existing sewage gas production system is complicated in structure, low in biogas production efficiency, low in automatic degree and the like. The system for generating the sewage gas by the straw comprises a straw crusher, a methane tank, and a delivery device which is arranged between the straw crusher and the methane tank; a rotating mechanism capable of driving a moving cutter cylinder and making a moving blade tangent with a fixed blade is arranged on the straw crusher; the delivery comprises a transport cylinder, a delivery pipe and a fan; the methane tank comprises a tank body, a tank cover, a connecting pipe 1 and an air storage tank; the methane tank is provided with a control mechanism 1 and a control mechanism 2; the first control mechanism 1 can stabilize the pressure of the methane tank; and the control mechanism 2 can adjust the temperature of the methane tank. The system disclosed by the invention has the advantages of simple structure, high gas production efficiency, security, stability, and high automatic degree; and the energy source can be saved.

Owner:ZHEJIANG FORESTRY UNIVERSITY

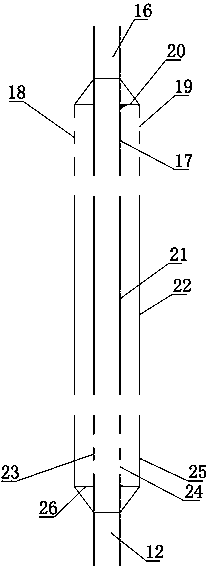

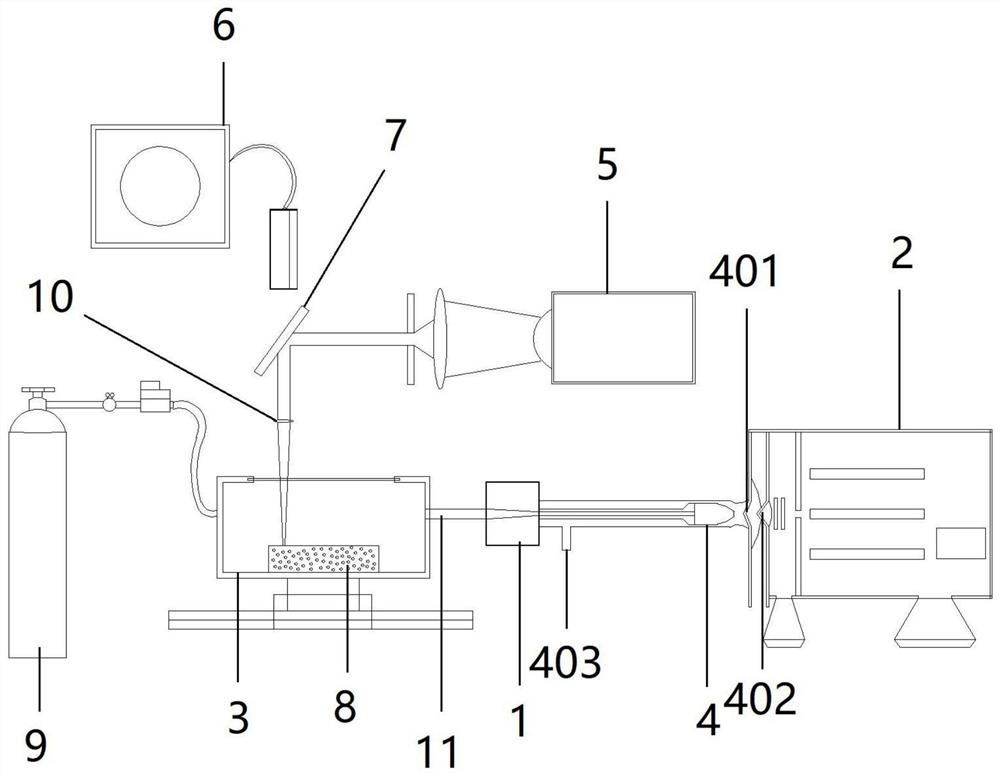

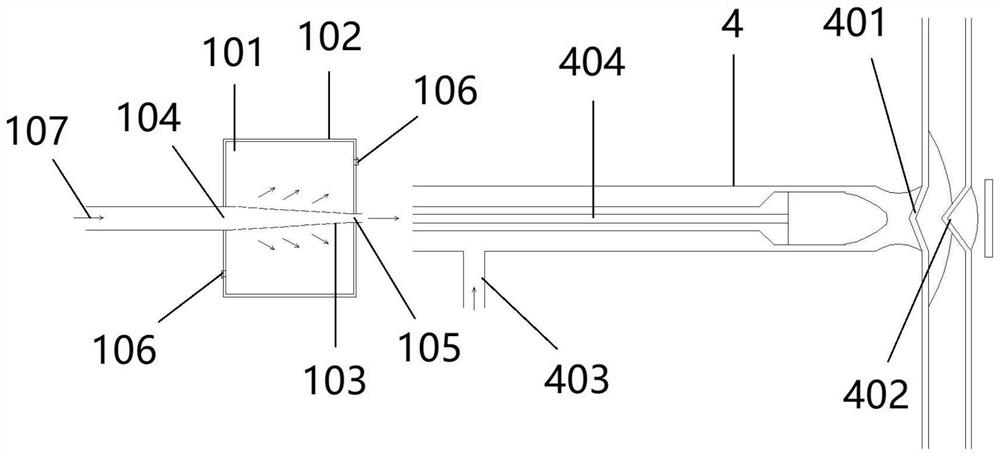

Aerosol sample injection focusing device of laser ablation plasma mass spectrometer

PendingCN111855791AIncrease concentrationIncreased number of ionsWithdrawing sample devicesMaterial analysis by electric/magnetic meansPhysical chemistrySemipermeable membrane

The invention discloses an aerosol sample injection focusing device of a laser ablation plasma mass spectrometer. The device comprises an aerosol focalizer, a plasma mass spectrometer, an ablation pool and a laser. A sample to be ablated is placed in the ablation pool; carrier gas aerosol is conveyed into a carrier gas aerosol hose connected with the other end of the ablation pool; the carrier gasaerosol hose is connected with a gas inlet tube orifice of the aerosol focalizer and is used for oozing carrier gas; the rear end of a semi-permeable membrane tube is connected with a gas outlet tubeorifice; a sealing box surrounds the semi-permeable membrane tube to form an aerosol focalizer cavity; an electric flashboard is installed outside a gas release tube orifice to control the pressure in the aerosol focalizer cavity; and the carrier gas aerosol in a central tube enters the plasma mass spectrometer after being atomized and ionized, and a to-be-detected element in the aerosol is detected. By discharging the carrier gas, the ion concentration of the to-be-detected element entering the plasma mass spectrometer is increased, so that the sensitivity of the instrument is improved, andthe detection limit of the to-be-detected element is effectively improved under the condition that other instruments and devices are not changed.

Owner:SHANDONG INST OF GEOLOGICAL SCI

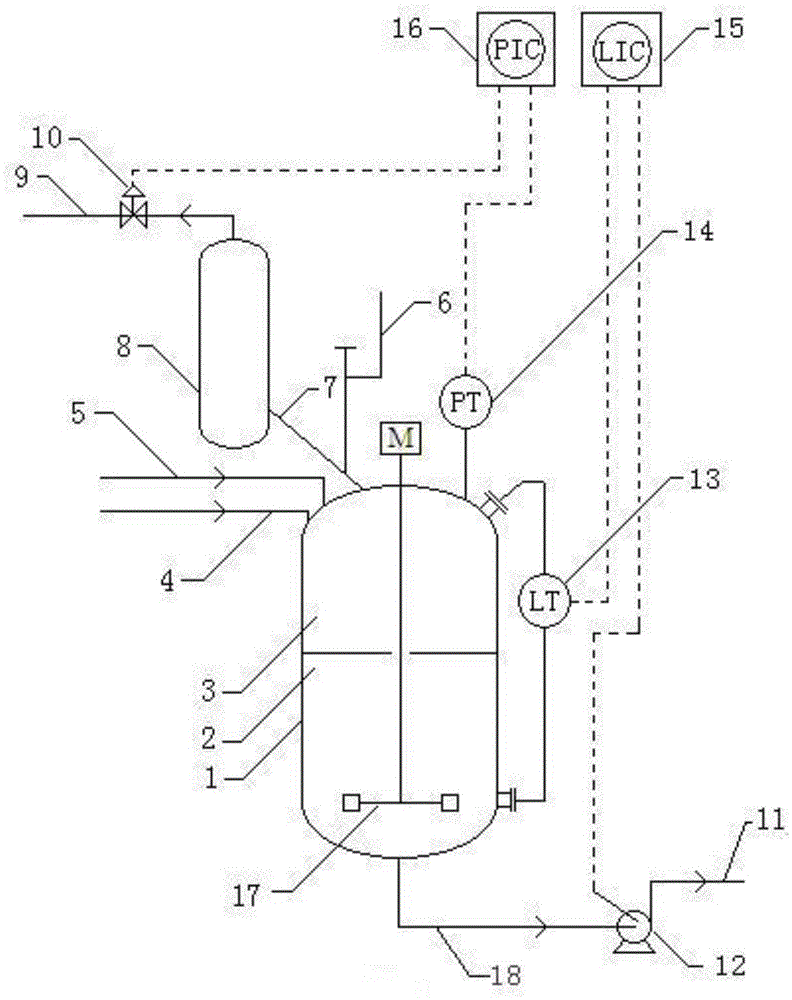

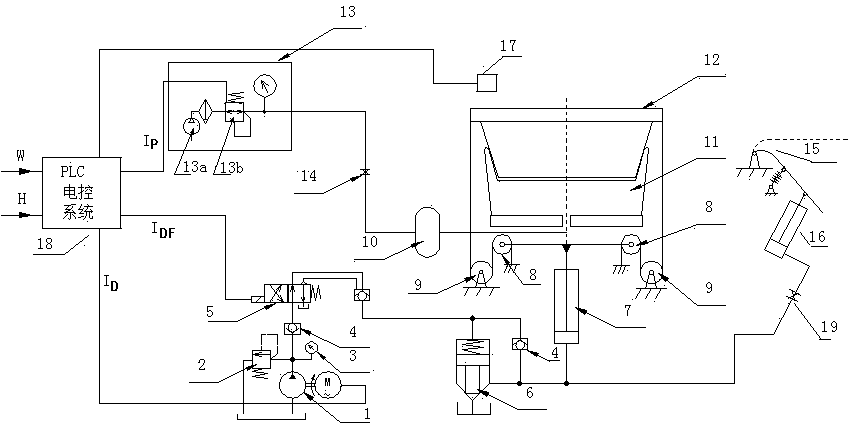

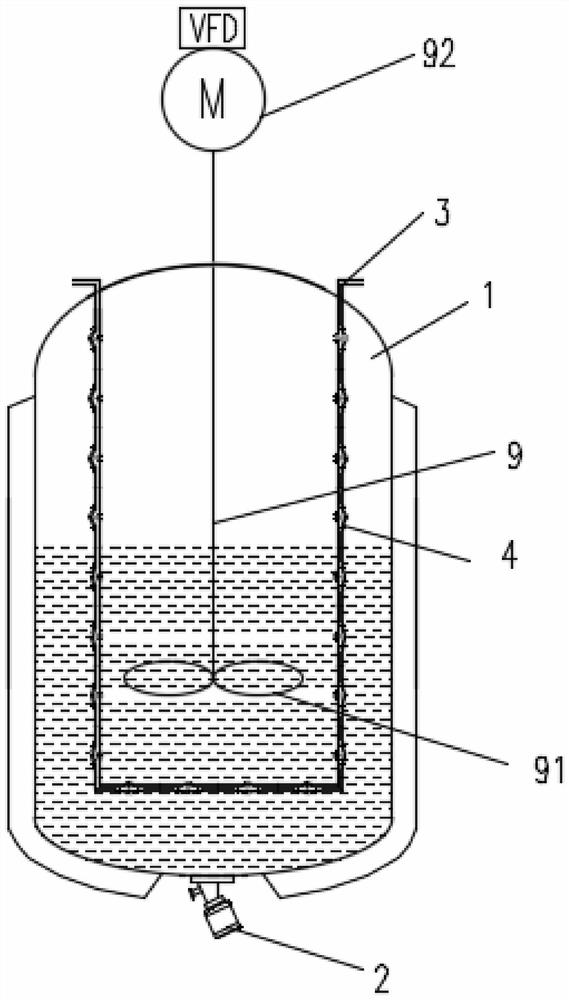

Method and automatic control system for producing polyisobutylene by continuous polymerization

ActiveCN104193858BAutomatic pressure controlEasy and accurate automatic controlChemical industrySimultaneous control of multiple variablesAutomatic controlControl system

The invention discloses a method and an automatic control system for carrying out continuous polymerization production of polyisobutene and belongs to the field of production process control. The method comprises the following steps: continuously adding reaction raw materials and a catalyst into a reactor according to a specified proportion to carry out polymerization reaction, continuously discharging reaction products from the bottom of the reactor, wherein the automatic control system for carrying out continuous polymerization production of polyisobutene is used for automatically controlling the liquid level and the pressure of the reactor; presetting the liquid level and the set pressure value of the reactor according to the actual production, carrying out real-time measurement on the liquid level and the pressure of the reactor by virtue of the automatic control system, comparing measured values with preset values, calculating and outputting a control signal so as to control the liquid level and the pressure of the reactor within a control range of the set values to realize the continuous and automatic production of polyisobutene.

Owner:SHANDONG HONGRUI NEW MATERIAL TECH

Mobile glass-lined reactor having regulating function

InactiveCN106179163ATemperature measurementAutomatic pressure controlChemical/physical/physico-chemical stationary reactorsElectricityThermometer

The invention discloses a mobile glass-lined reactor having a regulating function and belongs to the technical field of glass-lined reaction devices. The mobile glass-lined reactor comprises a tank body, a tank cover, a steam outlet, a stirrer with a stirring blade, a motor, an electric cabinet, a rotating speed sensor and action wheels. The motor is connected with the stirrer, the electric cabinet is electrically connected with the motor, the rotating speed sensor is installed on the stirring blade at the bottom of the stirrer, a thermometer I penetrating the tank cover to be vertically placed in the tank body is arranged in the tank body, the tank body is further provided with the steam outlet, the steam outlet is provided with a pressure meter and an automatic pressure release valve, the lower portion of the tank body is provided with a thermometer II horizontally placed in the tank body, the number of the action wheels is three, and the action wheels are installed at the bottom of the tank body to be of a triangular structure. The mobile glass-lined reactor has the advantages of being simple in structure and capable of accurately controlling reaction temperature and intensity of pressure, saving labor force and being high in stability and mobile and the like.

Owner:安庆钰龙橡塑机械制造有限公司

Mobile glass lining reaction vessel with vibrating function and regulating function

InactiveCN106076226ASimple structureImprove work efficiencyProcess control/regulationChemical/physical/physico-chemical moving reactorsRelief valveThermometer

The invention discloses a mobile glass lining reaction vessel with a vibrating function and a regulating function, and belongs to the technical field of glass lining reaction devices. The mobile glass lining reaction vessel comprises a vessel body, a vessel cover, a steam inlet, a stirrer with a stirring blade, a motor, an electric control cabinet, a revolution speed sensor and an electromagnetic vibrator; the motor is connected with the stirrer, the electric control cabinet is electrically connected with the motor, the revolution speed sensor is installed on the stirring blade arranged at the bottom of the stirrer, a first thermometer which penetrates through the vessel cover to be vertically arranged in the vessel body is arranged in the vessel body, the vessel body is further provided with a steam outlet, the steam outlet is provided with a pressure gauge and an automatic pressure relief valve, the lower portion of the vessel body is provided with a second thermometer which is horizontally arranged in the vessel body, three action wheels are installed at the bottom of the vessel body to form a triangular structure, and the electromagnetic vibrator is installed at the bottom of the vessel body. The mobile glass lining reaction vessel has the advantages that the structure is simple, the reaction temperature and pressure can be precisely controlled, and labor is saved.

Owner:安庆钰龙橡塑机械制造有限公司

Space stable-pressure fountain pen

The present invention is a space stabilized water pen for astronauts to write in space. The motor is connected to the components of the ink pressure tank and the ink booster pump in the hole of the pen holder. The two are connected by a pipe. The check valve is installed on the connecting pipe, the pressure switch is installed on the outer wall of the pressure tank, and the pump casing is a closed tube. The tube is movably connected to a screw shaft, the micromotor is connected to the screw shaft, the pump casing is provided with an ink pipe, the micromotor and the battery are installed at the end of the pen holder, the pen tip is installed in the front hole of the pen holder, the capillary tube connects the pen tip with the regulator tank, and the battery The pressure switch is electrically connected with the micro-motor, and the pressure switch controls the stop and start of the micro-motor and the ink pressure in the pressure-stabilizing tank. This space stabilized water pen can automatically adjust the ink pressure, which is very convenient to use in space.

Owner:王秋华

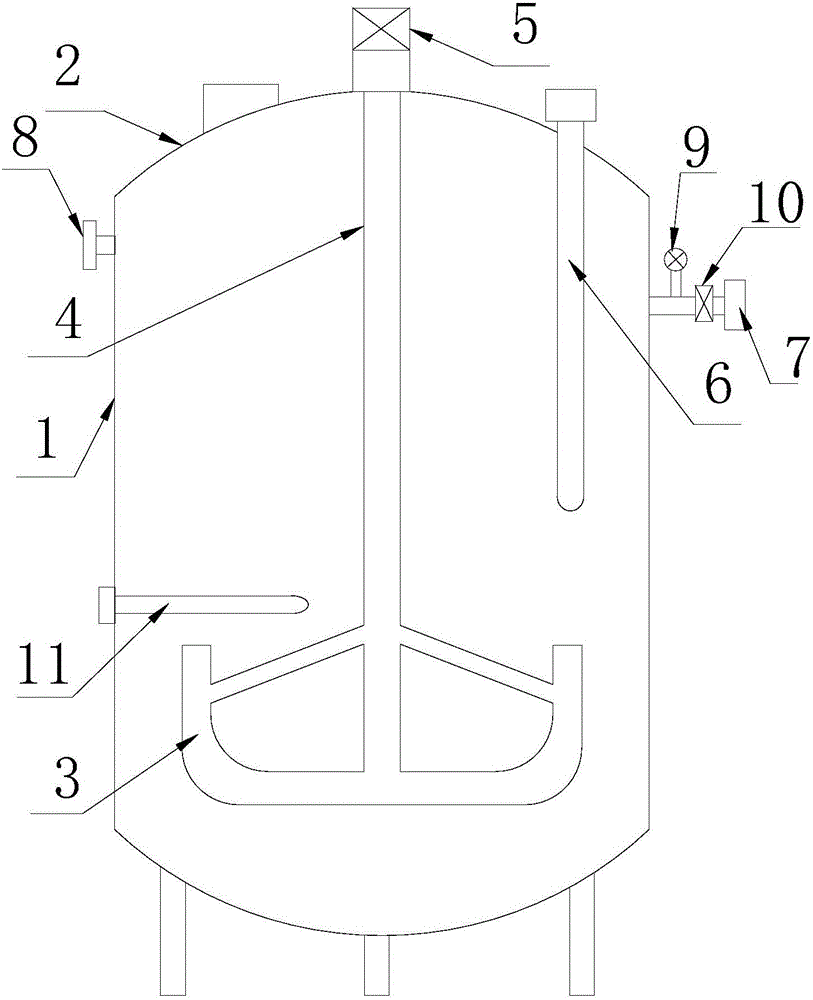

Glass-lined reactor

InactiveCN106076223ASimple structureImprove work efficiencyProcess control/regulationChemical/physical/physico-chemical stationary reactorsThermometerReaction temperature

The invention discloses a glass-lined reactor, and belongs to the technical field of glass-lined reaction devices. The glass-lined reactor comprises a tank body, a tank cover, a steam inlet, a stirrer with stirring blades and a motor, wherein the motor is connected with the stirrer, a thermometer I penetrating the tank cover is vertically placed in the tank body, a steam outlet is formed in the tank body and is provided with a pressure gauge and an automatic pressure release valve, a thermometer II horizontally placed in the tank body is arranged on the lower portion of the tank body, the thermometer I and the thermometer II are placed on two sides of the stirrer respectively, and the thermometer II is placed above the stirring blades. The glass-lined reactor has the advantages of simple structure and capabilities of accurately controlling reaction temperature and pressure and reducing manpower.

Owner:安庆钰龙橡塑机械制造有限公司

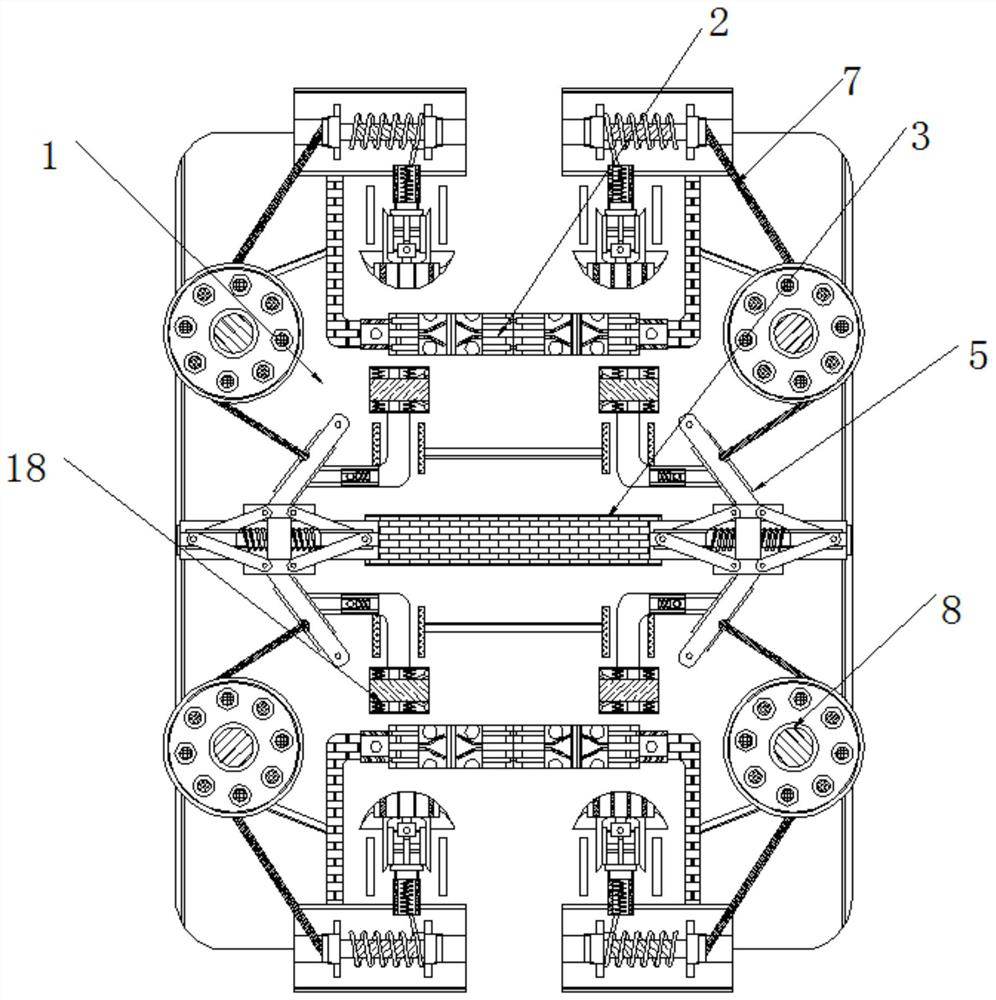

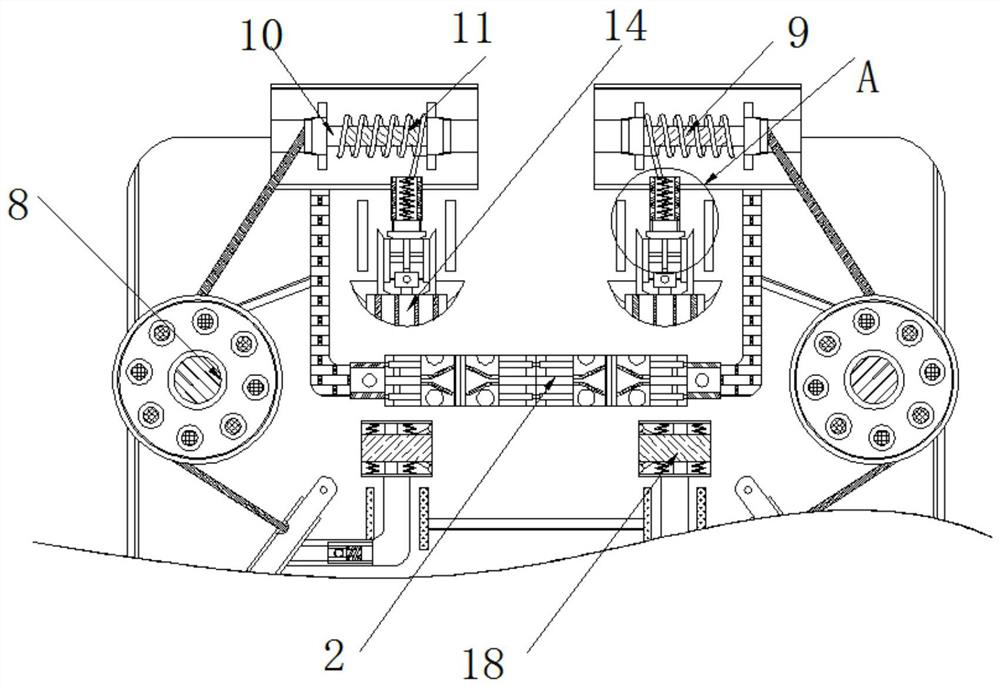

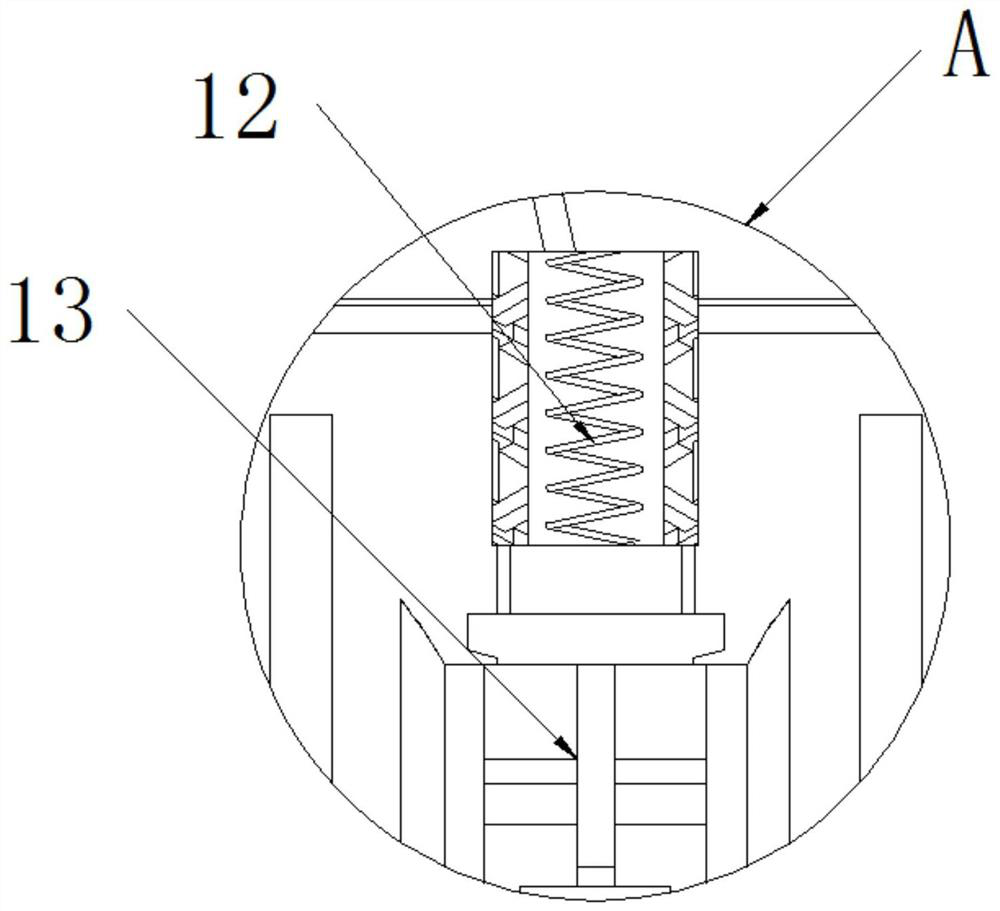

Strength-assisting bouncing platform device

InactiveCN106669089AAutomatic pressure controlAchieving assist heightSpring boardsInternal pressureAutomatic control

The invention relates to a strength-assisting bouncing platform device which comprises a platform board and a backward somersault treadle. An air spring is arranged at the bottom of the platform board, a treadle oil cylinder is arranged at the bottom of the backward somersault treadle, an electric control device is arranged in a jump-assisting platform, the control output end of the electric control device is connected with a hydraulic device and a pneumatic device through signal lines, and a data input of the electric control device comprises an optoelectronic switch installed on the platform board. An electric control system automatically controls the inner pressure of the air spring according to the weight W of an athlete and the required jump-assisting height H. Due to the fact that the rigidity of the air spring can be controlled according to an inflation pressure, an assisting force of the spring can be changed in the same jump-assisting stroke to meet the required jump-assisting height H.

Owner:王坤

Corrugated board processing intelligent device capable of automatically adjusting pressing force

InactiveCN112644136ALower resistanceImprove magnetismMechanical working/deformationControlling laminationStructural engineeringElectromagnet

The invention relates to the technical field of corrugated boards, and discloses a corrugated board processing intelligent device capable of automatically adjusting pressing force, wherein the device comprises a pressing roller; the surface of the pressing roller is fixedly connected with a permanent magnet, the bottom of a buffer pad is fixedly connected with a pressing rod, the bottom end of the pressing rod is movably connected with a sliding block, and the side surface of the sliding block is fixedly connected with a push-pull rod; the other end of the push-pull rod is movably connected with a piezoresistor; the other end of a connector lug is fixedly connected with an electromagnet; the other end of an adjusting rod is fixedly connected with a buffer air bag; when the thickness of a corrugated board is too large, the pressure of the pressing roller on the corrugated board is too large, and the pressing rod drives the push-pull rod to extrude the piezoresistor through a sliding block to drive the magnetism of the electromagnet to be enhanced; the distance between the pressing roller and a conveying belt is adjusted, and when the pressure on the two sides of the corrugated board is not uniform, the magnetism of the electromagnet on the pressed side is driven to be greater than that of the electromagnet on the other side, so that the pressing roller inclines towards the other pressed side, and the pressures on the two sides of the corrugated board are adjusted to be the same.

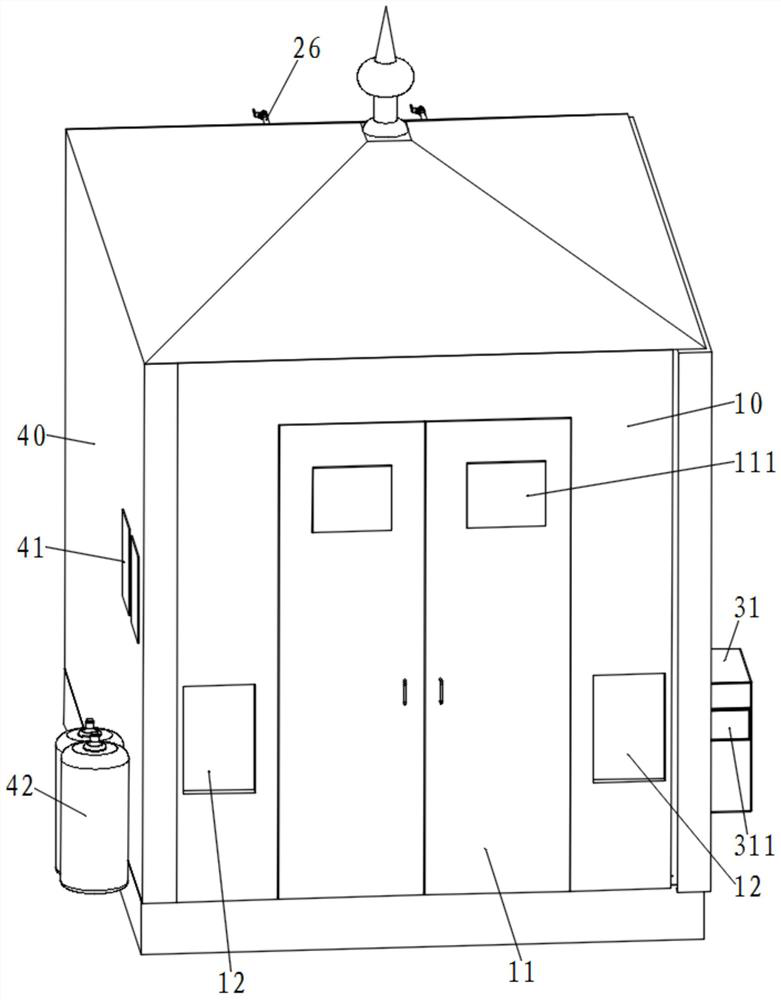

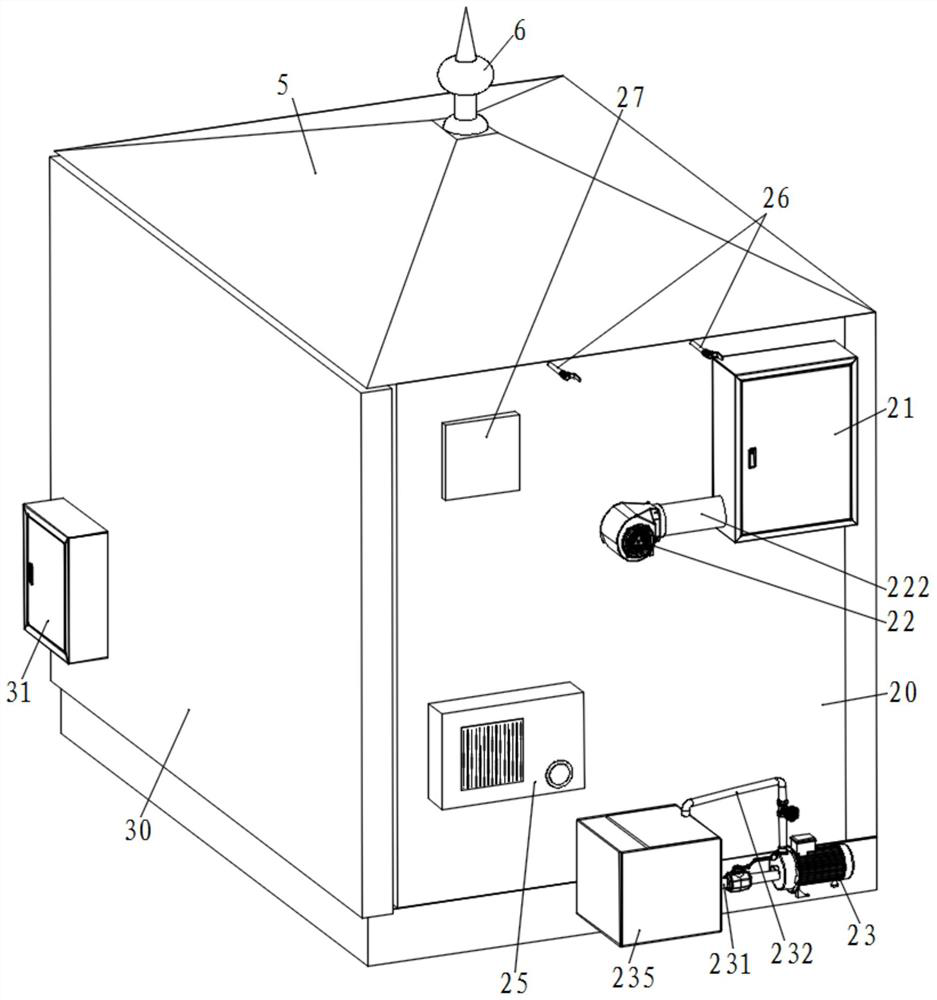

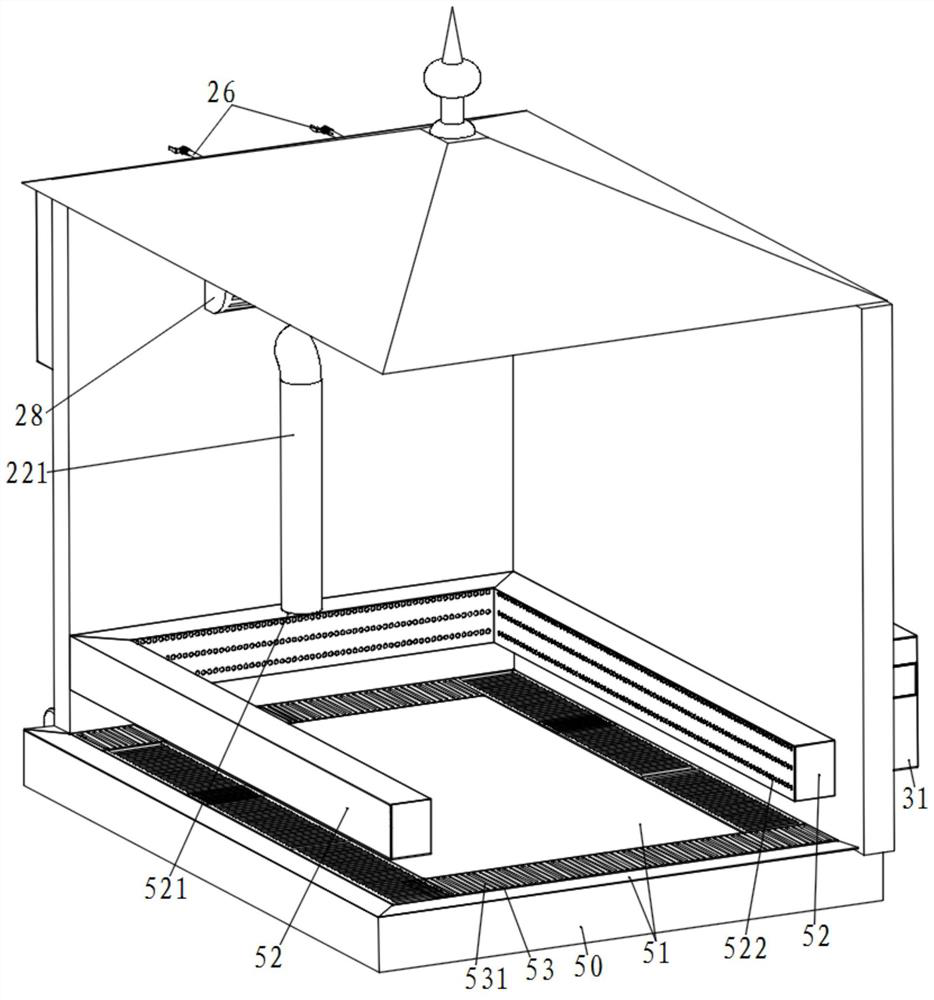

Movable intelligent hazardous waste warehouse

PendingCN113247507AAutomatic control monitoringAutomatic temperature controlCasings with display/control unitsLighting elementsAutomatic fire suppressionProcess engineering

The invention relates a movable intelligent hazardous waste warehouse. The movable intelligent hazardous waste warehouse comprises a bottom plate, a top plate, a front plate, a left plate, a rear plate and a right plate. An intelligent control device is arranged on the outer wall of the left plate and connected to a 5G module, and a spraying assembly, an anti-explosion window, a waste gas treatment assembly, a constant-temperature and constant-humidity outdoor unit and a waste liquid collecting assembly are arranged on the outer wall of the rear plate. An air conditioner indoor unit is arranged on the inner wall of the rear plate, and the constant-temperature and constant-humidity outdoor unit is connected with the air conditioner indoor unit. The right plate is provided with an automatic fire extinguishing assembly. The top end of the top plate is provided with a top tower, the bottom end of the top plate is provided with an anti-explosion fluorescent lamp, the top end of the bottom plate is provided with a liquid collecting tank, and the top end of the liquid collecting tank is provided with a regular quadrangular air pipe. The regular quadrangular air pipe is fixedly connected with the left plate, the rear plate and the right plate respectively. The movable intelligent hazardous waste warehouse has the advantages that the storage environment in the warehouse is automatically controlled, safety protection in the warehouse is automatically controlled, the number and weight ledger of goods in the warehouse is automatically generated, and the domestic blank is filled up.

Owner:张绍忠

A computer shell polishing equipment

ActiveCN110744411BGuaranteed efficiencyQuality assuranceGrinding carriagesPolishing machinesAutomatic controlPolishing

Owner:HUAIAN COLLEGE OF INFORMATION TECH

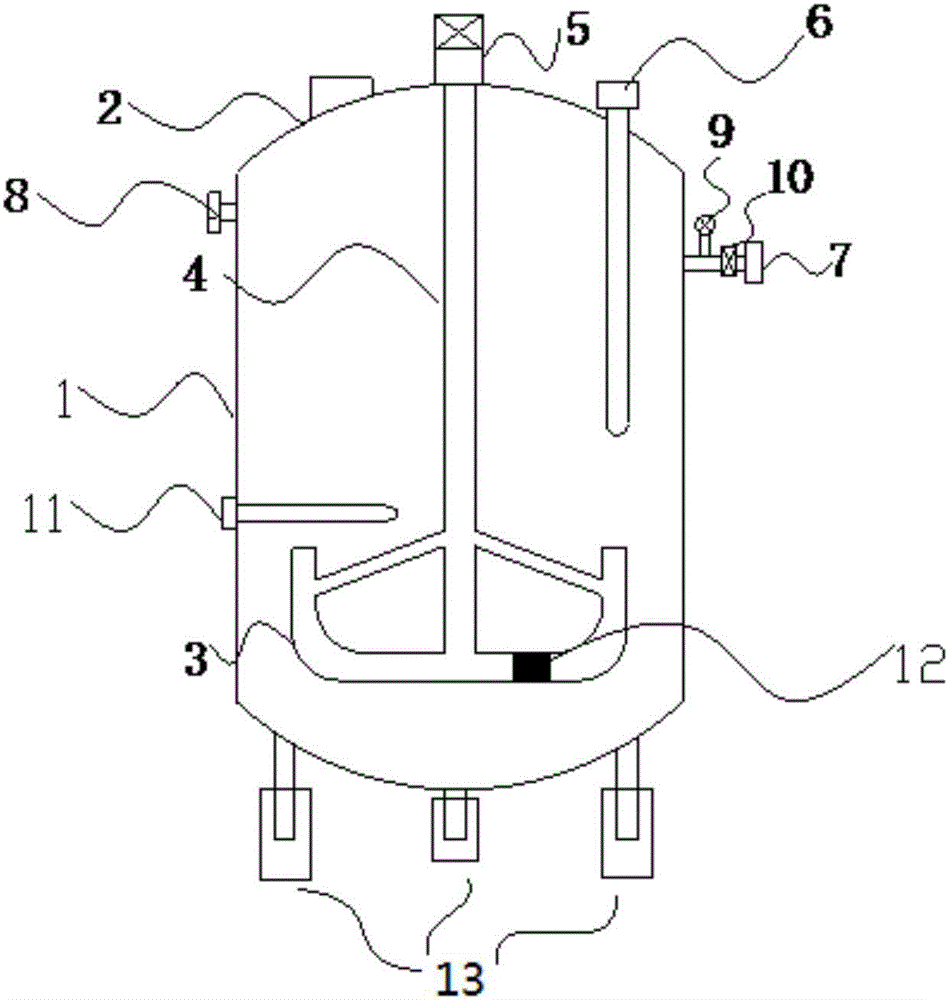

Plasma component rapid separation system

PendingCN112569645AAutomatic pressure controlSimple structureTransportation and packagingRotary stirring mixersEngineeringBlood plasma

The invention discloses a plasma component rapid separation system which comprises a reaction tank, a manual valve is arranged at the lower end of the reaction tank, a stirring mechanism is arranged in the reaction tank, a liquid adding pipeline is arranged in the reaction tank, and the liquid adding pipeline is arranged in a U shape in the reaction tank. Two openings in the upper end of the liquid adding pipeline penetrate through the reaction tank and extend outwards, a liquid adding valve is arranged on the liquid adding pipeline, and a groove allowing liquid to penetrate through is formedin the liquid adding valve. The plasma component rapid separation system can automatically control pressure, and is simple in structure and convenient to use.

Owner:HUALAN BIOLOGICAL ENG CHONGQING

Energy-saving machining equipment capable of ensuring uniform stress of mobile phone mainboard

InactiveCN112757198AAvoid destructionEven by forceWork holdersMetal-working hand toolsMobile phoneMachining

The invention relates to the technical field of mobile phone manufacturing, and discloses energy-saving machining equipment capable of ensuring uniform stress of a mobile phone mainboard. The energy-saving machining equipment comprises a machining base, a supporting plate is fixedly connected to the interior of the machining base, a protective frame is fixedly connected to the interior of the machining base, and a threaded column is rotatably connected to the interior of the protective frame; and the outer surface of the threaded column is movably connected with a moving plate, the outer surface of the moving plate is rotationally connected with a stretching frame, the outer surface of the stretching frame is movably connected with a first pull rope, and a rotating disc is rotationally connected to the position, located on the outer surface of the first pull rope, in the machining base. Through different release forces of the first pull rope, the rotation angle of a winding column is finally adjusted to be different, the release states of a second pull rope are different, the recovery effects of a limiting spring are different, the pressure of a positioning seat can be automatically controlled, damage to the mainboard is avoided, and the beneficial effect is brought to mobile phone machining.

Owner:青白江祝答卜机械租赁服务部

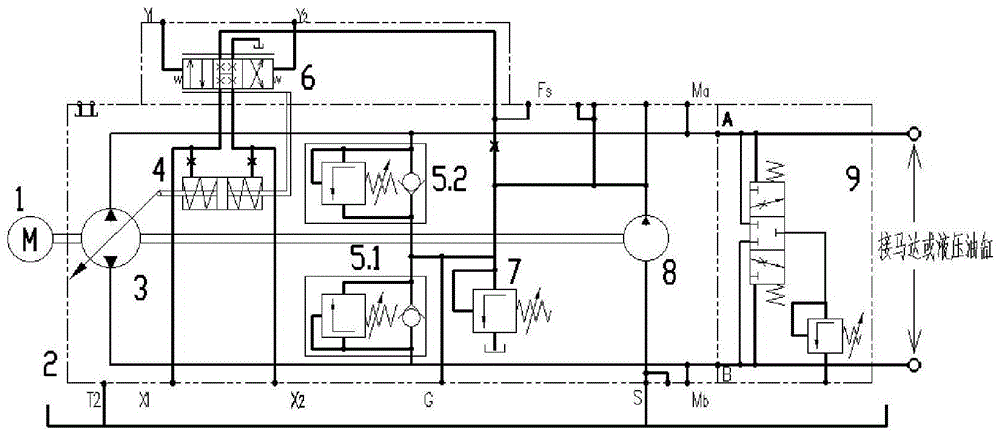

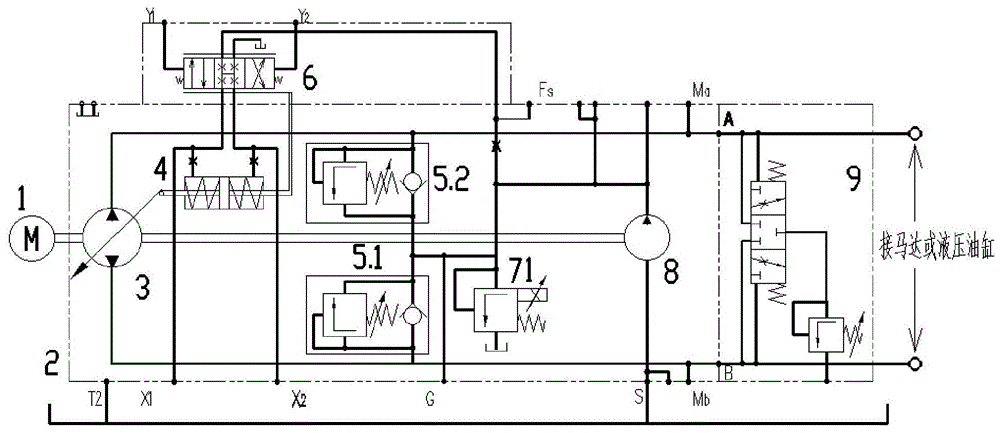

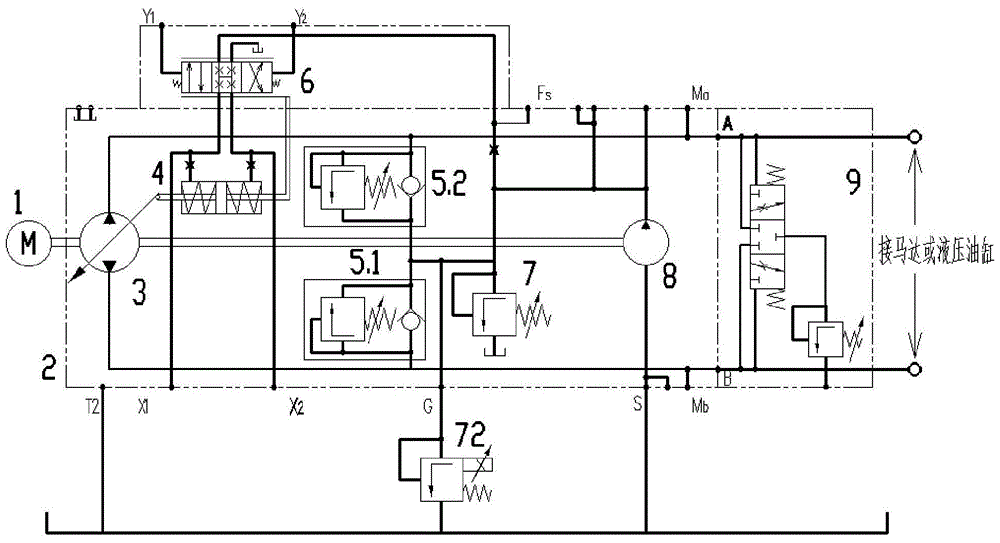

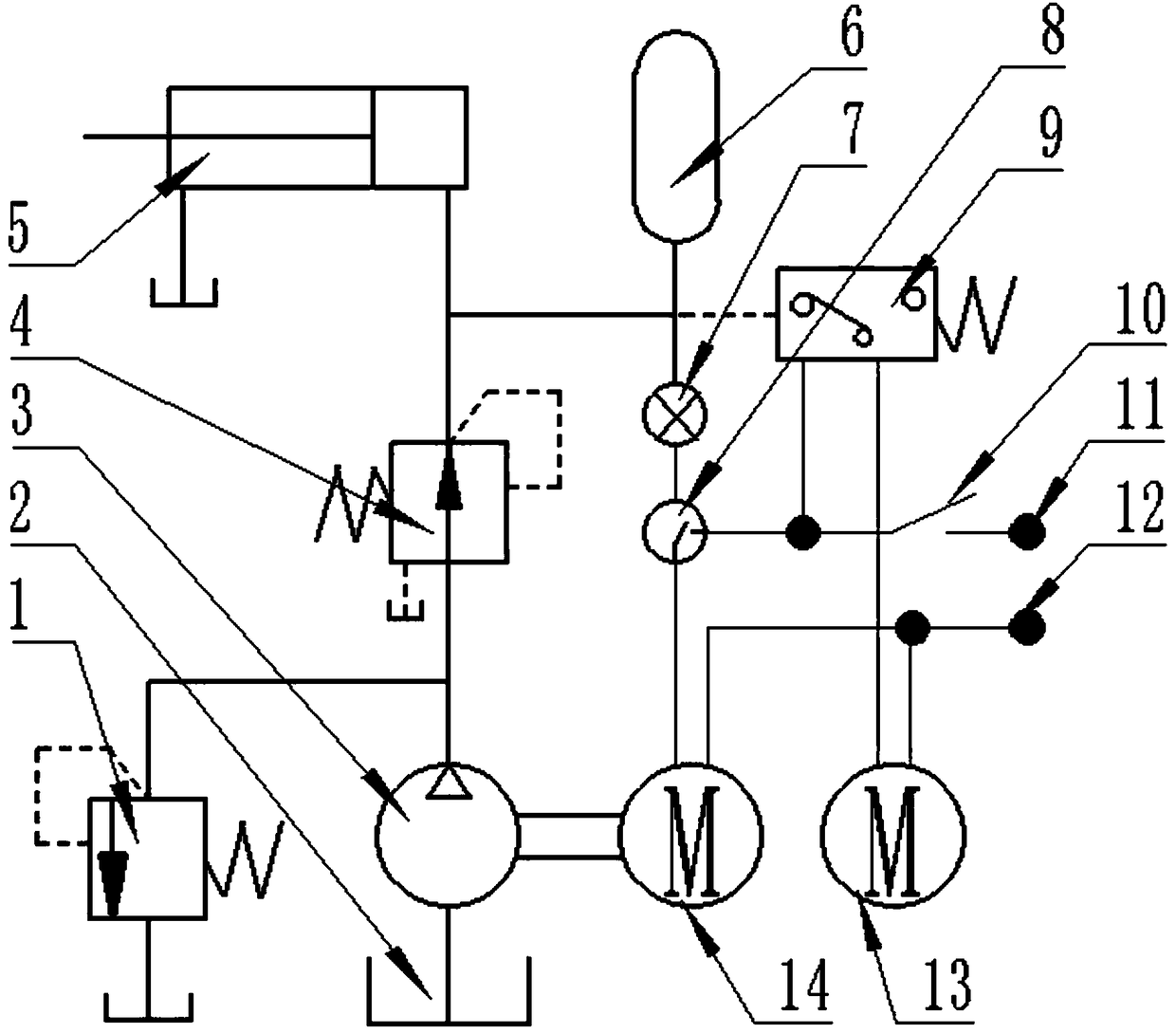

A closed oil pump hydraulic system and construction machinery with the same

ActiveCN104847719BAutomatic pressure controlGuaranteed pressureServomotorsEngineeringElectric control

The invention discloses a closed oil pump hydraulic system and engineering machinery having the same. The closed oil pump hydraulic system comprises a primer engine, a closed pump driven by the primer engine and used for outputting hydraulic power, an oil feeding pump driven by the primer engine and used for providing a control oil source and an oil feeding source to the operation of a closed pump, a pressure control device including an electric control valve arranged in an outlet of the oil feeding pump and used for controlling the pressure in the outlet of the oil feeding pump according to instructions, and an electric control device for monitoring a working state of the closed pump and controlling the connection and the disconnection of the electric control valve based on the working state of the closed pump. The closed oil pump hydraulic system can guarantee the pressure in the outlet of the oil feeding pump needed by the normal operation of the closed pump, and can realize the automatic operation of the oil feeding pump under lower pressure when the closed pump dose not work, so that the reduction of the energy consumption of the oil feeding pump is realized.

Owner:河北雷萨重型工程机械有限责任公司

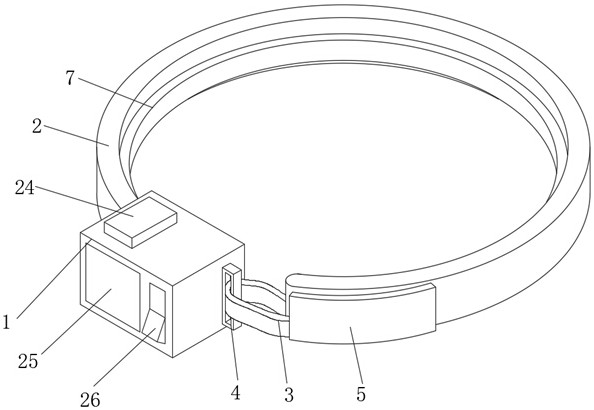

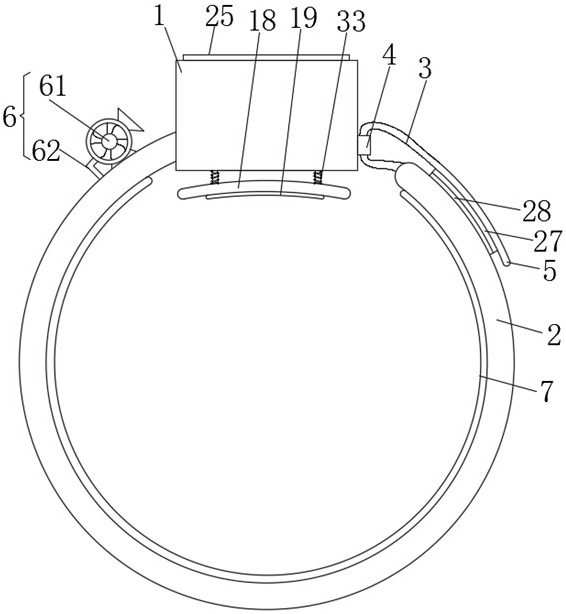

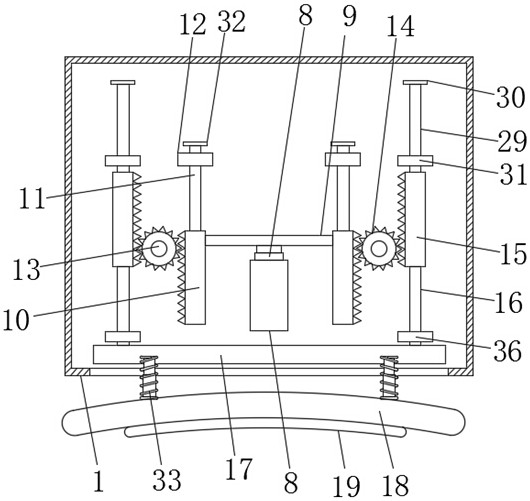

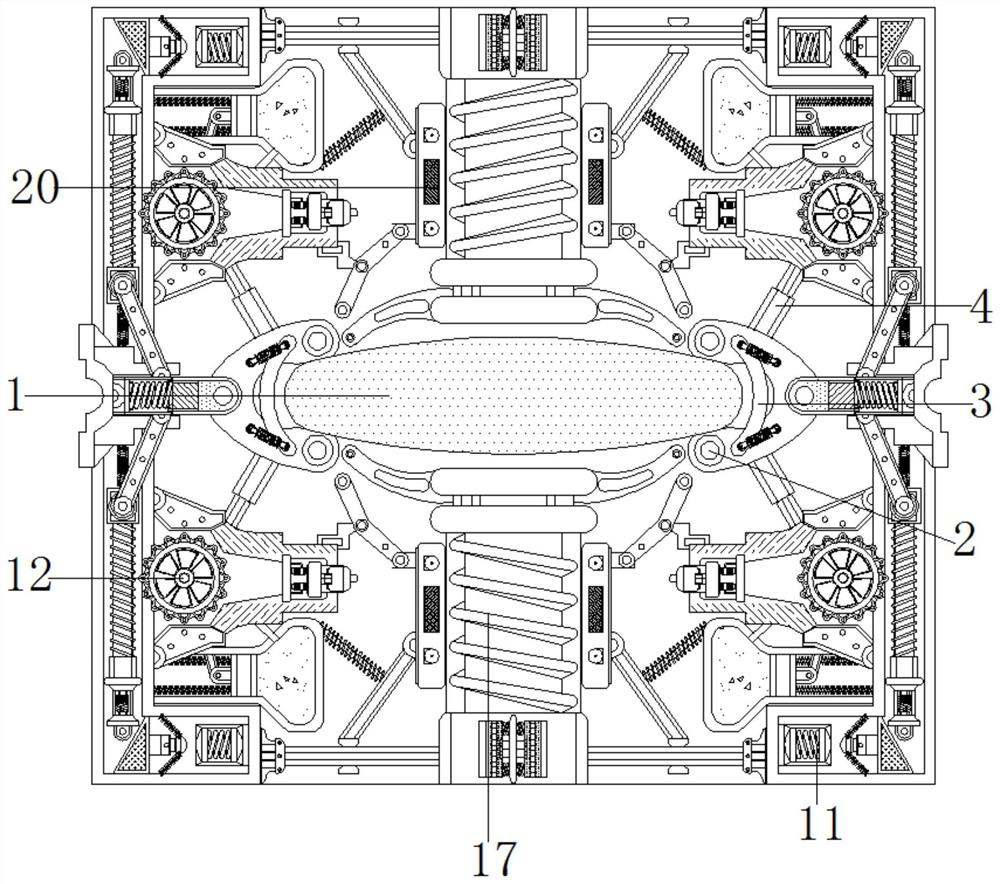

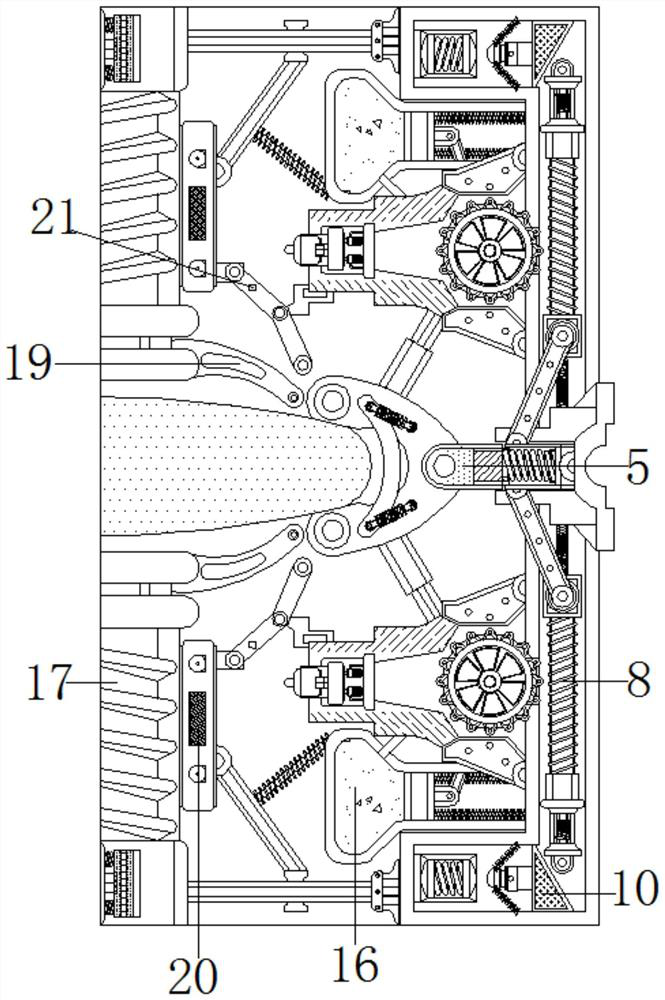

Femoral artery pneumatic compression device

InactiveCN113243963AImprove comfortImprove fitNon-adhesive dressingsFeet bandagesThighCompression device

The invention relates to the technical field of medical instruments, and discloses a femoral artery pneumatic compression device which comprises a control box, and an inflatable binding belt is installed on the left side of the control box; the thigh femoral artery is sleeved with the inflatable binding belt, the hook face of a hook-and-loop fastener is attached to the hook face of the hook-and-loop fastener through pulling of an adjusting rope, a miniature air blower is started, air flow is driven to enter an inflatable layer through an air inlet pipe, the inflatable layer bulges to be attached to and tightly press the thigh of a patient, therefore the inflatable binding belt is firmly installed, the comfort level of the patient is enhanced, and the attaching effect is improved; an air cylinder drives a push rod to push a first toothed bar to move, the first toothed bar drives a gear to rotate on the surface of a connecting rod and drives a second toothed bar to move, the second toothed bar drives a telescopic rod to push a telescopic plate to move, the telescopic plate drives an arc-shaped pressing plate to extrude an affected part, and a buffer spring is compressed; and an absorbent cotton block absorbs the blood of the patient, and a pressure sensor automatically adjusts the expansion and contraction according to the arterial pressure of an affected part, so that the compression force is automatically controlled, and the convenience is improved.

Owner:深圳麦普奇医疗科技有限公司

Polishing self-adaptive polishing pressure self-cleaning intelligent device for optical lens

InactiveCN112757097AReduce curvatureReduce extrusion pressureOptical surface grinding machinesGrinding drivesOptic lensMechanical engineering

The invention relates to the technical field of optics, and discloses a polishing self-adaptive polishing pressure self-cleaning intelligent device for an optical lens. The intelligent device comprises the lens, a clamping plate is movably connected to the surface of the lens, a threaded rod is movably connected to the inner wall of a sliding groove, a piezoresistor is movably connected to the side surface of an inclined plate, a gear is movably connected to the surface of the threaded rod, the surface of the gear is movably connected with an air bin, the surface of the gear is movably connected with a piston rod, the other end of the piston rod is movably connected with a piston plate, the surface of the lens is movably connected with a polishing disc, and the bottom end of the rotating rod is fixedly connected with an electromagnet. In the lens polishing process, the thickness is reduced, the magnetism of the electromagnet is increased, the pressure of the polishing disc and the lens is gradually reduced, excessive polishing is prevented, the threaded rod moves downwards to drive the gear to rotate, scraps diffused during lens polishing are sucked into the air bin, and the piston rod and the piston plate reciprocate in the horizontal direction, so that the chippings in the piston plate are compacted.

Owner:王永凤

Test loop and test method for testing mechanical seal for nuclear main pump

PendingCN113776753AAutomatic pressure controlAvoid safety hazardsPump testingMeasurement of fluid loss/gain rateExpansion tankControl system

The invention relates to a test loop for testing a mechanical seal for a nuclear main pump. The test loop comprises a main loop system and a pressure control system; the main loop system comprises a water tank and a mechanical sealing tool; an outlet of the water tank is connected with an inlet of the mechanical sealing tool through a main pipeline; a plunger pump is arranged on the main pipeline; a backflow outlet of the mechanical sealing tool is connected with an inlet of the water tank, and the water tank and the mechanical sealing tool form a closed loop; the pressure control system comprises an expansion tank and a pressure source; wherein the expansion tank provides static pressure for a closed loop formed by the water tank and the mechanical sealing tool, and the first medium in the water tank flows to the mechanical sealing tool along the main pipeline under the power provided by the plunger pump and flows back to the water tank through the mechanical sealing tool so as to perform a sealing test on the mechanical sealing tool. The test loop for testing the mechanical seal for the nuclear main pump has the advantages of being clean in medium, capable of conducting a thermal shock test, high in safety and the like.

Owner:SEC KSB NUCLEAR PUMPS & VALVES

A control system of a hand-held polishing machine with stable pressure

ActiveCN106425861BImprove polishing qualityLow skill level requiredPolishing machinesAutomatic grinding controlAutomatic controlFuel tank

The invention discloses a stable pressure control system for a handheld polisher, comprising an oil tank, a hydraulic oil pump, a relief valve, a hydraulic cylinder, a pressure measurer, a central processing unit, a pressure switch, a manual switch, a power positive pole, a power negative pole, a first motor and a second motor; the oil tank is connected with the hydraulic oil pump which is connected with the relief valve, the relief valve is connected respectively with the hydraulic cylinder, the pressure measurer and thee pressure switch, and the hydraulic cylinder is connected to the oil tank; the power positive pole is connected to the manual switch, the manual switch is connected respectively to the pressure switch and the central processing unit, the pressure switch is connected to the first motor, the first motor is connected to the power negative pole, the central processing unit is connected to the pressure measurer, the central processing unit is connected to the second motor, the second motor is connected to the power negative pole, and the power output end of the second motor is connected to the hydraulic oil pump. The stable pressure control system provides automatic pressure control and has stable pressure, can provide reliable polishing quality for a polisher and has low technical skill requirements on workers.

Owner:重庆前进焊接材料制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com