Method and automatic control system for producing polyisobutylene by continuous polymerization

An automatic control system and polyisobutylene technology, applied in the field of continuous polymerization of isobutene to produce polyisobutene, and continuous polymerization to produce polyisobutene, can solve problems such as unfavorable production stability, changes in production line process conditions, and production efficiency decline, and achieve convenient and efficient production process control. Accurate, avoid vaporization loss, more controllable pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

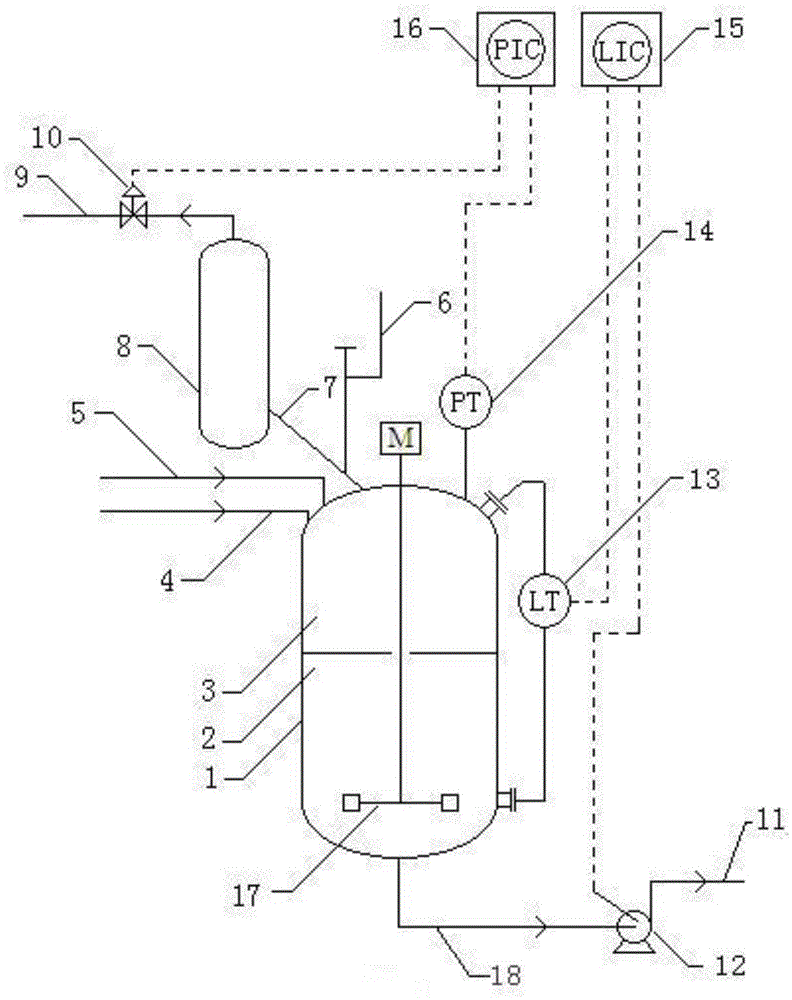

[0060] The method for producing polyisobutene by continuous polymerization and the automatic control system of the present invention are used to produce polyisobutene.

[0061] The raw material used comes from concentrated mixed C4 after catalytic cracking in an oil refinery, wherein the content of isobutene is 47% (weight ratio, the same below), the content of diolefins is less than 0.05%, and an aluminum trichloride system catalyst is used.

[0062] The flow rate of raw material mixed carbon four is 1840kg / h, along pipeline 4 raw material feeding pipelines, add continuously from the upper part of the reactor, the addition amount of aluminum trichloride in the corresponding catalyst is 0.50% of the isobutene addition in the raw material mixed carbon four, trichloro The flow rate of aluminum trichloride in the aluminum system catalyst is 4.32kg / h, which is continuously added from the upper part of the reactor along the catalyst feed pipe of pipeline 5, fully mixed under the act...

Embodiment 2

[0072] Repeat the method for producing polyisobutene by continuous polymerization described in Example 1 and the automatic control system to produce polyisobutene, the difference is that the liquid level setting value is 60%, and the residence time is 50min. The polyisobutene number average produced by this embodiment The molecular weight is 1295, the molecular weight distribution is 2.13, and the conversion rate of isobutylene is 96%.

Embodiment 3

[0074] Repeat the method for continuous polymerization described in Example 1 to produce polyisobutene and the automatic control system to produce polyisobutene, the difference is that the raw material is the mixture of pure isobutene and normal hexane obtained from MTBE catalytic cracking, and the mass proportion is 1:2, The amount of aluminum trichloride added in the catalyst is 0.15% of the amount of isobutylene added in the raw material, the flow rate of aluminum trichloride in the aluminum trichloride system catalyst is 0.92kg / h, the reaction temperature is -25°C, and the liquid level is 50% , the residence time is 42min, and the temperature of the condenser is -35°C. The polyisobutylene produced in this example has a viscosity-average molecular weight of 55,000, a molecular weight distribution of 2.87, and a conversion rate of isobutylene of 92%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com