A control system of a hand-held polishing machine with stable pressure

A control system and stable pressure technology, applied in the field of mechanical parts, can solve the problems of unstable polishing quality and high technical requirements, and achieve the effects of easy human control, low technical requirements and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

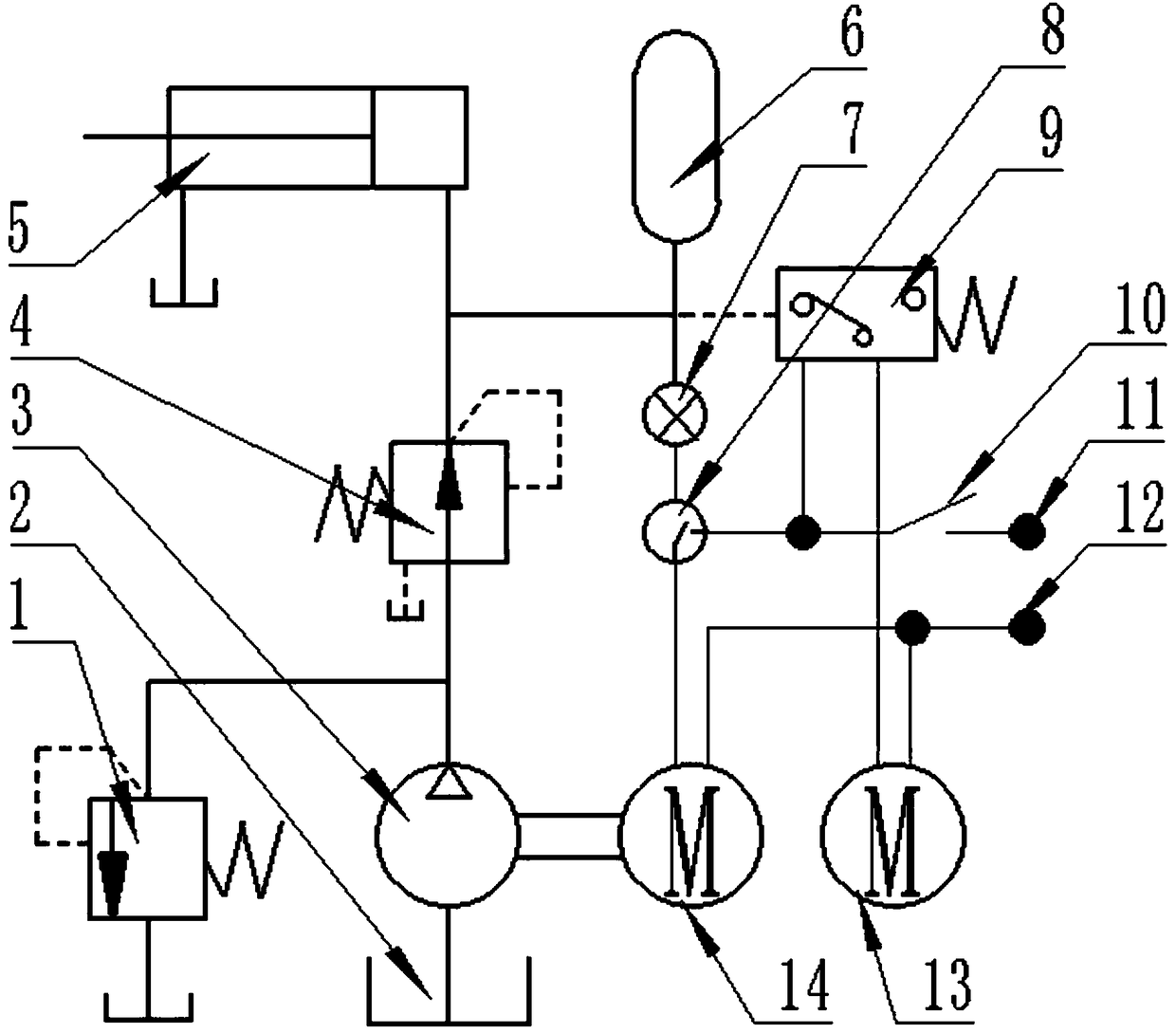

[0021] Such as figure 1 As shown, in order to overcome the defects of the prior art, the present invention provides a control system for a pressure-stabilized handheld polishing machine, which includes an oil tank 2, a hydraulic oil pump 3, a pressure reducing valve 4, a hydraulic cylinder 5, a pressure measuring device 7, CPU 8, pressure switch 9, manual switch 10, power supply positive pole 11, power supply negative pole 12, first motor 13 and second motor 14; the oil tank 2 is connected to the liquid inlet end of the hydraulic oil pump 3, and the liquid outlet of the hydraulic oil pump The end is connected to the liquid inlet end of the pressure reducing valve 4, the liquid outlet end of the pressure reducing valve 4 is respectively connected to the rodless cylinder of the hydraulic cylinder 5, the pressure measuring device 7 and the control end of the pressure switch 9, and the rod cylinder of the hydraulic cylinder 5 is connected to the oil tank 2. The positive pole 11 of...

Embodiment 2

[0025] This embodiment is further improved on the basis of embodiment 1, as figure 1 As shown, a safety valve 1 is arranged between the hydraulic oil pump 3 and the pressure reducing valve 4. Prevent the safety accident caused by the jamming of the pressure reducing valve 4 to generate pressure.

[0026] In order to make the system pressure more stable, an accumulator 6 is arranged between the pressure reducing valve 4 and the hydraulic cylinder 5 .

[0027] In order to enable the central processing unit 8 to control the opening and closing of the circuit, a normally closed switch is provided in the central processing unit 8, the opening pressure of the normally closed switch is greater than the closing pressure of the normally closed switch, and the disconnection of the normally closed switch The pressure is equal to the rated output pressure of the pressure reducing valve 4.

[0028] In order to make the system work stably and reliably, the pressure switch 9 is a normally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com