Metallographical sample electrolytic polishing device applied to laboratory

A laboratory electrolytic polishing technology, applied in the field of electrolytic polishing equipment for laboratory metallographic samples, can solve the problem that the electrolyte temperature and polishing time cannot be automatically controlled, the temperature and time cannot be well controlled, and the current and voltage cannot be adjusted independently And other problems, to achieve good polishing effect, controllable working temperature, and improve the effect of polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

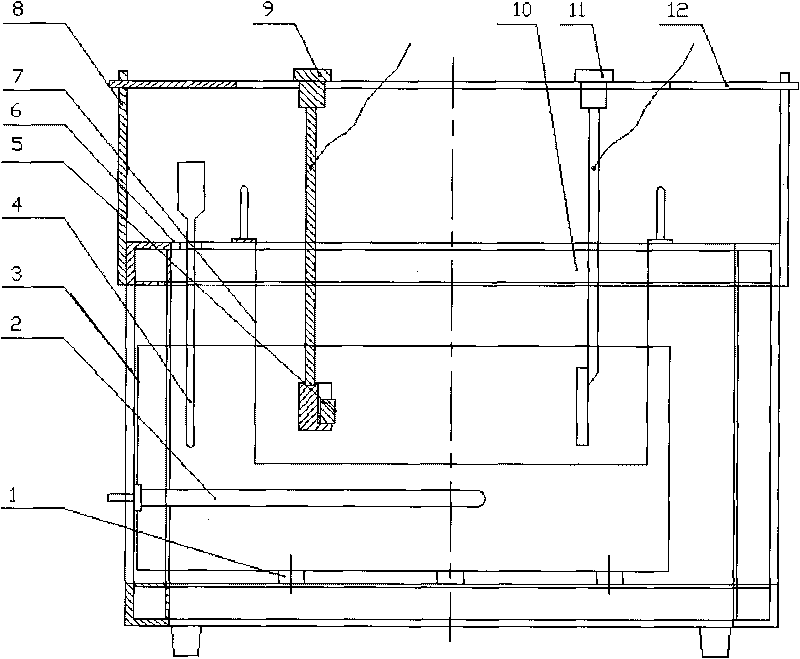

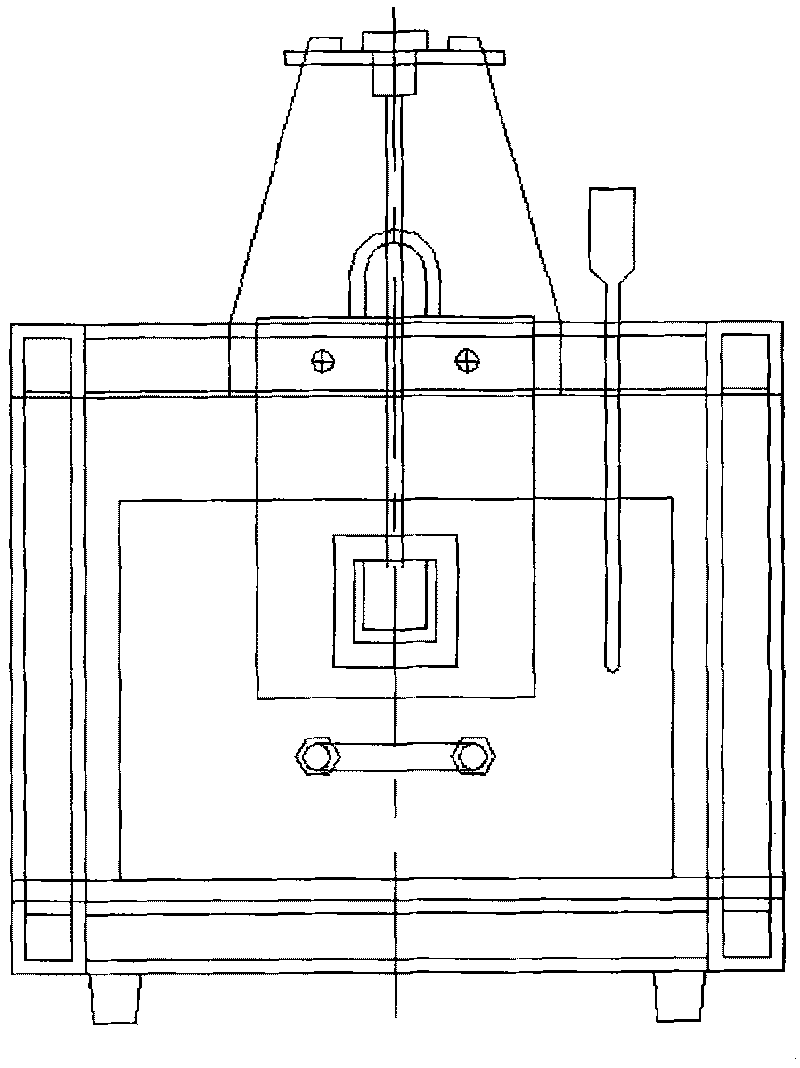

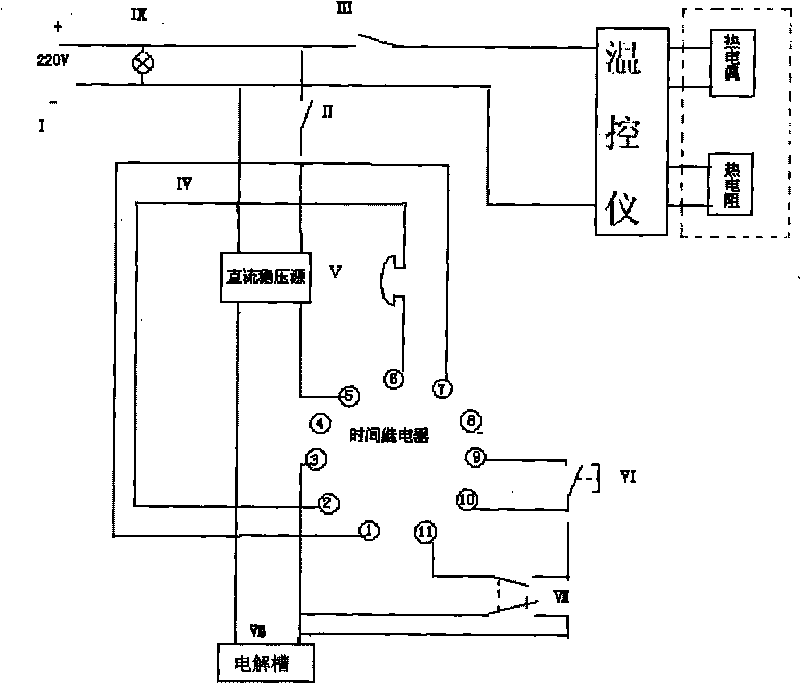

[0018] Such as figure 1 , figure 2 As shown, the laboratory electrolytic polishing device for metallographic samples of the present invention includes a working voltage and current density adjustment system, an electrolyte constant temperature system, an automatic electrolysis time control and automatic alarm system, and an electrolytic cell 7, wherein the working voltage and current density adjustment system It consists of a DC stabilized voltage source connected in series with moving electrodes. The electrolyte constant temperature system consists of a temperature controller, a heating element 2, a shell, a heating tank 3 and a thermocouple 4. The electrolysis time automatic control and automatic alarm system consists of a time relay and a buzzer. The electrolytic cell 7 is composed of an electrolytic cell frame 10, an anode electrode 9, and a cathode electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com