Cup rabbet polishing device

A technology of polishing device and cup mouth, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding workpiece support, etc., can solve the problems of not smooth enough cup mouth, cut lips, and unsightly appearance of cup mouth, etc., to achieve Improve the use experience, use safe and reliable, and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

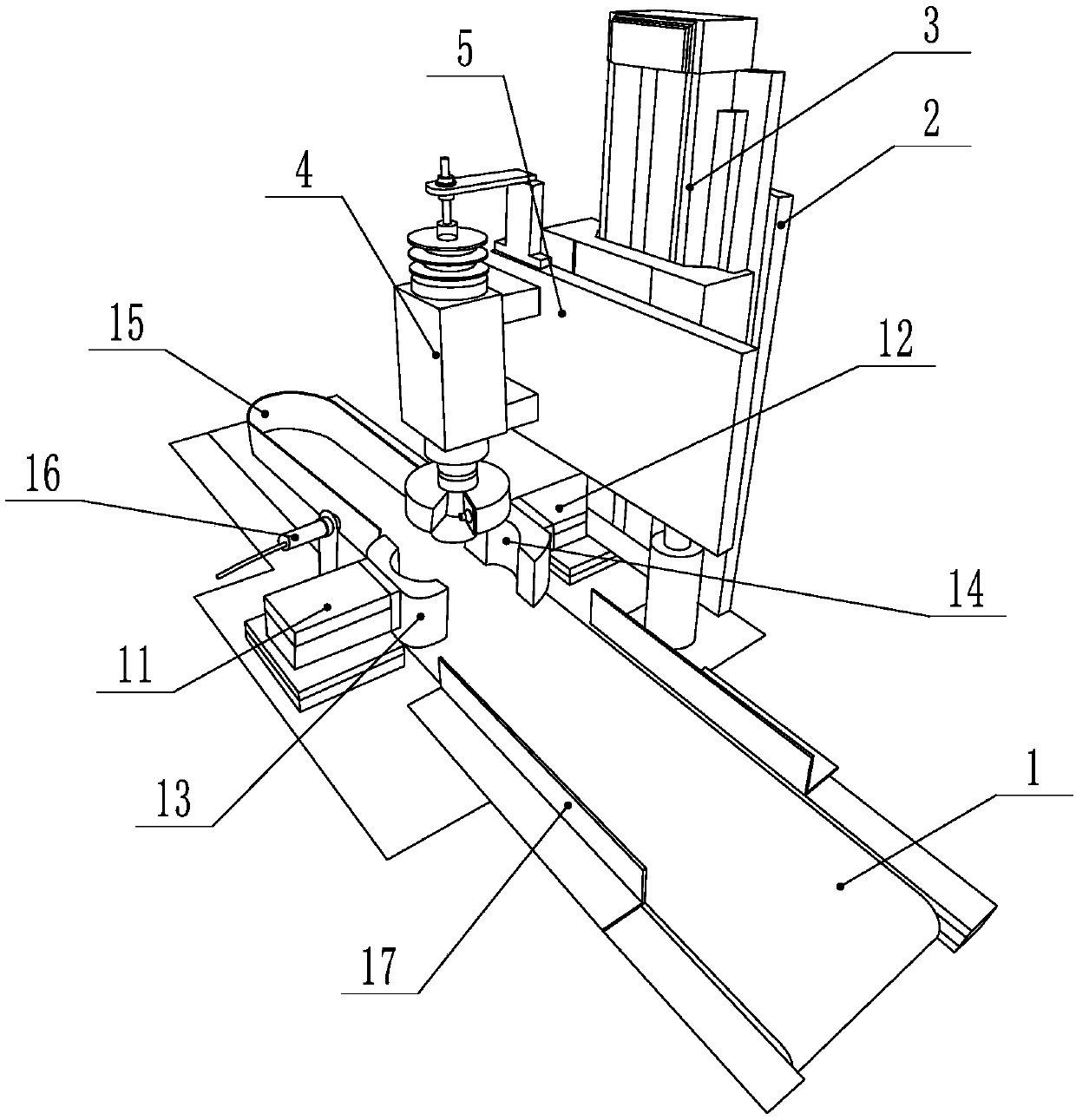

[0022] The present invention will be further described below with specific embodiment, see figure 1 —3:

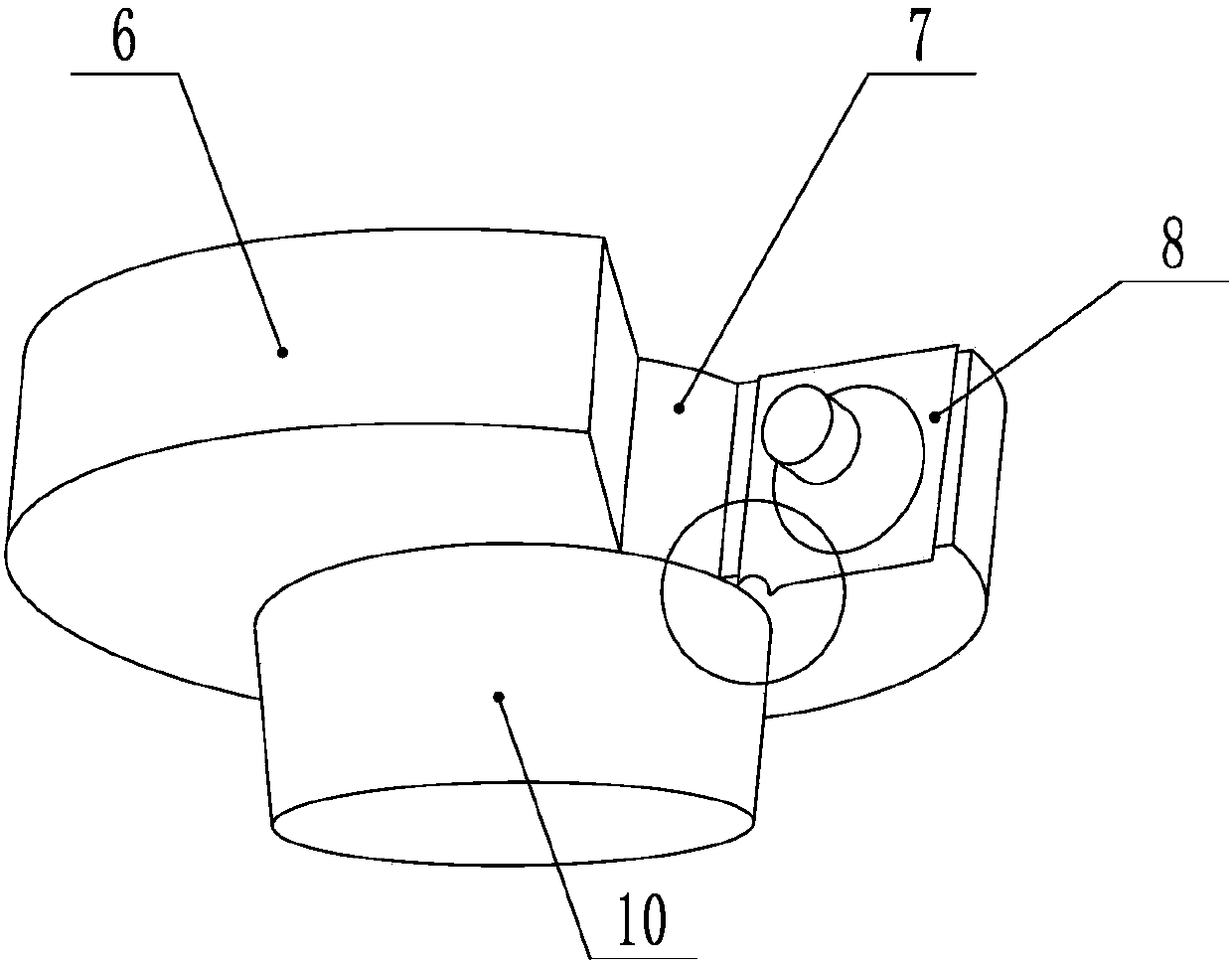

[0023] A kind of cup polisher, comprises conveyor belt device 1, on the frame 2 of one side of conveyor belt device 1, guide rail and first air cylinder 3 are vertically installed, and motor 4 is connected with guide rail by motor mounting plate 5, and The motor 4 is driven by the first cylinder 3 to move up and down along the guide rail. A polishing cutter head 6 is arranged on the rotating shaft of the motor 4. On the conveyor belt device 1 below the polishing cutter head 6, a device is provided to carry out the cup transfer on the conveyor belt device 1. clamping device, the polishing cutter head 6 can polish the cup mouth of the cup clamped by the clamping device.

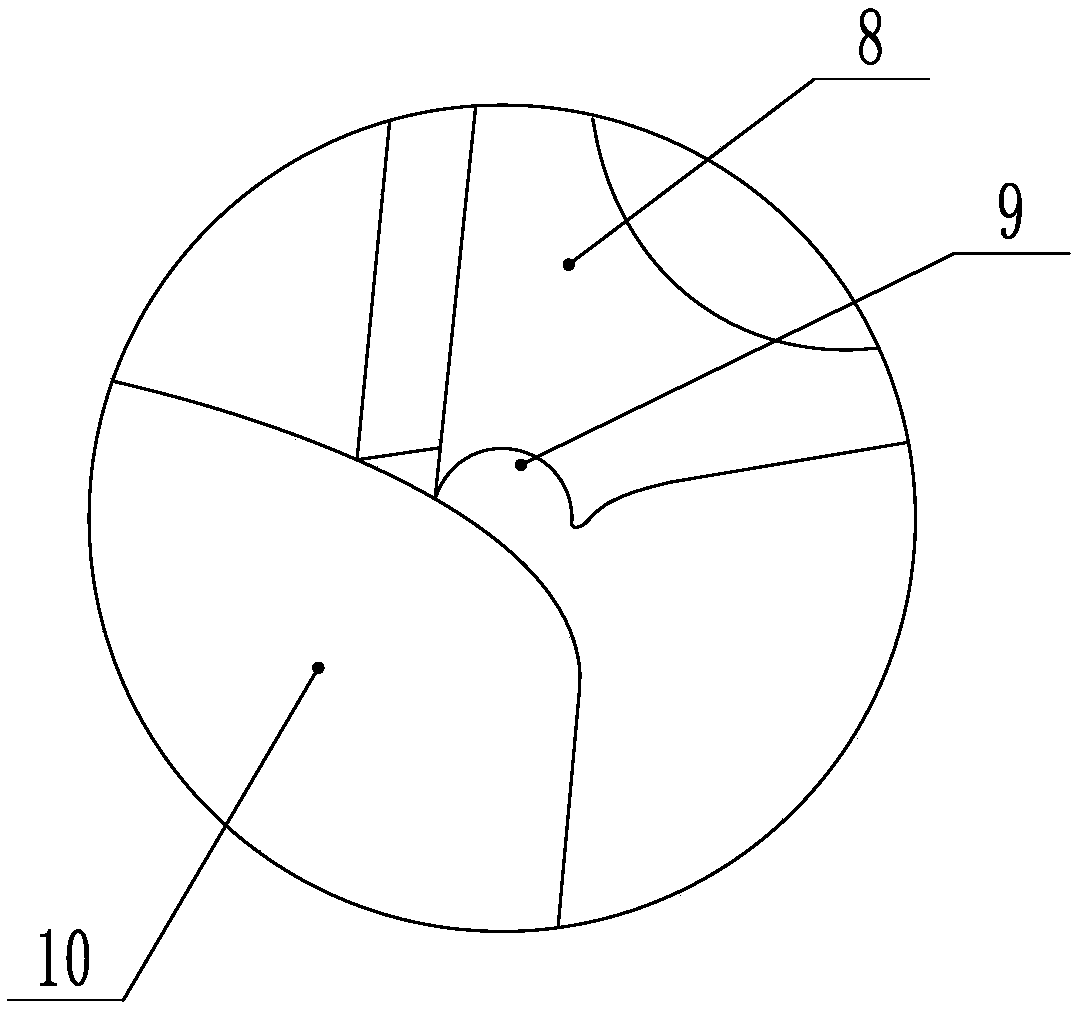

[0024] Specifically, the polishing cutter head 6 includes a cylinder on which a notch 7 is axially arranged, and a polishing blade 8 is arranged on one side of the inner wall of the notch 7, and the polish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com