Tunnel kiln with automatic temperature control system

A temperature control system and technology of tunnel kiln, applied in the field of tunnel kiln, can solve the problems of inability to carry out scientific production management, inability to achieve air convection effect, affecting the preheating effect of preheating section, etc., to save labor costs and improve preheating. Heat effect, effect of improving cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

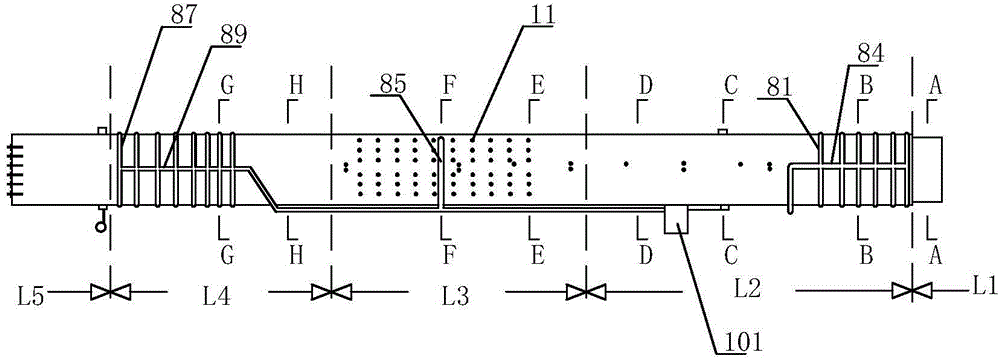

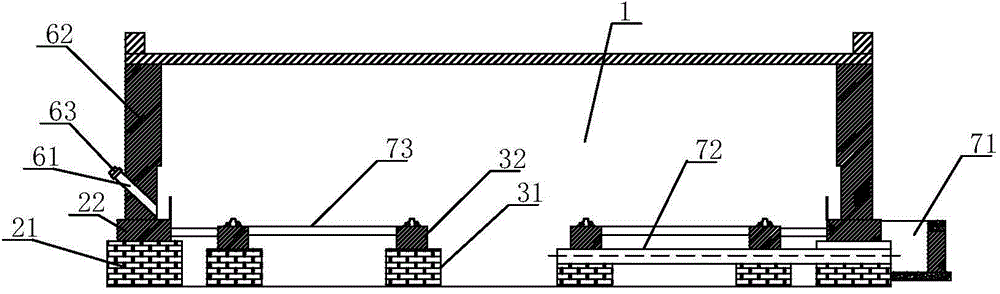

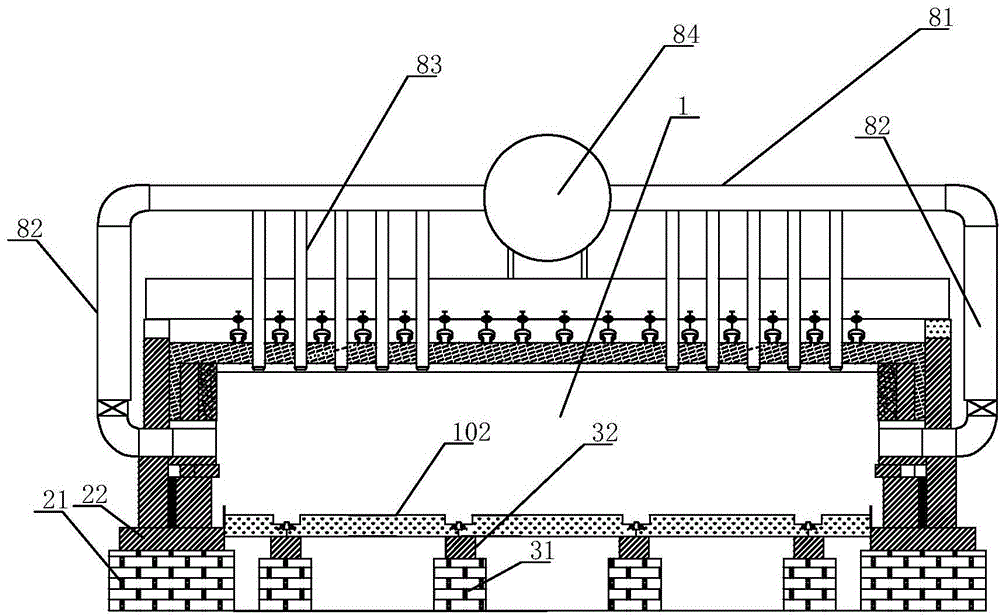

[0032] see Figure 1-Figure 16 , the present embodiment has the tunnel kiln of automatic temperature control system, comprises the kiln body that extends laterally and the kiln car that travels in described kiln body, and kiln body comprises kiln top, kiln wall and working channel 1, and working channel 1 is in the extending direction The upper part includes the inlet section L1, the preheating section L2, the roasting section L3, the heat preservation section L4 and the cooling section L5. The kiln wall includes a wall platform 21 for fixing on the foundation, and the wall platform 21 is made of rubble bricks. , the wall platform 21 is provided with a cushion layer 22 formed by pouring concrete.

[0033] The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com