Patents

Literature

263results about How to "Improve warm-up effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

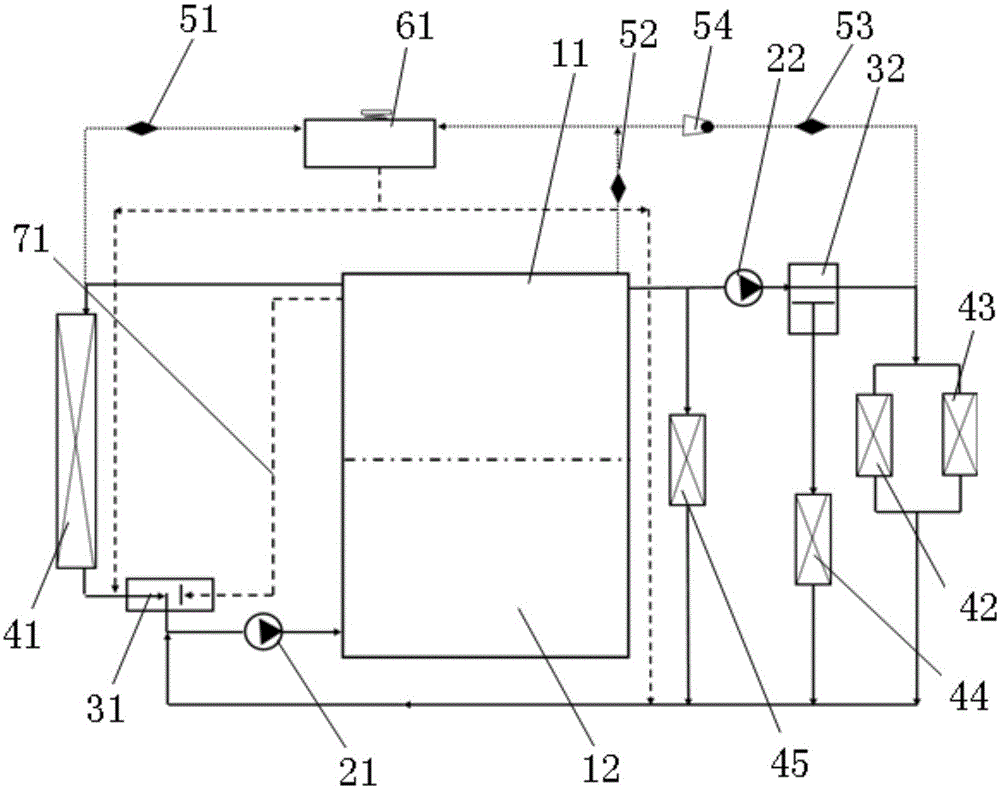

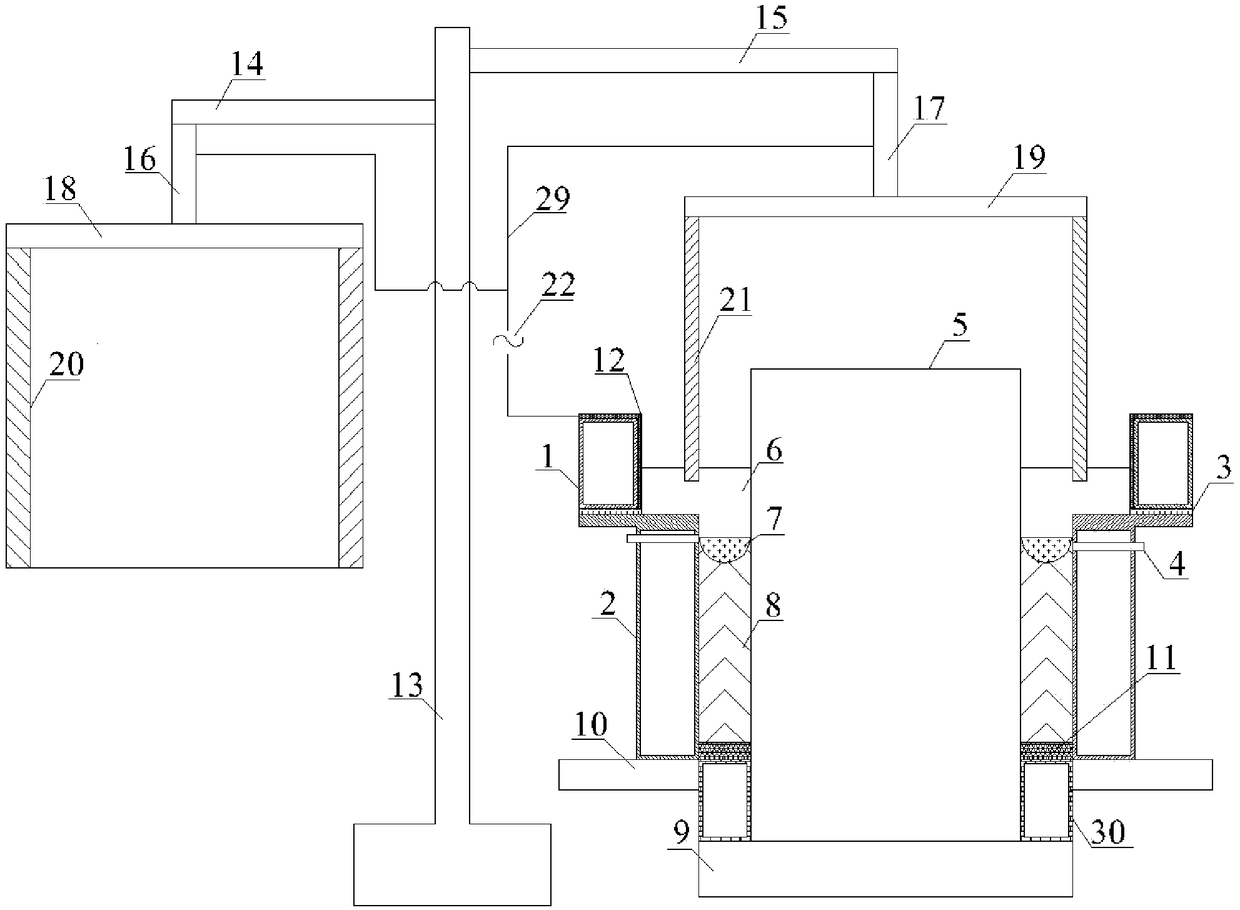

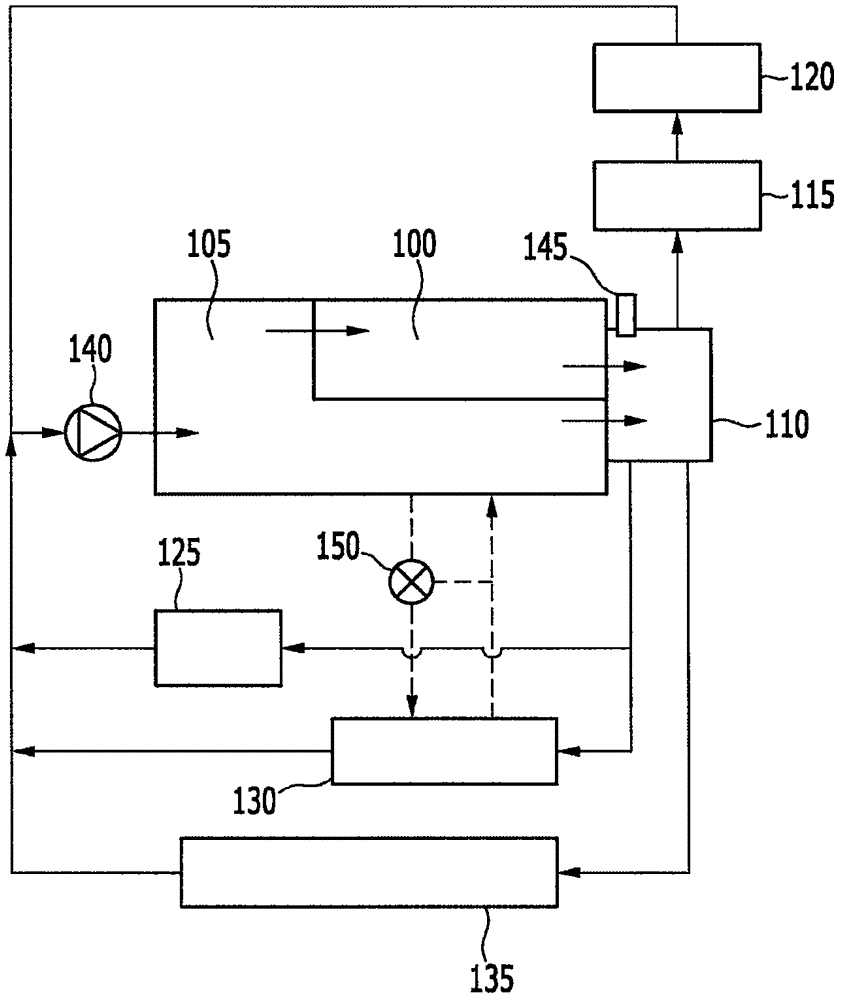

Cooling system of power assembly

InactiveCN105134357AAchieve reasonable controlImprove cooling effectLiquid coolingCoolant flow controlWater flowThermostat

The invention relates to a cooling system of a power assembly. The cooling system comprises an engine, a first cooling water pump, a radiator, a second cooling water pump, a first thermostat, a second thermostat, an engine oil cooler, a gearbox oil cooler, a warm air blower and a connecting pipeline. By means of the cooling system of the power assembly, it is guaranteed that an engine is warmed up rapidly during cold engine starting, the whole vehicle major cycle and the unnecessary minor cycle at the low temperature can be closed through the first thermostat and the second thermostat, and more water flow circulates between an engine cylinder and a cylinder cover through an engine minor cycle pipeline; and heat exchange is reduced, and the engine warming-up speed is increased. When the temperature of the water of the engine is low, the minor cycle of a gearbox oil cooling system is reduced at the low temperature through the second thermostat so that it can be guaranteed that the gearbox oil does not exchange heat with the cooling water of the engine at the low temperature; and the oil temperature of a gearbox is increased more rapidly, and then a better lubrication effect is achieved.

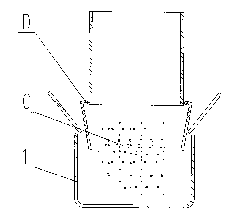

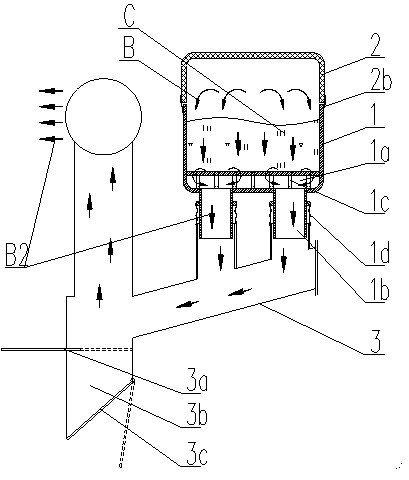

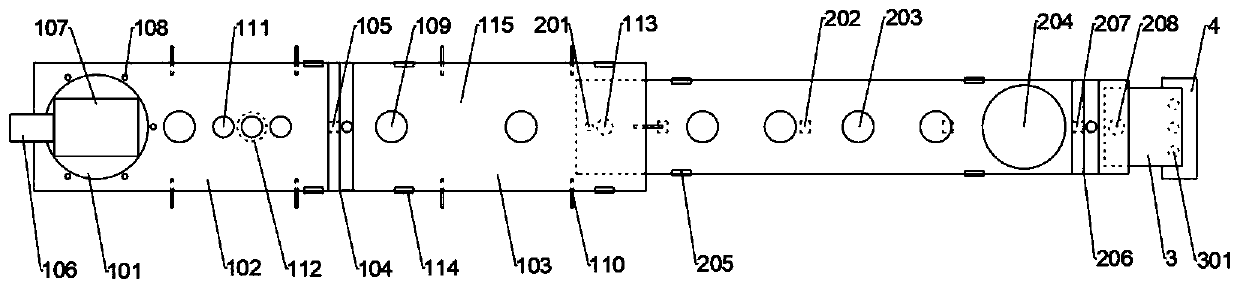

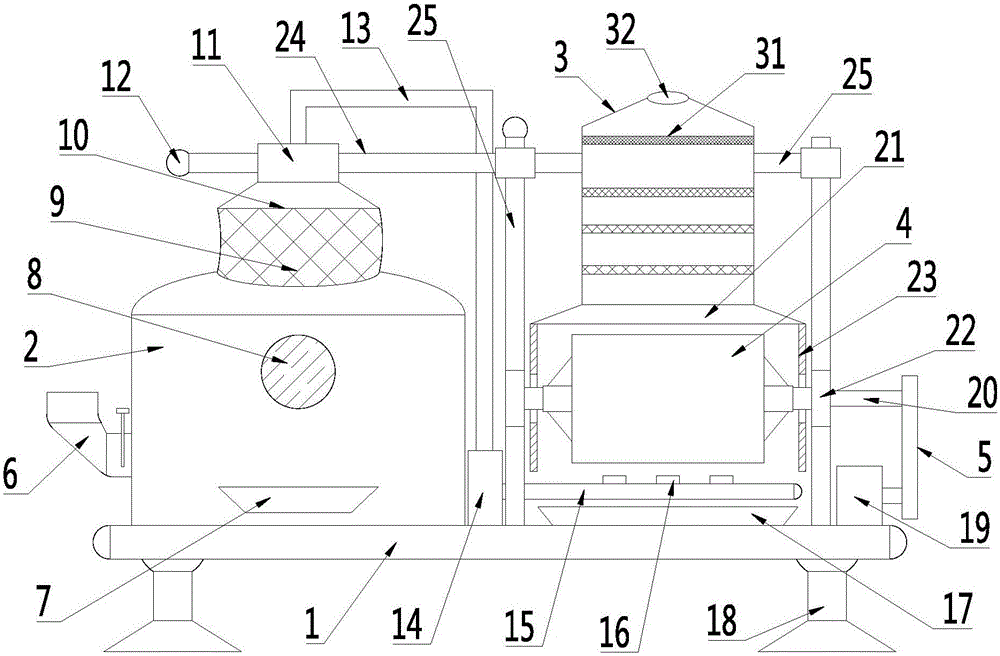

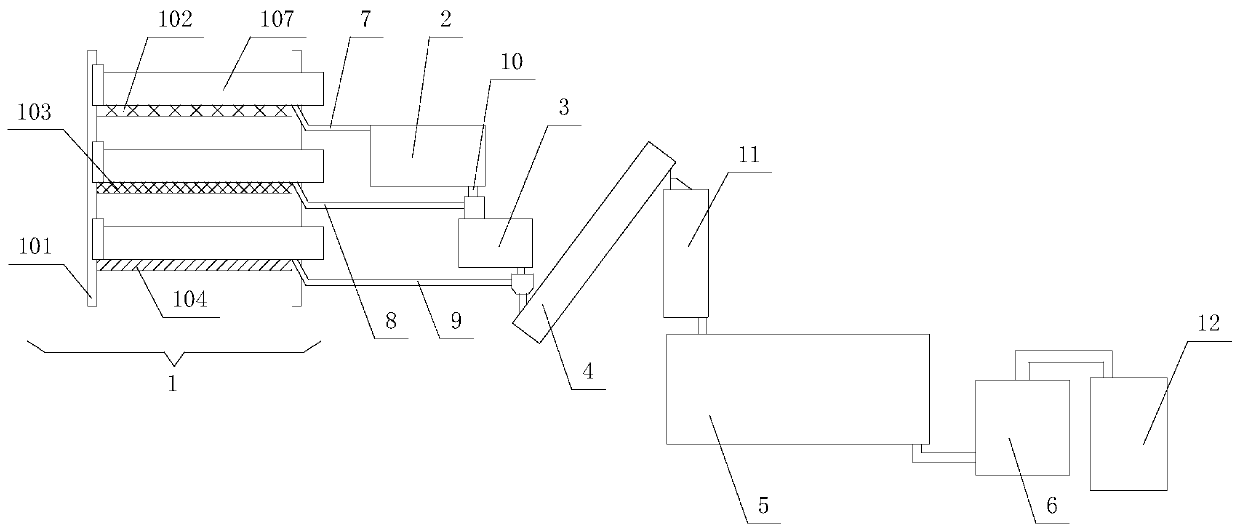

Device for preheating and conveying scrap steel

InactiveCN101825396AExtend your lifeReduce wearCharge manipulationPreheating chargesSmelting processNew energy

The invention discloses a device for preheating and conveying scrap steel, which comprises a conveying groove (1) obliquely formed relatively to the horizontal plane. A fume guide hood (2) is arranged on the conveying groove (1); the lower end of the conveying groove (1) extends into an electric furnace (A) through an opening on a side wall of the electric furnace (A); a bottom-open long distributing groove (D) is formed above the other end of the conveying groove (1) and is installed above a material receiving section of the conveying groove (1) through a lifting device (Q); the bottom-open long distributing groove (D) is in a top view projection of the material receiving section of the conveying groove (1) along a longitudinal direction; the scrap steel is longitudinally arranged at the groove bottom of the material receiving section of the conveying groove (1) in the form of strips; and the scrap steel (C) is fed into the electric furnace (A) through the conveying groove (1). The device has small length, high heat exchanging efficiency, low lifting operation rate, small wear and maintenance, energy conservation and environment friendliness, lowers investment and operation costs and uses new energy-saving and environment-friendly technology with popularization value on smelting processes, such as the electric furnace and the like.

Owner:CISDI ENG CO LTD

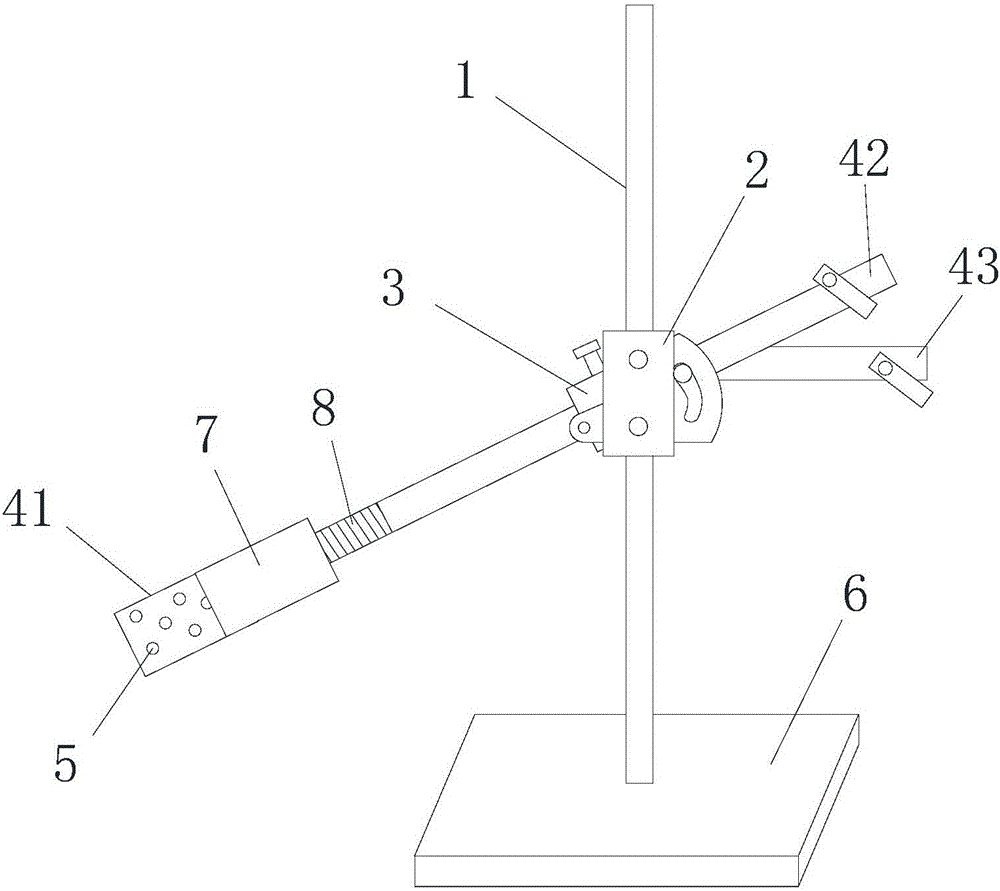

Coaxial hollow tungsten electrode TIG device and welding gun thereof, using method and application

InactiveCN106312270AThe structural design is exquisite, reasonable and creativeSave energyWelding electrode featuresManufacturing technologyEngineering

The invention discloses a coaxial hollow tungsten electrode TIG device and a welding gun thereof, a using method and application and belongs to the technical field of electric arc additive manufacturing. The welding gun of the TIG device comprises a gun body and a hollow tungsten electrode, wherein the front end of the gun body is provided with a ceramic nozzle. The gun body is internally provided with a protective air cavity, and an air inlet hole communicated with the protective air cavity is formed in the gun body and used for being connected with an air source. The hollow tungsten electrode is arranged in the gun body, the front end of the hollow tungsten electrode extends out of the ceramic nozzle, and the middle of the hollow tungsten electrode is provided with a hollow wire feeding cavity. The side wall of the hollow tungsten electrode is provided with an air hole, and the air hole enables the wire feeding cavity of the hollow tungsten electrode to be communicated with the protective air cavity of the gun body. The welding gun is good in welding wire preheating effect, an additive manufacturing cracking phenomenon is avoided, the deposition efficiency is high, the welding speed is quick, weld defects are fewer, and the welding quality is high. According to the device, superspeed and high-quality electric arc additive manufacturing can be performed, and the device is particularly suitable for additive manufacturing of active metals such as copper and aluminum as well as alloy thereof. According to the using method, high quality weld joints can be obtained, and the welding quality is improved.

Owner:JIANGSU ASWEMET PRECISION TECH CO LTD

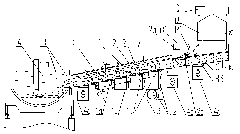

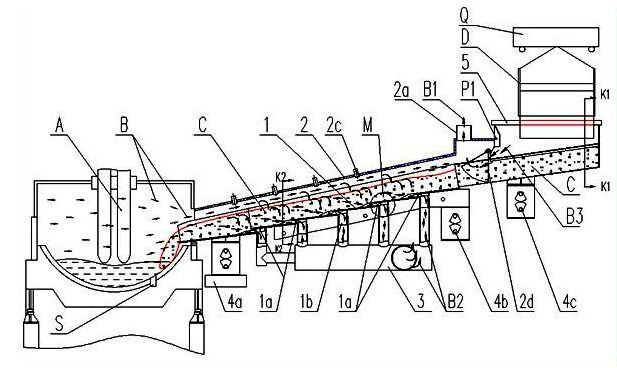

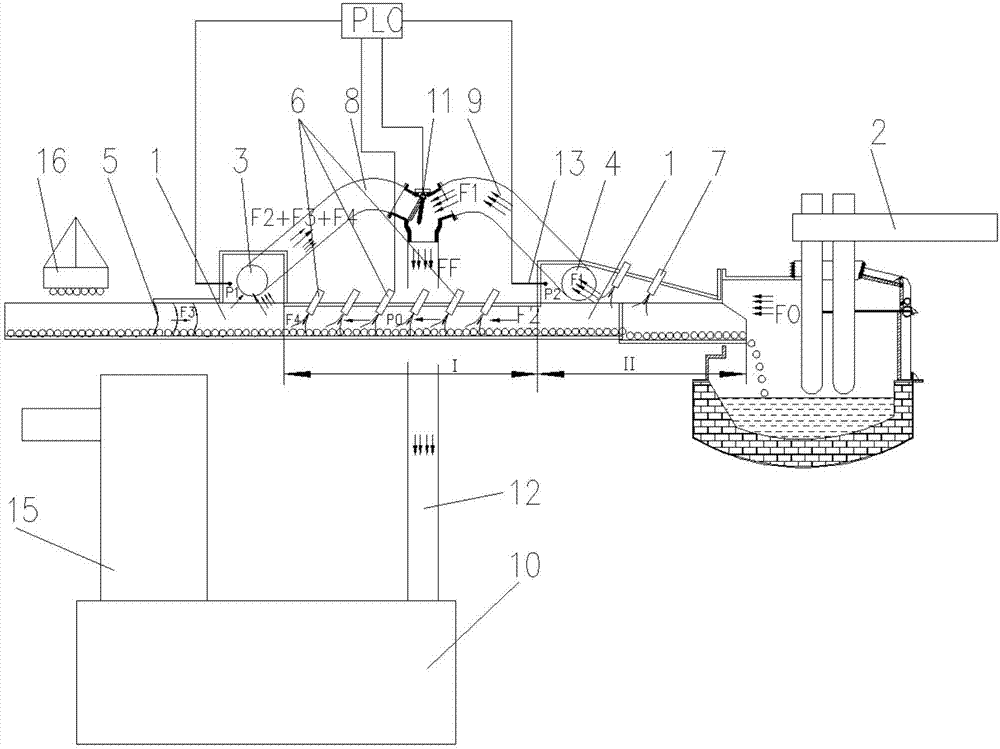

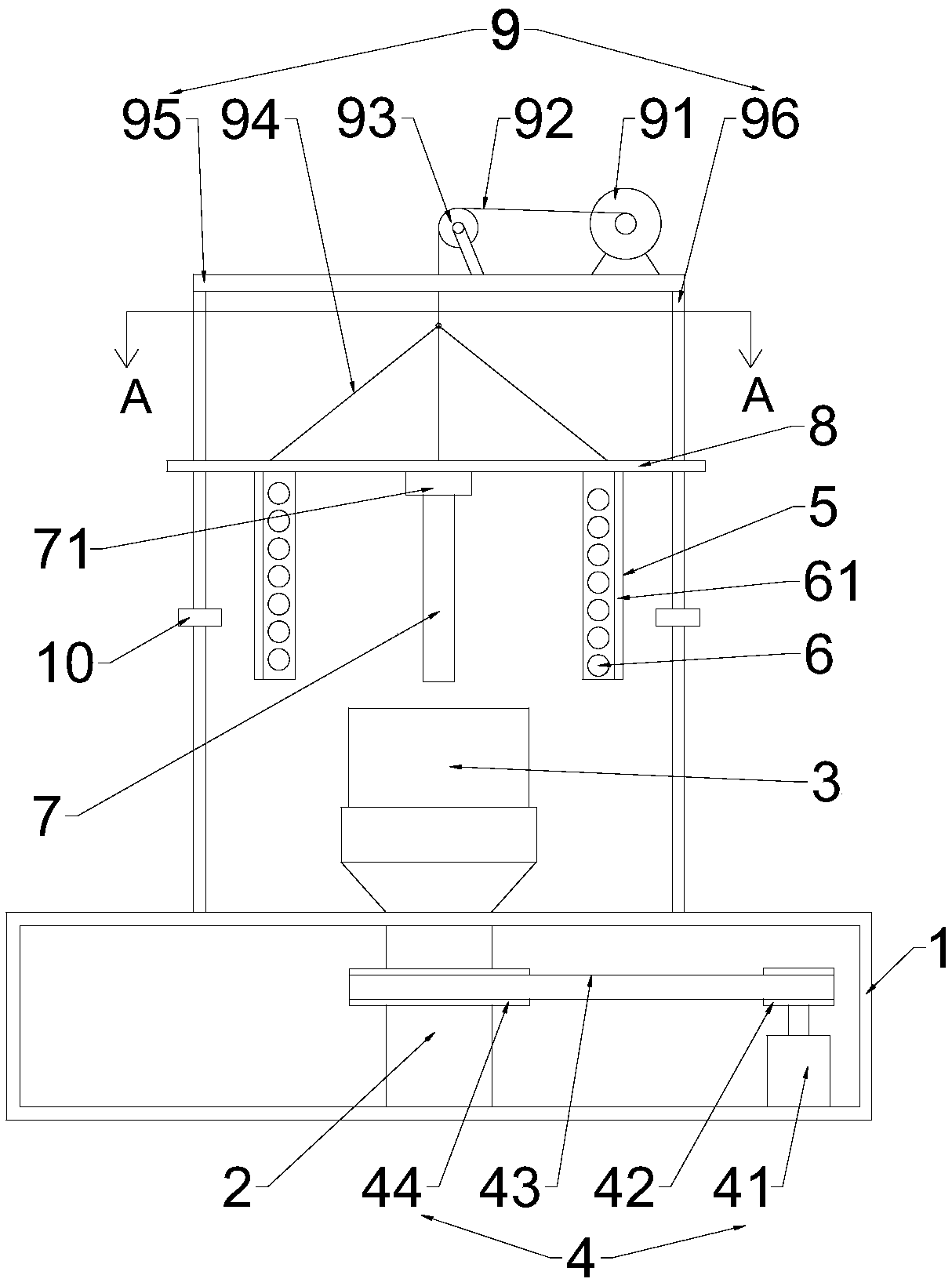

Scrap steel pre-heating conveyor with short process

InactiveCN101907401AExtend your lifeReduce wearCharge manipulationPreheating chargesNew energyEngineering

The invention discloses a scrap steel pre-heating conveyor with a short process, comprising a conveying trough (1) which is provided with a fume guiding hood (2) and is inclined relative to the horizontal plane. The lower end of the conveying trough (1) extends into an electric furnace (A) via an opening on the sidewall of the electric furnace (A); a bottom-opened long distributing trough (D) is arranged above the other end of the conveying trough (1), is arranged above a material receiving section of the conveying trough (1) by a swing device (Q), and is arranged in the downward projection of the material receiving section of the conveying trough (1) longitudinally; and scrap steels (C) are longitudinally arranged at the bottom of the material receiving section of the conveying trough (1) in a strip shape, and then the conveying trough (1) conveys the scrap steels (C) into the electric furnace (A). The scrap steel pre-heating conveyor with a short process is short, has high heat exchange efficiency, low operation rate of a crane, small abrasion, less maintenance, energy conservation, environment protection and reduces investment and operation cost, thus the invention is a new energy-saving and environment-friendly technology with promotional value in smelting technique, such as electric furnaces and the like.

Owner:CISDI ENG CO LTD

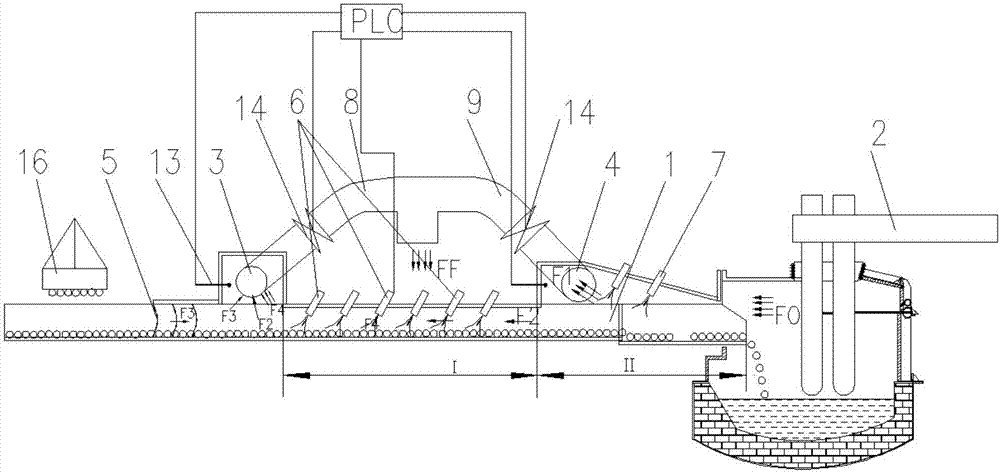

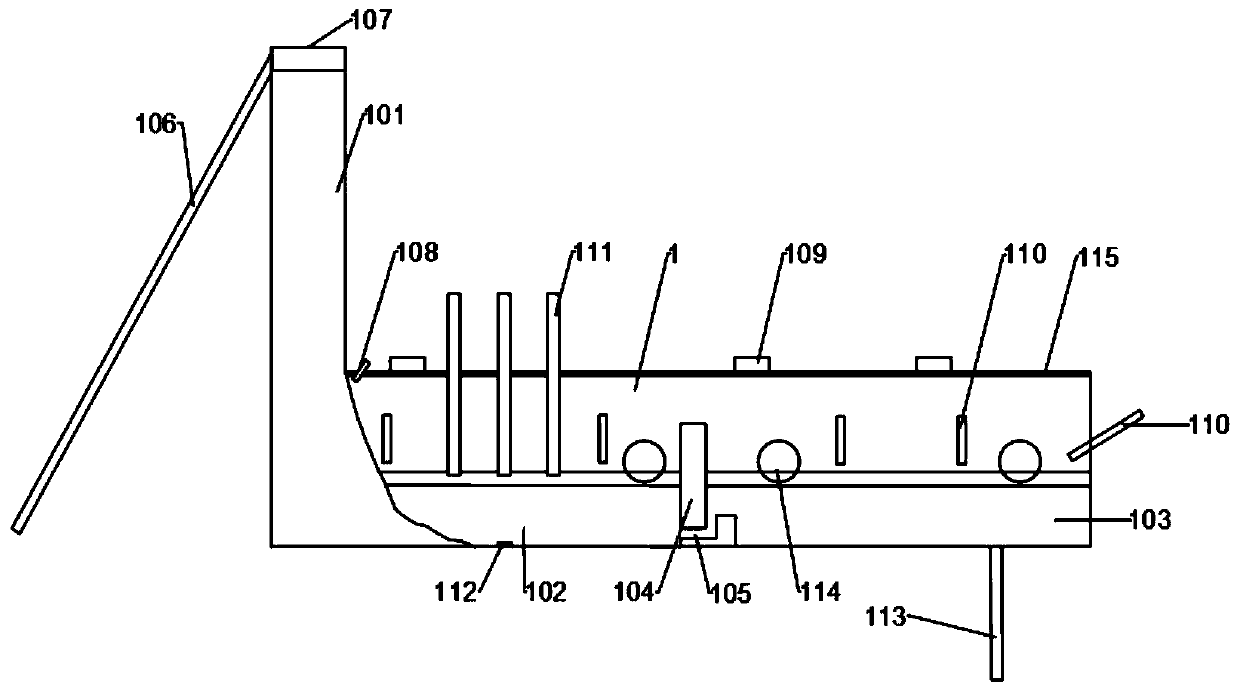

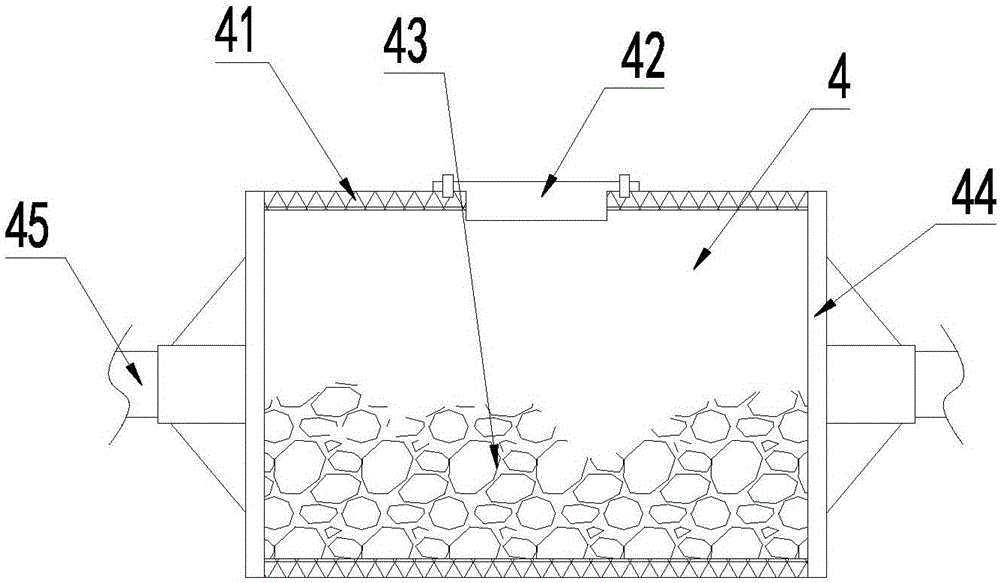

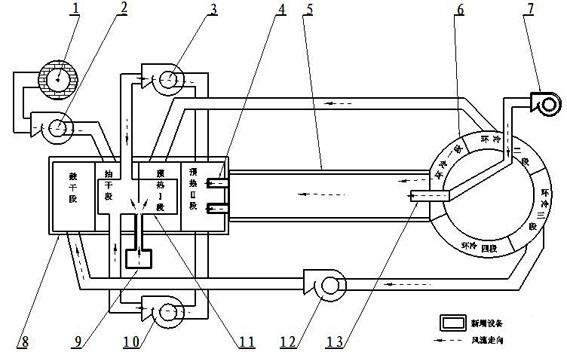

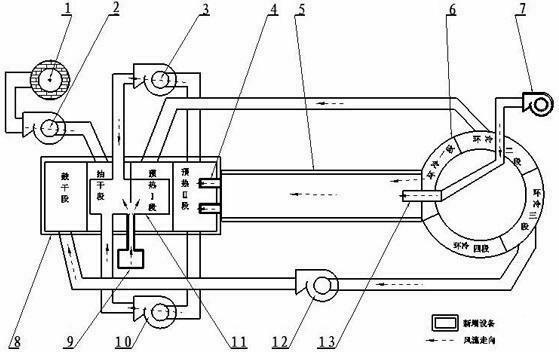

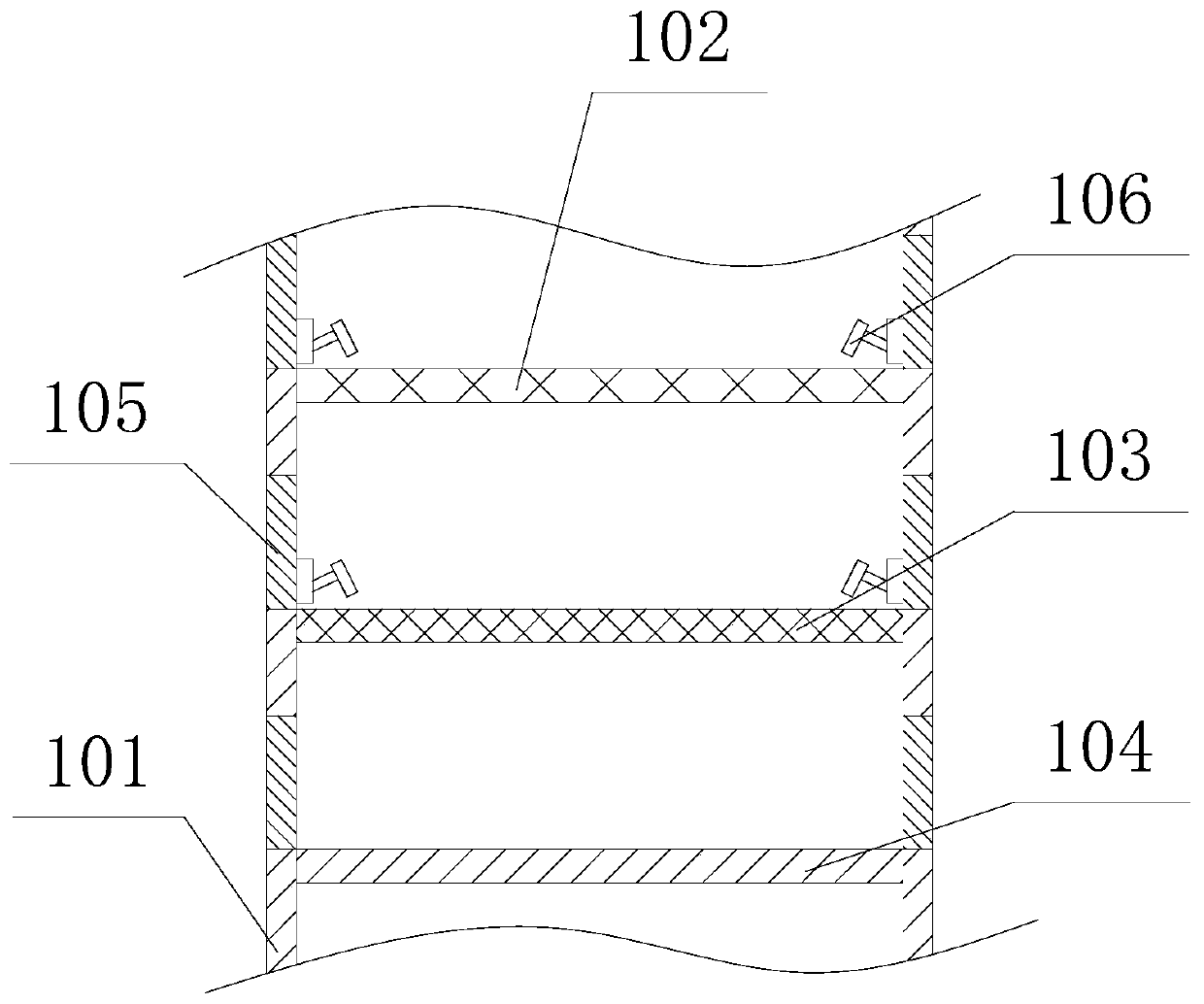

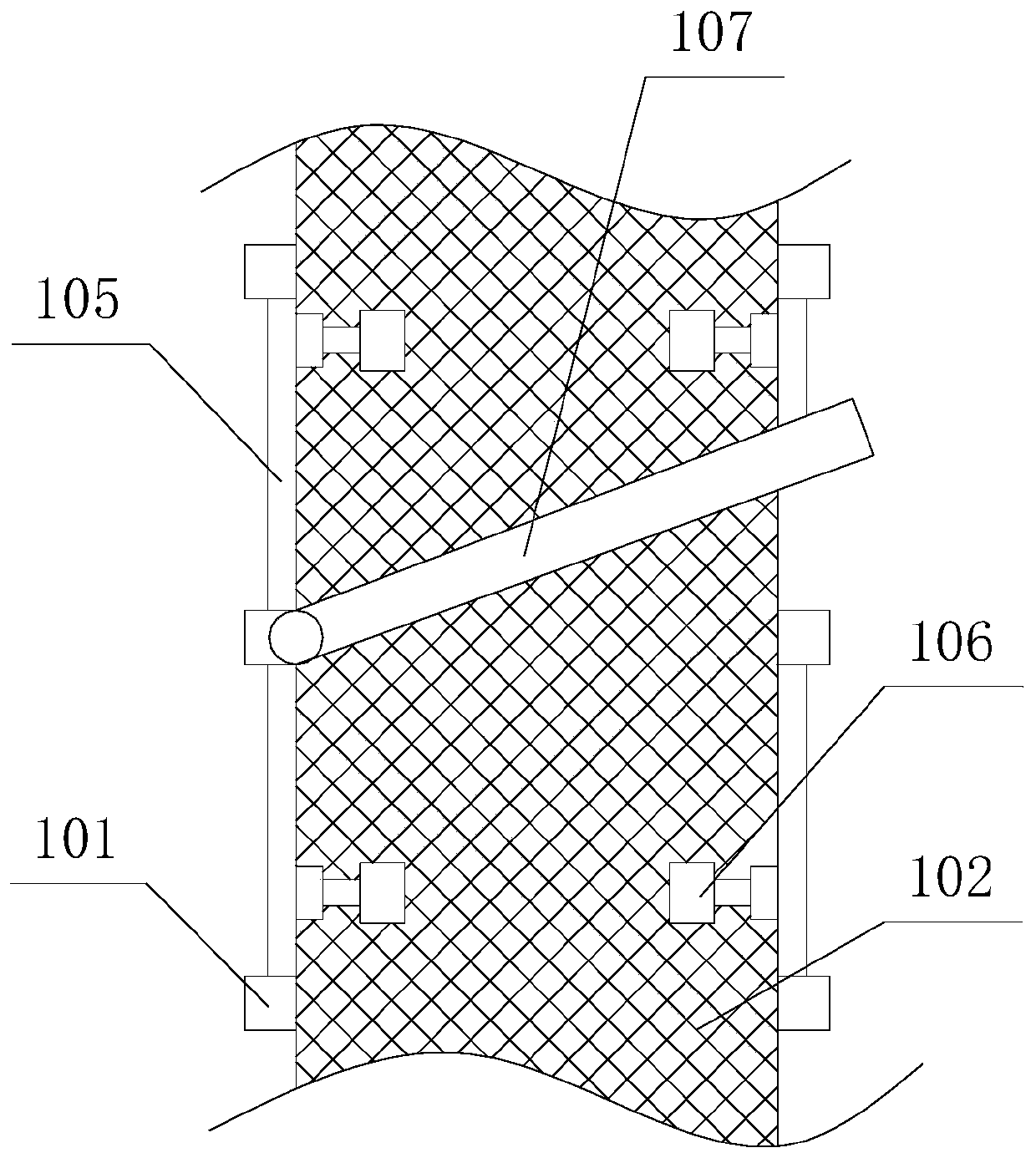

Horizontal continuous feeding and preheating device and strengthened preheating method thereof

ActiveCN107460274AImprove combustion thermal efficiencyImprove heat transfer effectCharge manipulationPreheating chargesCold airElectric arc furnace

The invention belongs to the field of metallurgical technologies and discloses a horizontal continuous feeding and preheating device and a strengthened preheating method of the horizontal continuous feeding and preheating device. According to the scheme, two dust removal openings are correspondingly formed in the front portion and the rear portion of a horizontal continuous feeding and preheating duct, and the horizontal continuous feeding and preheating duct is divided into a strengthened preheating region and a smoke preheating region by the front dust removal opening and the rear dust removal opening; burners are mounted in the strengthened preheating region, and the two dust removal openings are correspondingly connected with smoke adjustment distributors through smoke pipelines; the dust removal negative pressure of the second dust removal opening is balanced by the jet flow dynamic pressure of the multiple rows of bruners in the strengthened preheating region; and the micro-negative pressure requirement of the first dust removal opening is controlled through a pressure sensor, so that the mixing amount of cold air of the first dust removal opening is reduced, the preheating efficiency of the burners and smoke of an electric arc furnace on steel scrap is improved, and the production is more environmentally-friendly.

Owner:CISDI ENG CO LTD +1

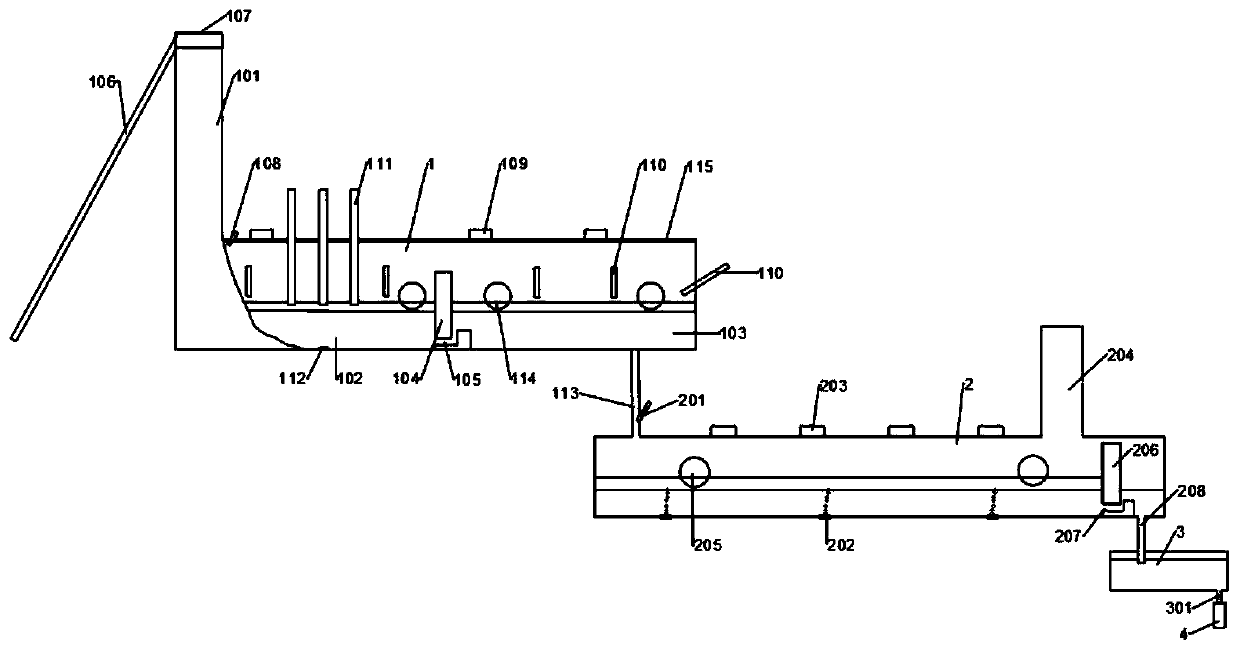

All-scrap continuous steelmaking system and smelting process

ActiveCN111100968AAvoid contactReduce wasteProcess efficiency improvementSteelmakingSmelting process

The invention relates to the technical field of steelmaking, and provides an all-scrap continuous steelmaking system and a smelting process. Through the division of the scrap steel smelting process into six procedures of preheating, fusion, preliminary smelting, refining, finishing and casting, the different smelting procedures can be performed in different devices; through the cooperation betweencontinuous feeding and continuous casting, the dynamic balancing of material and energy flow among a smelting bed, a refining bed and a tundish can be kept, thereby achieving stable, efficient, low-cost, high-quality and long-life all-scrap continuous steelmaking production; and by the use of the all-scrap continuous steelmaking system and the smelting process, the electricity consumption per tonof steel can be reduced by 50 kWh or above, the energy consumption can be reduced by 10 kgce or above, the product quality can be improved, the smelting rhythm can be accelerated, and the productioncost can be reduced.

Owner:UNIV OF SCI & TECH BEIJING

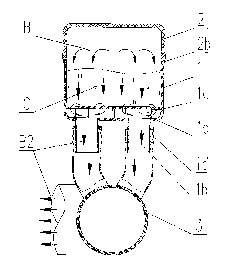

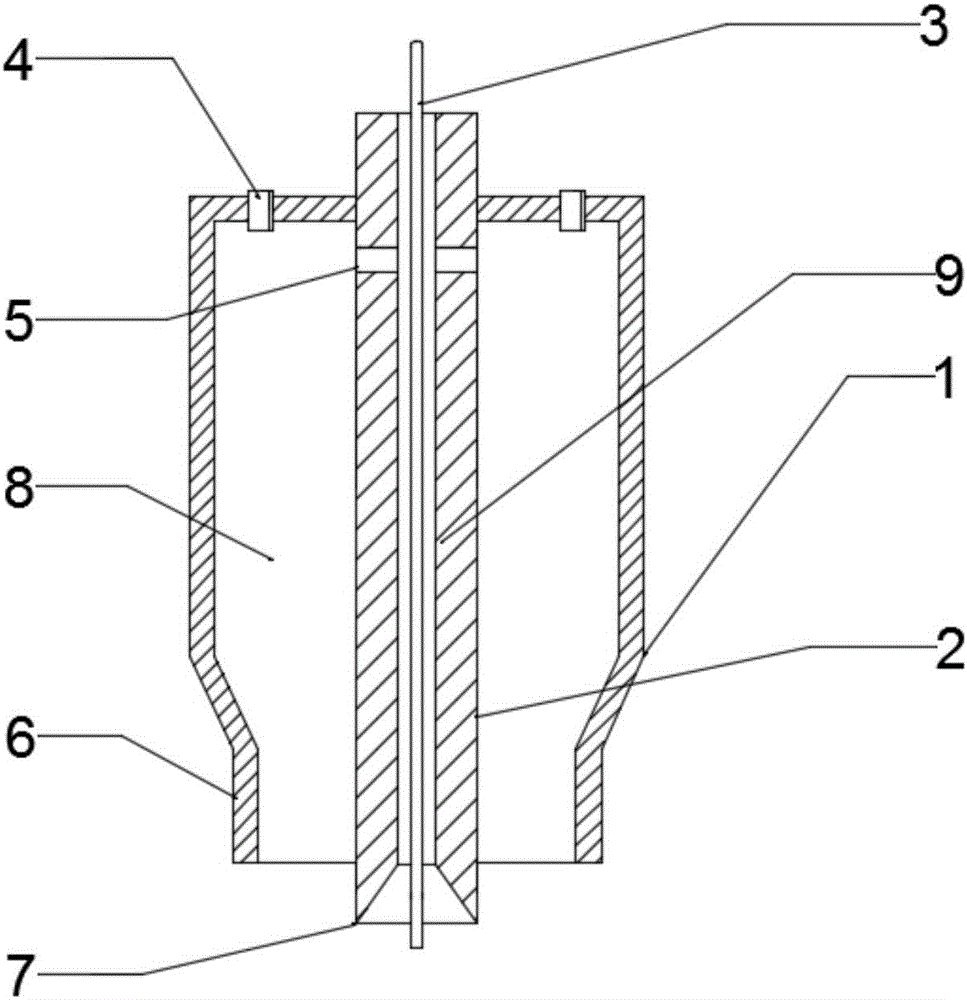

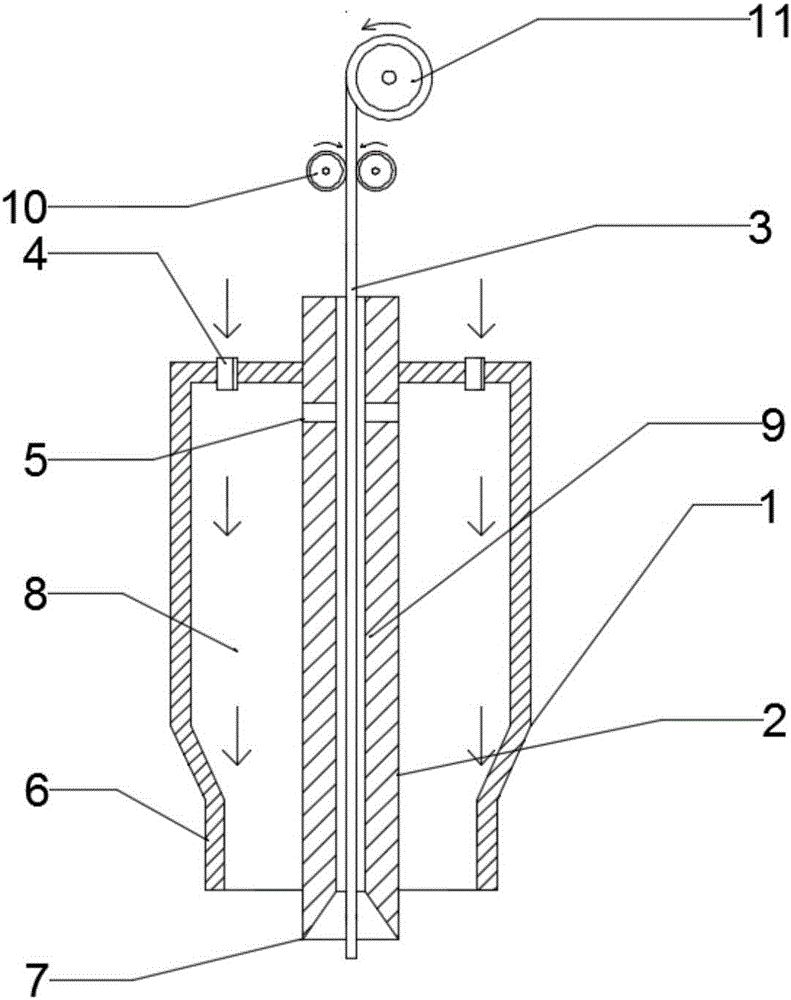

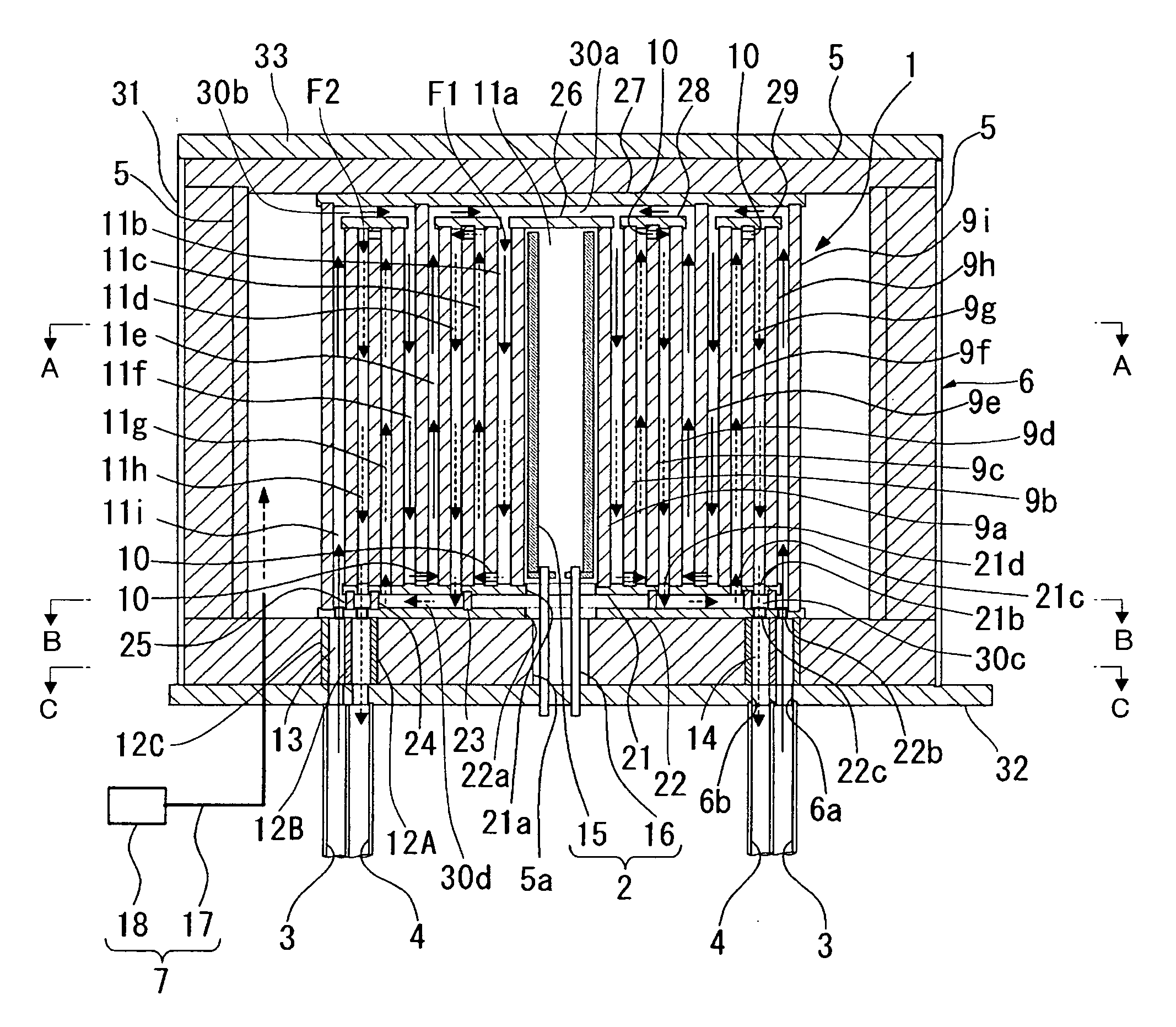

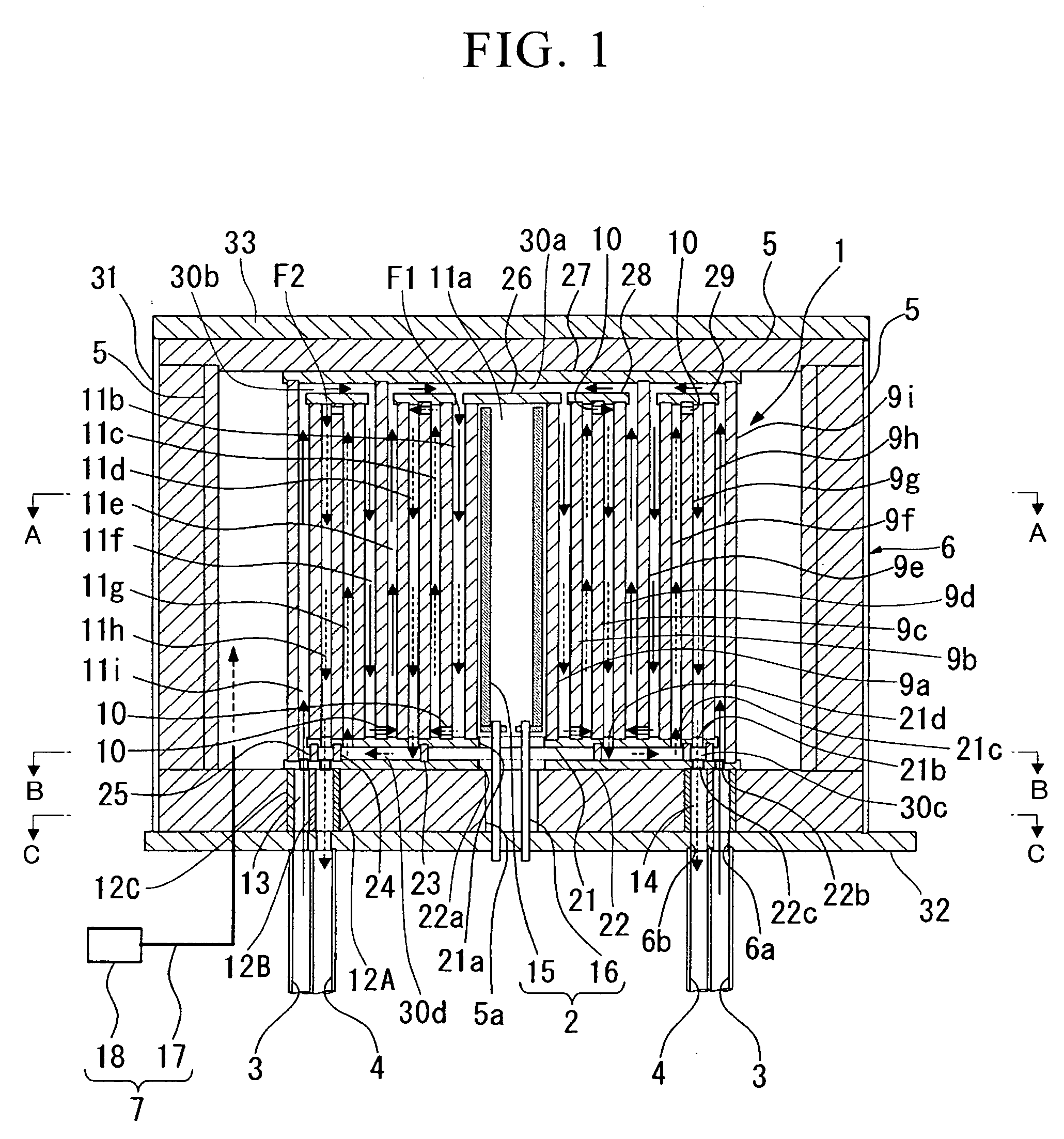

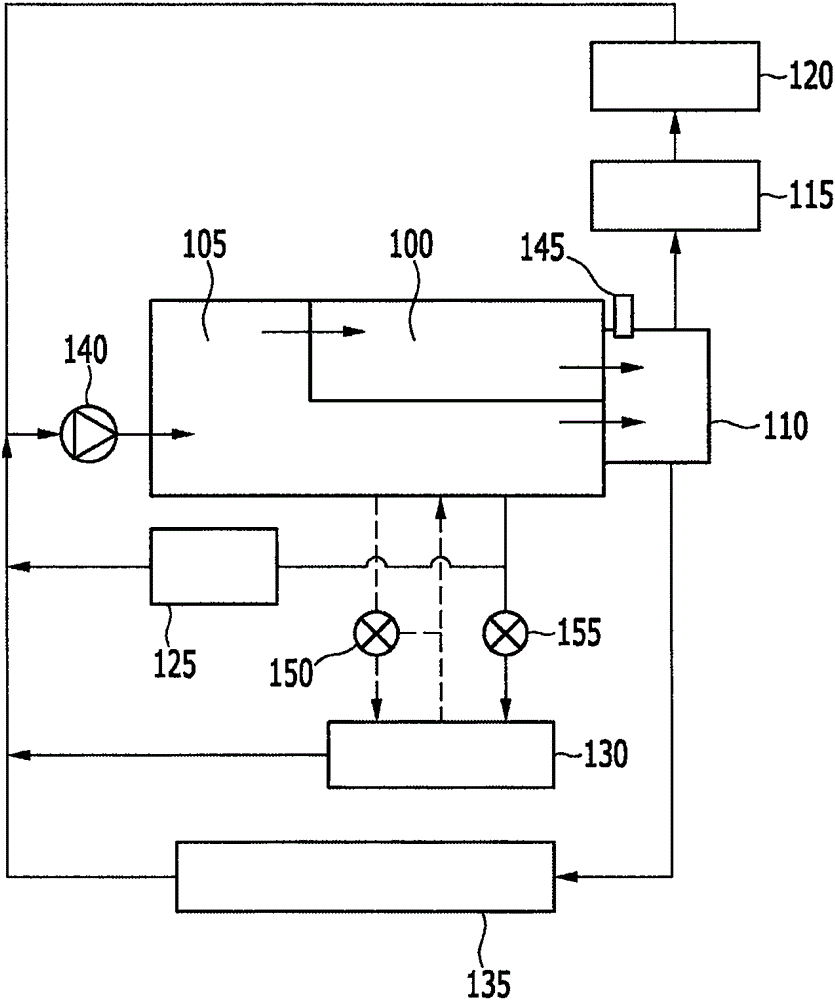

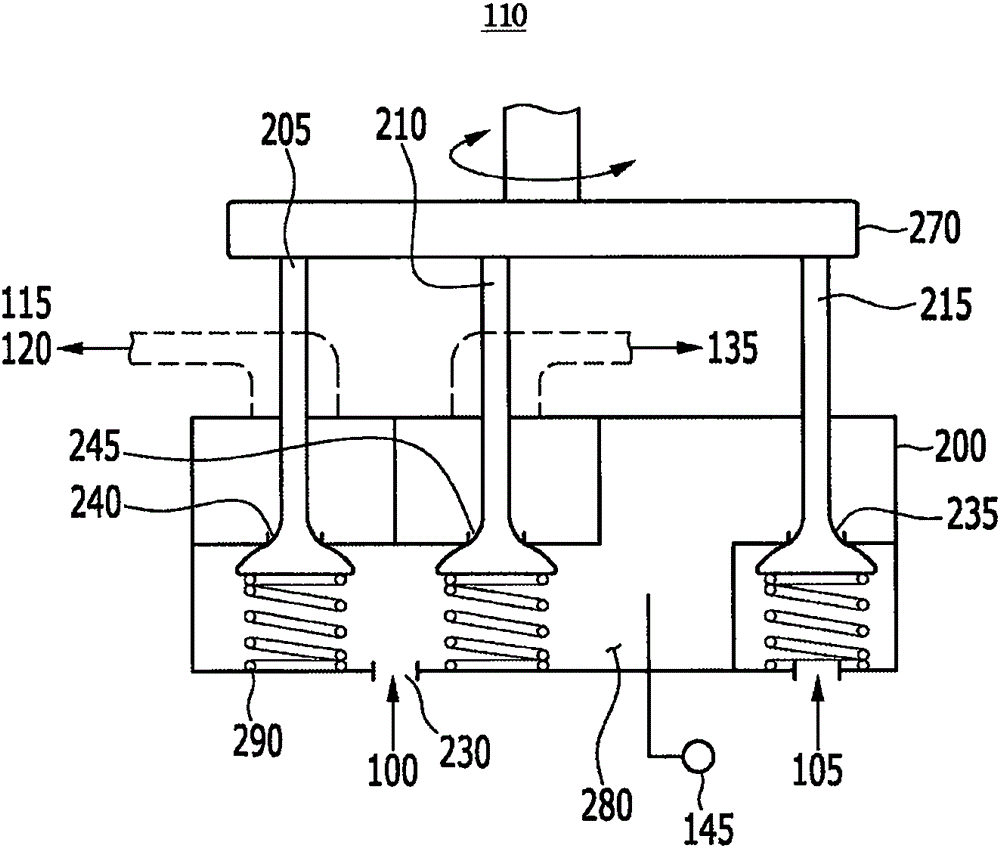

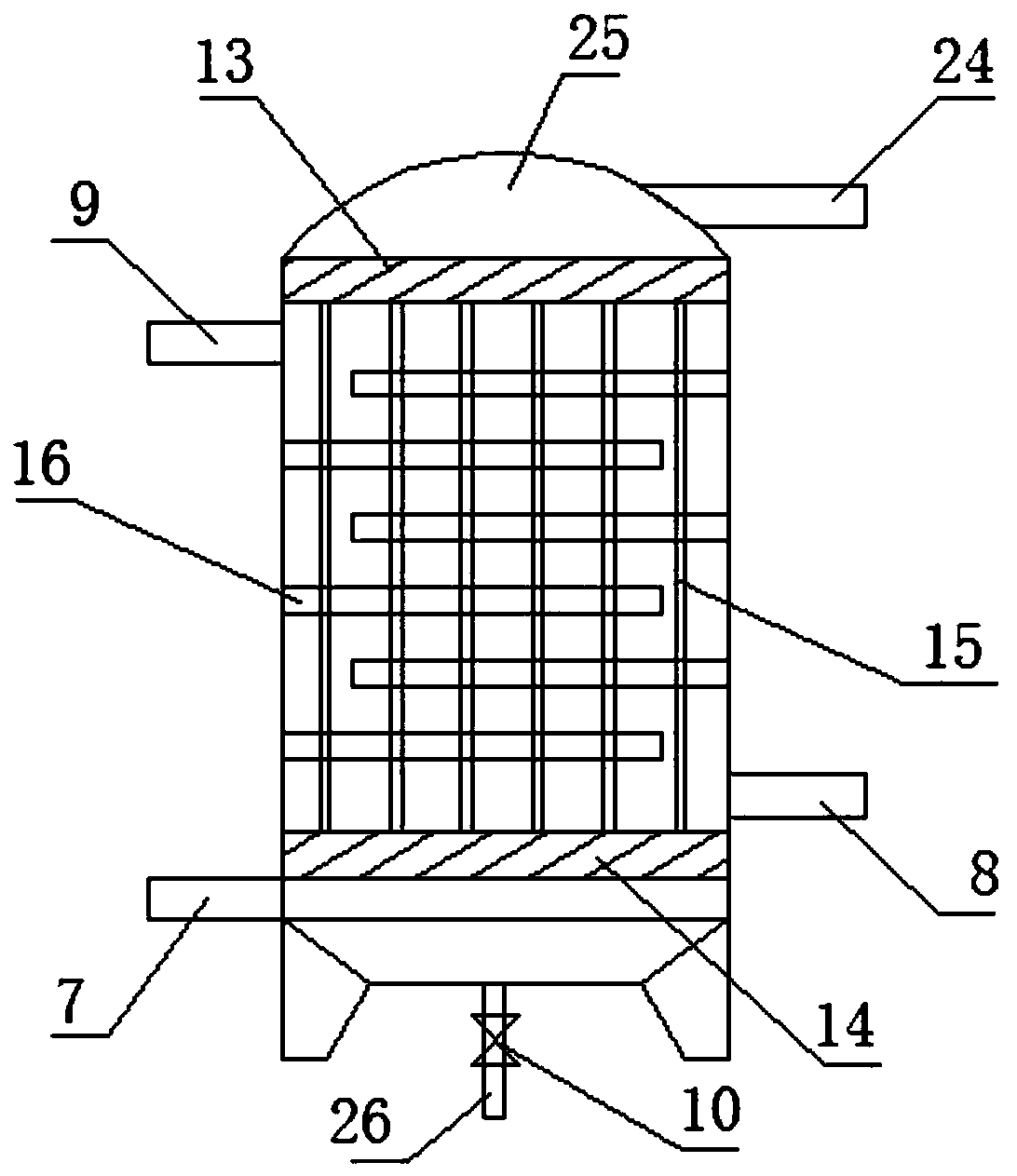

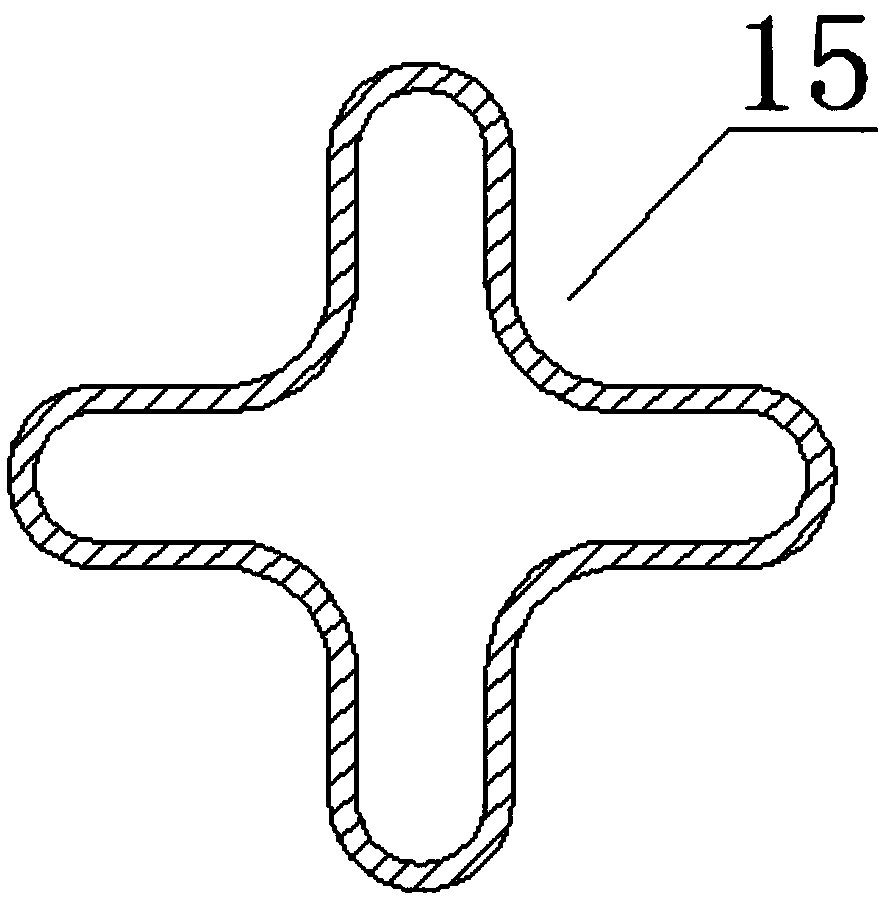

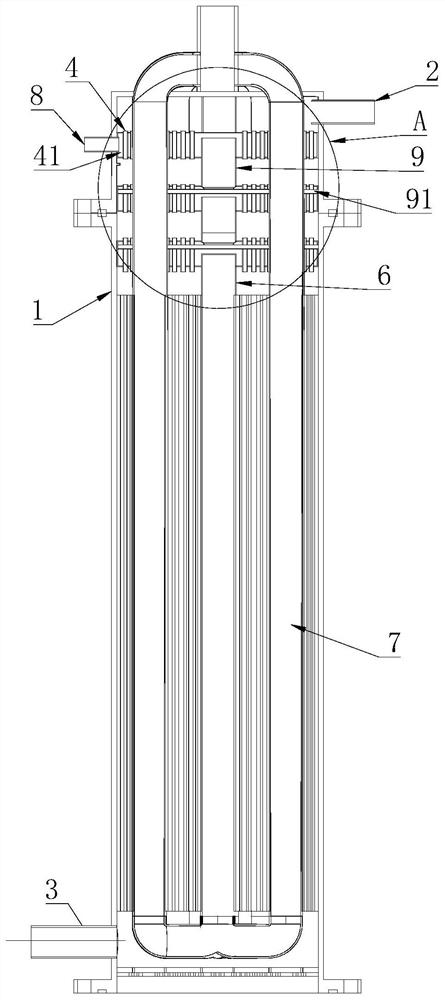

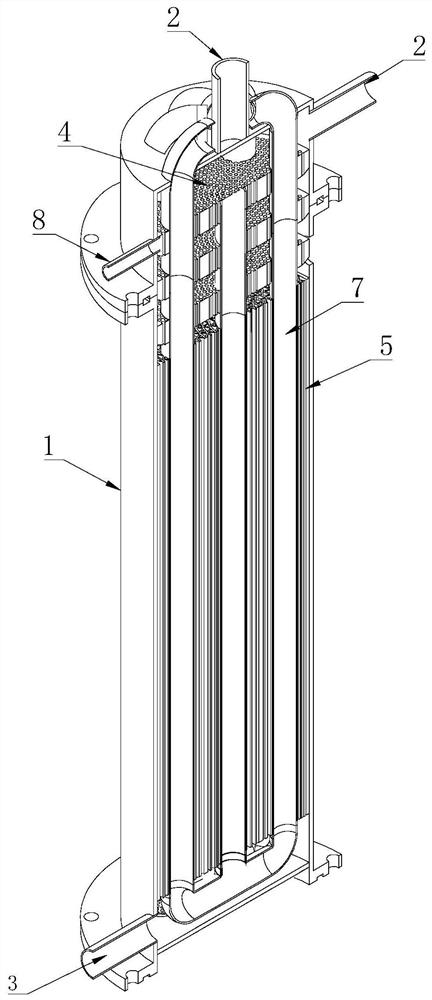

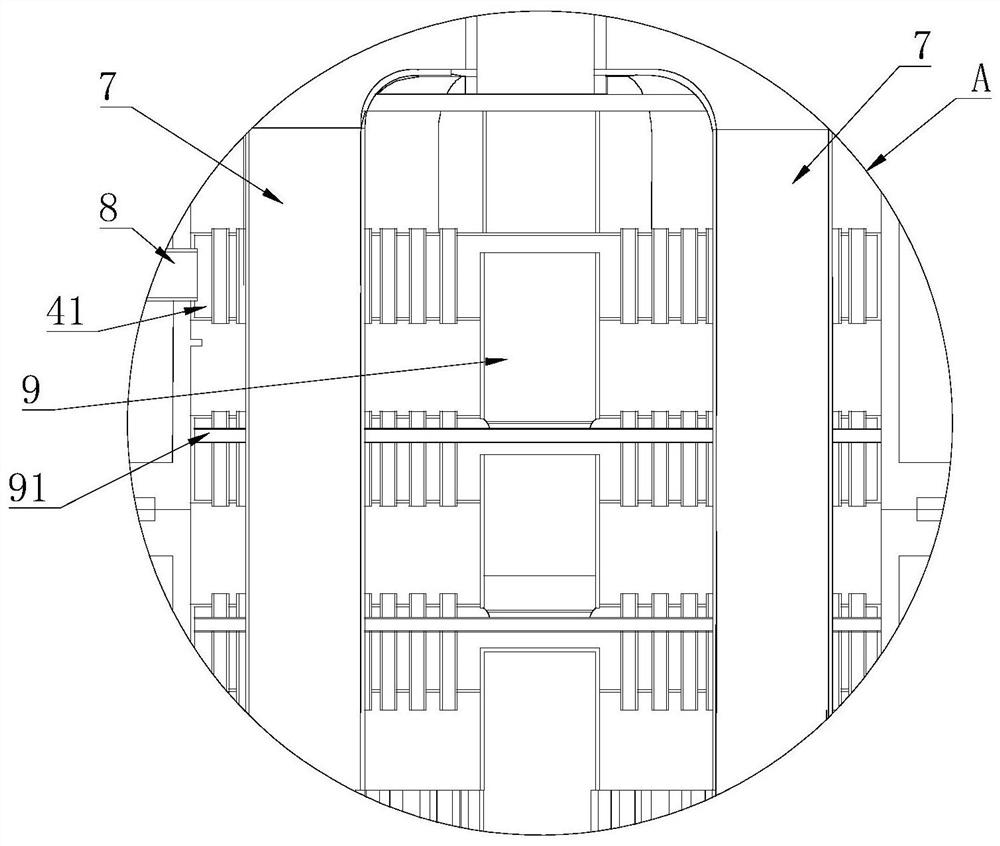

Apparatus for Producing Trichlorosilane

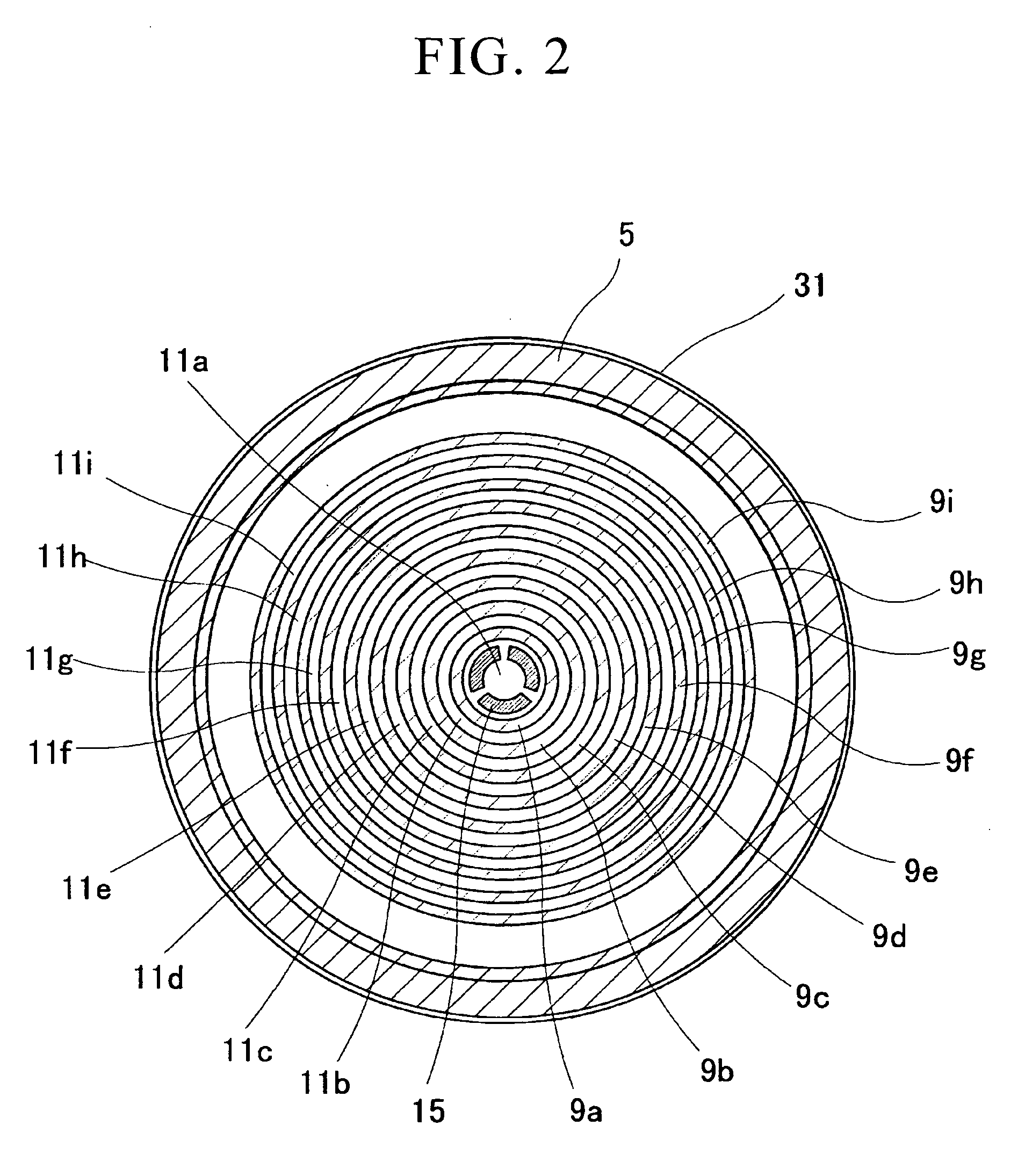

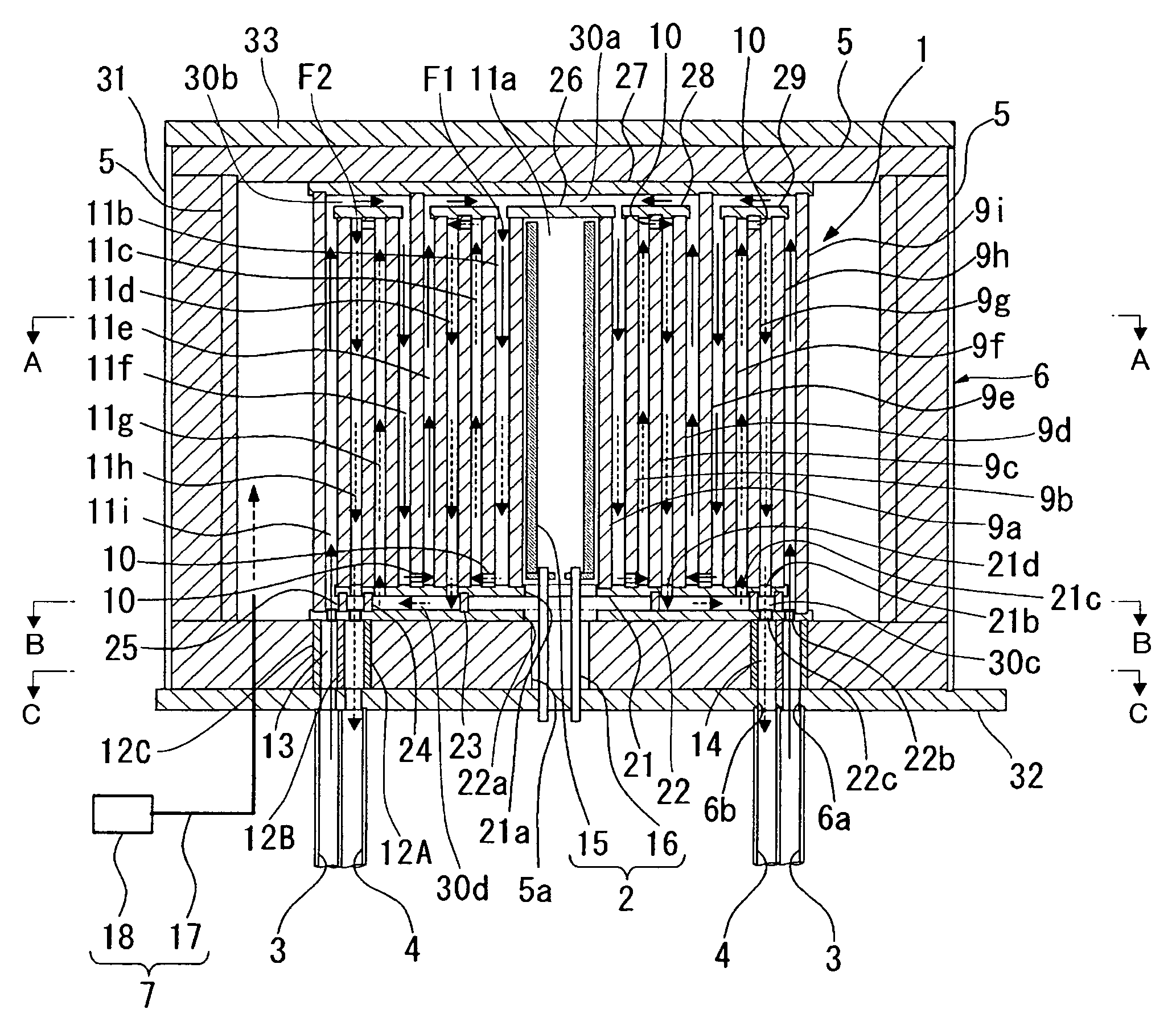

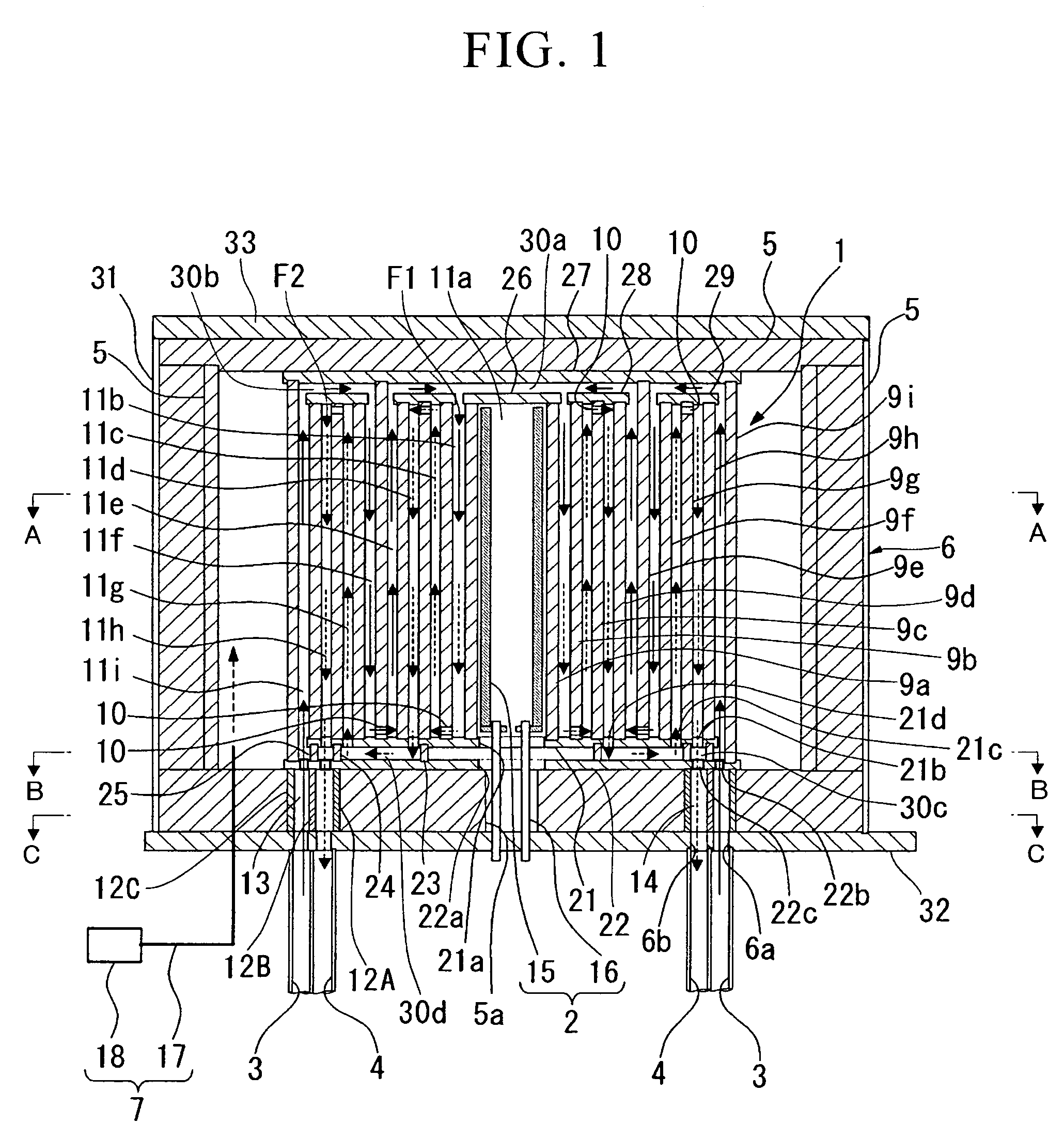

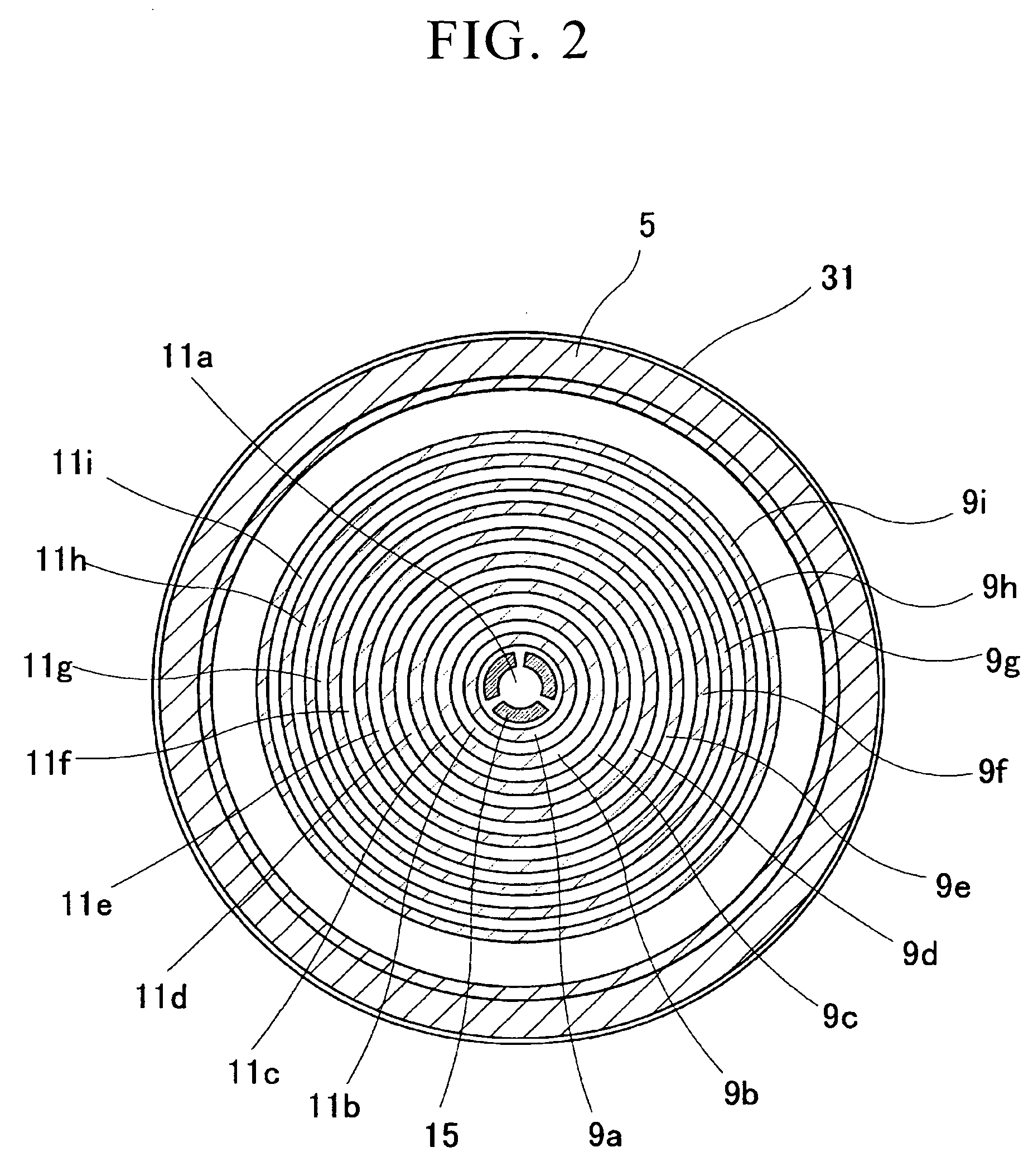

ActiveUS20090155140A1Small sizeHigh thermal efficiencyCatalytic gas-gas reactionSilicon halogen compoundsHydrogenProduct gas

An apparatus for producing trichlorosilane, including: a reaction vessel in which a supply gas containing silicon tetrachloride and hydrogen is supplied to an internal reaction passageway to produce a reaction product gas containing trichlorosilane and hydrogen chloride; a heating mechanism having a heater that heats the interior of the reaction vessel; a gas supply section that supplies the supply gas in the reaction vessel; and a gas discharge section that discharges the reaction product gas from the reaction vessel to the outside, wherein the heater is disposed in the center of the reaction vessel, and the reaction passageway is disposed in the periphery of the heater.

Owner:HIGH-PURITY SILICON CORP

Apparatus for producing trichlorosilane

ActiveUS7964155B2Small sizeHigh thermal efficiencyCatalytic gas-gas reactionSilicon halogen compoundsHydrogenSilicon tetrachloride

An apparatus for producing trichlorosilane, including: a reaction vessel in which a supply gas containing silicon tetrachloride and hydrogen is supplied to an internal reaction passageway to produce a reaction product gas containing trichlorosilane and hydrogen chloride; a heating mechanism having a heater that heats the interior of the reaction vessel; a gas supply section that supplies the supply gas in the reaction vessel; and a gas discharge section that discharges the reaction product gas from the reaction vessel to the outside, wherein the heater is disposed in the center of the reaction vessel, and the reaction passageway is disposed in the periphery of the heater.

Owner:HIGH-PURITY SILICON CORP

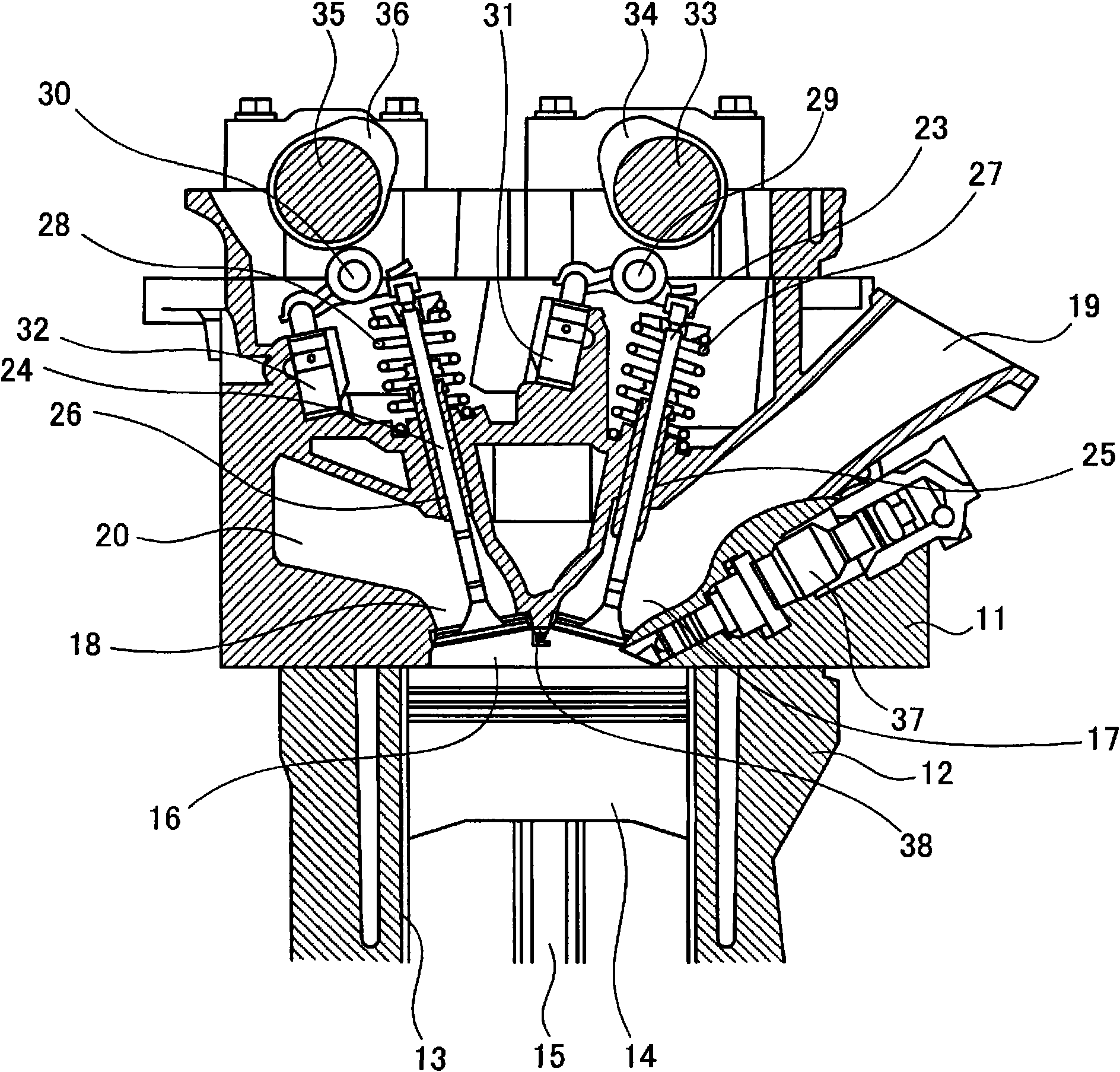

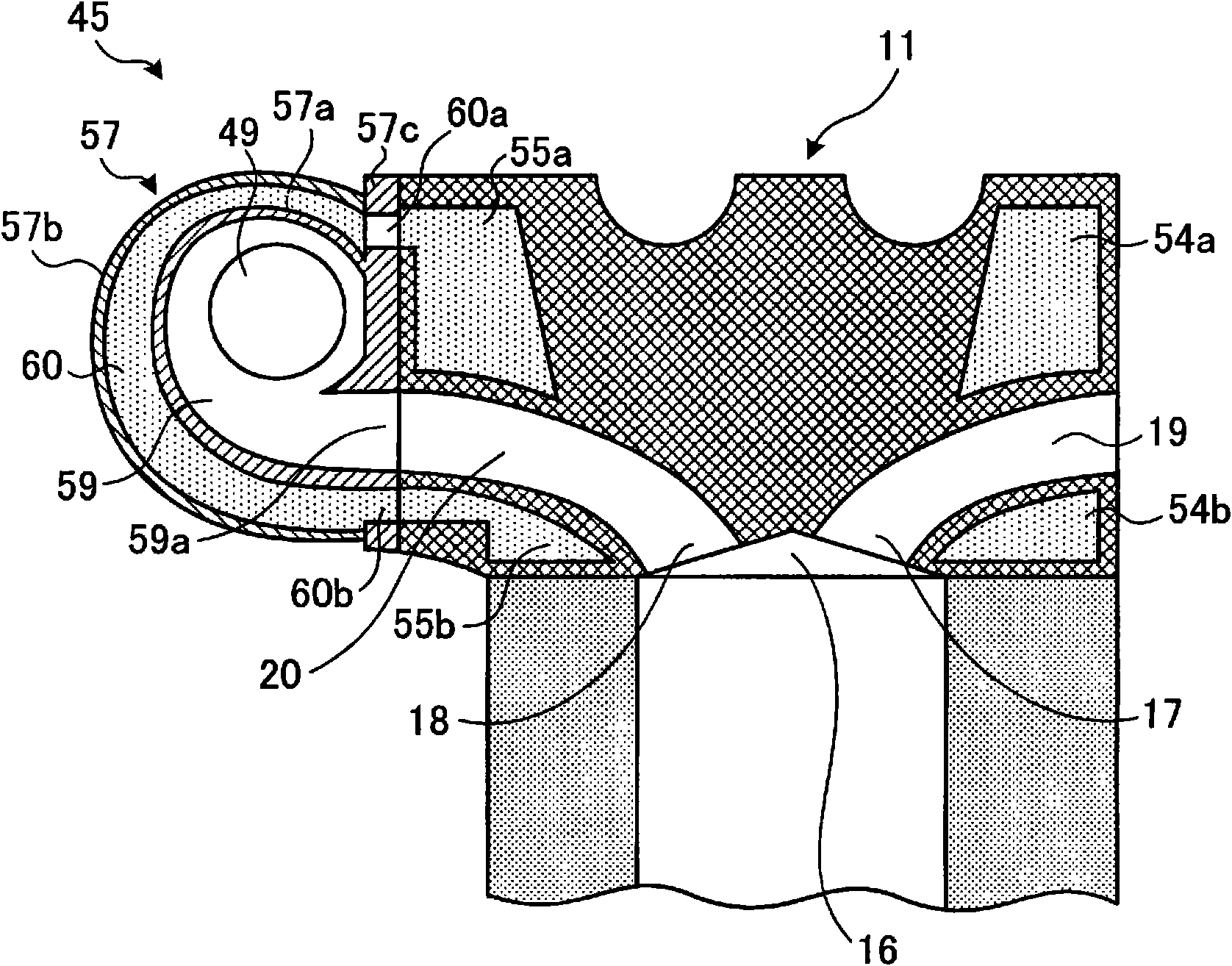

Cylinder head for internal combustion engine

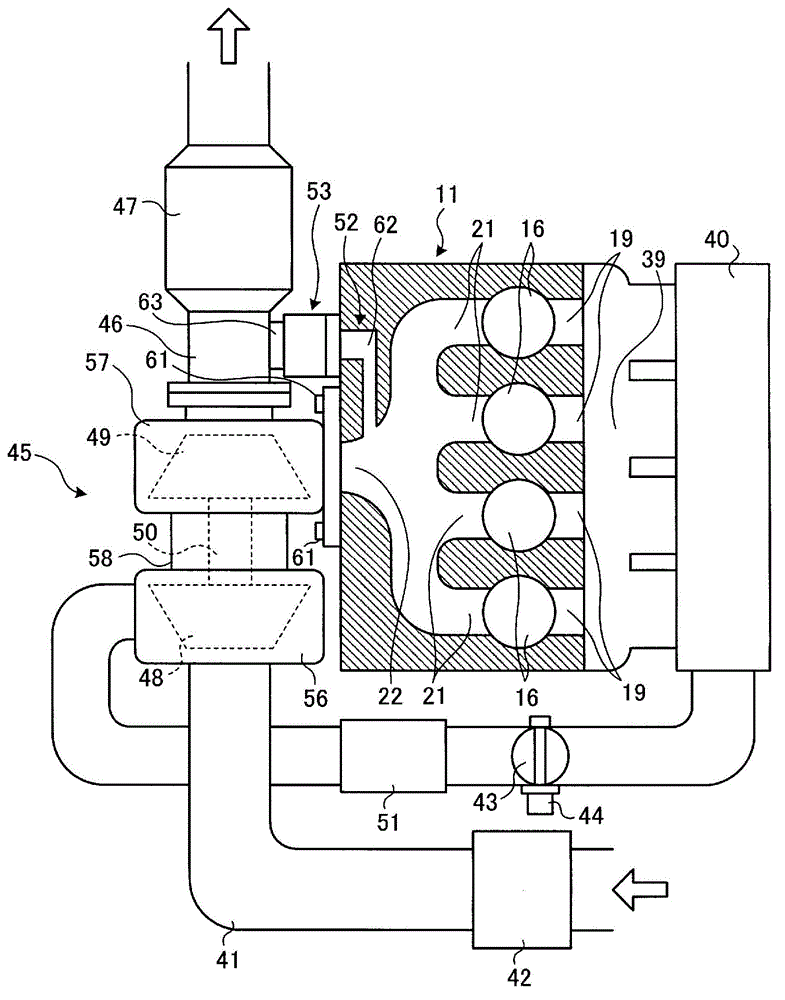

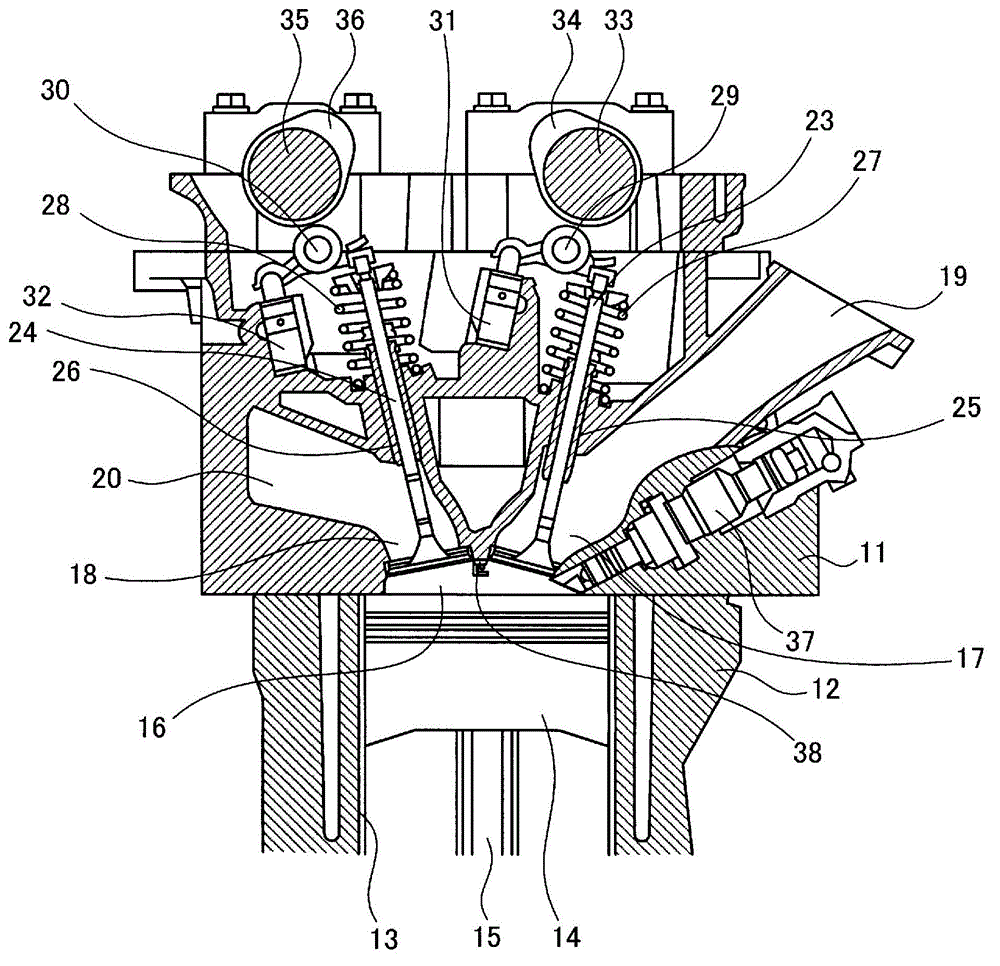

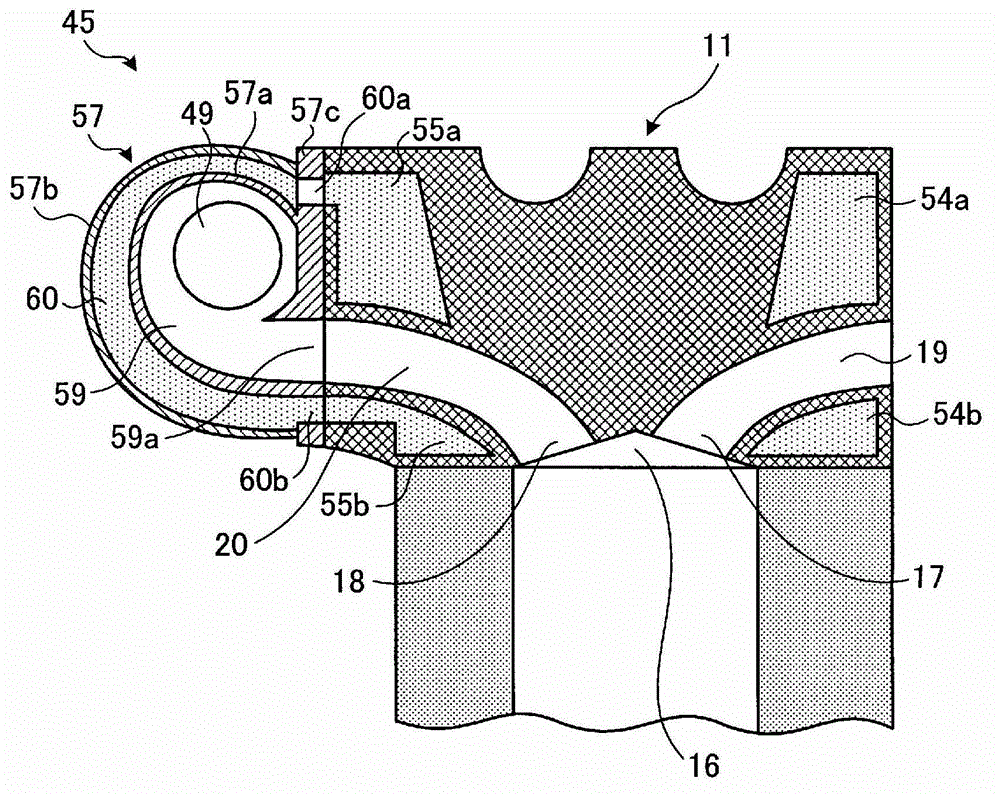

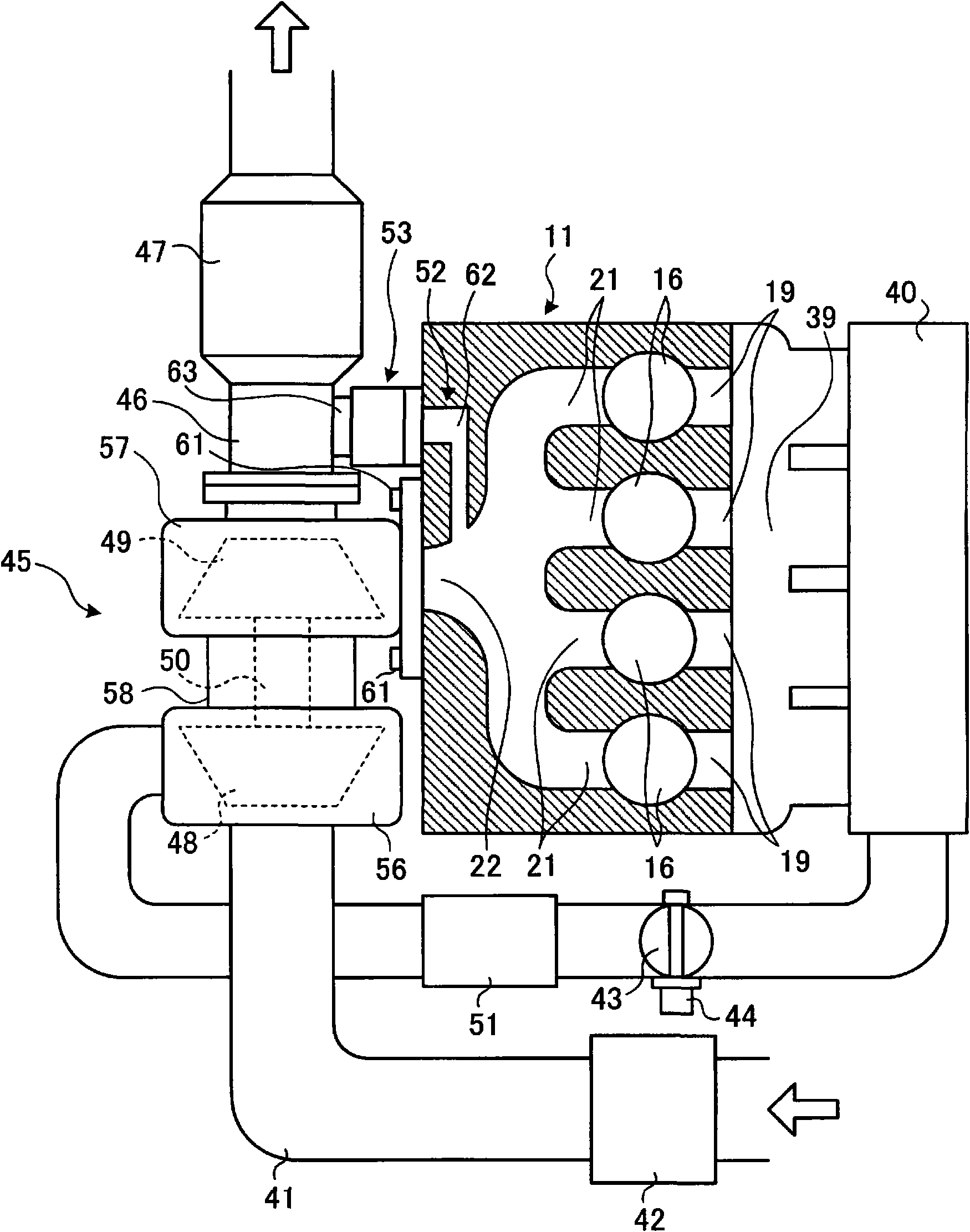

InactiveCN102865154AImprove warm-up effectReduce the temperatureInternal combustion piston enginesExhaust apparatusTurbochargerCylinder head

One ends of an exhaust path 20 communicate with a plurality of combustion chambers 16 through exhaust ports 18, respectively, an assembling section 22 is provided on the other ends of the exhaust path 20, and a turbo supercharger 45, an exhaust tube 46 and an exhaust purification catalyst 47 are connected to the assembling section 22, on the other hand, a bypass path 52 communicating from the exhaust path 20 to the exhaust tube 46 and the exhaust purification catalyst 47 by bypassing a turbo supercharger 45 is provided and an exhaust control valve 53 capable of opening and closing the bypass path 52 is provided, and a bypass hole 62, which is a part of the bypass path 52, is provided in the cylinder head 11. In the cylinder head of the internal-combustion engine, catalyst warm-up performance is improved and a device is made compact-sized.

Owner:TOYOTA JIDOSHA KK

Cylinder head for internal combustion engine

InactiveCN101600876AImprove warm-up effectReduce the temperatureCasingsInternal combustion piston enginesCombustion chamberCylinder head

In a cylinder head for internal combustion engine according to the invention, one ends of an exhaust path 20 communicate with a plurality of combustion chambers 16 through exhaust ports 18, respectively, an assembling section 22 is provided on the other ends of the exhaust path 20, and a turbo supercharger 45, an exhaust tube 46 and an exhaust purification catalyst 47 are connected to the assembling section 22, on the other hand, a bypass path 52 communicating from the exhaust path 20 to the exhaust tube 46 and the exhaust purification catalyst 47 by bypassing a turbo supercharger 45 is provided and an exhaust control valve 53 capable of opening and closing the bypass path 52 is provided, and a bypass hole 62, which is a part of the bypass path 52, is provided in the cylinder head 11. In the cylinder head of the internal-combustion engine, catalyst warm-up performance is improved and a device is made compact-sized.

Owner:TOYOTA JIDOSHA KK

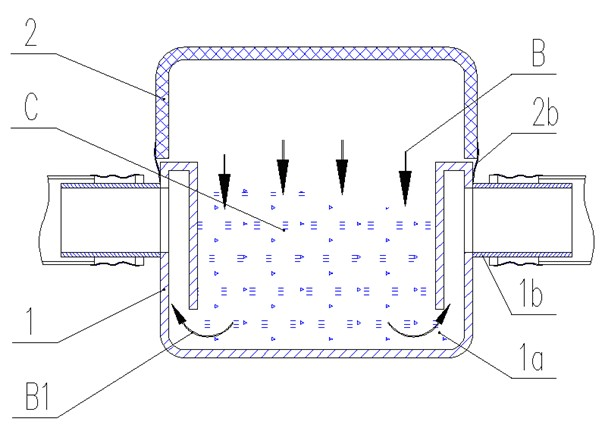

Device and method for casting large-sized compound steel ingot by using graphite electrode ring for preheating electroslag

The invention provides a device and method for casting a large-sized compound steel ingot by using a graphite electrode ring for preheating electroslag. The device comprises a T-shaped electric conduction crystallizer, supporting arms and a lined electroslag furnace, wherein two transverse arms on a support are respectively used for lifting and dropping the graphite electrode ring and a self-consuming electrode ring; the lined electroslag furnace is used for slagging and pouring premelting slag into the T-shaped electric conduction crystallizer; and an annular bottom water tank is arranged onan ingot introducing plate. The method comprises the following steps of: (1) putting a core rod in the T-shaped electric conduction crystallizer, slagging the premelting slag in the lined electroslagfurnace, and forming a slag tank by pouring; (2) lowering the graphite electrode ring, and causing the graphite electrode ring, the slag tank, the upper crystallizer, a casting power source and the traverse arms to form an electric conduction loop, and heating the surface of the core rod and the slag tank by electrifying; and (3) when a preset temperature reaches, moving away the graphite electrode ring, inserting the self-consuming electrode ring into the slag tank, and carrying out electroslag casting. The method has high utilization rate of heat, can prevent interlayer slag from being generated on the compound interface of the steel ingot, facilitates the improvement of the quality of the steel ingot and simplifies the production equipment.

Owner:NORTHEASTERN UNIV LIAONING

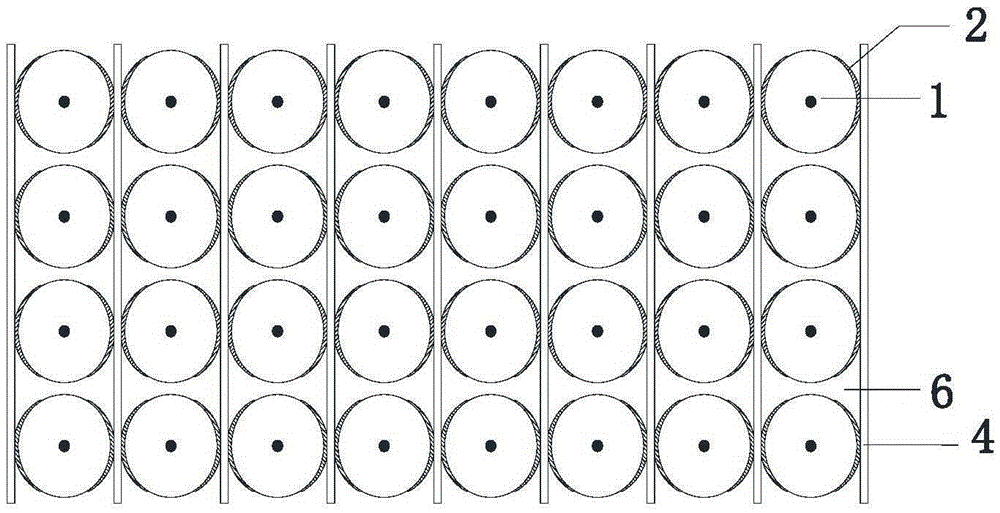

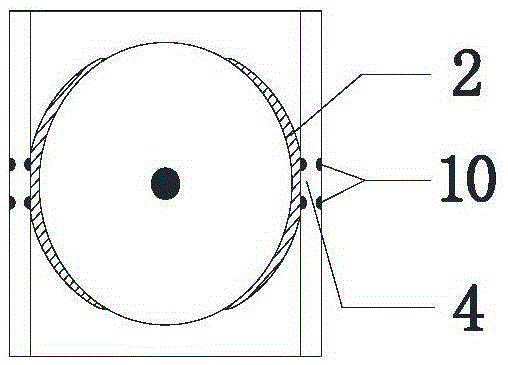

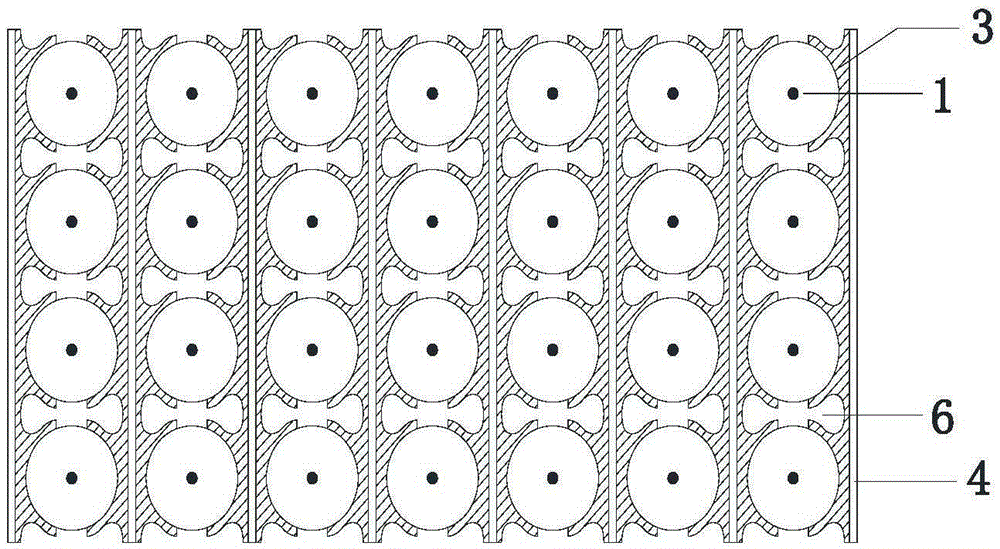

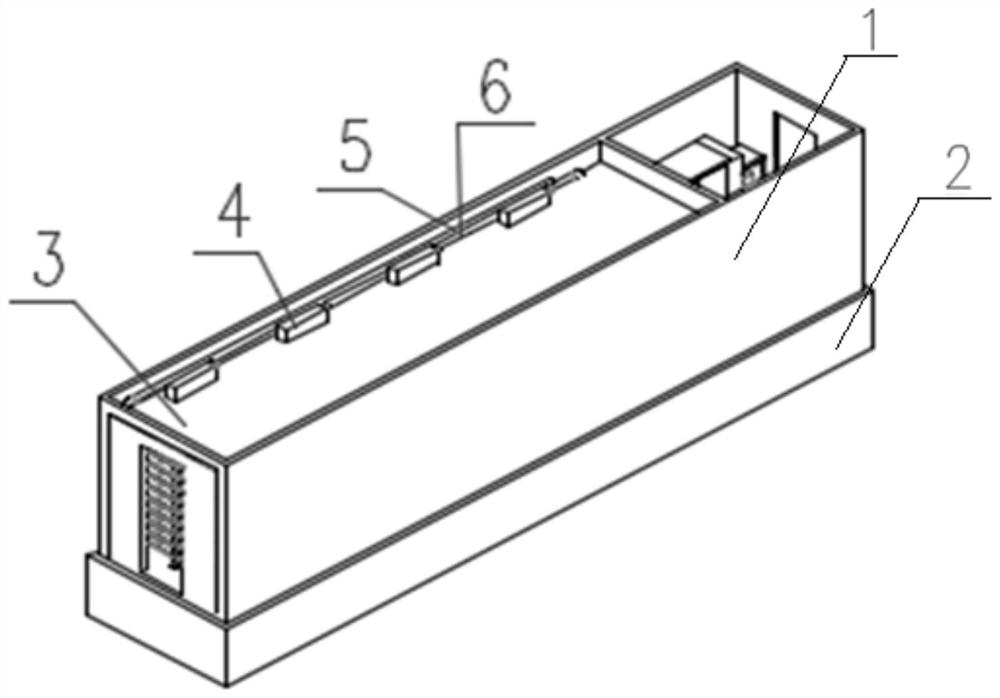

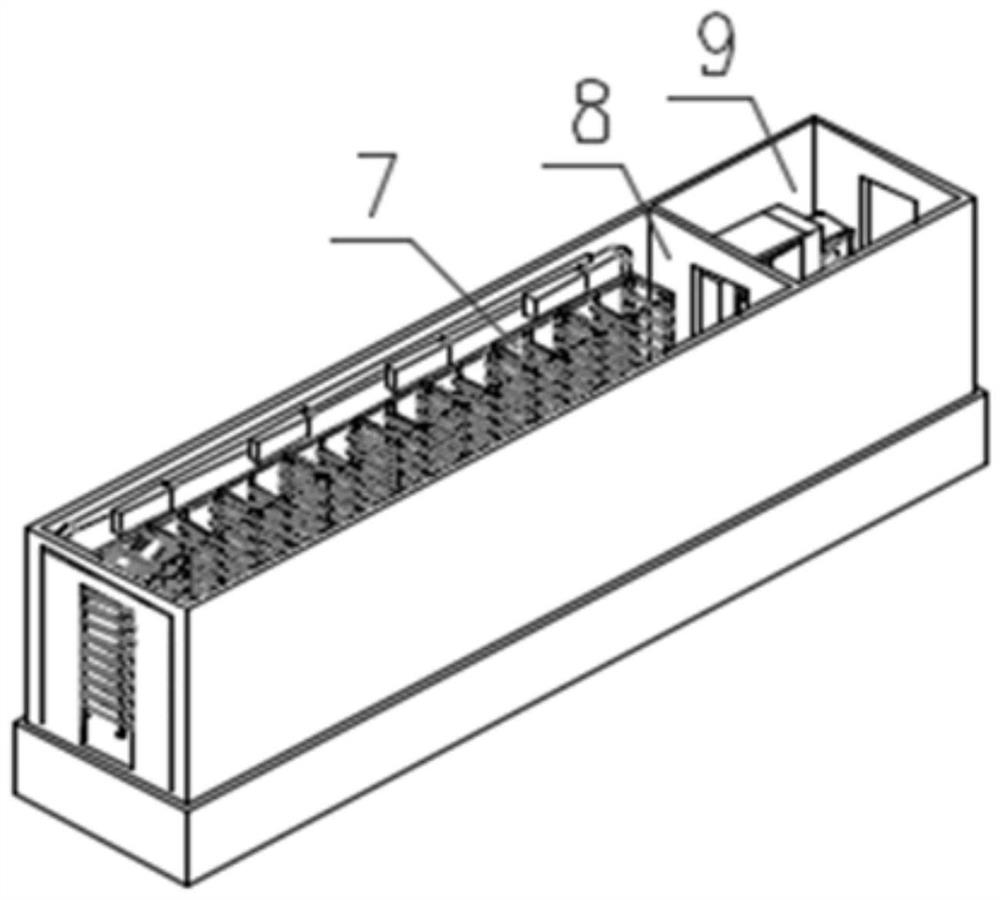

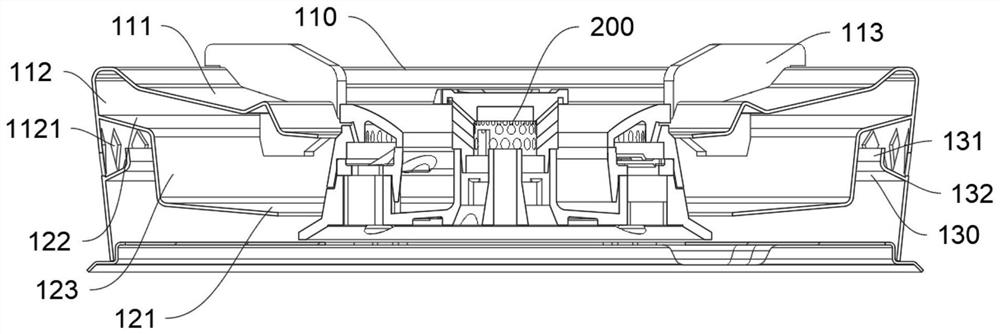

Heat management system and method of cylindrical battery pack

The invention relates to a heat management system and method of a cylindrical battery pack. The heat management system of the cylindrical battery pack comprises an anomalous heat-conducting plate, a micro-heat tube array plate and a heat source. When dissipating heat, the planar structure of the plate surface of the anomalous heat-conducting plate is stuck with an evaporation section of the micro-heat tube array plate, and the evaporation section of the micro-heat tube array plate after absorbing the heat energy of the cylindrical battery pack delivered by the anomalous heat-conducting plate is subjected to a heat tube effect, and then heat exchange with the outside is carried out by the condensing section of the micro-heat tube array plate; when pre-heating, a heat source is arranged at the evaporation section of the micro-hot tube array plate, the planar structure of the plate surface of the anomalous heat-conducting plate is stuck with the condensing section of the micro-heat tube array plate, the evaporation section of the micro-heat tube array plate after absorbing the heat energy of the heat source is subjected to the heat tube effect, then the heat is discharged through the condensing section of the micro-heat tube array plate and then the heat is conducted to the cylindrical battery pack through the anomalous heat-conducting plate. The heat management system integrates a heat dissipation function and a heating function, guarantees uniform temperature of the cylindrical battery pack, is high in heat conduction efficiency, compact in volume and light in weight, and improves the heat exchange efficiency and effect.

Owner:赵耀华

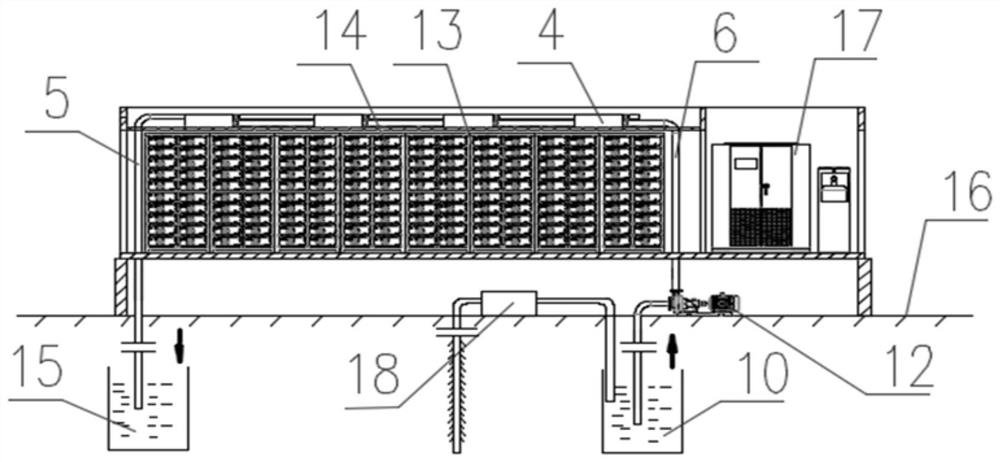

Method for cooling container energy storage system through underground water and temperature adjusting system thereof

The invention discloses a method for cooling a container energy storage system through underground water and a temperature adjusting system thereof. According to the method, an internal circulation cooling mode is adopted, specifically, underground water of a constant-temperature water layer is pumped and then fed into a hot water reservoir through a plurality of fan coils, and meanwhile the temperature adjusting system pumps air in a battery cabin; the extracted air in the cabin respectively flows through each fan coil through internal circulation air ducts to exchange heat with the underground water, and the air in the cabin is blown into the battery cabin to realize cooling; when the temperature in the battery cabin is still continuously higher than the high-temperature threshold value in the internal circulation cooling mode, the temperature adjusting system is switched into an external circulation cooling mode, the internal circulation air ducts are switched into external circulation air ducts communicated with the outside, and the external circulation air ducts suck external air, and the external air flows through each fan coil and then is blown into the battery cabin to realize cooling. Under the condition that direct refrigeration or heating is avoided in a low-temperature environment, the temperature of the energy storage system in different working states is adjusted.

Owner:安徽海螺新能源有限公司

Engine system having coolant control valve

ActiveCN106481433AFunction increaseImprove warm-up effectLiquid coolingOperating means/releasing devices for valvesCylinder headProcess engineering

An engine system includes a cylinder block and a cylinder head. A coolant control valve unit is engaged with the cylinder head to receive a coolant exhausted from the cylinder block and a coolant exhausted from the cylinder head. The coolant control valve unit controls a coolant to be supplied to a heater, a radiator, and an oil cooler and controls the coolant exhausted from the cylinder block. The coolant control valve unit receives the coolant from the cylinder head, supplies the coolant to the oil cooler, and controls the coolant distributed to the heater and the coolant exhausted from the cylinder block.

Owner:HYUNDAI MOTOR CO LTD

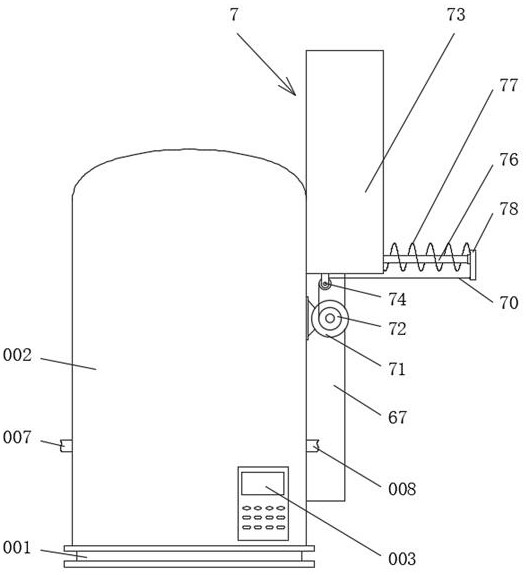

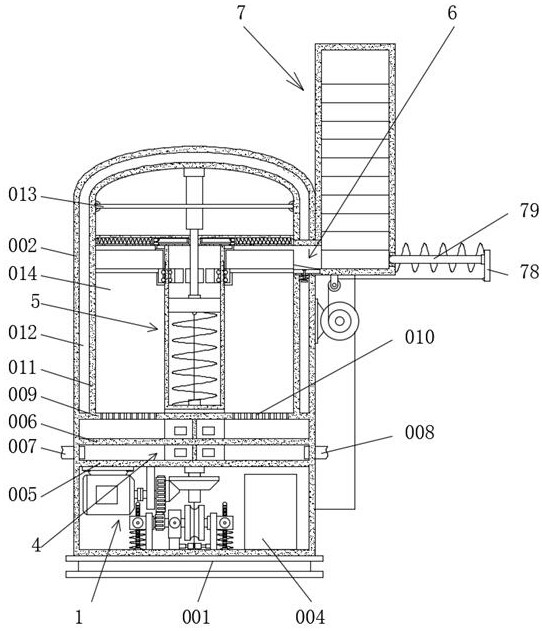

Industrial-boiler flue gas waste heat recycling device

ActiveCN106500517AImproved drying and preheatingSimple device structureIncreasing energy efficiencyWaste heat treatmentProcess engineeringCoal

The invention discloses an industrial-boiler flue gas waste heat recycling device which comprises a base, an industrial boiler, a flue gas filter tank, a coal preheating tank and a soot collecting tank. The flue gas filter tank and the coal preheating tank are arranged between stand columns installed on the base separately, a second dust hood is fixedly installed on the lower portion of the flue gas filter tank, the upper portion of the second dust hood communicates with the lower portion of the flue gas filter tank, and the coal preheating tank is rotationally connected with the two stand columns through rolling bearings; and an exhaust pipeline is arranged under the coal preheating tank, the exhaust pipeline communicates with a suction pipeline through a negative pressure fan, the exhaust pipeline is located over the soot collecting tank, the coal preheating tank comprises an enclosing plate, a movable cover, side plates and a rotating rod, and multiple filter screens are fixedly installed in the flue gas filter tank from top to bottom in sequence. The industrial-boiler flue gas waste heat recycling device is simple in structure, reasonable in design, capable of effectively utilizing waste heat of flue gas in the boiler for drying and preheating coal and improving the burning efficiency of the coal and high in practicability.

Owner:BRIGHT THERMAL EQUIP CO LTD

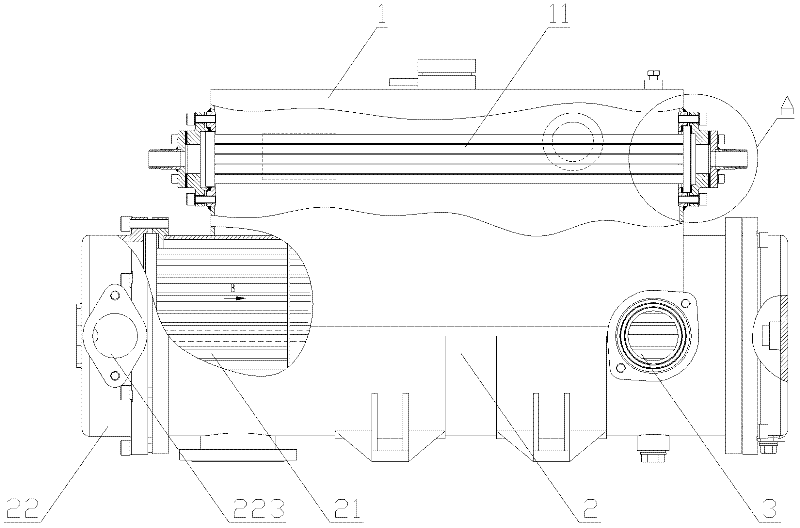

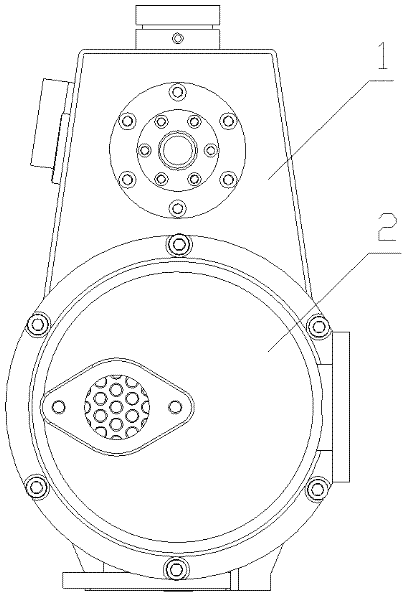

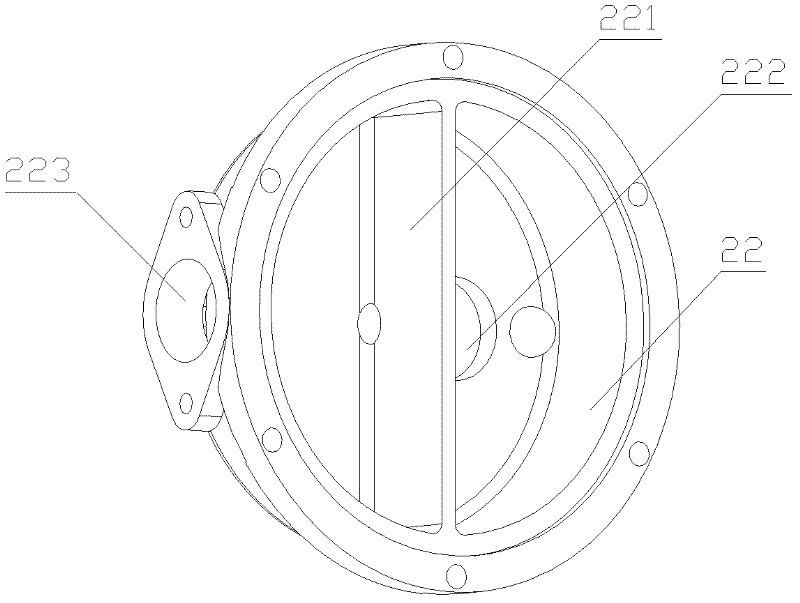

Ship diesel engine and heat exchange device thereof

ActiveCN102383978ACompact structureSimple structureMachines/enginesThermal treatment of fuelEngineeringFuel oil

The invention discloses a ship diesel engine and a heat exchange device thereof. The public heat exchange device comprises a fuel oil preheater and a seawater cooler, wherein the fuel oil preheater comprises a fuel oil channel and a first heat exchange cavity containing the fuel oil channel; the seawater cooler comprises a seawater pipeline and a second heat exchange cavity containing the seawater pipeline, and the shell of the fuel oil preheater is fixedly connected with the shell of the seawater cooler; and the cooled high temperature media of a ship diesel engine body are directly communicated with the first heat exchange cavity and the second heat exchange cavity. The heat exchange device provided by the invention has the advantages of compact structure, small integral structure, and no needs to occupy large space; and the structure is simple, the processing difficulty is small, and the cost is low; in addition, the interfaces of the heat exchange device are small, the probabilityof fault is greatly reduced, and the maintenance work load is decreased; and meanwhile, the high temperature media directly enter the first heat exchange cavity and the second heat exchange cavity, the high temperature media can directly exchange heat with fuel oil, the thermal loss can be effectively decreased, and the preheating effect of fuel oil is improved.

Owner:WEICHAI POWER CO LTD

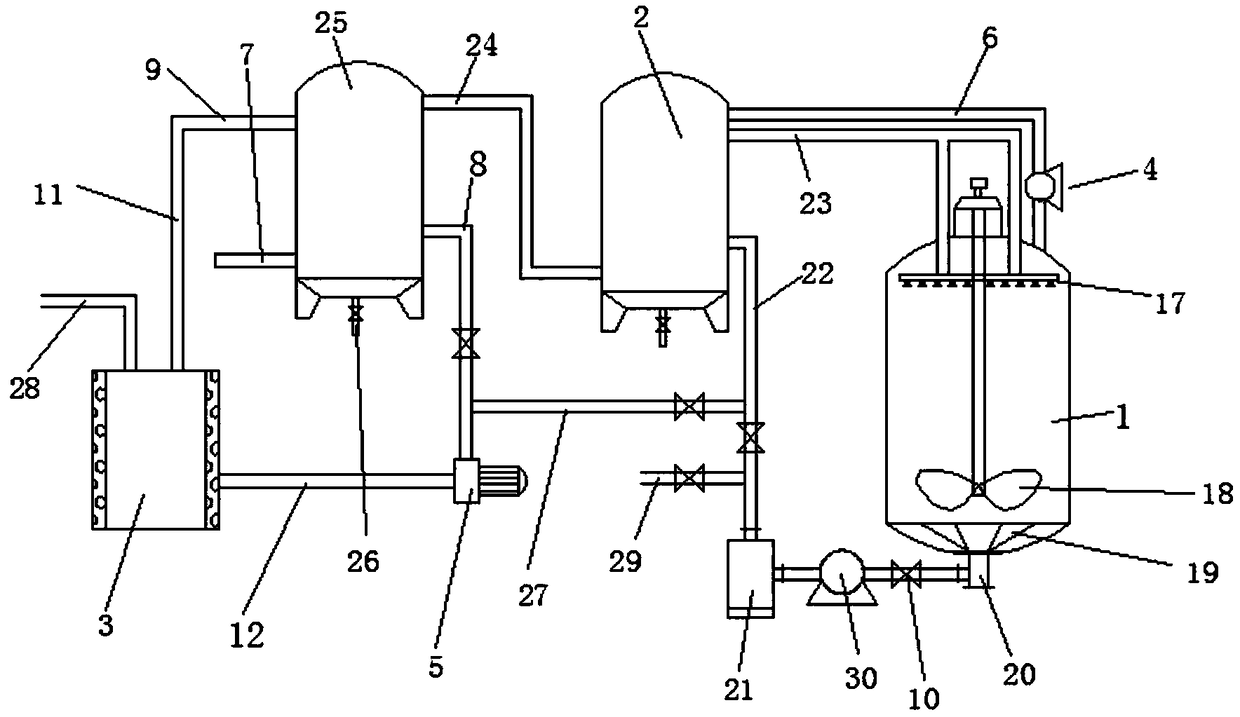

Ultrafine ammonium paratungstate evaporative crystallization device and crystallization method

PendingCN108837551AReduce production energy consumptionImprove heat transfer effectEvaporationSolution crystallizationAmmonium paratungstateTungstate

The invention discloses an ultrafine ammonium paratungstate evaporative crystallization device and a crystallization method. The ultrafine ammonium paratungstate evaporative crystallization device comprises an evaporative crystallizer, a first heat exchanger, a second heat exchanger and an ammonium tungstate insulated circulating tank from the left to right or from the right to left, wherein a first steam pipeline and a filtrate return pipe are communicated between the upper part of the evaporative crystallizer and the first heat exchanger; a compressor is arranged on the first steam pipeline;the first heat exchanger and the second heat exchanger are connected through a second steam pipeline; an ammonium hydroxide discharge pipe is arranged in the middle of the bottom of the second heat exchanger, and a circulating pump is arranged on one side of the bottom; an ammonium tungstate insulated circulating tank outlet pipe is communicated between the ammonium tungstate insulated circulating tank and the input end of the circulating pump. By utilizing the ultrafine ammonium paratungstate evaporative crystallization device disclosed in the invention, the ammonium tungstate solution in the ammonium tungstate insulated circulating tank is preheated by heat carried by the steam discharged from the evaporative crystallizer, so that the production energy consumption is reduced, and filterpressing is performed in the evaporative crystallization process so as to obtain fine crystals.

Owner:HUNAN MAOTIAN SHIJIE NEW MATERIALS CO LTD

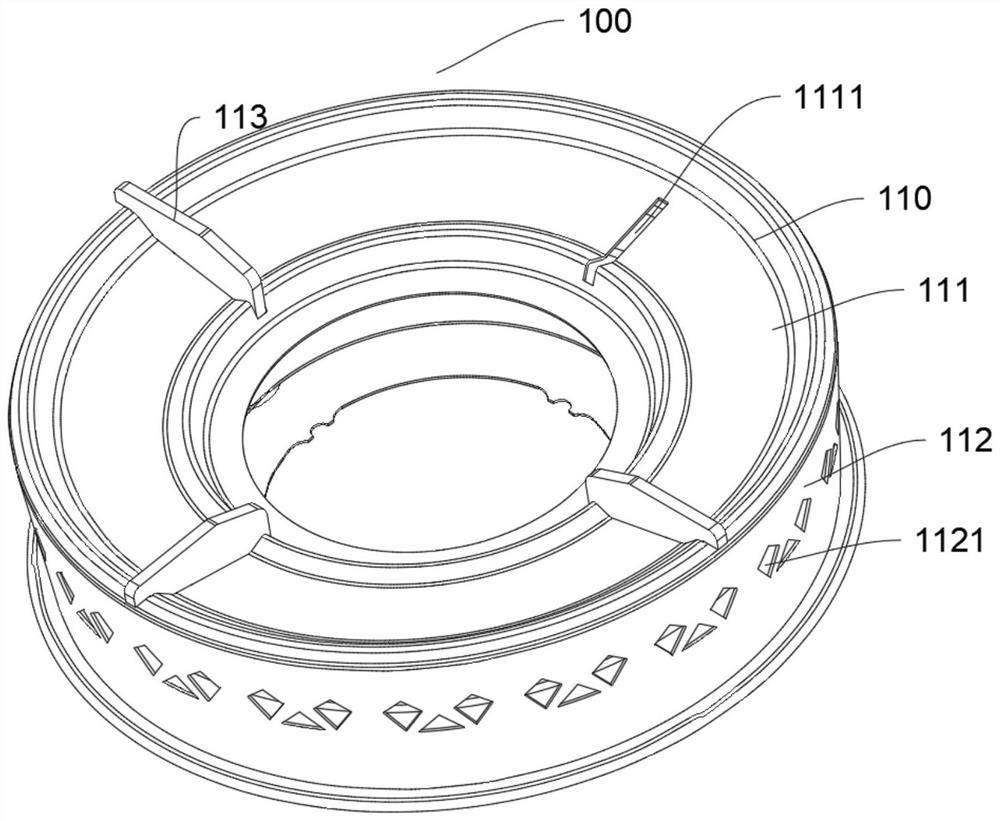

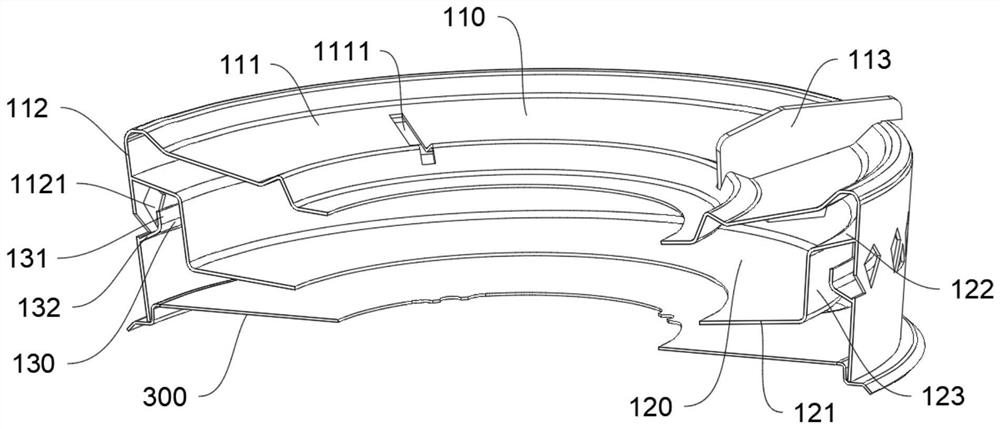

Stove energy gathering cover and gas stove

ActiveCN111998417AImprove warm-up effectHigh thermal efficiencyDomestic stoves or rangesStoves/ranges topsThermal radiationGas cooking stove

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

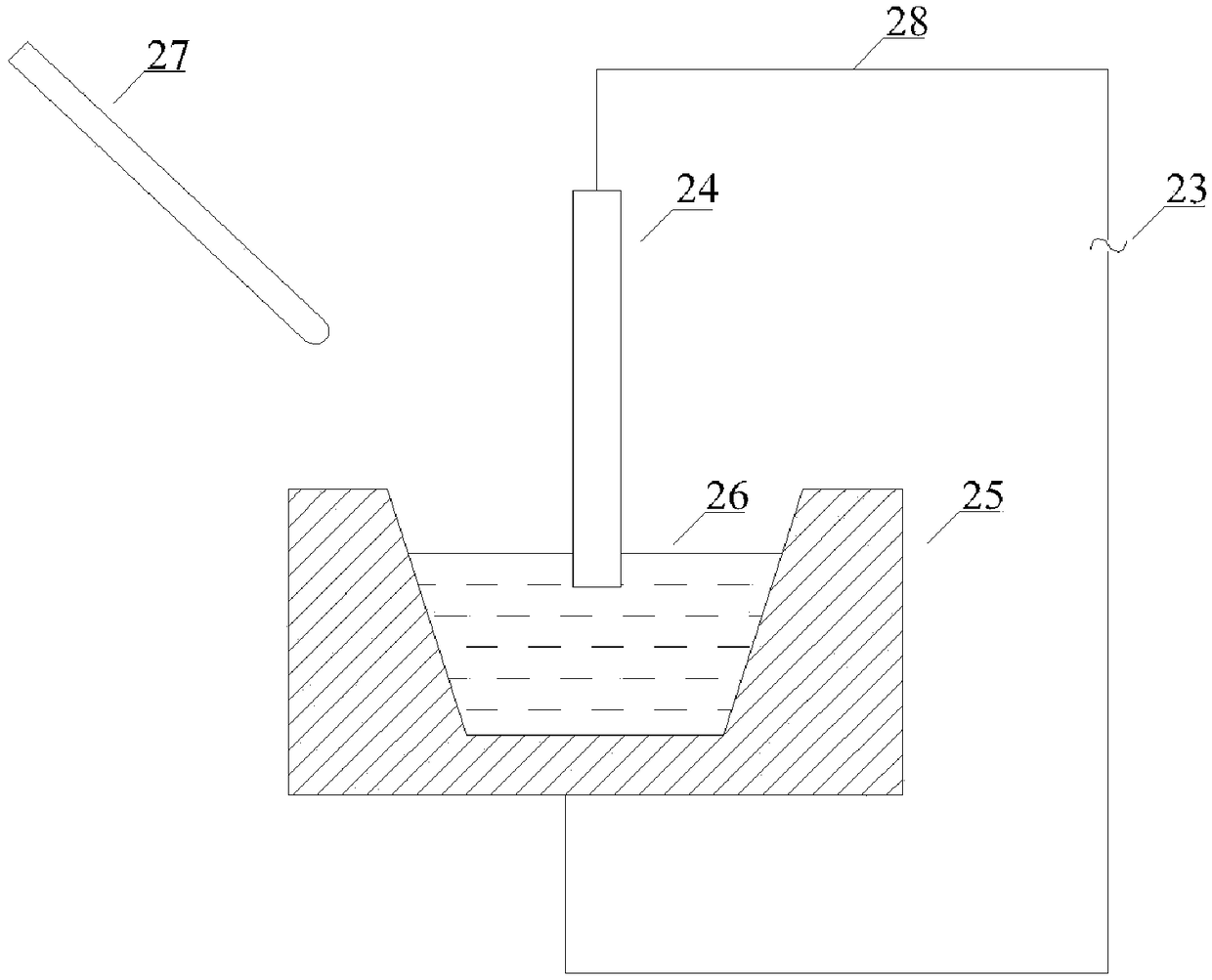

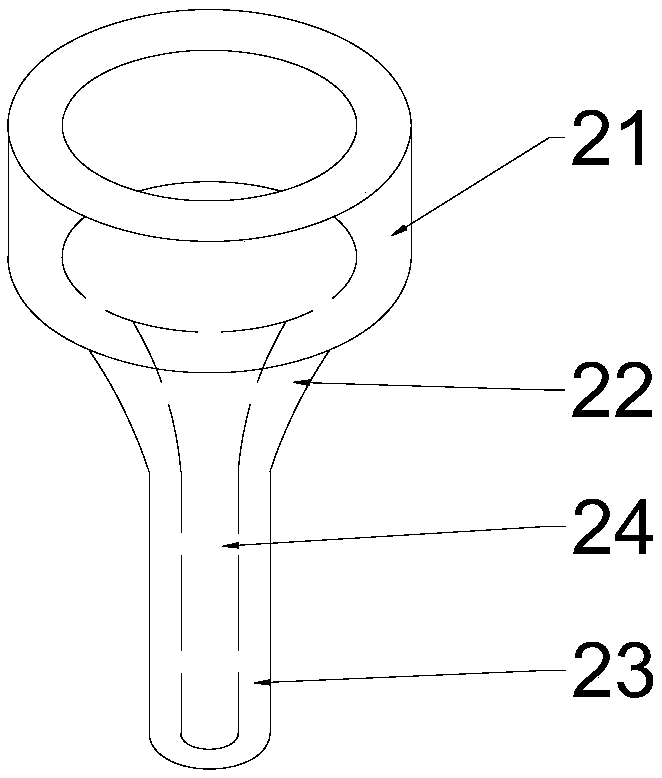

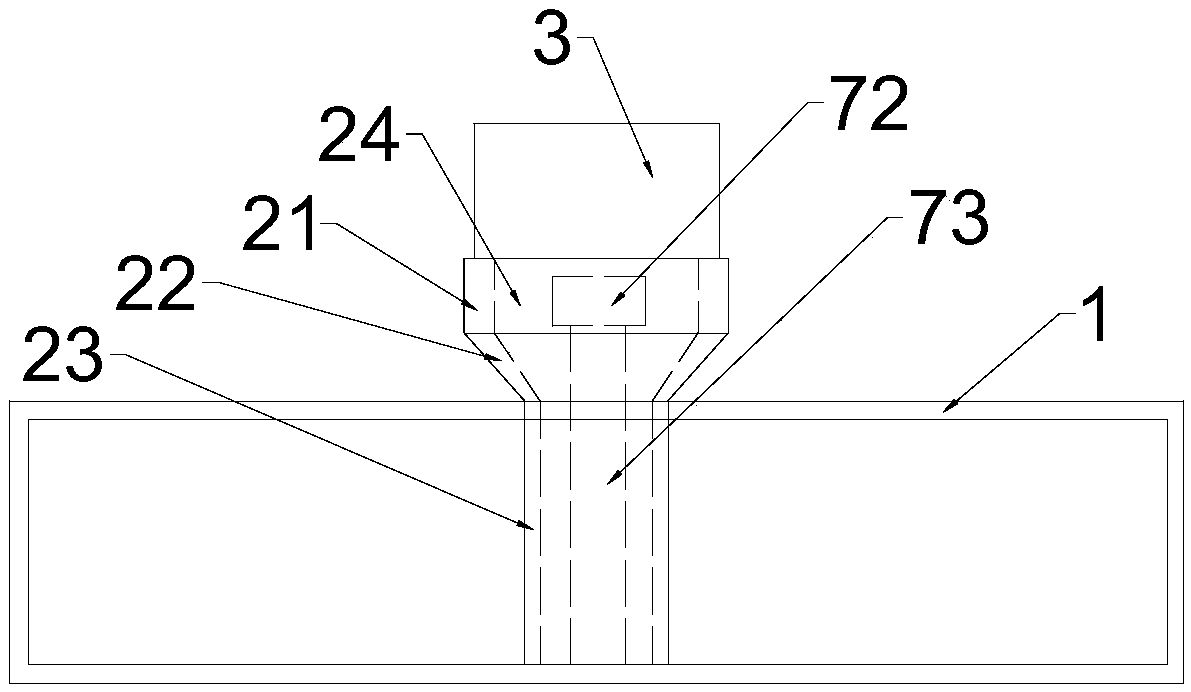

Mould preheating device

The invention provides a mould preheating device. The mould preheating device comprises a hollow base, a mould supporting shaft for fixing a mould is arranged at the center of the base, the mould supporting shaft sequentially comprises a supporting column, a transition shaft and a rotary shaft from top to bottom, the bottom end and the mid-upper side wall of the rotary shaft are rotatably fixed onthe base , the rotary shaft inside the base is connected with a rotating device, a ring-shaped heating housing is arranged above the mould, the heating housing is internally provided with heating wires, the top surface of the heating housing is fixed on a lifting plate, an electromagnetic heating rod is coaxially arranged at the center of the heating housing, the top end of the electromagnetic heating rod is fixed to an upper heating seat, the upper heating seat is fixed on the lifting plate, a cavity accommodating a lower heating seat is arranged at the center of the mould supporting shaft,the lower heating seat is arranged at the top of the cavity, the lower heating seat is fixed to the bottom surface of the base, the two heating seats serve as electrodes of the electromagnetic heatingrod, and the lifting plate is connected with a lifting device. The mould preheating device is capable of heating the inside wall and the outside wall of the mould at the same time, and the mould heating uniformity is improved.

Owner:TIANJIN MOTOR DIES

Method and system for optimizing drying grate-rotary kiln oxidate pellet thermal regulation

A method and a system for optimizing a drying grate-rotary kiln oxidate pellet thermal regulation are characterized in that a blower is adopted to pressurize the combustion air of a center burner; the pressure of the combustion air is increased to 18 to 25 KPa; the length of the flame of the center burner of a rotary kiln is controlled to be 15 to 17 m; a heat source point is added in a gas hood to increase the temperature of the preheating segment II of a drying grate by 100 to 150 DEG C; hot air of 500 to 1,000 DEG C are supplied to an air drying segment and a preheating segment I; and the system comprises a pressurizing device, the heat source point and a hot air supply device. The invention has the advantages that reasonable drying and preheating temperature gradient is formed, the drying and preheating effect is improved, energy is saved, the proportion of production of hematite is improved from the highest 40 percent to 100 percent, the hot air volume of the drying grate is sufficient, the hot air temperature is standard, the drying and preheating effect of fresh pellets is remarkably improved, the yield is increased, the consumption of coal gas is lowered, the powder entering the kiln is reduced, and the phenomenon that ring forming is liable to be caused by high-temperature powder feeding of the rotary kiln.

Owner:LIUZHOU IRON & STEEL

Self-heating methanol reforming hydrogen production reactor

ActiveCN112892460AImprove conversion rateHighly integratedProcess control/regulationHydrogenThermodynamicsHigh energy

The invention discloses a self-heating methanol reforming hydrogen production reactor, and aims to provide the self-heating methanol reforming hydrogen production reactor which integrates preheating, reforming reaction and catalytic combustion and has the advantages of high integration level, strong functionality and high energy utilization rate. The self-heating methanol reforming hydrogen production reactor comprises a reactor body, the reactor body is provided with a preheating cavity and a reaction cavity from top to bottom, the preheating cavity is provided with an exhaust port, and the reaction cavity is provided with a fuel inlet; the preheating cavity is provided with a first honeycomb-shaped carrier, the reaction cavity is provided with a second honeycomb-shaped carrier, the second honeycomb-shaped carrier is provided with a material guide pipe and a plurality of reforming pipes in a penetrating manner, and the material guide pipe is communicated with the bottom ends of the reforming pipes; and the upper ends of the reforming pipes penetrate through the first honeycomb-shaped carrier and extend to the outer side of the reactor body, the first honeycomb-shaped carrier is provided with a heat exchange cavity, and the heat exchange cavity is communicated with a reforming raw material inlet and a material guide pipe. The reactor is suitable for the technical field of hydrogen production devices.

Owner:NINGBO SHENJIANG TECH

Gypsum powder preparation process and system

InactiveCN110423026AAvoid Repeated FragmentationReduce crushing energy consumptionGrain treatmentsEngineeringCrusher

The invention discloses a gypsum powder preparation process and system. The system comprises a conveying device, a jaw crusher, a hammer crusher, a feeding device, a rotary kiln calcining pot and a centrifugal pulverizer which are arranged in sequence, wherein the conveying device comprises a primary conveyer belt, a secondary conveyer belt and a third conveyer belt; discharge baffle plates are correspondingly mounted on the primary conveyer belt, the second conveyer belt and the third conveyer belt; a primary collecting plate which communicates with the jaw crusher, a secondary collecting plate which communicates with the hammer crusher and a third collecting plate which communicates with the feeding device are additionally arranged on a rack; a waste heat channel is formed between the feeding device and the rotary kiln calcining pot; and the centrifugal pulverizer is connected with a storage tank. As ores are graded in a conveying process, energy consumption for continuously crushingthe ores can be reduced, and the ore crushing efficiency can be improved; and in addition, due to adoption of the waste heat channel and a novel centrifugal pulverizing component, the product qualitycan be further improved, and the energy consumption cost for production can be lowered.

Owner:康定龙源穗城石膏有限责任公司

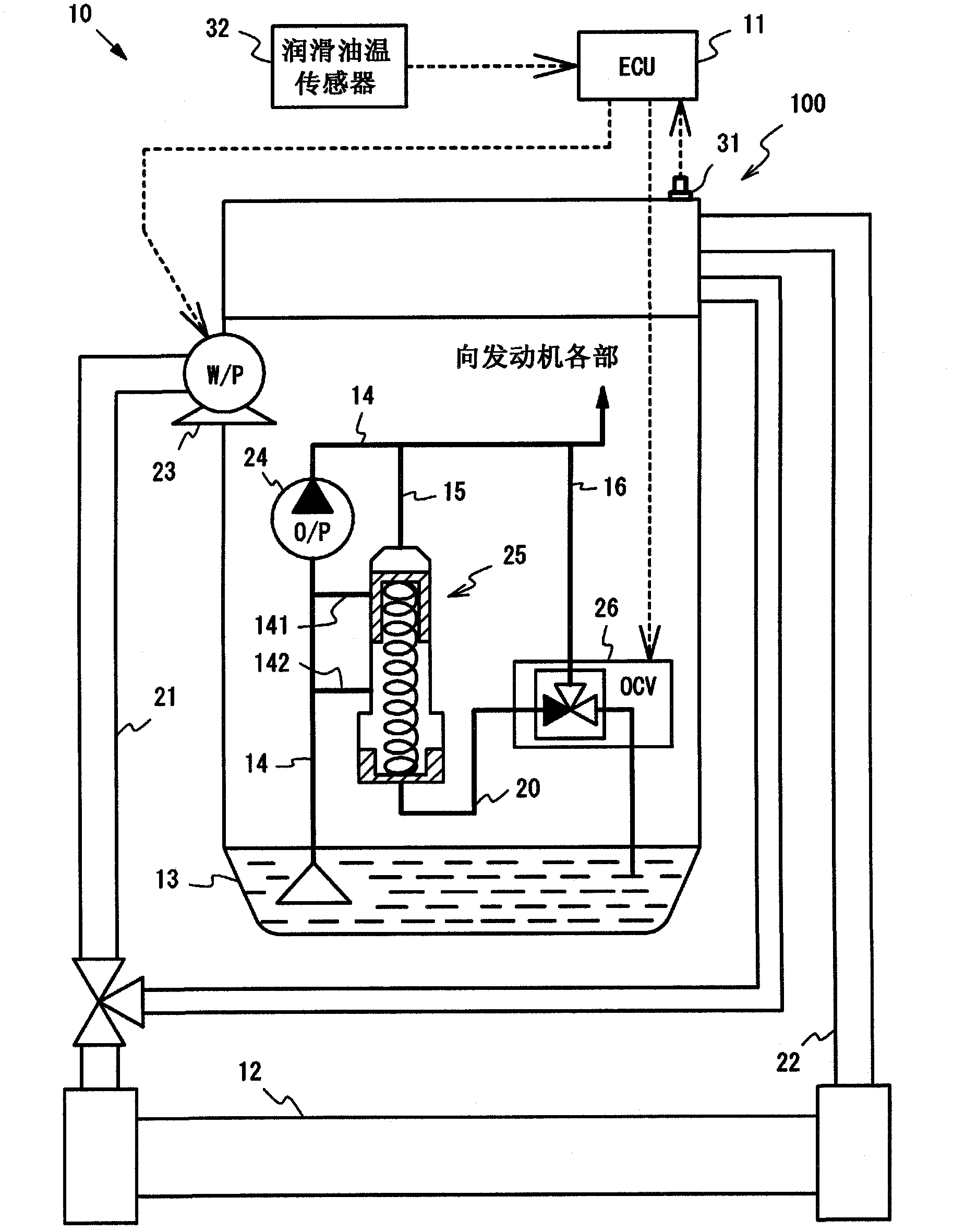

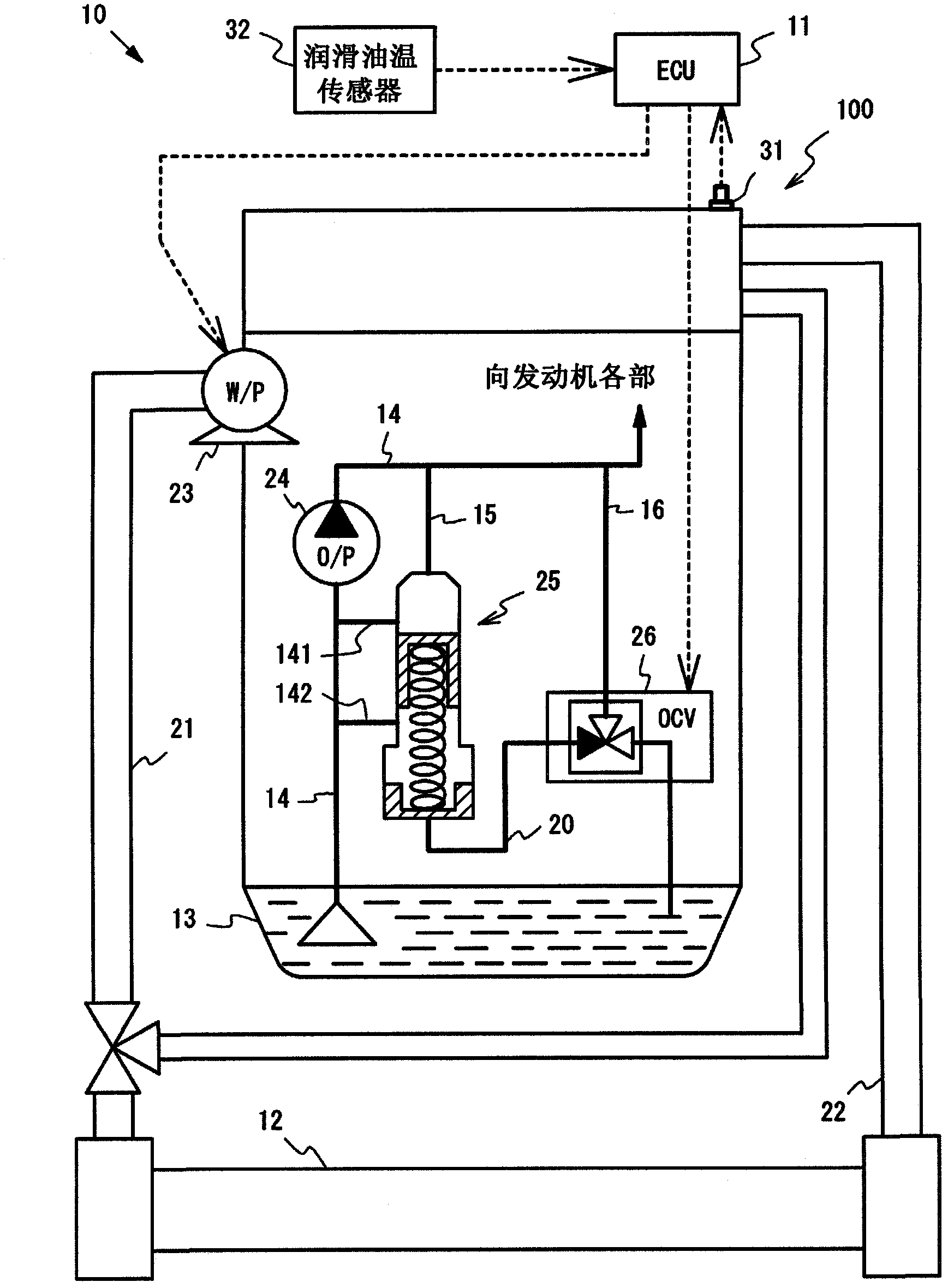

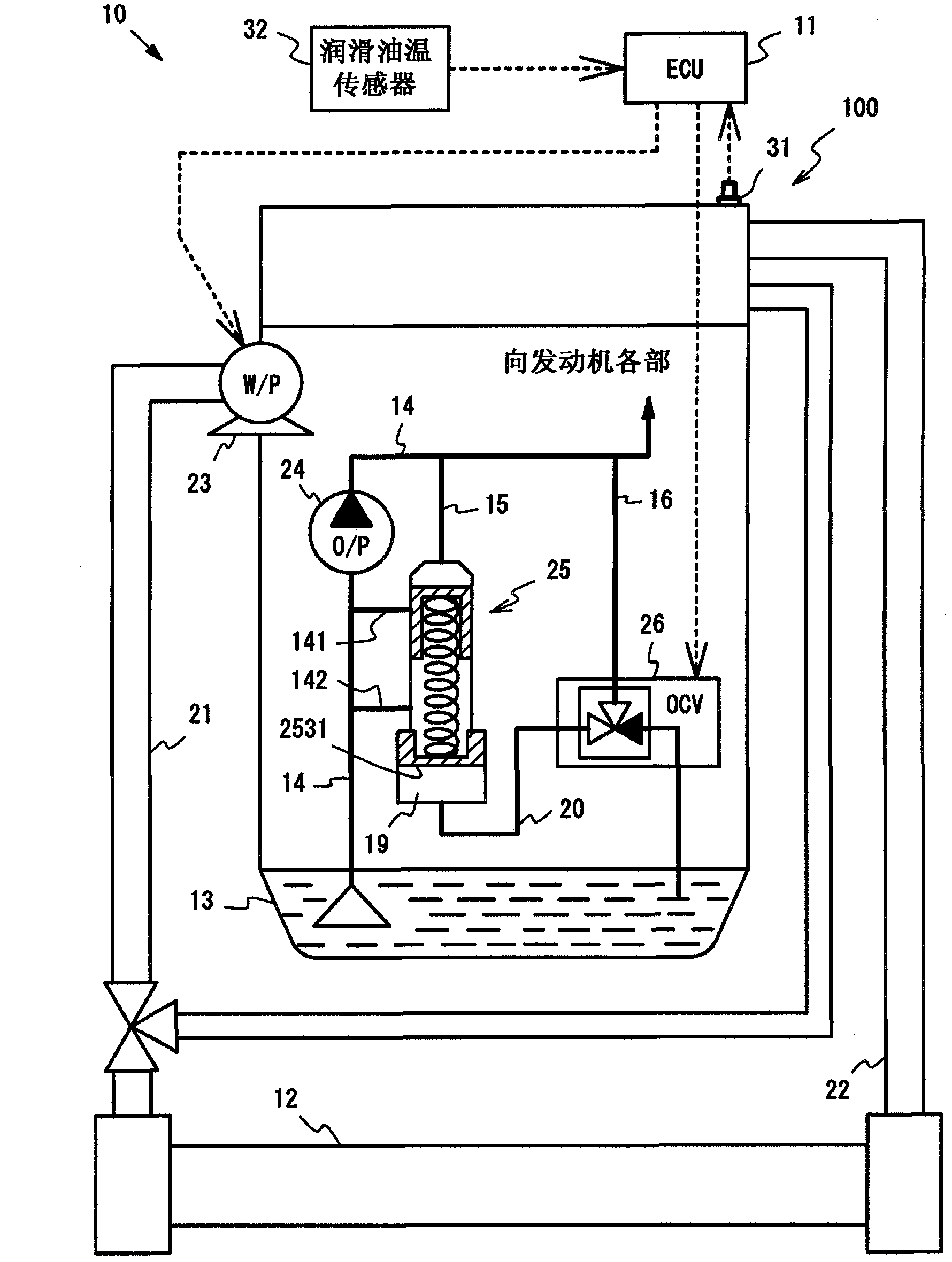

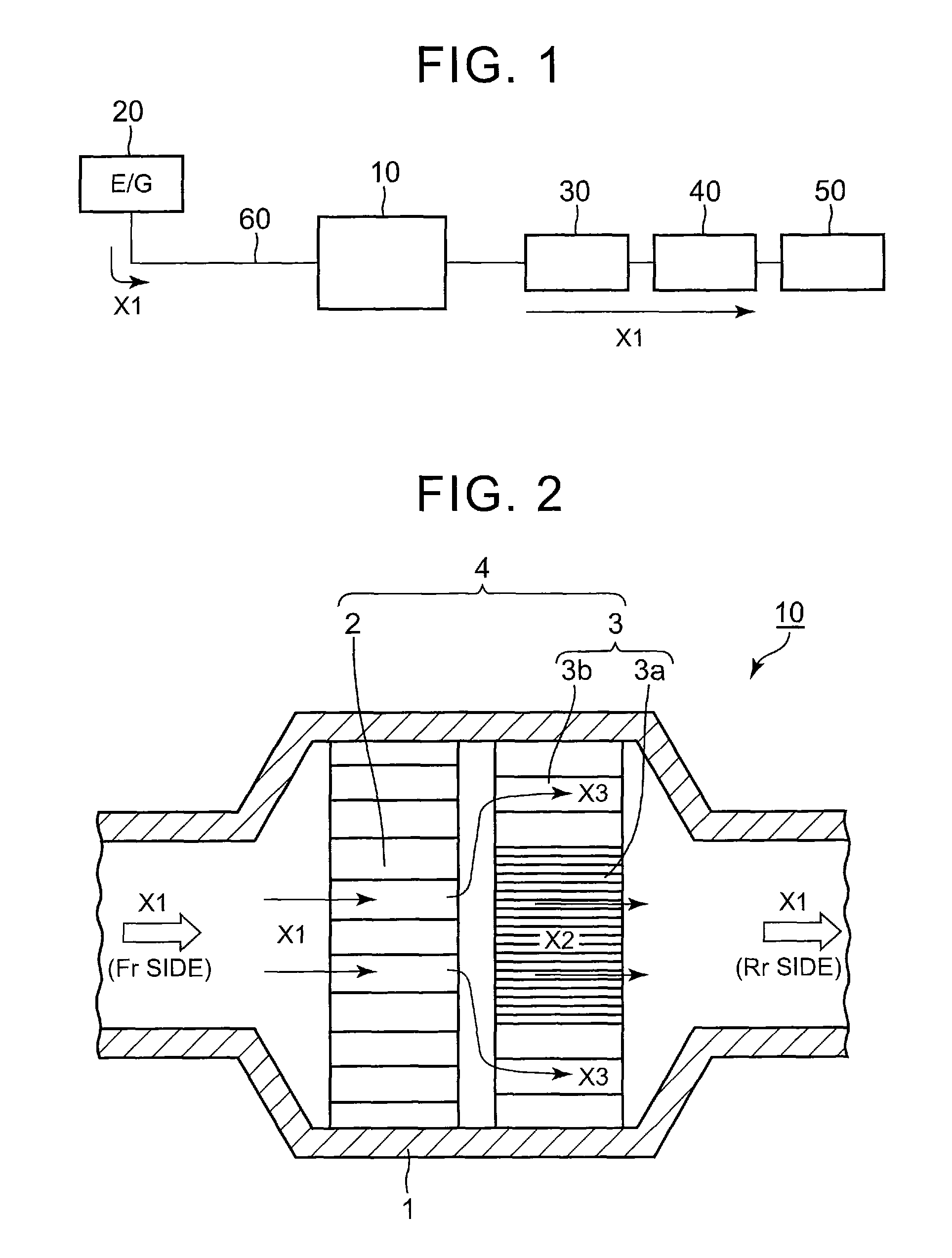

Control device for internal combustion engine

InactiveCN102105658AImprove warm-up effectCoolant flow controlMachines/enginesElectromagnetic clutchControl system

A vehicle control system (10) is equipped with a water pump (23) that is equipped with an electromagnetic clutch, an oil relief device (25) and an OCV (26), a water temperature sensor (31), and an ECU (11). Based on the detection result of the water temperature sensor (31), the ECU (11) disengages the electromagnetic clutch of the water pump (23) and stops the circulation of cooling water, and instructs the OCV (26) to adjust the lubricating oil pressure to the low-pressure side by means of the oil relief device (25). Based on the detection result of the water temperature sensor (31) after the electromagnetic clutch of the water pump (23) has been engaged for a prescribed period of time, the ECU (11) determines whether to stop executing the adjustment of the lubricating oil pressure to the low-pressure side by means of the oil relief device (25).

Owner:TOYOTA JIDOSHA KK

Exhaust gas incinerator of compact structure

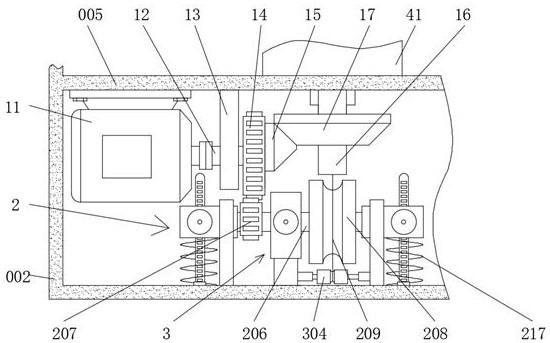

InactiveCN105387474AGood preheating effectImprove warm-up effectIncinerator apparatusSpatial structureEngineering

The invention relates to the technical field of incinerators, in particular to an incinerator of a compact structure. The incinerator comprises an incinerator shell and a partition plate installed in the incinerator shell, the partition plate divides the incinerator shell into a left cavity and a right cavity, and the right cavity is provided with a preheating device; the preheating device comprises a heat conduction pillar, a helix pipe and multiple interlayers, wherein the helix pipe is arranged on the heat conduction pillar in a sleeving mode, the heat conduction pillar is fixedly installed on the partition plate, the interlayers are sequentially arranged in the right cavity in the axis direction of the heat conduction pillar, the interlayers separate the right cavity into multiple closed circulation cavities, each circulation cavity is internally provided with a baffle which separates the corresponding circulation cavity, through holes for communicating every two adjacent circulation cavities are formed in the interlayers, the through holes formed in every two adjacent interlayers are located at the two sides of the corresponding baffle respectively, exhaust gas advances in the multiple circulation cavities in a circulatory mode, the preheating effect of the exhaust gas is improved, space is utilized sufficiently, the structure is compact, and the preheating device is not needed to be made to be large and long. The exhaust gas incinerator has the advantages of being simple in structure, low in cost, small in size, high in waste heat utilization rate and the like.

Owner:CHANGZHOU JINTAN HANGUANG TECH CO LTD

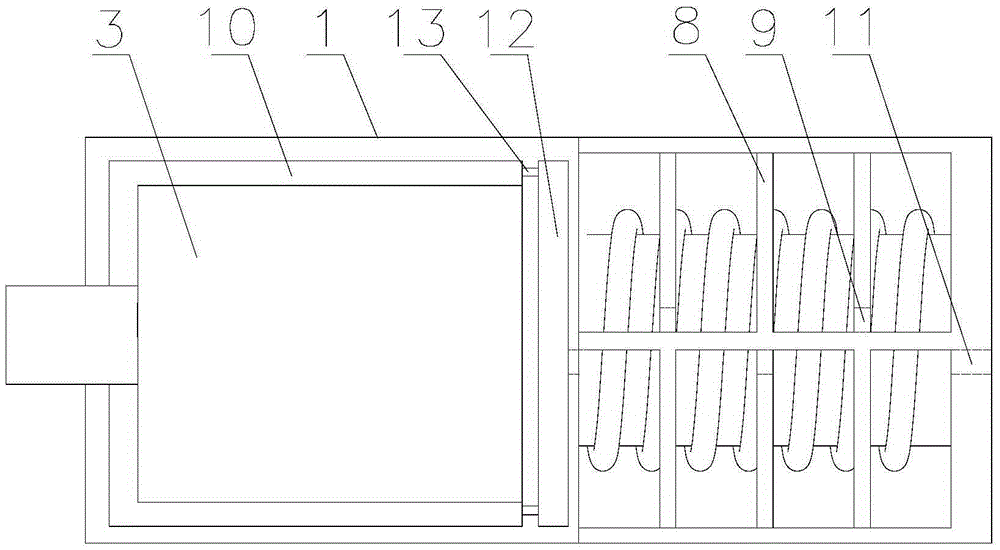

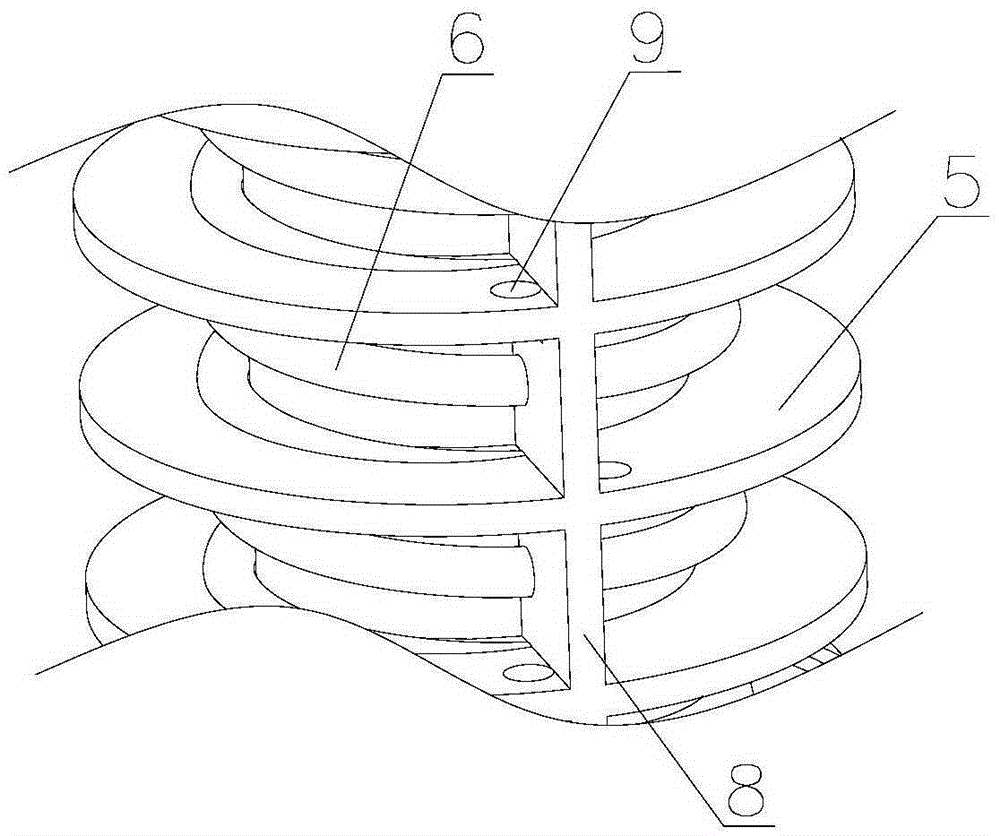

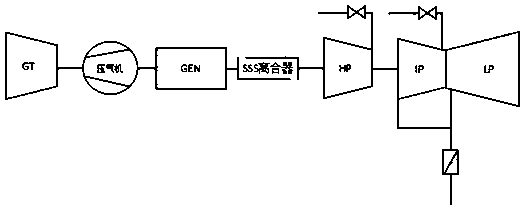

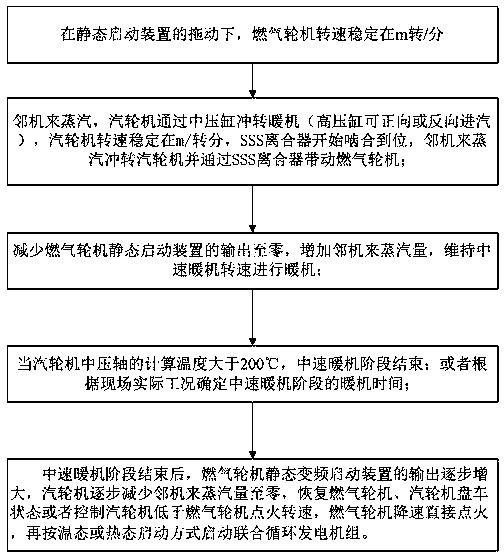

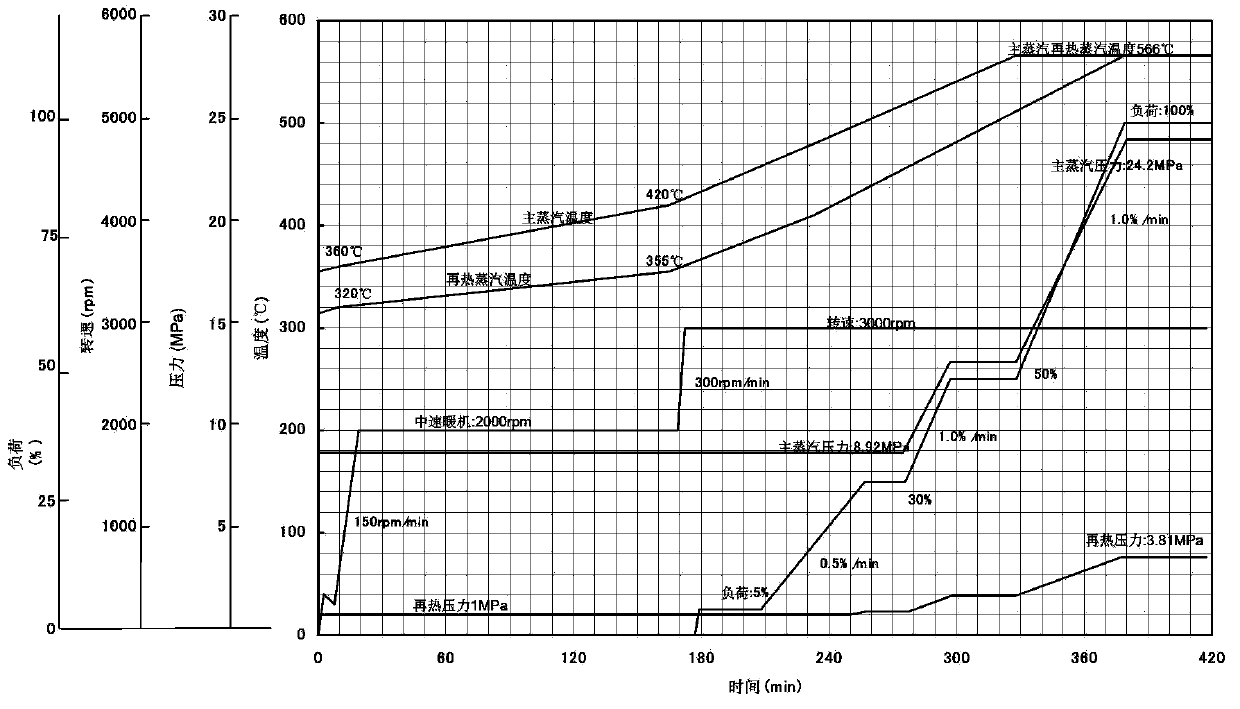

Cold start method of gas-and-steam combined cycle power generating unit

InactiveCN107740712AIncrease steam intakeShorten the timeGas turbine plantsEngine startersHot startFuel gas

The invention relates to a cold start method of a gas-and-steam combined cycle power generating unit. The cold start method specifically comprises the following steps that 1, under dragging of a static variable-frequency starting device, the rotating speed of a gas turbine is stabilized at m rpm; 2, steam is fed from adjacent machines, specifically, a turbine conducts impulse starting on a warmingturbine through an intermediate-pressure cylinder, at this time, a high-pressure cylinder forwards or reversely feeds steam, the rotating speed of the turbine is stabilized at m rpm, an SSS clutch begins to be engaged in place, the steam fed from the adjacent machines conducts impulse starting on the turbine, and the gas turbine is driven by the SSS clutch; 3, the output of the static variable-frequency starting device of the gas turbine is reduced to be 0, the quantity of the steam fed from the adjacent machines is increased, and the rotating speed of the medium-speed warming turbine is maintained for turbine warming; 4, when the calculation temperature of an intermediate-pressure shaft in the turbine is larger than 200 DEG C, the medium-speed warming turbine stage is finished, or the turbine warming time of the medium-speed warming turbine stage is determined according to the actual on-site working conditions; and 5, after the medium-speed warming turbine stage is finished, the output of the static variable-frequency starting device of the gas turbine is gradually increased, the quantity of the steam, fed from the adjacent machines, of the turbine is gradually decreased to be 0,the turning states of the gas turbine and the turbine are restored, or the turbine is controlled to be smaller than the gas turbine in ignition rotating speed, the gas turbine slows down to directlyignite, and then the combined cycle power generating unit is started in a warm or hot start mode.

Owner:ZHUHAI YUHAI ELECTRIC POWER CO LTD +1

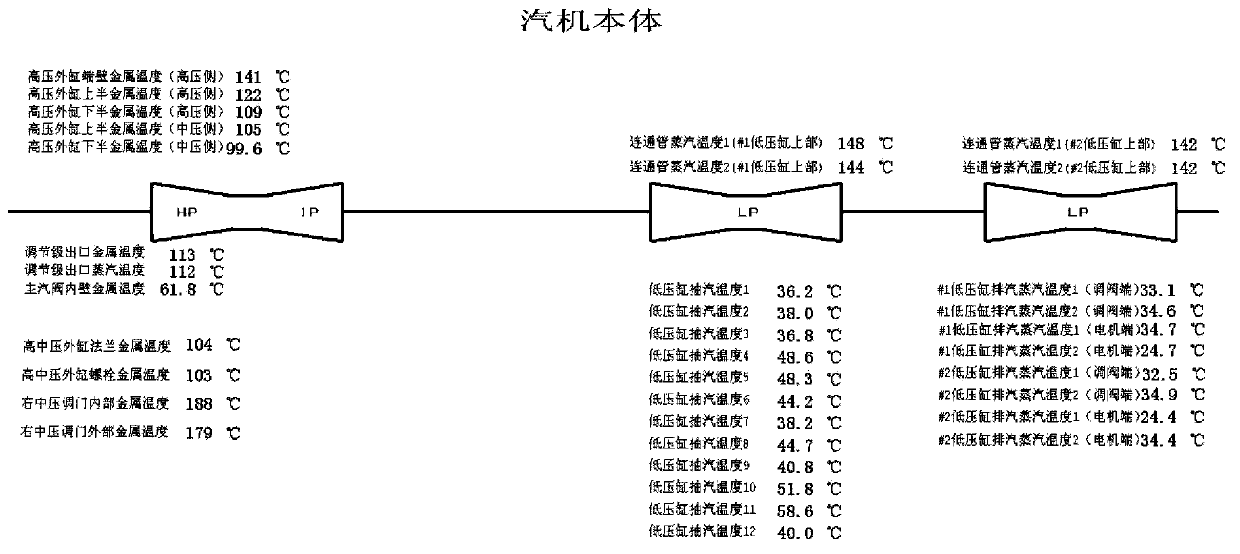

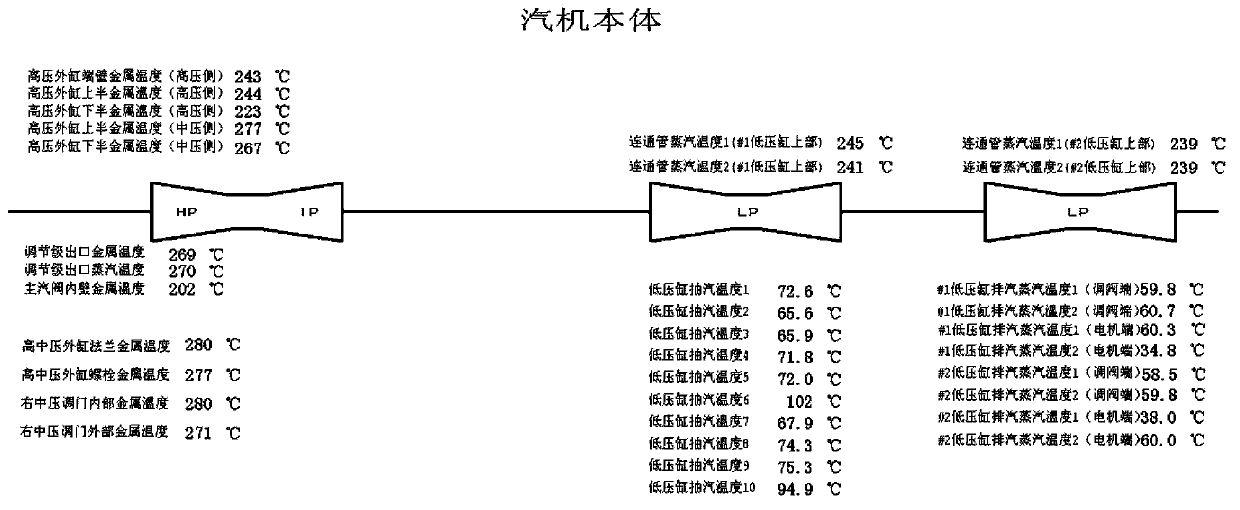

Parameter-variable supercritical unit warming method

InactiveCN103388496AImprove warm-up effectReduce startup timeSteam engine plantsStart timeEngineering

A parameter-variable supercritical unit warming method is characterized in that in a supercritical unit jointly started by a high-pressure cylinder and a medium-pressure cylinder, the parameters of a turbine are 3.0MPa / 360 DEG C in main steam and 0.1MPa / 320 DEG C in reheating steam; and in a high-speed warming period, the parameters are gradually changed to be 6.0MPa / 390 DEG C in main steam and 0.7MPa / 355 DEG C in the reheating steam. The parameter-variable supercritical unit warming method can improve the warming effect of the supercritical unit turbine, and enables each security monitoring parameter of the unit to be more easy to control, thus shortening the starting time of the unit and saving the fuel consumption in the starting process of the unit.

Owner:YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST +1

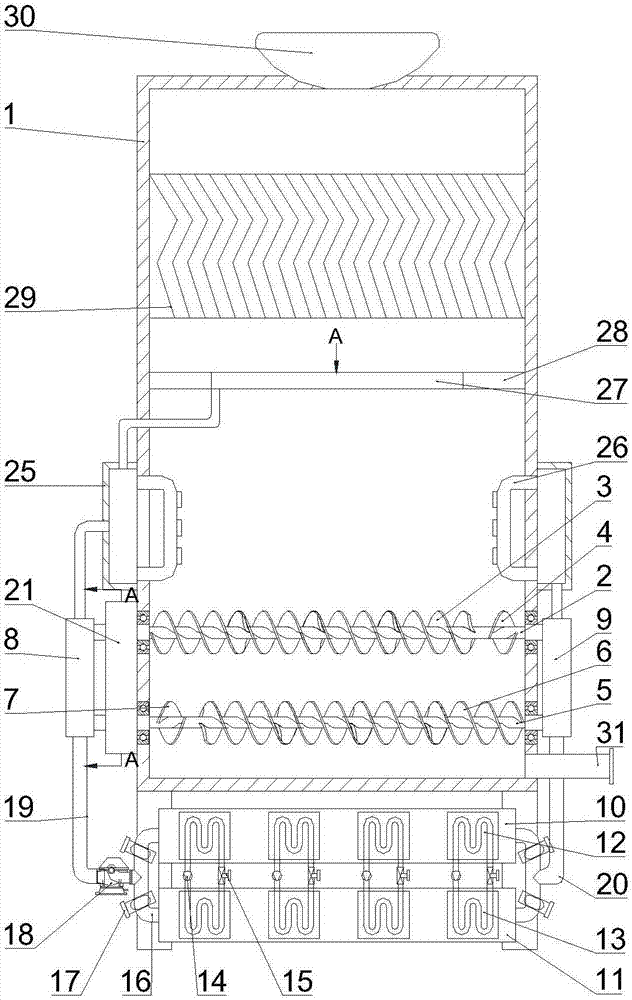

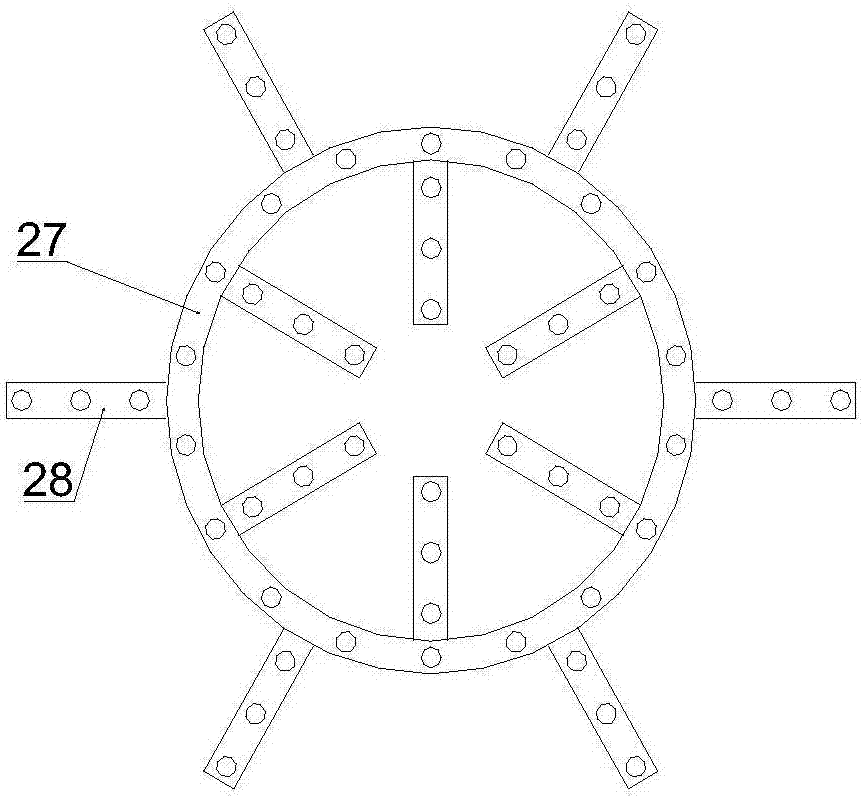

Preheating and precooling integrated device for concrete aggregate

InactiveCN107471434AImprove warm-up effectEvenly dispersedCement mixing apparatusSpiral bladeElectromagnetic valve

The invention discloses a preheating and precooling integrated device for concrete aggregate. The falling concrete aggregate makes contact with rising hot gas so that heat can be absorbed by the concrete aggregate. Owing to the fact that communicating pipes are distributed in a radial shape, overflowed hot gas is evenly dispersed, and the situation that the concrete aggregate makes contact with the hot gas is facilitated; the spiral directions of a first pushing spiral blade and a second pushing spiral blade are opposite, thus the concrete aggregate is stirred in a left-right reciprocating mode; in the stirring process, heat of a first hollow rotary shaft and a second hollow rotary shaft is absorbed by the concrete aggregate, and the preheating effect on the concrete aggregate is further improved; and when the concrete aggregate needs to be precooled, a corresponding electromagnetic valve is opened, and then a three-way pipe can communicate with a cooling tank. According to the preheating and precooling integrated device for the concrete aggregate, the concrete aggregate can be selectively preheated and precooled, the preheating and precooling efficiency is high, and the construction time is saved.

Owner:李小强

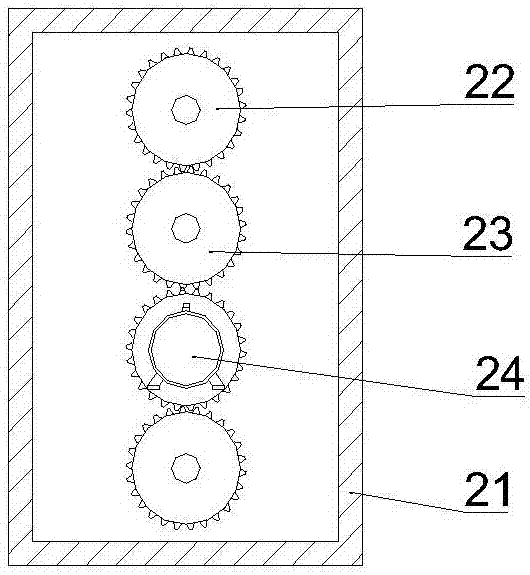

Efficient and safe regenerative combustion VOCs purification system

ActiveCN112268286AImprove warm-up effectImprove practicalityIncinerator apparatusPtru catalystCombustion

The invention discloses an efficient and safe regenerative combustion VOCs purification system. The efficient and safe regenerative combustion VOCs purification system comprises a base, wherein a shell is fixedly installed on the top surface of the base, and a control panel is fixedly installed on the obverse side of the shell. The inlet air flow and the outlet air flow are separated through a flow guide device, the inlet air flow and the outlet air flow cannot be mixed with each other, meanwhile, the flow guide device can transmit the heat of the outlet air flow to the inlet air flow, and thepreheating effect on the inlet air flow is improved. By means of the cooperation of the control panel, a control module, a driving device, a lifting limiting device, a locking device, a rotating device, a conveying device and a pushing device, a sector-shaped catalyst block is automatically replaced in a non-stop mode, and therefore the continuity of the volatile organic chemical treatment process is ensured, manual participation is not required in the sector-shaped catalyst block replacing process, the time and the labor are saved, the automation degree is high, and the practicability of theefficient and safe regenerative combustion VOCs purification system is improved.

Owner:南大恩洁优环境技术江苏股份公司

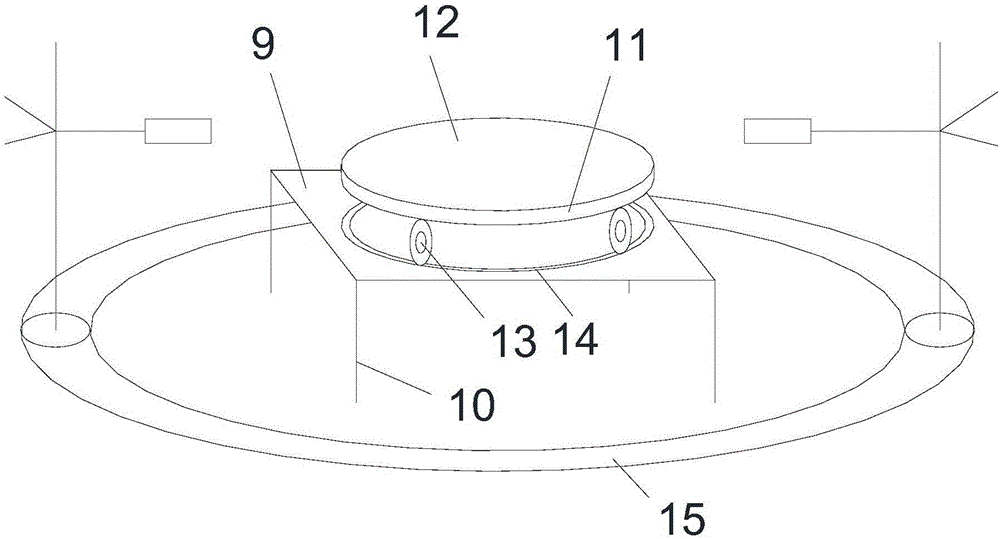

Mold baking equipment

InactiveCN106079323AImprove warm-up effectIncrease the baking areaCasting apparatusEngineeringMechanical engineering

The invention discloses mold baking equipment. The mold baking equipment is composed of a mold bearing platform (9), a mold baking gun conveying rail (15) and a mold baking gun, wherein the mold baking gun conveying rail (15) is a round conveying rail, and the mold bearing platform (9) is arranged in the circle center of the round conveying rail; and a flame outlet of the mold baking gun faces the circle center of the round conveying rail, and the mold baking gun is fixedly connected to the mold baking gun conveying rail (15) so that the mold baking gun and the mold baking gun conveying rail (15) can move synchronously. The equipment is simple in structure and convenient to operate, the mold baking area is enlarged, and a mold can be preheated more evenly and more effectively.

Owner:WUHU HUANGYAN IND

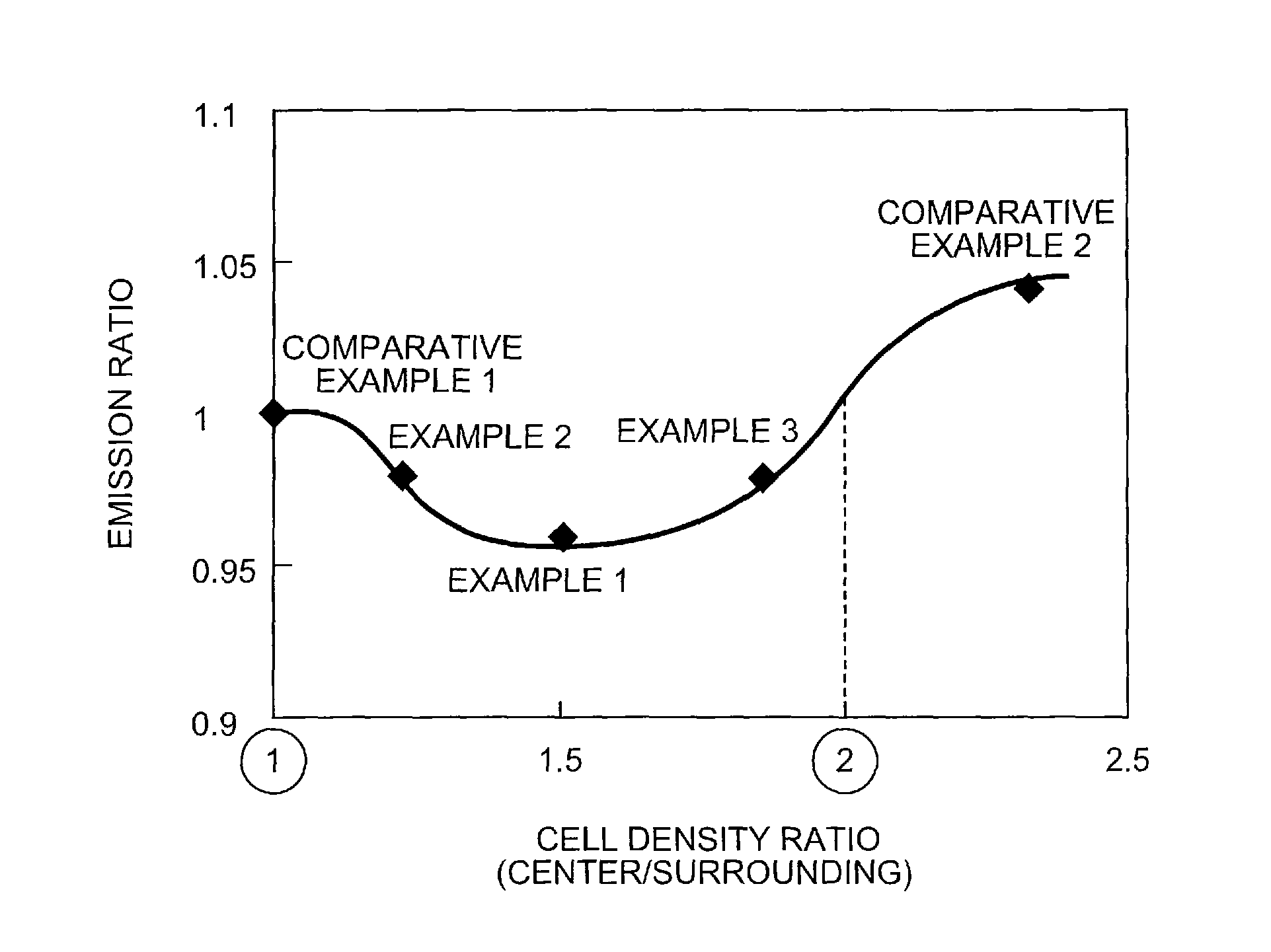

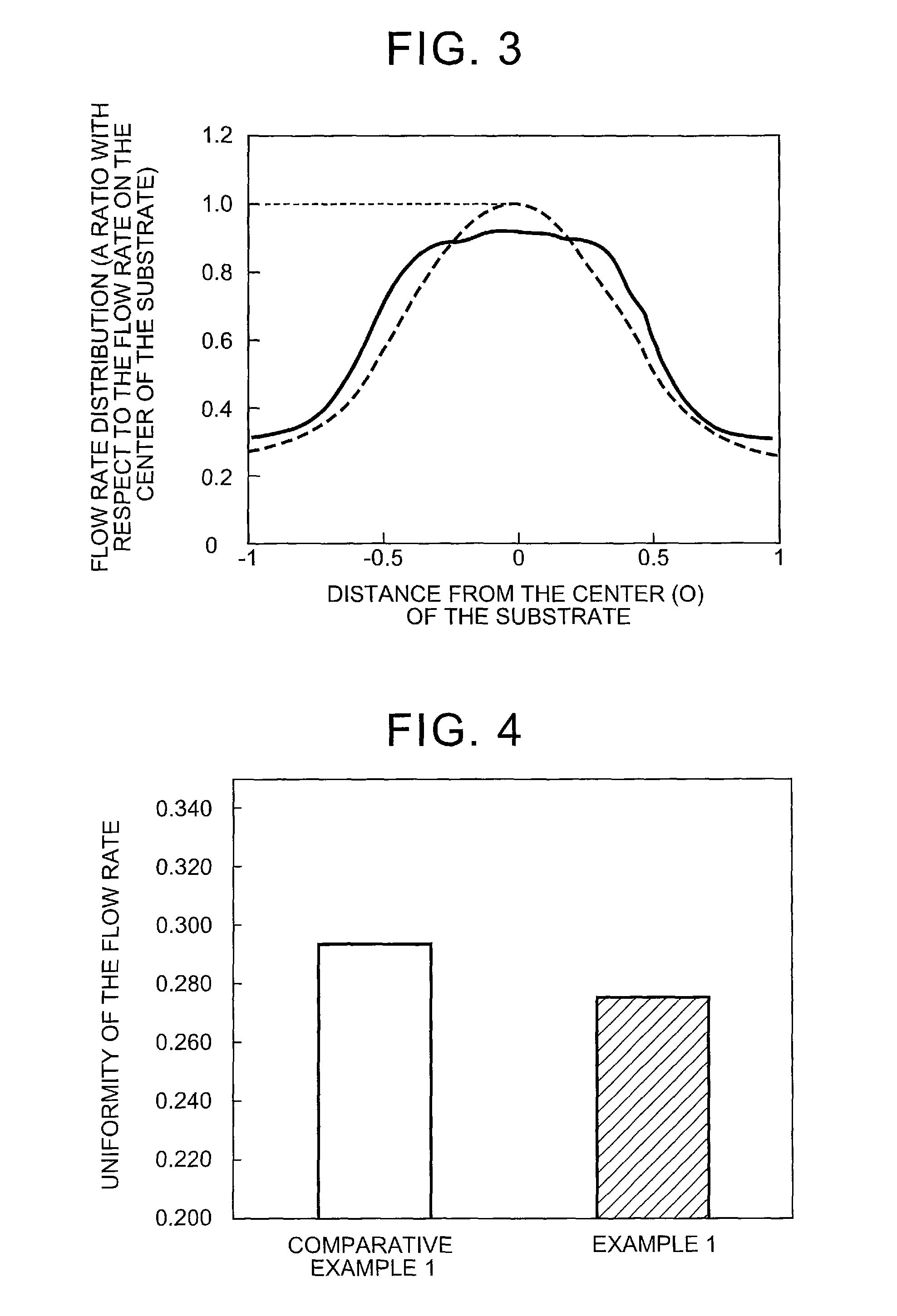

Catalytic converter

ActiveUS9352310B2Improve warm-up effectImprove exhaust gas purification performanceInternal combustion piston enginesDispersed particle separationEngineeringCell density

A catalytic converter including: a cell structured first substrate; and a cell structured second substrate provided at a downstream side of the first substrate. The first substrate has a uniform cell density. The second substrate includes a center area with a first cell density and a surrounding area with a second cell density that is lower than the first cell density. The first substrate and the second substrate are mounted in tandem.

Owner:TOYOTA JIDOSHA KK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com