Preheating and precooling integrated device for concrete aggregate

A concrete aggregate and driving device technology, applied in clay preparation devices, cement mixing devices, chemical instruments and methods, etc., can solve problems such as low heating efficiency, restricting the efficiency of heating concrete in mixing buildings, and easy damage to steam pipes, etc. Achieve high preheating and precooling efficiency, improve preheating effect, and save construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

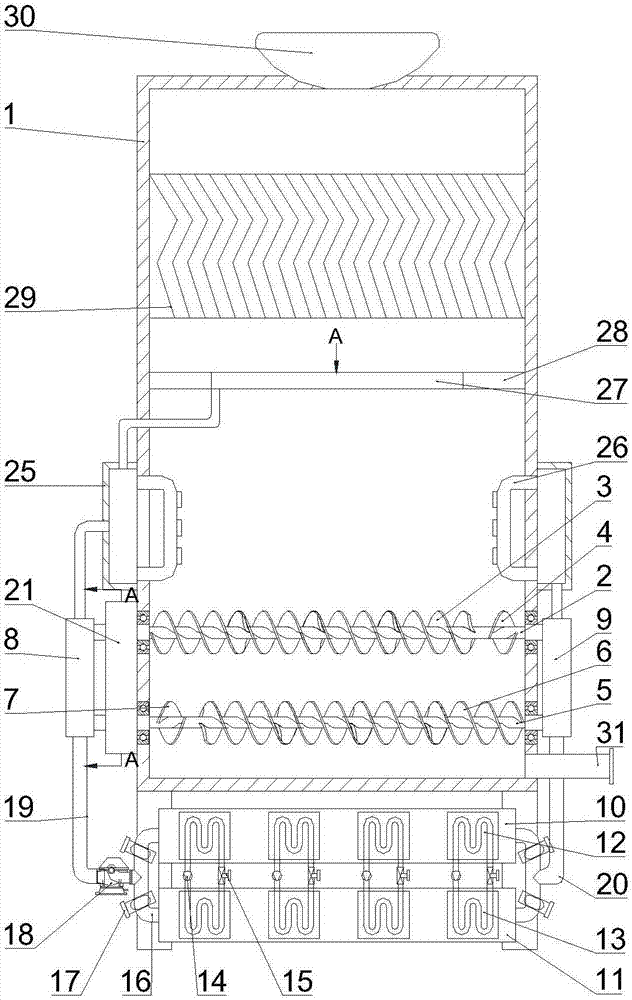

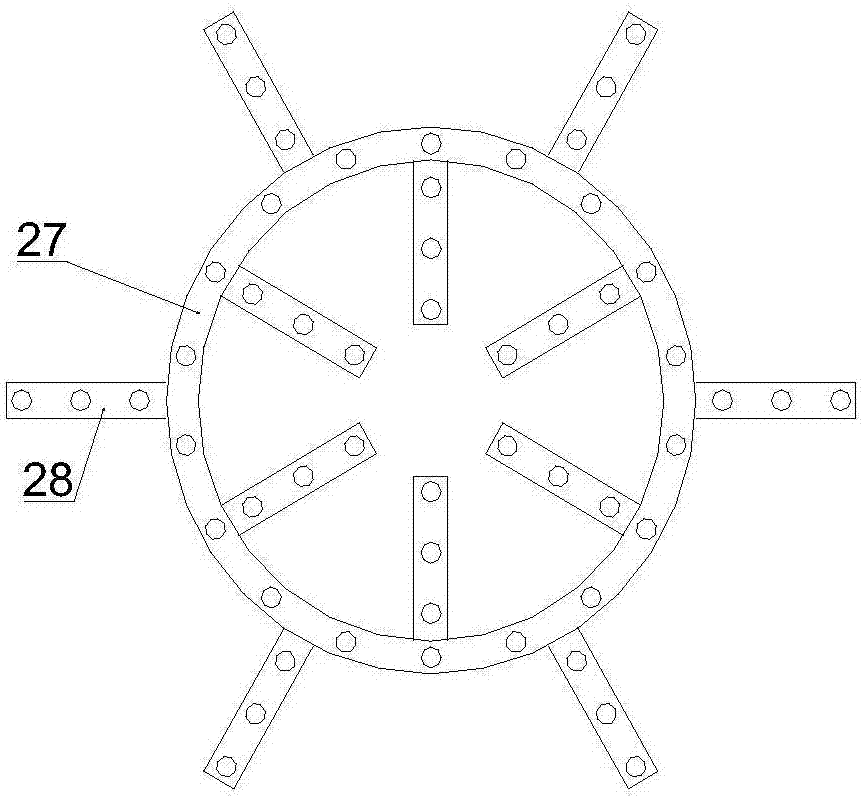

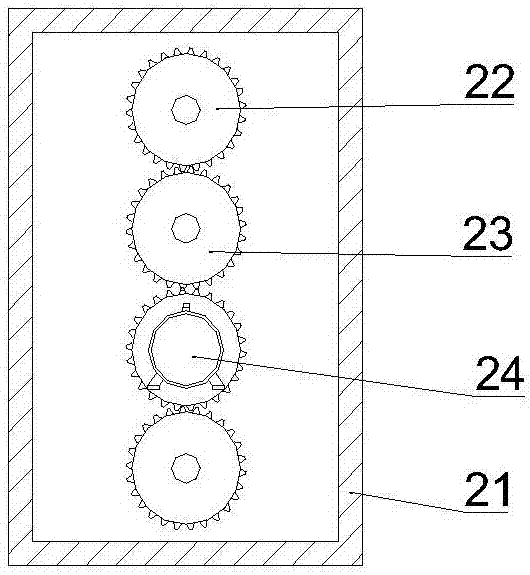

[0018] see Figure 1-3 , an integrated device for preheating and precooling concrete aggregates, comprising a mixing drum 1, a first hollow rotating shaft 2 is arranged laterally on the inner lower side of the mixing drum 1, and a second hollow rotating shaft is arranged laterally on the inner lower side of the mixing drum 1. Rotating shaft 5, the first hollow rotating shaft 2 and the surface of the second hollow rotating shaft 5 are respectively fixedly connected with the first pushing screw blade 3 and the second pushing screw blade 6, the first pushing screw blade 3 and the second pushing screw blade The spiral direction of the material screw blade 6 is opposite, and the first hollow shaft 2 and the second hollow shaft 5 are respectively connected to the side wall of the mixing drum 1 in rotation, and the left side of the mixing drum 1 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com