Parameter-variable supercritical unit warming method

A supercritical unit and variable parameter technology, applied in the direction of machines/engines, mechanical equipment, steam engine installations, etc., can solve the problems of prolonging the warm-up time at medium speed, low metal temperature of steam turbine cylinder block and rotor, economic loss, etc. The effect of controlling start-up time, saving fuel consumption, and shortening start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

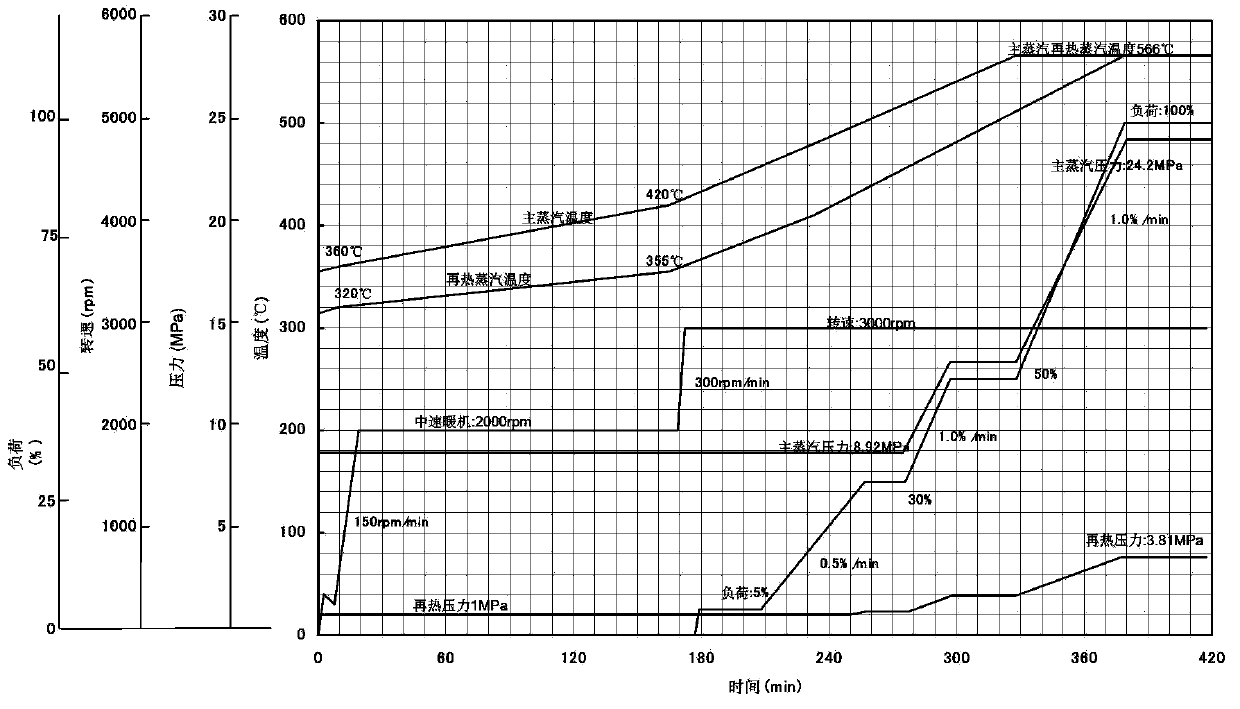

[0014] In the cold start-up operation of supercritical thermal power units, rationally adjust the boiler combustion and slip parameters to drain and warm the main and reheat steam pipes, so that the steam turbines have the start-up conditions in advance, and the steam parameters reach the main steam 3.0MPa-4.0MPa / 360 ℃-370℃: reheat steam: 0.1MPa-0.3MPa / 320℃-330℃; during high-speed warm-up period, the steam parameters gradually change to: main steam 6.0MPa-7.0MPa / 380℃-390℃: reheat steam :0.7MPa-0.9MPa / 355℃-365℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com