Device and method for casting large-sized compound steel ingot by using graphite electrode ring for preheating electroslag

A graphite electrode, electroslag casting technology, applied in the field of metallurgy and casting, can solve the problems of large-scale composite ingot quality defects, large steel ingots are not well solved, etc., to achieve stable interface performance, strong anti-accident ability, eliminating the need for cutting effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

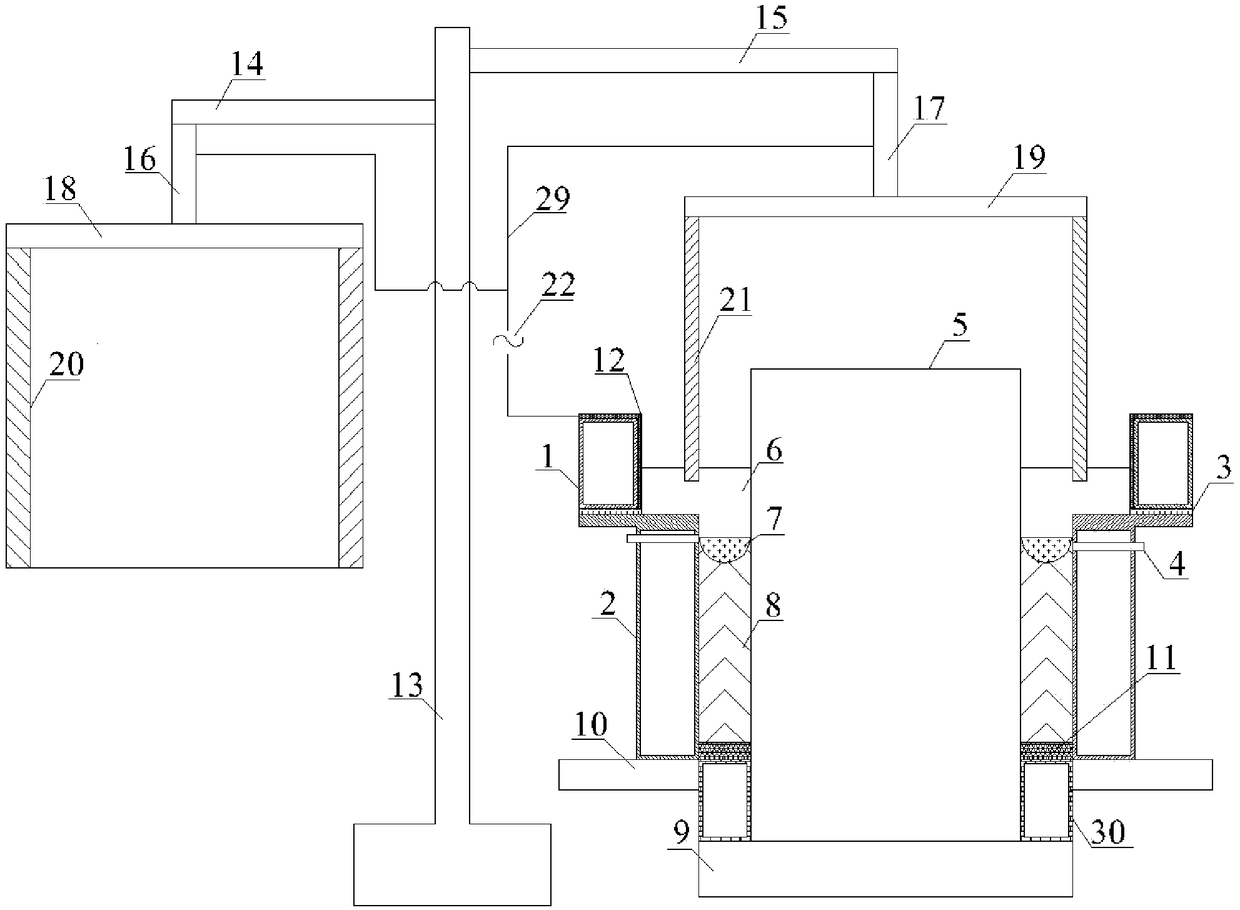

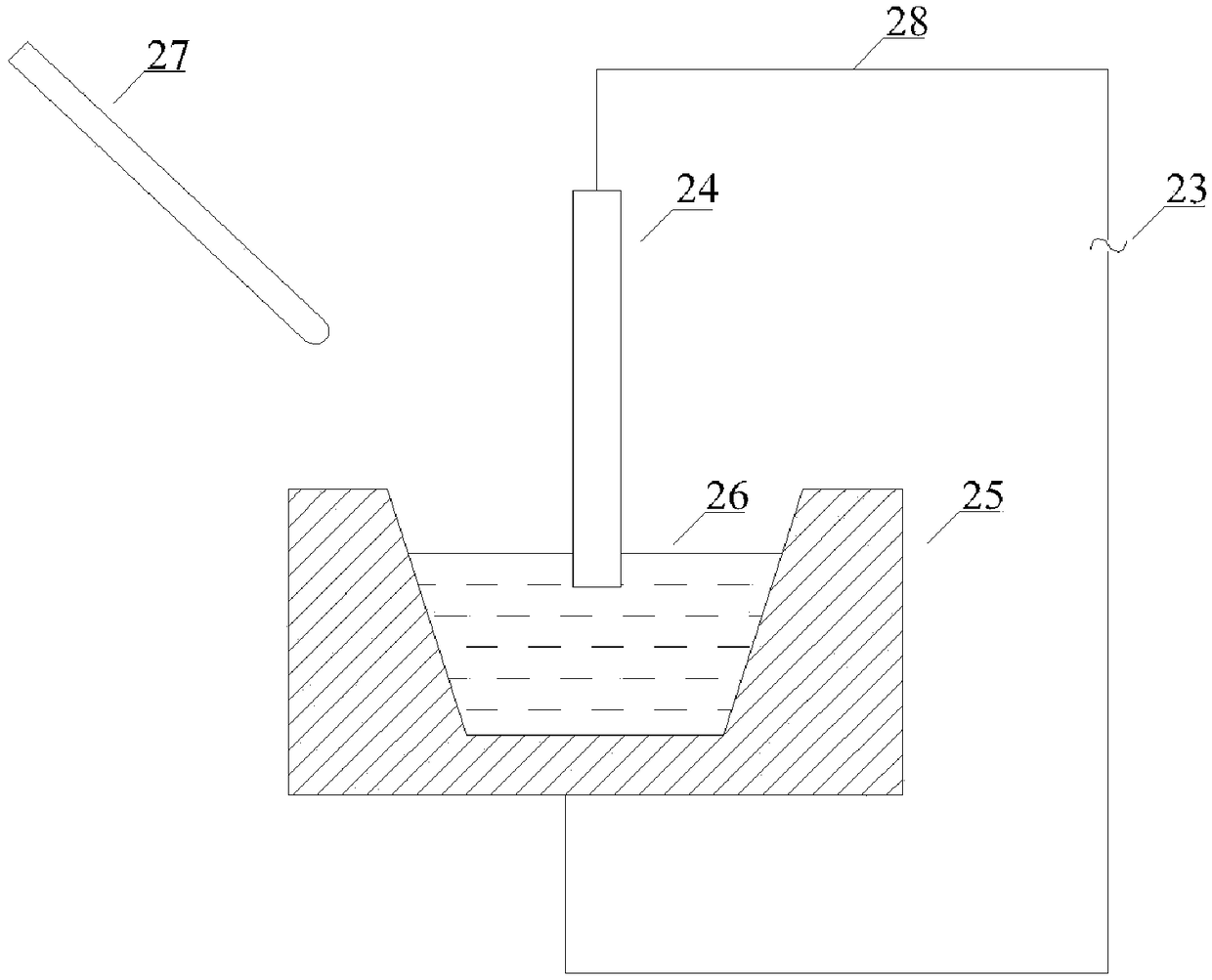

[0055] The material of the mandrel used is No. 45 steel, the material of the consumable electrode ring is high-speed steel, and the diameter of the mandrel is 170mm; the diameter of the prepared composite steel ingot is 260mm;

[0056] The surface of the mandrel is firstly cut to remove the skin, then coated with anti-oxidant, and then placed in the T-shaped conductive crystallizer, the axis of the mandrel coincides with the axis of the T-shaped conductive crystallizer; the axis of the mandrel coincides with the axis of the T-shaped conductive crystallizer And inserted into the annular bottom water tank; the gap between the annular bottom water tank and the inner wall of the lower crystallizer is filled with alumina powder, the gap between the annular bottom water tank and the mandrel is filled with alumina powder, and the alumina powder is used to prevent liquid slag pool Leakage; the cladding layer covers the top surface of the annular bottom water tank and the inner and oute...

Embodiment 2

[0066] Method is with embodiment 1, and difference is:

[0067] The material of the mandrel is high speed steel;

[0068] When the ingot drawing of electroslag casting starts, the voltage during casting is 40V and the current is 3500A.

[0069] The prepared composite steel ingot has no slag inclusion layer, and the composite interface is good.

Embodiment 3

[0071] Method is with embodiment 1, and difference is:

[0072](1) the material that adopts mandrel is the composite steel ingot of embodiment 2, after surface turning, the diameter of mandrel is 255mm, and the material of consumable electrode ring is high-speed steel;

[0073] (2) The diameter of the composite steel ingot prepared is 350mm; After the ingot drawing of electroslag casting starts, the voltage during melting and casting is 40V, and the electric current is 5000A;

[0074] The prepared composite steel ingot has no slag inclusion layer, and the composite interface is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com