Patents

Literature

86results about How to "Reduce crushing energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crusher

InactiveCN102806126AHigh cutting forceSmooth crushing processGrain treatmentsAgricultural engineeringStructural engineering

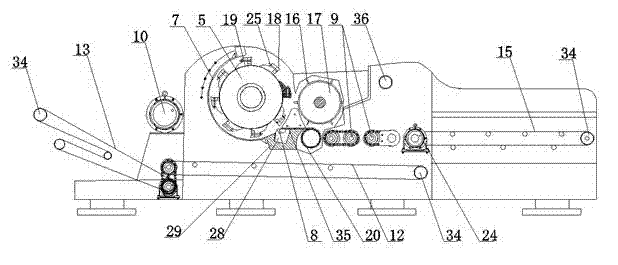

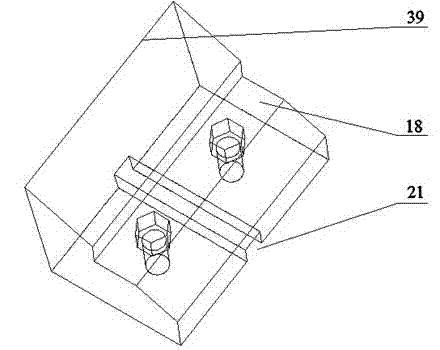

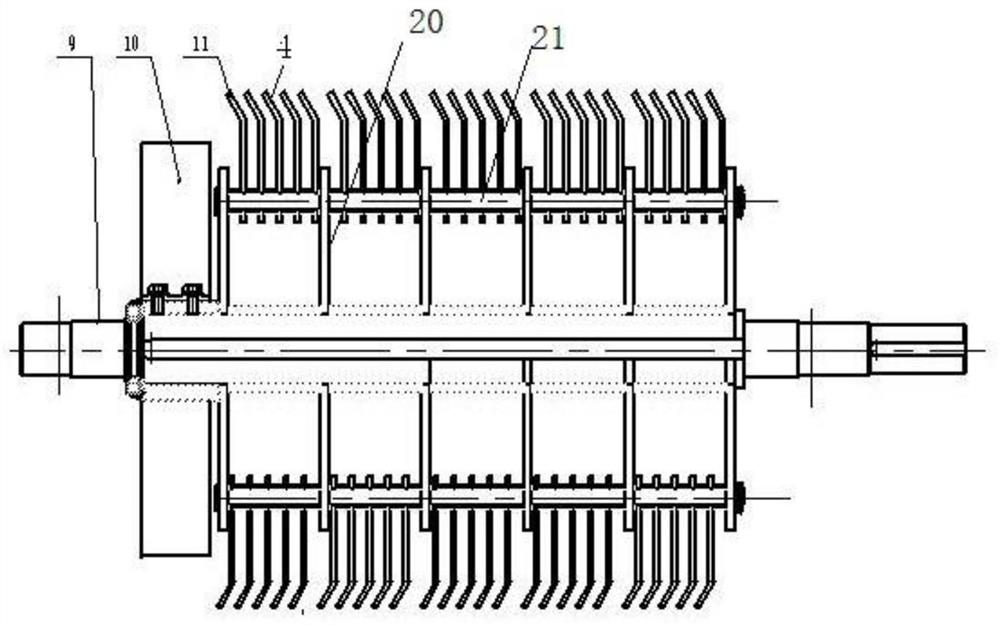

The invention discloses a crusher. The crusher comprises a charging device, a discharging device, a feeding device and a crushing device; the feeding device consists of feeding rollers and a material poking roller; the crushing device consists of a rotor, a fixed cutter and a filter screen; the circumference of the rotor is provided with fly-cutter seats; the included angles between the adjacent fly-cutter seats are equal on the circumference; fly-cutters are fastened on the fly-cutter seats through bolts; gaps are reserved between blades of the fly cutters and the fixed cutter; the fixed cuter is fastened on a fixed cutter beam by a bolt through a pressing plate; the fixed cutter beam is connected with the feeding rollers through a feeding transition plate; and the feeding rollers are parallel to each other, and the rotation directions of the feeding rollers are consistent with each other; and the material poking roller is fixed on a material fixing roller cover in which a hinge is taken as a rotation center. The crusher is high in crushing efficiency, low in energy consumption, and good in effect of crushing wood, core wood, cotton straw and other biomass, is suitable for crushing municipal solid waste and industrial refuse simultaneously and runs stably.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Raw material pretreatment method for straw-based seedling raising pot, product and production method of seedling raising pot

InactiveCN105625073ALarge aspect ratioImprove toughnessPulping with acid salts/anhydridesPulping with inorganic basesPretreatment methodAdhesive

The invention discloses a raw material pretreatment method for a straw-based seedling raising pot, a product and a production method of the seedling raising pot. The raw material pretreatment method comprises the following steps: straw materials are dried, subjected to impurity removal and crushed; water accounting for 1.5-6 times by mass of the straw materials is added for wetting; cooking or steam explosion or combined treatment of cooking and steam explosion is performed; cooling is performed; drying and crushing are performed. With adoption of the method, the usability of the straw-based seedling raising pot can be improved, the dosage of an adhesive can be used, and the production cost can be reduced.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

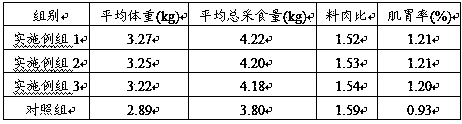

Integral-grain wheat-type chicken-in-meat compound feed and preparation method thereof

ActiveCN103392937AMeeting nutritional needsAddress nutritional needsFood processingAnimal feeding stuffGrape seedPeanut meal

The invention discloses integral-grain wheat-type chicken-in-meat compound feed and a preparation method thereof. The compound feed consists of the following raw materials: corn, integral-grain wheat, rice bran meal, soya-bean oil, 46% soybean meal, 46% peanut meal, stone flour, calcium hydrogen phosphate, dry powder of Chinese cabbage leaves, grape seed powder, liquid compound enzyme, bee pollen and premix. The preparation method comprises steps of crushing, mixing, pelletizing and spraying. The beneficial effects are that: the compound feed is scientific in ratio, economical and practical; by adding integral-grain wheat in daily ration of the chicken-in-meat, not only the nutritional requirement of the chicken-in-meat is fully satisfied, the problem of difficult digestion of integral-grain wheat is solved because of the ratio of the various raw materials, intestines and stomach are prevented from damage caused by superfine feed, but also the crushing energy consumption during feed processing is reduced and feed cost is reduced.

Owner:SHANDONG NEW HOPE LIUHE GROUP

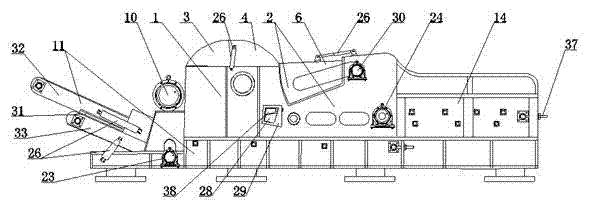

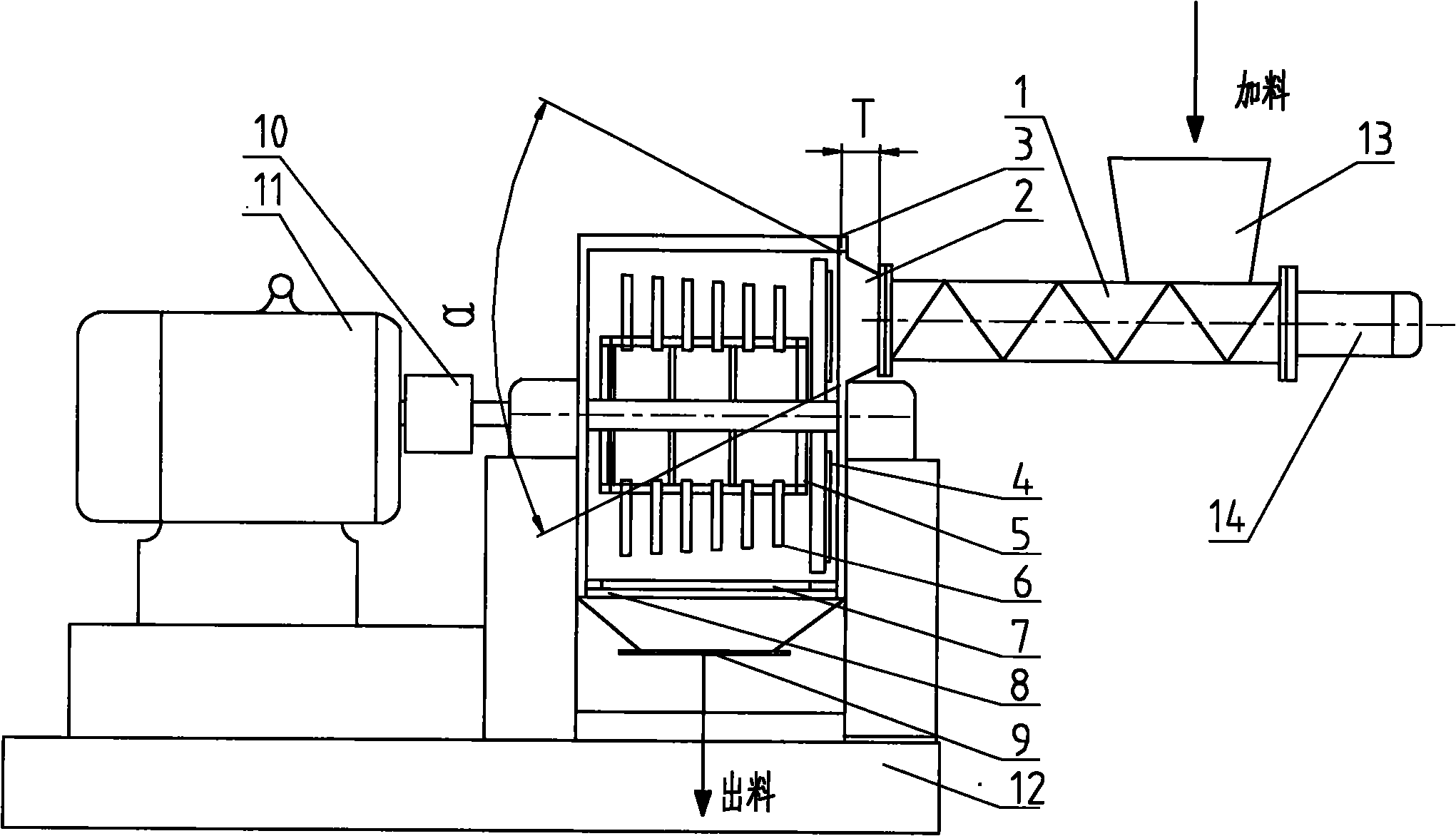

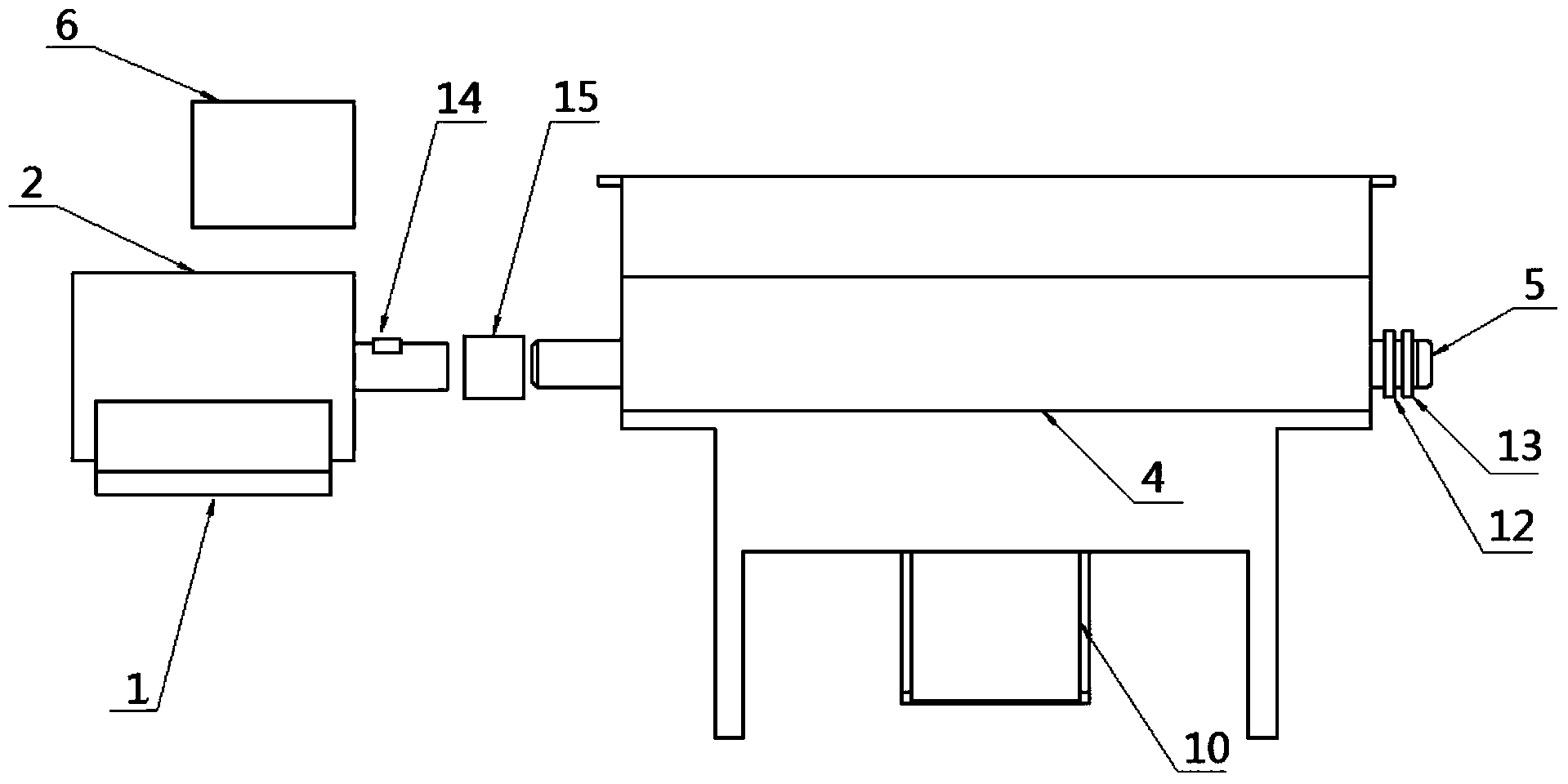

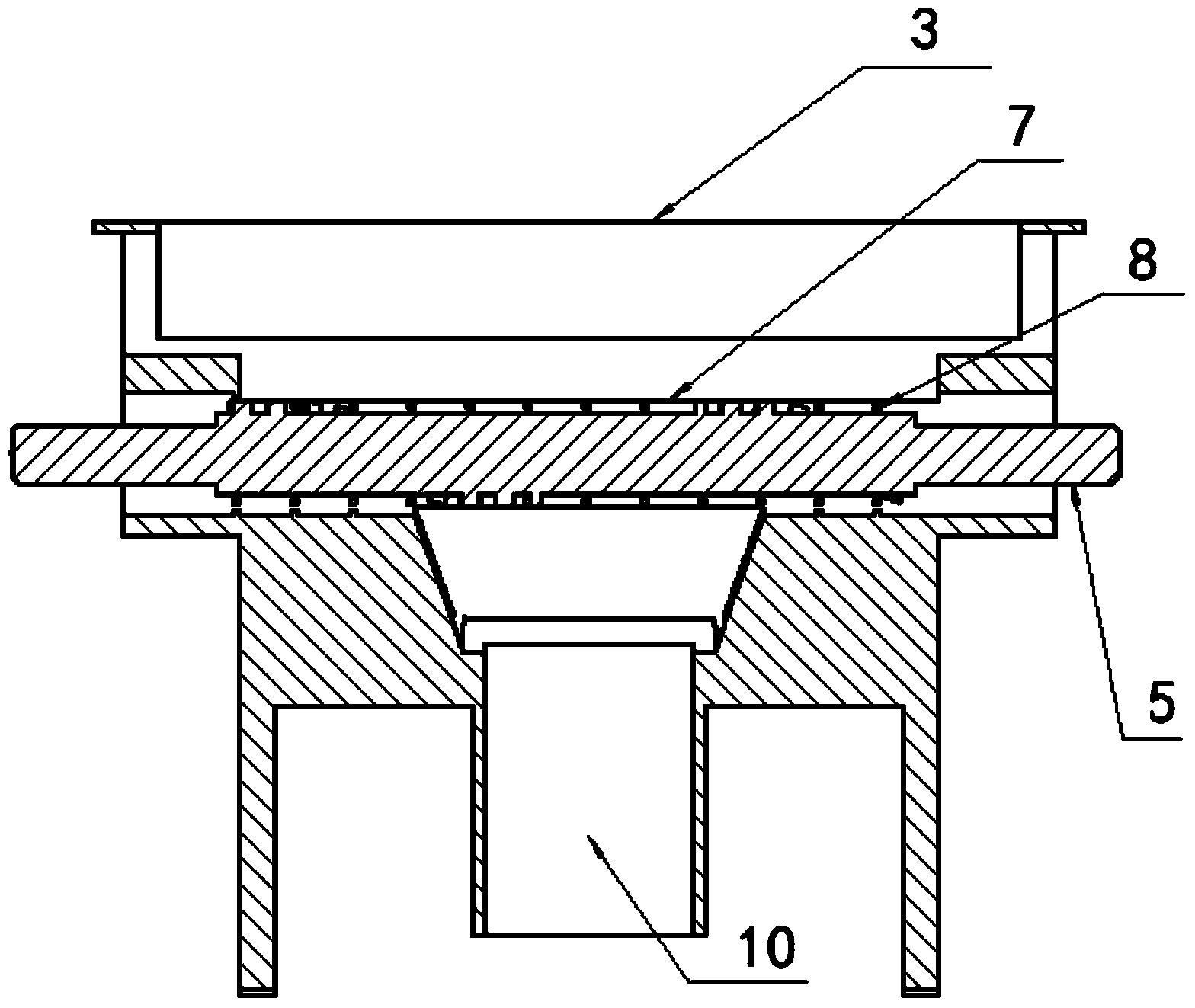

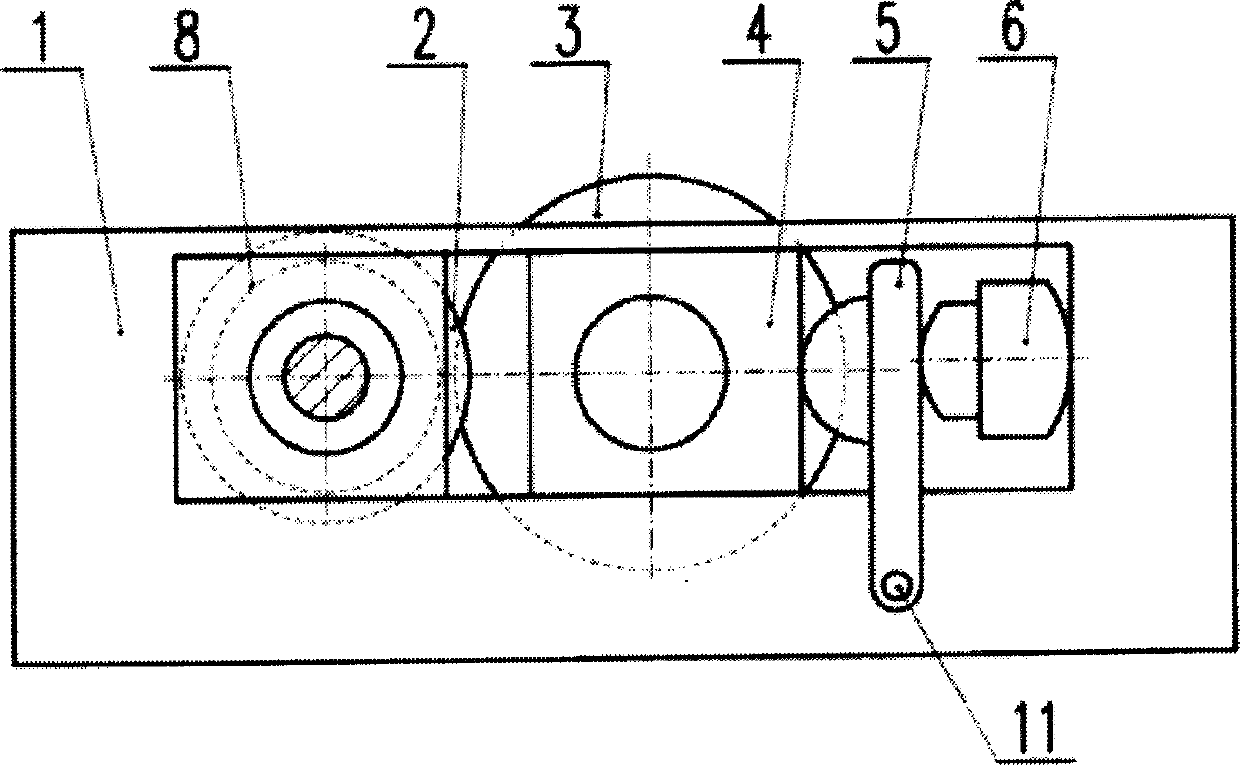

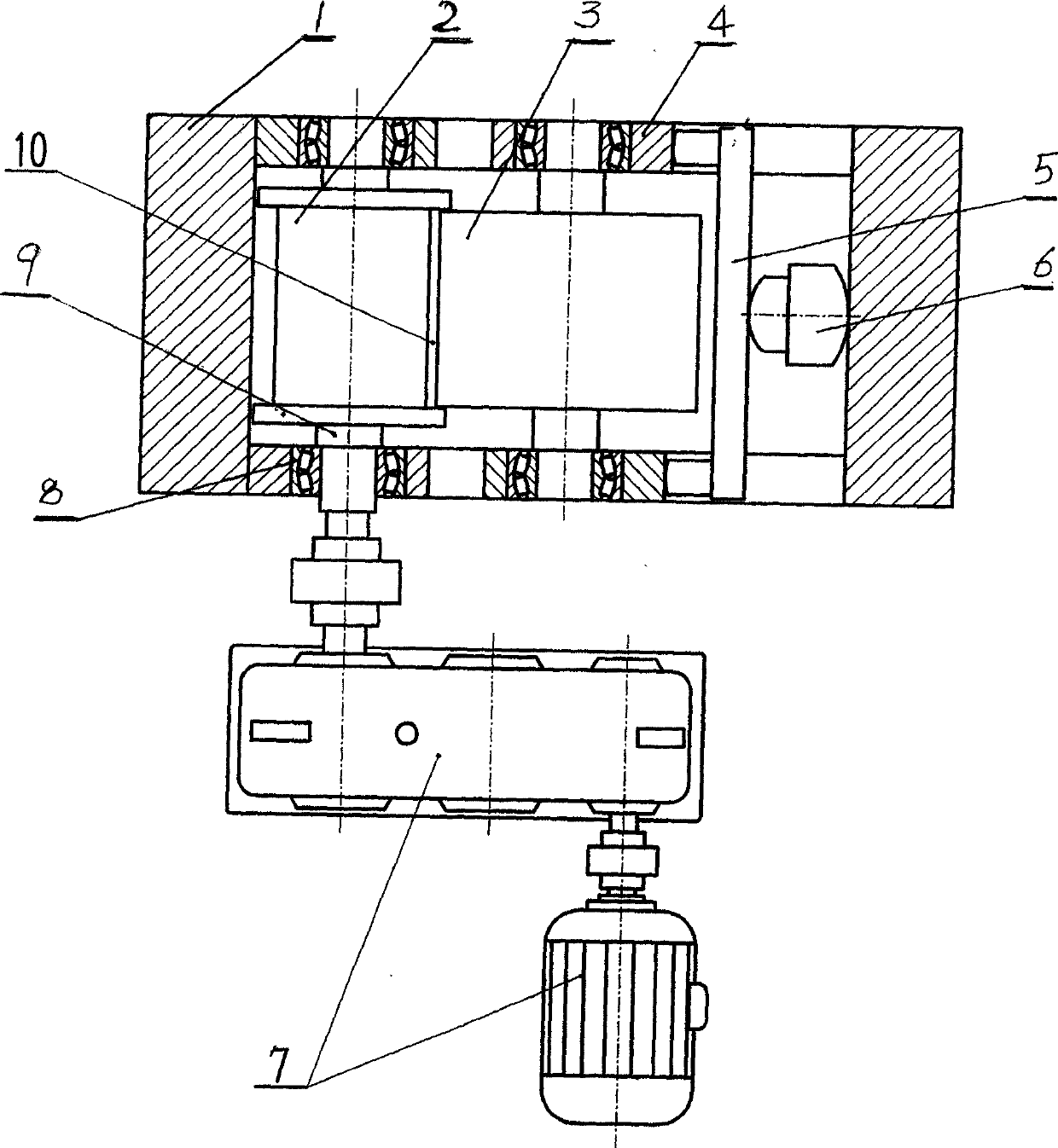

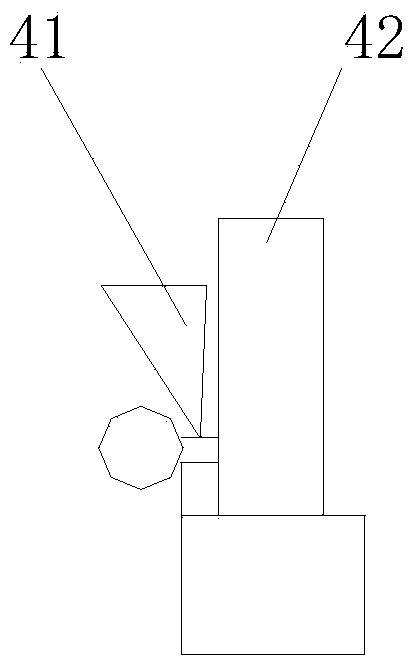

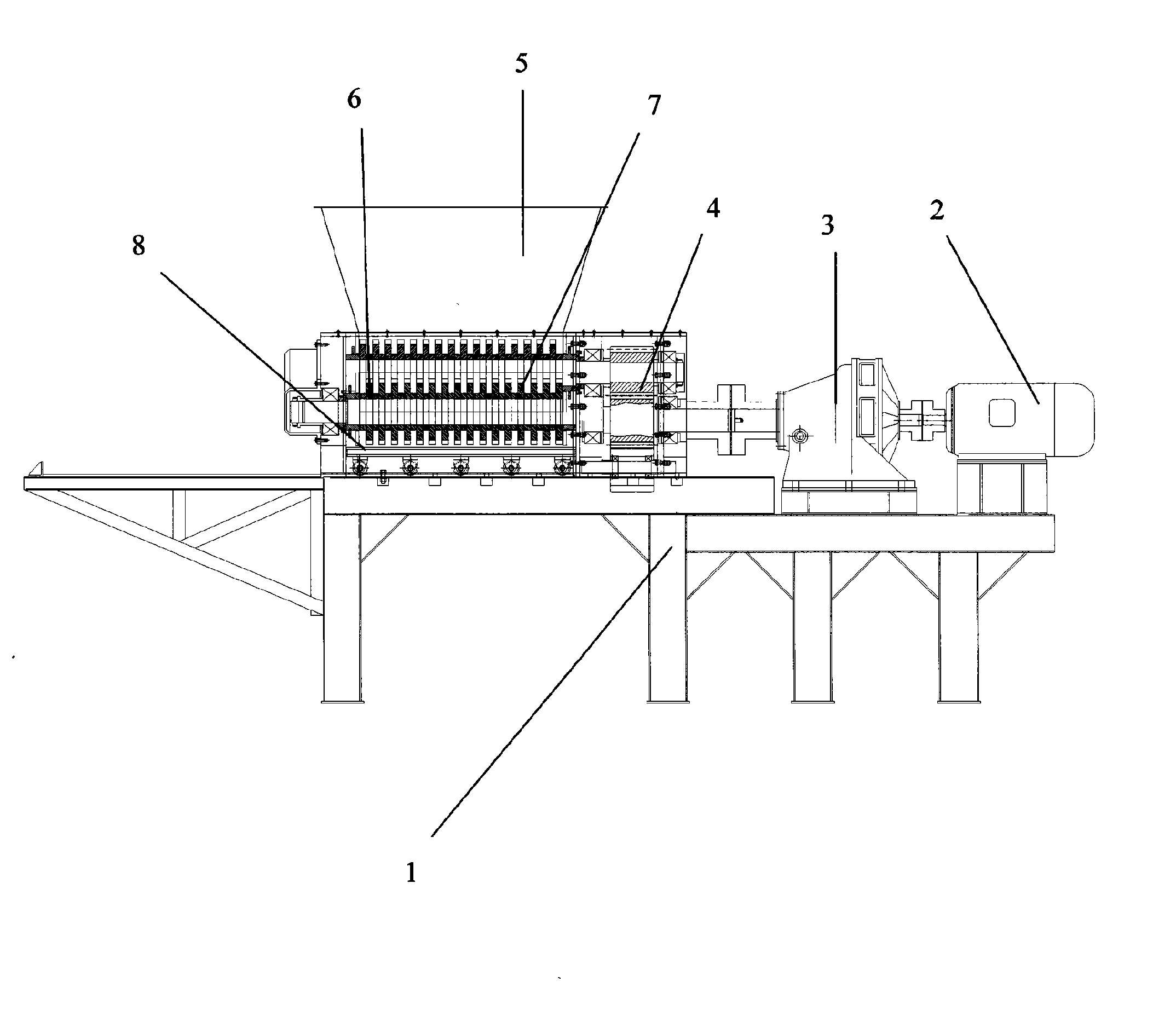

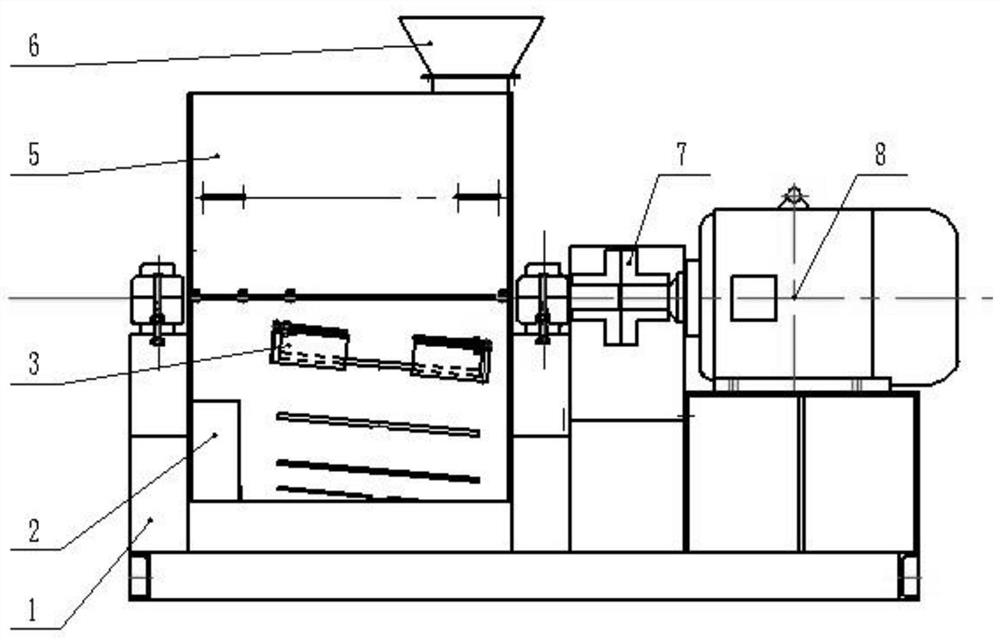

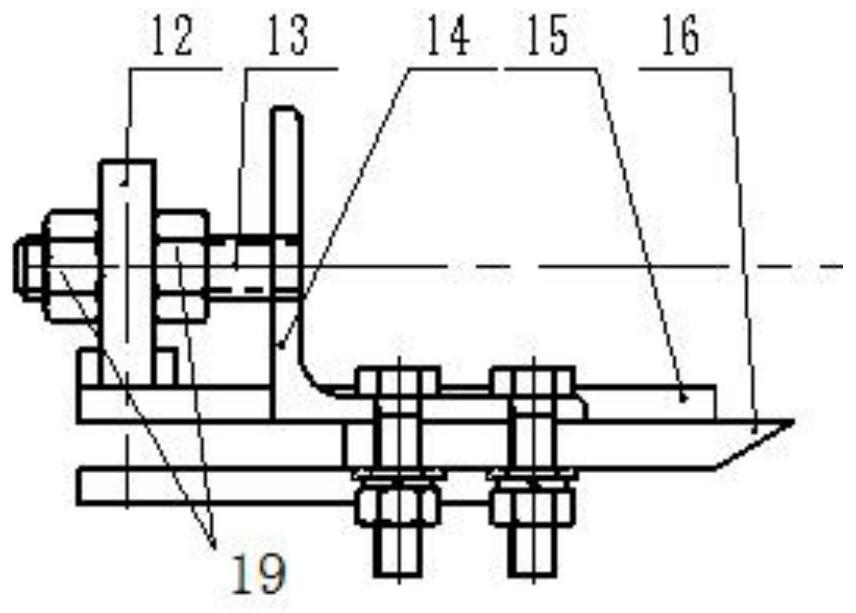

Special cut-off pulverizer for enteromorpha

The invention relates to a special pulverizer structure for enteromorpha for pulverizing long-fiber connected materials, in particular to a special cut-off pulverizer for enteromorpha. In the invention, a power shaft of a stand (12), provided with a motor (11), extends into a shell (3), a cylindrical rotor (5) is fixedly arranged on the power shaft, and a plurality of rows of hammer pieces (6) are fixed on the outer surface along the shaft; the upper part at the other side of the shell (3) is provided with a feed hole, a cylindrical feed drum is outwards extended through a diffusion type feedsection (2) which is big inside and small outside, and a forced material supply auger (1) is also arranged; the starting end of the feed drum is provided with a charging hole (13); the power shaft isprovided with a cut up mechanism (4) close to the feed hole; the lower part of the shell (3) is pressed by a screen pressing frame (8) to be provided with a screen net (7), and a discharge hole (9) is arranged below the shell; a plurality of slit cutting holes (42) are uniformly arranged on a cut up disk (41); and a protuberant cutter (43) is arranged at a side edge along the radial direction of the cutting holes (42). The invention changes the form of the traditional pulverizer, is additionally provided with the cutting mechanism, improves the pulverizing efficiency and has quite strong adaptability and high efficiency on long-fiber materials.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Method for producing calcium fluoraluminate clinker through aluminum cell carbon waste

ActiveCN107352819AImprove adsorption capacityAdd depthClinker productionCalcium in biologyTunnel kiln

The invention discloses a method for producing calcium fluoraluminate clinker through aluminum cell carbon waste. The method comprises the following steps of 1, securing treatment, wherein crushing is performed, a detoxicating agent solution is sprayed in an atomization mode to obtain a granulated detoxicating material; 2, fuel treatment, wherein a catalytic oxidant is added, and homogenizing modification is performed to obtain fluorine-containing fuel; or the catalytic oxidant, lime and water are added to be stirred or rolled and mixed or pulverized through a wet process or filtered or filtered and washed to obtain dealkalized fluorine-carbon residue fluorine-containing fuel; 3, manufacturing a raw material, wherein waste alumina, calcium raw materials and waste gypsum are prepared, grinding and homogenizing are performed, and plastifying molding is performed; 4, manufacturing the clinker, wherein the material is fed into a tunnel kiln or a vertical kiln to be calcinated and quenched to obtain the clinker. The clinker obtained through the method can be supplied to dual high early strength cement production, and has the good economical efficiency and good performance; the method can utilize a large quantity of aluminum silicon and calcium containing waste; the method is safe, simple, large in handling capacity, low in energy consumption, low in cost, free of secondary pollution and suitable for industrial production.

Owner:长沙紫宸科技开发有限公司

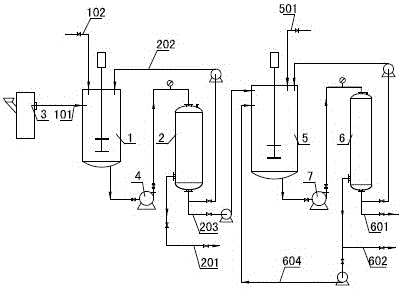

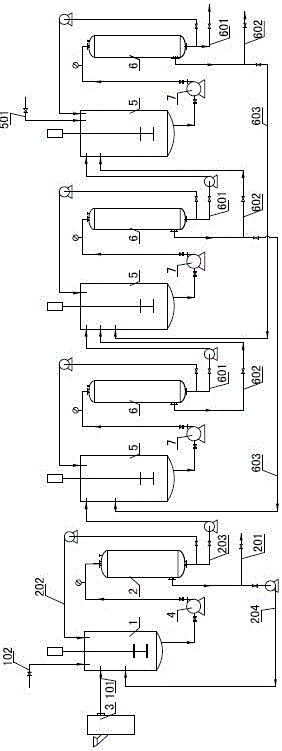

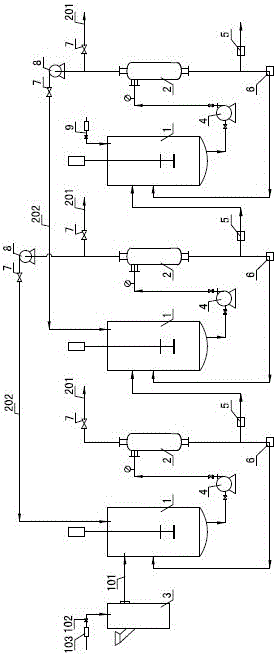

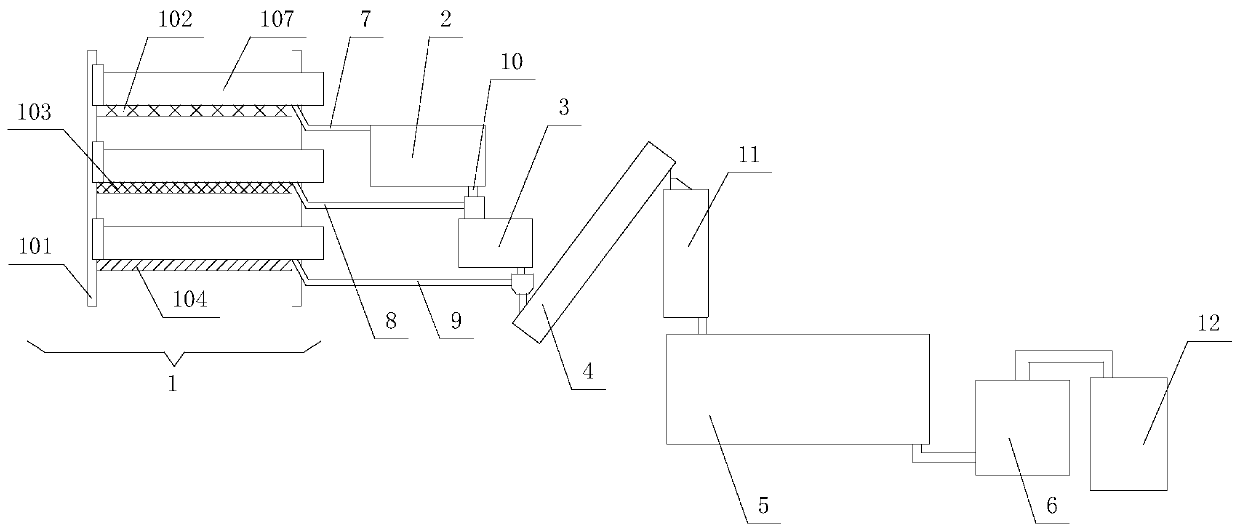

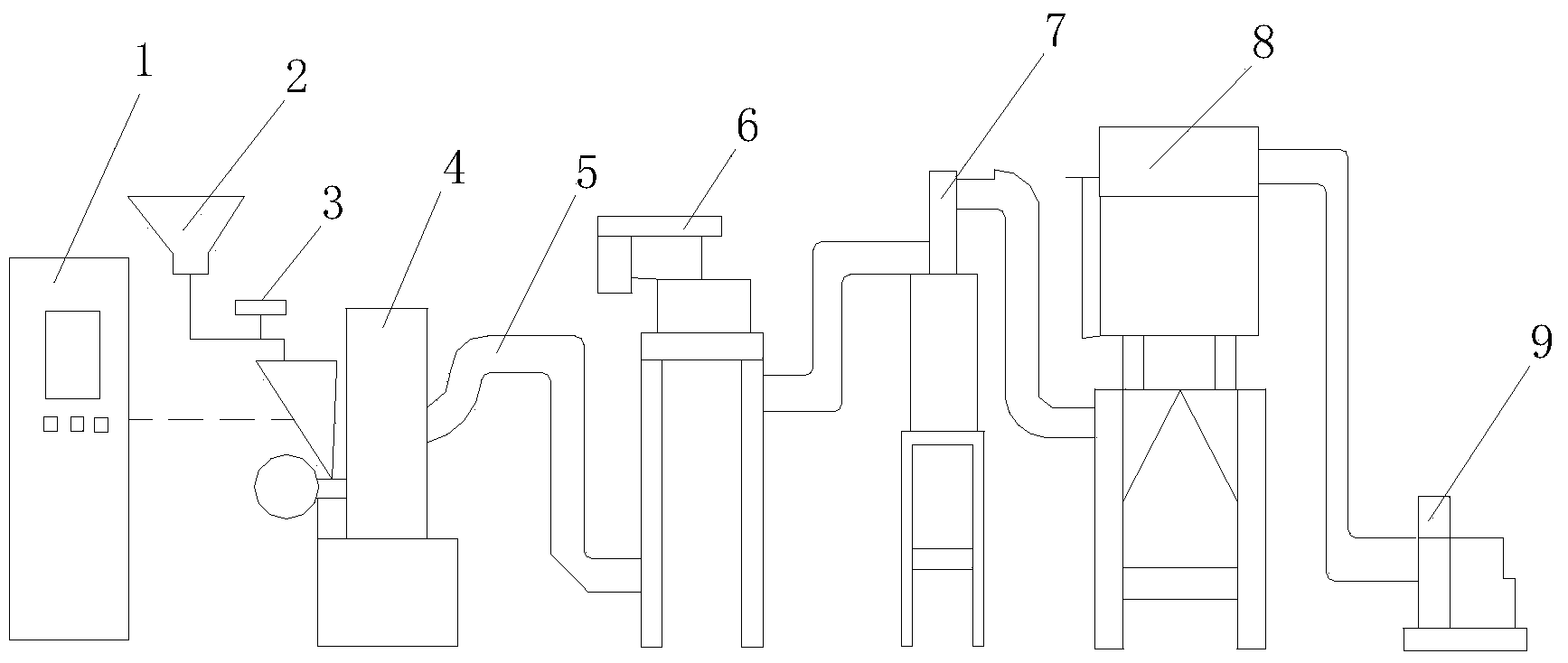

Multistage extraction unit for animal and plant raw materials, and method and application thereof

InactiveCN106362434AReduce crushing energy consumptionImprove filtration efficiencySolid solvent extractionSolventPulverizer

The invention relates to a multistage extraction unit for animal and plant raw materials, and a method and application thereof, belonging to the technical field of animal and plant extraction. The extraction unit comprises an extraction tank (1), a filtration membrane filter (2), a pulverizer (3) and a concentrated solution membrane separation device, wherein the extraction tank (1) is connected with the pulverizer (3) through a raw material delivery pipe (101), and connected with a feed port of the filtration membrane filter (2) through a first pump (4) via a pipeline; a filtrate outlet of the microfiltration membrane filter (2) is connected with a filtrate output pipe (201); and a concentrated solution outlet of the filtration membrane filter (2) is respectively connected with the extraction tank (1) through a concentrated solution return pipe (202) and connected with the concentrated solution membrane separation device through a concentrated solution delivery pipe (203). The extraction unit can pulverize the raw materials into fine powder and perform membrane separation extraction, has the advantages of high extraction efficiency and high yield, and is capable of obviously enhancing the concentration of the obtained filtrate, reducing the solvent consumption and lowering the production cost.

Owner:王芹

Slag cake crusher capable of dynamically adjusting speed and control method thereof

The invention provides a slag cake crusher capable of dynamically adjusting speed and a control method thereof. The slag cake crusher comprises a driving motor, a crushing chamber and a control system, wherein a feeding hole is formed at the upper end of the crushing chamber; a discharging hole is formed at the lower end of the crushing chamber; a crushing roller shaft is arranged inside the crushing chamber; the crushing roller shaft is connected with the driving motor through a coupler; spiral cutter teeth are welded on the surface of the crushing roller shaft; convex teeth are arranged on the inner wall of the crushing chamber; gaps are formed between the convex teeth and spiral cutter teeth; the control system comprises a power supply, a PLC (Programmable Logic Controller) controller, a man-machine interaction device, a frequency changer, a coder mounted on a shaft of the driving motor and a temperature senor mounted on the crushing roller shaft; the PLC controller comprises a speed controller and a temperature correction rotation speed controller. By improving the structure of the slag cake crusher and using a double closed-loop dynamic control adjustment method, the automatic control of crushing process and speed is achieved, the dynamic change of slag cake crushing load is automatically adapted, and the crushing force and crushing efficiency are maximized.

Owner:JIANGSU UNIV

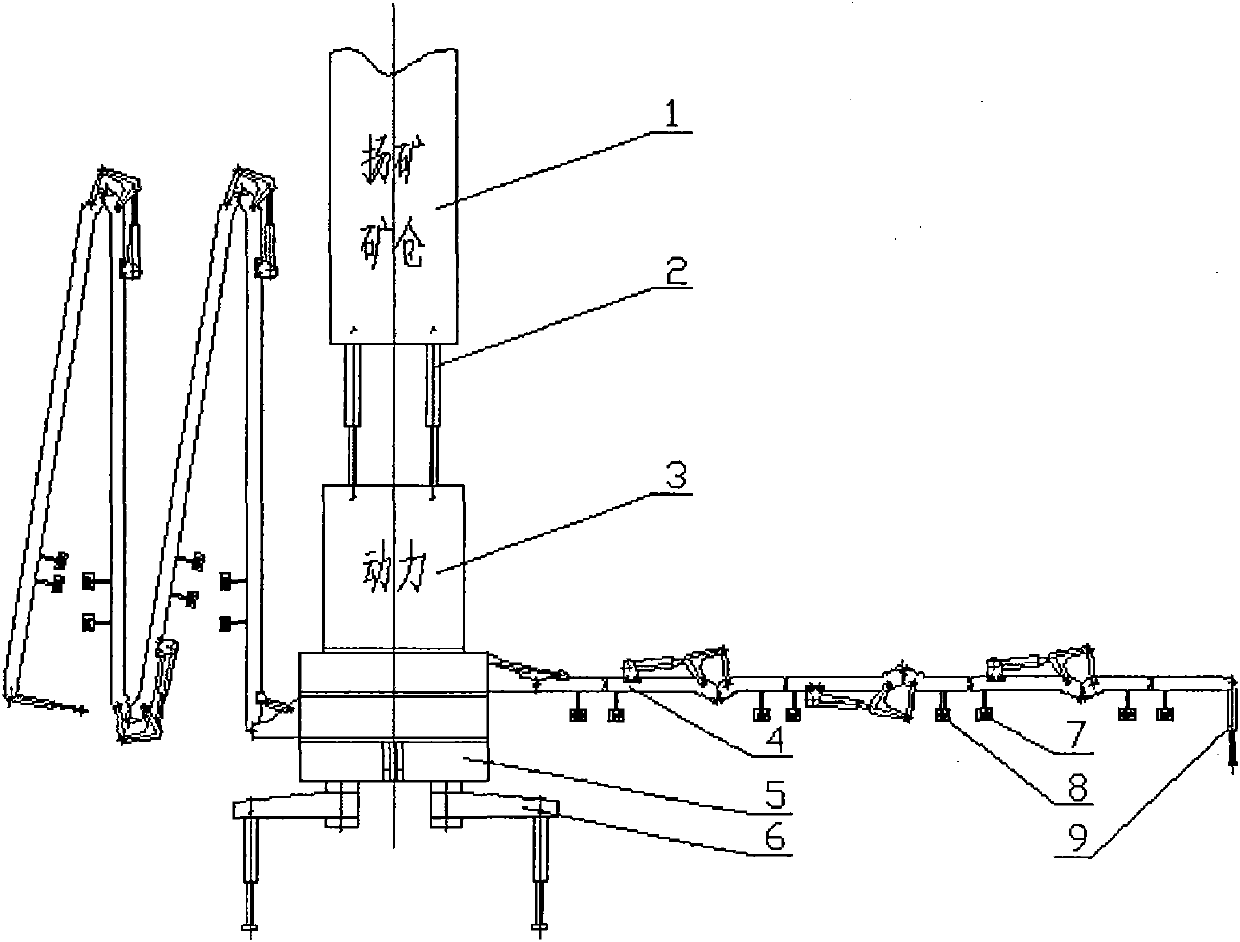

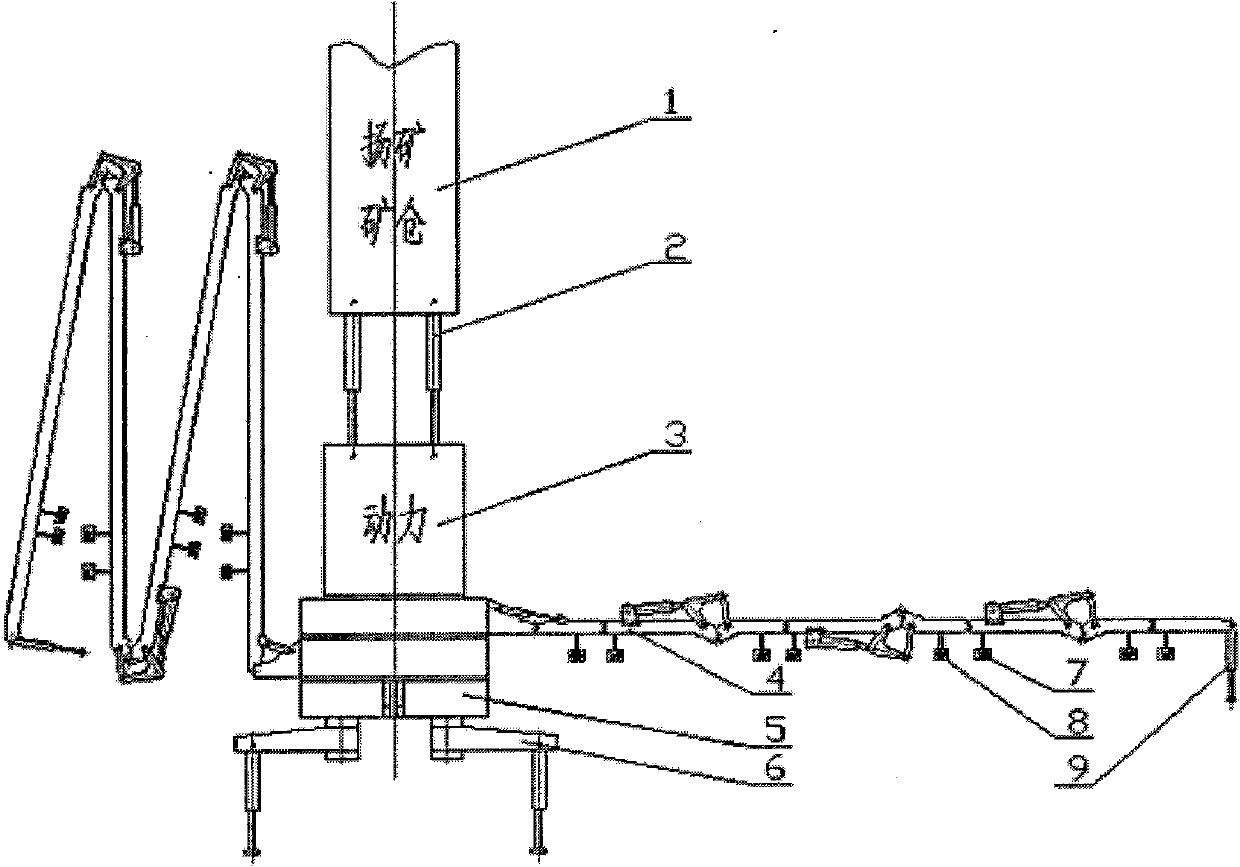

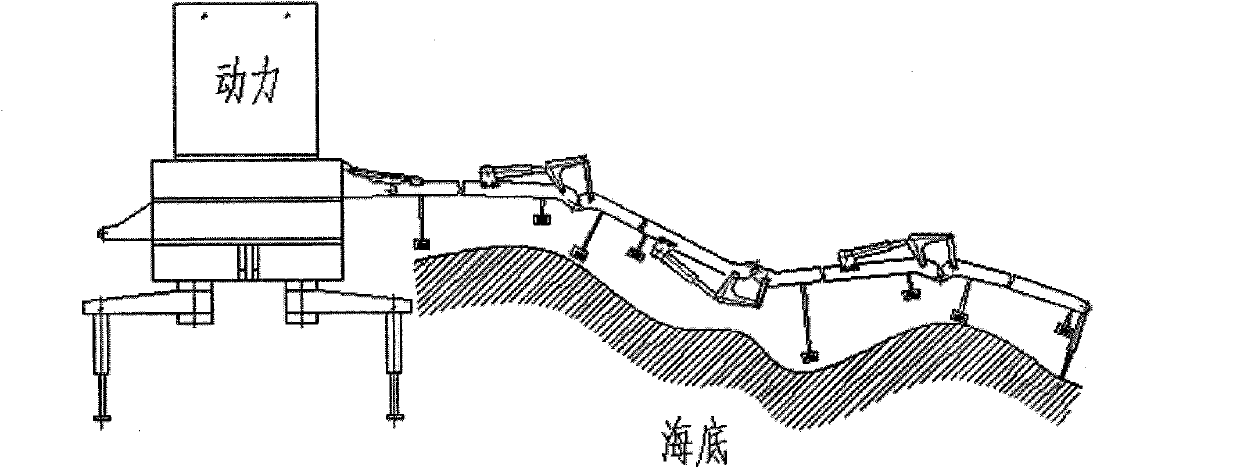

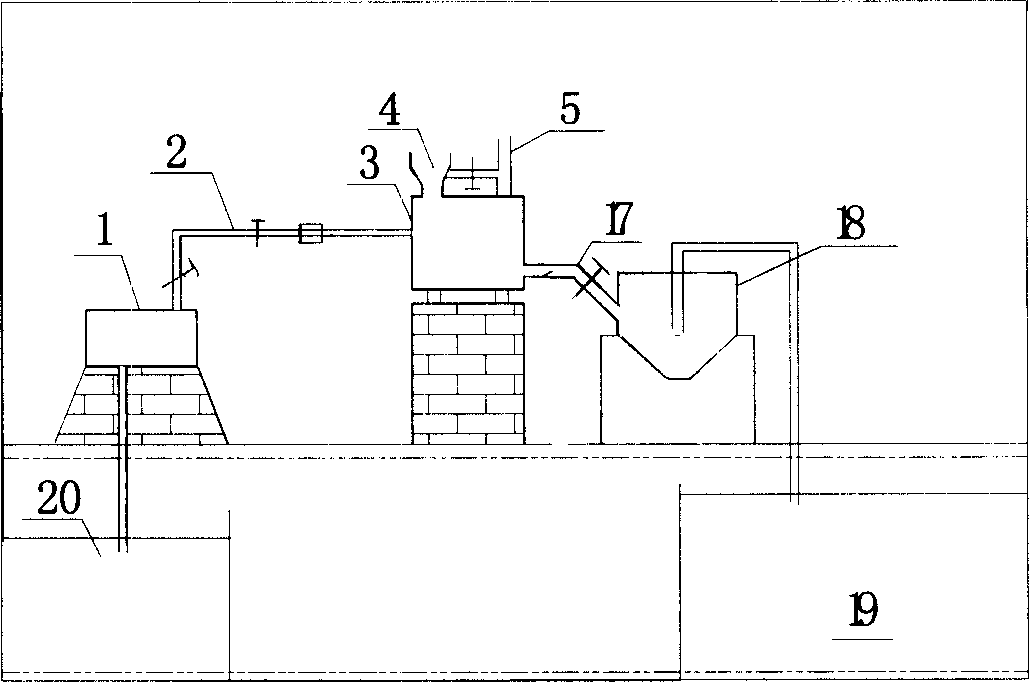

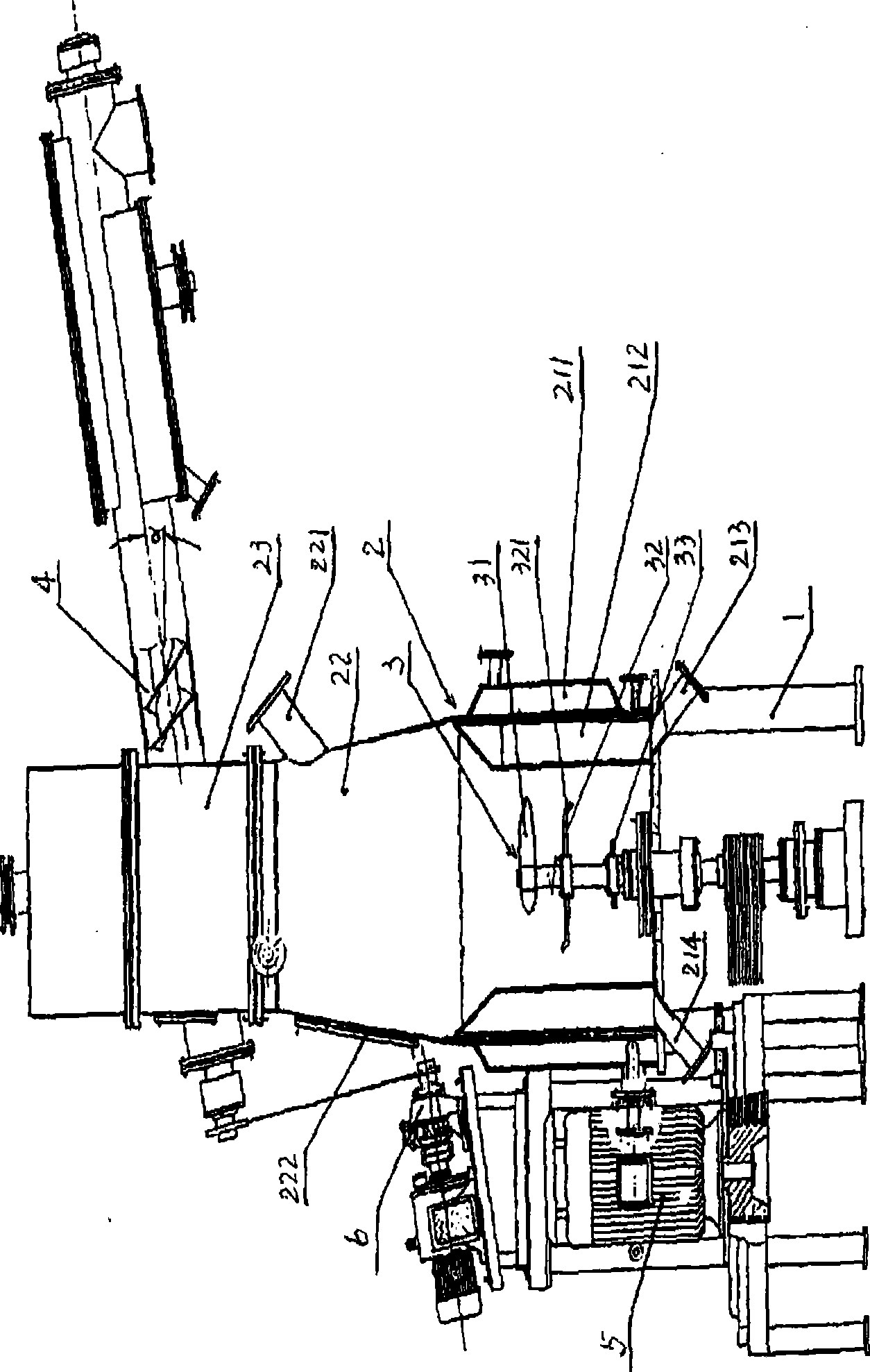

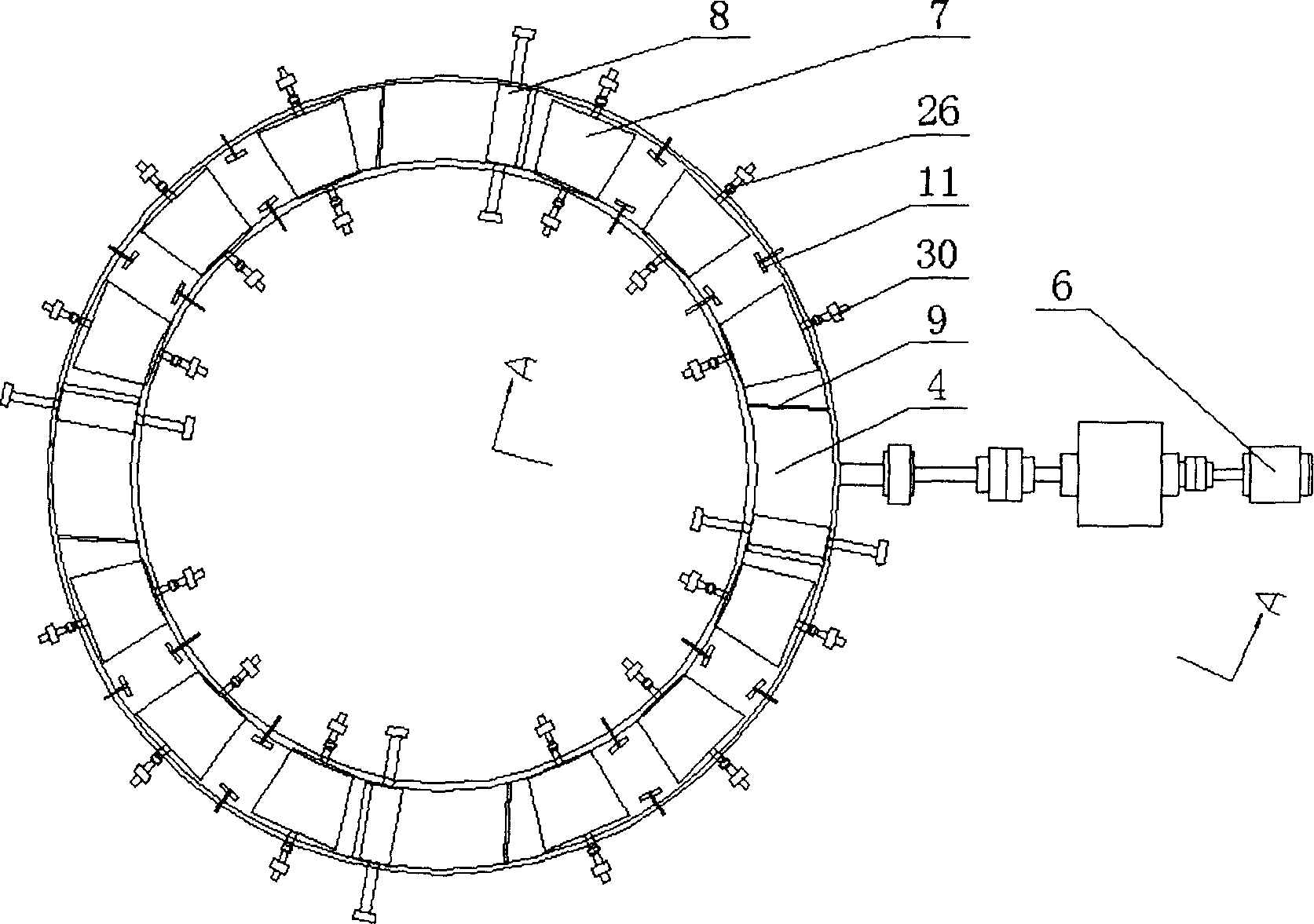

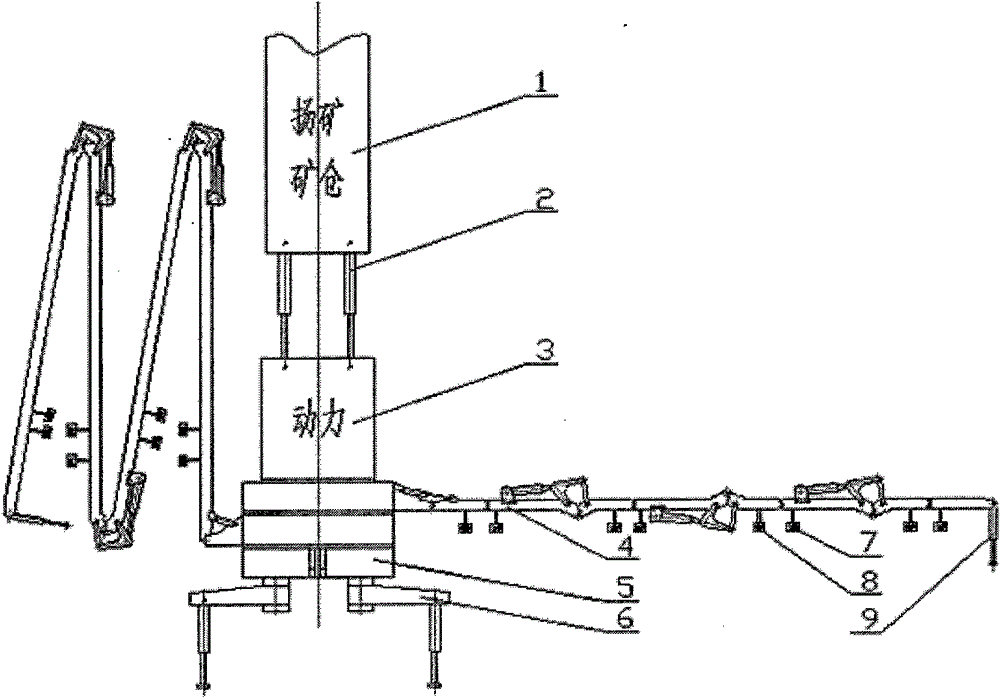

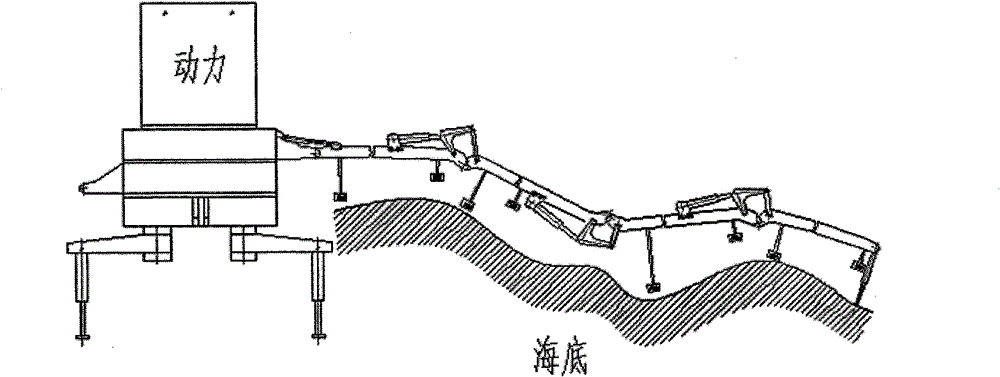

New method and equipment for mining submarine cobalt crusts

InactiveCN101906971AImprove collection qualityReduce crushing energy consumptionMineral miningSubmarineEngineering

The invention relates to new method and equipment for mining submarine cobalt crusts, wherein the method comprises the following steps of: (1) placing an acquisition platform to a seabed from a water-surface supporting ship; (2) starting the acquisition platform, extending out and leveling hydraulic supporting feet, and compacting the whole system by a lifting hydraulic cylinder so as to ensure the stability of the whole working; (3) extending out three folding type supporting arms, preliminarily determining the height of an acquisition mechanism, and fixing supporting legs; (4) starting an acquisition mechanism driving device installed on the acquisition platform, operating the acquisition mechanism to carry out crushing operation, collecting the crushed cobalt crusts through the acquisition mechanism and sending to a lifting ore bin; (5) after mining a corresponding fan-shaped area, carrying out angle adjustment on the three supporting arms through a rotary mechanism until finishingthe mining of a round ore region with the diameter of 100m; and (6) transporting the acquired cobalt crusts to the water-surface supporting ship through a lifting device. The invention also comprisesthe corresponding equipment. The invention has low mining cost, high efficiency, simple equipment and high reliability and is applicable to mining the submarine cobalt crusts on a large scale.

Owner:CENT SOUTH UNIV

Biomass crusher

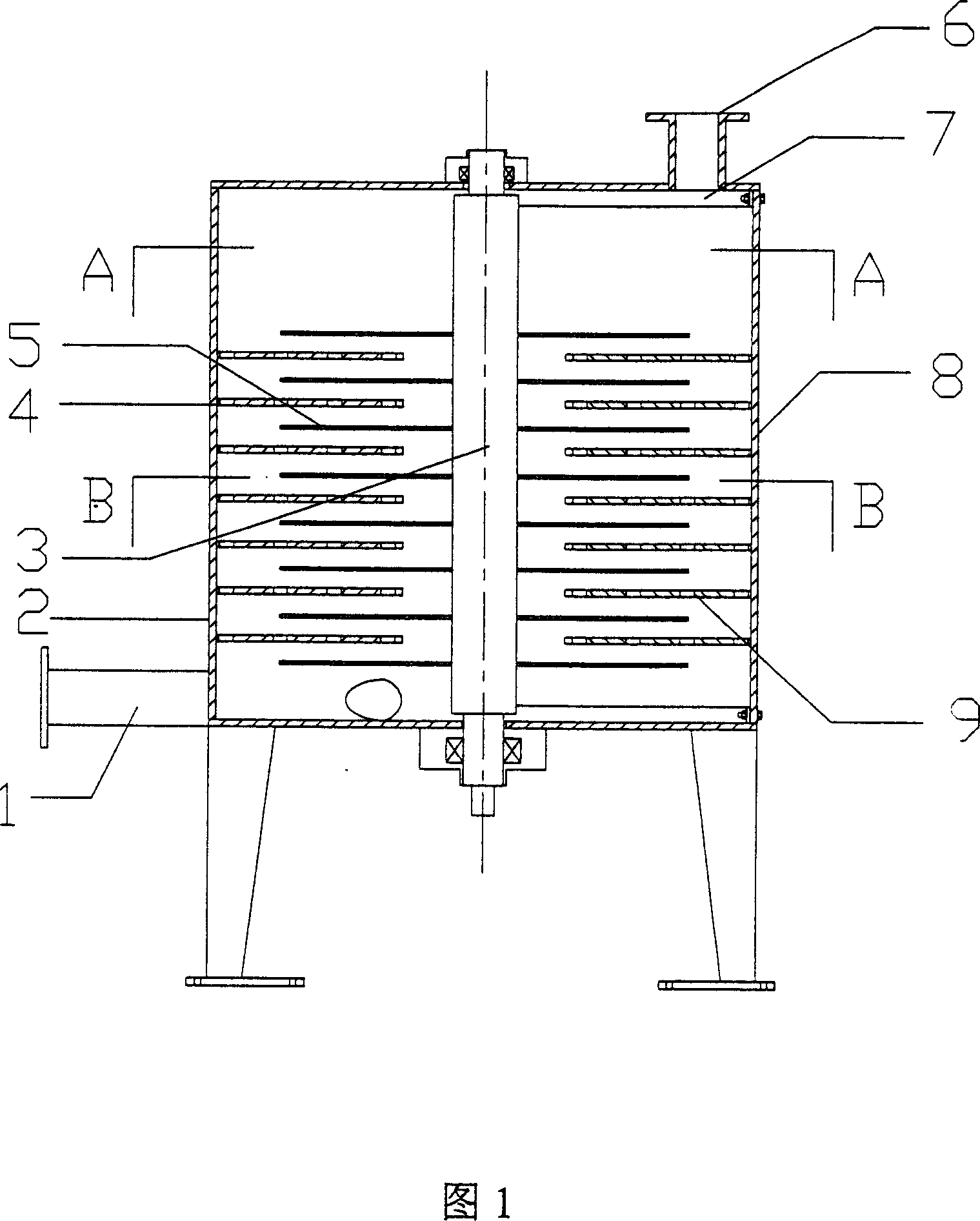

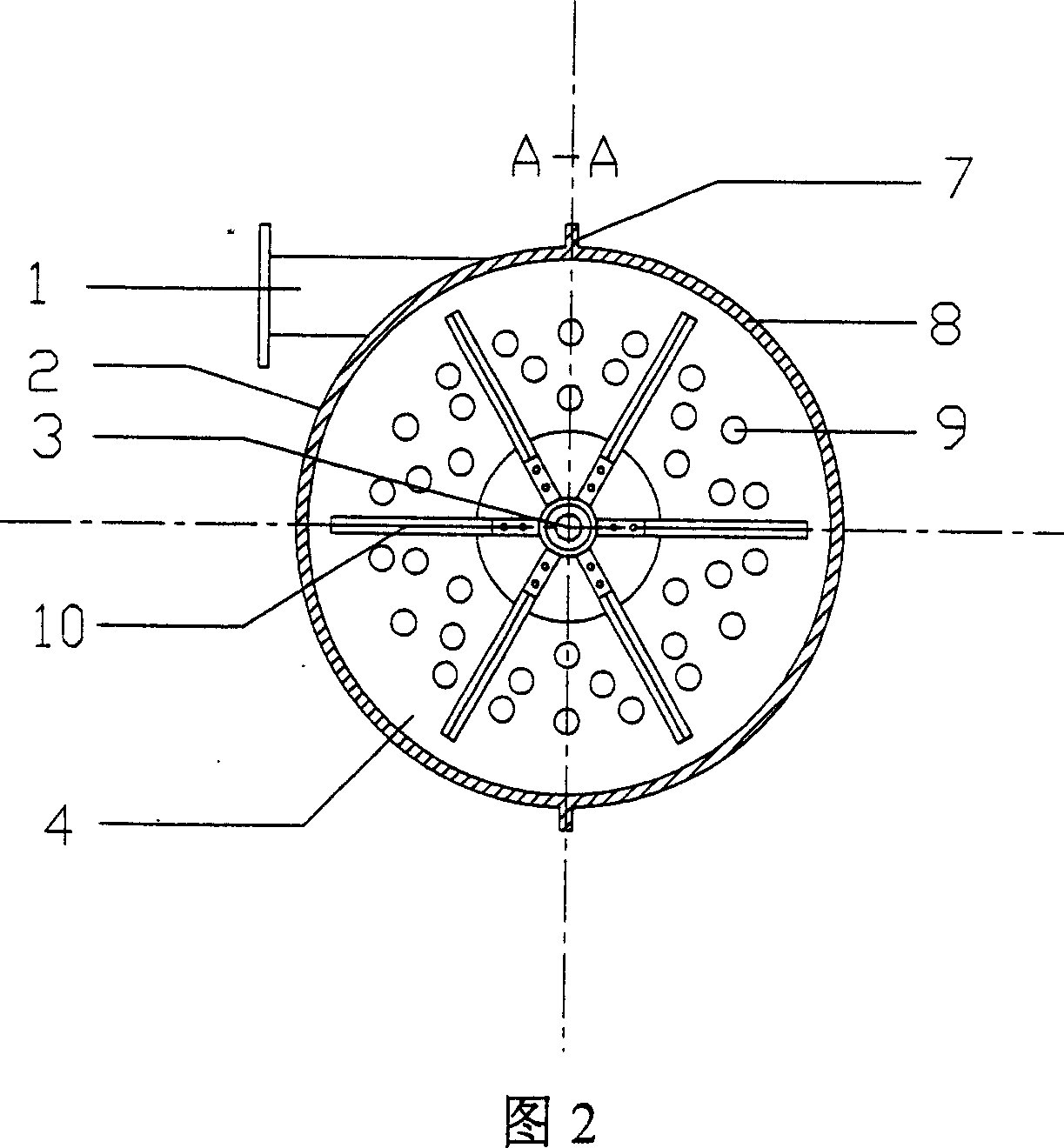

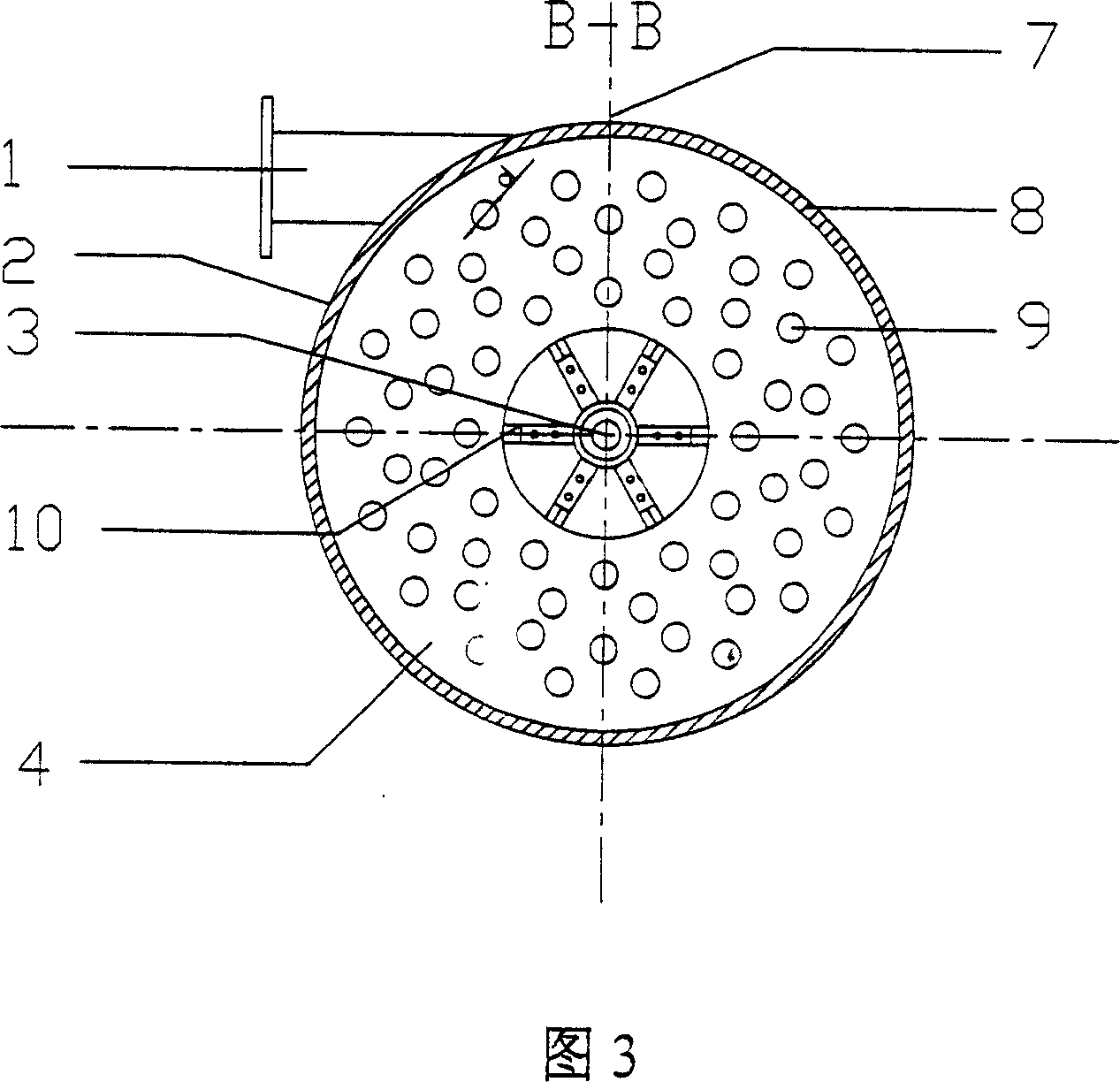

The biomass crusher has the structure comprising one barrel with material inlet and material outlet and divided axially into two parts fixed with flanges, one main shaft mounted in the axial center of the barrel, several layers of cutting knifes mounted perpendicularly to the main shaft; and several layers of ring plates with holes mounted on the barrel wall. There are gap between the cutting knifes and the barrel wall, gap between the ring plates and the main shaft, gap between two layers of ring plates and gap between the cutting knifes and the ring plates. The present invention has compact structure, small crushed product size, low power consumption, high production efficiency and convenient maintenance.

Owner:HUAZHONG UNIV OF SCI & TECH

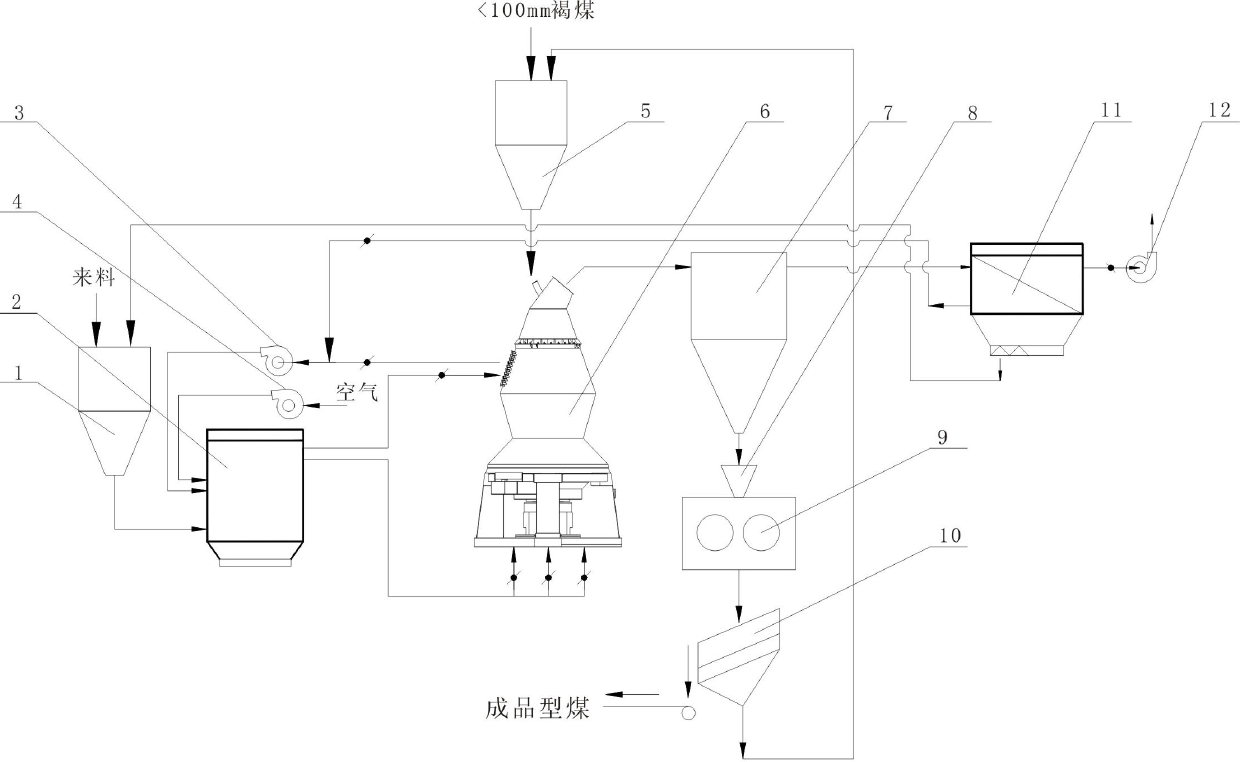

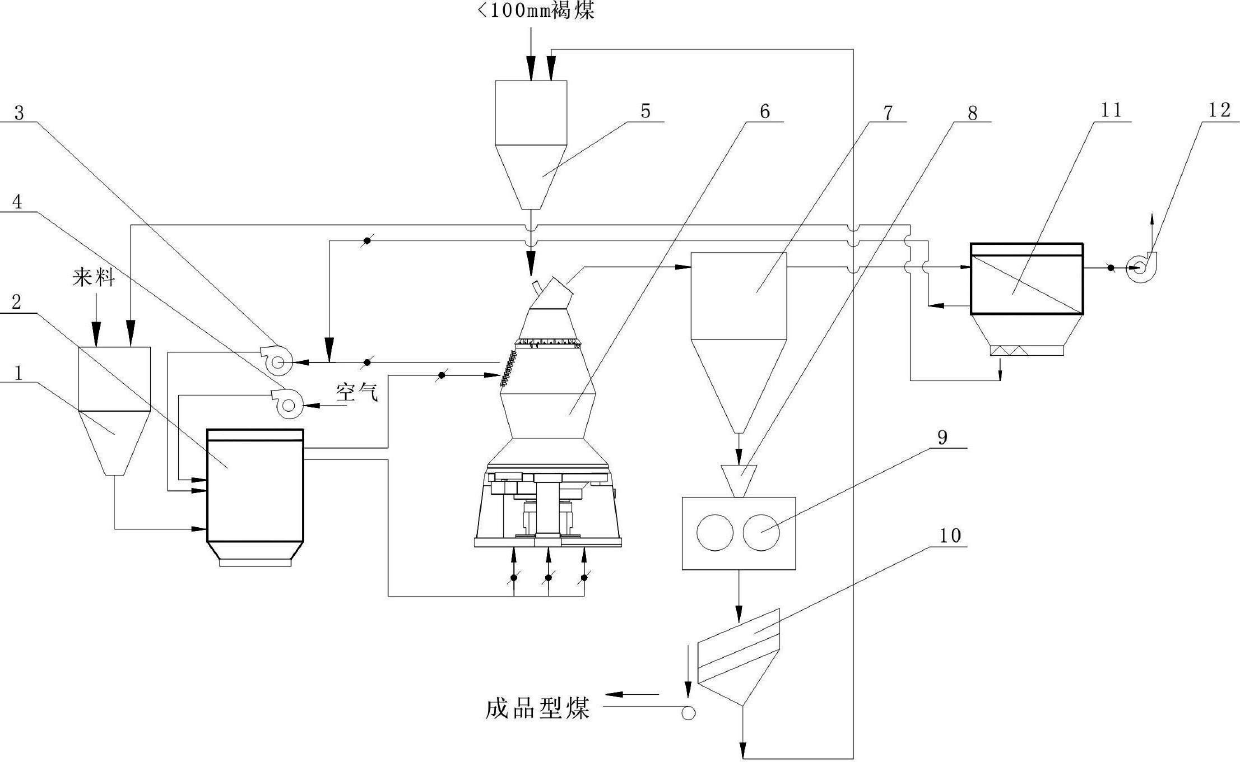

Integral process and device for crushing, drying, forming and upgrading lignite containing moisture

The invention discloses an integral process and a device for crushing, drying, forming and upgrading lignite containing moisture. The lignite with 20-50% of moisture and less than 100mm of granularity is sent into an integral crushing-drying device. The integral crushing-drying device crushes the lignite to have the granularity of less than 3mm, and high-temperature smoke produced by a smoke system is sent into the integral crushing-drying device at high speed to enable the crushed fine lignite particles and lignite power to be dried from bottom to top. Dried fine lignite particles and dried lignite power are driven by the high-speed high-temperature smoke to enter a cyclone separator to be separated. Separated fine lignite particles and separated lignite power enter a prepressing helical device from the position under the cyclone separator, and the lignite materials are prepressed and then enter a high pressure forming machine to be pressed and formed into finished lignite products. The device mainly comprises the smoke system, the integral crushing-drying device, the cyclone separator, the prepressing helical device and the high pressure forming machine. The integral process and the device for crushing, drying, forming and upgrading the lignite containing moisture is low in investment operating cost, high in upgrading efficiency and good in upgrading quality.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

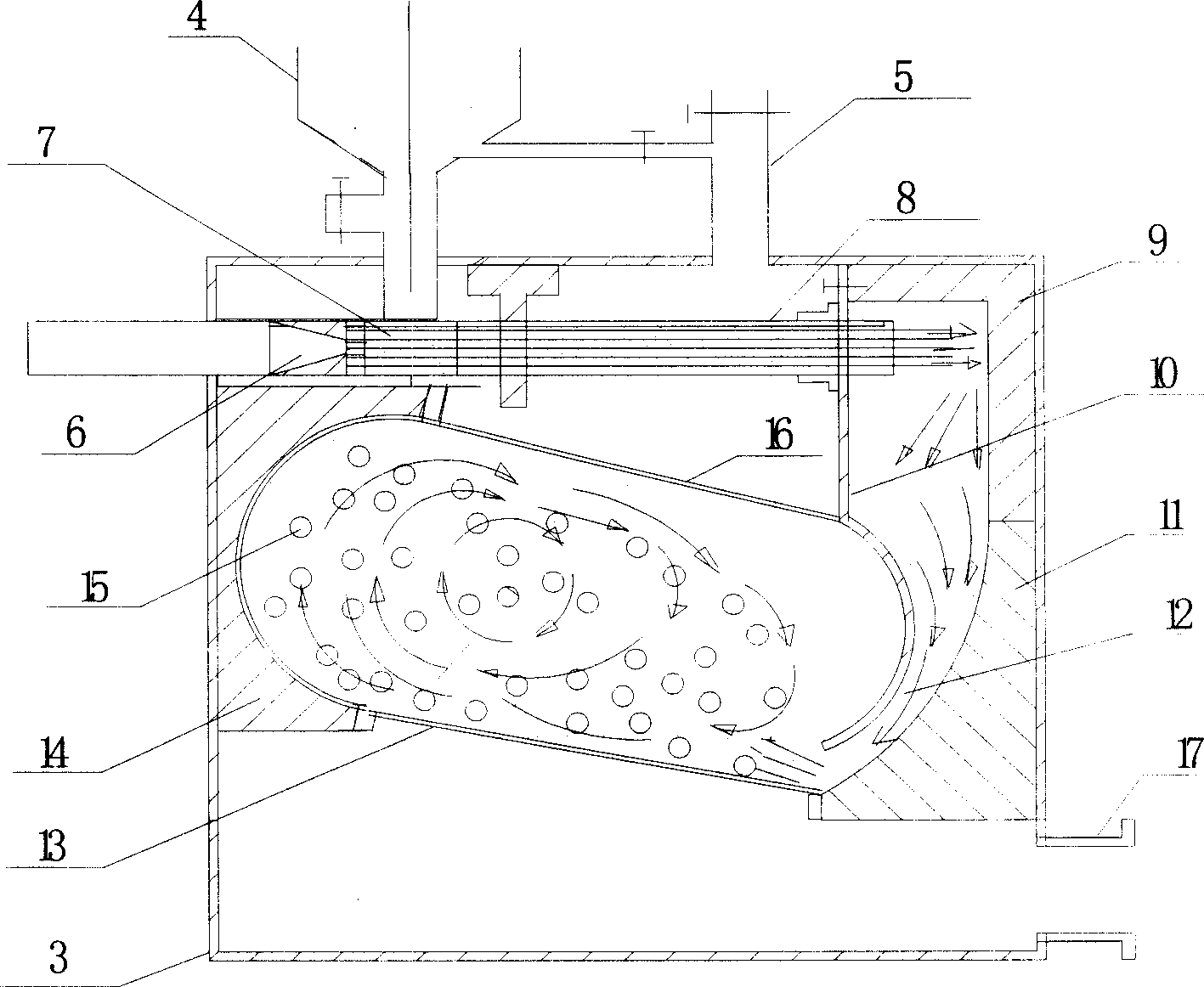

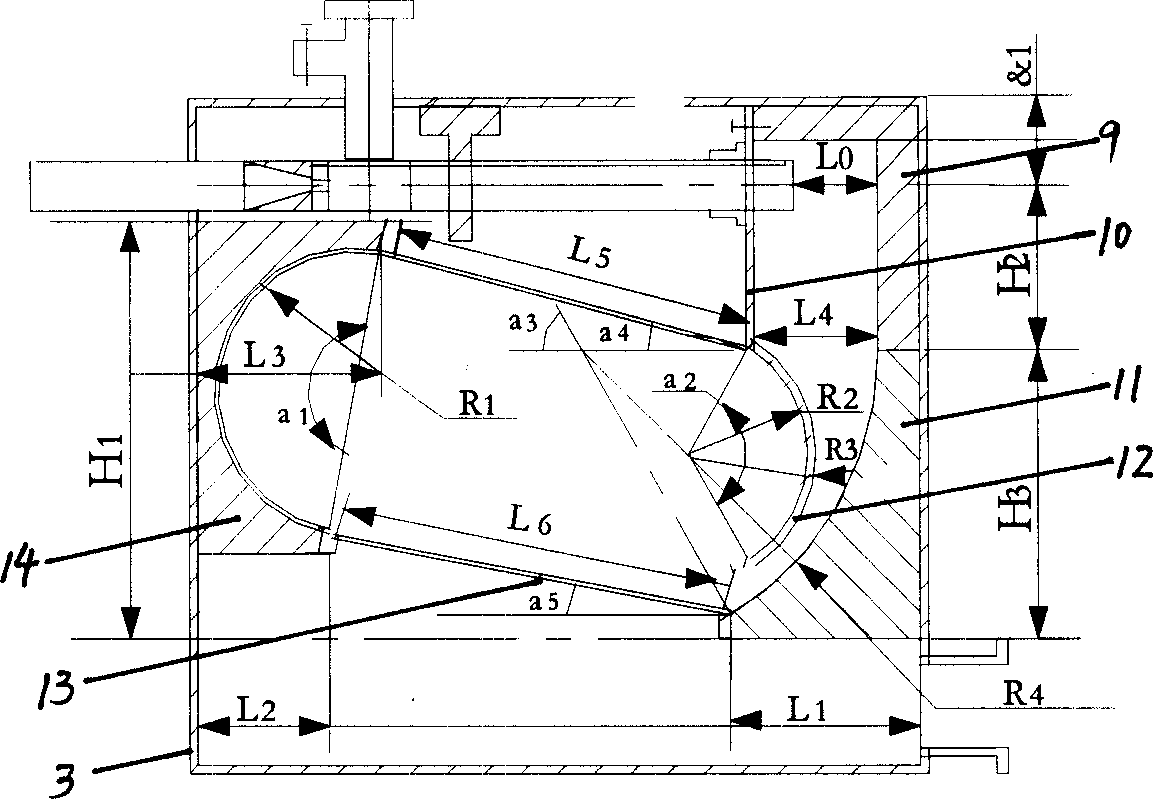

Combined hydraulic ultrafine powder grinding device

InactiveCN1911520AReduce crushing energy consumptionImprove crushing efficiencyGrain treatmentsWater jetEngineering

The combined hydraulic superfine crushing and grinding apparatus includes a crushing box and a material box. The crushing box is provided with high pressure nozzle, mixing cavity, accelerating tube and jet target, and has also baffle, curved guide target, curved guide body, sieve pore board, top board, etc to form one spoon shaped crushing space with grinding balls. The combined hydraulic superfine crushing and grinding apparatus combines the crushing, grinding, vibrating and other effects of high pressure water jet, has best utilization of the energy of high pressure water jet, and possesses features of simple structure, wide applicable range and continuous production.

Owner:XIAN UNIV OF TECH

Beneficiation method for ilmenite

InactiveCN106755998AReduce consumptionReduce crushing energy consumptionFlotationMagnetic separationHigh pressureMaterials science

A beneficiation method for ilmenite is characterized by comprising the following steps that firstly, a high-pressure roller mill conducts pulverized grinding to -3 mm, and iron selecting is conducted; secondly, iron selecting tailings are ground to P80 0.140 mm; thirdly, strong magnetism concentrates are obtained through strong magnetic separation enrichment, and the magnetic field intensity ranges from 0.6 T to 0.7 T; fourthly, the strong magnetism concentrates are ground to P80 0.070 mm; fifthly, after being subjected to desulfuration, the strong magnetism concentrates are subjected to primary roughing, four-time fine selecting and primary scavenging, flotation titanium concentrates are obtained, and SYR3 is adopted as a collecting agent of the ilmenite; and sixthly, titanium concentrates obtained through flotation are subjected to acid leaching, final titanium concentrates are obtained, the immersion liquid is 10% sulfuric acid, the titanium concentrates obtained through flotation are subjected to acid leaching for 3 h at the temperature approximately ranging from 80 DEG C to 85 DEG C, the liquid-solid ratio is 7:1, the titanium concentrates are obtained through three times of filtering and washing, and the qualified titanium concentrates in which the content of TiO2 is larger than 45% are obtained.

Owner:SHENYANG RES INST OF NONFERROUS METALS

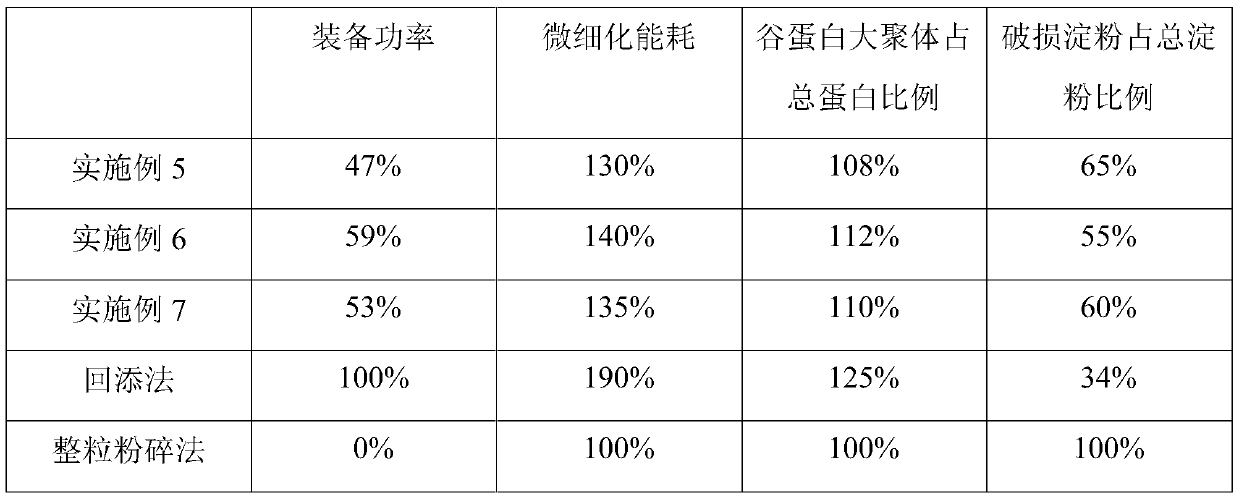

Preparation method of wheat whole wheat flour

InactiveCN110013903AHigh densityImprove crushing efficiencyFood preservationFood dryingWholemeal flourWater content

The invention discloses a preparation method of wheat whole wheat flour. The preparation method of the wheat whole wheat flour comprises the following steps that 1) grinding is performed to obtain non-flour components of wheat bran and wheat germ with part of endosperm and flour; and 2) the non-flour components undergo micronization treatment and then are mixed with the flour components to preparethe whole wheat flour. According to the preparation method, through microwave drying, the water content of the non-flour components is reduced, the enzyme activity of the non-flour components are inactivated and reduced, the easy-to-crush property of the wheat bran is improved, the micronization efficiency and stability of the non-flour components are improved, the micronization energy consumption of the non-flour components is reduced, and the shelf life is prolonged; and meanwhile, through the process that the wheat bran, the wheat germ and the endosperm are properly separated and then micronization is performed, materials needing to be micronized are reduced, the preparation energy consumption of whole wheat flour is further reduced, excessive crushing of the endosperm is avoided, thenatural structure of the protein and the starch is kept, and the basis of the quality of the whole wheat product is laid.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

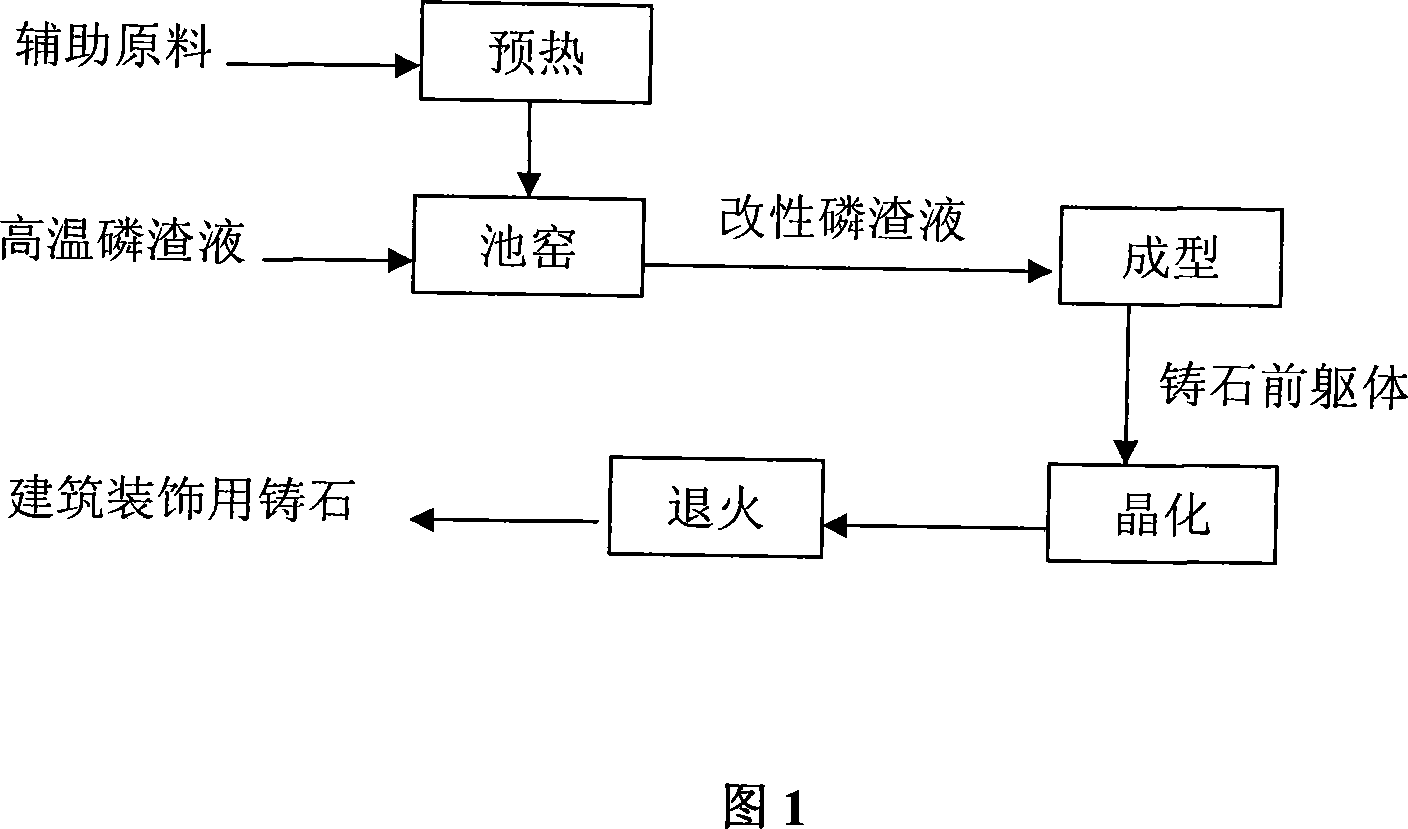

Production technique for preparing architectural ornament phosphorus slag cast stone by employing high-temperature phosphorus slag liquid

The invention relates to a technique for the preparation of phosphorus dregs cast stone used for construction decoration and using high temperature phosphorus dregs fluid. The invention is characterized in that: firstly, the configuration and the preheating of auxiliary raw material: quartz sand and kaoline are taken as auxiliary raw materials and heated to 1,300-1,450 DEG C; secondly, hot ingredient: the high-temperature phosphorous dregs fluid, which is discharged from a phosphorus electric stove, passes a fluid groove and flows into a pond kiln, and the auxiliary raw material is put into a pond kiln simultaneously, wherein, the quality ratio of the phosphorus dregs to the auxiliary raw material is 65-75:25-35; thirdly, melting: the melting mix of the phosphorous dregs and the auxiliary raw material reaches 1,450-1,580 DEG C; fourthly, shaping; last, crystallization and annealing: the crystallization is processed under 1,000-1,150 DEG C for 60-120 minutes, and then is annealed to room temperature, thus a product is made. The invention can effectively use the thermal energy of the high-temperature phosphorous dregs fluid to realize the conversion of the phosphorous dregs fluid into the resources and reduce the energy consumption and the cost of cast stone production, thereby causing the phosphorous dregs cast stone adaptive to the purpose of large-scale construction decoration.

Owner:浙江中地大科技有限公司

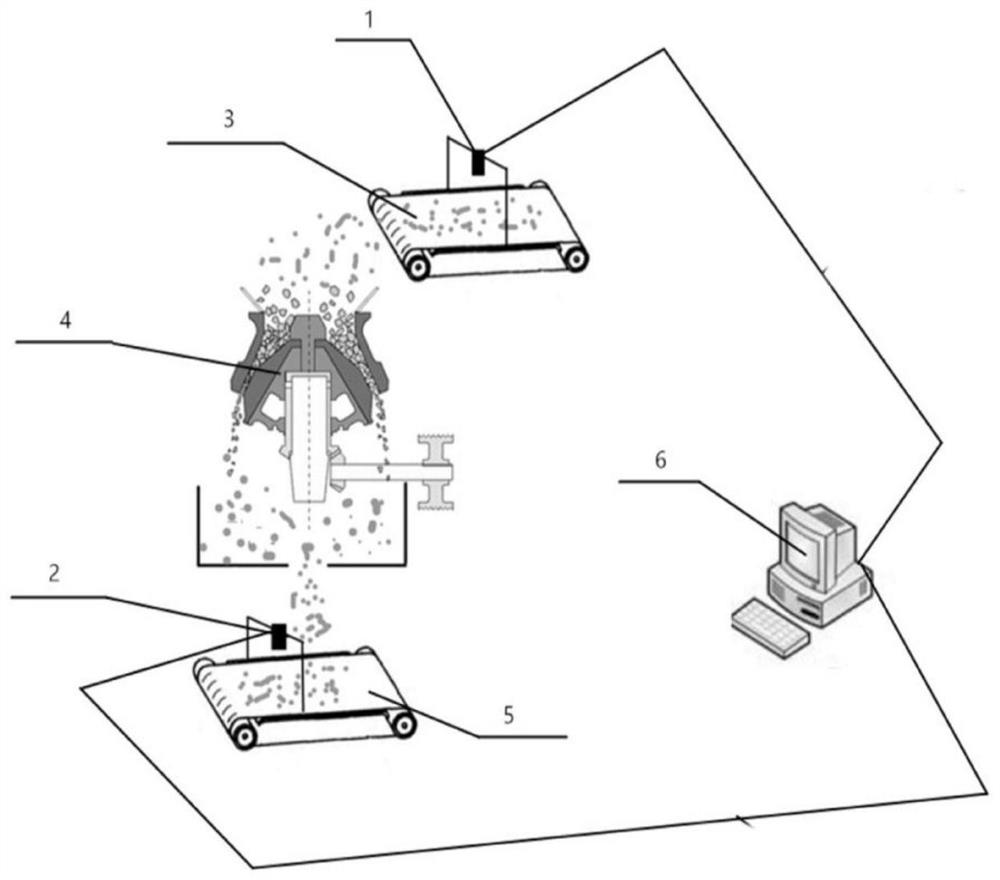

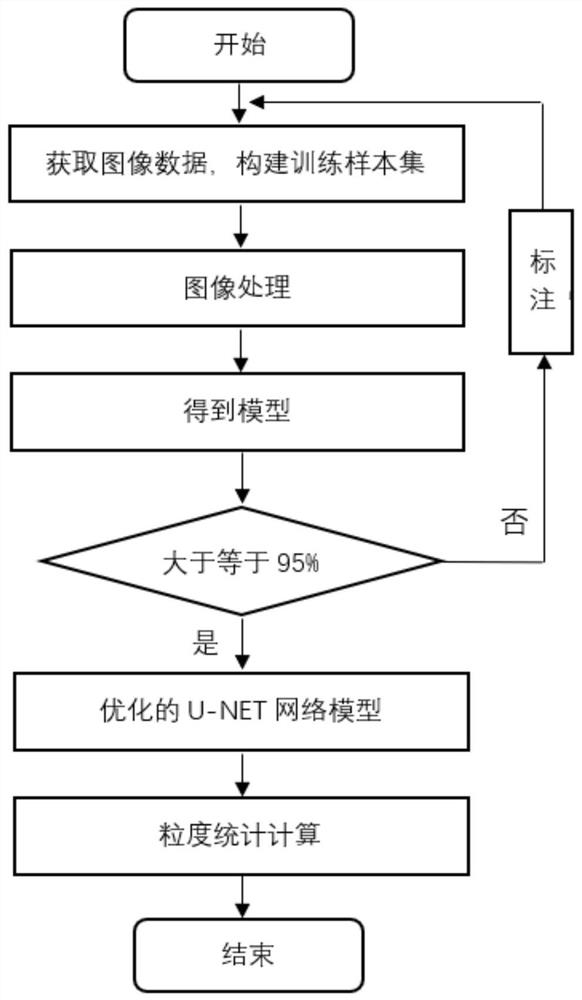

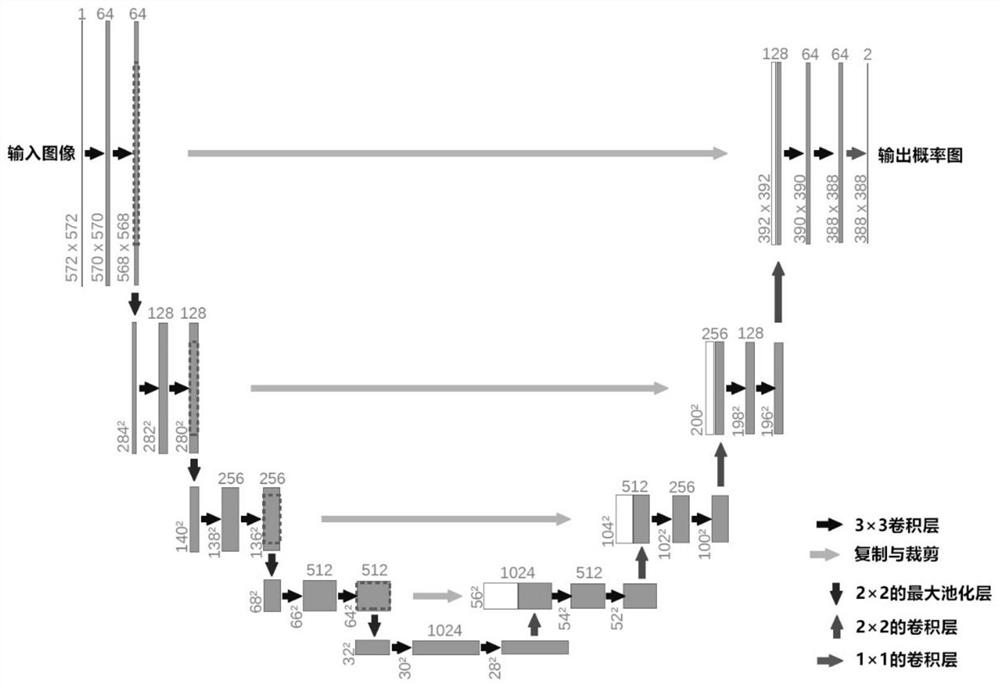

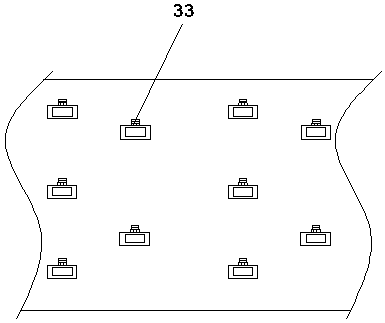

Ore granularity grading method and system based on image and deep neural network

ActiveCN112419397ARealize automatic controlImprove crushing efficiencyImage enhancementImage analysisAutomatic controlEngineering

The invention relates to an ore granularity grading method and a system based on an image and a deep neural network, and the system comprises a crusher, a belt conveyor and a control system, and is characterized in that a camera electrically connected with the control system is arranged above the belt conveyor; the method comprises the following steps: 1) collecting ore image data by the camera and transmitting the data to a control system, and constructing an ore granularity training sample set by a computer; 2) performing image preprocessing on the training sample set to enhance the image and reduce the noise; 3) optimizing the training sample set to obtain a model; 4) performing ore granularity segmentation on the ore image by applying the obtained optimized U-NET network model; and 5)performing granularity statistical calculation on the image segmentation result to obtain ore diameter and granularity distribution. The method has the advantages that the ore granularity can be detected and displayed on line in real time, and a foundation is laid for efficient production of an automatic control crusher.

Owner:ANSTEEL GRP MINING CO LTD

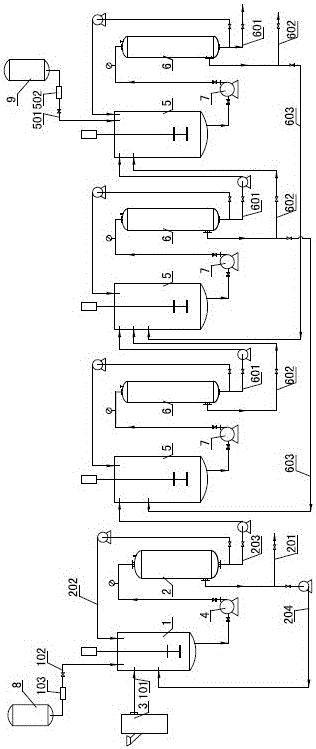

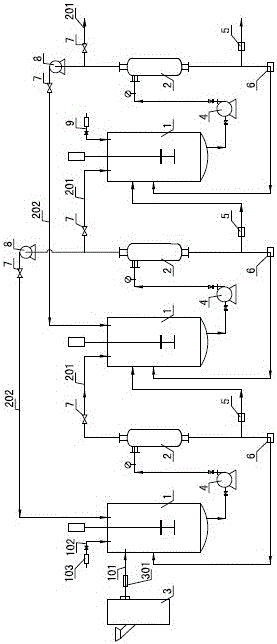

Multistage separation device for animal and plant raw materials as well as method and application thereof

InactiveCN106422408AImproved yield and leaching efficiencyReduce crushing energy consumptionFatty-oils/fats refiningEssential-oils/perfumesSolventPulverizer

The invention discloses a multistage separation device for animal and plant raw materials as well as a method and an application thereof, and belongs to the technical field of plant extraction. The multistage separation device comprises separating devices and a pulverizer (3), wherein each separating device comprises a leaching tank (1) and a solid-liquid separator (2); the leaching tank (1) is connected with the pulverizer (3) by virtue of a raw material conveying pipe (101); a discharge port of the leaching tank (1) is connected with a feed port pipeline of the solid-liquid separator (2) by virtue of a pump (4); a separated liquid outlet of the solid-liquid separator (2) is connected with a separated liquid output pipe (201); a solid material outlet of the solid-liquid separator (2) is connected with a first conveyor (5); a plurality of the separating device are arranged on the multistage separation device in a multistage mode from top to bottom along a solid material conveying direction. The multistage separation device for the animal and plant raw materials can pulverize the raw materials into powder for solid-liquid separation extraction, is high in extraction efficiency and yield, and can obviously increase the concentration of the obtained separated liquid, reduce the use level of a solvent, and reduce the production cost.

Owner:王芹

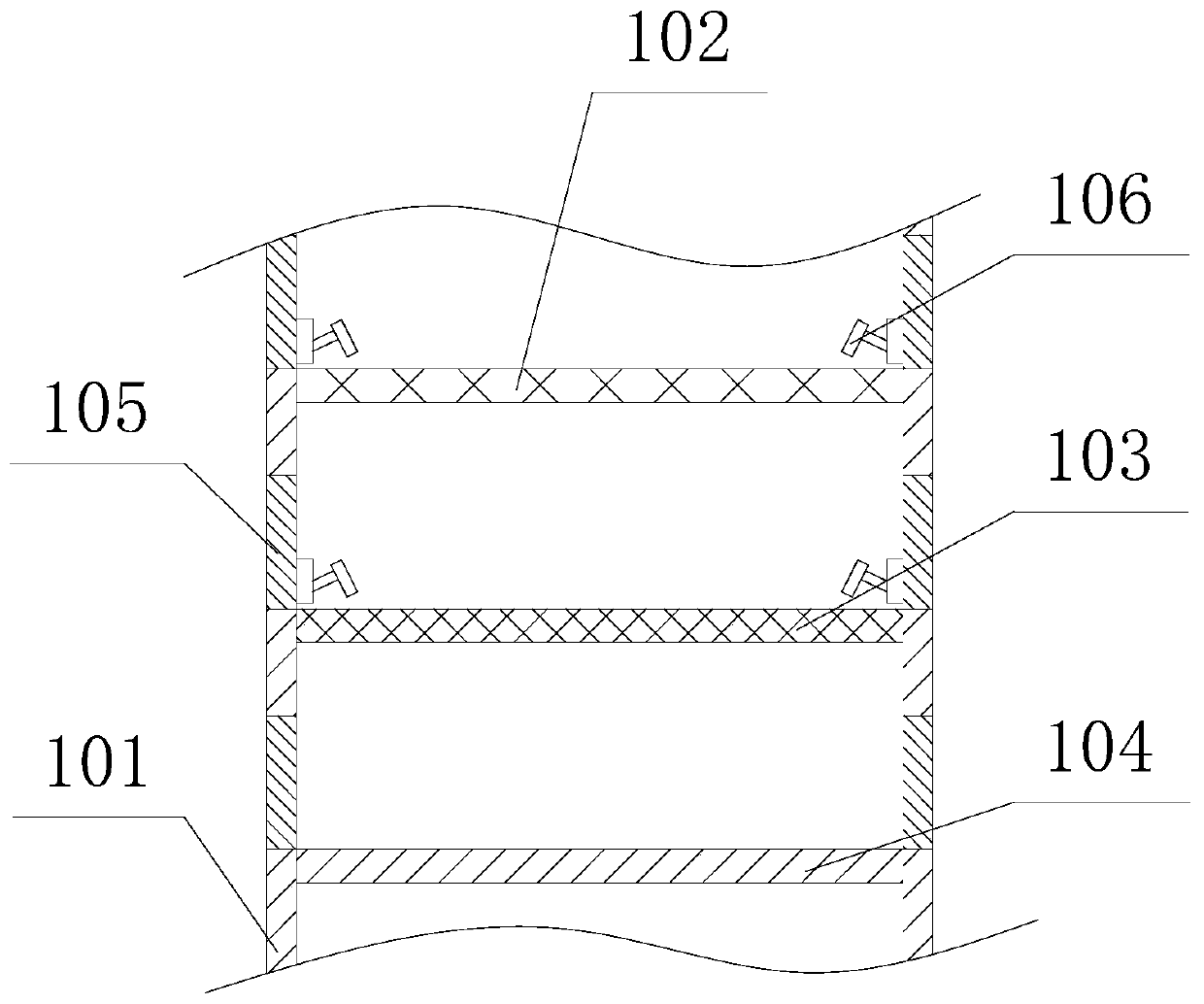

Device for microwave auxiliary breaking of waste concrete of different strengths

ActiveCN110104978AReduce crushing energy consumptionImprove qualitySolid waste managementConcrete recyclingHeating time

The invention discloses a device for microwave auxiliary breaking of waste concrete of different strengths, and relates to the technical field of waste concrete recycling. A monitoring device is installed on a breaking machine, the monitoring device is connected with a controller, and the controller is connected with an aggregate conveying device and a microwave heating device; the monitoring device detects a pressure signal when waste concrete is broken, the strength grade of the waste concrete is judged, strength information is transmitted to the controller, the controller transmits the signal to the aggregate conveying device and the microwave heating device, controls the conveying speed of the aggregate conveying device for waste concrete fragments, and controls the power and heating time of microwave transmission of the microwave heating device, and breaking separation is performed after microwave treatment. The device has the advantages that the problems that an existing breakingdevice is large in energy consumption, and the quality of produced regenerative aggregates is poor are solved, the breaking consumption of waste concrete is lowered, the production efficiency of theregenerative aggregates is improved, and the quality of the regenerative concrete aggregates is improved.

Owner:NANTONG UNIVERSITY

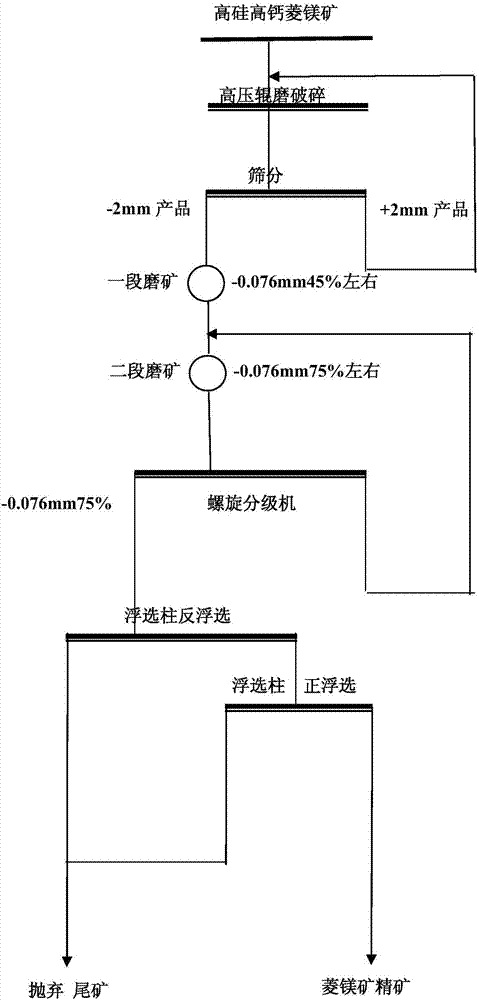

Low-cost mineral processing technology for high-silicon high-calcium magnesite

The invention relates to a low-cost mineral processing technology for high-silicon high-calcium magnesite. The low-cost mineral processing technology comprises the steps of raw material crushing operation, grinding operation and flotation operation. The low-cost mineral processing technology is characterized by comprising the following specific technological steps that raw magnesite is crushed through a medium crusher, grinding operation is conducted through a closed circuit grinding assembly composed of a primary grate ball mill, a secondary grate ball mill and a spiral grading machine, an overflow product with the particle size of 70-80% of the overflow product being -0.076 mm is obtained and subjected to flotation operation adopting primary reverse flotation and primary obverse floatation, the magnesite comprising 46.50-47.00% of magnesium oxide, 0.80-1.50% of silicon dioxide and 0.90-2.00% of calcium oxide is obtained, wherein the concentrate yield is 82.00-90.00%, and the recovery rate is 81.45-85.00%. The low-cost mineral processing technology has the advantages that flotation operation adopting only primary reverse flotation and primary obverse floatation, thus, the grade of the silicon dioxide in the high-silicon high-calcium magnesite can be lowered to 0.5-1.5% from 2%, the content of silicon is lowered by 50% or above, the grade of the calcium oxide is lowered to 1-2% from 3%, and the content of calcium is lowered by 50% or so.

Owner:中冶北方(大连)工程技术有限公司

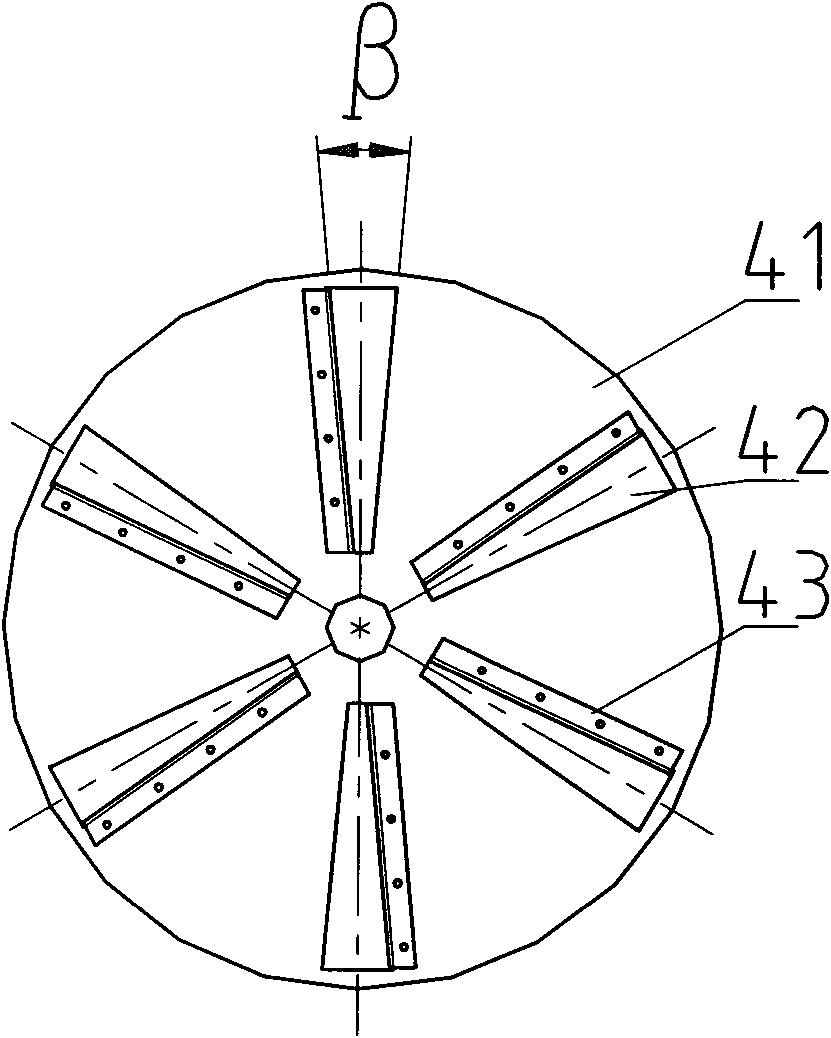

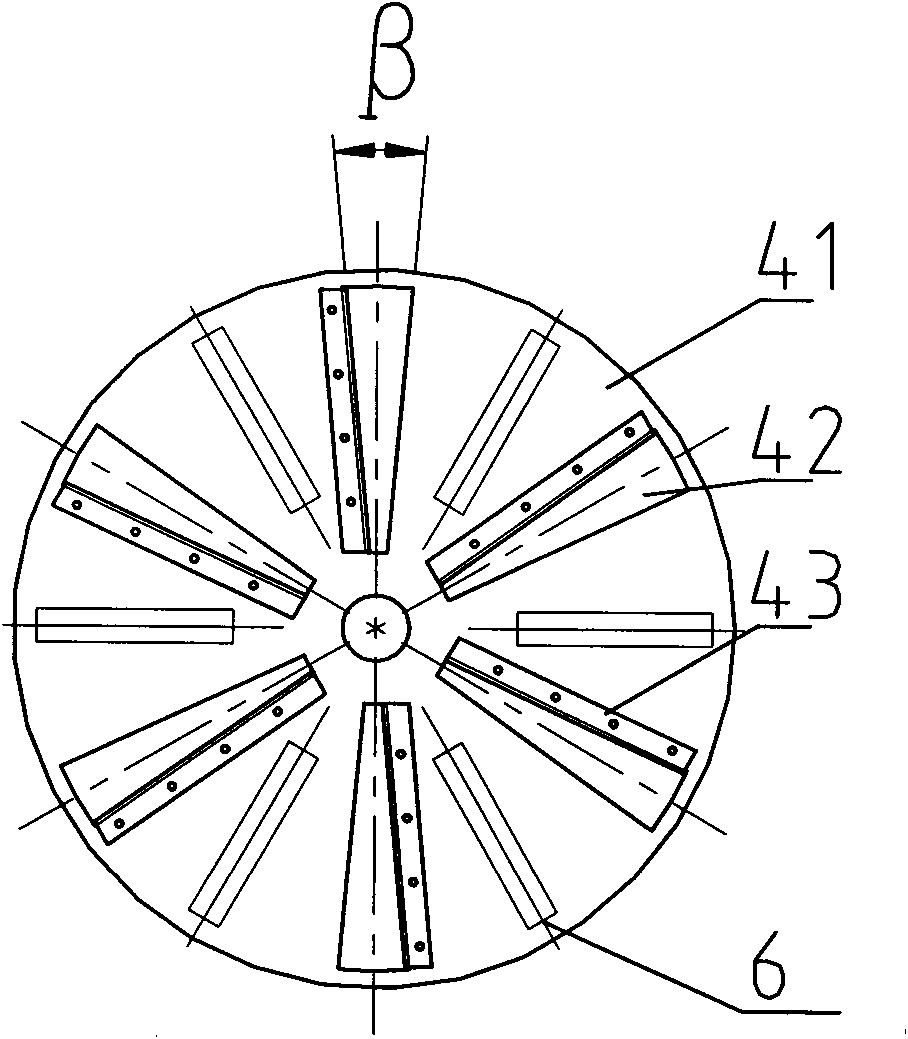

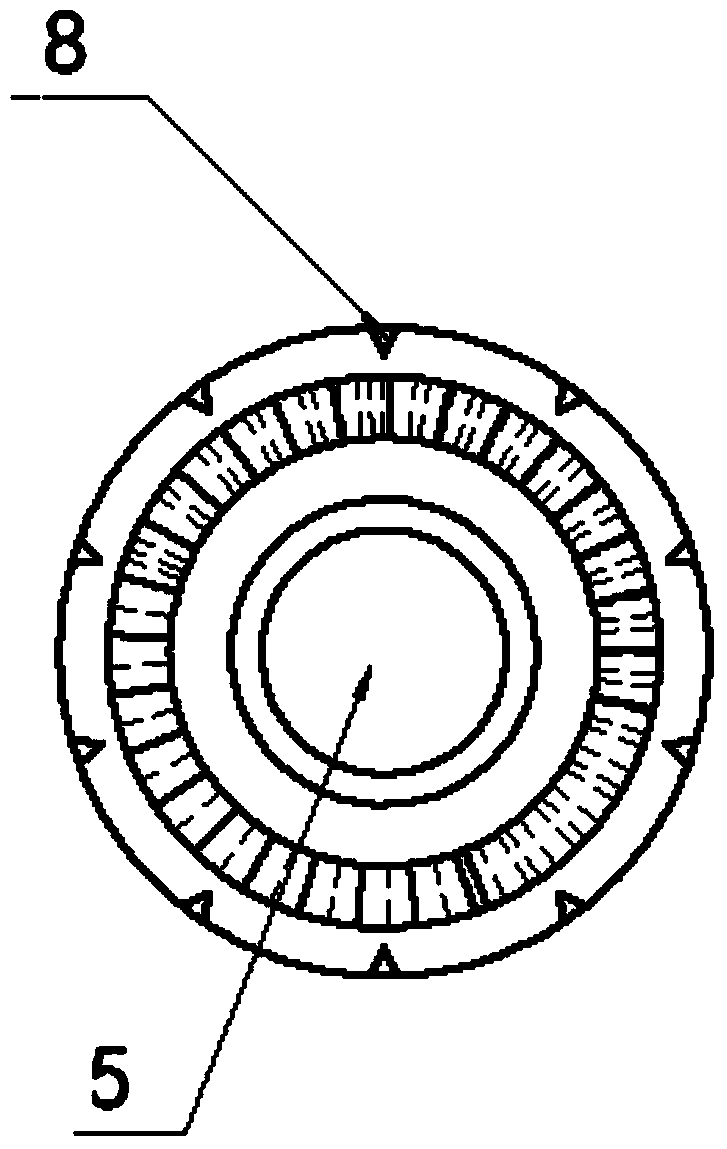

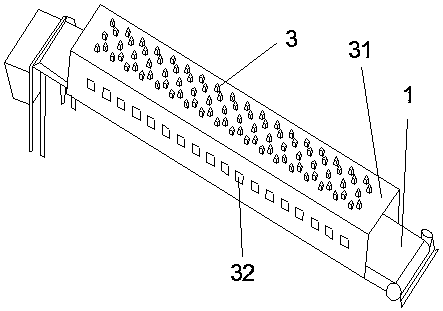

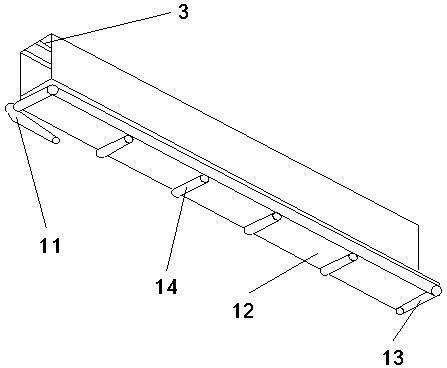

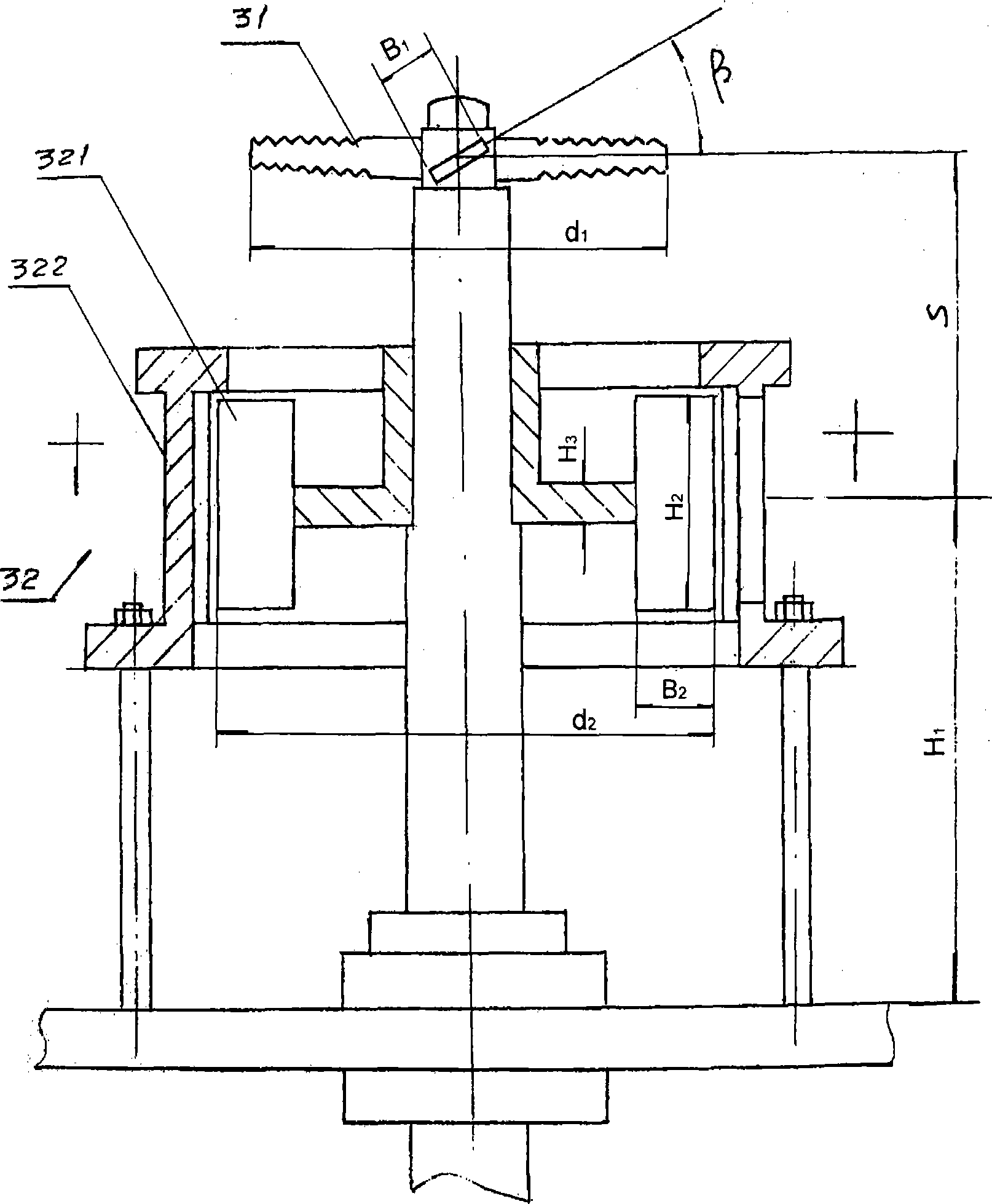

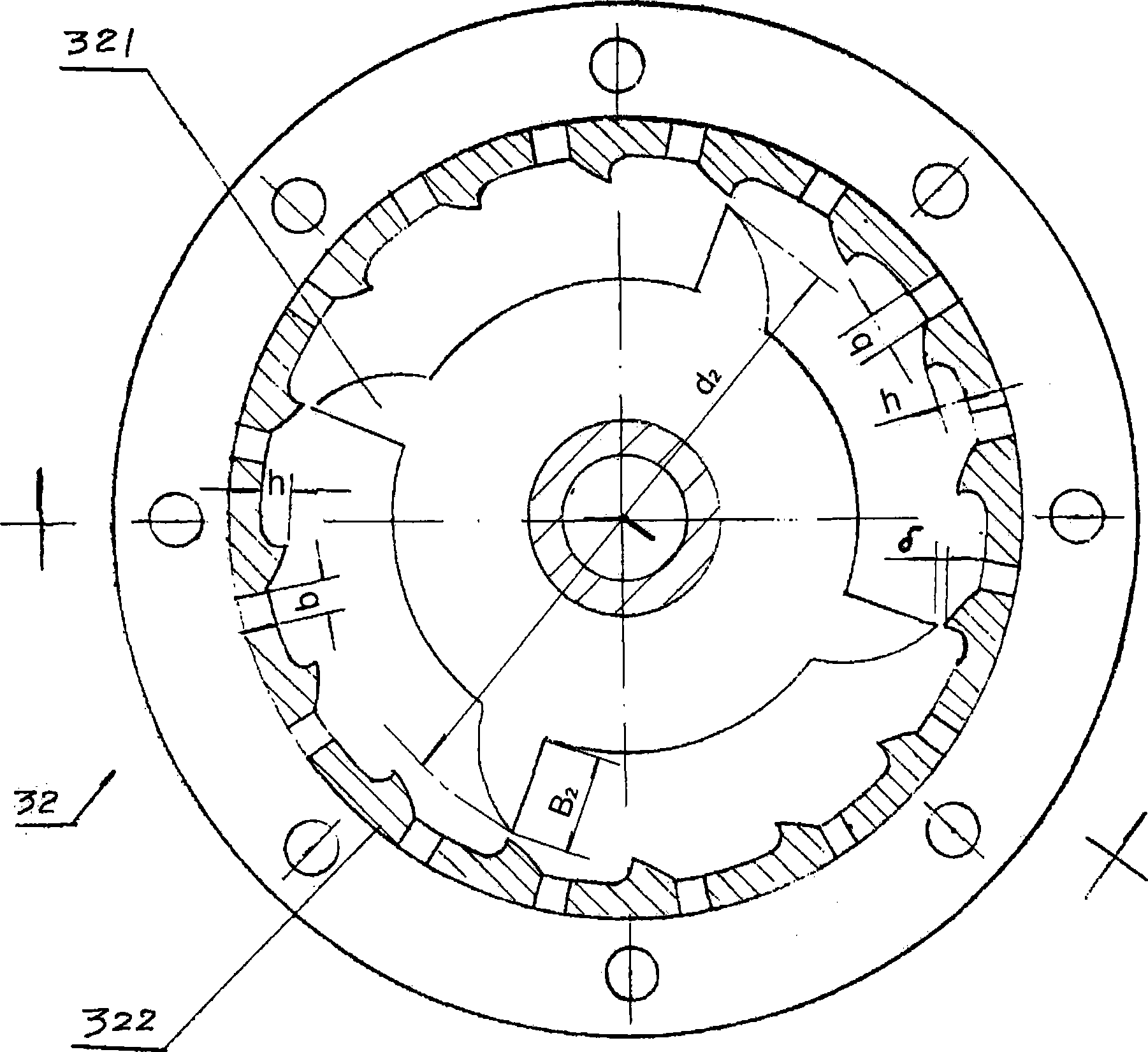

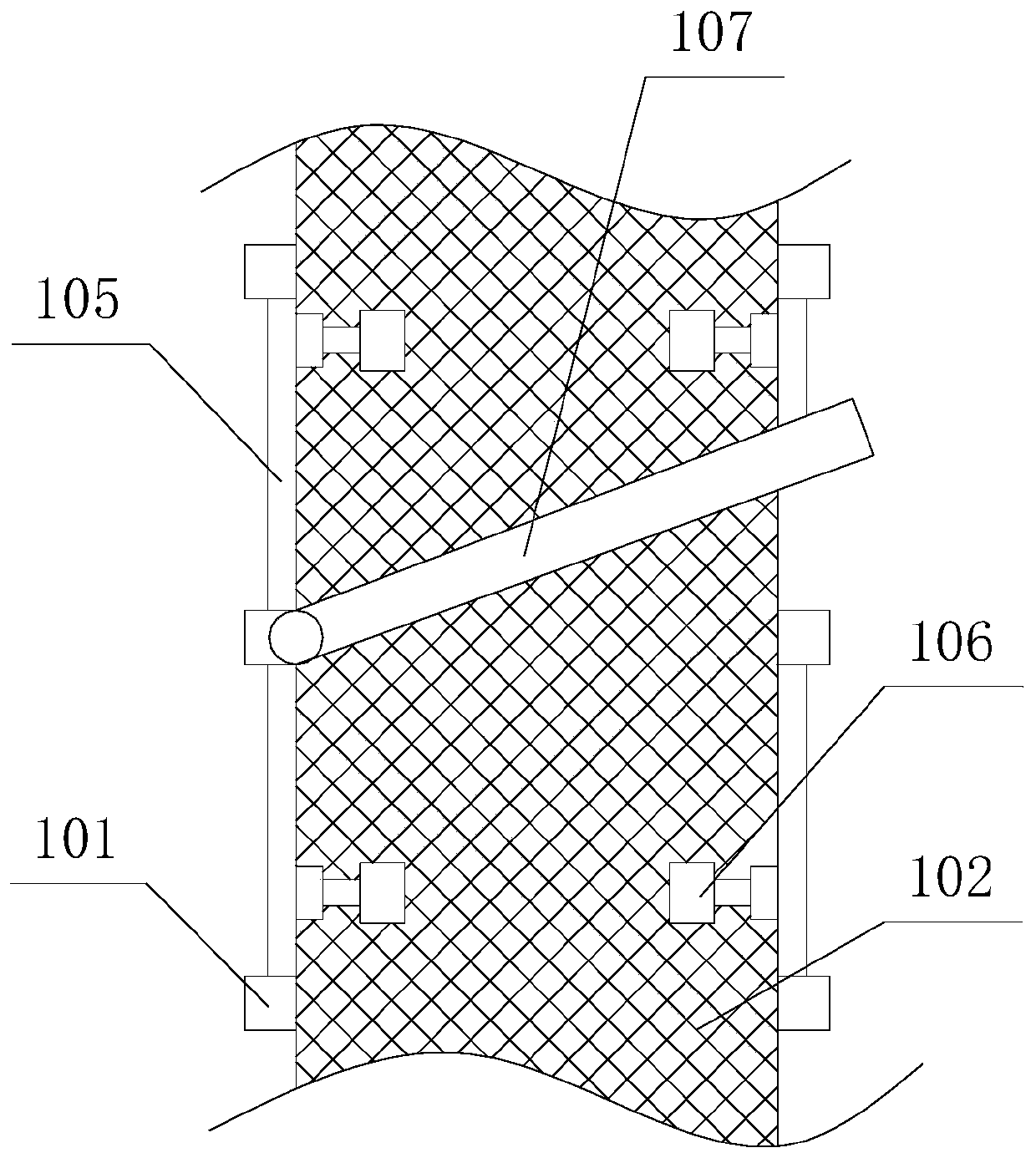

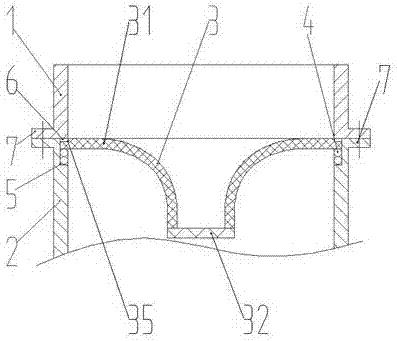

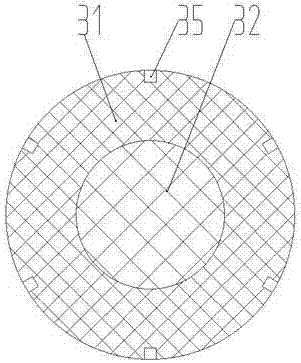

Crushing device and crushing method for preparing suspended polytetrafluoroethylene (PTFE) resin

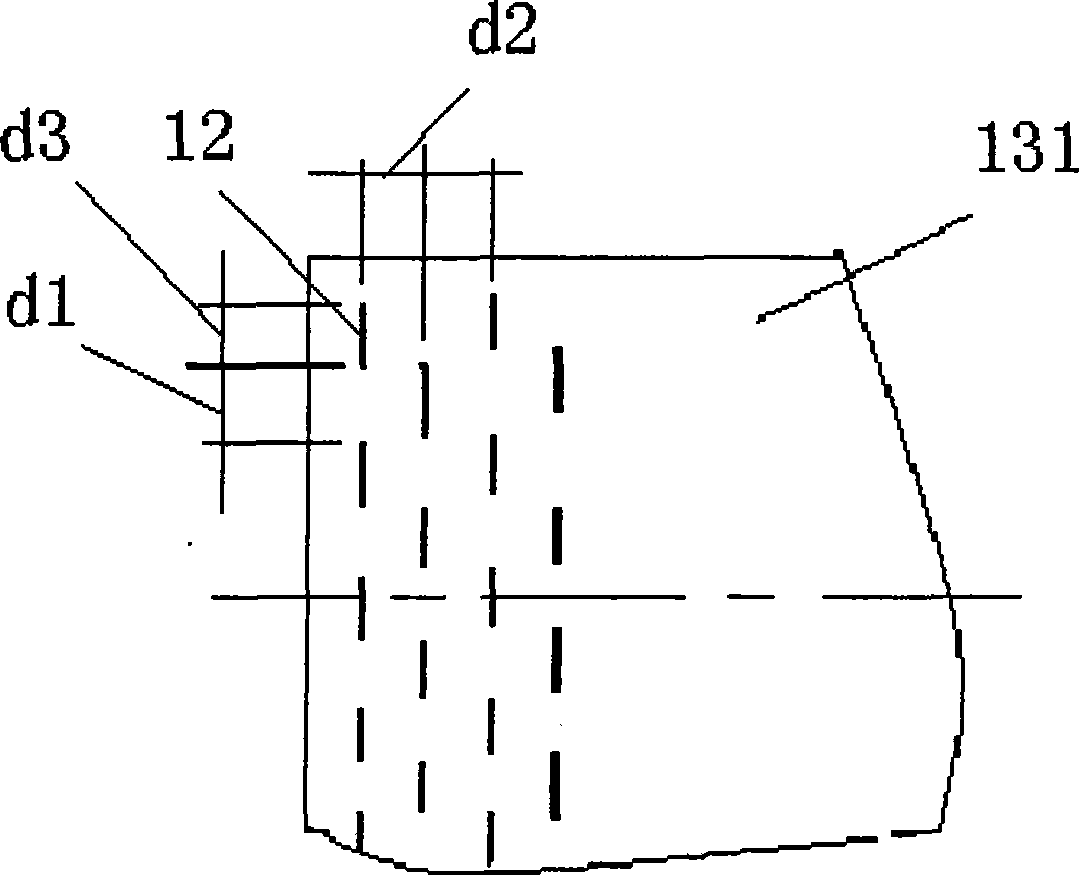

The invention discloses a crushing device (3) used in PTFE resin prepared through adopting a high-pressure suspension method. The crushing device consists of an upper layer paddle blade (31) and a lower layer paddle blade (32), wherein the upper layer paddle blade (31) is a bias cutting paddle blade and consists of toothed whirling paddles arranged on a rotating shaft; the intersection angle beta between the bias cutting paddle blade (31) and a horizontal plane is between 20 and 70 degrees; the lower layer paddle blade (32) is an impact paddle blade and consists of a rotating blade (321) arranged on the rotating shaft and an arc trough-shaped gear ring (322) fixed with the rotating blade (321) concentrically; the arc trough-shaped gear ring comprises a concentric ring protruding towards the circle center along the inside ring of the gear ring and a protrusion with a recess arranged at one end of the inner ring of the ring near the circle center against the rotating direction of the rotating blade; a straight strip trough is arranged between two arc trough-shaped grooves; and the height h of the concave protrusion is between 3 and 20 mm, while the breadth b of the straight strip trough is between 2 and 20 mm.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD +1

Gypsum powder preparation process and system

InactiveCN110423026AAvoid Repeated FragmentationReduce crushing energy consumptionGrain treatmentsEngineeringCrusher

The invention discloses a gypsum powder preparation process and system. The system comprises a conveying device, a jaw crusher, a hammer crusher, a feeding device, a rotary kiln calcining pot and a centrifugal pulverizer which are arranged in sequence, wherein the conveying device comprises a primary conveyer belt, a secondary conveyer belt and a third conveyer belt; discharge baffle plates are correspondingly mounted on the primary conveyer belt, the second conveyer belt and the third conveyer belt; a primary collecting plate which communicates with the jaw crusher, a secondary collecting plate which communicates with the hammer crusher and a third collecting plate which communicates with the feeding device are additionally arranged on a rack; a waste heat channel is formed between the feeding device and the rotary kiln calcining pot; and the centrifugal pulverizer is connected with a storage tank. As ores are graded in a conveying process, energy consumption for continuously crushingthe ores can be reduced, and the ore crushing efficiency can be improved; and in addition, due to adoption of the waste heat channel and a novel centrifugal pulverizing component, the product qualitycan be further improved, and the energy consumption cost for production can be lowered.

Owner:康定龙源穗城石膏有限责任公司

Multifunctional feeding device for vertical sieving and vibrating sand making machine

PendingCN107282276AAvoid easy cloggingBroken evenly and fullySievingScreeningBreaking strengthEffective solution

The invention discloses a multifunctional feeding device for a vertical screen vibrating sand making machine, which comprises a feeding box body, a material distribution plate and elastic parts; the upper end of the feeding box body is an incompletely closed feeding The lower end surface is a fully-opened discharge port; in the feed box, a distribution plate is arranged transversely relative to its axis; an elastic member is axially arranged between the distribution plate and the feed box; The feed box is located on the square of the impeller of the sand making machine, and the material distribution plate, the impeller, the feed pipe of the sand making machine, and the vibrating mechanism of the sand making machine are arranged correspondingly on the same axis from top to bottom; The material distributing mechanism and the vibrating mechanism on the vertical vibrating vibrating machine work together to make the material make full use of the collision force, and the crushing strength is greater. The above structure can effectively solve the problem of unsmooth discharge of materials in the vibrating vibrating vertical vibrating mechanism and sand making. The problem of low crushing efficiency and insufficient crushing of materials has greatly improved the crushing efficiency and quality of materials, and reduced the energy consumption of crushing.

Owner:尹国祥

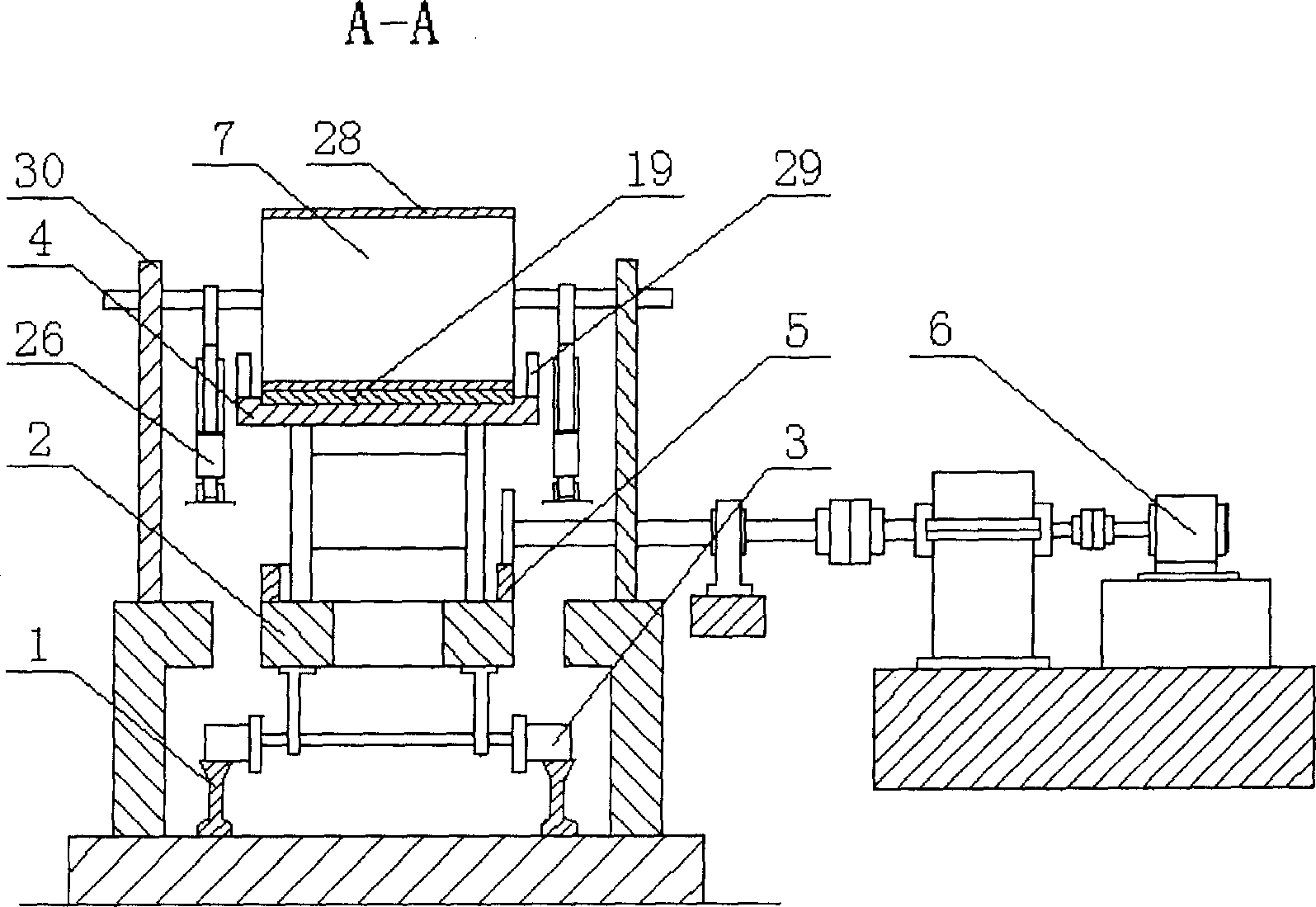

Unit roll-disk breaker

InactiveCN1712136AIncreased crush strengthEfficient crushingGrain treatmentsHydraulic cylinderGear wheel

A unit-type roller-disk pulverizer is composed of an annular grinding disk made up by embedding a flat lining plate on the annular flat bed car on an annular track, an annular machine frame, a toothed ring linked via gear to power mechanism, and 2-10 grinding units on said annular grinding disk. Said grinding unit consists of 2-6 grinding rollers with hydraulic cylinder at its both ends, pulverized material layer controller, unloader, plate cleaner for grinding roller, and material collecting small scraper.

Owner:吴碧碧

Double-roll crusher

The double roller crusher for crushing mineral in mine, metallurgical and building material industry includes frame, and fixed roller and movable roller installed on the bearing seats on the frame. It features the crushing cavity formed with the shaft shoulders on the rollers, the driving unit installed on the fixed roller, and the sync board installed on the back of the movable roller bearing seats, with bottom hinged to the bottom frame and back pushed with the pressure unit on the frame. The present invention has the advantages of simple structure, saving in power, sync shift of the movable roller bearing seats, no 'edge effect' in the side baffles on roller ends and long service life.

Owner:张立建

Energy-saving type smash grading device

The invention discloses an energy-saving type smash grading device. The energy-saving type smash grading device comprises an electric control cabinet, a feed bin, an iron separation, an ultrafine grinder, pipelines, an ultrafine grader, a cyclone dust extractor, a dust collector and a fan, wherein the electric control cabinet is arranged on one side of the feed bin, the iron separator is arranged at the other side of the lower part of the feed bin, the ultrafine grinder is arranged blow the iron separator, and the ultrafine grinder, the ultrafine grader, the cyclone dust extractor, the dust collector and the fan are sequentially connected through the pipelines; the electric control cabinet is packaged by a shell, a cooling fin and a solar photovoltaic plate are arranged on the shell, and a storage battery is arranged in the electric control cabinet. The energy-saving type smash grading device has the advantages that the structure is simple, an over-smashing phenomenon is avoided, and the smashing energy consumption is reduced; the energy-saving type smash grading device has strong adaptability to materials and can avoid dust pollution, meanwhile, the materials are simple and convenient to exchange and clean, the energy is saved, and the environment is protected.

Owner:宁夏祺腾数据产业发展有限公司

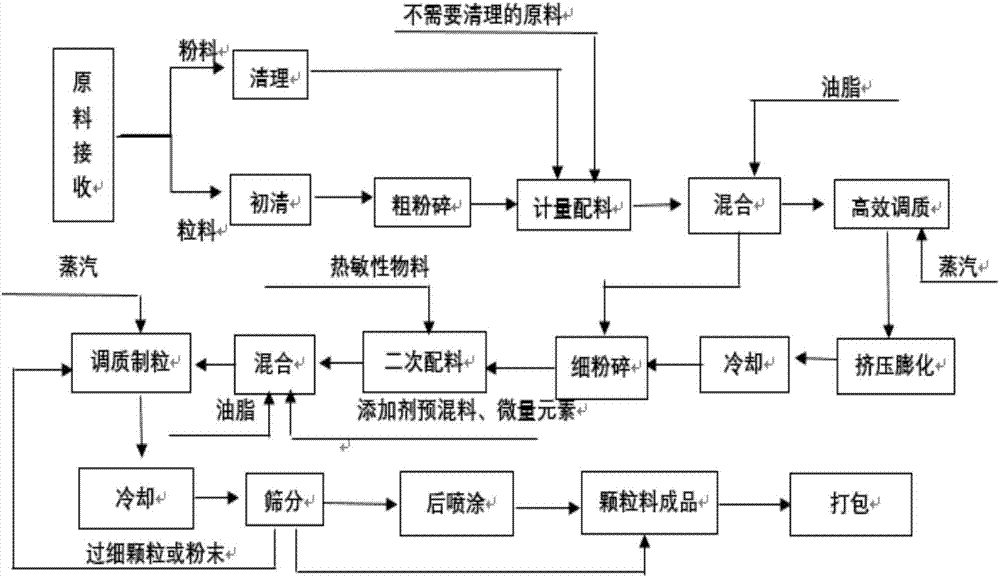

Production method of bulk ingredient-expanded sinking aquatic feed

InactiveCN107149056ANo drying process requiredImprove ripenessWorking-up animal fodderFood additivePrill

The invention relates to a production technology of sinking aquatic feed molded by carrying out extruding expansion and ring die pelletizing on a bulk ingredient. The production technology comprises the steps of carrying out efficient tempering and extruding expansion on mixed powder which is free from a heat-sensitive component and a feed additive, so as to cure the bulk ingredient, cooling, finely crushing and then adding the heat-sensitive component and the feed additive; after that, tempering, pelletizing and molding. The sinking aquatic feed processed by the method has the advantages of high curing degree, stable quality, easy quality control, and less loss of the heat-sensitive component compared with expanded sinking pellet feed; furthermore, a ring die pelletizing process is adopted in granule formation, so that an aquatic feed expander and a drying machine do not need to be arranged, and steam consumption is further greatly reduced; the formula is wide in adaptability, and high-starch formula sinking feed is easily produced.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

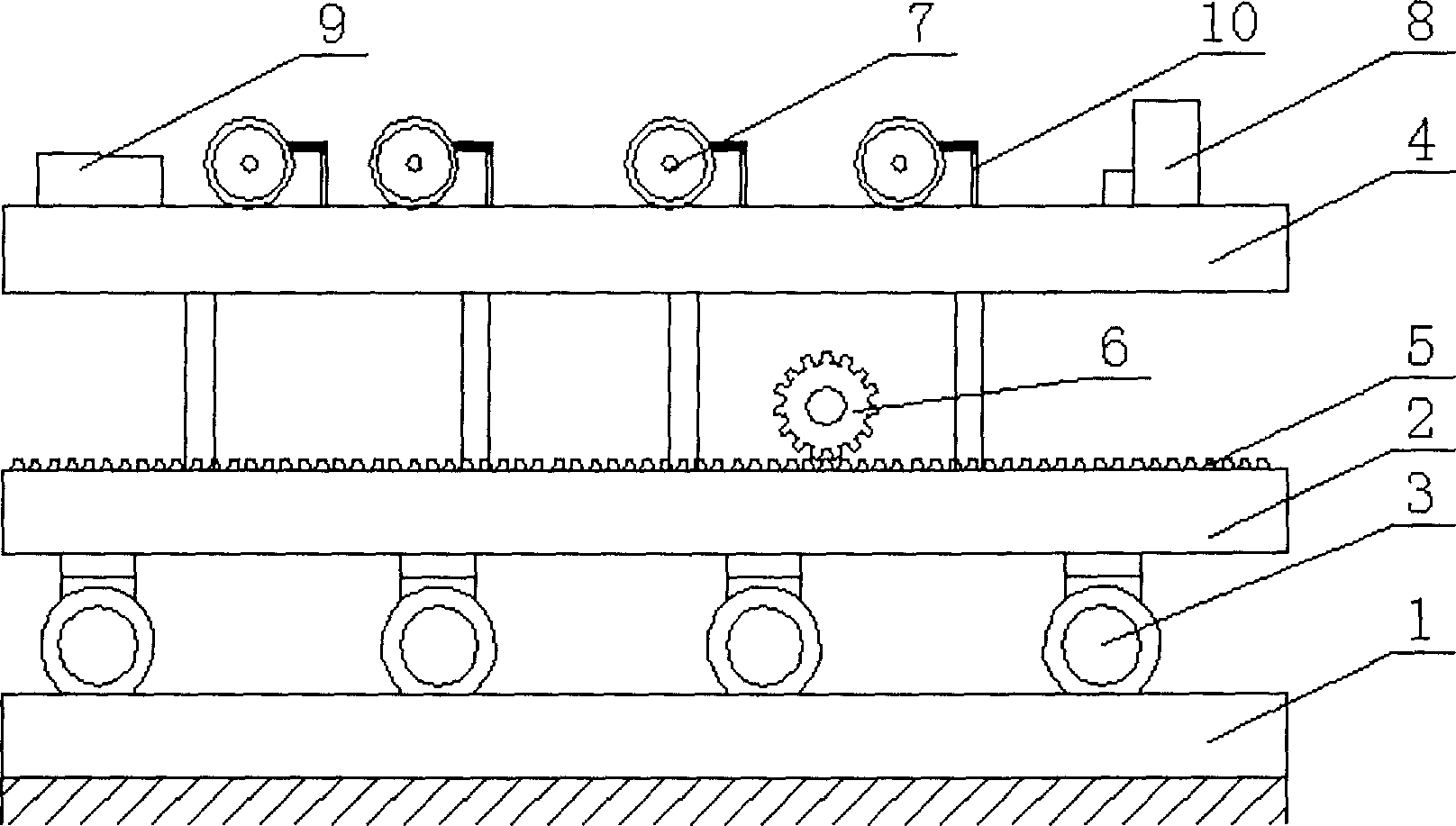

Crusher for discarded household appliances

The invention provides a crusher for discarded household appliances, which comprises a bracket (1) and a crushing bucket (5), wherein the bracket (1) is provided with a motor (2) which is connected with a transmission gear (4) via a shaft coupling (3); and the crusher is characterized in that: four shafts (6) are arranged in the crushing bucket (5), distributed in a concave arc shape and are connected with the transmission gear (4) respectively; and the four shafts (6) are provided with blades (7) respectively. The crusher for the discarded household appliances provided by the invention adoptsa structure of four shafts distributed in the concave arc shape so as to fully attach to the appearance of an object to be crushed, facilitate fully crushing and tearing the object to be crushed andavoid extruding the crushed materials into a ball.

Owner:CHANGSHU RIXIN MACHINERY

Method for producing solid fuel by exploding biomass waste through flue gas

The invention discloses a method for producing solid fuel by exploding biomass waste through flue gas and relates to the field of waste resource recycling and biomass energy sources. The method comprises the steps of 1) biomass waste crushing, including cutting up the biomass waste to 10-150 mm; 2) flue gas explosion, including filling the biomass waste into a steam explosion tank, after the steam explosion tank is sealed, feeding flue gas in for 10-60 seconds until reaching a pressure of 1.0-3.0 MPa, and after the temperature is maintained to be 100-200 DEG C for 0.5-30 minutes, relieving the valve suddenly to achieve instant releasing and decompression of materials; (3) extrusion forming, including extruding the steam-exploded biomass waste into extrusion-formed solid fuel through a forming machine. The method for producing the solid fuel by exploding biomass waste through the flue gas has the advantages of reducing the collecting, conveying and storing cost of raw materials; reducing the energy consumption during raw material crushing and extrusion forming; facilitating recycling and reduction of the flue gas; being easy to operate, high in processing efficiency, low in cost and applicable to mass production.

Owner:JIANGNAN UNIV

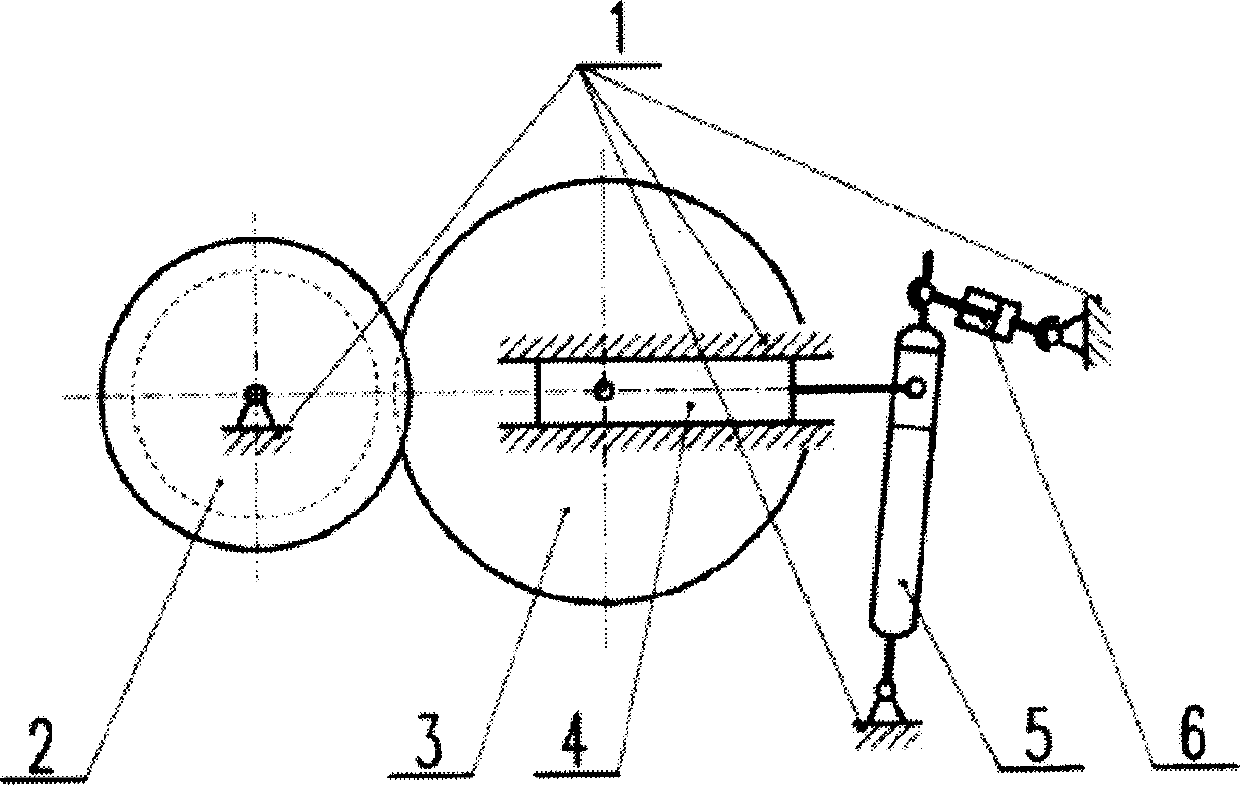

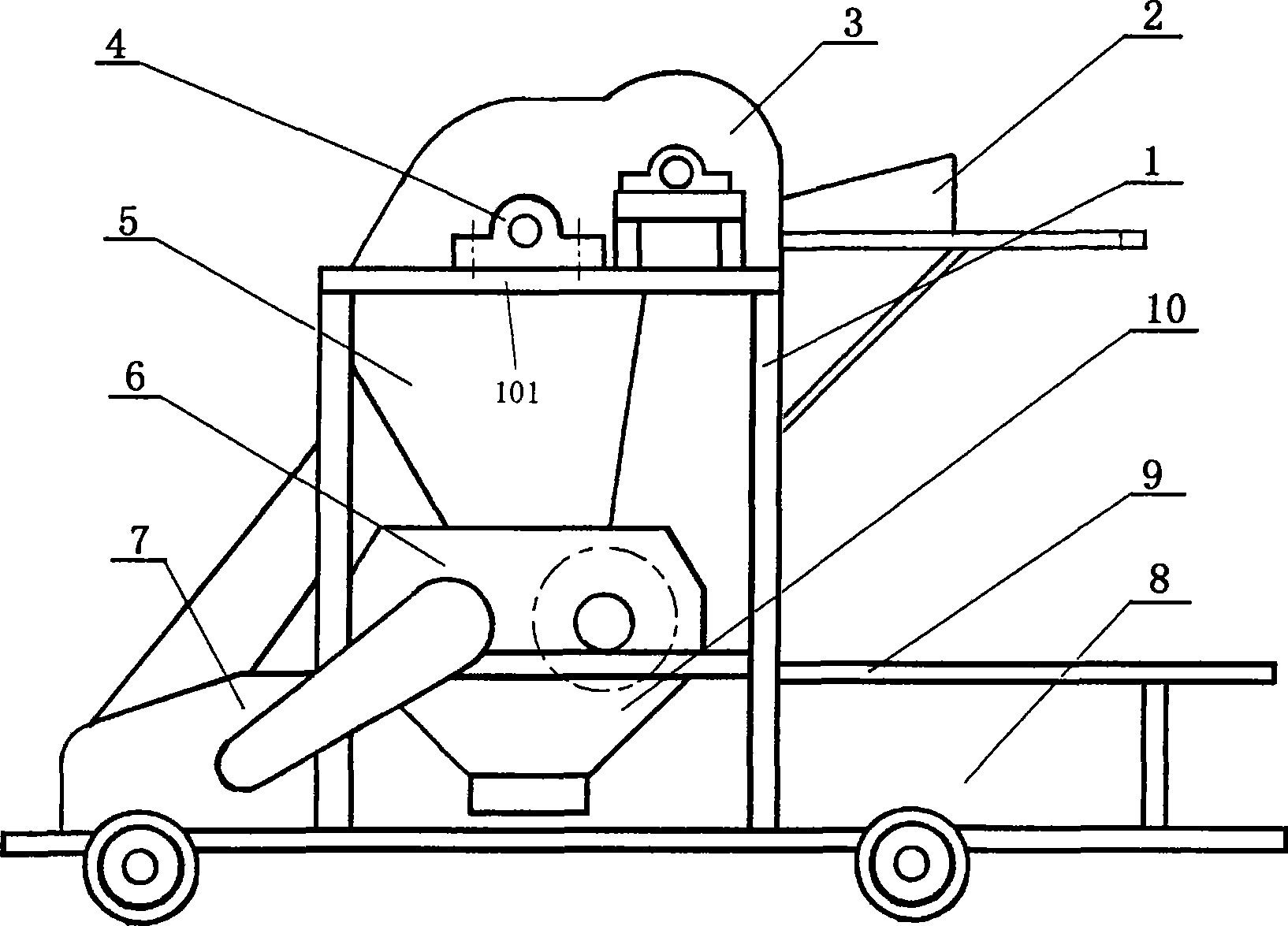

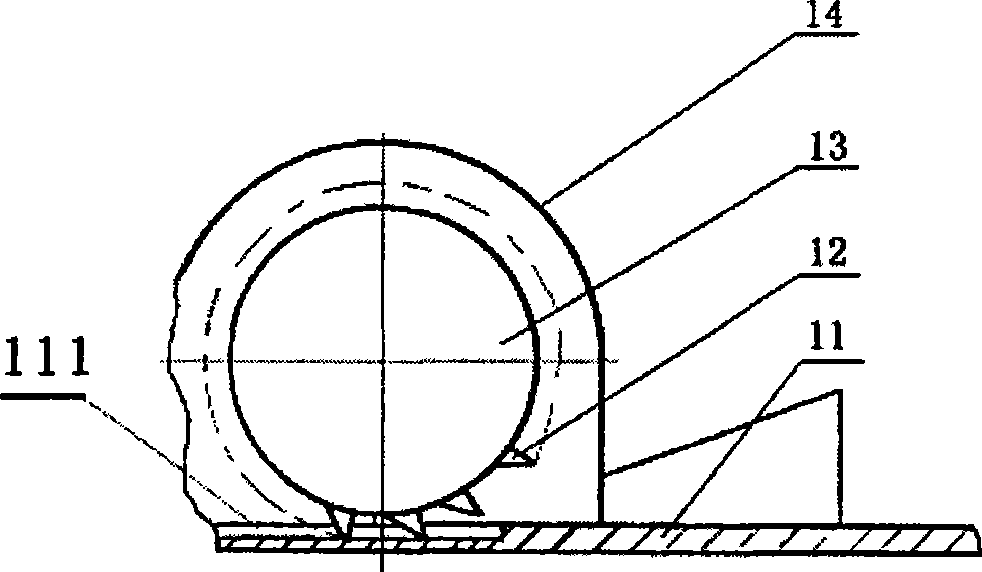

Movable biomass compact molding apparatus and molding roll

InactiveCN101367271AEfficient crushingReduce energy consumptionPressesEngineeringMechanical engineering

The invention discloses a movable biomass compaction molding apparatus, which has a frame. A grinding device and a molding device are fixed on the frame; an outlet of the grinding device is arranged above a feed port of the molding apparatus; the molding device is a double-roller type molding device which comprises a pair of concave-convex rollers which can rotate, have adjustable interval and are fixed on the frame; the circumference surface of each roller is provided with a concave die part and a convex die part; radial molding holes are arranged on the concave die parts of the rollers; the axis of each roller is provided with an axial through hole along the axial direction; and the radial molding holes are communicated with the axial through hole. The movable biomass compaction molding apparatus provided by the invention adopts cold molding technology and one-step compaction molding, and does not need drying, heating or cooling, thereby having the advantages of low energy consumption, high efficiency and low cost. Biomass raw materials can be processed in production place and are convenient to use. The molding apparatus adapts the power input design for electric and diesel engines, so as to suit the areas which are scattered in land parcel and short or electrical power, fully utilize resources and benefit vast farmers.

Owner:北京汉坤科技有限公司

High-efficiency fresh and wet biomass crusher and fixed knife system

PendingCN112024081ASolve the circulation layer problemIncrease cut pointCuttersGrain treatmentsAgricultural scienceAgricultural engineering

The invention discloses a high-efficiency fresh and wet biomass crusher and a fixed knife system. The high-efficiency fresh and wet biomass crusher mainly comprises a machine base, a crushing chamber,the fixed knife system, a rotor, a feeding port, a discharging port, a direct-coupled transmission mechanism and a motor. The fixed knife system is applied to the high-efficiency fresh and wet biomass crusher. The fixed knife system comprises fixed knives, a fixed knife rest and a fixed knife adjusting mechanism. The invention also discloses a coaxial fan applied to the high-efficiency fresh andwet biomass crusher. The coaxial fan comprises a blade shaft sleeve and three wing-type hollow blades. According to the high-efficiency fresh and wet biomass crusher, the fixed knife system and the coaxial fan, the specific design is made based on the physical characteristics of various fresh and wet biomass raw materials, the crushing efficiency is greatly improved, the crushing particle size distribution range of the materials is greatly reduced (the average particle size is 0.1-2.5 mm), the screening is not needed, and the high-efficiency fresh and wet biomass crusher, the fixed knife system and the coaxial fan can be widely applied to the fine crushing of the materials of crop straws, vines, vegetables, various herbages, traditional Chinese medicine residues and the like with differentmoisture contents, and have wide application prospects in the field of agricultural production.

Owner:湖南三块铁机械科技有限公司

New method for mining submarine cobalt crusts

InactiveCN101906971BImprove collection efficiencyExtend your lifeMineral miningHydraulic cylinderEngineering

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com