High-efficiency fresh and wet biomass crusher and fixed knife system

A biomass and high-efficiency technology, used in grain processing, agricultural machinery and tools, cutting equipment, etc., can solve the problems of difficult to achieve crushing particle size, limited shearing times, limited shearing points, etc., and achieve good aerodynamics. Features, high-strength shearing ability, and the effect of ensuring user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

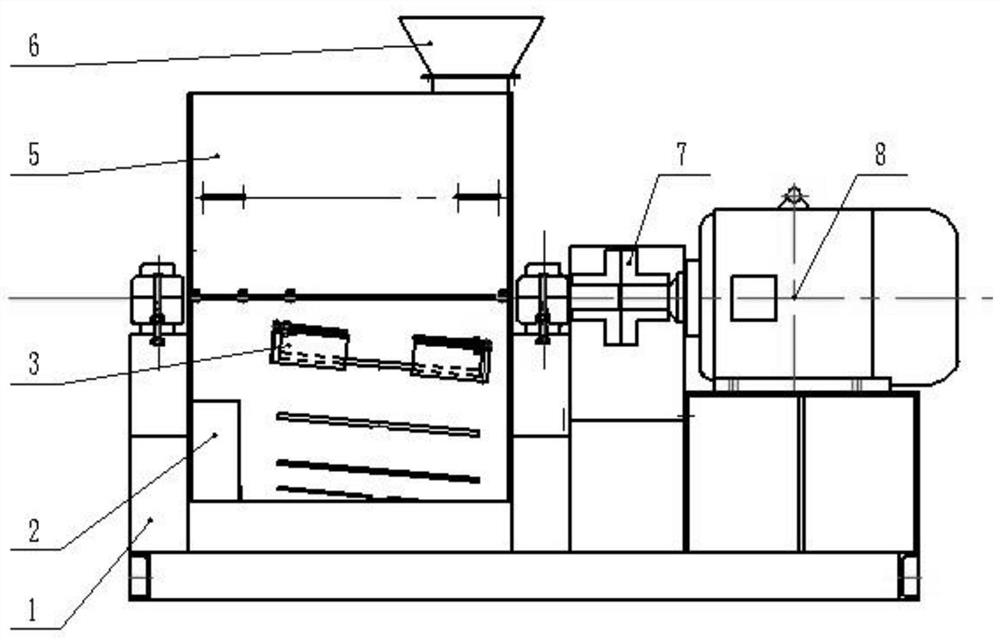

[0051] A high-efficiency fresh and wet biomass pulverizer, the main structure of which includes a machine base, a pulverization chamber, a fixed knife and a fixed knife adjustment mechanism, a rotor, a material inlet, a material outlet, a direct transmission mechanism and a motor.

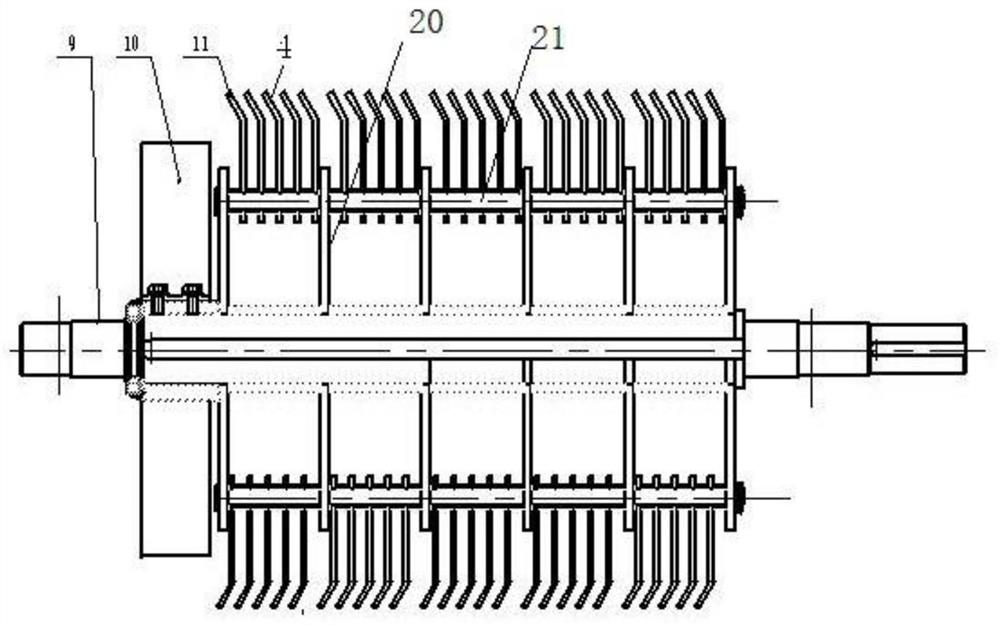

[0052] The working diameter of the rotor is 600mm, and the effective crushing length is 600mm. The rotor is composed of a moving knife group and a coaxial fan. The moving knife group consists of 4 groups with a total of 100 moving knives. The distance between the adjacent two groups of moving blades is staggered along the axial direction. Equipped with Y series 37kw secondary motor, the linear speed of moving knife group is 92m / s.

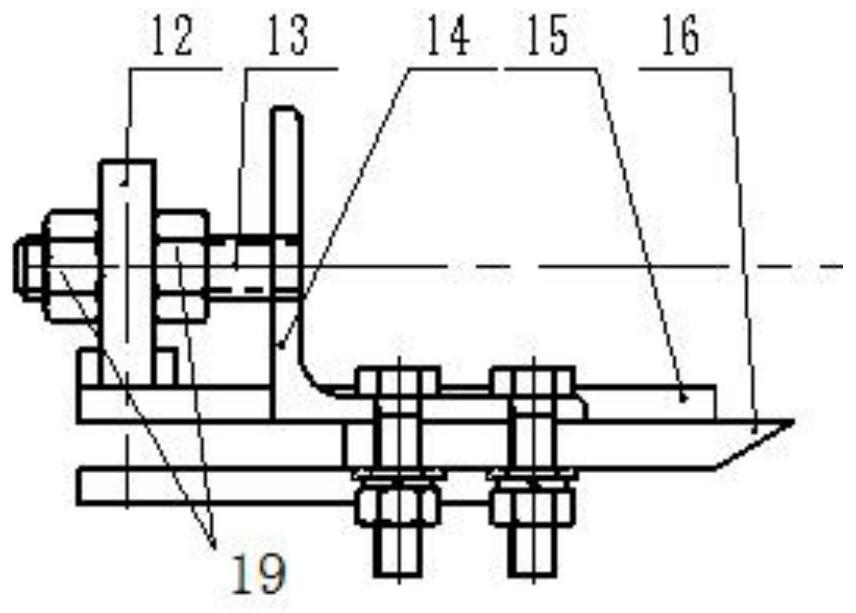

[0053] The crushing chamber is composed of upper and lower half cylinders to form a cylindrical crushing chamber. The fixed knife system is installed on the lower half cylinder. The fixed knife system includes a fixed knife, a fixed knife holder and a fixed knife adjustm...

Embodiment 2

[0058] A high-efficiency fresh and wet biomass pulverizer, the main structure of which includes a machine base, a pulverization chamber, a fixed knife and a fixed knife adjustment mechanism, a rotor, a material inlet, a material outlet, a direct transmission mechanism and a motor.

[0059] The working diameter of the rotor is 1190mm, and the effective crushing length is 800mm. The rotor is composed of a moving knife group and a coaxial fan. The moving knife group consists of 8 groups with a total of 280 moving knives. The distance between the adjacent two groups of moving blades is staggered along the axial direction. Equipped with Y series 75kw four-stage motor, the linear speed of moving knife group is 92m / s.

[0060] The crushing chamber is composed of upper and lower half cylinders to form a cylindrical crushing chamber. The fixed knife system is installed on the lower half cylinder. The fixed knife system includes a fixed knife, a fixed knife holder and a fixed knife adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com